Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Electron beam machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electron-beam machining (EBM) is a process where high-velocity electrons concentrated into a narrow beam are directed toward the work piece, creating heat and vaporizing the material. EBM can be used for very precise cutting or boring of a wide variety of metals. Surface finish is better and kerf width is narrower than those for other thermal cutting processes.

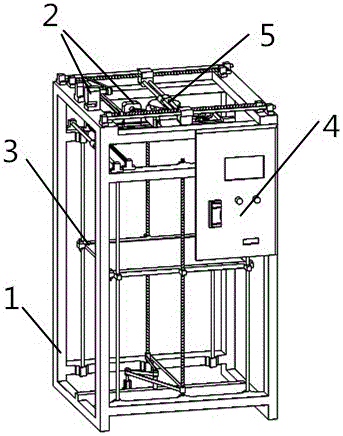

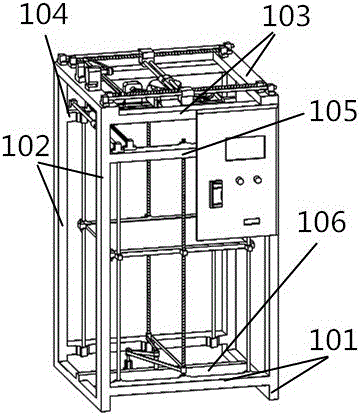

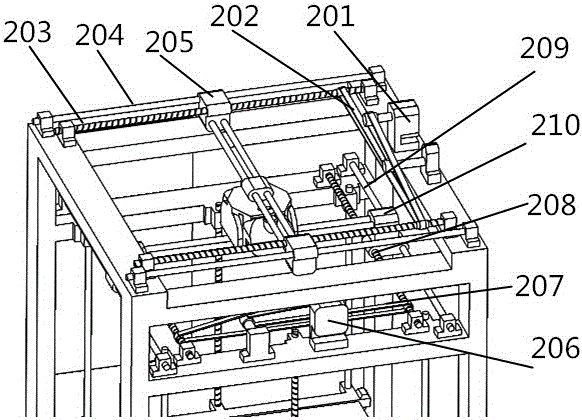

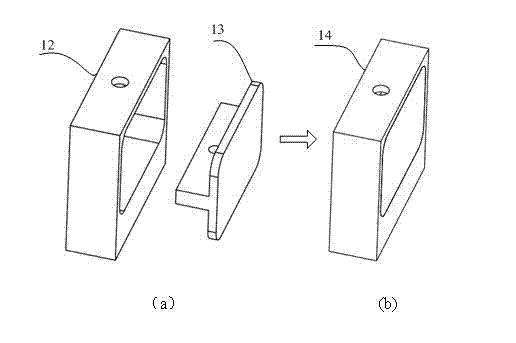

Multifunctional machining integrated machine for additives and consumables

InactiveCN106670808AGuaranteed levelGuaranteed calmAdditive manufacturing apparatusOther manufacturing equipments/toolsElectron beam machiningUltrasonic machining

The invention discloses a multifunctional machining integrated machine for additives and consumables. The multifunctional machining integrated machine for the additives and the consumables comprises a structural frame, a driving device, a work platform, a digital control device, a function conversion device and a machine device capable of achieving modular replacement. The driving device comprises a driving motor, a conveying belt, a lead screw and a guide rail. The digital control device comprises an input device, a memorizer, a controller, an arithmetic unit and an output device. The machining device capable of achieving modular replacement comprises a 3D printing device, a laser machining device, a digital control machining device, an ultrasonic machining device, an electronic beam machining device, an electrosparking device and a plasma machining device. All the machining devices can be modularly replaced on the function conversion device according to needs. A user can select one or more machining devices to cooperatively carry out fast modeling, forming and precision machining. The multifunctional machining integrated machine for the additives and the consumables is convenient to use and efficient in machining, saves resources and has high economical efficiency.

Owner:SUZHOU UNIV OF SCI & TECH

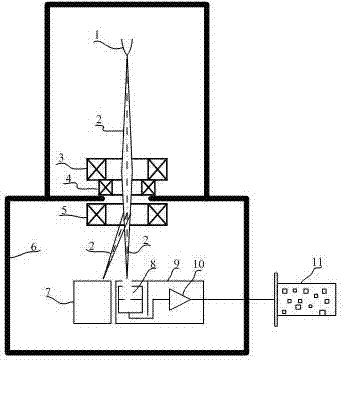

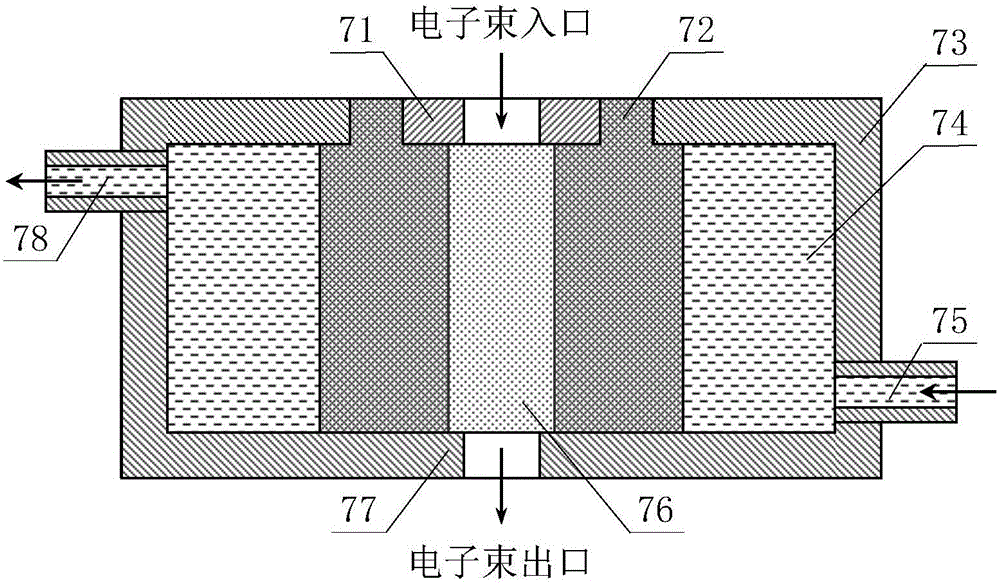

Faraday cup sensing device used in electron beam processing beam quality test

ActiveCN102353978APrevent escapeImprove collection efficiencyX/gamma/cosmic radiation measurmentWeak currentAlloy

The invention discloses a Faraday cup sensing device used in an electron beam processing beam quality test. The Faraday cup sensing device comprises: a Faraday cup, an aluminum shell and a signal switching and amplification circuit. The Faraday cup and the signal switching and amplification circuit are arranged in the aluminum shell. The signal switching and amplification circuit is connected with an acquisition card of an industrial personal computer which is out of a vacuum chamber of an electron beam quality test system. Electron beam of the electron beam quality test system is collected by the Faraday cup and is flowed into the signal switching and amplification circuit through a cable. A weak current signal is processed by the signal switching and amplification circuit, then is converted into a digital signal by the acquisition card and is stored in the industrial personal computer. The Faraday cup comprises two electron beam aperture collection electrodes and one electron beam seam collection electrode. The aluminum shell comprises: an aluminum alloy shell and an aluminum alloy cover. By using the device, collection efficiency of the electron beam can be raised; multiple vacuum-pumping processes can be avoided. Amplifying the signal can obviously raise a signal to noise ratio.

Owner:NANJING UNIV OF SCI & TECH

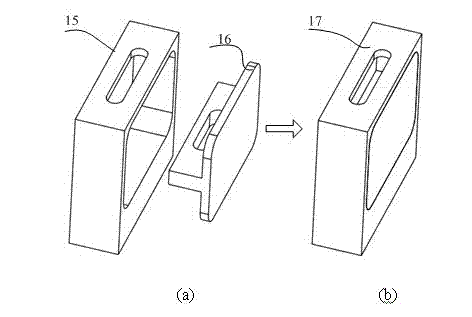

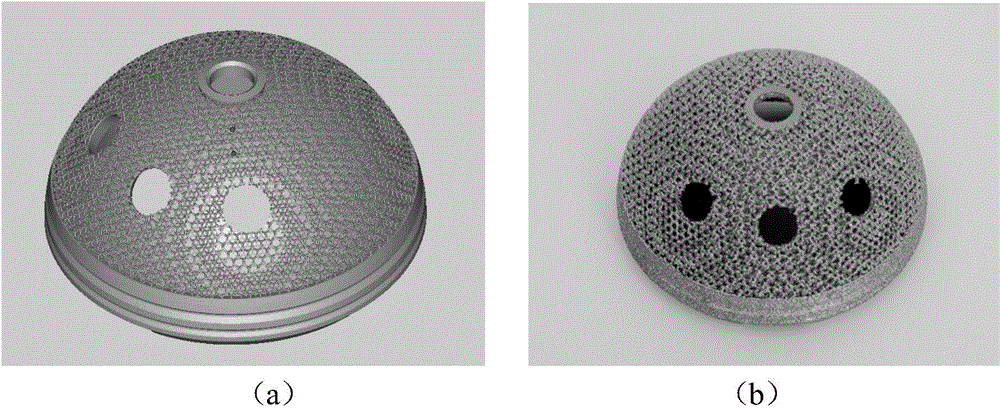

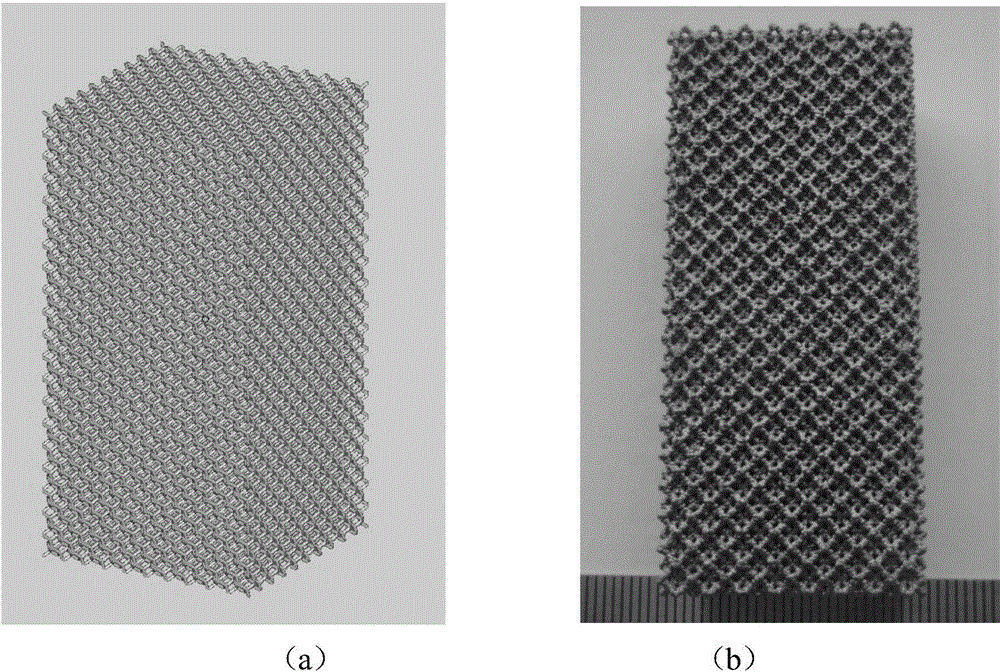

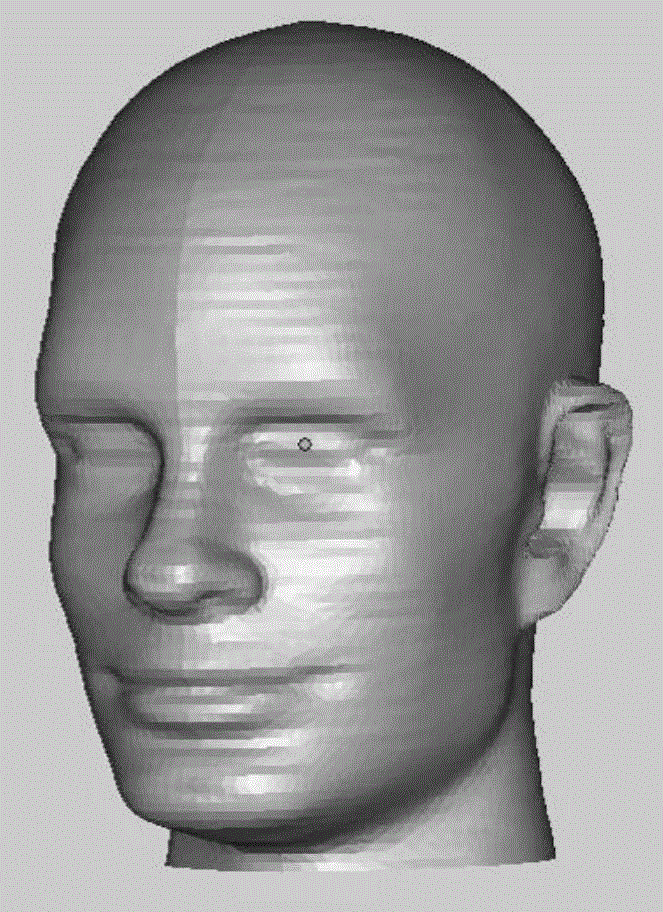

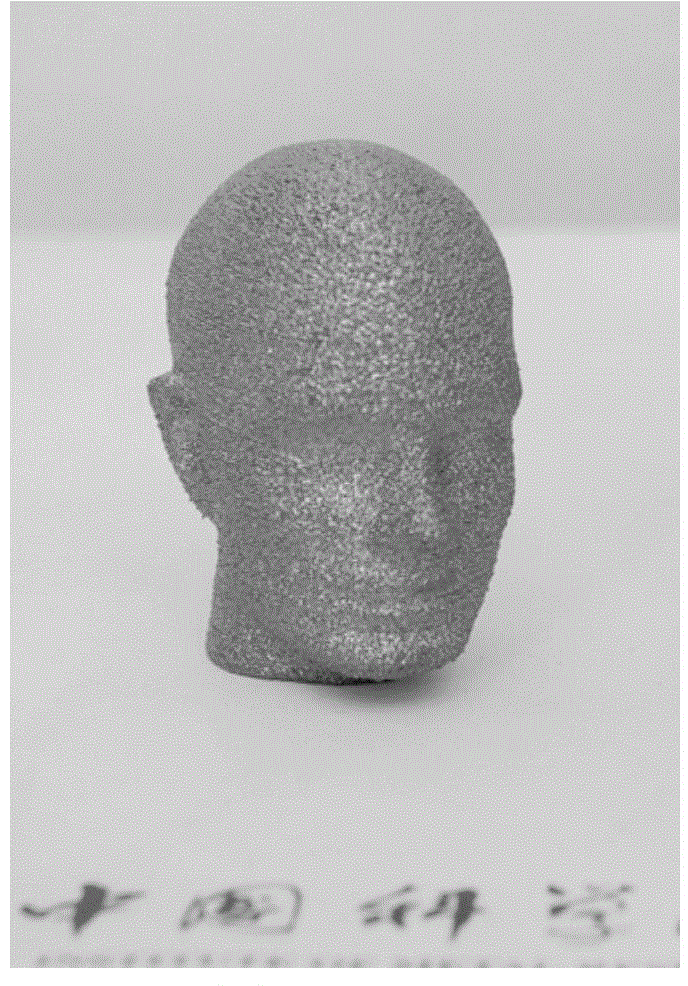

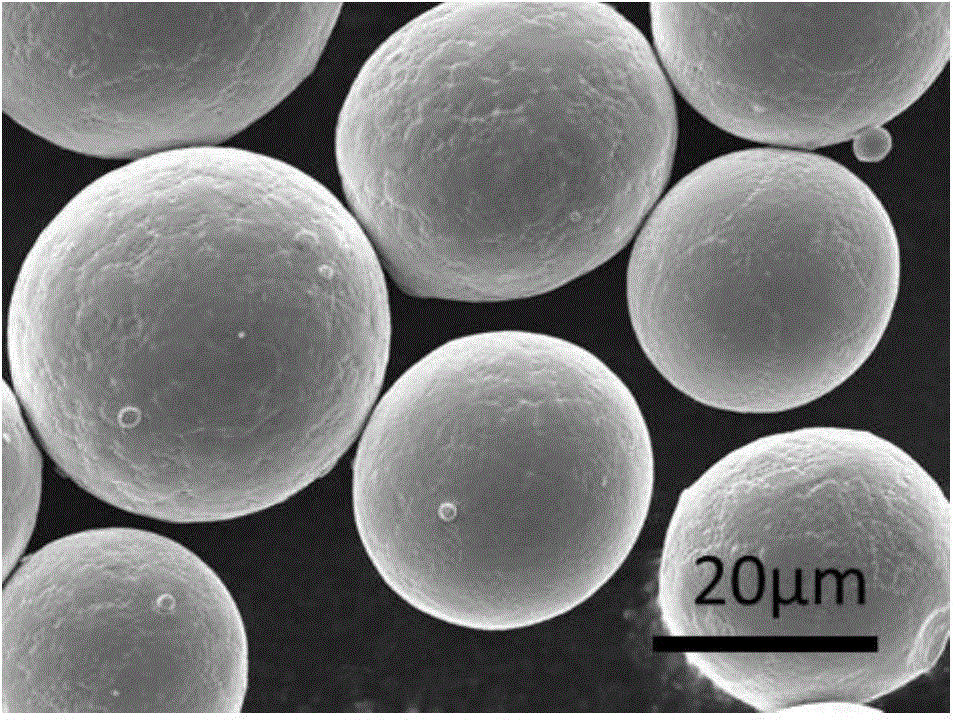

Preparation method for high-performance low-modulus medical titanium alloy three-dimensional metal part

