Smelting method for improving copper strip plasticity

A copper strip and plasticity technology, which is applied in the smelting field of copper strip, can solve problems such as rolling cracking, good thermal conductivity, and poor fluidity of copper water, and achieve the effects of improving high-temperature plasticity, increasing elongation, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

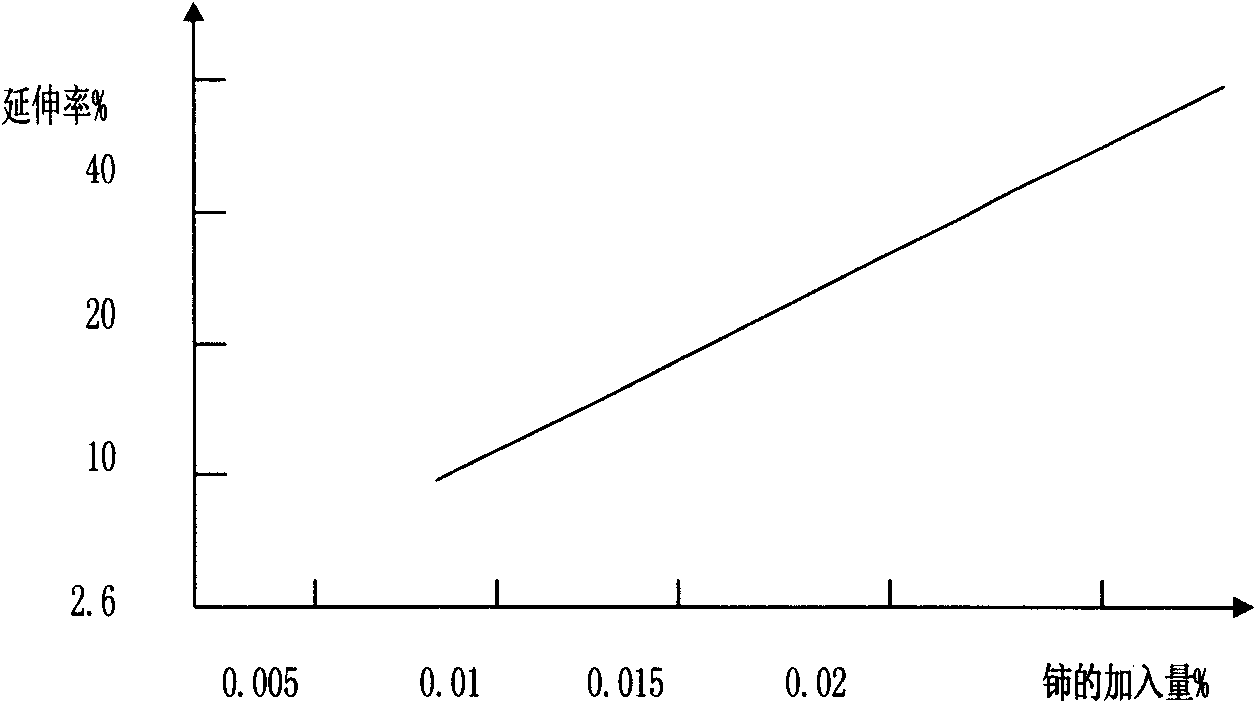

[0010] Embodiment: Add rare earth element cerium to pure copper, cerium is added in the form of master alloy, and the input amount is 105-120 grams per ton of copper water, stir evenly after adding, remove slag, take samples, stand still and then draw cast. Drawing parameters: lead stroke 12.5-15mm, reverse push 0.5-1mm, pause 2-3s, drawing temperature 1210-1260℃, drawing speed 2.5-2.8mm / s, inlet water temperature 15-30℃, outlet water temperature 40 -55°C.

[0011] The grade and composition of alloy cerium are

[0012] Cerium-rich rare earth metal grades

[0013] After the addition of cerium, under the condition of other process conditions unchanged, the test shows that the surface cracks are less, the oxygen content is 10-20ppm, the conductivity reaches more than 98%, the thickness of the cold-rolled red copper strip is 0.08mm, and its tensile strength can be Up to 350-380MPa, hardness HV is 100-120, softening temperature > 380°C, the effect is obvious, suitable fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com