Water-based finish coating composition for appearance effect of bus body and its preparation method

A technology for water-based topcoats and buses, applied in multi-color effect coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem that water-based coatings cannot be applied, achieve the requirements of colorful appearance, and improve the effect of appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

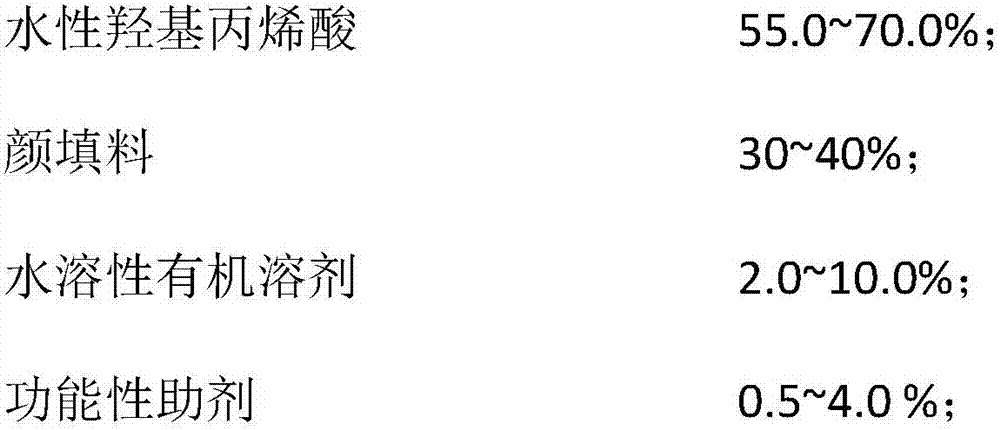

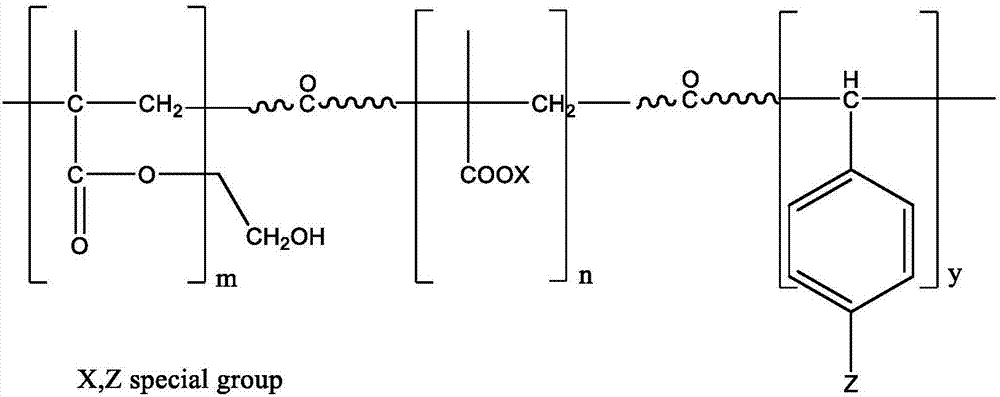

Method used

Image

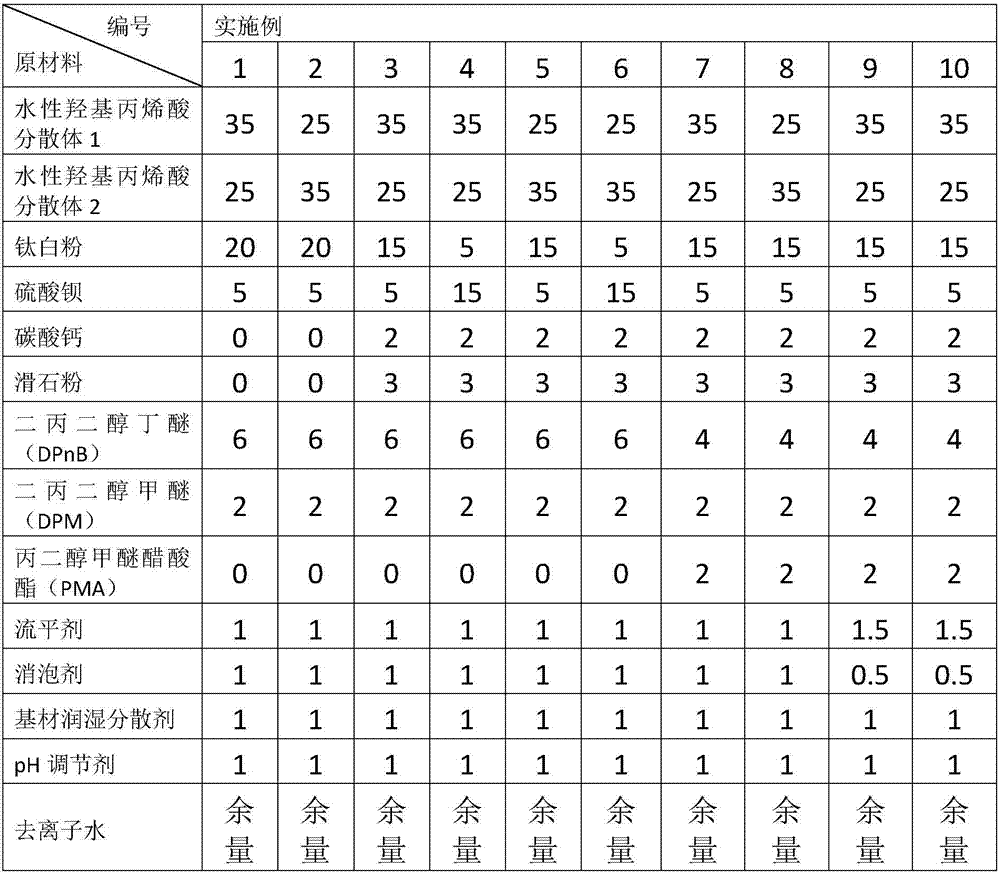

Examples

Embodiment B

[0053] The specific preparation steps of the water-based finish paint composition B component of the high appearance effect of the bus body in the embodiment B component 1-10 are as follows:

[0054] 1. Disperse the water-based isocyanate curing agent accounting for 60.0-80.0% of component B in a disperser at a speed of 500-800r / min for 10-15 minutes to obtain a uniformly dispersed curing agent dispersion. The isocyanate content of one of the water-based isocyanate curing agents is 9.0% to 24.0% by weight of the solid content, and the solid content is 70% to 100% by weight; The weight percent is 9.0-24.0%, and the solid content is 70%-100% by weight; the isocyanate content of the third water-based isocyanate curing agent is 18.0-48.0% by weight, and the solid content is 18.0-48.0% by weight. Calculated as 70% to 100%.

[0055] 2. After uniformly dispersing the water-soluble organic solvent accounting for 20.0-40.0% of component B, add it to the above curing agent dispersion u...

Embodiment

[0059] The specific preparation steps of the water-based finish paint composition B component of the high appearance effect of the bus body in the embodiment A+B components 1-10 are as follows:

[0060] 1. Disperse 75-90.0% of the A component and 25%-10.0% of the B component in the disperser at a speed of 500-800r / min for 20-30 minutes to obtain a dispersed Uniform dispersion. The balance was made up with deionized water.

[0061] Table 3. Composition of Embodiment A+B Components 1-10

[0062] (unit: mass percentage)

[0063]

[0064] The test method of the water-based finish paint composition prepared by embodiment A+B component 1~10 is as follows: measure the glossiness of paint film with the gloss meter of German BYK company, the film thickness of every group of paint is 40-50um; Fog The shadow value is also measured by the haze meter of BYK in Germany. The haze value of 5 points is taken for each group, and then the average value is taken; the DOI is also measured by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com