Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Eliminate crack defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling the cross crack of blank angle of high nitrogen steel casting board containing vanadium

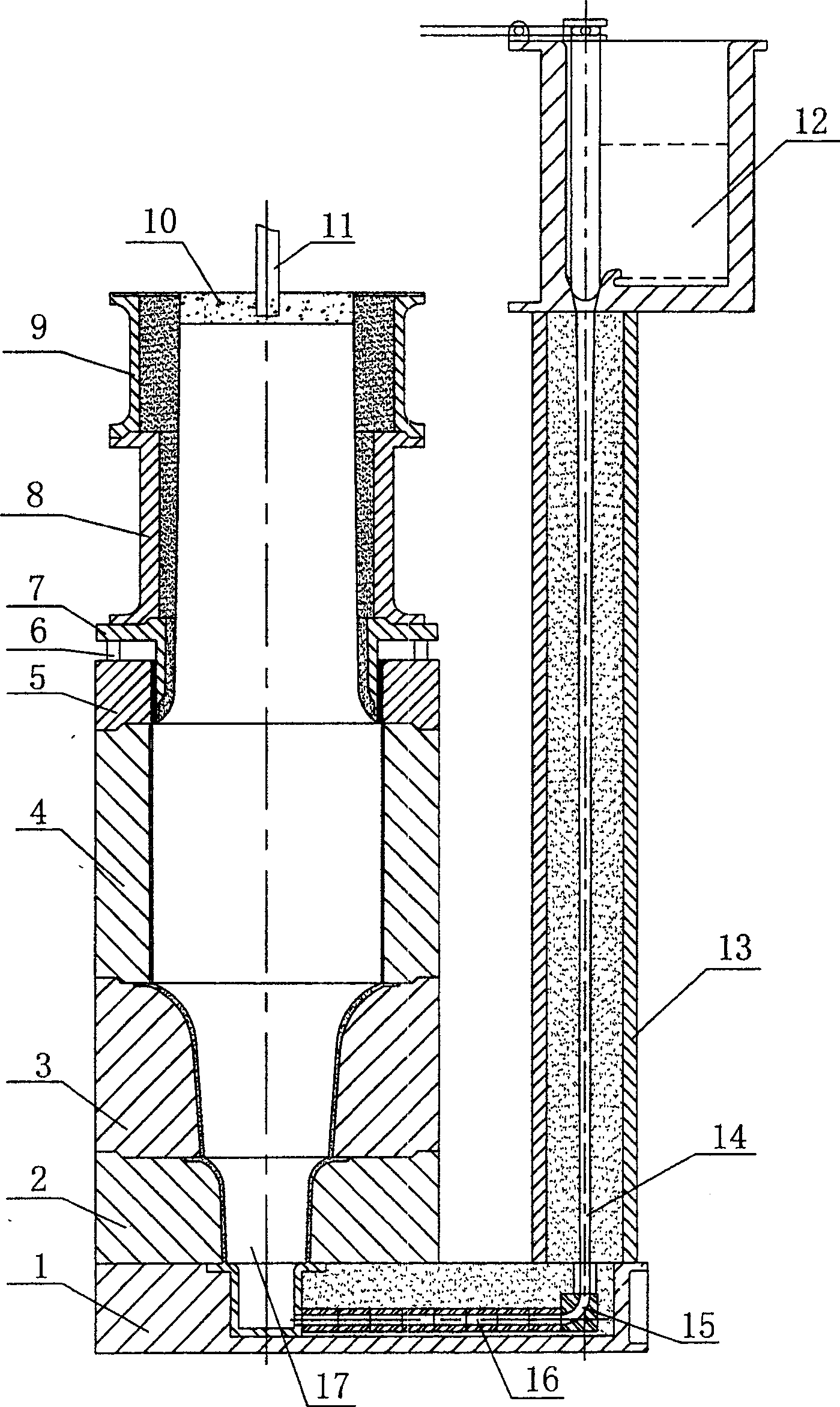

The invention discloses a transverse crack control method of high nitrogen steel continuous casting plate billet angle containing vanadium, the method can not only effectively eliminate transverse crack defect of the continuous casting billet surface and skin inferior angle, but also can eliminate the continuous casting billet surface longitudinal crack and surface transverse crack defect. The method synthetically applies following technique measures: presetting the mold cooling water amount, the wide face cooling water amount is 3000-30500 L / min, the narrow face cooling water amount is set to 360-365 L / min; improving casting pulling rate, the casting pulling rate is stabilized in 0.8-1.5 m / min, the vibration frequency is 140-210 Hz; after spruing the casting pulling rate, quickly putting casting powder into the mold, the alkalinity of the casting powder is 1.0-1.40, the melting point is 1100-1160 DEG C, when at 1300 DEG C, the viscosity is 0.10-0.40 Pa.s; reducing the second cool segment casting billet cooling water amount, and controlling the continuous casting ratio water amount in 0.55-0.60 L / kg by static or dynamic adjusting method.

Owner:PANZHIHUA IRON AND STEEL

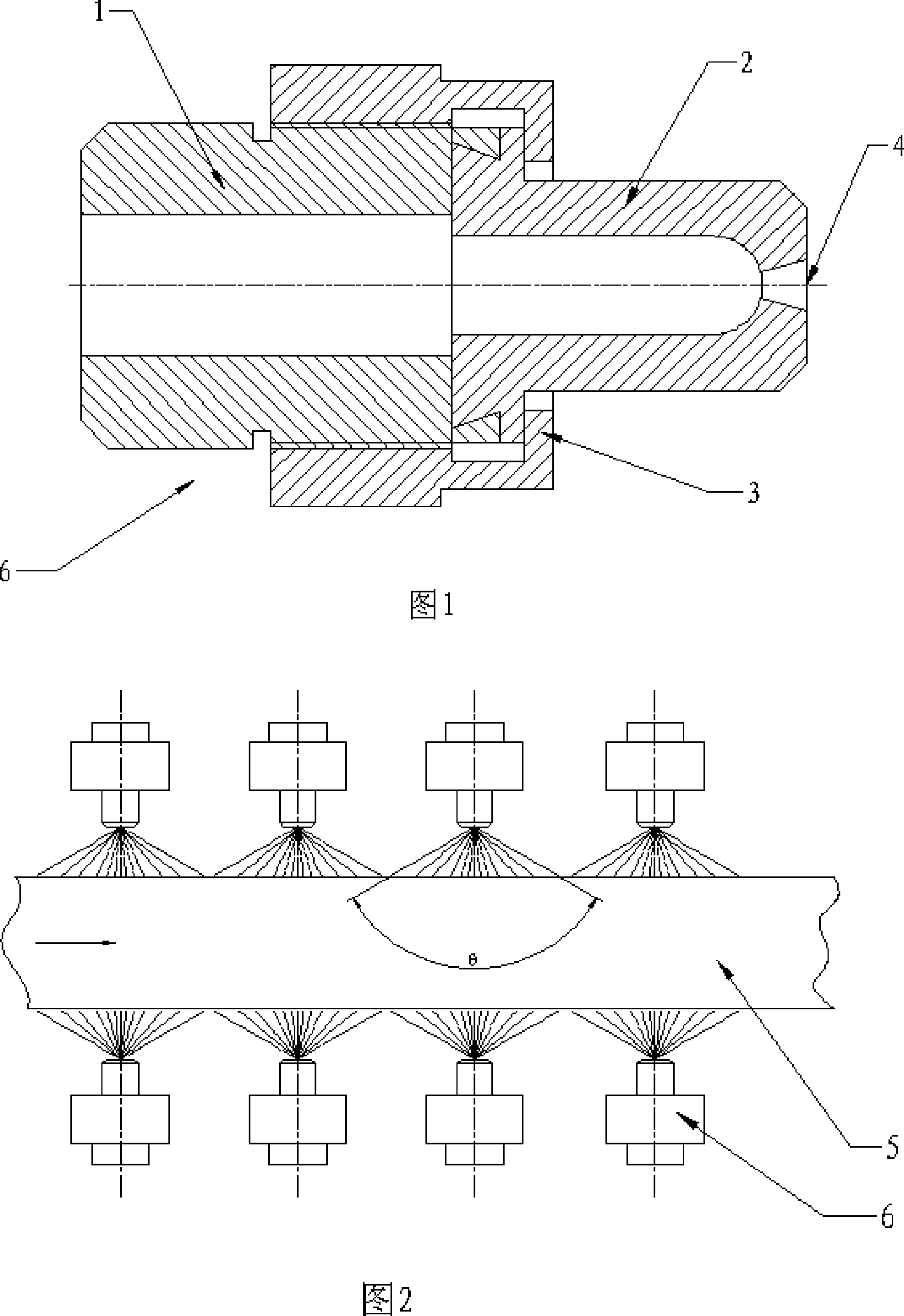

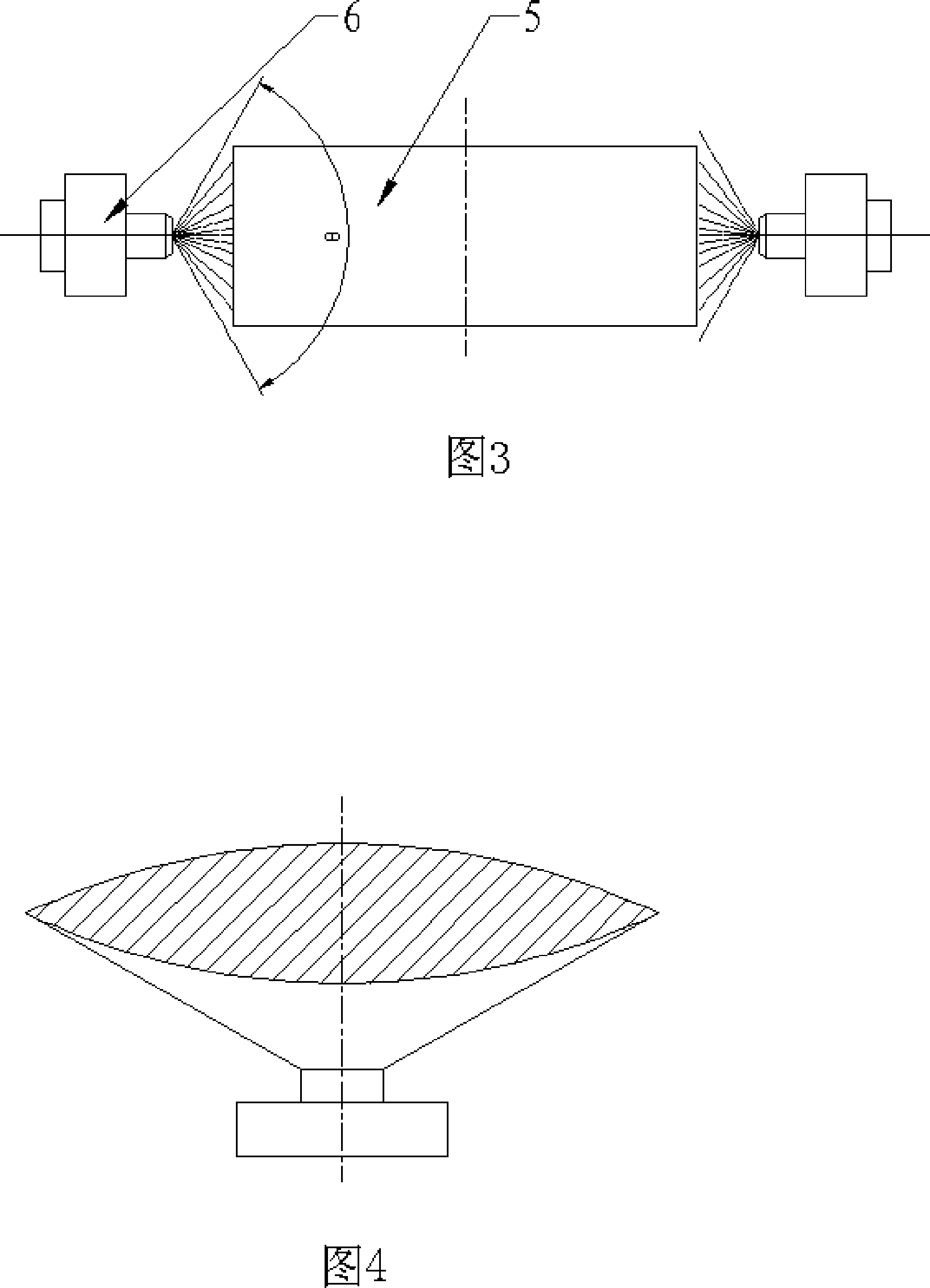

Straight arc casting machine alloy steel sheet billet continuous casting foot roller segment narrow surface cooling method

The present invention discloses a straight-curved type casting machine low-alloy steel slab continuous casting full-rolling section narrow face cooling method, and is aimed at solving the problem of that on the casting blank surface corner portion of low-alloy steel the transverse crack can be easily produced. Said invention belongs to the field of metal continuous casting blank cooling and surface quality control technology. Said method is characterized by that in the full-rolling section of continuous casting straight-curved type casting machine slab said invention utilizes the nozzles which are symmetrically mounted at left side and right side of casting blank pouring direction to cool the narrow face of said casting blank, and adopts rectangular nozzles to symmetrically and simultaneously cool the narrow faces of left and right two sides of casting blank. Said invention also discloses a kind of rectangular nozzle for said method, the water outlet hole of its sprayer is a hole with rectangular section. Said invention can reduce casting blank cooling strength of full-rolling section under the crystallizer and can improve casting blank cooling uniformity, so that it can eliminate casting blank surface corner portion transverse crack defect of continuously-cast high-strength low-alloy steel whose steel quality is P510L, P590L, J55 and X52, etc.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Process for preparing large cast steel support roller

The process of making cast steel supported roller is suitable for integral casting of cast steel supported roller of 5-100 ton weight. The present invention has adopts computer simulation, coating iron mold with sand, rotary cavity filling, heat insulating casting head technology, electrically casting head heating technology and sliding roller neck technology; and designs pouring system and casting mold design by means of new design principle and successive solidification principle. Adopting sliding roller neck technology and electrically casting head heating technology can avoid cracking in the cast steel supported roller.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

Cooling method for preventing microcracks on wheel steel continuous casting slabs

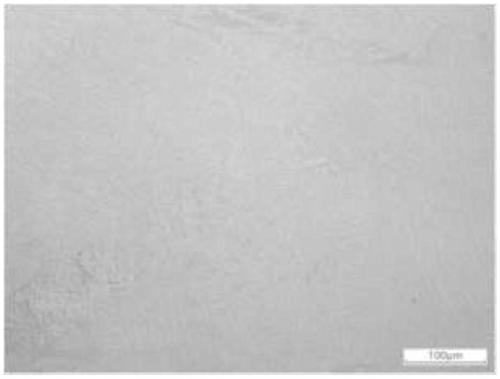

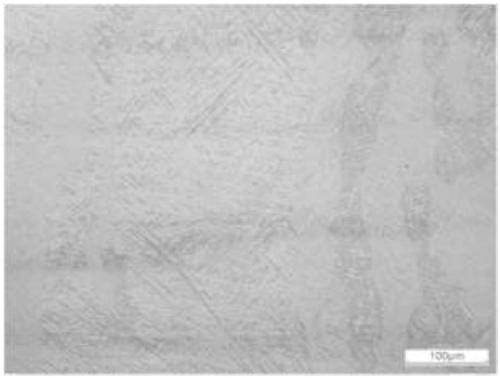

The invention relates to a continuous casting process, especially relates to a cooling method for preventing microcracks on wheel steel continuous casting slabs. The method of the invention improves the secondary cooling technique in the wheel steel slab continuous casting process, can effectively prevents generation and expansion of the microcracks on the wheel steel continuous casting slabs, such as star like crack, check crack, transverse crack, etc., on the surface or under the surface. The cooling method is a secondary cooling technique, concretely comprising: when the casting blank passing through the two cooling zones, controlling surface temperature of the casting blank in a range from 950 DEG C to 990 DEG C at the support and guide zone, and controlling surface temperature of the casting blank in a range from 950 DEG C to 100 DEG C at pulling and straighten zone. The method can makes surface and subsurface coagulating organization compact for the wheel steel continuous casting slabs, eliminates defects of star like crack, check crack and transverse crack on the surface or under surface of the casting blank, flawless rate of casting blank reaching 100%, and provides high grade casting blank for producing high quality wheel steel.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