ActiveCN106312060AIncrease productivityLow costAdditive manufacturing apparatusIncreasing energy efficiencyElectron beam machiningCompressive strength

The invention discloses a preparation method for a high-performance low-modulus medical titanium alloy three-dimensional metal part, and belongs to the technical field of electron beam machining. The preparation method is suitable for rapid-forming preparation of a low-modulus medical titanium-alloy-system complex-structure metal part containing 10-35 wt% of Ti-Nb, 0-15 wt% of Zr, and 0-15% of Sn and Ta. The preparation method comprises the steps that firstly, the titanium alloy three-dimensional metal part is prepared through the EBM technique; secondly, hot isostatic pressing treatment is conducted on the prepared three-dimensional part at the temperature of 900-1200 DEG C; and finally, heat treatment is conducted on the titanium alloy part. Through the technological process, the excellent-comprehensive-mechanical-performance low-modulus medical titanium alloy complex-structure three-dimensional part with the compressive strength being 5 MPa or over, the tensile strength being 600 MPa or over, the elasticity modulus being lower than 90 GPa, the ductility being 10% or over and the fatigue strength being 300 MPa or over can be obtained, and the preparation method can be widely applied to the medical field and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

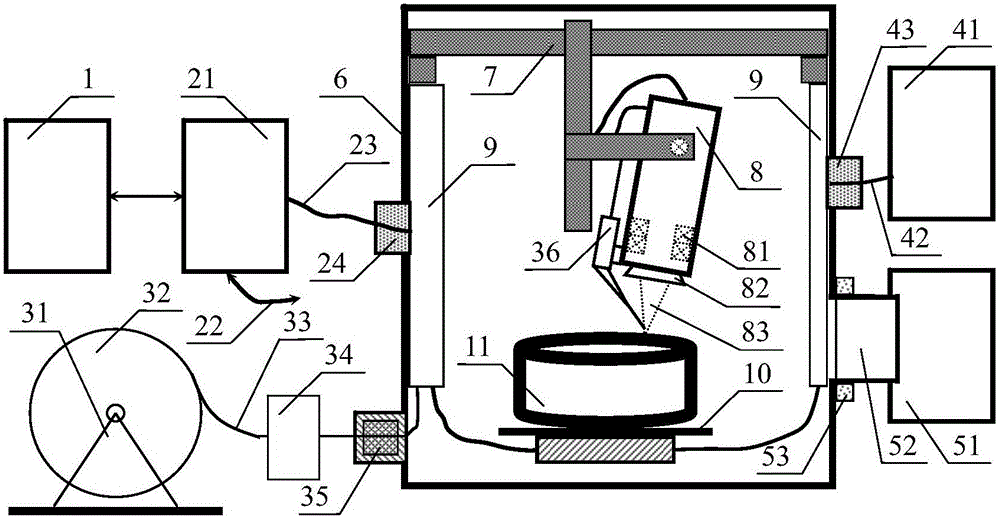

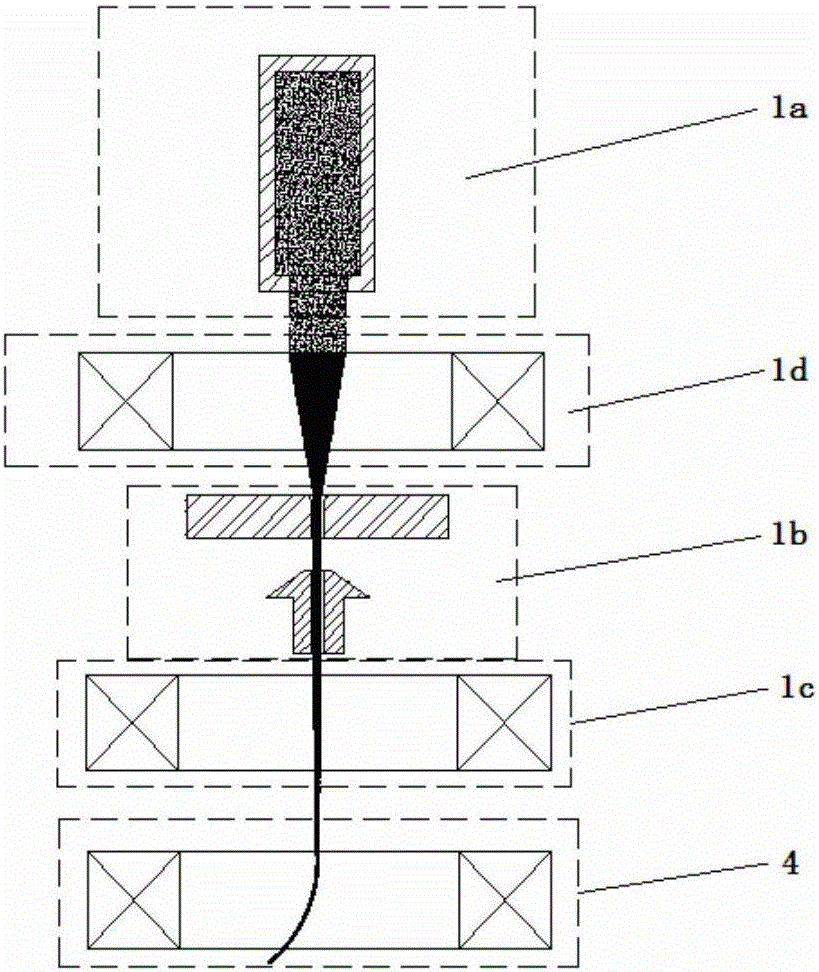

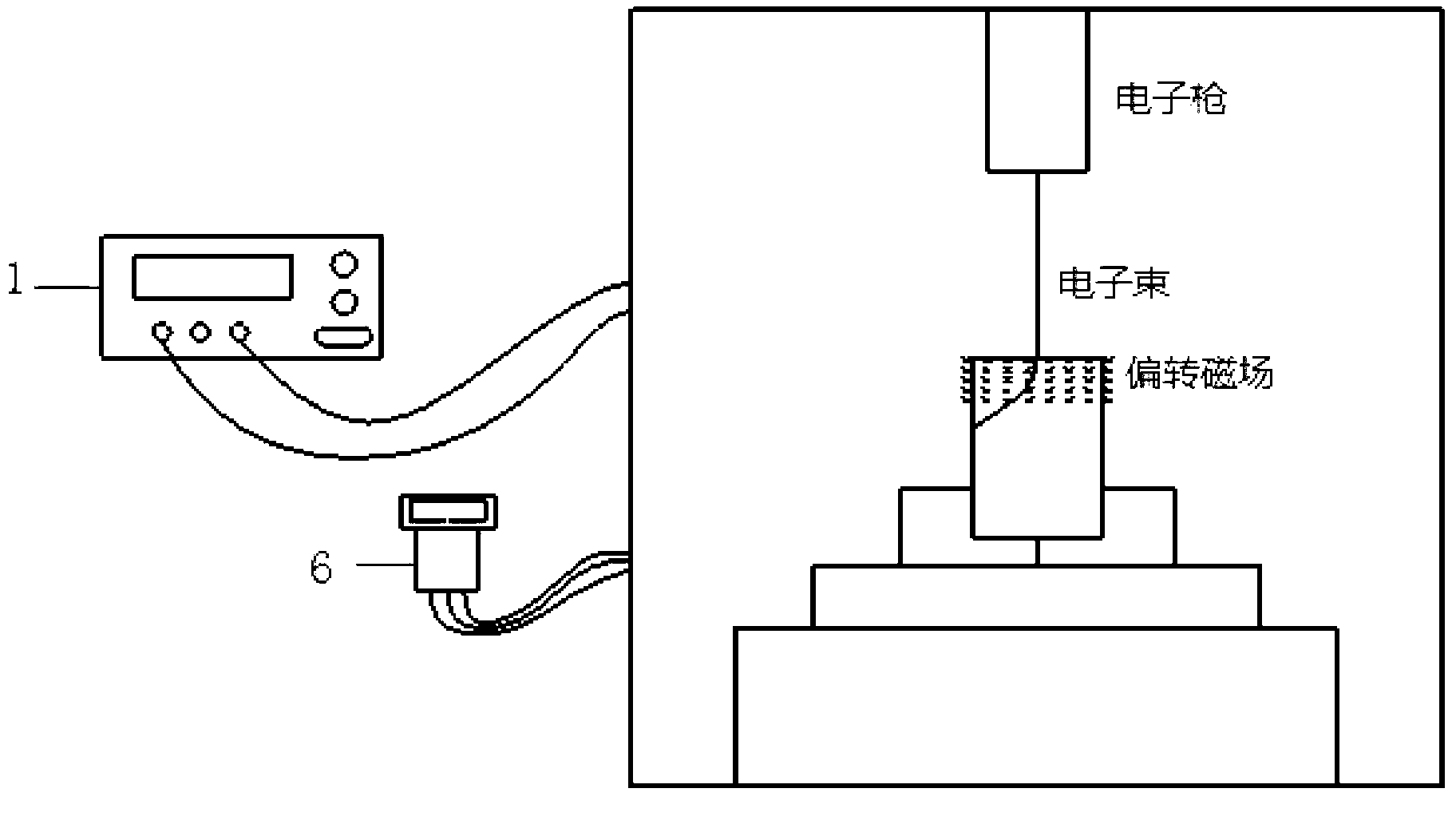

Wire-feeding type electron beam material-increasing manufacturing equipment and operating method thereof

InactiveCN105904079ASolving Online Monitoring ProblemsImprove manufacturing precisionElectron beam welding apparatusElectron beam machiningSecondary electrons

The invention discloses wire-feeding type electron beam material-increasing manufacturing equipment and an operating method thereof. A deflecting and scanning device and a secondary electron receiving device are further mounted on an electronic gun. The deflecting and scanning device and the secondary electron receiving device are connected to a central control unit. When an electron beam sent out by the electronic gun processes a manufacturing layer of a fixed segment of a workpiece, an exciting current of the deflecting and scanning device is controlled by the central control unit, so that the electron beam of the electronic gun turns around to quickly scan the manufacturing layer of the fixed segment, the secondary electron receiving device transmits secondary electronic signals received in a back-scanning process to the central control unit, and the central control unit synchronously records the secondary electronic signal of each scanning point on the fixed segment; after scanning, the central control unit analyzes and processes the recorded secondary electronic signal data so as to determine whether the edge of the manufacturing layer of the fixed segment reaches an expected value or not and determine whether the manufacturing layer of the fixed segment has hole defects or not for the convenience of immediate repair.

Owner:GUILIN THD TECH CO LTD

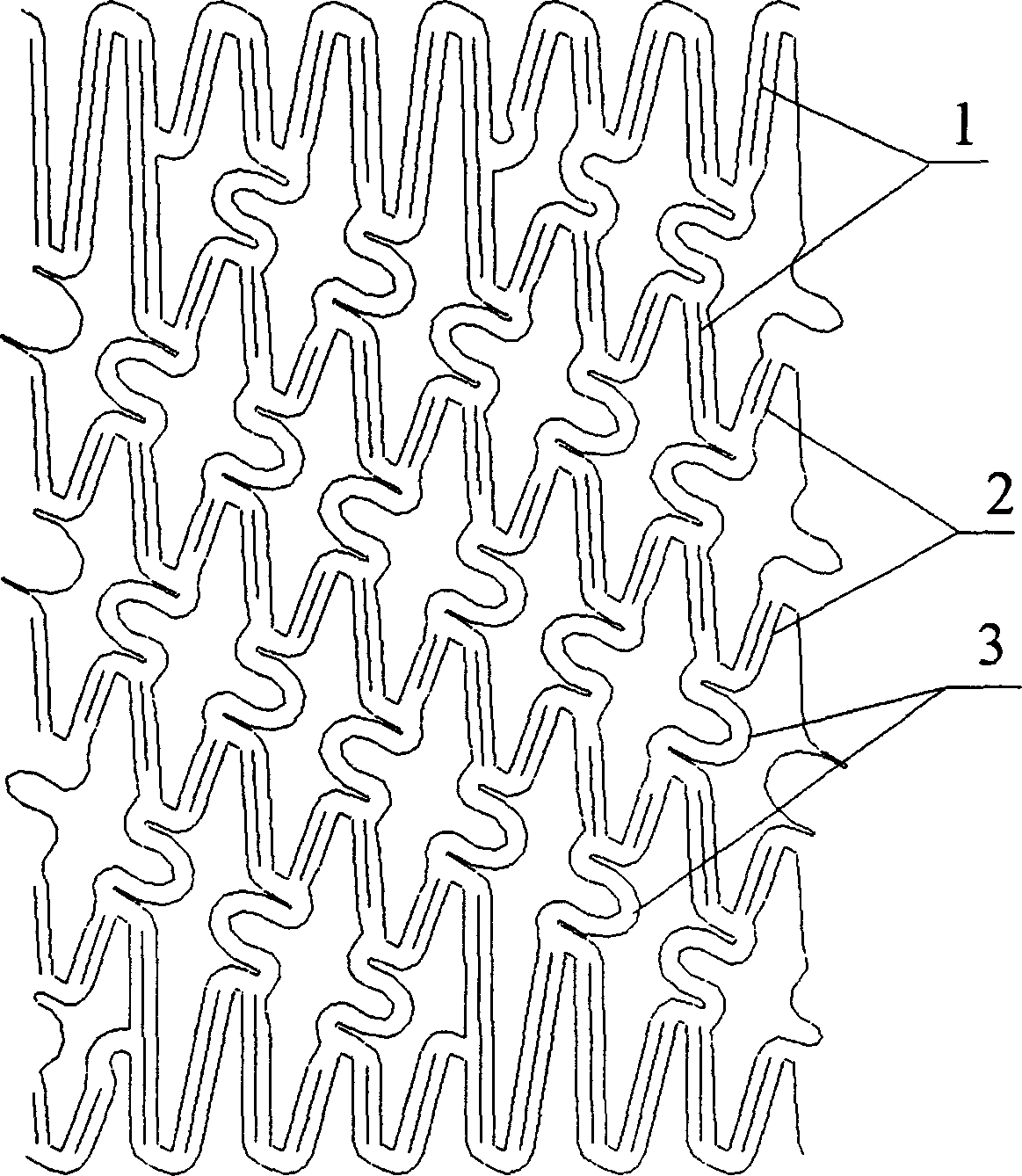

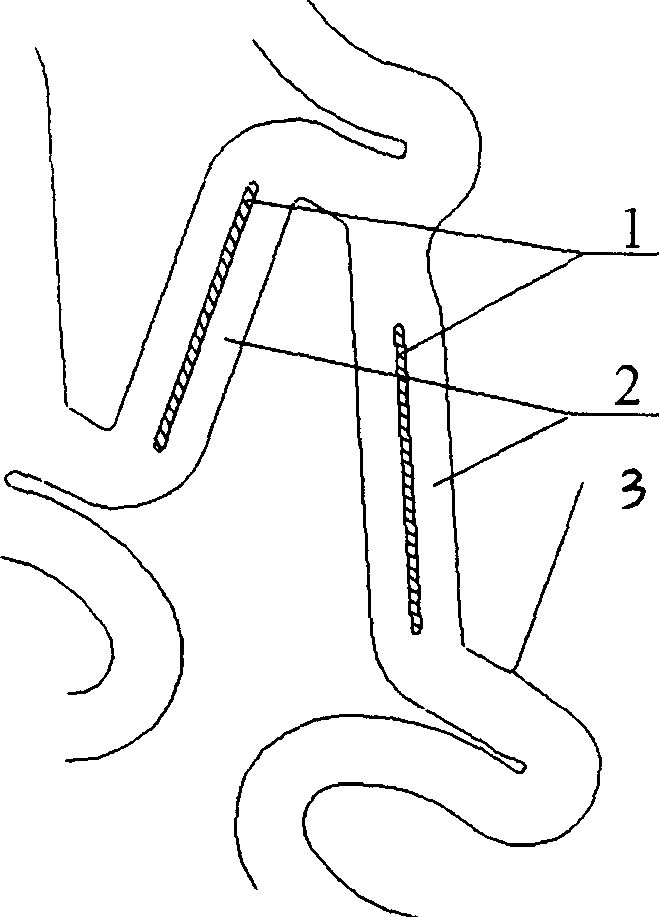

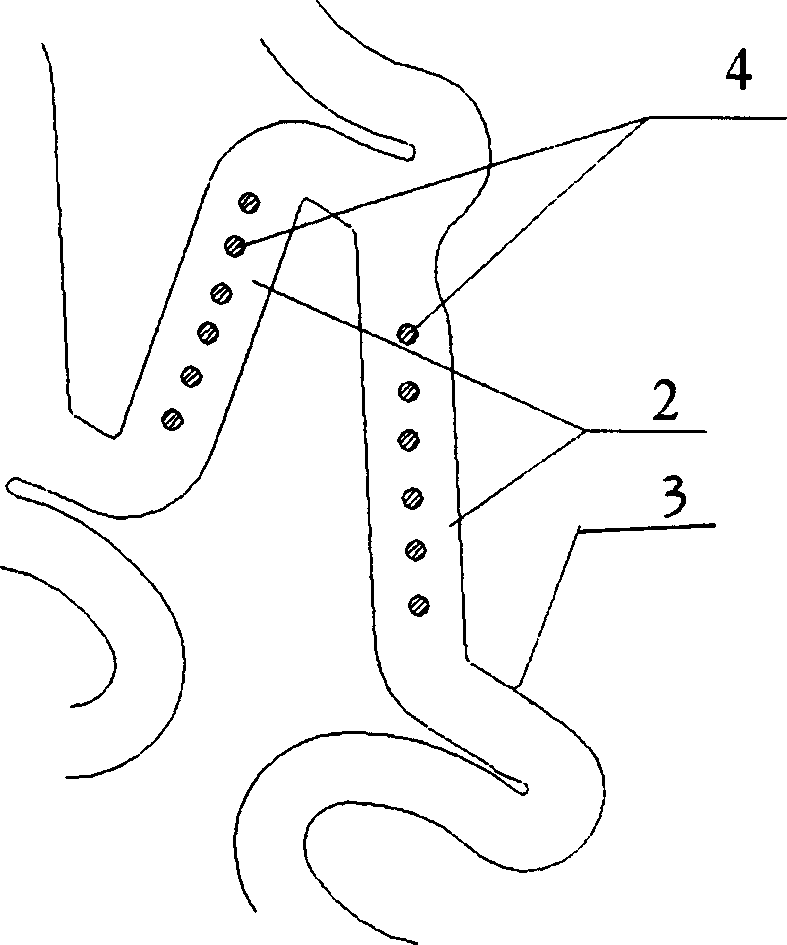

Vascular stent mounted with non penetrable slot or blind hole and its preparing method

The present invention proposes one kind of blood vessel rack with blind slot or blind hole, and belongs to medical equipment technology. The blood vessel rack consists of straight main bearing bars and connecting bars, and the main bearing bars have blind slot or blind hole in the outer surface for embedding medicine coating. The blind slots or blind holes in the main bearing bars have depth not affecting the bearing capacity of the bars, the slots may be in different shapes, and the holes may be distributed regularly or irregularly. The blind slots or blind holes are made through laser machining, electric beam machining or chemical etching. The blood vessel rack of the present invention has improved medicine coating attaching capacity, prolonged medicine releasing period and less re-stenosis.

