Fe-based austenite alloy oil sleeve and manufacturing method for high-acidity deep well

A manufacturing method and technology for oil casing, which are applied in casing, metal rolling, metal rolling, etc., can solve the problem that the extrusion rate cannot meet the industrialization requirements of oil casing, and achieve higher production costs and high high temperature strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

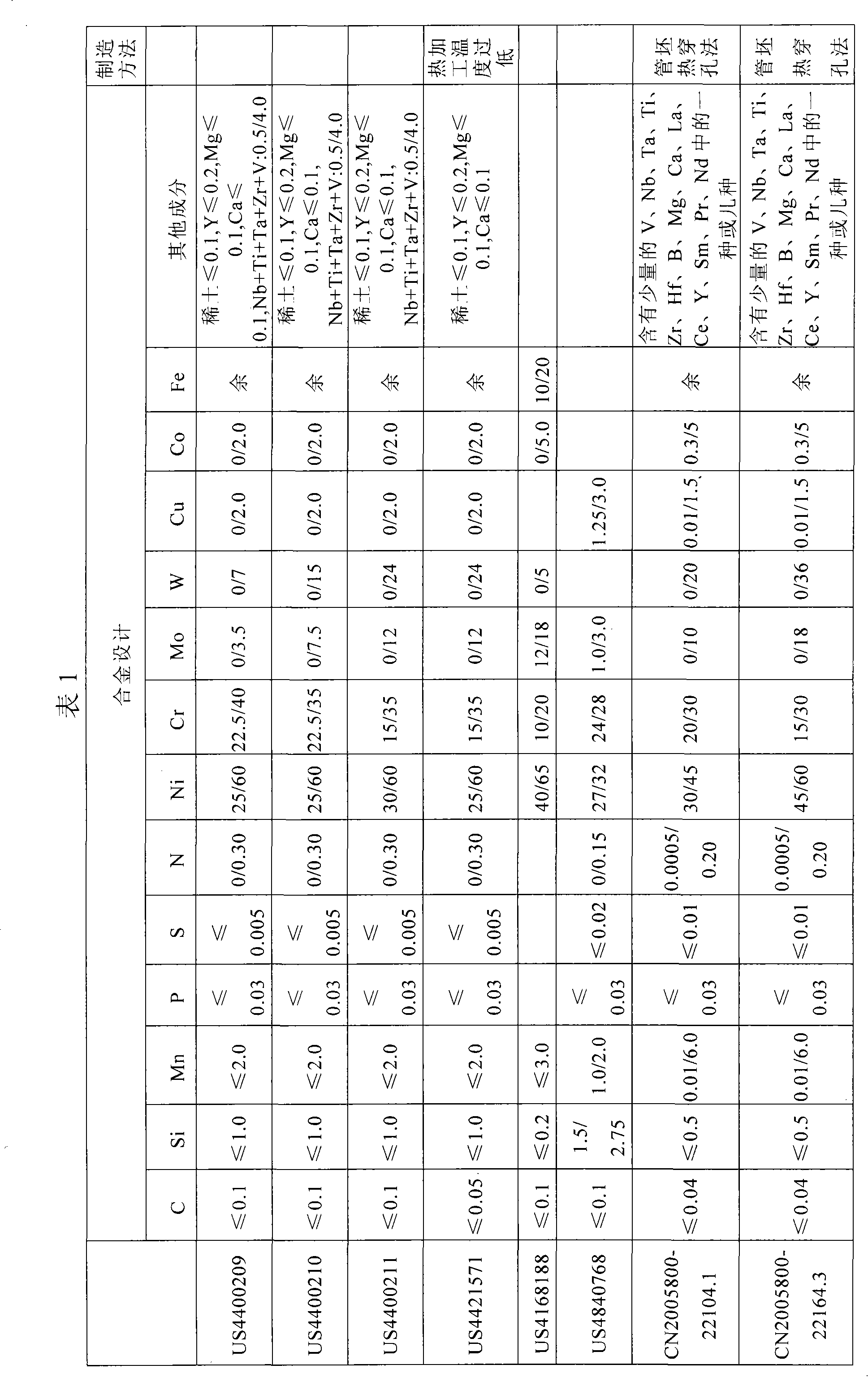

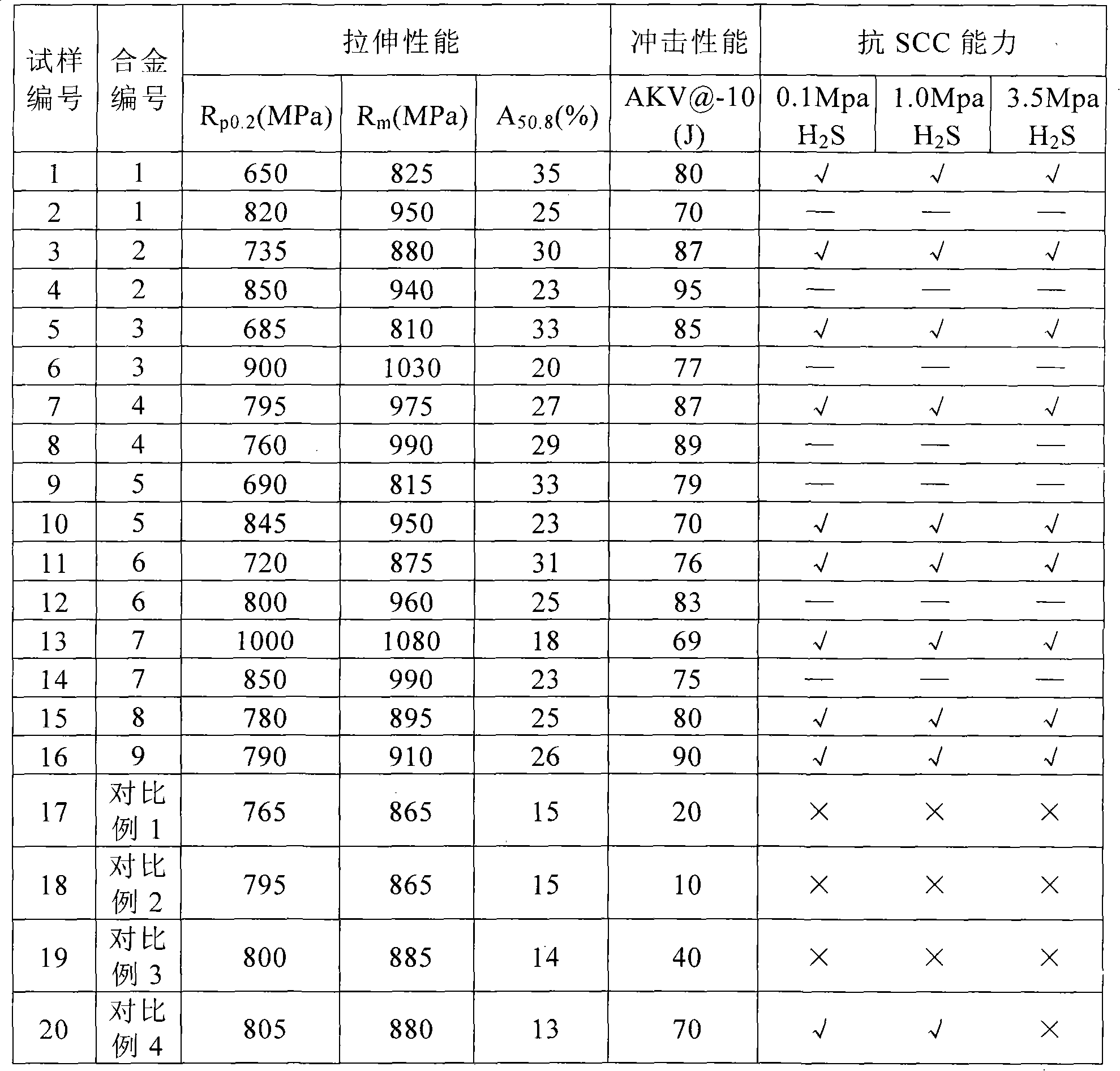

[0081] The Fe-based austenitic alloy with the chemical composition shown in Table 2 was melted by an electric arc furnace (EAF) combined with an argon-oxygen decarburization furnace (AOD) and electroslag remelting (ESR), and cast into a steel ingot with a diameter of 500 mm. Wherein the comparative example 4 alloy is equivalent to the alloy composition in US Patent No. 4,840,768.

[0082] Table 2

[0083] implement

example

C

Si

mn

P

S

Ni

Cr

Mo

Al

Cu

o

ppm

other

Fe

1

0.008

0.53

1.76

0.007

0.005

34.15

33.72

2.42

0.11

1.38

32

Ca 0.003

margin

2

0.022

0.78

2.95

0.010

0.006

38.49

21.52

2.83

0.15

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com