Low-gloss soft-touch modified thermoplastic resin and preparation method thereof

A thermoplastic resin, low-gloss technology, applied in the field of low-gloss and soft-touch modified thermoplastic resin and its preparation, can solve the problems of complex processing technology, low surface gloss, performance loss, etc., and achieve simple production process, low gloss, low gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

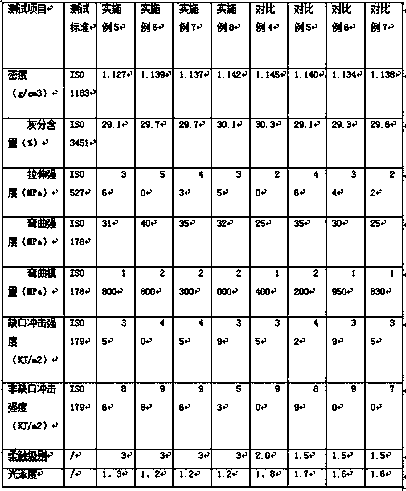

Embodiment 1

[0051] 50KG of polypropylene (brand 548RQ, melt index 28), 20KG of elastomer masterbatch (EPDM rubber, polypropylene elastomer masterbatch, hardness of Shore A 65), 5KG of nylon 6, 22KG of talcum powder (brand HYT-04C, 3000 mesh) and 0.1KG antioxidant 1010, 0.1KG antioxidant 168, 0.4KG lubricant, 0.6KG flow modifier, 0.8KG coupling agent, mixed at high speed and put into twin-screw extrusion Melting process in the machine, the set temperature of the twin-screw extruder is 190-230°C, the speed of the main machine is 400r / min, the speed of the pelletizer is 600r / min, and the product pellets with low gloss and soft touch are obtained by traction cooling and pelletizing.

Embodiment 2

[0053] 56KG of polypropylene (grade 548RQ, melt index 28), 20KG of elastomer masterbatch (EPDM rubber, polypropylene elastomer masterbatch, hardness of Shore A 65), 2KG of nylon 6 and 0.1KG of antioxidant 1010, 0.1KG antioxidant 168, 0.4KG lubricant, 0.6KG flow modifier, 0.8KG coupling agent, after high-speed mixing evenly, put into the twin-screw extruder for melting treatment, and the set temperature of the twin-screw extruder is 190-230°C, the speed of the main engine is 400r / min, the speed of the pelletizer is 600r / min, 22KG talc powder (brand name is HYT-04C, 3000 mesh) is added into the melt from the side feeding weight loss scale, and it is cooled and cut by traction. The product particles with low gloss and soft touch are obtained.

Embodiment 3

[0055] 53KG polypropylene (grade 548RQ, melt index 28), 5KG PA6 (grade PA6 28200, viscosity 2.7), 20KG elastomer masterbatch (EPDM rubber, polypropylene elastomer masterbatch, hardness is Shore A 65), 22KG talc powder (brand is CP250, 3000 mesh), and 0.1KG antioxidant 1010, 0.1KG antioxidant 168, 0.4KG lubricant, 0.6KG flow modifier, 0.8KG coupling agent, high-speed mixing After uniformity, put it into a twin-screw extruder for melting treatment. The temperature of the twin-screw extruder is set at 190-230°C, and the speed of the main machine is 400r / min. After being pulled, cooled and pelletized, the product pellets with low gloss and soft touch are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com