Owner:BEIJING AMSINO MEDICAL

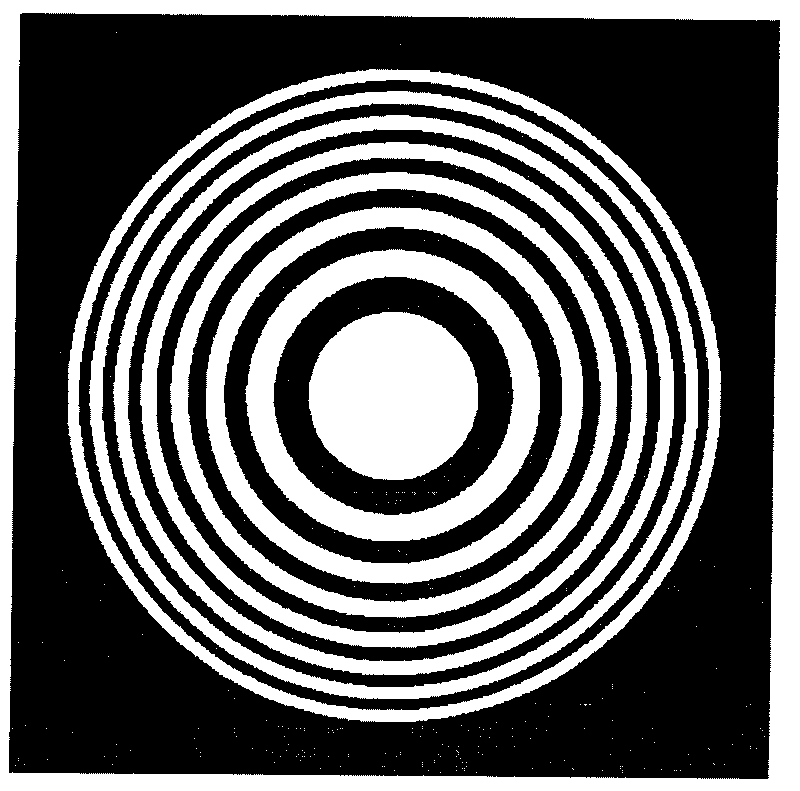

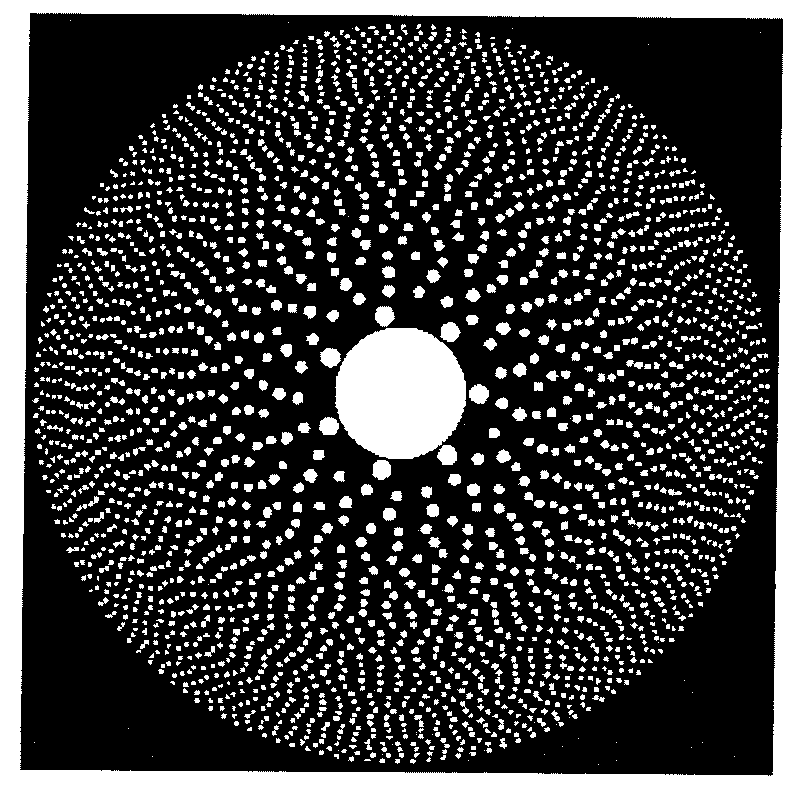

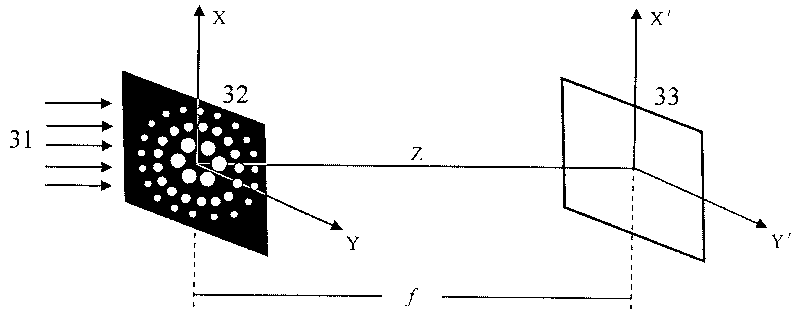

Phase type photon sieve

A phase type photon sieve is improved from a conventional Fresnel zone plate structure and consists of orifices distributed on transparent and non-transparent annulus of the Fresnel zone plate randomly, wherein Pi-phase shift is existed between the orifices on the transparent annulus and the orifices on the non-transparent annuls, and phase difference is achieved by accurately controlling etching depth of each annulus. Manufacturing process of the phase type photon sieve is completed by an electro beam machining process. Compared with the Fresnel zone plate, the phase type photon sieve can keep high diffraction efficiency and simultaneously has more excellent resolution capacity. Compared with an amplitude photon sieve, the phase type photo sieve can keep high resolution capacity and simultaneously has more excellent diffraction efficiency. As an excellent nano-level diffraction imaging device, the phase type photon sieve can be widely applied to fields of photo-etching, astronomical observation, air shot, weapon vision and the like.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Electronic gun device for high-voltage gas discharge

ActiveCN104505325AExtend cathode lifeMove fastElectric discharge tubesElectron beam machiningCold cathode

The invention provides an electronic gun device for high-voltage gas discharge. The electronic gun device comprises a cathode insulator, a high-voltage insulator, a sealing top cover, a first section of gun shell, an insulating trap, an anode, a second section of gun shell, a first focusing coil, a second focusing coil and a deflection scanning coil, wherein the cathode insulator, the high-voltage insulator, the sealing top cover, the insulating trap and the anode are positioned in the first section of gun shell; the first focusing coil, the second focusing coil and the deflection scanning coil are positioned in the second section of gun shell; the cathode insulator, the high-voltage insulator, the insulating trap, the anode, the first focusing coil, the second focusing coil and the deflection scanning coil are coaxial and are sequentially distributed along the axis from top to bottom. According to the electronic gun device for the high-voltage discharge, the cathode life can be greatly prolonged, which is conductive to expanding the application field of a cold cathode electron beam machining technology.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