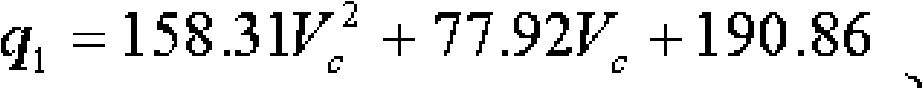

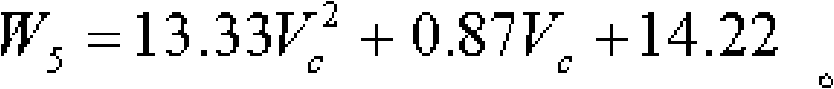

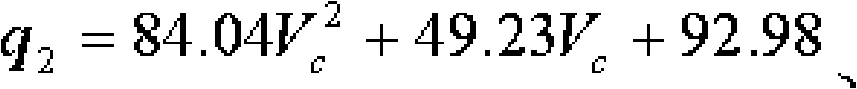

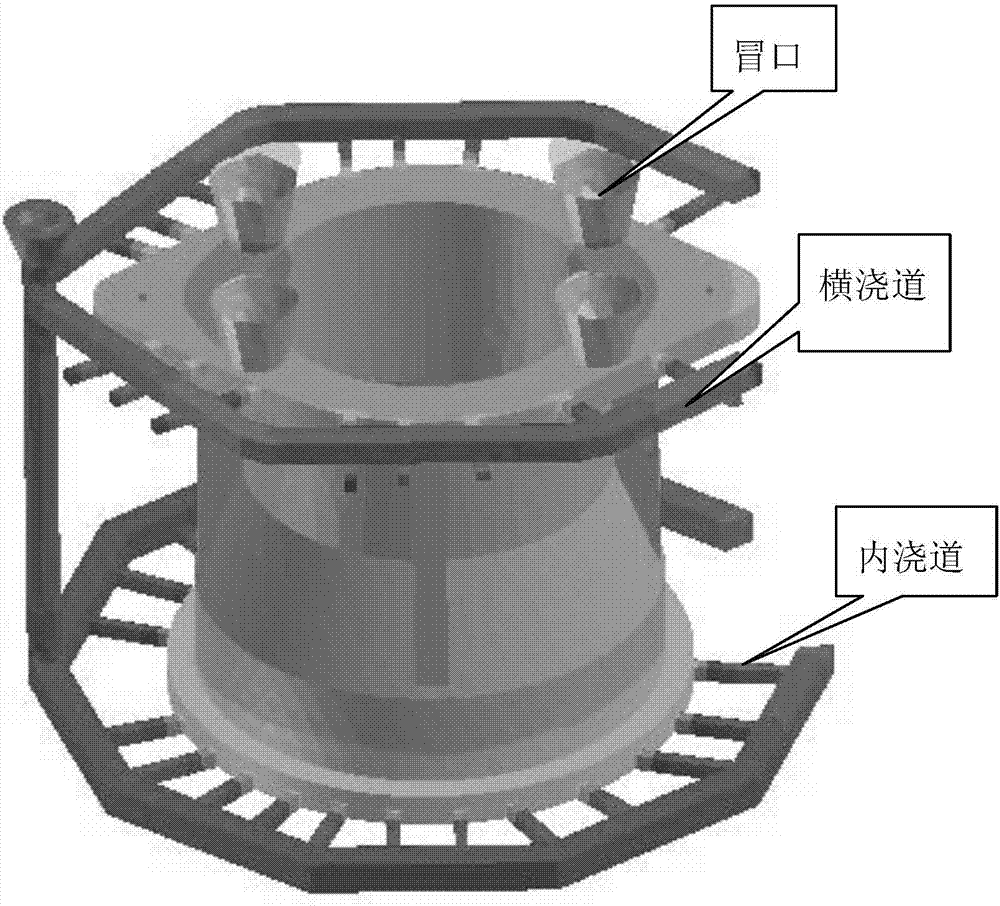

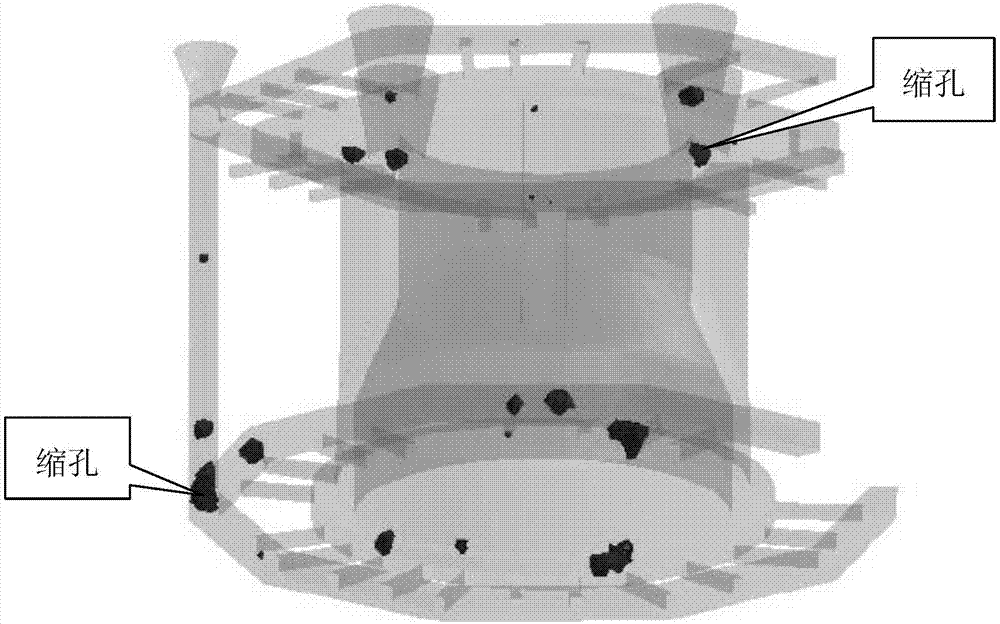

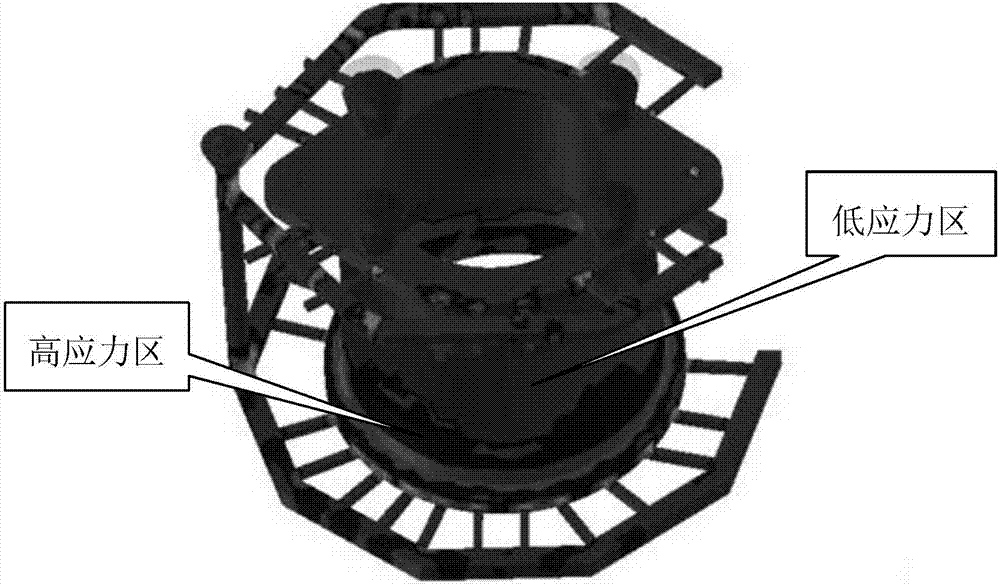

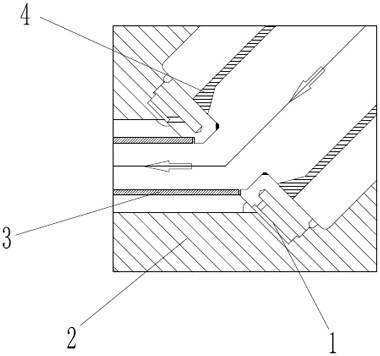

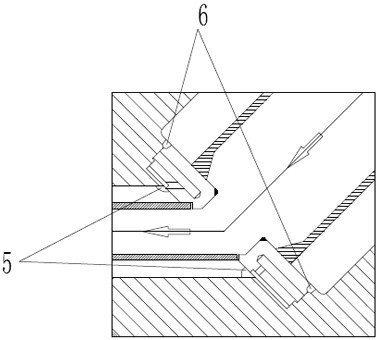

Casting system capable of eliminating detects of ZG35 valve casting and design method thereof

PendingCN107159845AEliminate shrinkageEliminate crack defectsFoundry mouldsFoundry coresDesign methodsMaterials science

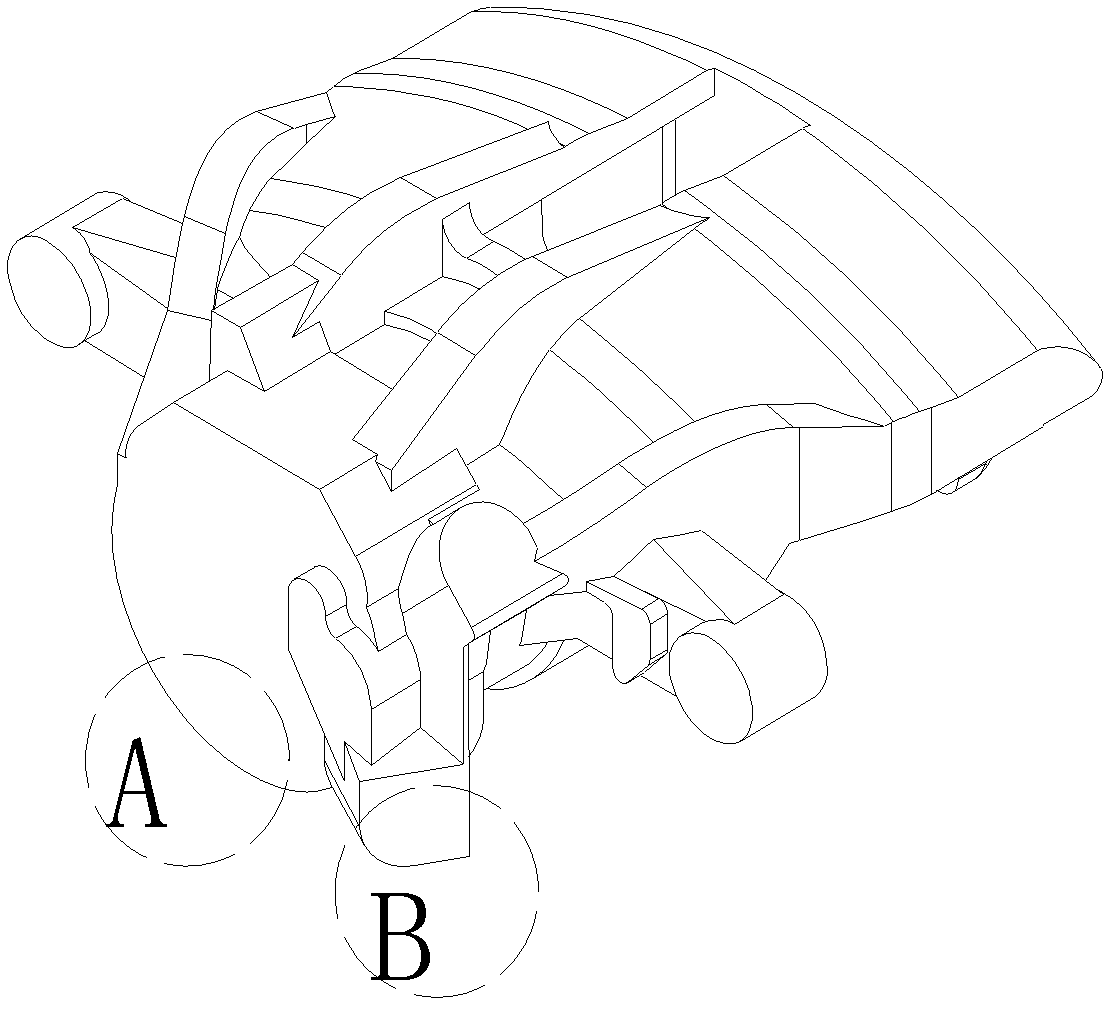

The invention discloses a casting system capable of eliminating detects of a ZG35 valve casting and a design method thereof. The casting system comprises risers, a gating system and a chilling block. The gating system adopts a step-type gating system and comprises a sprue cup, a straight gate, a bottom layer ingate and an upper layer ingate. The sprue cup is used for pouring of molten metal liquid and connected with the straight gate. The straight gate is connected with the bottom layer ingate and the upper layer ingate. The chilling block is arranged at a hot spot at the bottom of the casting. The risers comprise the top risers and the side riser. The top risers are arranged over a flange on the top of the casting, and the side riser is arranged on the side face of a flange at the bottom of the casting. According to the casting system, the defects of shrinkage, dispersed shrinkage and cracking of the ZG35 valve casting can be effectively eliminated, the rate of finished products is increased, and mechanical performance of the ZG35 valve casting is improved.

Owner:HEBEI UNIV OF TECH

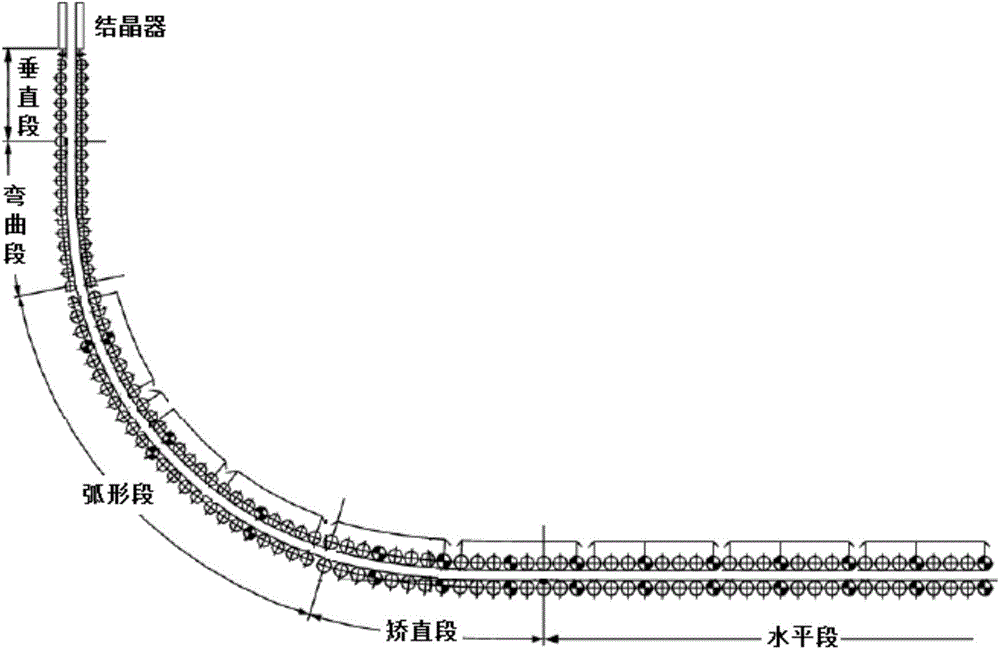

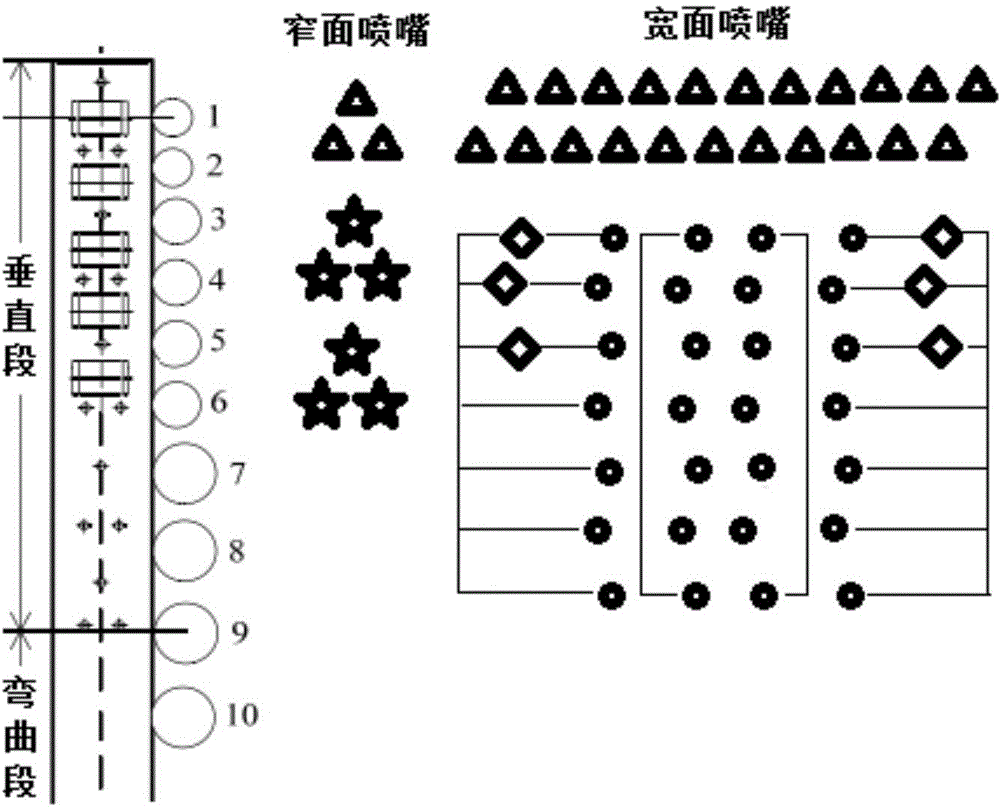

Secondary cooling nozzle arranging method for improving surface plasticity of casting blank and secondary cooling control method

