High-formability boron-containing steel with tensile strength higher than or equal to 320 MPa and production method

A technology of tensile strength and production method, applied in the field of high formability boron-containing steel and production, can solve the problems of strict limitation of N content, long-term vacuum treatment, increase of manufacturing cost, etc., and achieve the reduction of the occurrence rate of slab crack defects , Improve the uniformity of product organization and save heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

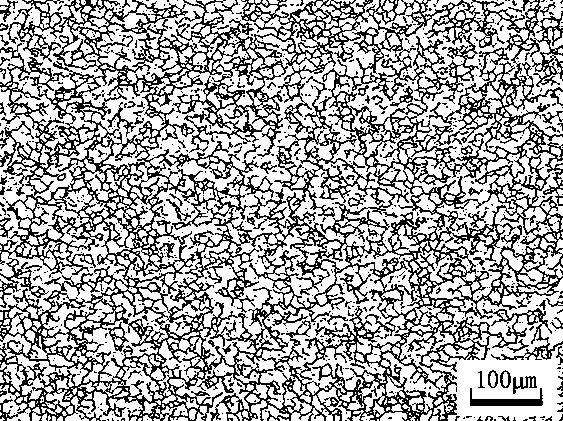

Image

Examples

Embodiment Construction

[0055] The present invention is described in detail below:

[0056] Table 1 is the value list of the chemical components of each embodiment of the present invention and comparative examples;

[0057] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0058] Table 3 is a list of various embodiments of the present invention and comparative performance detection situations;

[0059] Table 4 is a list of the corrosion resistance detection of each embodiment of the present invention and comparative examples.

[0060] Each embodiment of the present invention is produced according to the following preparation methods:

[0061] 1) After smelting, the billet is continuously cast, during which the mold taper is 0.8-0.9% / m, the casting speed is 0.8-1.4m / min, the secondary cooling water ratio is 0.9-1.1l / kg, and the straightening temperature is 800 ~950℃;

[0062] 2) Heating the slab in sections: control the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com