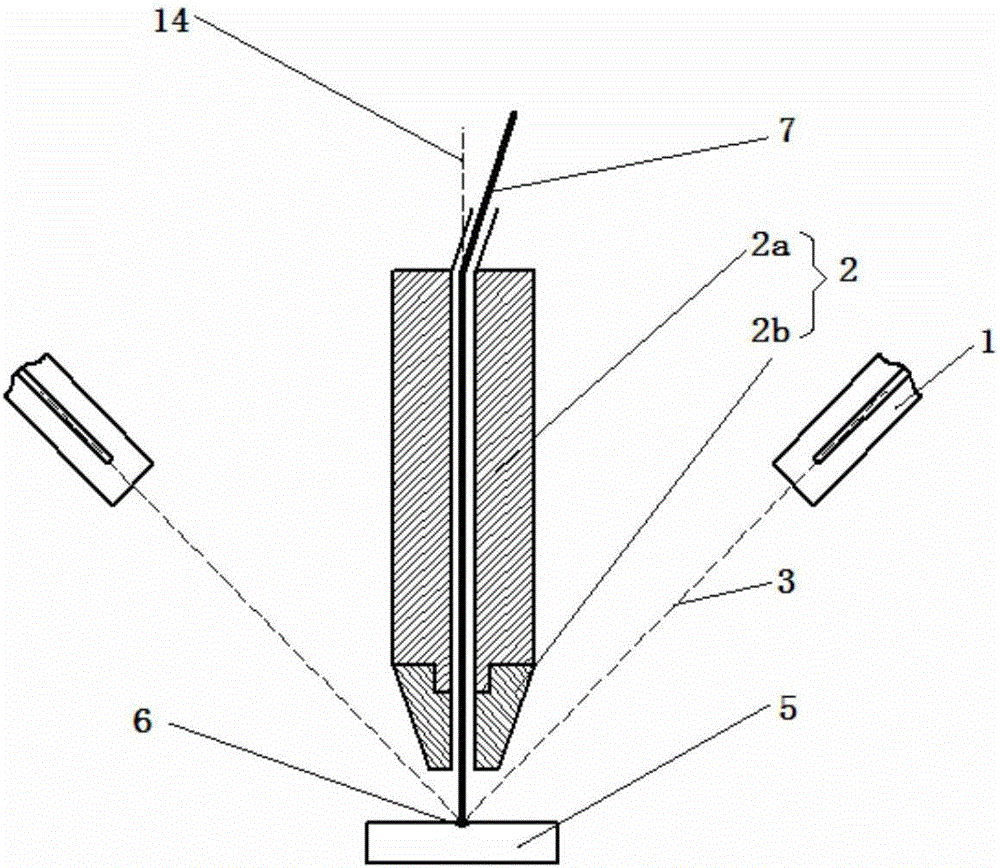

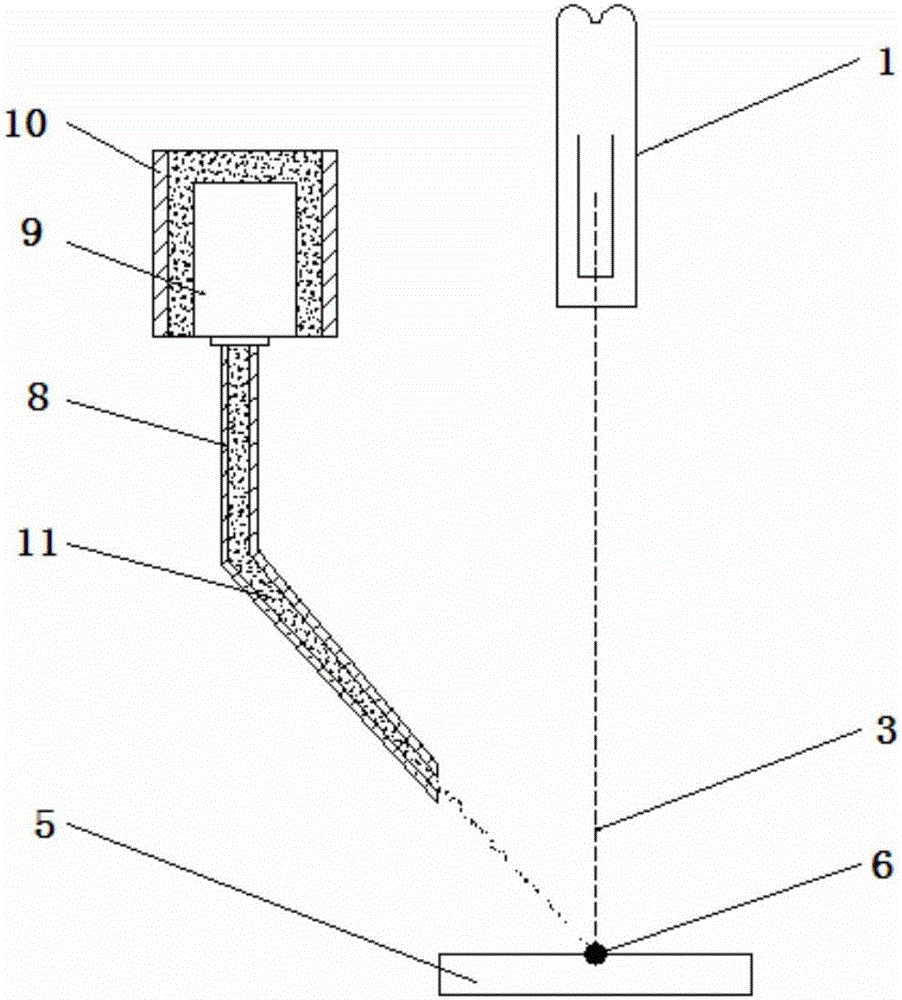

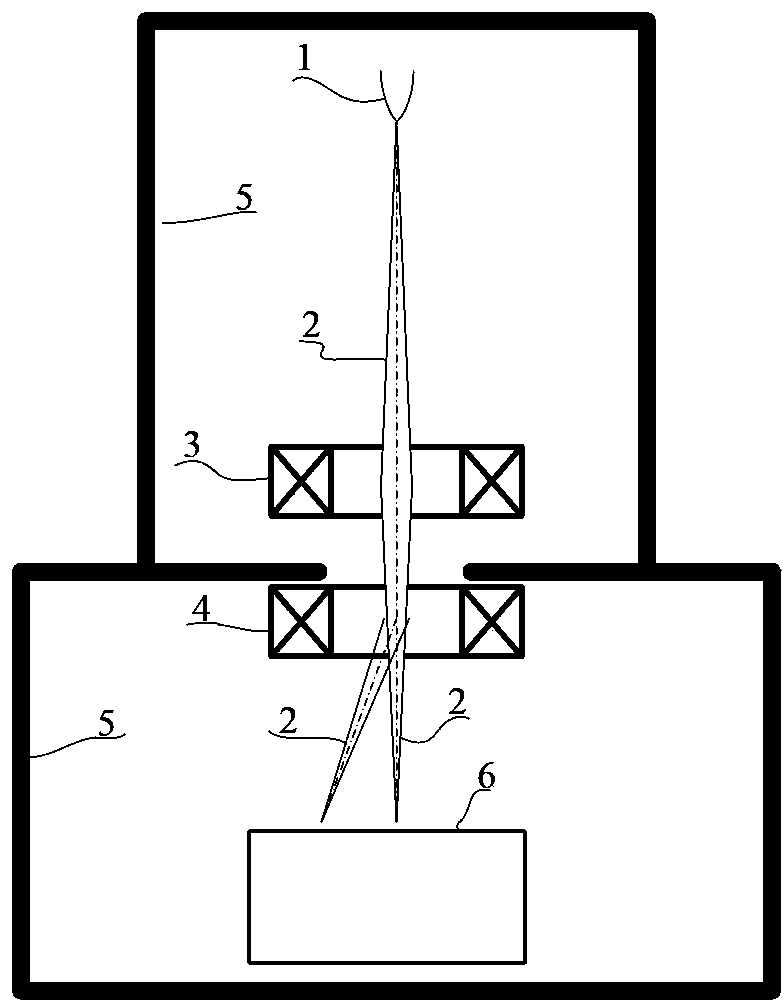

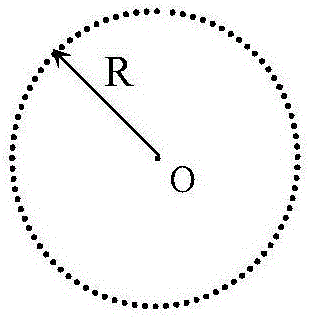

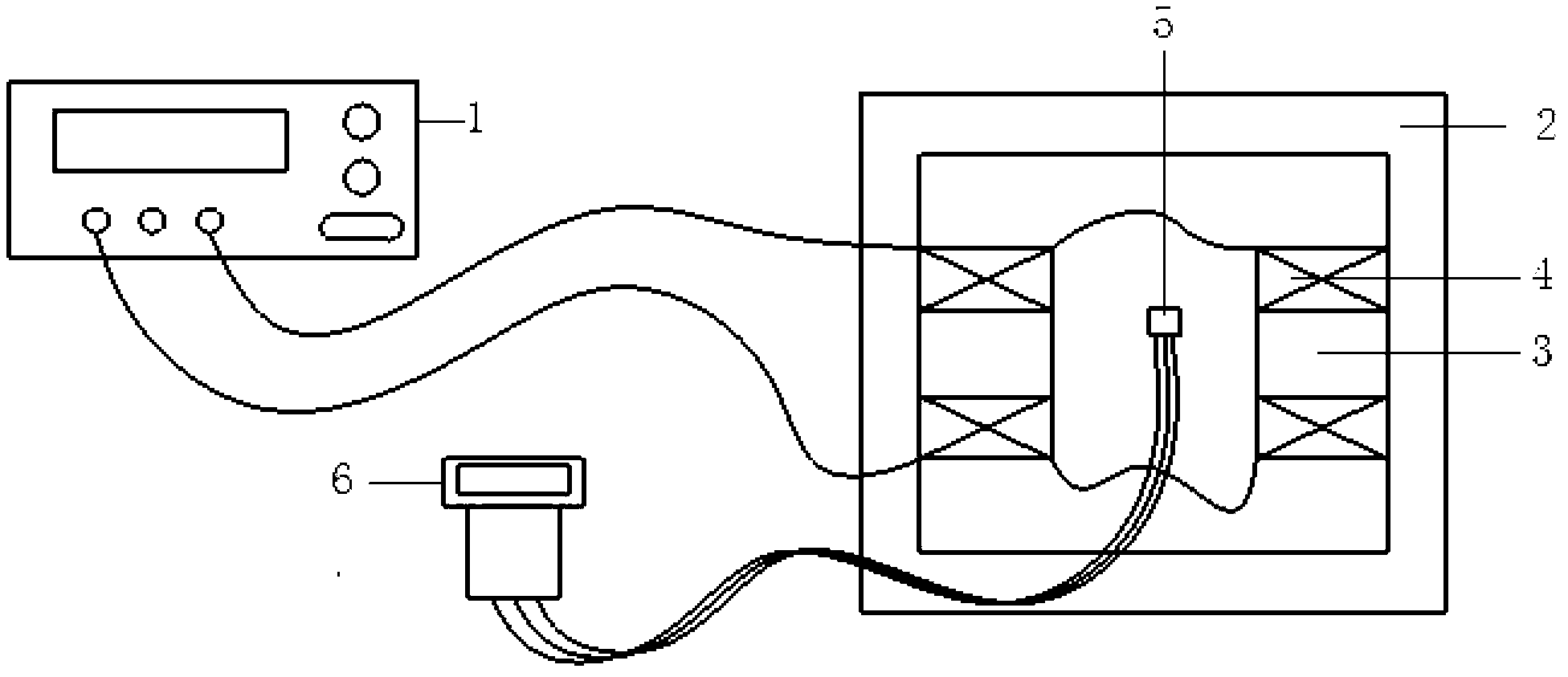

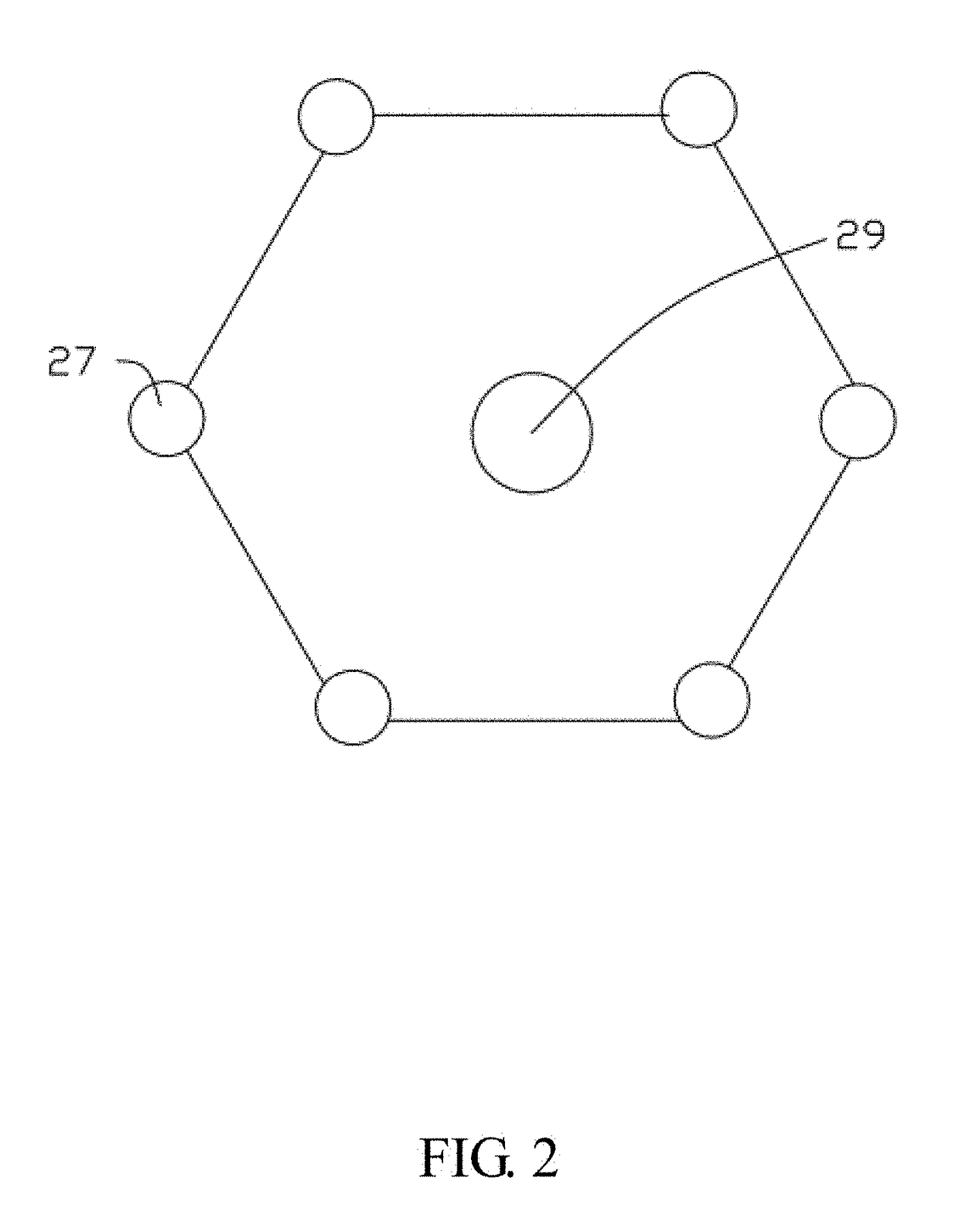

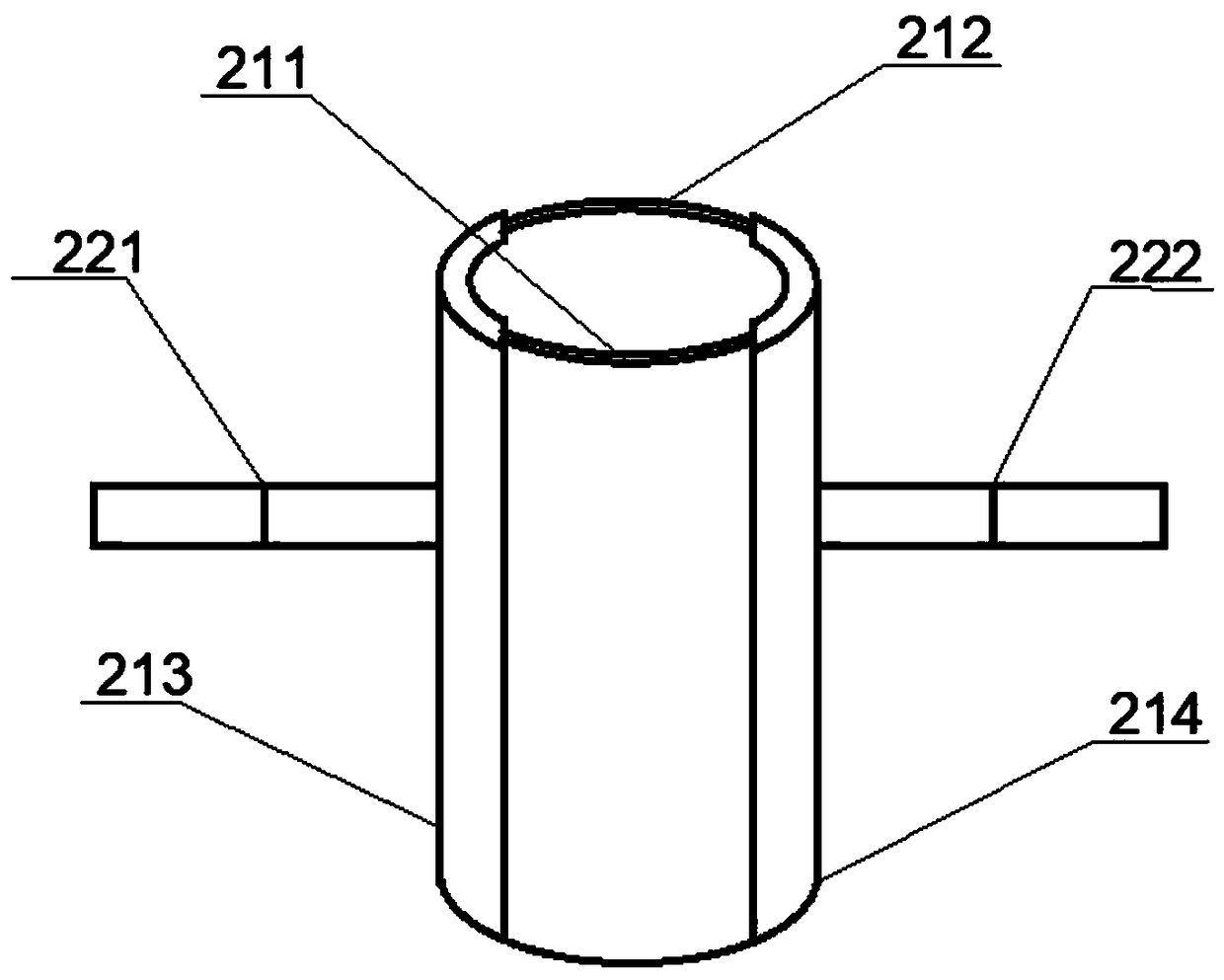

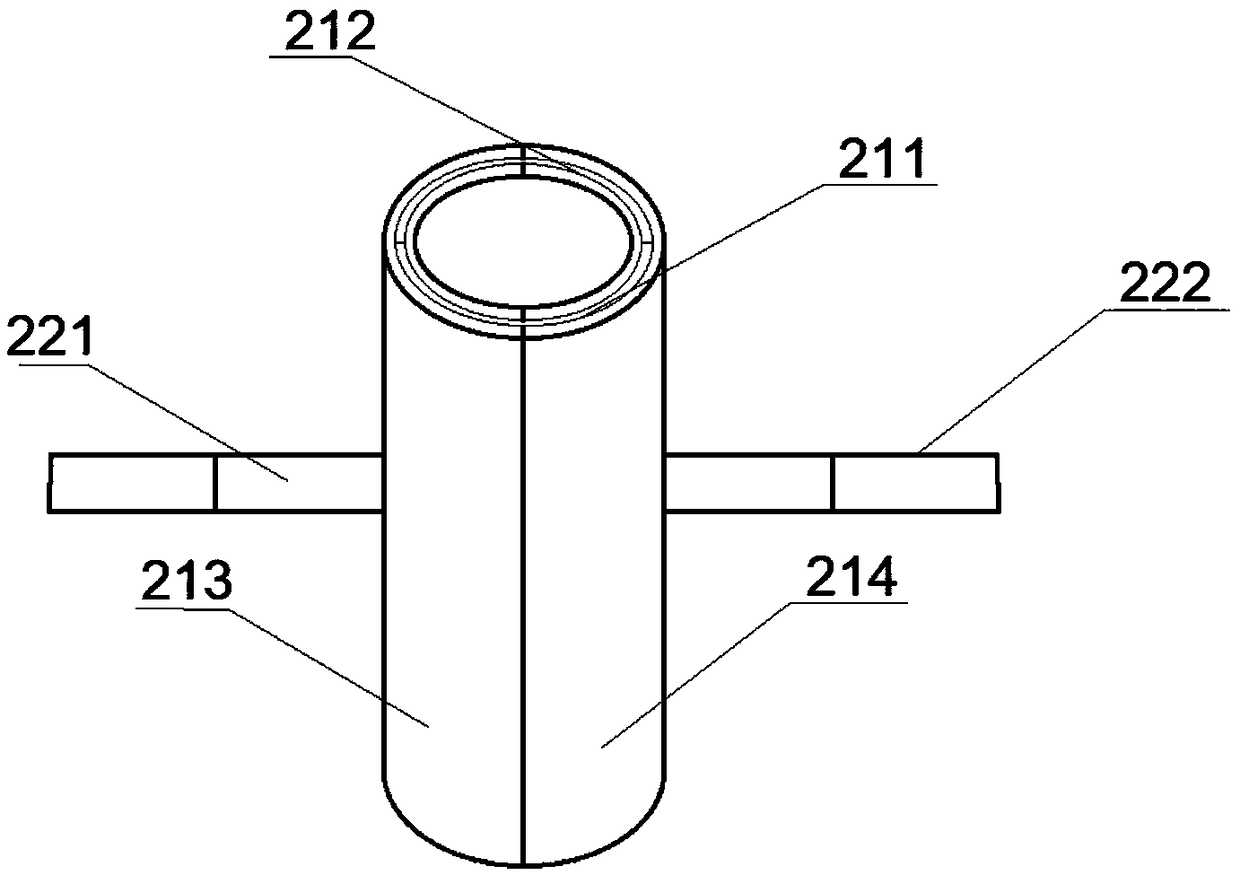