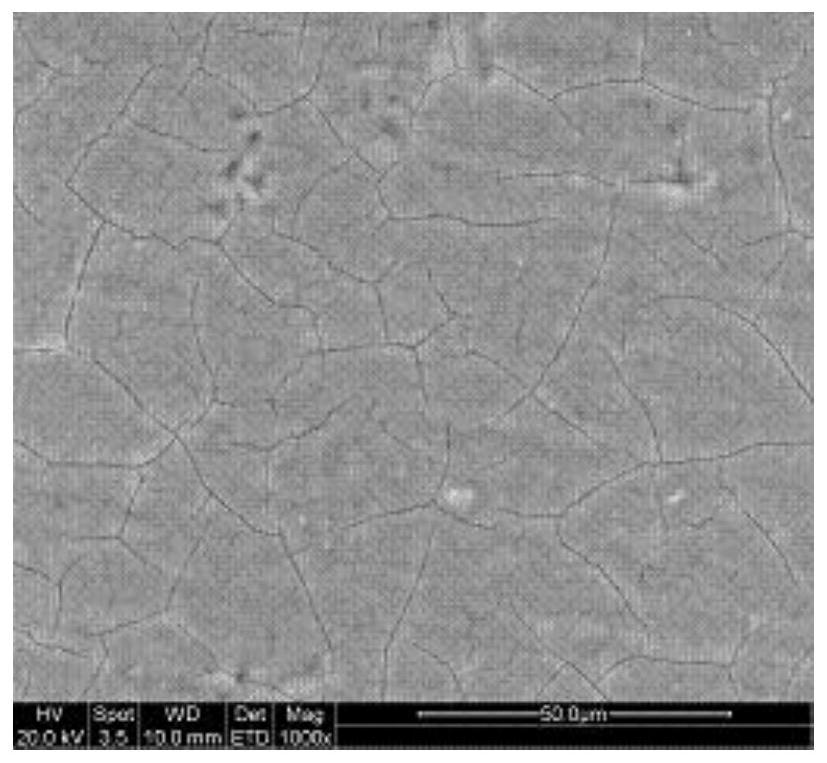

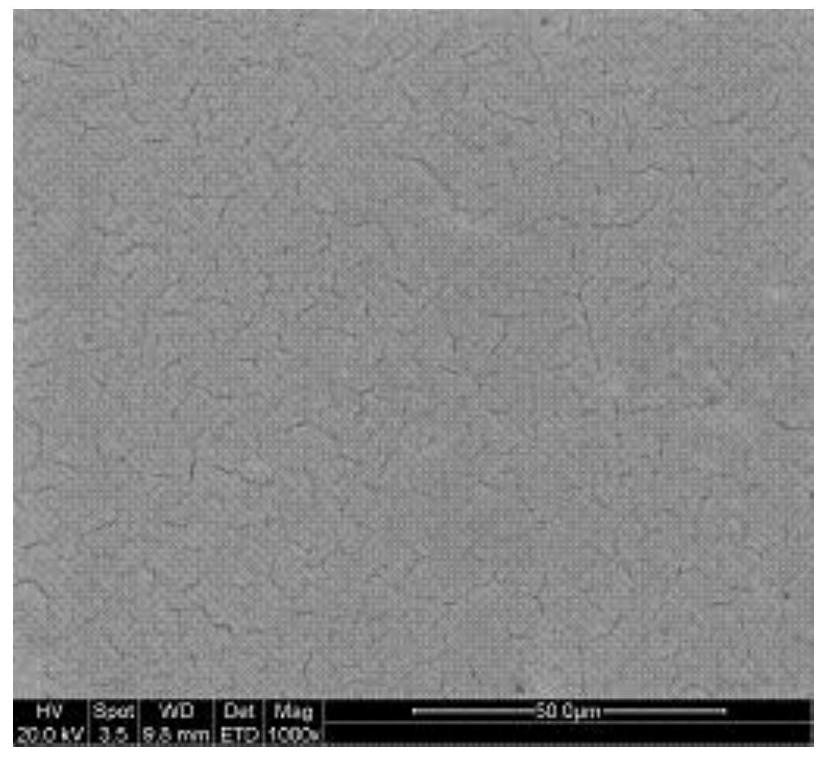

InactiveCN104607609AInhibit precipitation behaviorImprove high temperature plasticityHot TemperatureGrain boundary

The invention relates to a secondary cooling nozzle arranging method for improving surface plasticity of a casting blank and a secondary cooling control method. In the secondary cooling nozzle arranging method, wide nozzles and narrow nozzles are formed in the vertical section of a continuous casting machine, and the wide nozzles and the narrow nozzles are controlled by independent loops respectively; after a continuous casting blank is discharged from a crystallizer, by the secondary cooling nozzle arranging method, the casting blank is forcibly cooled with the amount of secondary cooling water of 15-40m<3> / h to rapidly reduce the surface temperature of the casting blank to below 750 DEG C; narrow corner nozzles and wide corner nozzles in a lower area of the vertical section are closed to rapidly raise the surface temperature of the casting blank to about 1100 DEG C, and from the bent section to the horizontal section, a conventional cooling mode is adopted with the amount of the secondary cooling water of 2-10m<3> / h. In the secondary cooling nozzle arranging method, the changing course of the surface temperature of the casting blank enables the surface tissue of the casting blank to experience once heat treatment, so that the surface tissue of the casting blank is greatly thinned; after rewarming, a dense austenitic tissue is formed on the surface of the casting blank, the precipitation amount of a grain boundary ferrite film is inhibited at the same time, and the high-temperature plasticity of the surface of the casting blank is radically improved.

Owner:CISDI ENG CO LTD

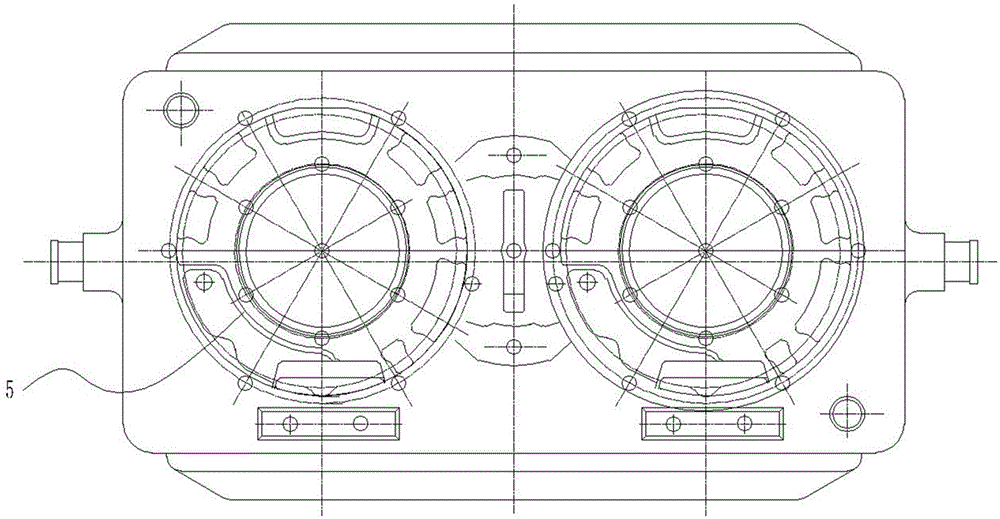

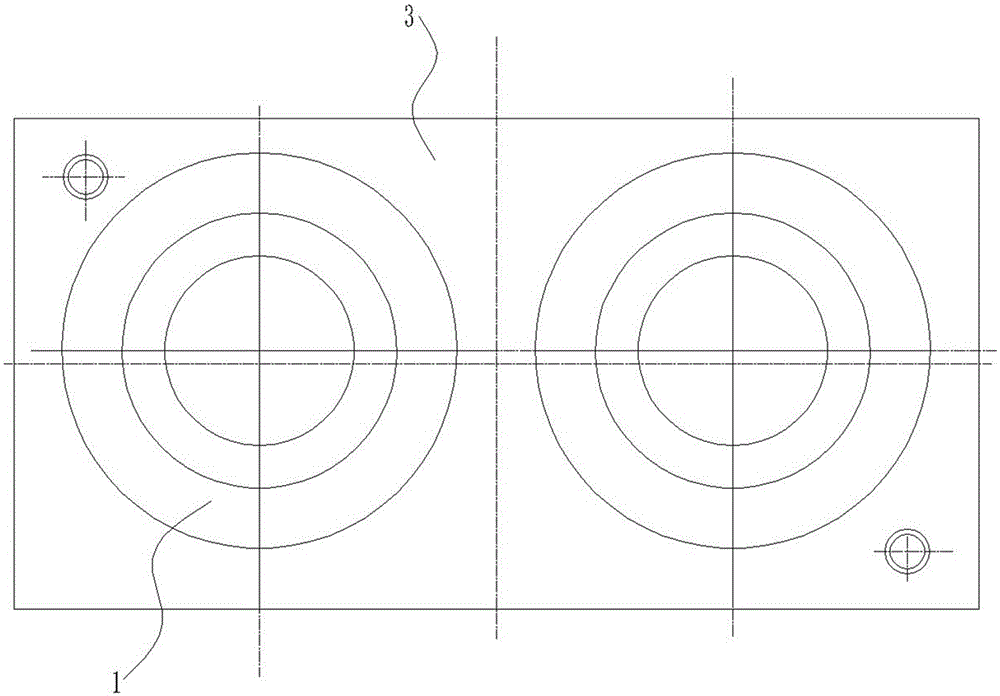

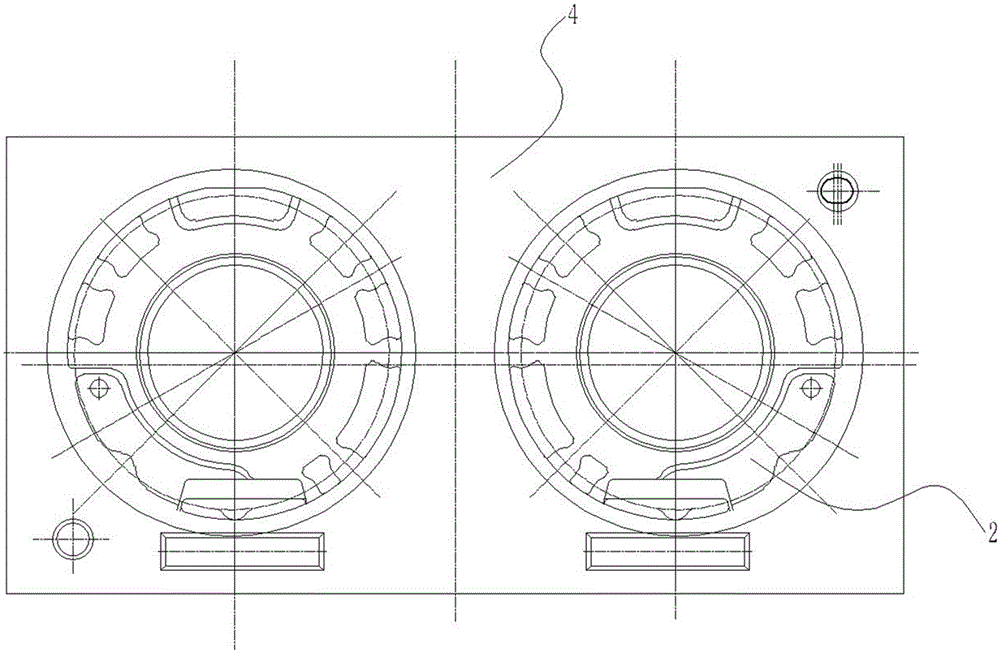

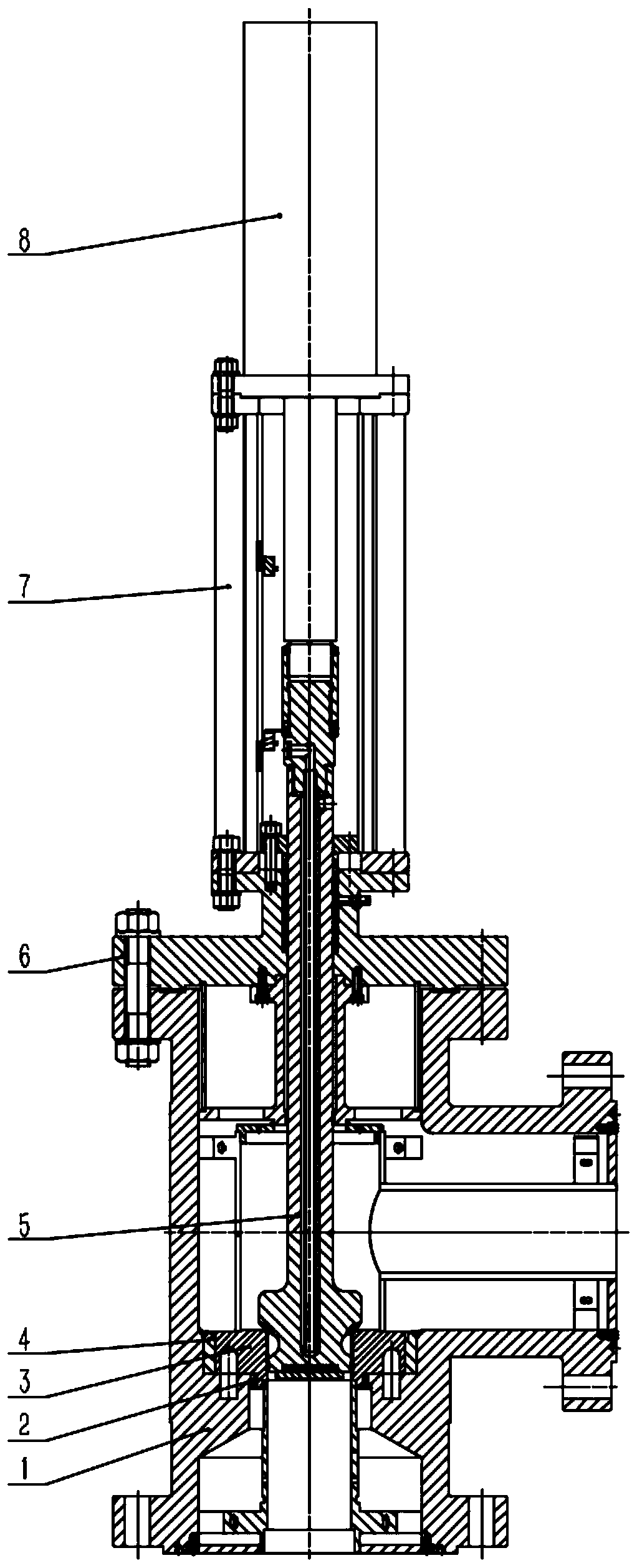

Method for casting bearing cap on subway locomotive by using sand faced permanent iron molding technology

InactiveCN105108064AReduce weightGood lookingFoundry mouldsFoundry coresEconomic benefitsHeat treated

The invention relates to a method for casting a bearing cap on a subway locomotive by using a sand faced permanent iron molding technology. According to the method, a complete cavity which is in the shape of the bearing cap is obtained through the sand faced permanent iron molding technology, a bearing cap part can be directly casted for a next core, so that the appearance and the inner quality of castings are improved effectively, scrappage of the castings is reduced, the weight of the castings is reduced by 20%, heat treatment and hole drilling processing are not required for the casted bearing cap, and shortcomings of inside shrinkage, a shrinkage cavity and cracks of the bearing cap are overcome effectively. In addition, the technology of the method is simple, a large amount of time, labor cost and equipment cost are saved, and the production efficiency of enterprises is improved greatly. By the method, production cost can be reduced by 35%, economic benefit is obvious, a market prospect is wide, and the method can be conveniently popularized and used for most of foundry enterprises.

Owner:侯马市晋烽机械铸造有限公司

Hot valve and manufacturing method thereof

PendingCN111594627AConsistent expansionFulfil requirementsLift valveMetal working apparatusInterference fitValve seat

The invention provides a hot valve and a manufacturing method thereof. The hot valve comprises a valve body and a valve seat, wherein the valve seat is located in an inner cavity of the valve body. The hot valve further comprises a spacer bush made of the same material as the valve body, the spacer bush is located on a sealing face between the valve body and the valve seat, and the spacer bush isin interference fit with the valve seat and welded to the valve body. Compared with the prior art, according to the technical scheme provided by the invention, dissimilar metal welding is converted into same metal welding by adopting interference fit and hot charging processes, so that the expansion amount of parts on the two sides of a weld joint is consistent when the temperature is changed, thedefect of weld joint cracking is eliminated, and the requirement of a wind tunnel test device on the hot valve is met.

