Method of reducing casting defect for casting part in casting process

A technology for casting defects and castings, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve problems that affect processing operations, incomplete shakeout, small adaptability, etc., to reduce difficulty and production costs, and achieve good economy Benefits, the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

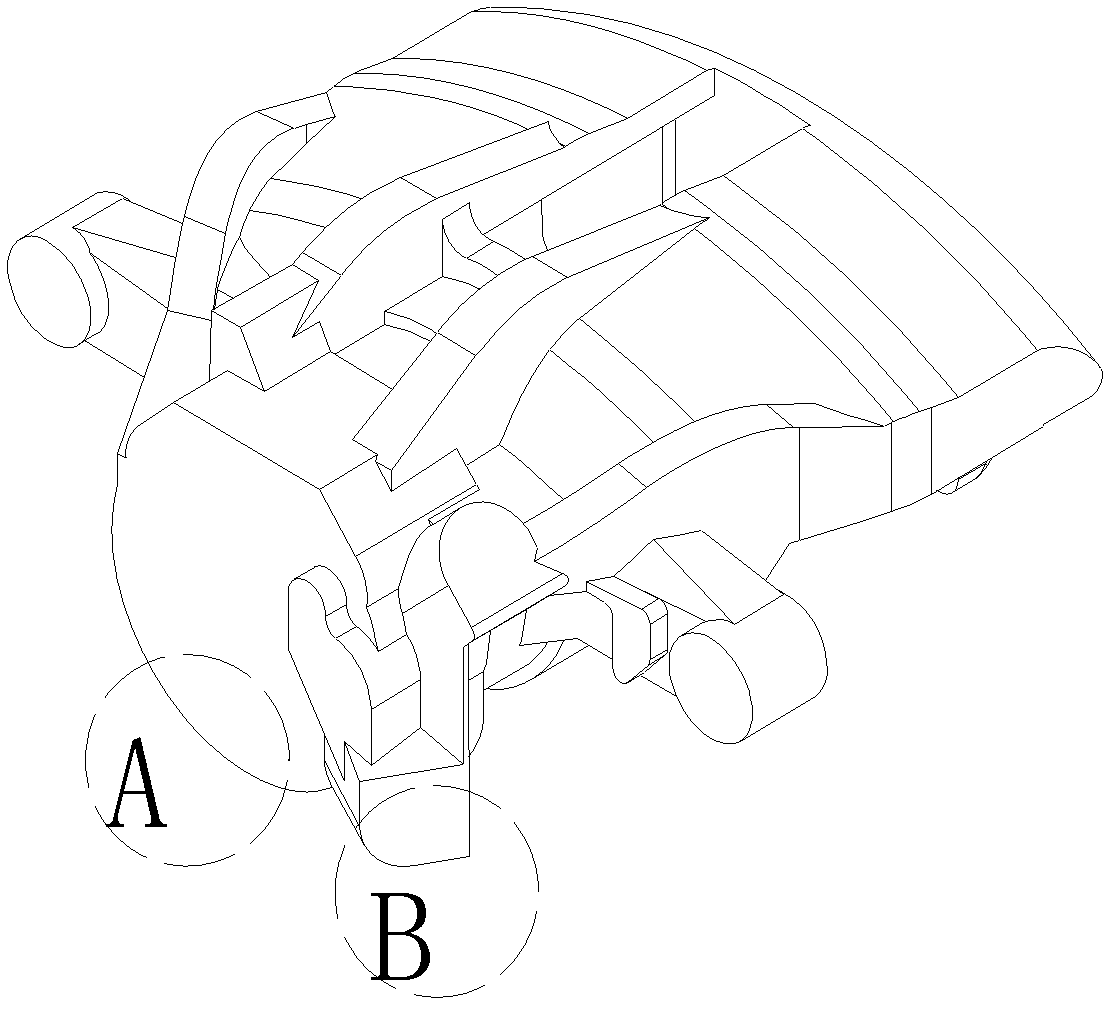

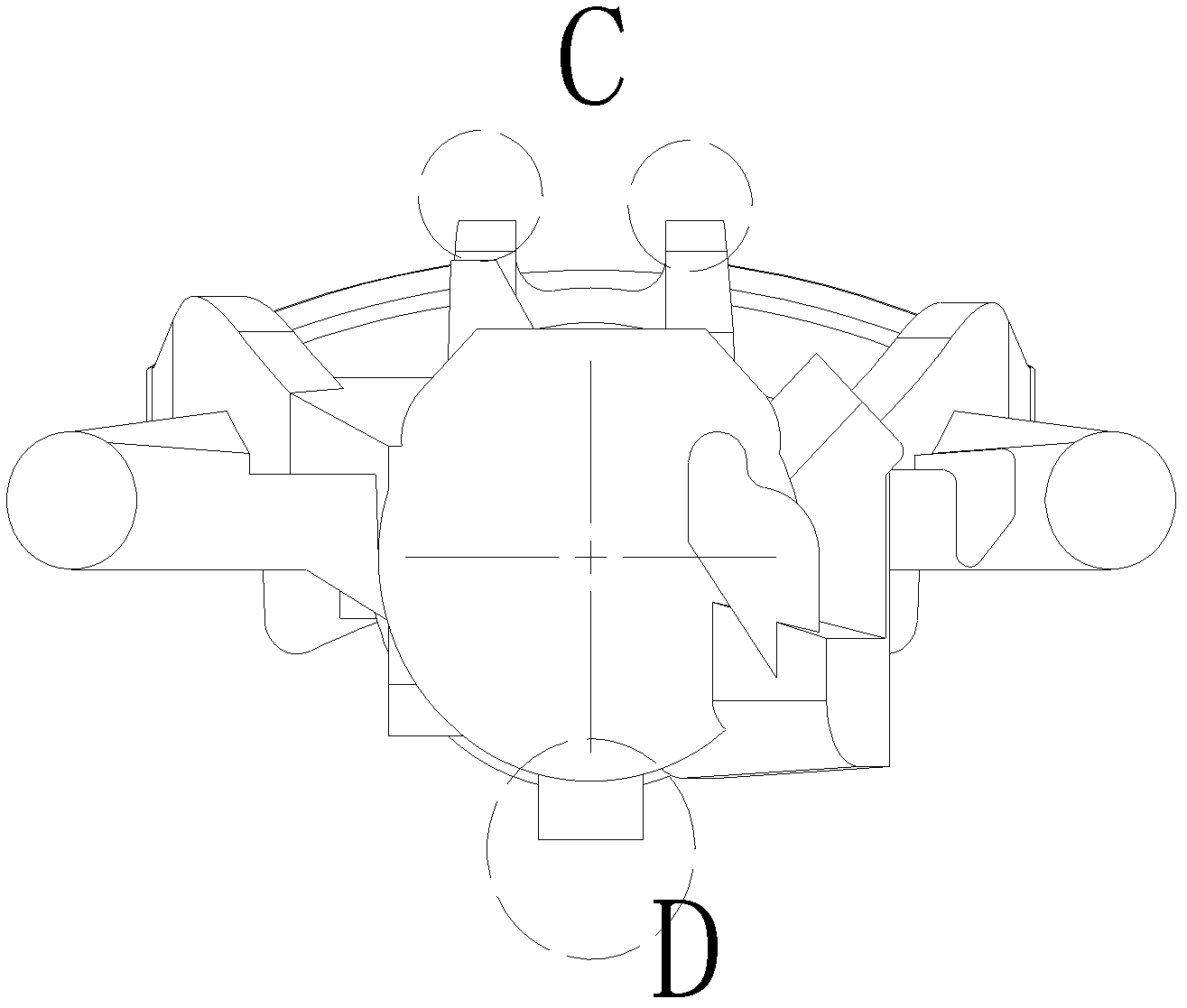

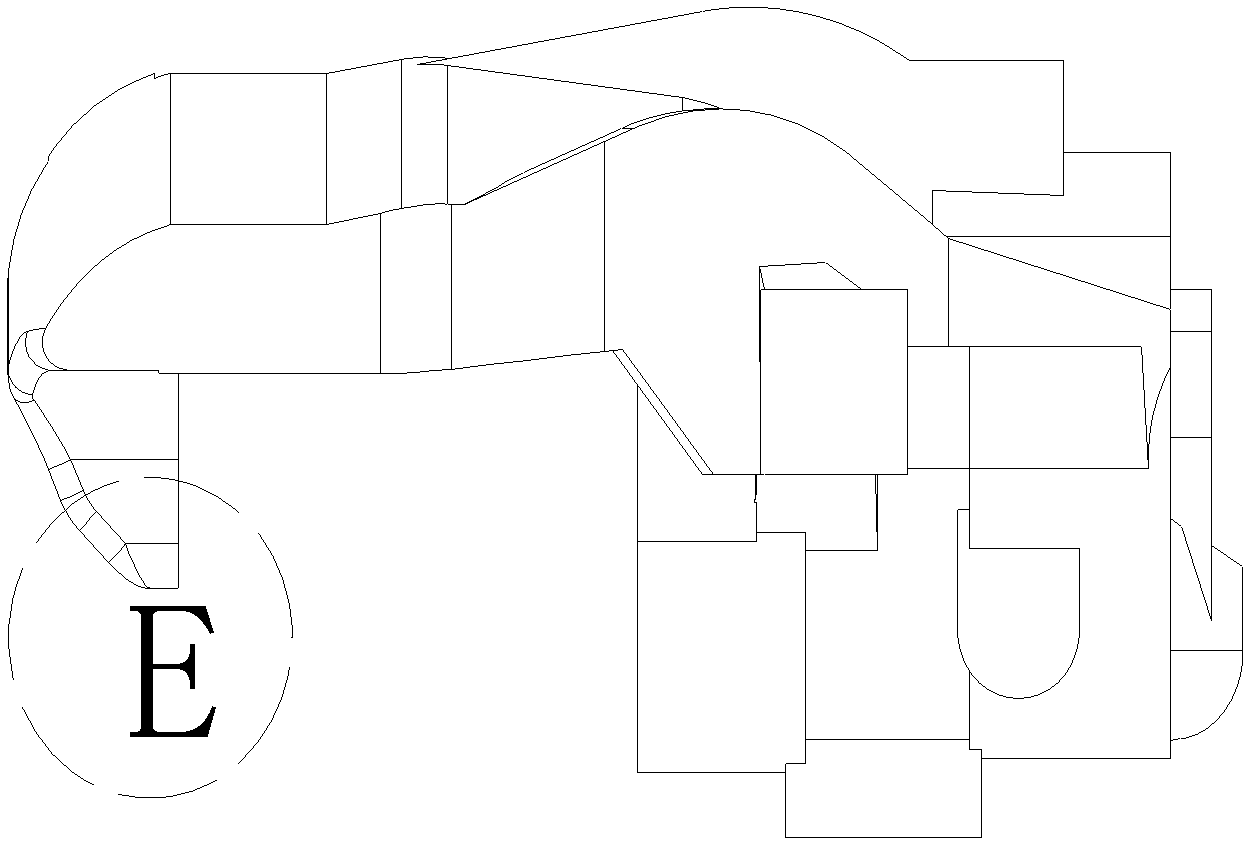

[0026] A method to reduce casting defects in the casting process of castings, such as Figure 5 Shown, compared to Figure 4 In the process layout of the existing mold, a support column 1 is added to the mold casting system. After the mold is installed on the molding machine, there is a cavity for the support column in the cavity of the sand making, which is formed on the casting system 2 after being poured After the mold (sand mold, castings and its pouring system) is fed into the sand-shaking equipment by the conveyor belt, the supporting column is added to the pouring system, no matter how the vibrating drum shake-out bed vibrates and rotates, such as Image 6 As shown, the support pillars at the four corners of the casting will be firmly in contact with the roller wall, thereby reducing or avoiding the occurrence of bumps, and the crack defects caused by the bumps have been eliminated.

[0027] Such as Figure 7 , Among them, the support column is 20-50mm higher than the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com