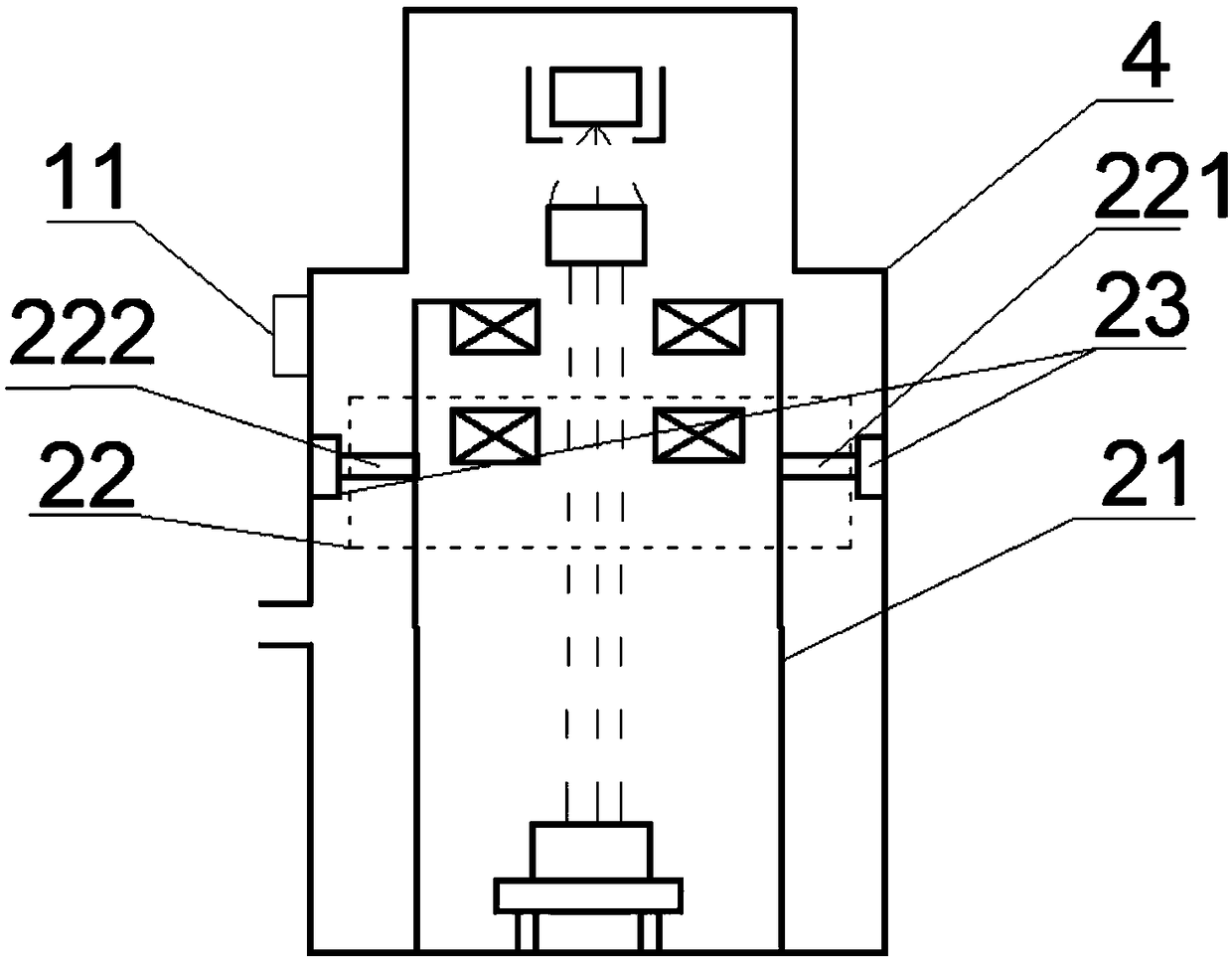

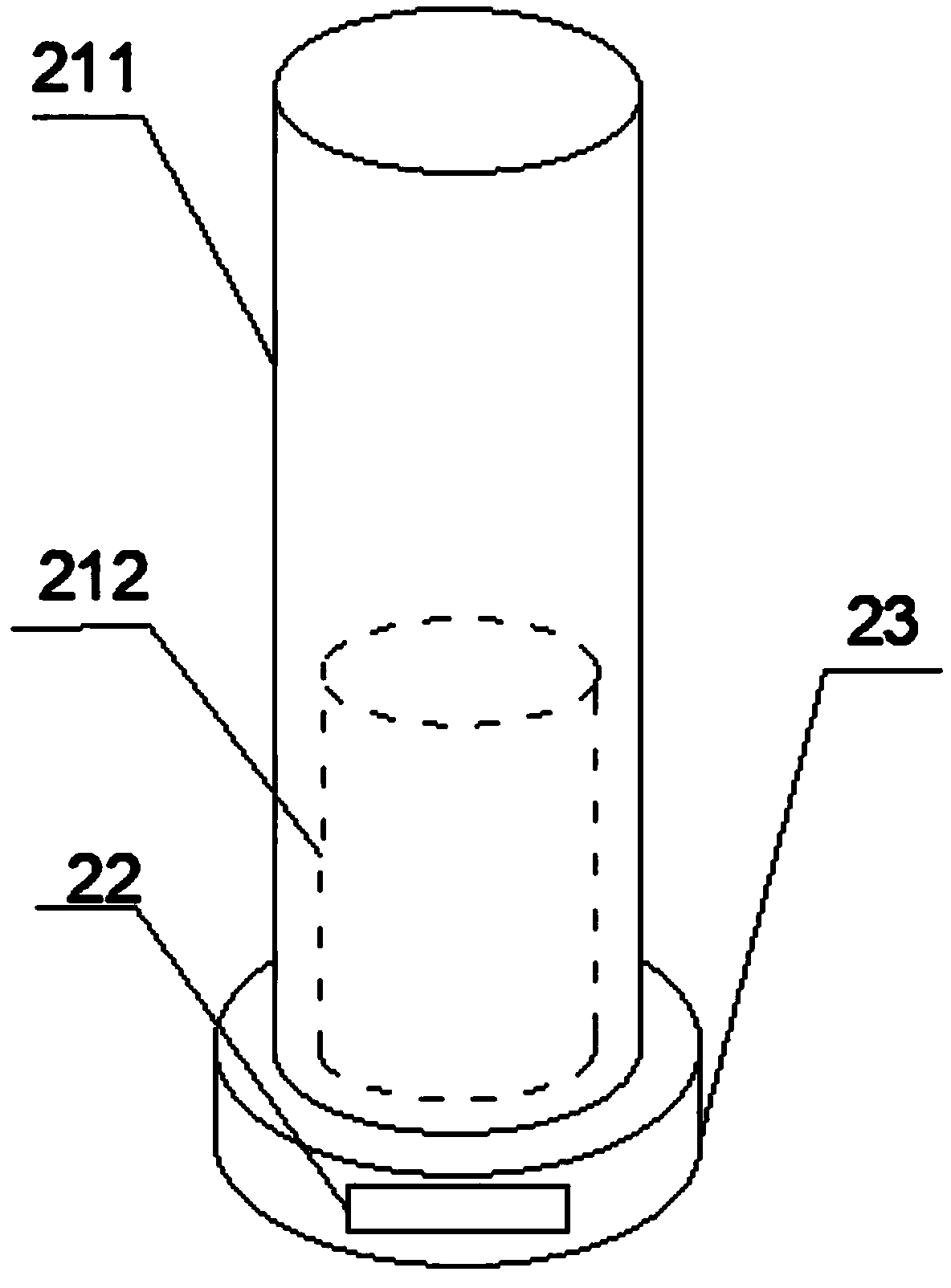

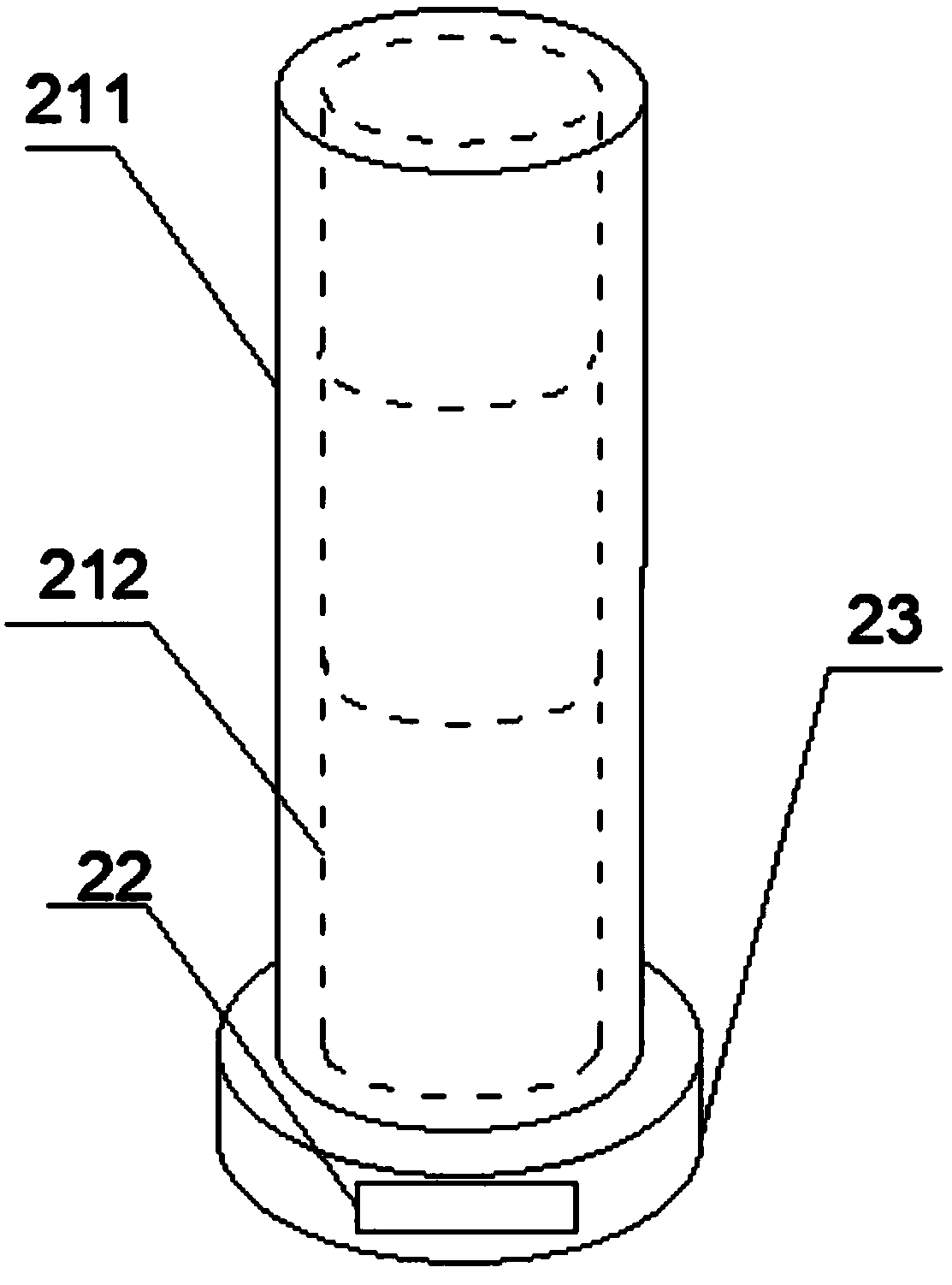

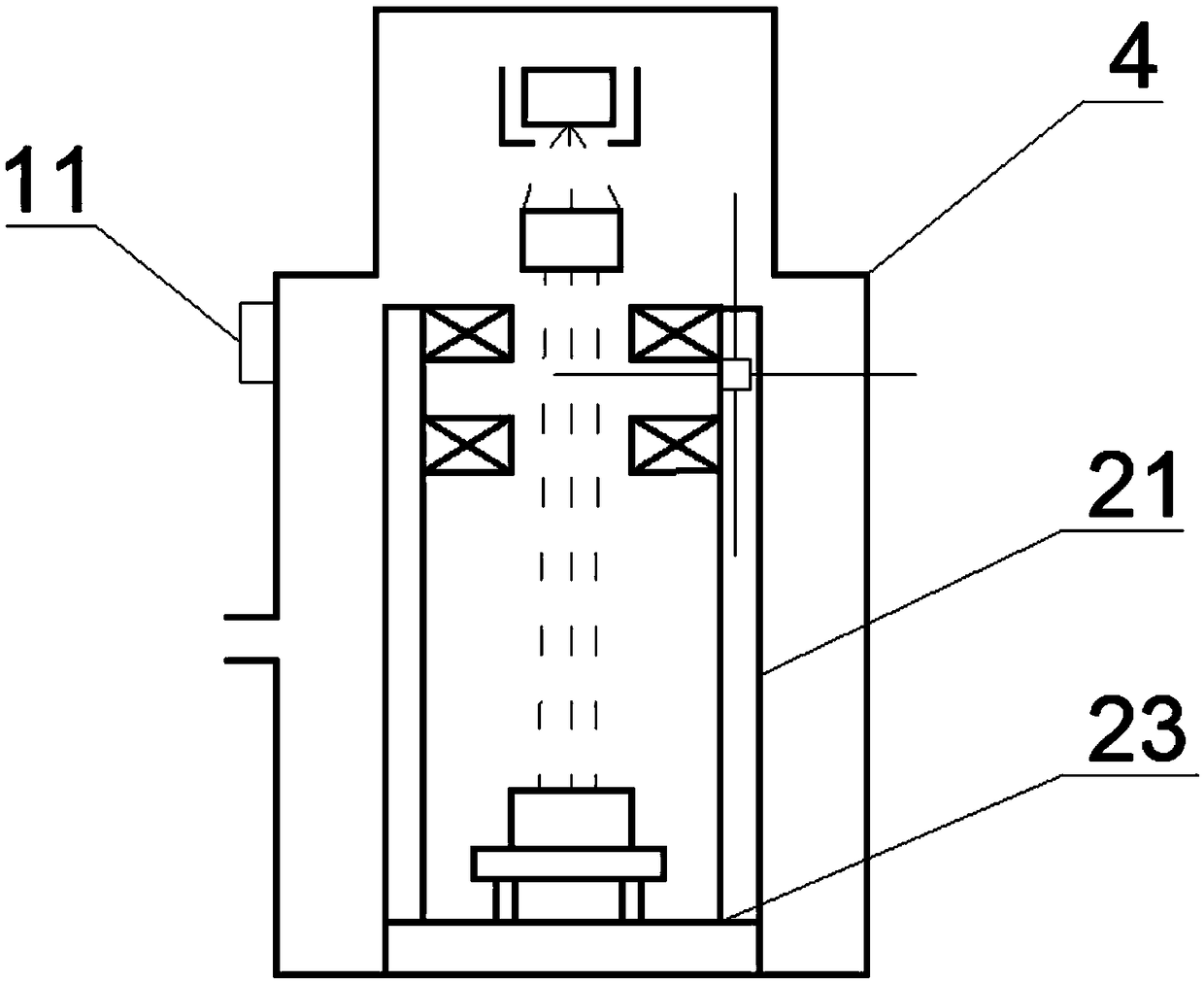

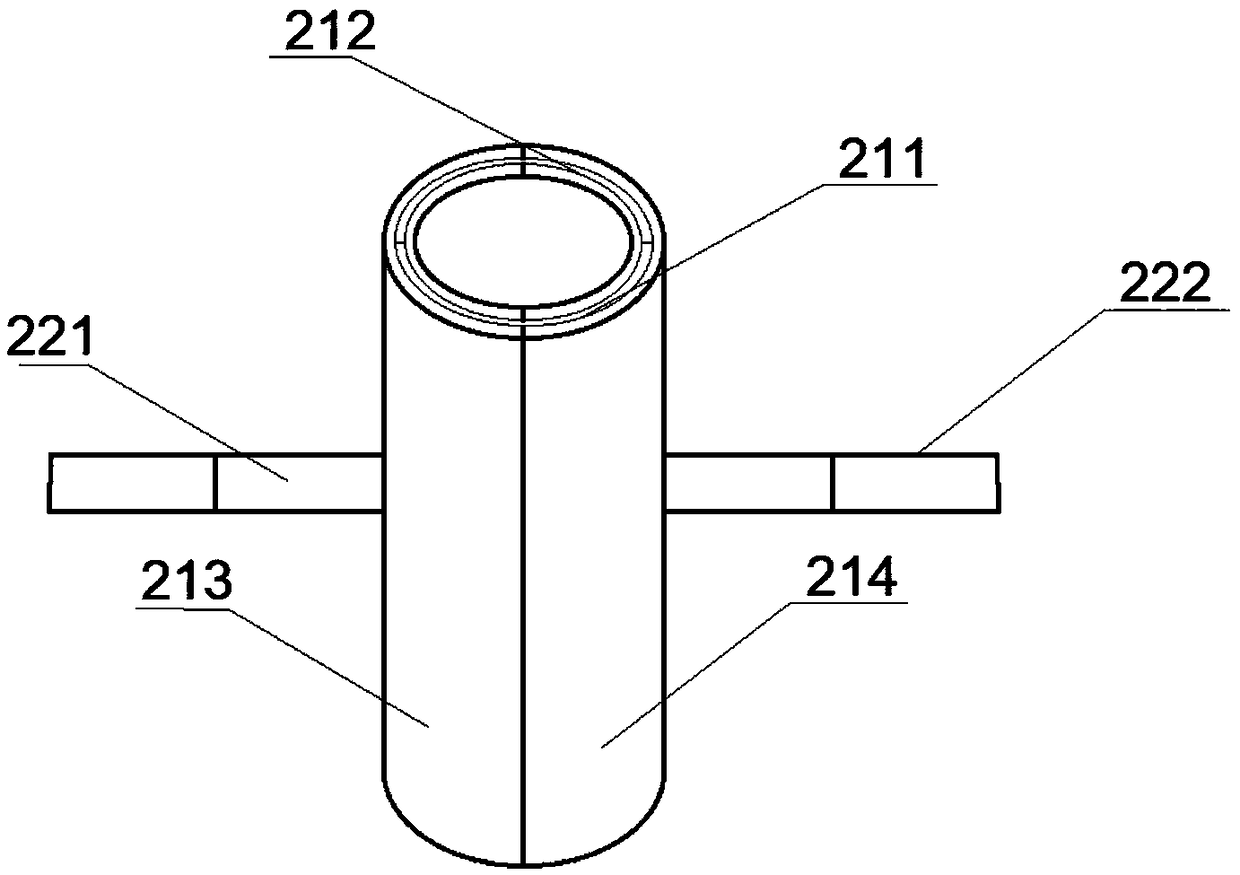

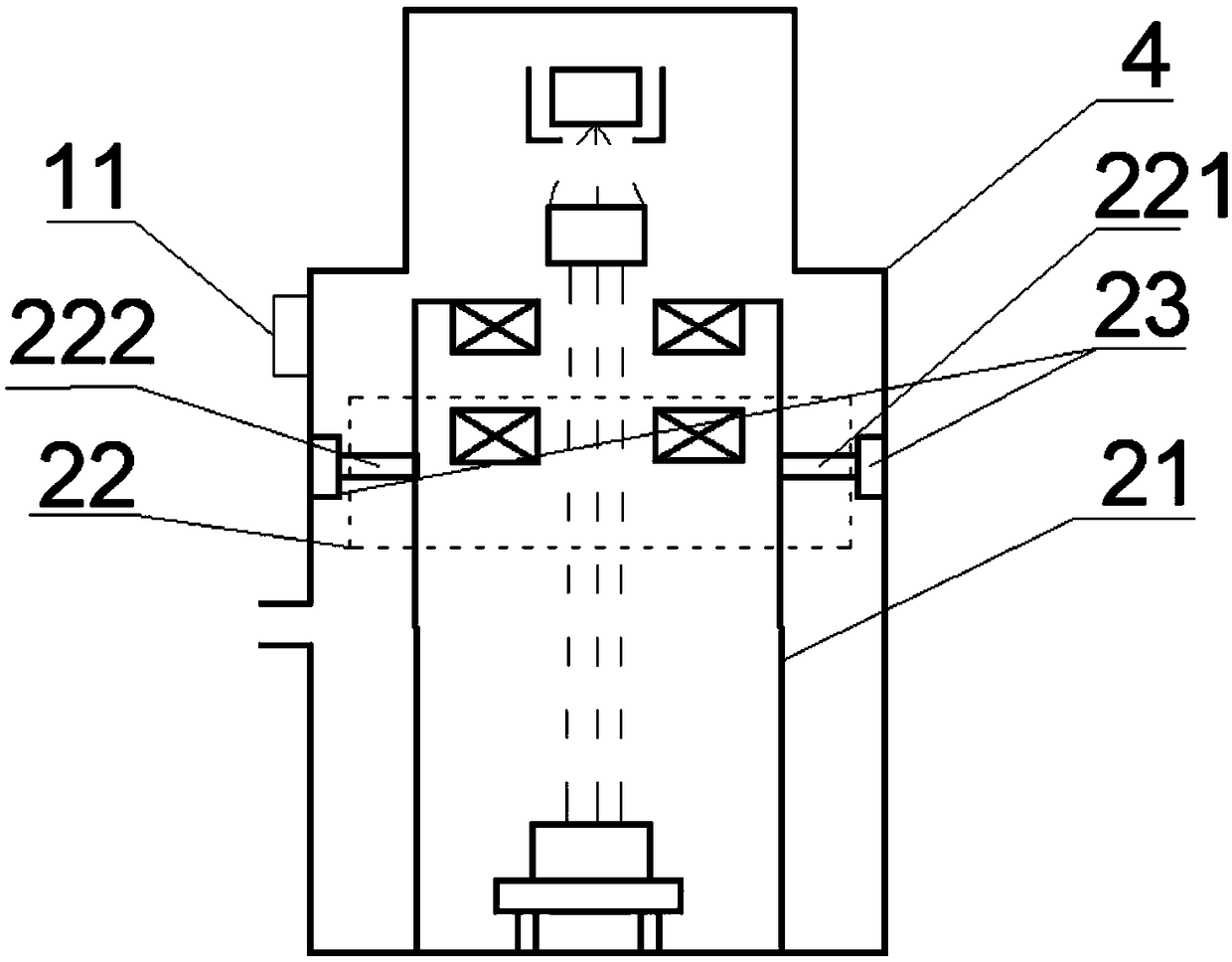

Electron beam processing system and processing method of multi-electron beam central wire feeding