Owner:中国空气动力研究与发展中心超高速空气动力研究所 +1

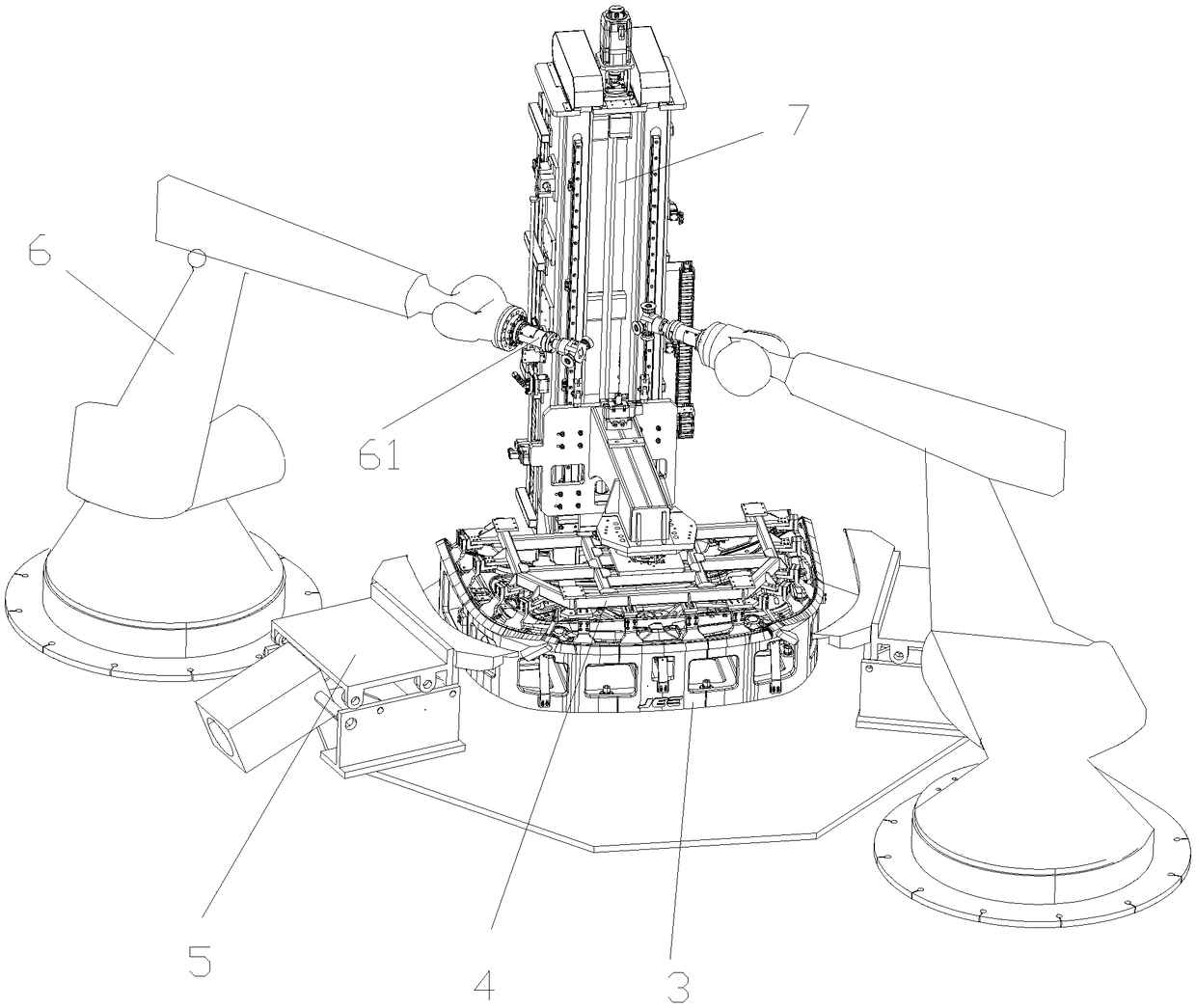

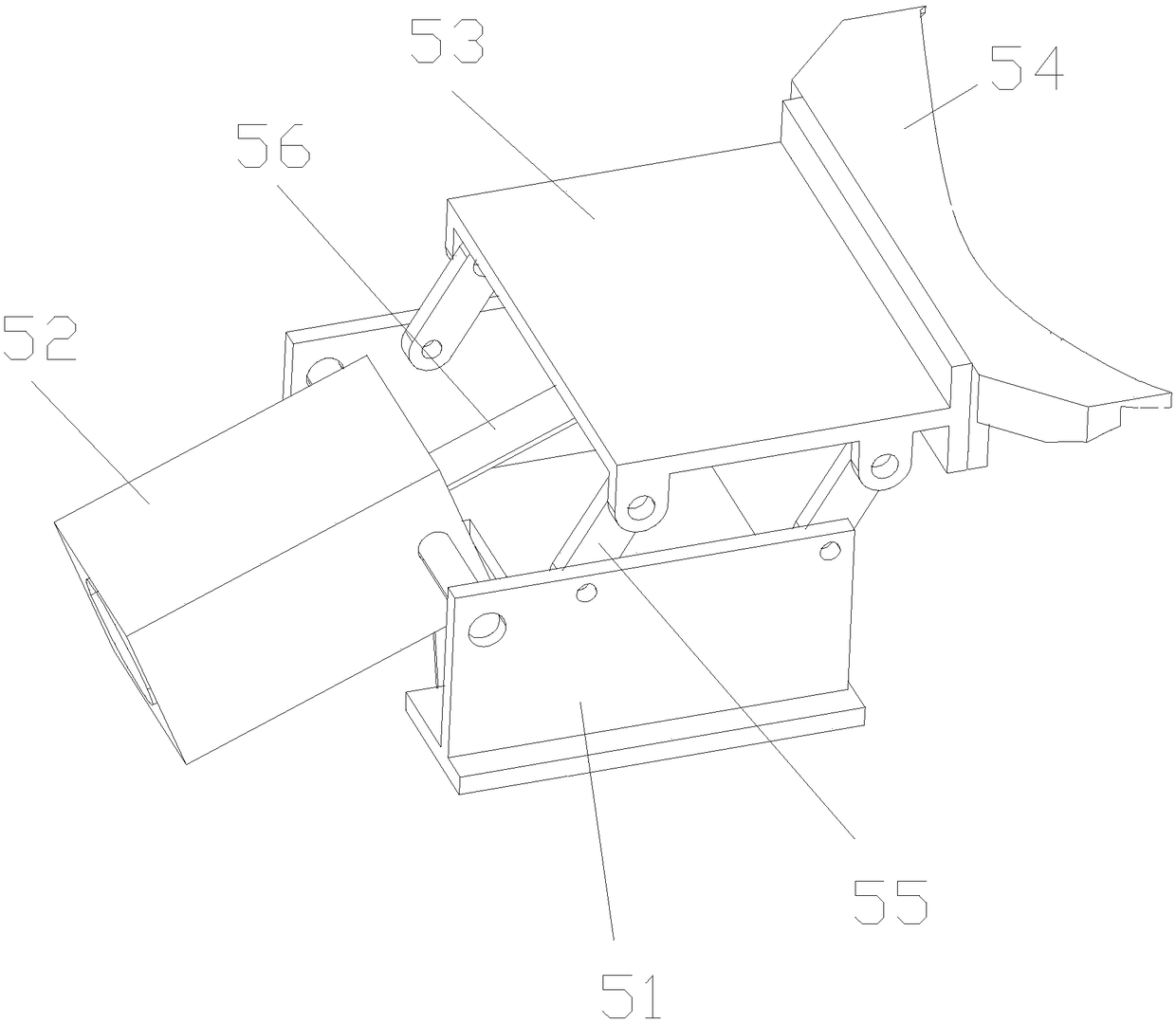

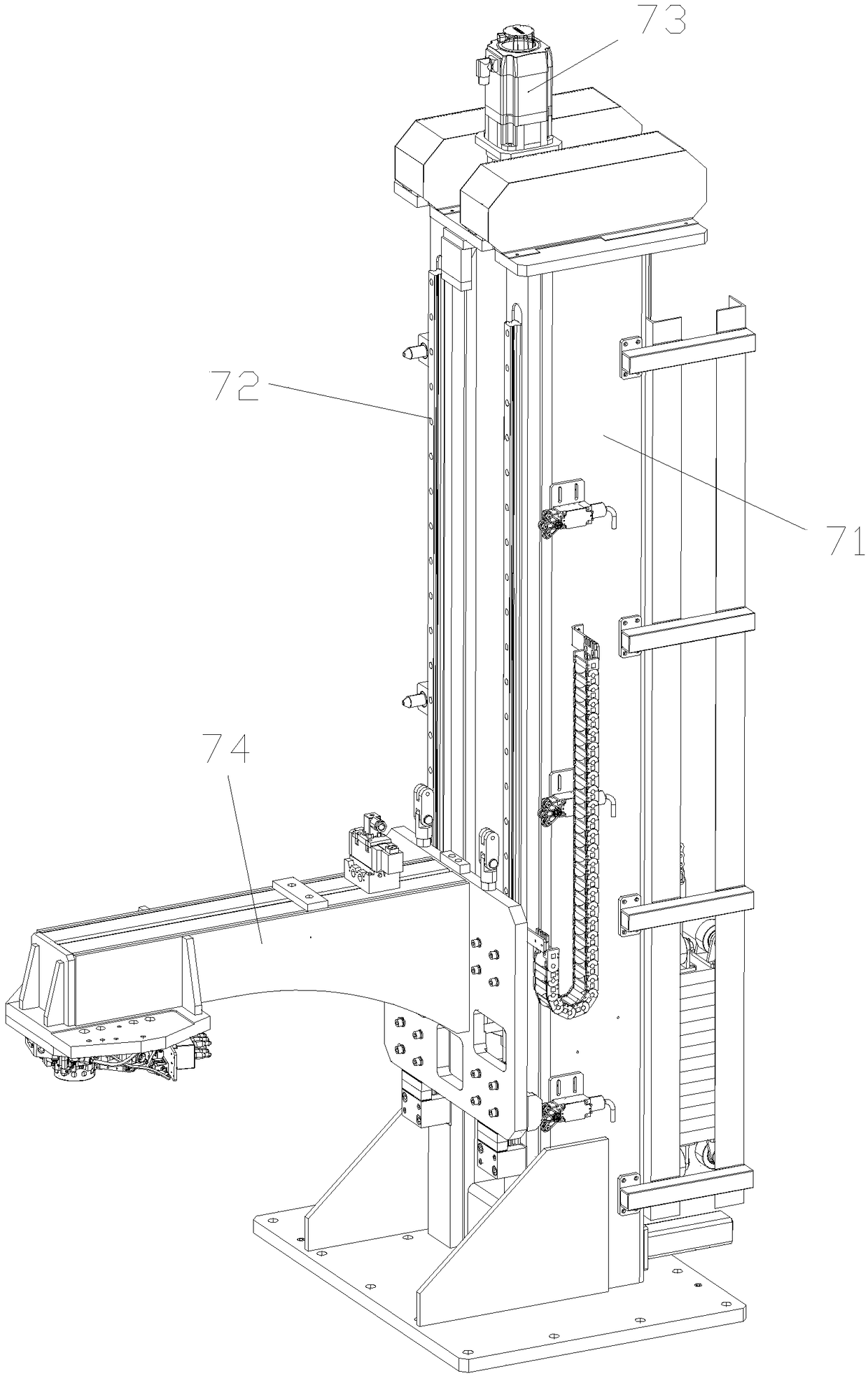

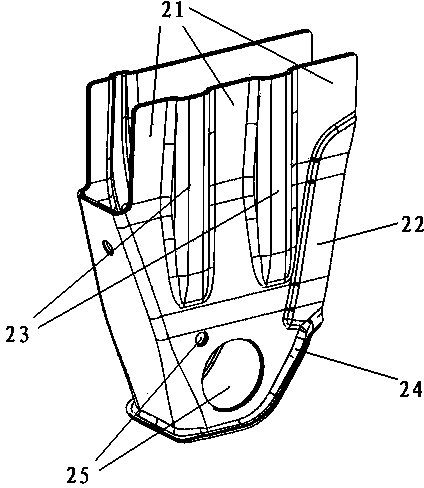

Edge rolling process and device for aluminum alloy door cover with large opening angle

InactiveCN109454140AQuality assuranceReduce the number of hemming stepsMaterials scienceAluminium alloy

The present invention discloses an edge rolling process and an edge rolling device for an aluminum alloy door cover with a large opening angle; the edge rolling process comprises the following steps of: Step 1, feeding: placing plates on a forming die, and positioning and pressing the plates downward by an upper edge rolling gripping tool which moves downwards; Step 2, edge pre-wrapping: operatingan edge wrapping mechanism located around the forming die to conduct edge pre-wrapping of a part with the large opening angle of an outer plate edge; after the opening angle of the outer plate edge is less than 90 degrees, controlling the edge wrapping mechanism to leave the outer plate edge so as to complete edge pre-wrapping; and Step 3, edge rolling: operating an edge rolling robot located around the forming die; and conducting edge rolling to an entire edge of the outer plate through an edge rolling tool on the edge rolling robot before completely wrapping an edge of an inner plate with the edge of the outer plate. The edge rolling device comprises the forming die, the edge rolling gripping tool, the edge wrapping mechanism and the edge rolling robot. Compared with a prior art, the device and the method in present invention have the following advantages that: the number of edge rolling times is reduced, edge rolling cracks are eliminated, and the edge rolling efficiency is improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

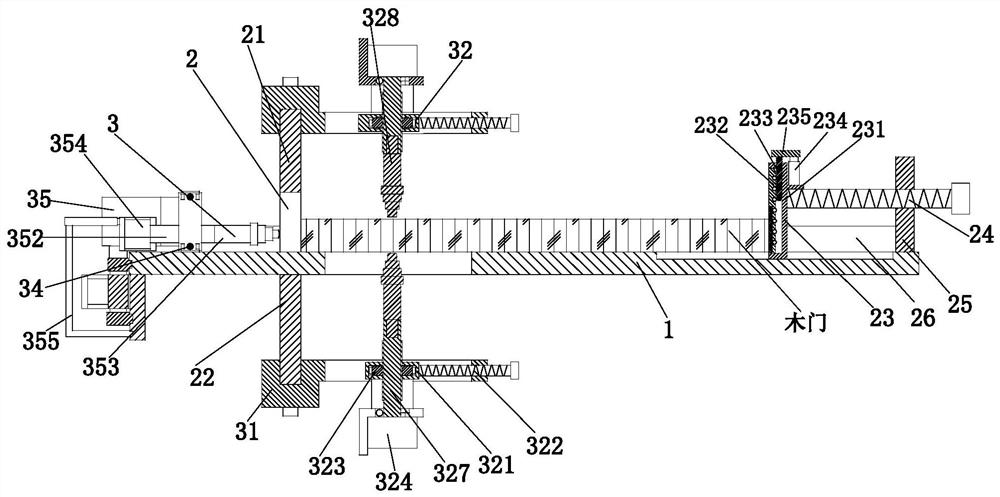

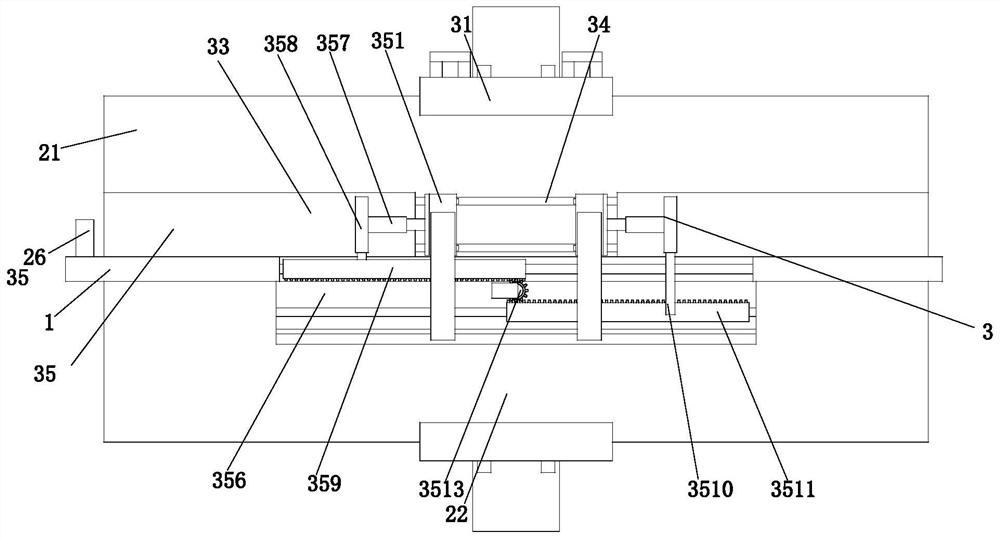

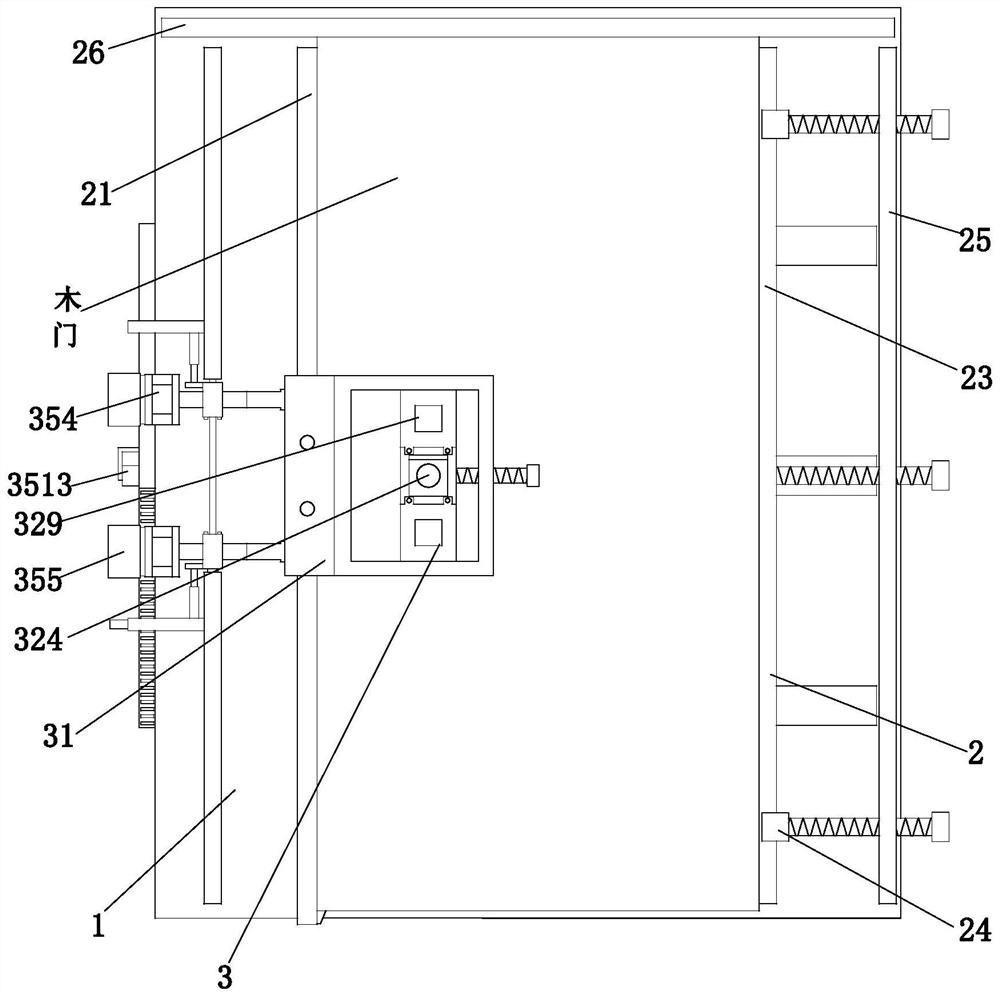

Environment-friendly wooden door manufacturing and slotting processing equipment and manufacturing and processing method

ActiveCN111761669AEliminate cracking defectsReduce manufacturing costWood mortising machinesWood slotting machinesKeyholeManufacturing engineering

The invention relates to an environment-friendly wooden door manufacturing and slotting processing equipment and a manufacturing and processing method. The equipment comprises a workbench, a locking device and a slotting device, wherein the locking device is installed in the middle of the workbench, the slotting device is installed on the left side of the workbench, the right side of the workbenchis provided with an adjusting chute, the left side of the workbench is provided with a strip working groove, and the back of the workbench is provided with a lifting groove. In the environment-friendly wooden door manufacturing and slotting processing equipment, after positioning the wooden door through the locking device, the opening operations of a front lock hole and a side lock body slot of the wooden door are completed respectively with the cooperation of a first slotting mechanism and a second slotting mechanism in the slotting device. When a front keyhole is processed, the upper and lower operations are performed at the same time, which can eliminate the defects that may cause the keyhole to crack when the hole is drilled on only one side of the wooden door. In addition, the slotting device can be applied to the opening of a variety of specifications of keyholes and lock body slots to effectively save production costs.

