Secondary cooling nozzle arranging method for improving surface plasticity of casting blank and secondary cooling control method

A technology of control method and arrangement method, which is applied in the field of metallurgy, can solve the problems of failure to completely eliminate the defects of transverse cracks at the corners of the slab, and the insufficient improvement effect of transverse cracks, and achieve the goal of eliminating crack defects, improving high-temperature plasticity, and inhibiting precipitation behavior Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

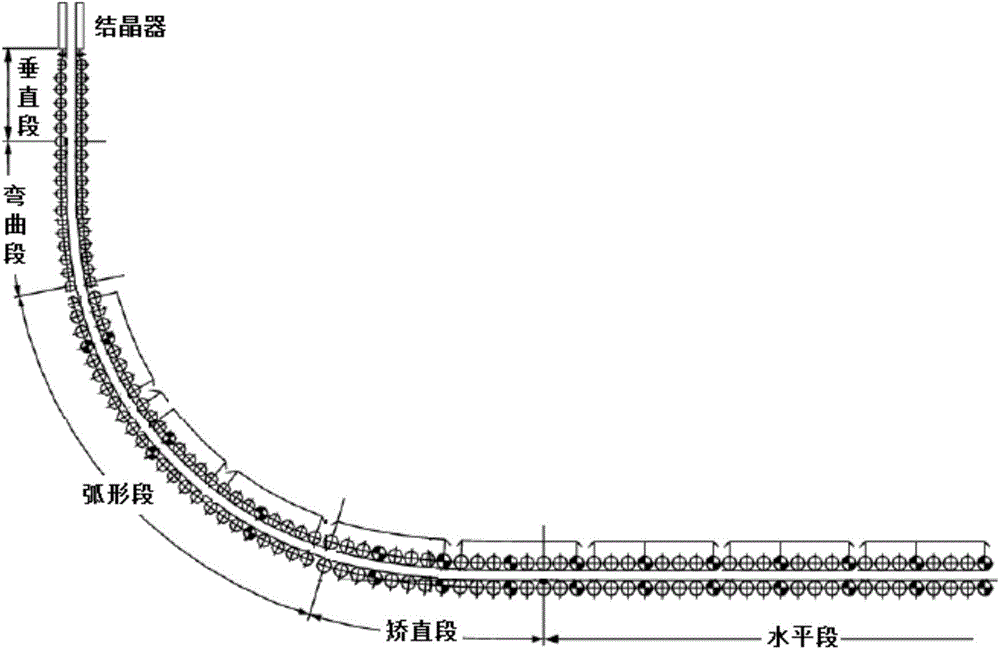

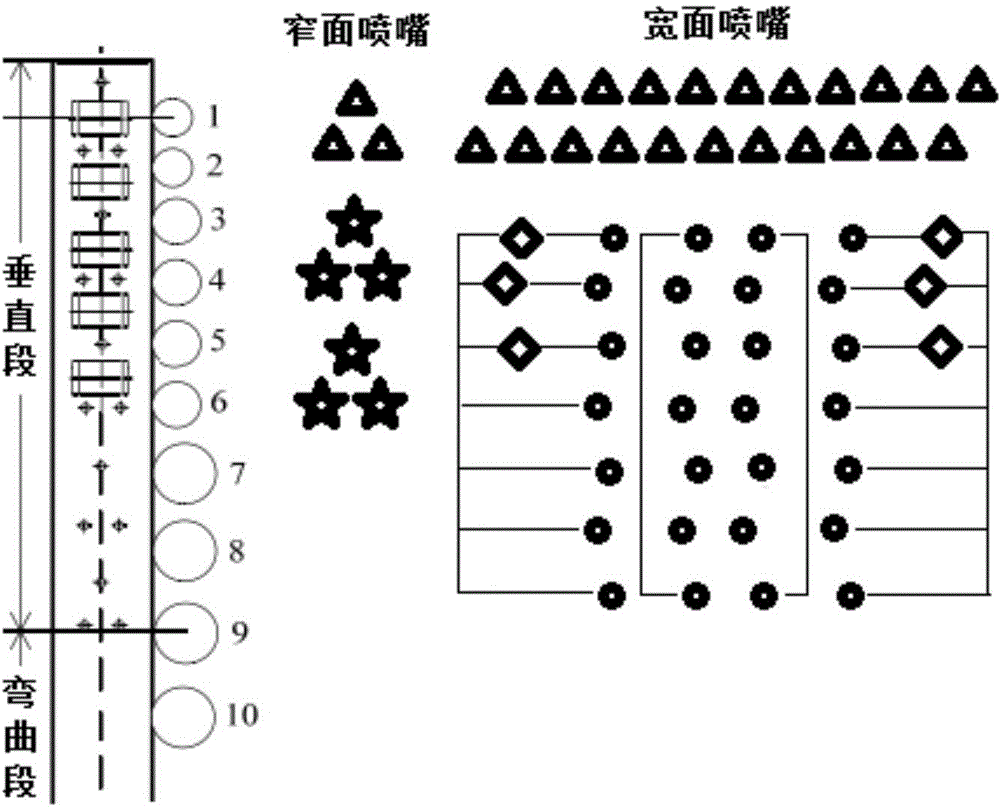

[0024] A steel factory uses a vertical curved continuous casting machine to produce billets with a section of 190mm×1650mm. The steel type is ordinary carbon steel Q235, the casting speed is 1.1m / min, and the specific water volume of the conventional secondary cooling is 0.6L / kg. The layout of the nozzles in the vertical section is transformed, and the wide and narrow secondary cooling circuits in this area are transformed into an independent control mode, and the nozzles are all-water nozzles. After the slab exits the crystallizer, the cooling water flow rate on the wide surface is 25m 3 / h, the flow of cooling water on the narrow side is 8m 3 / h.

[0025] During the production process, the cracks on the surface of the slab were first observed manually, and then the surface cracks of the slab were detected by flame cleaning and hot acid corrosion after the slab was cooled. No cracks were found on the surface of the slab.

Embodiment 2

[0027] A steel factory uses a vertical curved continuous casting machine to produce billets with a cross-section of 230mm×1870mm. The flow of cooling water on the wide surface after the crystallizer is 28m 3 / h, the flow of cooling water on the narrow side is 10m 3 / h.

[0028] After the slab was off-line and cooled, the surface cracks of the slab were detected by hot acid corrosion method, and no crack defects were found on the surface of the slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com