ActiveCN106392290AGood uniformity of energy distributionSimple structureElectron beam welding apparatusElectron beam machiningAtomic physics

The invention discloses an electron beam processing system and processing method of multi-electron beam central wire feeding. The electron beam processing system comprises a plurality of electron beam guns and a wire feeding system, wherein the electron beam guns comprise electron beam generation systems, electron beam acceleration systems, electron beam accumulation systems and electron beam deflection systems; the wire feeding system comprises a wire feeding pipe and a wire feeding nozzle; the wire feeding nozzle is connected at the lower part of the wire feeding pipe; the wire feeding pipe and the wire feeding nozzle are arranged on a central axis of the structure; and the plurality of electron beam guns are in uniform lattice distribution along the circumference of the central axis. According to the electron beam processing system, the isotropy of electron beams on the surface of a workpiece can be guaranteed, the quality uniformity of the processed workpiece is improved, the processing process is continuous and unintermittent, the electron beam gun structures and a central wire feeding structure do not interfere with each other, and the processing system is applicable to electron beam processing fields of electron beam welding, electron beam cladding, electron beam metal 3D printing, and the like.

Owner:辽宁新锋精密光电科技有限公司

Method for rapidly forming Ti-6Al-4V three-dimensional metal parts by electron beams

InactiveCN104550949AHigh tensile strengthHigh elongationTurbinesOther manufacturing equipments/toolsElectron beam machiningTi 6al 4v

The invention relates to the technical field of electron beam machining, in particular to a method for rapidly forming Ti-6Al-4V three-dimensional metal parts by electron beams. The method is suitable for rapid forming and preparation of various complex-structure Ti-6Al-4V metal parts. The method comprises the steps of firstly, preparing the Ti-6Al-4V three-dimensional metal parts; secondly, carrying out hot isostatic pressing treatment on the prepared three-dimensional parts under 800-1000 DEG C; finally, carrying out annealing treatment on titanium alloy components under 700-1000 DEG C and aging treatment on the titanium alloy components under 400-600 DEG C. Through the technological processes, the Ti-6Al-4V complex-structure three-dimensional metal parts, of which the tensile strength is higher than 900MPa, the ductility is higher than 10%, the fatigue strength is higher than 500MPa, and the impact toughness is higher than 30J / cm<2>, with excellent comprehensive mechanical properties can be obtained and can be widely applied to the fields of spaceflight, medical treatment and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

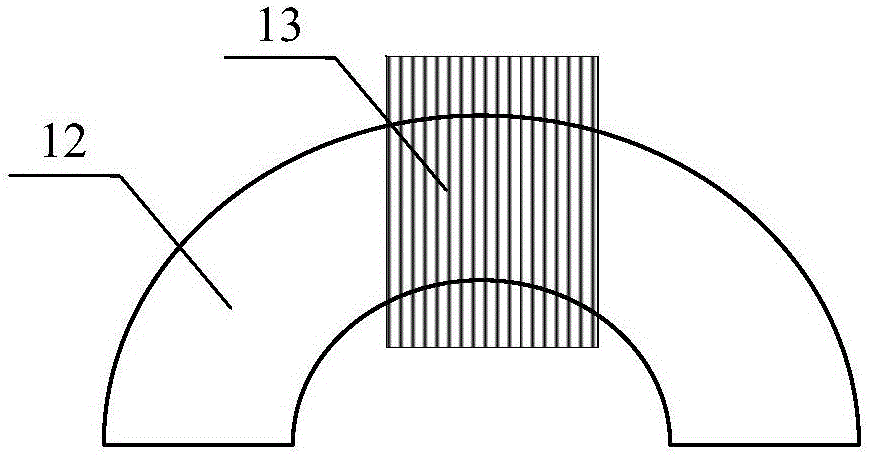

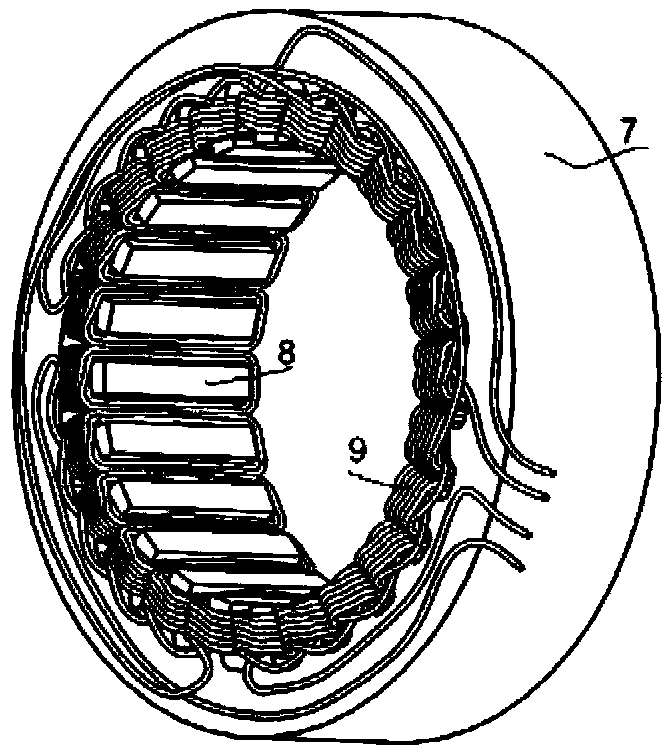

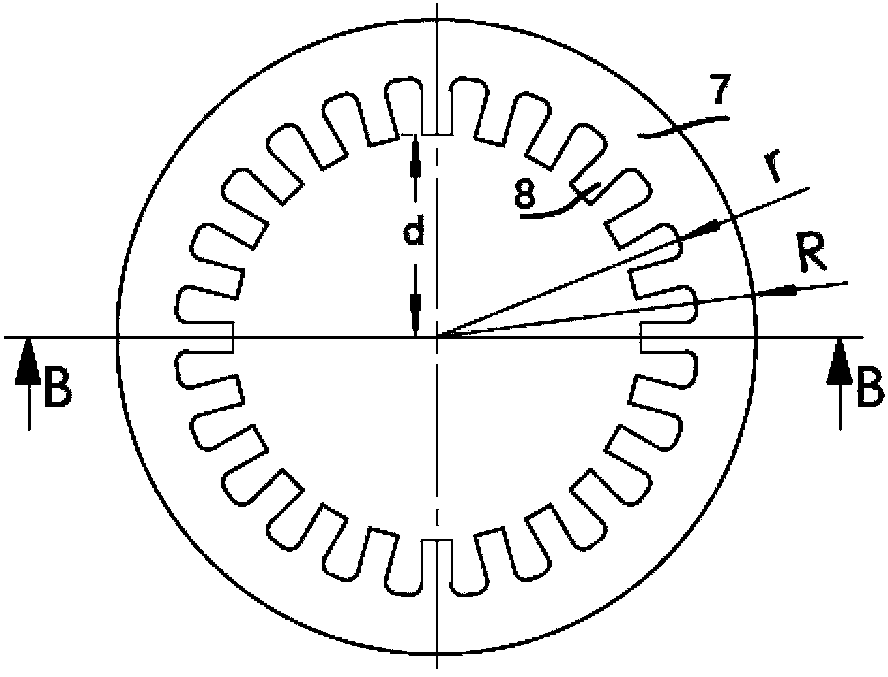

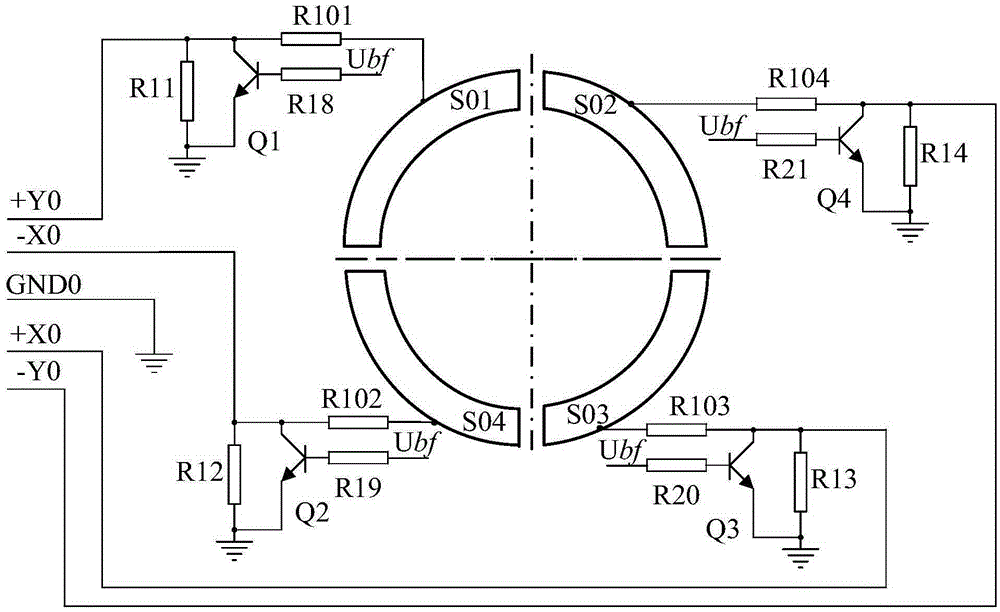

Electromagnetic deflection scanning coil for machining electron beam

InactiveCN103406657AImprove uniformityIncrease deflection scan frequencyElectron beam welding apparatusElectron beam machiningMagnetic poles

The invention discloses an electromagnetic deflection scanning coil for machining an electron beam. The electromagnetic deflection scanning coil comprises a magnetic core framework and coil windings (9). The magnetic core framework comprises a magnetic ring (7) and magnetic poles (8) which are formed integrally. The coil windings (9) are wound on all the magnetic poles (8) of the magnetic core framework, the number of the magnetic poles (8) is 4N, N is the integer larger than or equal to 3, and the magnetic poles (8) of the magnetic core framework are made of a soft magnetic material. By means of the electromagnetic deflection scanning coil of the structure, the evenness of an electron beam deflection scanning magnetic field is improved, the size and the weight of coils are reduced, and manufacture cost is saved. In addition, by means of the soft magnetic material, deflection scanning frequency of the electron beam is improved, and eddy-current loss is reduced.

Owner:NANJING UNIV OF SCI & TECH

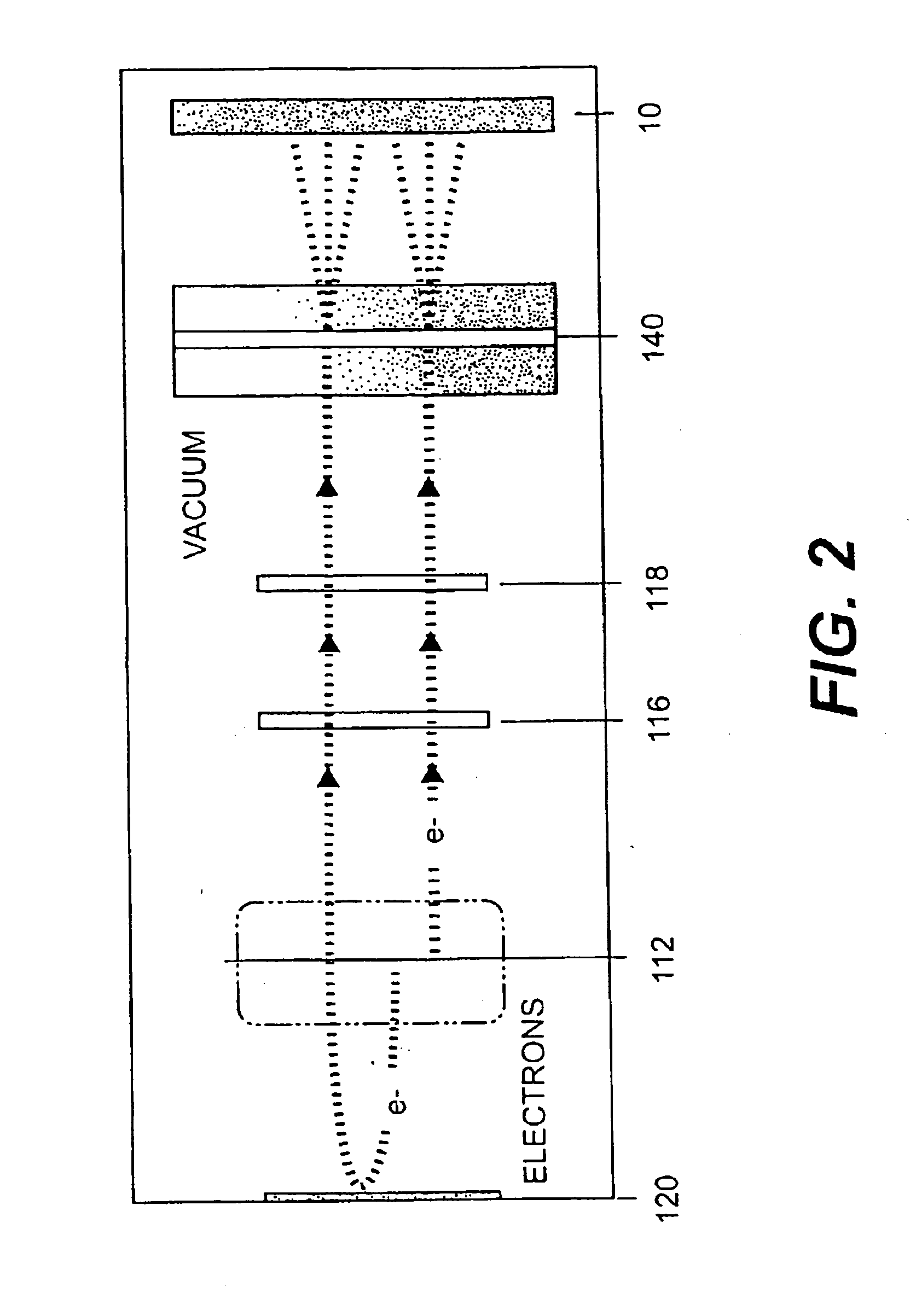

Materials treatable by particle beam processing apparatus

The present invention is directed to materials treatable by electron beam (EB) processing, such as materials for flexible packaging. The material comprises a substrate; an ink formulation on at least a portion of the substrate, the ink formulation comprising ink and at least one monomer selected from acrylate esters, vinyl ethers, cycloaliphatic diepoxides, and polyols; and a lacquer on at least a portion of the ink formulation, the lacquer comprising at least one monomer selected from acrylate esters, vinyl ethers, cycloaliphatic diepoxides, and polyols. The processing apparatus for EB treating the material operates at a low voltage, such as 125 kVolts or less.