Owner:浙江索福绿建实业有限公司

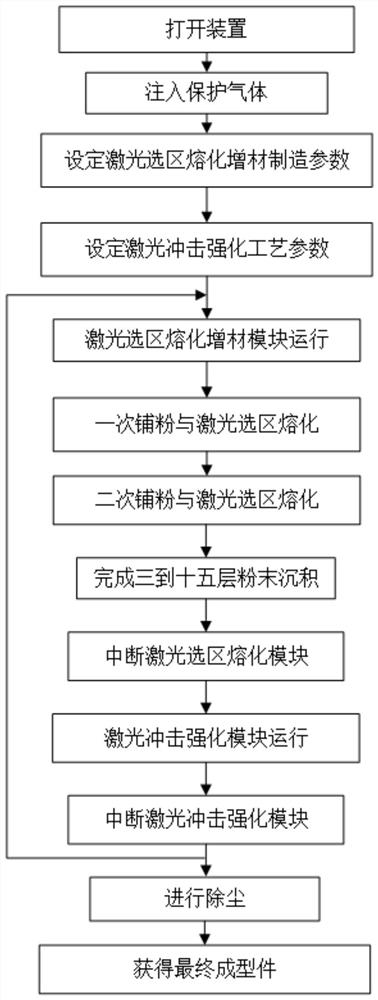

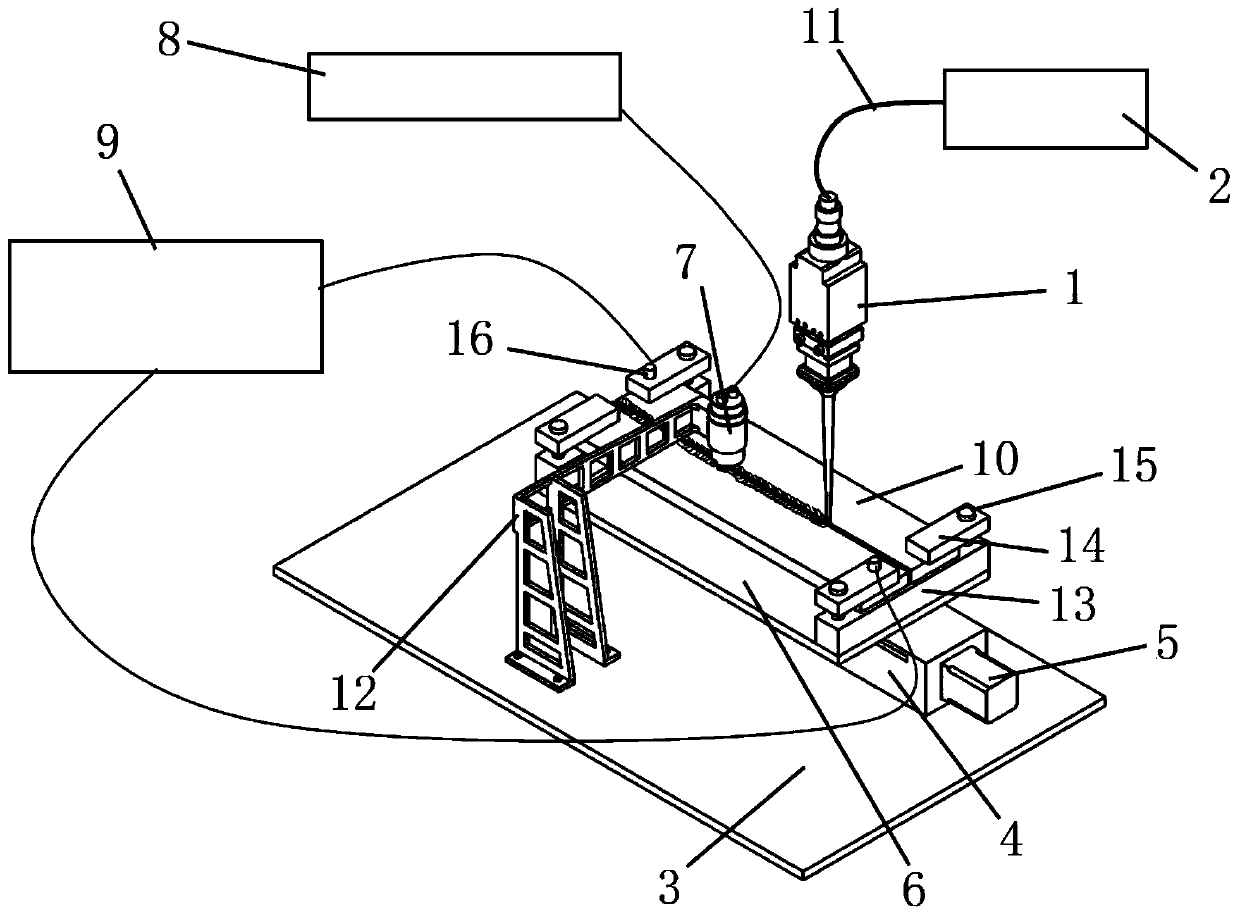

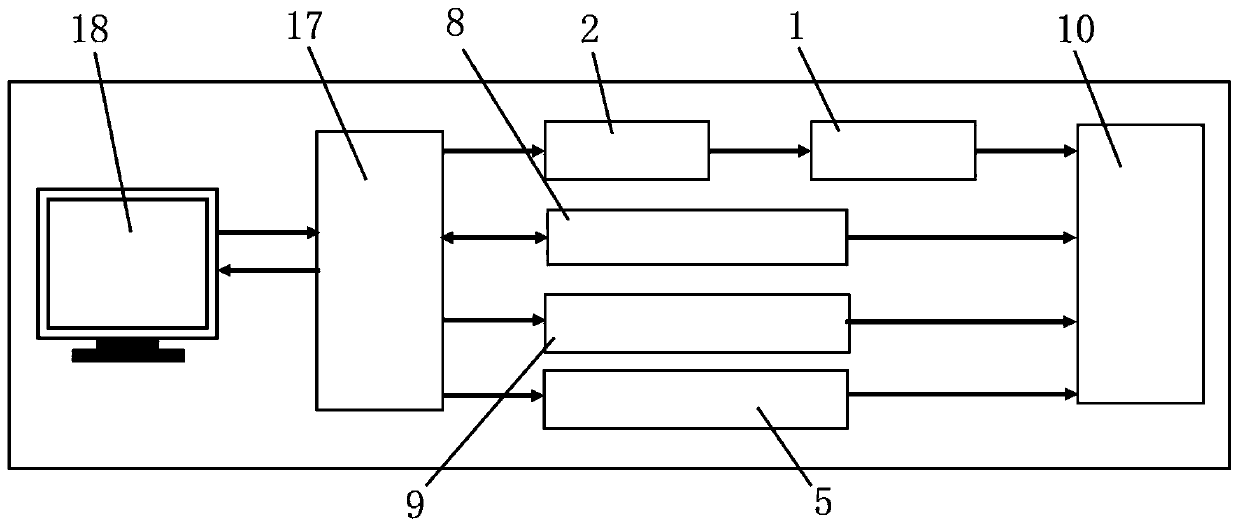

Selective laser melting and laser shock peening composite additive manufacturing device and method

PendingCN112756628AImprove machining accuracyIncrease productivityAdditive manufacturing apparatusSelective laser meltingManufacturing technology

The invention discloses a selective laser melting and laser shock peening composite additive manufacturing device and method. A selective laser melting additive manufacturing technology and a laser shock peening technology are mutually combined, and the device is reasonable in structural design, easy to operate and high in applicability; metal powder is evenly laid through a powder laying device, two powder storage chambers and a powder laying guide rail, laser beam multi-angle scanning is achieved through a scanning galvanometer system and a laser scanning generator, namely, the selective laser melting additive manufacturing process is carried out, and an additive component in a preset shape can be efficiently and rapidly produced; and laser shock peening is carried out on the surface of an additive material in a thermal state, so that air hole and crack defects inside the additive material component are eliminated, the surface stress state of the additive component is regulated and controlled, and the problems that the fatigue life of a part is shortened, the geometric structure of the part is distorted and cracks are generated in the material due to the tensile residual stress generated in the selective laser melting additive process are effectively solved, so that the purpose of improving the performance of the component is achieved.

Owner:BEIHANG UNIV

Laser welding joint crack detecting and intensifying system

PendingCN110052711AStrong penetrating powerHigh sensitivityLaser beam welding apparatusWeld seamEngineering

The invention discloses a laser welding joint crack detecting and intensifying system which comprises a laser head, a laser, a bottom plate, a sliding rail, a driving device, a clamp bottom plate, anelectro magnetic acoustic transducer, an ultrasonic fault detector and a high-voltage discharger, wherein the laser head is connected with the laser; the sliding rail is mounted on the bottom plate; the driving device is connected with the sliding rail; the clamp bottom plate is mounted on the sliding rail and is used for mounting a to-be-welded workpiece; the laser head is mounted above the workpiece; the electro magnetic acoustic transducer is mounted above the welding seam of the workpiece; the ultrasonic fault detector is connected with the electro magnetic acoustic transducer; and the high-voltage discharger is connected with plate bodies on the two sides of the welding seam of the workpiece separately. According to the laser welding joint crack detecting and intensifying system, theelectro magnetic acoustic transducer collects the wavelength signal of the welding joint, the ultrasonic fault detector detects the quality problem of the welding joint, the high-voltage discharger repairs and eliminates the crack defect to intensify the performance of the welding joint; and welding, detection, and intensifying are carried out simultaneously to improve the detecting and finishingefficiency.

Owner:GUANGDONG UNIV OF TECH

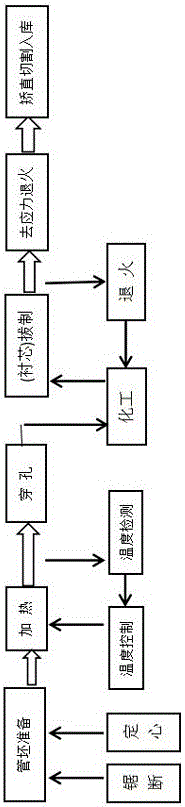

A production process of a seamless steel pipe used for rolling an integral finned pipe

A production process of a seamless steel pipe used for rolling an integral finned pipe is disclosed. The process includes sawing a raw material pipe blank off by adopting a sawing machine, subjecting the pipe blank to cold centering treatment through an automatic centering machine, heating the pipe blank in a continuous heating furnace, setting the heating temperature according to heating requirements, allowing the pipe blank temperature to be uniform through detecting the heating temperature in real time and through automatic closed-loop furnace temperature control, selecting and regulating tools and molds according to a rolling table in a punching rolling process, reasonably arranging the number of cold-drawing passes according to process requirements, arranging annealing steps among the passes, drawing a liner core in a finished-product pass, and performing stress relief annealing in a continuous roller hearth furnace after a steel pipe having a finished product dimension is obtained through drawing. Through adopting the production process, the rolled integral finned pipe is improved in quality and precision, and stable in organization performance. Safety performance of a manufactured heat exchanger is further improved, thus eliminating hidden dangers of leakage and explosion, and prolonging the service lifetime of the heat exchanger.

Owner:臧东生

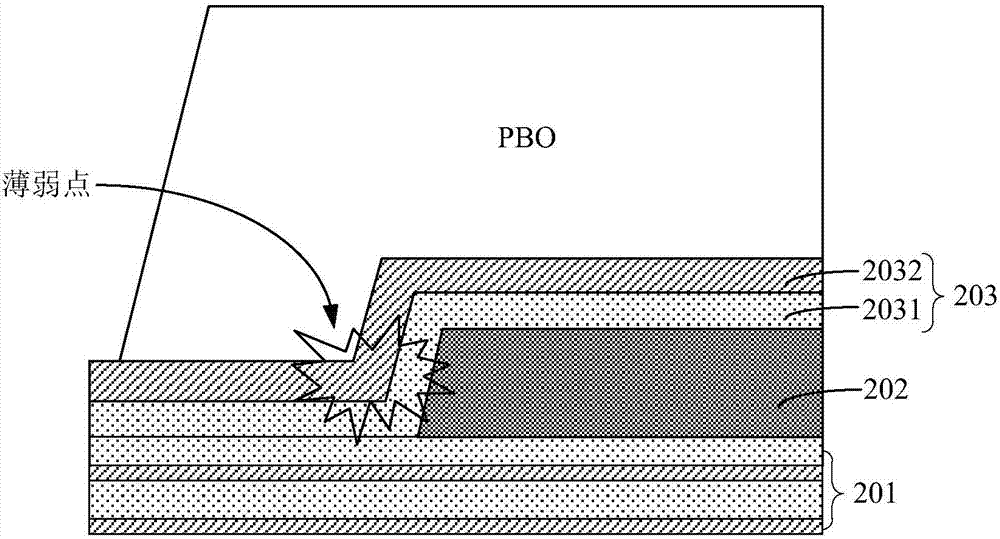

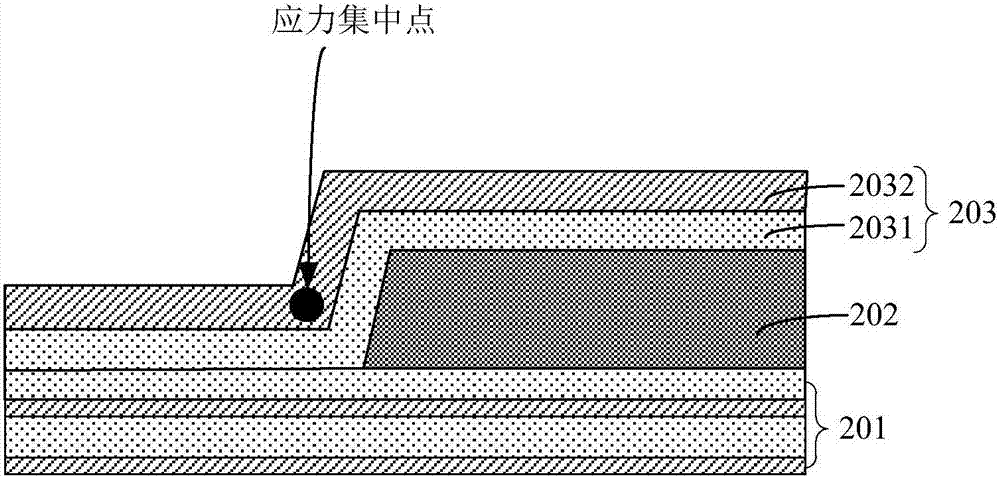

Semiconductor device, manufacturing method thereof and electronic device

ActiveCN107481976AImprove toughnessStrengthen weak pointsSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceCarbide

The invention provides a semiconductor device, a manufacturing method thereof and an electronic device. The semiconductor device comprises a substrate, a plurality of welding pad structures and a top part passivation layer, wherein the welding pad structures are disposed on the substrate at intervals in a protruding manner, and the side wall of each welding pad structure and the surface of the substrate on the outer side of the welding pad structure form a step angle; and the top part passivation layer covers the welding pad structures and the substrate on the outer periphery of the welding pad structures, and the top part passivation layer comprises a first oxide layer, a nitrogen-doped carbide layer and a first nitride layer which are laminated from bottom to top in sequence. The semiconductor device structure provided by the invention can effectively eliminate the passivation layer crack defects of advanced WLBGA products, and further improves the chip package integration problem, thereby improving the performance and reliability of the device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Deformable aluminum alloy metal powder material for additive manufacturing and preparation method thereof

InactiveCN107649675AEliminate crack defectsNo crack defectAdditive manufacturing apparatusTransportation and packagingAlloyMetal powder

The invention discloses a deformable aluminum alloy metal powder material for additive manufacturing and further discloses a preparation method for the deformable aluminum alloy metal powder for additive manufacturing. The deformable aluminum alloy metal powder material is composed of the following components of, by mass, 0.40-0.65% of Si, 0.1-0.7% of Fe, 0.15-0.4% of Cu, 0.05-0.15% of Mn, 0.8-1.2% of Mg, 0.04-0.35% of Cr, 0.05-0.25% of Zn, 0.01-0.15% of Ti, 0.2-0.5% of Sc and the balance Al, wherein the sum of the mass percentages of all the components is 100%. Through the deformable aluminumalloy metal powder for additive manufacturing, the cracking problem of existing 6061 aluminum alloy powder in the process of additive manufacturing is solved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

