Copper foil for printed circuit

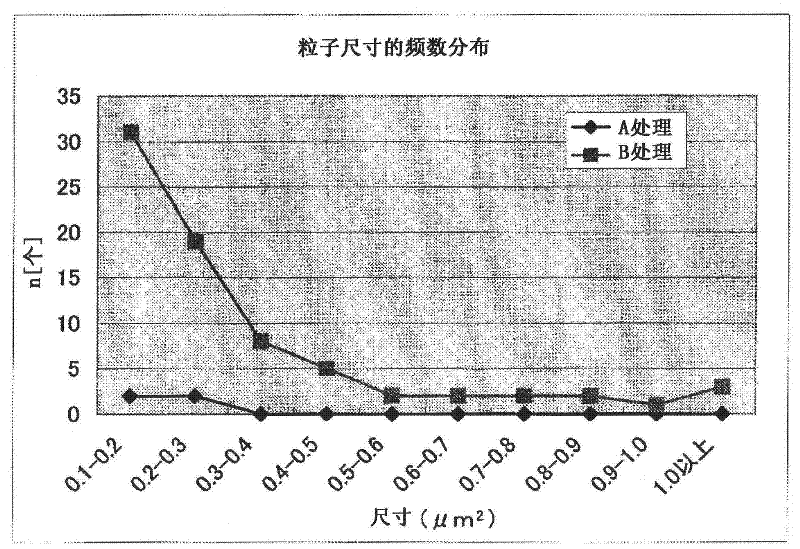

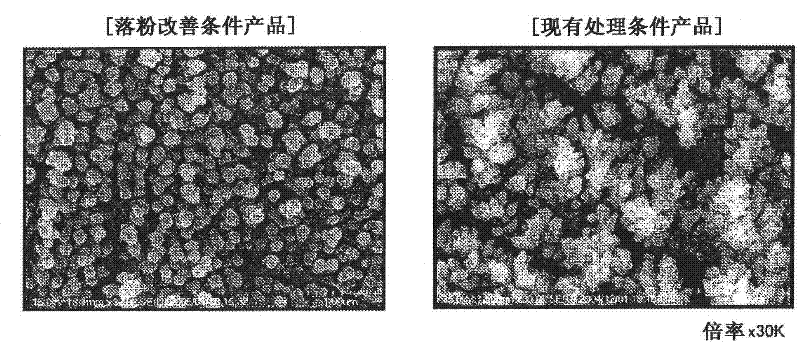

一种印刷电路、铜箔的技术,应用在印刷电路、印刷电路、印刷电路制造等方向,能够解决蚀刻残留、处理不匀、剥落等问题,达到高集成化提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0121] Hereinafter, it demonstrates based on an Example and a comparative example. In addition, this Example is just an example, and this invention is not limited to this example, ie, this invention also includes the other form or deformation|transformation contained therein.

[0122] (Example)

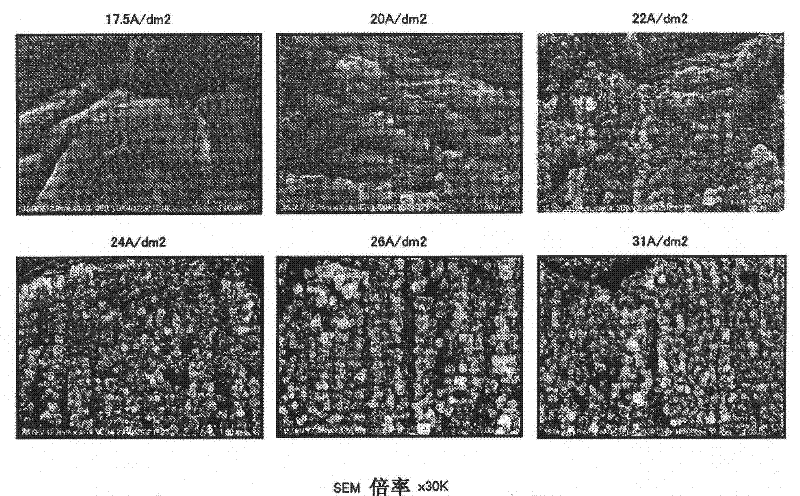

[0123] The rolled copper foil was roughened by copper-cobalt-nickel alloy plating within the range of conditions shown below. Attach 17mg / dm 2 Copper, 2000μg / dm 2 of cobalt and 500μg / dm 2 After the nickel, it is washed with water to form a cobalt-nickel alloy coating on it. At this time, the amount of cobalt deposited is 800-1400μg / dm 2 , nickel deposition is 400~600μg / dm 2 .

[0124] The bath composition and plating conditions used are as follows.

[0125] [Bath composition and plating conditions]

[0126] (A) Roughening treatment (Cu-Co-Ni alloy plating)

[0127] Cu: 15.5g / liter

[0128] Co: 6g / L

[0129] Ni: 11g / liter

[0130] pH: 2.5

[0131] Temperature: 30°C

[0132...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com