Owner:ENERGY SCI

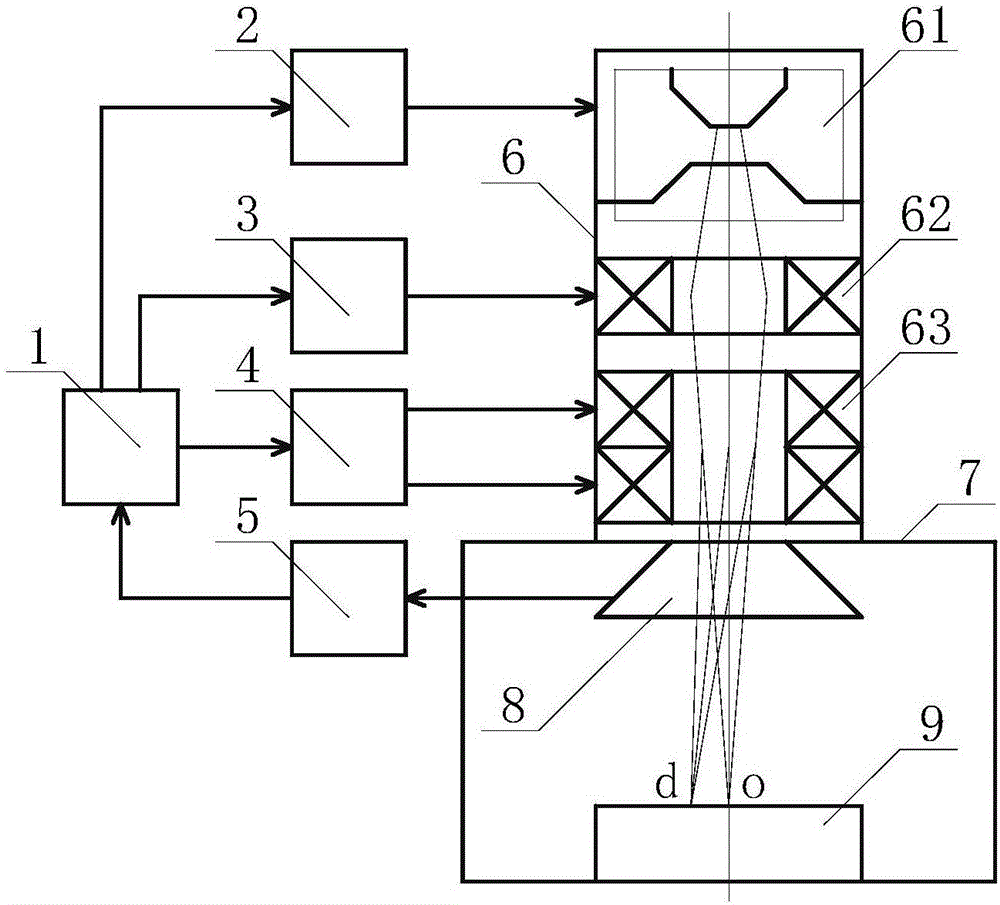

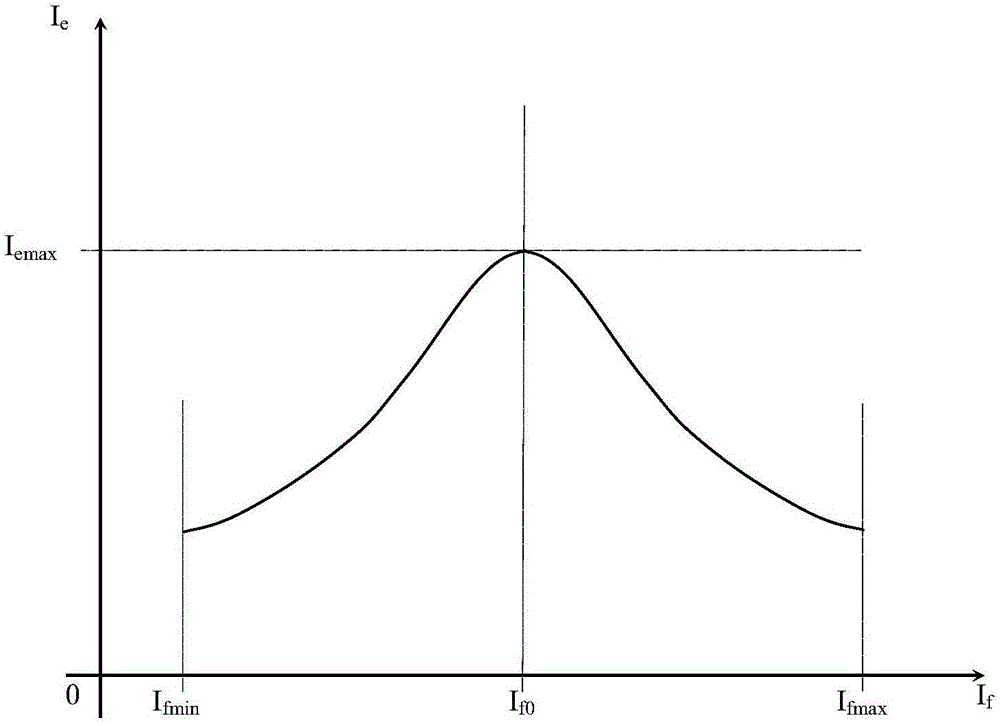

Automatic setting method and system for focusing currents on workpiece surface of electron beam processing equipment

ActiveCN106340339AAvoid drillingEasy accessRadiation/particle handlingElectric discharge tubesElectron beam machiningAcceleration voltage

The invention discloses an automatic setting method and system for focusing currents on a workpiece surface of electron beam processing equipment. Under the circumstances that the acceleration voltage and the electron beam of electron beam processing equipment are stable, a focusing current is adjusted to increase from a minimum value to a maximum value and a focusing current value If0+ corresponding to a maximum secondary electronic signal value during the gradually increasing discrete variation process is recorded; the focusing current is adjusted to decrease from a maximum value to a minimum value gradually and a focusing current value If0- corresponding to a maximum secondary electronic signal value during the gradually decreasing discrete variation process is recorded; and then on the basis of the focusing current value If0+ and the focusing current value If0-, a focusing current value If0 of focusing of an electronic beam on a metal test piece surface is calculated and determined and is set as a focusing current set value, so that the practical focusing working current is stabilized to be at the value. Therefore, a focusing current value can be obtained rapidly and precisely.

Owner:SINOPEC ENG +1

Energy controlling method in electronic beam machining

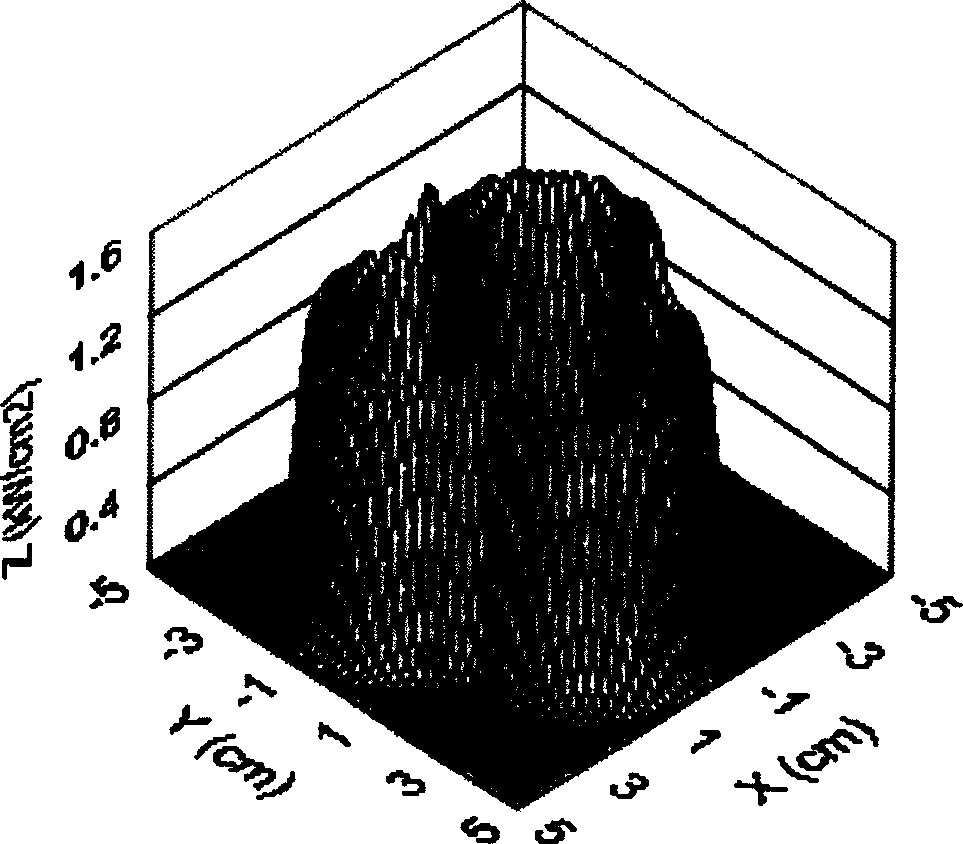

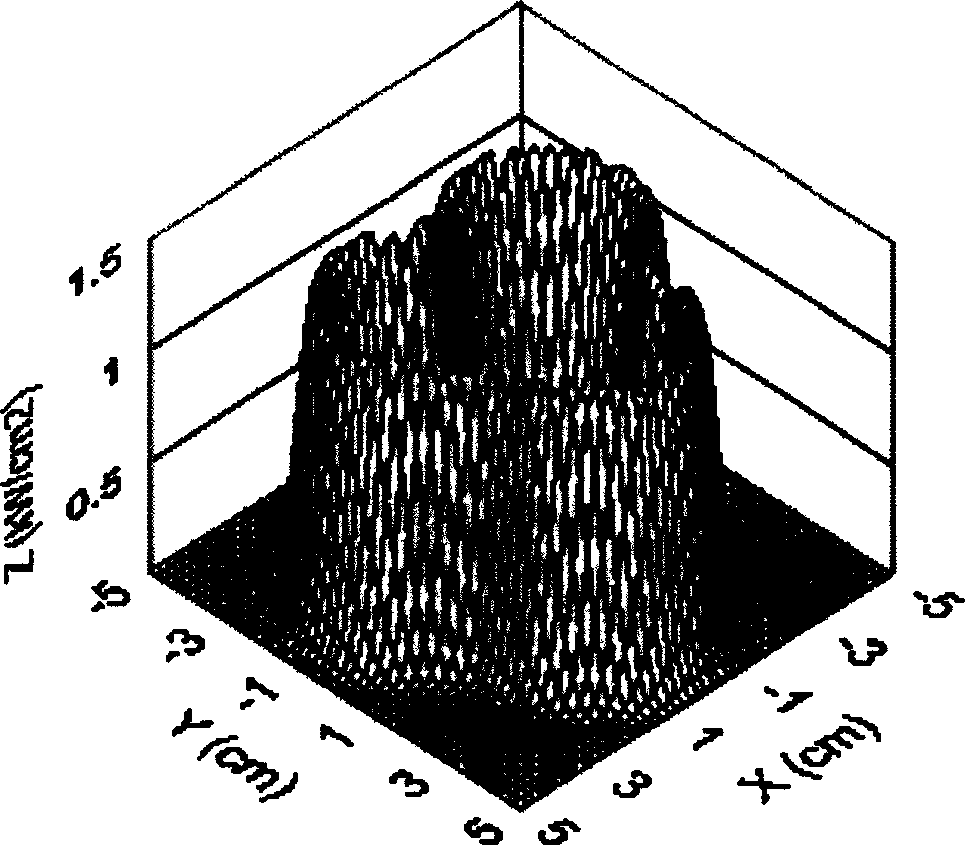

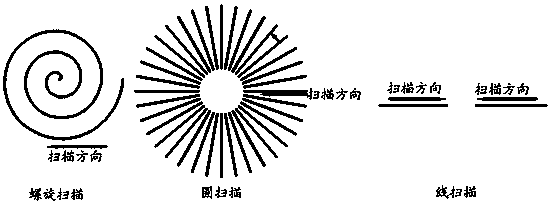

The invention relates to electron beam machining energy control method which is used in materials processing. According to the distributing demand of the energy density at the work piece, the number of the scanning point in each position of the scanning trace is distributed or the flow value of the electron beam is controlled, or both of the methods are adopted at the same time to control the energy density of the heated work piece surface. Then the required energy density distribution is gained at the surface of the heated work piece. Heterogeneous metal are welded by respectively controlling the amount of the scanning point at the both sides of the joint, the distribution of the scanning point, and the flow value of the electron beam to control the energy input at the both sides of the joint, so that the molten charge of the heterogeneous metal is adjusted at the both sides of the joint. The invention realizes the energy density control at the different position of the scanning trace, can respectively practice energy density control to each scanning trace at the condition that the scanning traces are many, and can effectively control the molten charge of the heterogeneous metal at the both sides of the joint while welding the heterogeneous metal.

Owner:SHANGHAI JIAO TONG UNIV +1

Electromagnetic deflection device for electron beam trajectory control and application thereof

InactiveCN103295862AMeet processing needsOvercome limitationsElectric discharge tubesBeam deviation/focusing by electric/magnetic meansBeam trajectoryElectron beam machining

The invention relates to an electromagnetic deflection device for electron beam trajectory control and application of the electromagnetic deflection device and belongs to the field of electromagnetism. According to the electromagnetic deflection device for the electron beam trajectory control, an excitation power source is arranged outside a vacuum chamber of an electron beam processing device, a magnetic field generating device is arranged in the vacuum chamber, a magnet yoke is of an enclosed type, iron cores are symmetrically distributed in the magnet yoke and fixed on the magnet yoke, hollow coils are fixed on the iron cores, parts are placed in an air gap space between the iron cores, the parts are arranged under an electronic gun of the electron beam processing device, the magnetic field generating device is connected with the excitation power source through a through-wall plug which is used for coil tap, and a probe of a Hall magnetic detector is arranged in the air gap space and connected with a processing display unit arranged outside the vacuum chamber through the through-wall plug. The electromagnetic deflection device for the electron beam trajectory control is used for controlling motion trajectory of electro beams so as to meet the processing requirement of parts with special shapes, can detect and adjust a generated magnetic field in real time, enables the strength of the magnetic field to meet the processing requirement, can be directly used with an existing electron beam processing device in an integrated mode through the through-wall plug, and is wide in application range and high in economic value.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

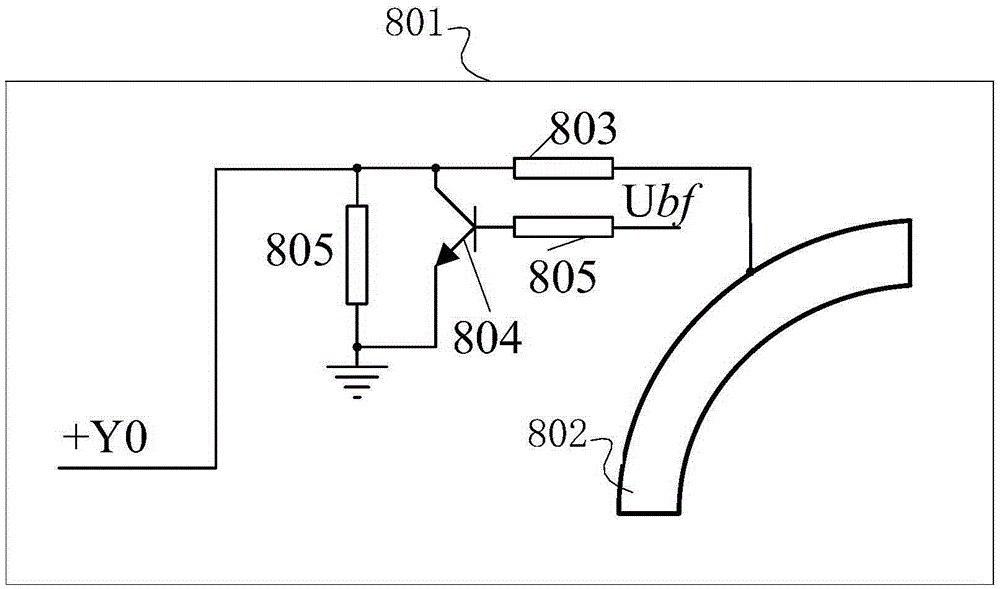

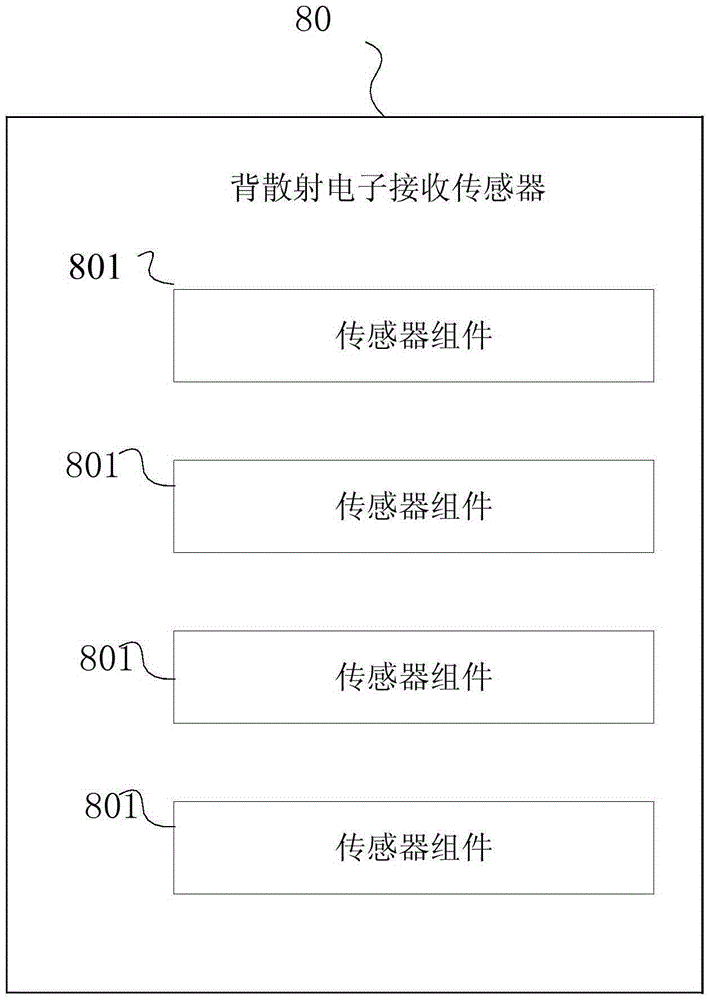

Backscattered electron receiving sensor and observation system for electron beam processing process