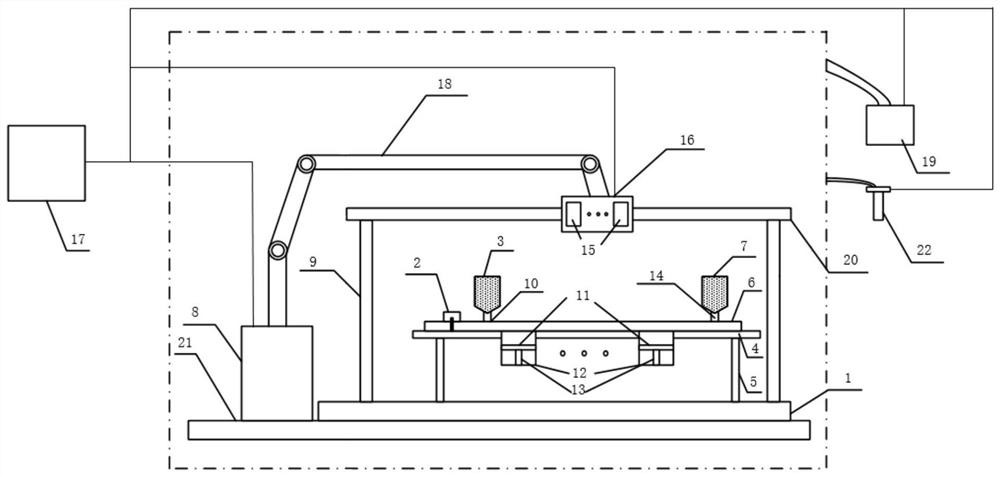

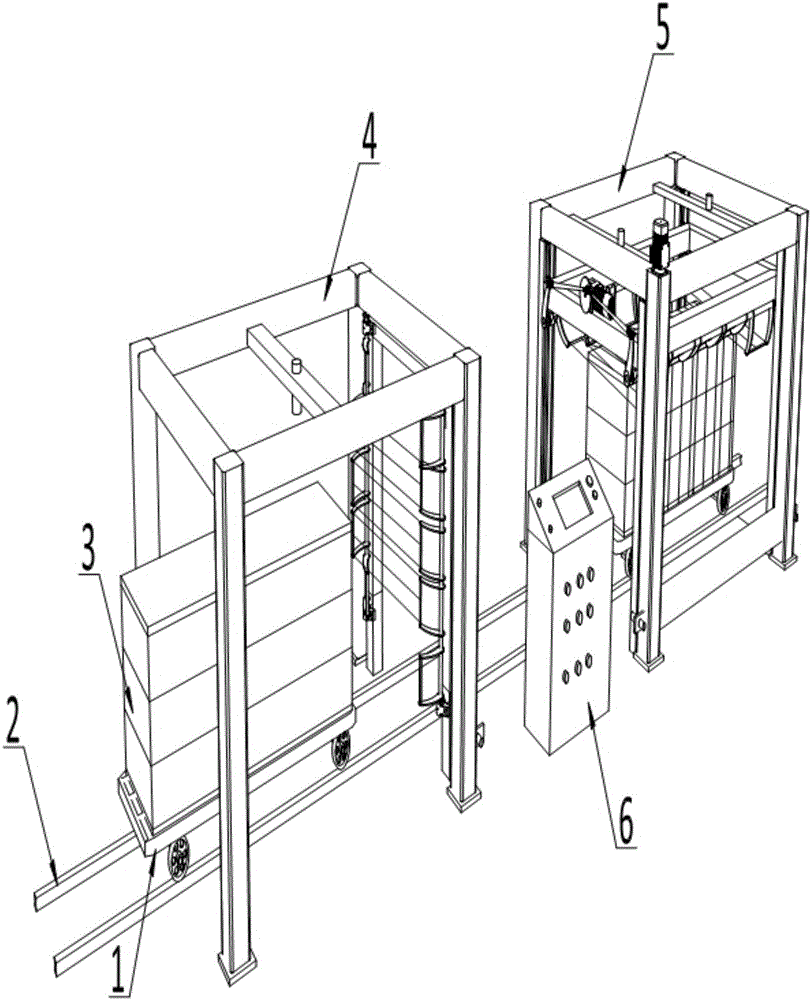

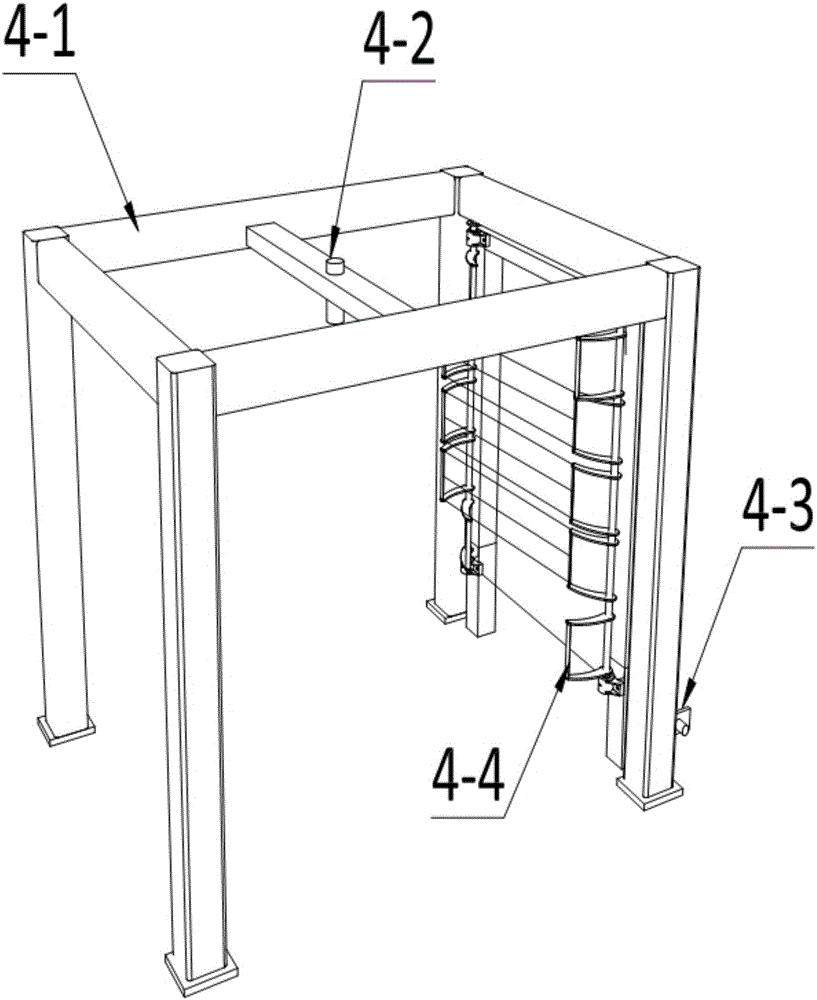

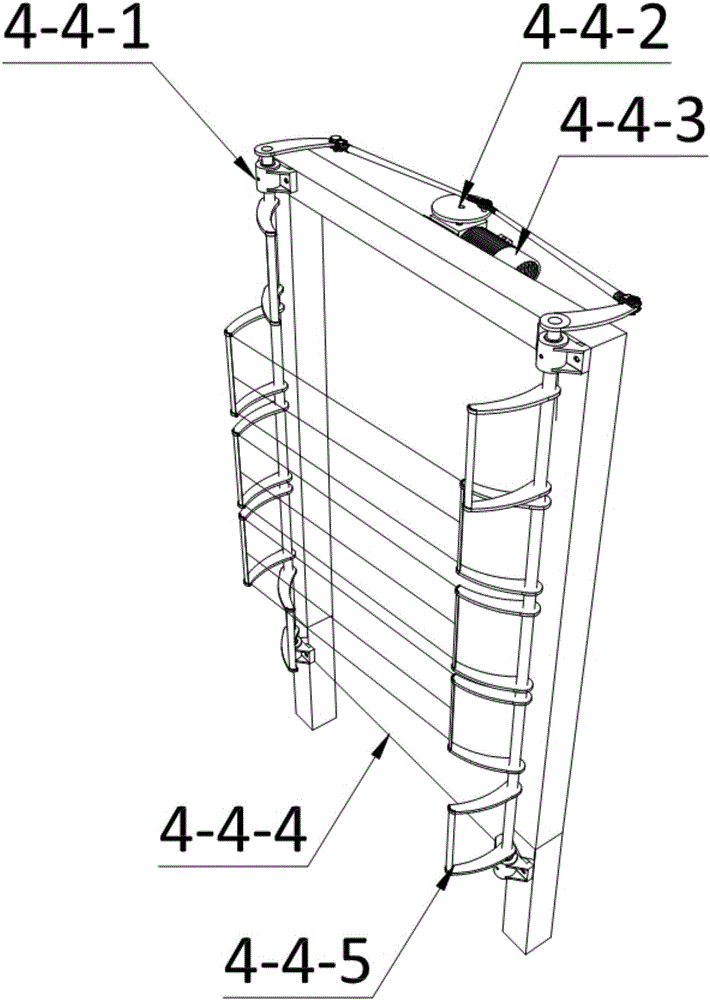

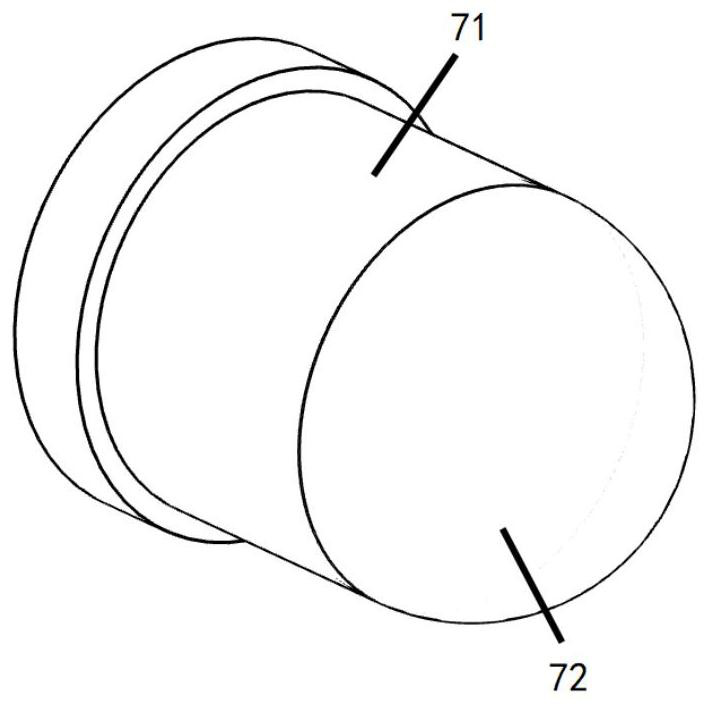

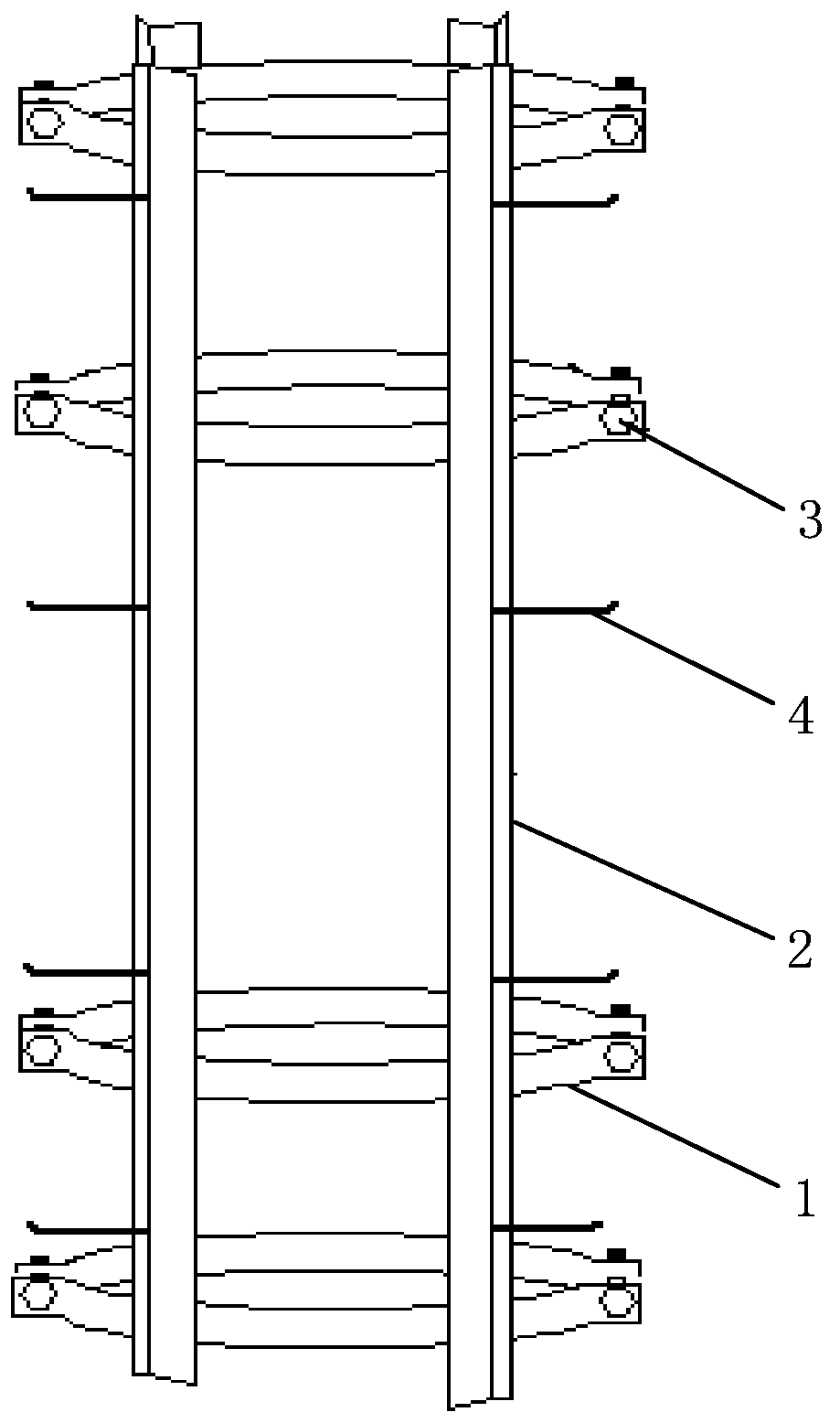

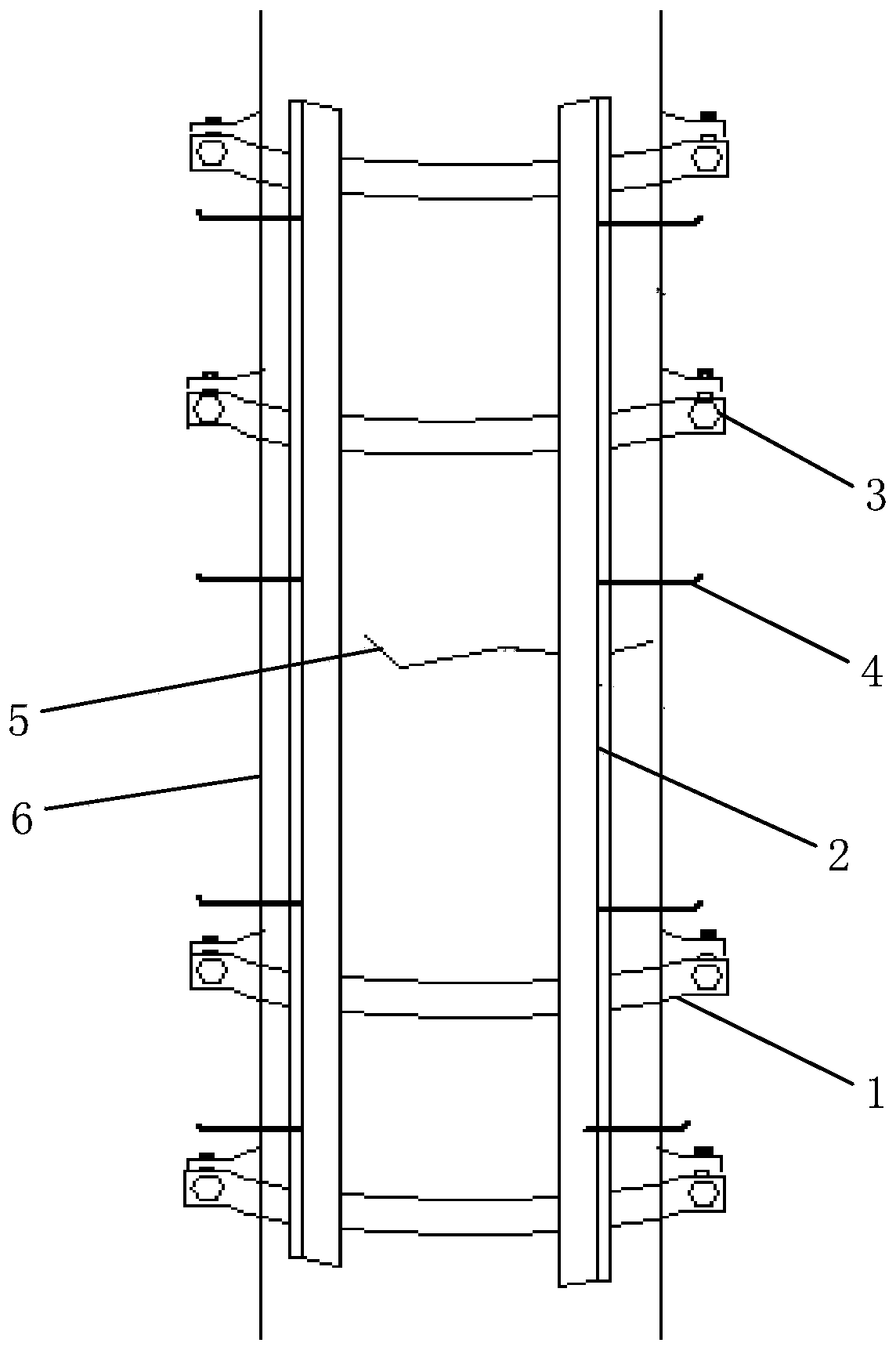

Aerated concrete cutting device and working method thereof

InactiveCN106217657ACompact structureIngenious designWorking accessoriesStone-like material working toolsStructural engineeringElectric control

The invention discloses an aerated concrete cutting device and a working method thereof. The aerated concrete cutting device is composed of a material trolley, steel rails, to-be-treated materials, a transverse cutting device, a longitudinal cutting device and an electric control center, wherein the steel rails are fixedly paved on the ground, the material trolley is arranged on the steel rail, and the material trolley is driven by a motor; the to-be-treated materials, which are placed on the material trolley, are of rectangular structures; the transverse cutting device and the longitudinal cutting device interpenetrate through the upper parts of the steel rails; and the electric control center is located between the transverse cutting device and the longitudinal cutting device. The aerated concrete cutting device disclosed by the invention is simple in structure, compact in machine type structure and little in space requirement; the device is high in degree of automation, and the device is simple and convenient to operate and control in the whole cutting process which is automatically finished; the device can effectively eliminate breakage and crack defects generated in a green body machining process.

Owner:XUZHOU UNIV OF TECH

Aluminum alloy electric arc additive manufacturing quality control system and method

ActiveCN112008198AEliminate stomataEliminate crack defectsAdditive manufacturing apparatusWelding/soldering/cutting articlesControl systemQuality control

The invention belongs to the field of additive manufacturing, and discloses an aluminum alloy electric arc additive manufacturing quality control system and method. Formed aluminum alloy accumulated metal is machined in a rotational friction plastic deformation manner, the defects of pores, cracks and the like possibly existing in original accumulated metal can be effectively eliminated, and meanwhile, aluminum alloy accumulated metal grains and a precipitation phase are refined, so that the mechanical property is improved, the problem that the forming quality is difficult to effectively control during aluminum alloy electric arc additive manufacturing is solved, the method is completely different from a process optimization and wire selection method in an existing electric arc additive manufacturing aluminum alloy component quality control technology, the manufacturing efficiency is high, the cost is low, and the forming quality is stable.

