High-efficiency halogen-free phosphorus-based gas-phase flame retardant and polymer materials containing the flame retardant

A flame retardant and high-efficiency technology, applied in the field of phosphorus-based gas-phase flame retardants and polymer materials, to achieve the effects of easy operation, easy acquisition and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

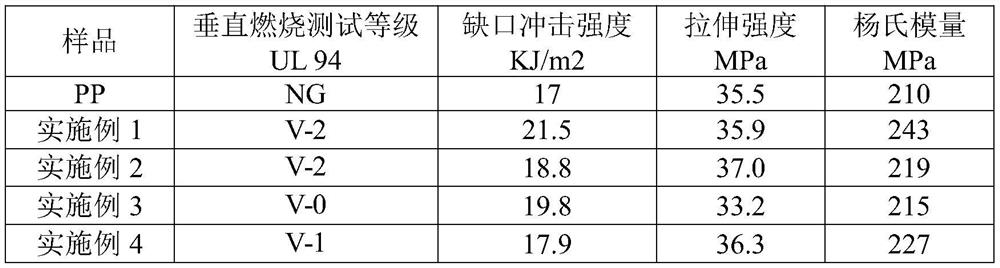

Examples

preparation example Construction

[0033] At the same time, the present invention also provides a method for preparing the above-mentioned high-efficiency halogen-free phosphorus-based gas-phase flame retardant. The prepared high-efficiency halogen-free phosphorus-based gas-phase flame retardant is composed of the following components in parts by mass: hindered phenolic antioxidant : 2-2.8 parts, flame retardant intermediate: 8-11 parts; the preparation method of the highly efficient halogen-free phosphorus-based gas-phase flame retardant comprises the following steps:

[0034] Step 1. Prepare an ethanol suspension of hindered phenol and an ethanol solution of a flame retardant intermediate according to the composition by mass of the flame retardant;

[0035] Step 2. Stir and heat the prepared ethanol suspension of hindered phenol, then add the prepared ethanol solution of the flame retardant intermediate to form a mixed solution of the two, and then react;

[0036] Step 3. Rotate the mixed solution after the r...

Embodiment 1

[0043] The high-efficiency halogen-free phosphorus-based gas-phase flame retardant of the present invention and the polypropylene material containing the phosphorus-based gas-phase flame retardant are prepared through this example.

[0044] (1) Add 0.25g of hindered phenol A to a 500mL three-necked flask, and then add 150ml of ethanol solvent to disperse under ultrasonic or high-speed stirring conditions to form a suspension;

[0045] (2) Add 1g of flame retardant intermediate DOPO into a 500mL three-necked flask, then add 200ml of ethanol solvent to disperse under ultrasonic or high-speed stirring conditions until completely dissolved to form a solution;

[0046] (3) Put the ethanol suspension of hindered phenol obtained in (1) in an oil bath and raise it to 60°C under magnetic stirring. After the temperature is constant, put the ethanol solution of the flame retardant intermediate obtained in (2) Slowly added to the oil bath to form a mixed solution of the two, and reacted f...

Embodiment 2

[0050] The high-efficiency halogen-free phosphorus-based gas-phase flame retardant of the present invention and the polypropylene material containing the phosphorus-based gas-phase flame retardant are prepared through this example.

[0051] (1) Add 0.28g of hindered phenol B to a 500mL three-necked flask, and then add 150ml of ethanol solvent to disperse under ultrasonic or high-speed stirring conditions to form a suspension;

[0052] (2) Add 0.8g of flame retardant intermediate DOPO into a 500mL three-necked flask, then add 200ml of ethanol solvent to disperse under ultrasonic or high-speed stirring conditions until completely dissolved to form a solution;

[0053] (3) Put the ethanol suspension of hindered phenol obtained in (1) in an oil bath and raise it to 65°C under magnetic stirring. After the temperature is constant, put the ethanol solution of the flame retardant intermediate obtained in (2) Slowly added to the oil bath to form a mixed solution of the two, and reacted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com