Insulating coating liquid for improving cracks of surface coating of oriented silicon steel, preparation method for insulating coating liquid, and oriented silicon steel plate

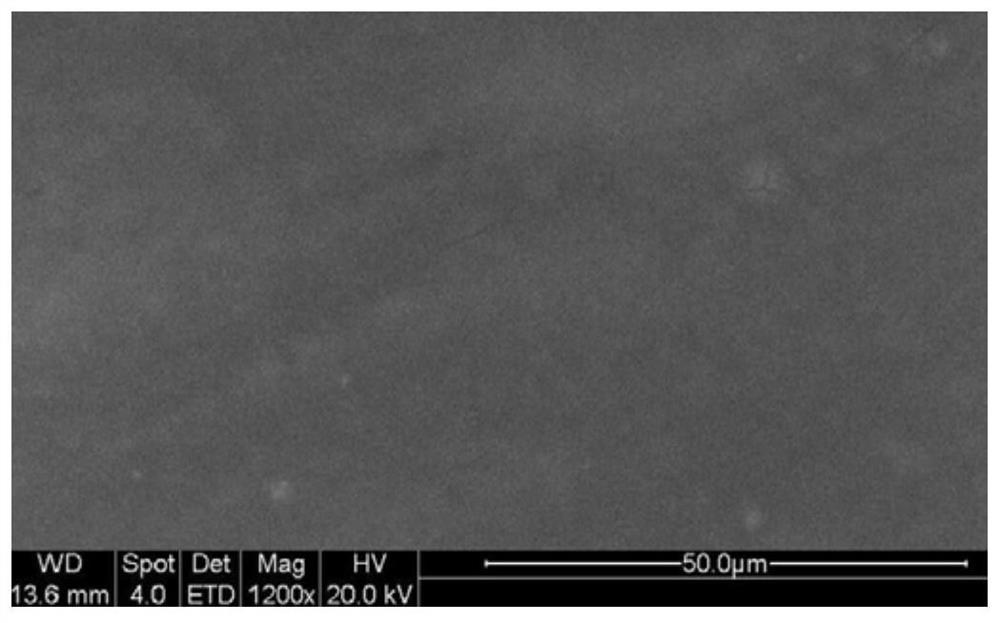

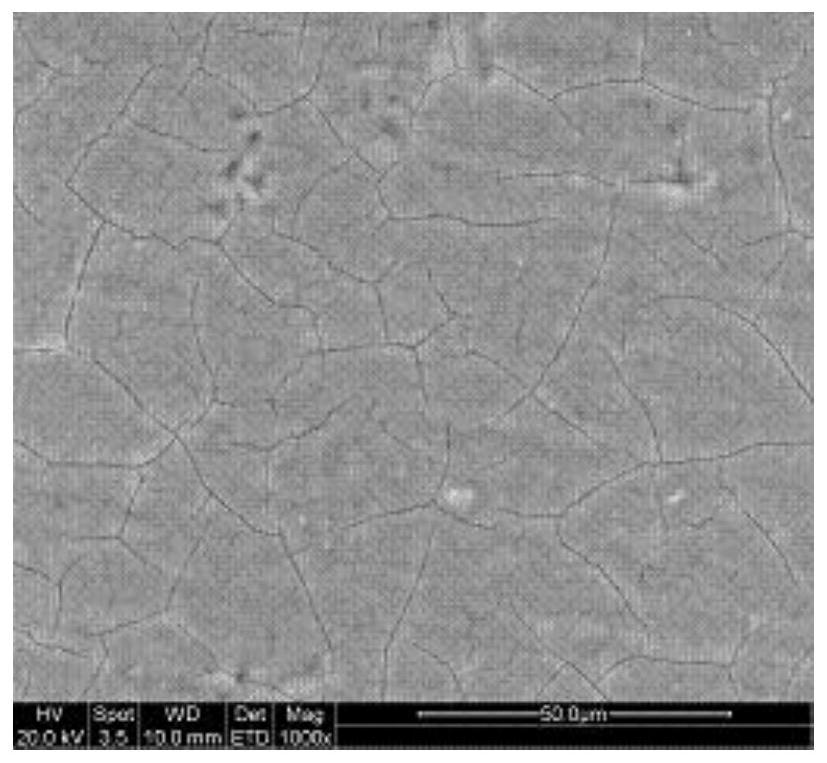

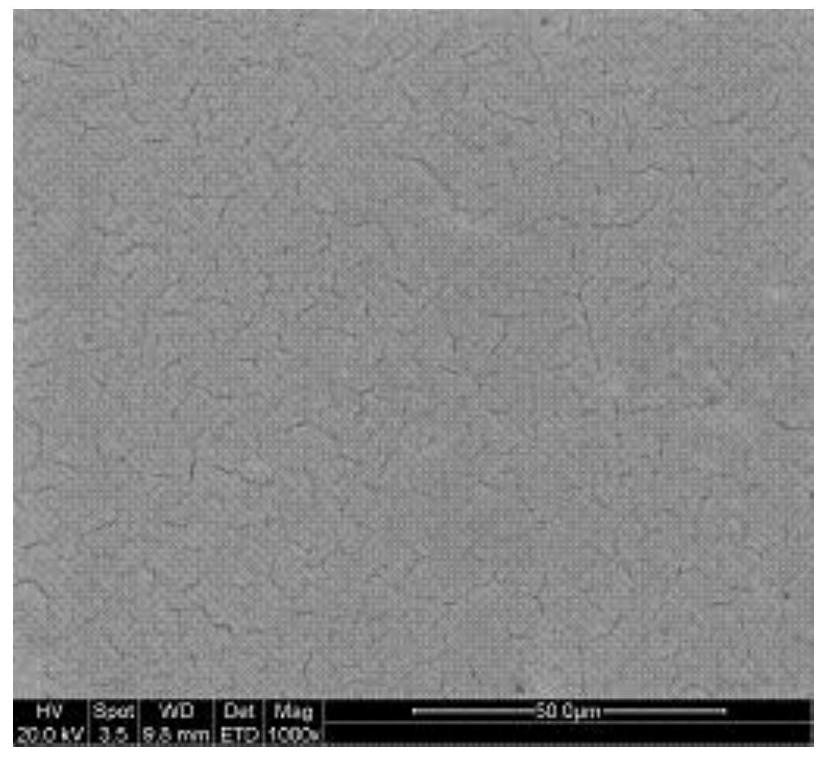

A technology of surface coating and oriented silicon steel, applied in the direction of metal material coating process, can solve the problems of iron core short circuit and high no-load loss, increase of surface friction coefficient, pulverization and poor adhesion, etc., to achieve improved Film-forming stability and toughness, improving coating strength and toughness, and eliminating microscopic surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0039] The invention provides an insulating coating solution for improving cracks on the surface coating of oriented silicon steel. The insulating coating solution comprises the following components: 100 parts by weight of phosphate solution, 2-10 parts by weight of magnesium oxide or magnesium hydroxide, chromic anhydride or chromium 10-20 parts by weight of acid salt, 2-10 parts by weight of boric acid, 80-200 parts by weight of silica sol, 2-10 parts by weight of zirconium sol, 10-20 parts by weight of organic solvent, 6-15 parts by weight of nano-zinc oxide, pentoxide 2-10 parts by weight of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com