Owner:HUAZHONG UNIV OF SCI & TECH

Cement electricity pole crack defect processing device and method

InactiveCN109881965AElimination of crack defectsEliminate crack defectsBuilding repairsTowersFastenerElectricity

The invention discloses a cement electricity pole crack defect processing device and a method. The cement electricity pole crack defect processing device comprises a plurality of flat iron hoops, a plurality of angle iron and fastening bolts, the multiple flat iron hoops are arranged at cement electricity pole cracks, and the flat iron hoops are fixedly connected through the fastening bolts; and the angle iron and the flat iron hoops are perpendicularly arranegd, and the outer sides of any side walls of the angle iron are welded to the outer sides of the flat iron hoops. According to the cement electricity pole crack defect processing device, the flat iron hoops are used as fastening pieces, the angle iron are used as longitudinal forced supporting pieces, and the cross welding of the angle iron and the outer sides of the flat iron hoops is firm. By adopting the processing device and method, cement electricity pole crack defects can be controlled without outage, the risk of cement electricity pole breakage is removed, and the outage cost is reduced. In addition, the pole changing work can be replaced, the work risk is reduced, material costs and labor costs as required are far lower than the cost of a whole cement electricity pole changing, and the defect processing cost is greatly reduced.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

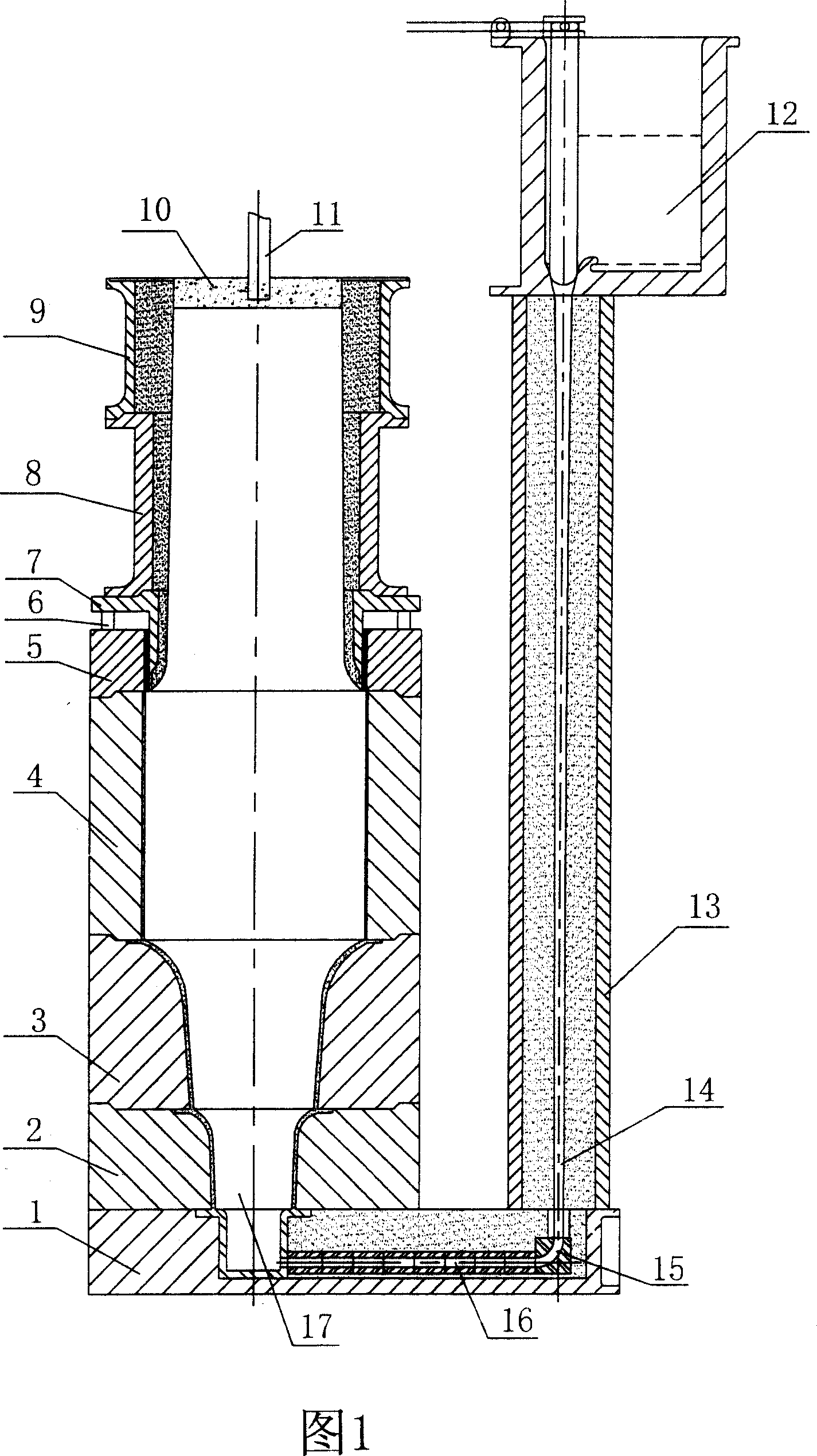

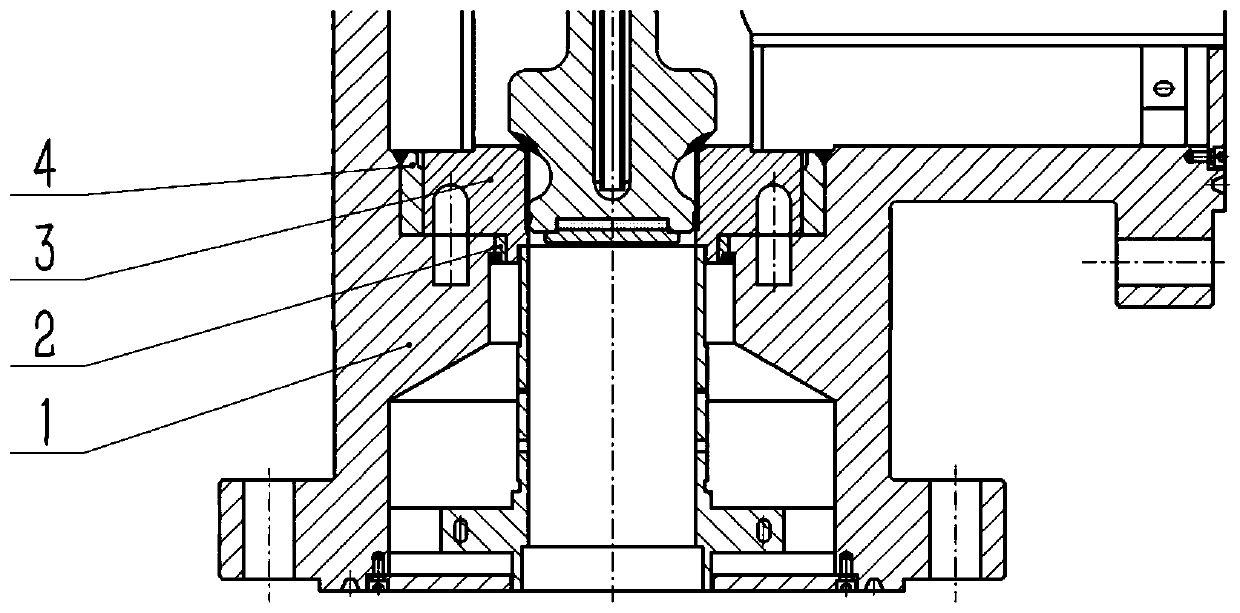

Process for preparing large cast steel support roller

The invention relates to a preparation process of a cast steel support roll. It is suitable for the overall casting process of cast steel support rolls with a net weight of 5 to 100 tons. The present invention is based on computer simulation, sand-covered iron mold, tangential inner gate rotary filling, thermal insulation riser technology, gating system design and casting mold design based on new gating system design principles and sequential solidification principles, etc. Electric heating riser technology and sliding roll neck technology are adopted. Electric heating riser technology is to conduct single-electrode or multi-electrode heating on the riser end of the roll to keep the metal liquid level at high temperature and increase the feeding capacity of the riser. The sliding roll neck technology is to install a sliding roll neck between the roll body and the upper roll neck, which is composed of a sliding roll neck inner sleeve and a sliding roll neck outer sleeve, and a cushion block is arranged between them. After pouring is completed for 5 to 30 minutes, the block is removed and the inner sleeve slides down to release the stress. The sliding roll neck technology and the electric heating riser technology adopted in the invention solve the crack problem of the cast steel backing roll.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

Near alpha titanium alloy metal powder material used for additive manufacturing and preparing method thereof

ActiveCN109648073AReduce the ratioEliminates tendency to crackAdditive manufacturing apparatusTransportation and packagingMetal powderTitanium alloy

The invention discloses a near alpha titanium alloy metal powder material used for additive manufacturing. The powder material comprises, by mass percent, 3.1 to 6.2% of Al, 1.0 to 2.1% of Zr, 0.4 to1.8% of Mo, 0.6 to 2.3% of V, 0.2 of Fe, 0.1% of Sn, 0.1% of C, 0.05% of N, 0.01% of H, 0.13% of O, 0.30% of inevitable impurities and the balance Ti, and the mass percent of the above components is 100%. The invention further discloses a preparing method of the near alpha titanium alloy metal powder material used for additive manufacturing. The method is used for the near alpha titanium alloy metal powder material, and the problem that an existing titanium alloy powder cannot meet the part strength need is solved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

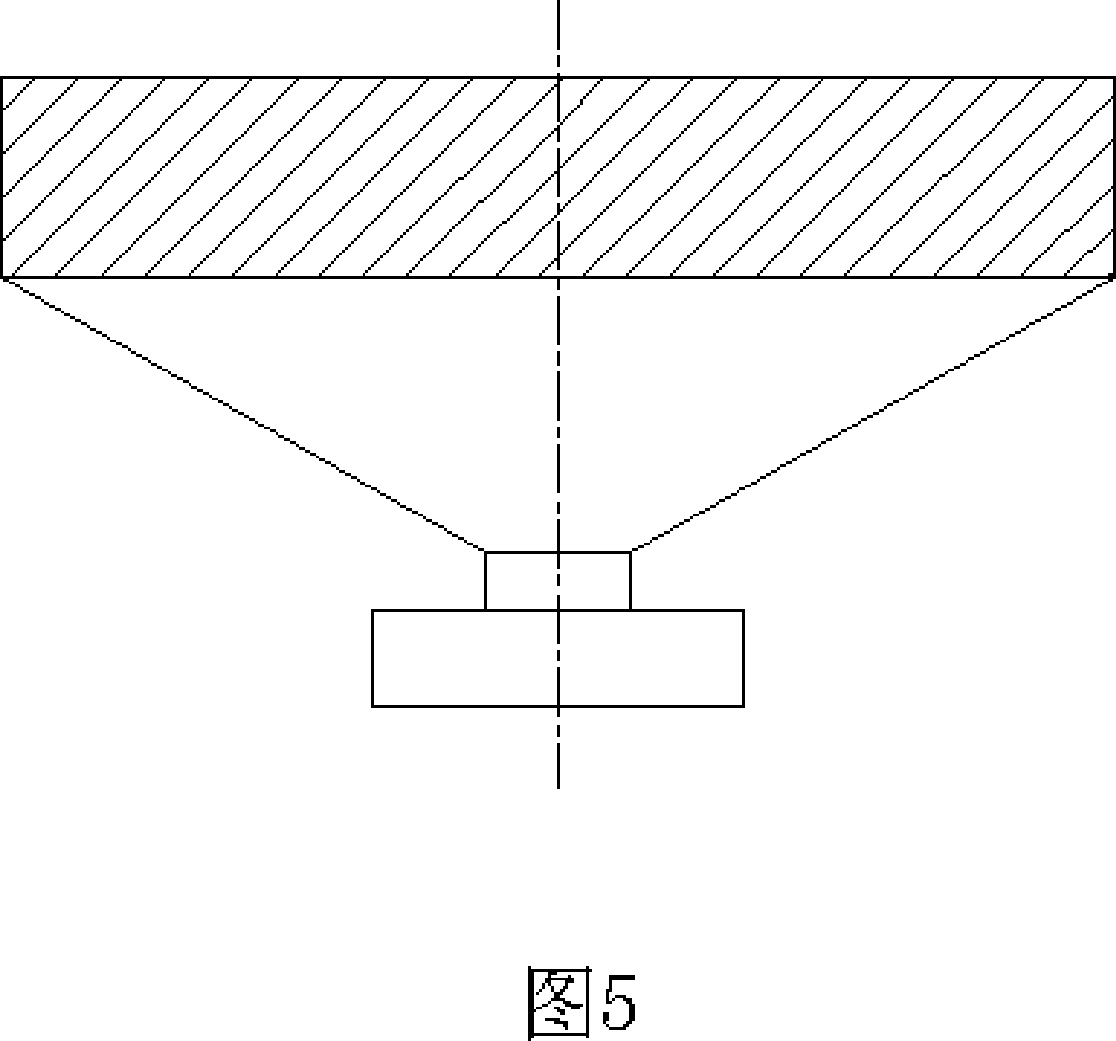

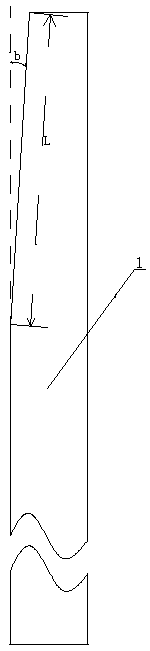

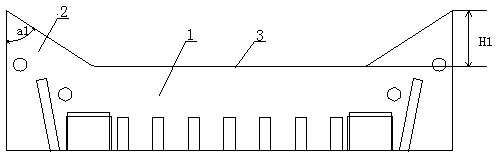

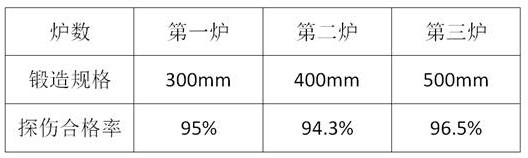

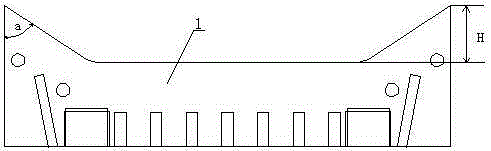

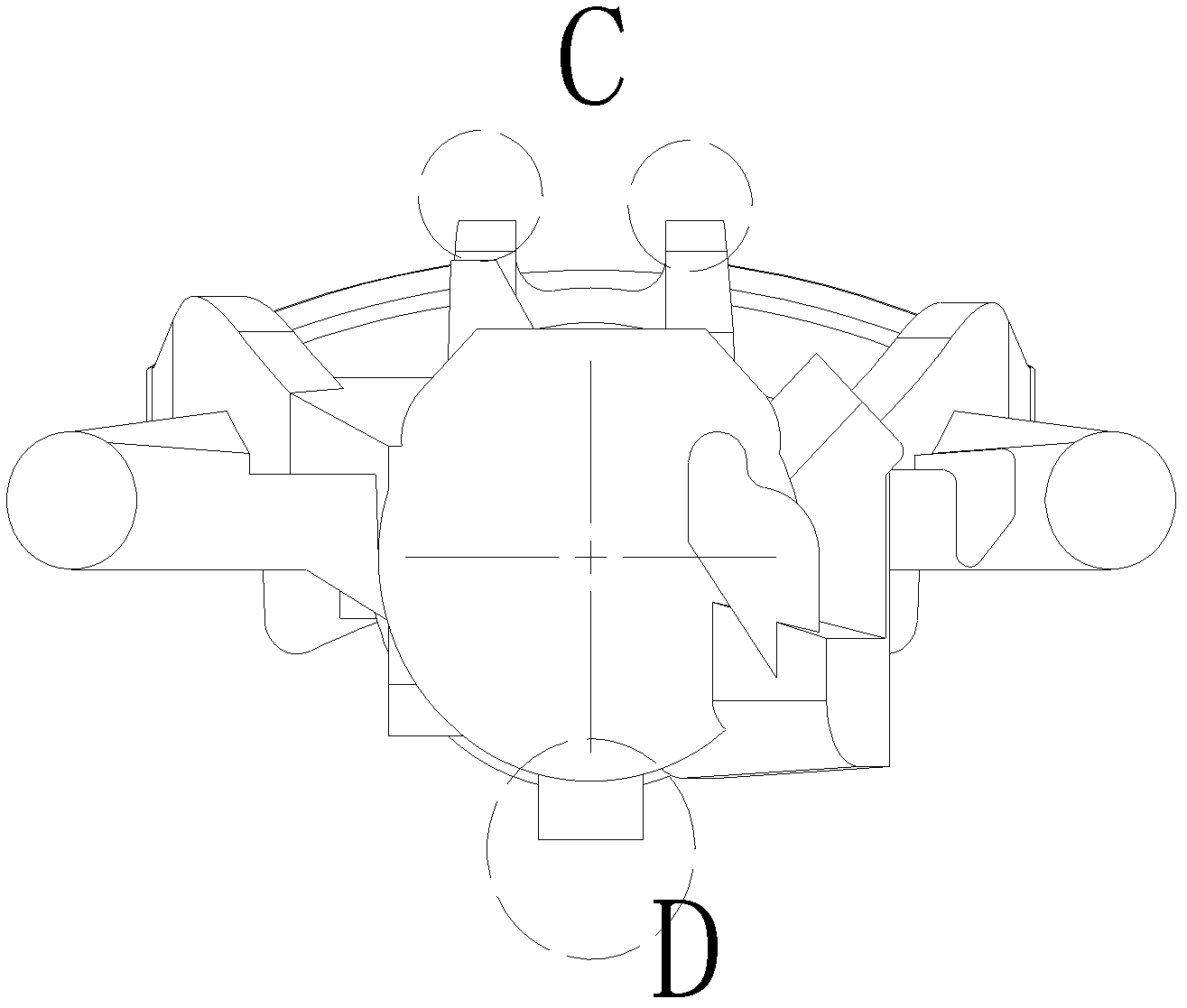

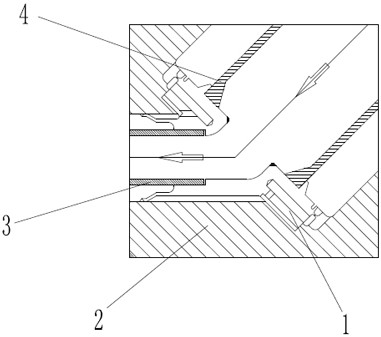

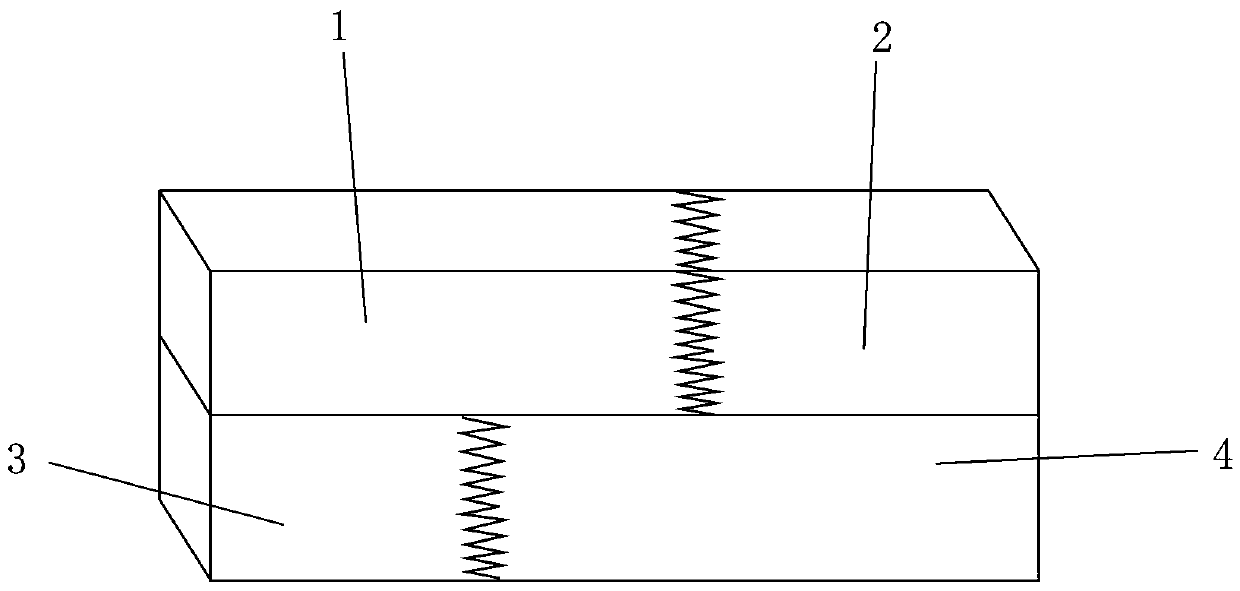

A kind of slab continuous casting chamfering crystallizer narrow surface copper plate

The invention discloses a narrow-faced copper plate of a slab continuous casting chamfering crystallizer, which includes a large surface area and a side chamfering area. The back of the large surface area and the side chamfering is provided with one or more cooling water tanks penetrating up and down. The longitudinal sectional view of the large-area working face is in the shape of broken lines. Under the action of chamfering, it is more beneficial for the steel billet to always stick to the inner wall of the crystallizer during the solidification process of molten steel.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

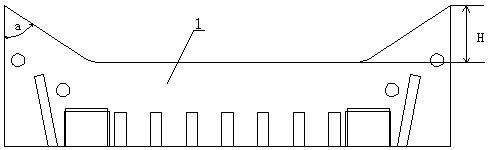

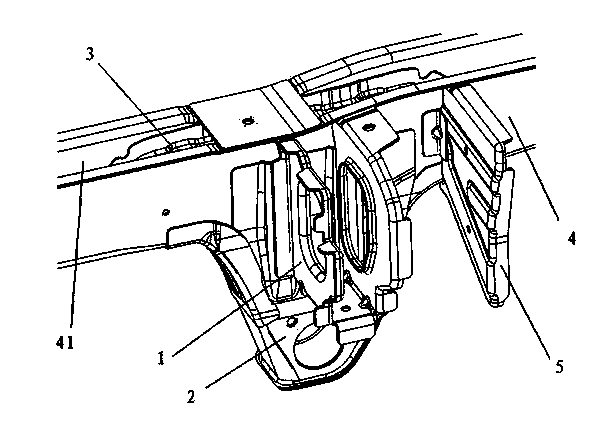

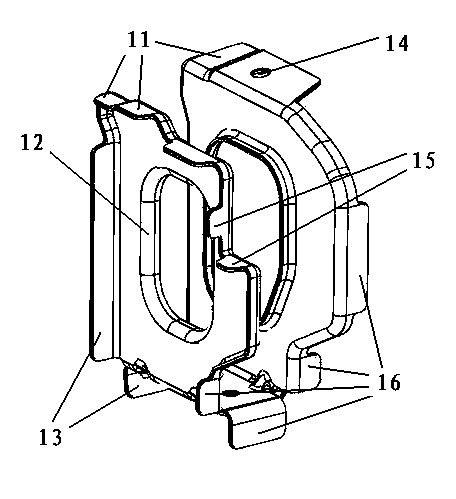

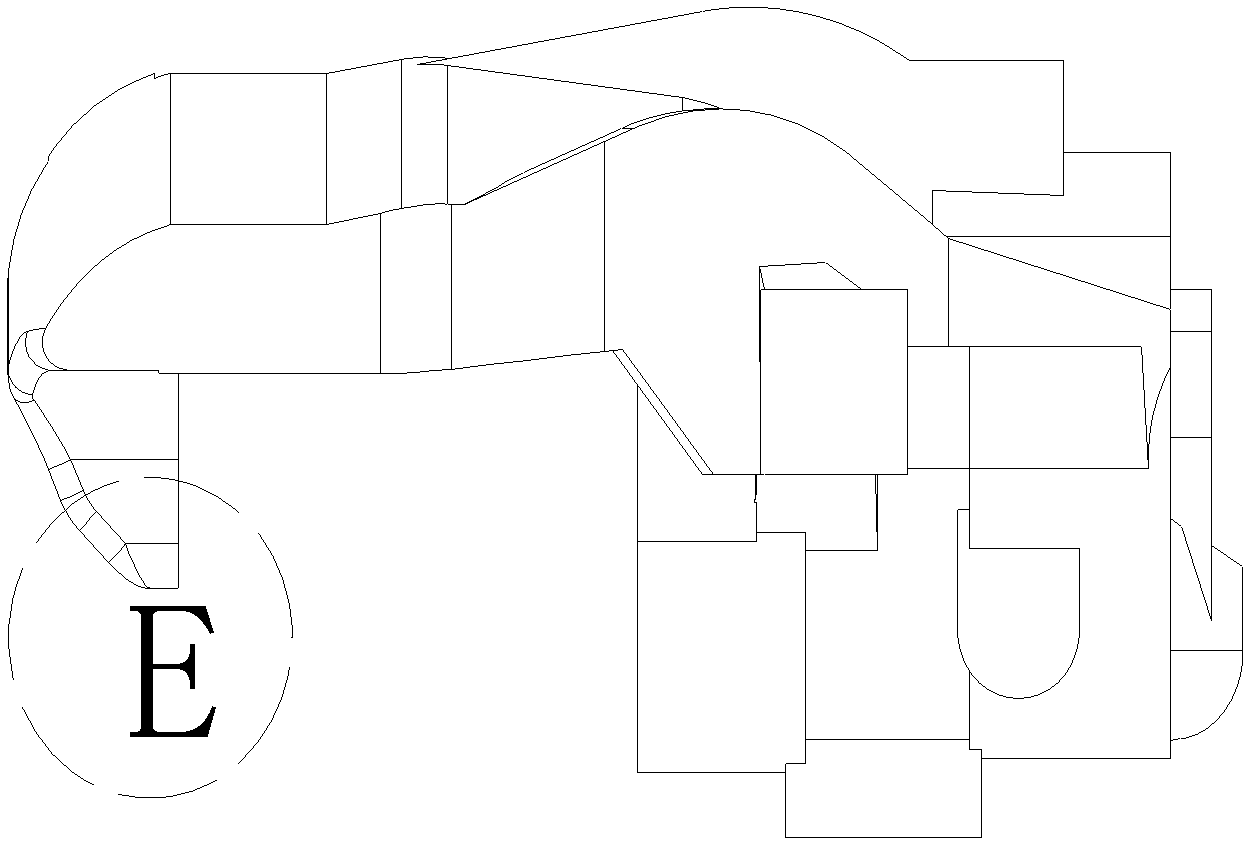

C pillar bottom connector structure

ActiveCN103847800AIncreased torsional stiffnessEliminate cracking defectsLeaf springsSuperstructure subunitsEngineeringMechanical engineering

The invention relates to an automobile body, in particular to a C pillar bottom connector structure of the automobile body. The C pillar bottom connector structure comprises a middle rear support plate, a front plate spring support, a middle partition of a rear crossbar, the rear crossbar and a middle rear support plate strengthening plate, wherein the rear crossbar is provided with an inner cavity, the middle partition of the rear crossbar is arranged in the inner cavity, the middle rear support plate strengthening plate is connected with a lateral side of the rear crossbar, the front plate spring support is connected with a lateral side of the rear crossbar, and the middle rear support plate is connected with the front plate spring support. The C pillar bottom connector structure has the advantages that torsional strength is strengthened, and fractures are eliminated effectively.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

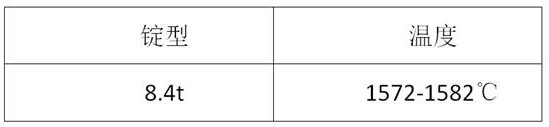

Method for improving flaw detection qualification rate of low-carbon, low-aluminum and high-chromium forging round steel

ActiveCN113770316AReduce inclusion contentImprove purityMolten metal pouring equipmentsElectric furnaceTemperature controlDie casting

The invention relates to the field of smelting, pouring and forging of ferrite heat-resistant steel. The method for improving the flaw detection qualification rate of the low-carbon, low-aluminum and high-chromium forging round steel adopts electric furnace smelting, LF furnace refining, VD treatment, die casting and forging for production, during die casting, the temperature from a steel ladle to a casting table is controlled to be 70-80 DEG C higher than a liquidus, argon seal protection is adopted during pouring, the die temperature is required to be 80-100 DEG C, low-carbon casting powder is adopted for pouring, the steel ladle is hung to the center of a die, the distance from the steel ladle to the bottom of the die is 150-200 millimeters, in the pouring process, a high-calorific-value heat generating agent is added into the die, and the heating temperature is made to be greater than 1500 DEG C. therefore, the feeding capacity of molten steel is improved, cracks in the center of a cast ingot are reduced, and the cracks can be reduced in the subsequent forging machining process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Chamfered crystallizer narrow-surface copper plate

The invention discloses a chamfered crystallizer narrow-surface copper plate which comprises a main surface area and side surface chamfered areas, wherein one or more cooling water tanks which run through in an up-down manner are arranged on the main surface area, and a cooling mechanism is arranged at the back part of each side surface chamfered area. The cooling mechanisms are triangular structure holes consisting of a plurality of cooling holes, and the cooling holes adopt round structures. Under the action of the chamfers, steel billets can be better clung to the inner wall of a crystallizer in the molten steel solidification process, so that the casting blank quality can be ensured.

Owner:HENAN XINGZHI PATENT SERVICE CO LTD

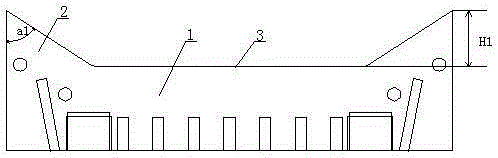

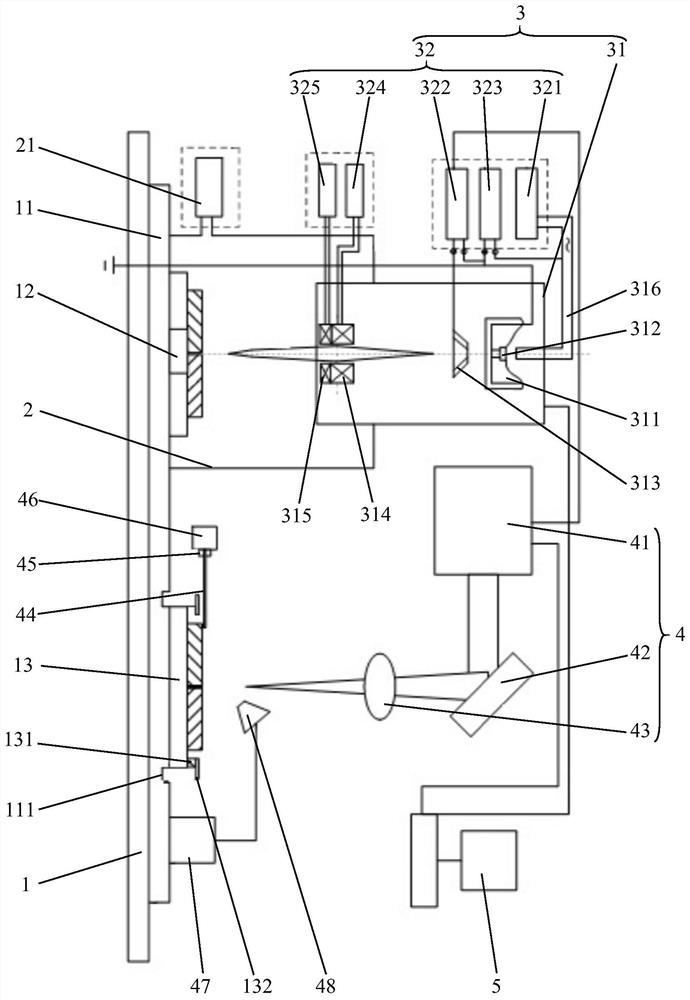

Step-by-step electron beam fusion welding and laser shock peening composite manufacturing device and method

PendingCN113118608AImprove applicabilityReasonable structural designElectron beam welding apparatusElectron beam machiningLaser beam machining

The invention discloses a step-by-step electron beam fusion welding and laser shock peening composite manufacturing device and method. The device comprises a workbench; a base plate is fixed to the top face of the workbench; a welding table and a peening table are fixed on the top surface of the base plate; a vacuum welding chamber is fixed to the base plate and covers the welding table; an electron beam machining assembly is used for emitting electron beams to the welding table; a laser beam machining assembly is used for emitting laser beams to the peening table; and a computer is used for controlling the electron beam machining assembly to emit the electron beams to a welding part and controlling the laser beam machining assembly to emit the laser beams to peen the welding part subjected to electron beam welding when the vacuum welding chamber is in a vacuum state. The residual tensile stress generated by a welding seam formed in the electron beam welding process can be eliminated, the crack tendency is remarkably reduced, the problem that the fatigue performance is reduced due to the traditional welding seam residual tensile stress is effectively solved, the influence of welding seam defects on the product performance is restrained, and the device and the method are suitable for preparing high-reliability welding parts.

Owner:BEIHANG UNIV

Insulating coating liquid for improving cracks of surface coating of oriented silicon steel, preparation method for insulating coating liquid, and oriented silicon steel plate

The invention provides an insulating coating liquid for improving the cracks of a surface coating of oriented silicon steel, a preparation method for the insulating coating liquid, and an oriented silicon steel plate. The insulating coating liquid comprises the following components in parts by weight: 100 parts by weight of phosphate solution, 2-10 parts by weight of magnesium oxide or magnesium hydroxide, 10-20 parts by weight of chromic anhydride or chromate, 2-10 parts by weight of boric acid, 10-20 parts by weight of an organic solvent, 80-200 parts by weight of silica sol, 5-20 parts by weight of zirconium sol, 6-15 parts by weight of nano zinc oxide, 2-10 parts by weight of antimony pentoxide sol and 80-120 parts of water. According to the invention, the oxide combination of zirconium oxide, zinc oxide, antimony pentoxide and the like has small particle size, high affinity with the coating liquid components, and high dispersity in a coating solution system, and the coating liquidhas high stability; and when the coating is dried to form a film, the oxide combination can neutralize the brittleness of film formation of surface silica sol, fill gap parts of the coating, improvethe stability and toughness of the film formation of the surface coating, and then integrally improve the strength and toughness of the coating, eliminate microcosmic surface cracks, and improve the magnetic performance of the oriented silicon steel.

Owner:WUHAN UNIV OF SCI & TECH +1

Method of reducing casting defect for casting part in casting process

InactiveCN102626767AImprove adaptabilityEliminate cracksFoundry mouldsFoundry coresMetallurgyCasting defect

The invention discloses a method of reducing a casting defect for a casting part in casting process. The method is achieved by: a cavity of a supporting column formed in a mold cavity during molding process of the casting part and a supporting column entity formed on a pouring system after pouring with the material of the supporting column entity being the same with that of the casting part. The method enables the casting part never to directly contact shakeout equipment, the latter inputted casting part and the pouring system, thereby avoiding crack defect caused by collision.

Owner:洛阳古城机械有限公司

Method for controlling the cross crack of blank angle of high nitrogen steel casting board containing vanadium

Owner:PANZHIHUA IRON AND STEEL

Weld structure and manufacturing method thereof

ActiveCN112222669BAvoid direct heat radiationSolve the problem of hot corrosionArc welding apparatusWorkpiece edge portionsButt weldingThermal insulation

The invention discloses a welding seam structure and a manufacturing method thereof, which are suitable for the connection of a valve seat and a valve body. The welding seam structure includes a tail butt welding seam and a head butt welding seam. With the setting of the heat preservation barrel at the head, the occurrence of stress fatigue failure of the weld is minimized, and at the same time, the weld avoids the direct heat radiation of the ultra-high temperature medium. The setting of the weld in the heat affected zone of the head makes the entire weld The area is safer and more reliable under harsh working conditions. The setting of weld strain grooves and weld strain zones can effectively prolong the occurrence of weld fatigue failure. With the same mechanical strength, the tail butt weld and head butt weld are used to connect the valve seat and the valve body to form equal strength welds, which improves the overall strength of the weld and eliminates the defect of cracks at the root of the corner weld.

Owner:中国空气动力研究与发展中心超高速空气动力研究所 +1

Plate with vertical patterns and transverse patterns

InactiveCN107856141AHigh strengthEliminate deformationWood veneer joiningTransverse planeAgricultural engineering

Vertical texture and horizontal texture boards are vertically connected by soft horizontal texture boards and soft vertical texture boards, and vertically connected by soft vertical texture boards and soft horizontal texture boards, and vertically connected by multiple soft boards in turn , multiple soft vertical grain boards and multiple soft horizontal grain boards are vertically connected and then connected horizontally one by one, and planed on all sides. This technology greatly improves the strength of soft wood boards and eliminates easy deformation and cracking. defect.

Owner:湖北厚友知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com