ActiveCN105405733AIncrease flexibilityHigh degree of automationMaterial analysis using wave/particle radiationElectric discharge tubesVoltage amplitudeElectrical resistance and conductance

The invention provides a backscattered electron receiving sensor and an observation system for an electron beam processing process. The backscattered electron receiving sensor comprises a sensor assembly, wherein the sensor assembly comprises an electron receiving pole plate, a current-limiting resistor, a transistor, a drive resistor and a sampling resistor; the electron receiving pole plate is connected with one end of the current-limiting resistor; a collector of the transistor is connected with the other end of the current-limiting resistor; an emitter of the transistor is grounded; the sampling resistor is connected between the collector and the emitter of the transistor in parallel; and a base of the transistor is connected with an external beam feedback adjusting circuit through the drive resistor. According to the backscattered electron receiving sensor, an electron beam feedback signal is used for adjusting a maximum voltage amplitude output by the backscattered electron receiving sensor as a control signal, so that the operation flexibility and automatic degree in the processing process of a vacuum electron beam processing device are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

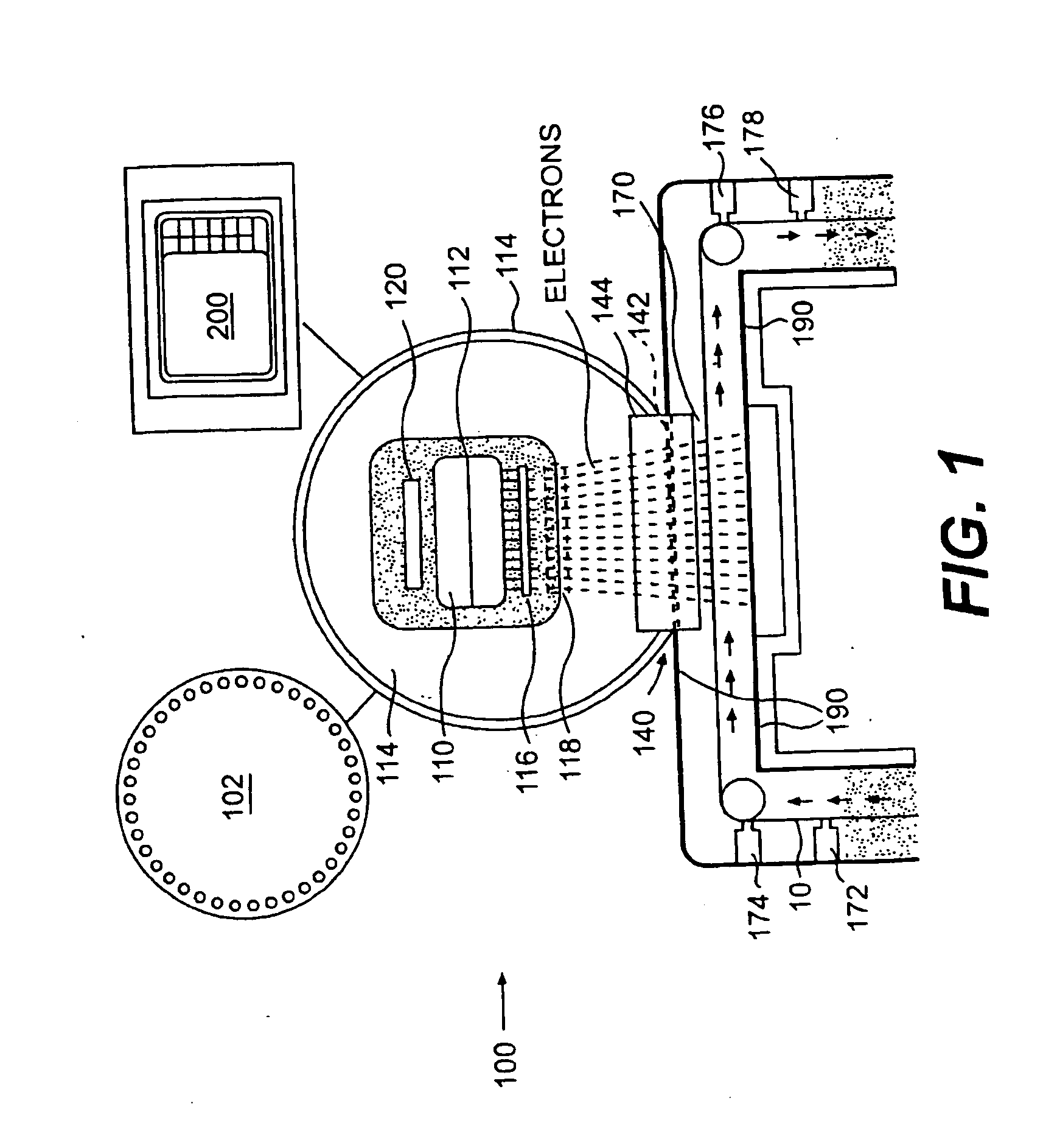

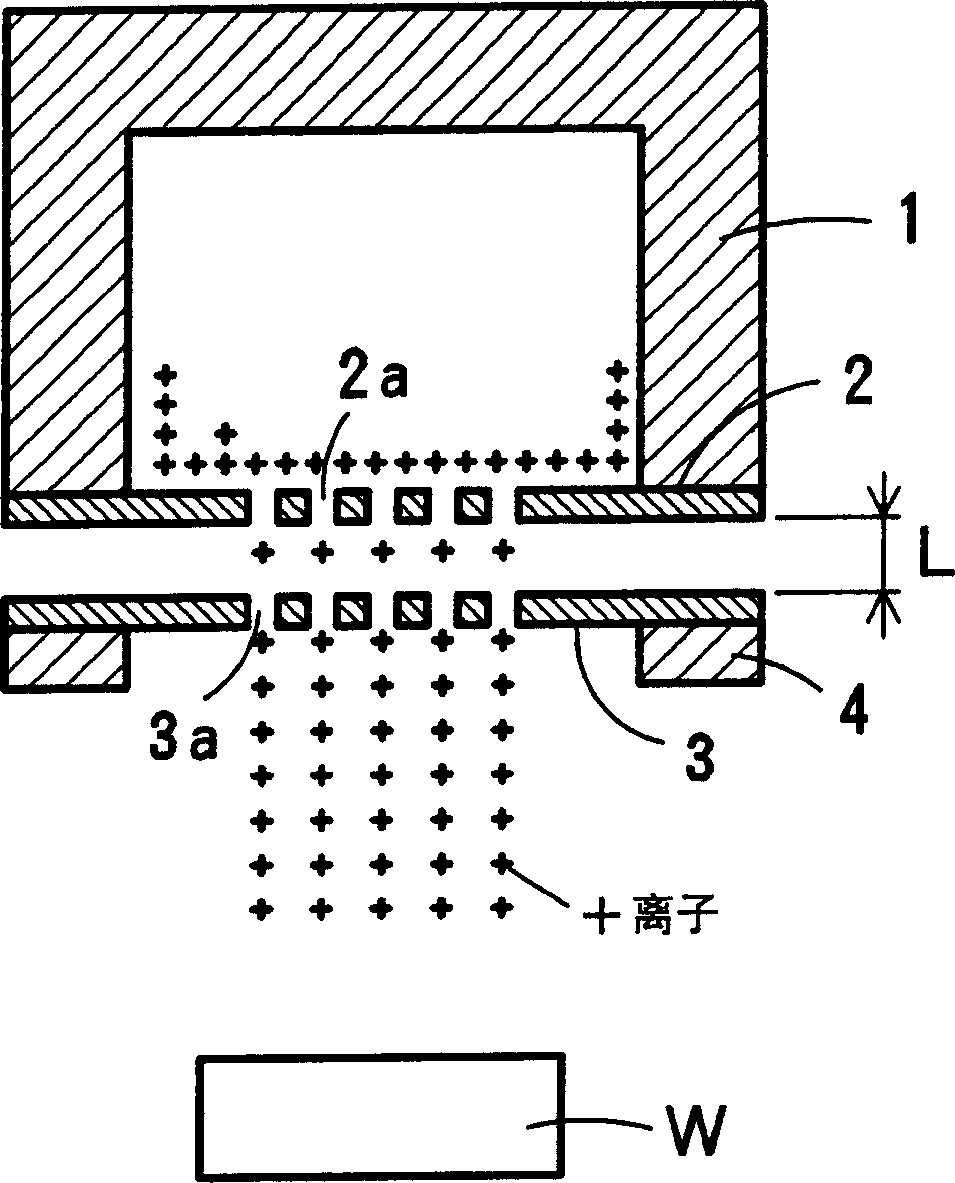

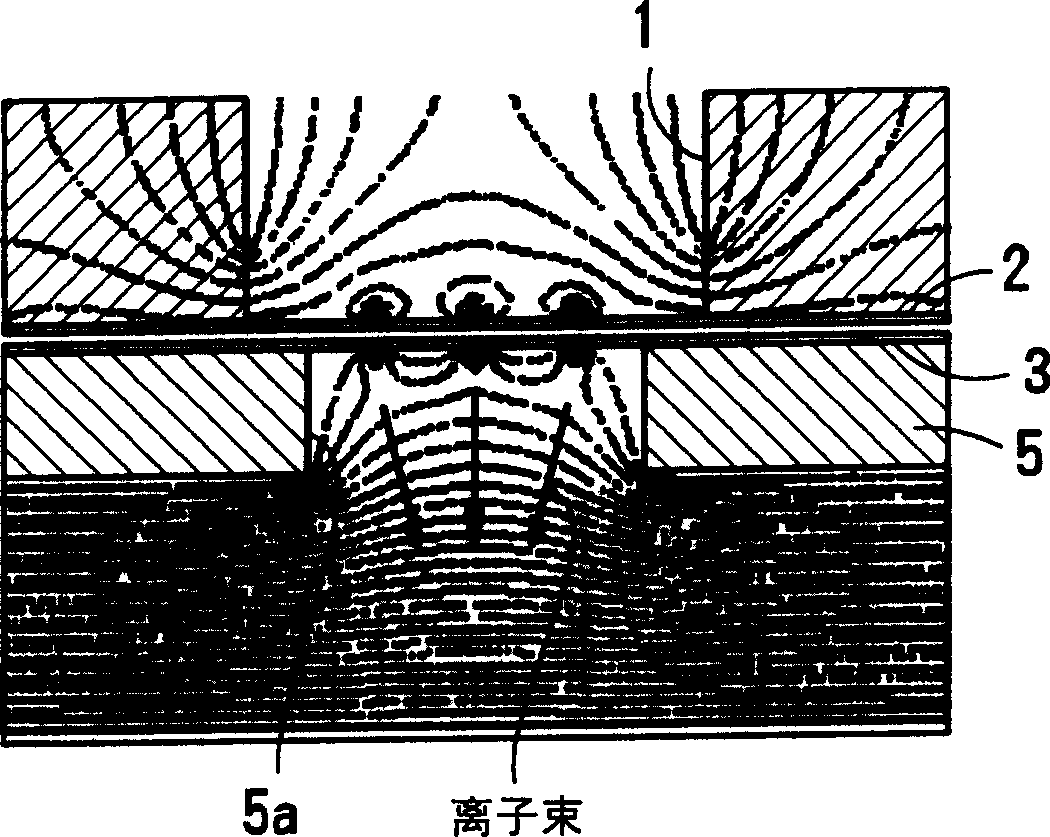

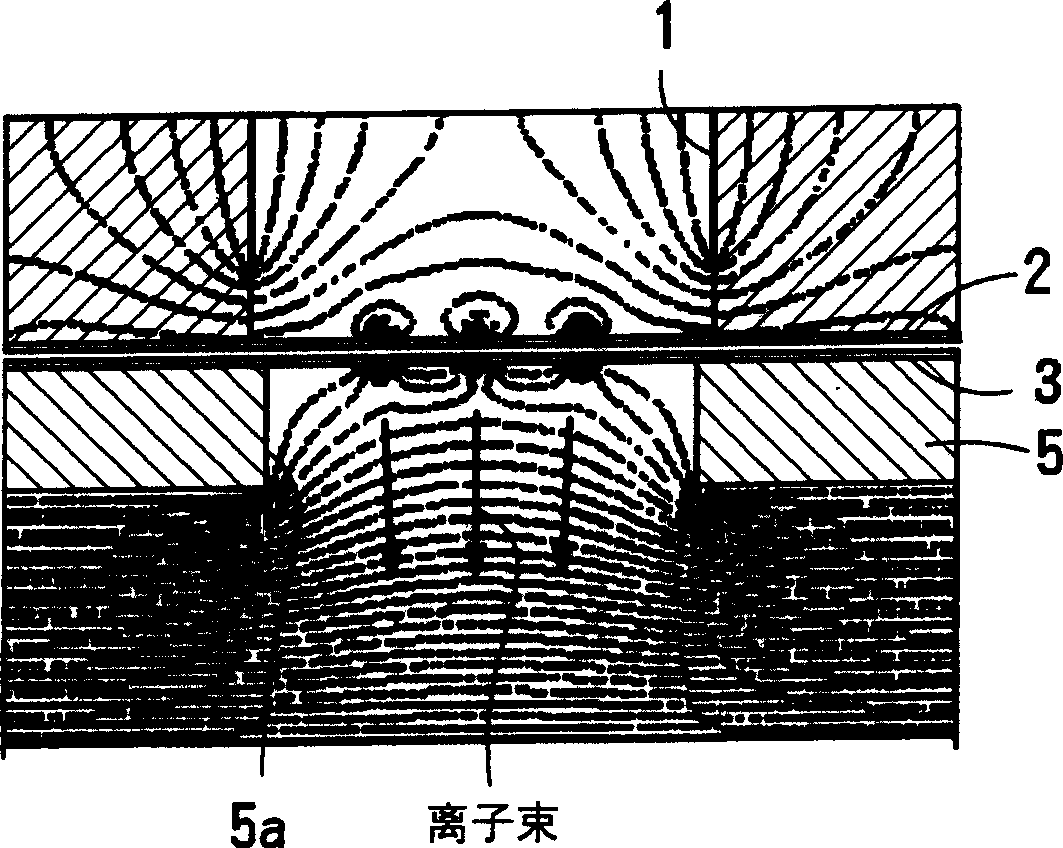

Electron beam processing apparatus

InactiveCN1577703ASemiconductor/solid-state device manufacturingIon beam tubesElectron beam machiningCooling effect

Provided is an electron beam processing device capable of preventing deviation of an ion beam to the center, and of keeping a cooling effect of an acceleration grid. This electron beam processing device is equipped with: a plasma generation chamber 1; a shielding grid 2 mounted on the front surface of an opening of the plasma generation chamber; the acceleration grid 3 disposed in front of the shielding grid with a space; and a cooling jacket 5 mounted on the front surface of the acceleration grid 3 and having an opening 5a wider than a range where fine pores 3a of the acceleration grid 3 are formed. By forming the opening 5a of the cooling jacket 5 into a shape gradually expanded toward the traveling direction of the ion beam, an equipotential line is set nearly parallel to the acceleration grid 3, so that deviation of the ion beam to the center can be restrained and the cooling effect to the acceleration grid 3 can be kept.

Owner:MURATA MFG CO LTD

Preparation method of titanium alloy pin fin tube by adopting electron beams

ActiveCN107649777AReliable manufacturingSolve technical problems that cannot be preparedElectron beam welding apparatusElectron beam machiningDiameter ratio

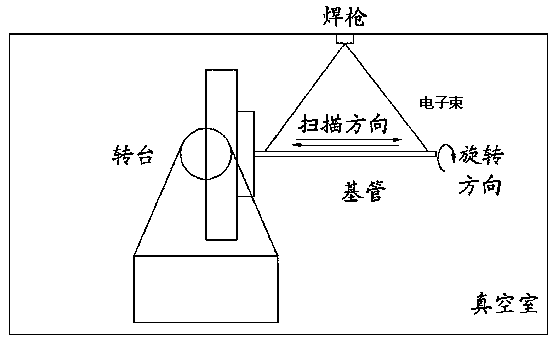

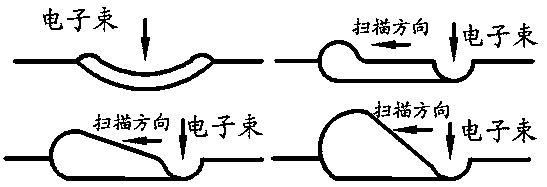

The invention relates to a preparation method of a titanium alloy pin fin tube by adopting electron beams. The preparation method comprises the following steps: 1, cleaning; 2, starting welding according to design: scanning the surface of a parent tube by adopting the surface focus or upper focus according to the scanning frequency, the scanning amplitude, the manufacturing scanning speed, the welding voltage, the beam current and the electron beam focus radius, enabling the parent tube to rotate on the tooling at the linear speed of 0.2 m / min, and then performing electron beam welding according to that the welding distance between the welding gun and the workpiece is 200-1000 mm, wherein the electron beam machining is carried out in a vacuum chamber; and 3, performing vacuum destressing annealing treatment. The preparation method of the titanium alloy pin fin tube by adopting the electron beams has the benefits as follows: the problem that the conventional titanium alloy pin fin tubecannot be prepared is solved, the contact thermal resistance is eliminated, the distribution density of pin fins is improved, the length-to-diameter ratio of the pin fins is increased, a larger secondary heat-transfer surface is obtained, the pitch diameter ratio of the tube bundle is reduced, the tube bundle is more compact, problems such as welding oxidation and welding defects are avoided, andthe overall effective heat exchange area of the pin fins is greatly increased.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

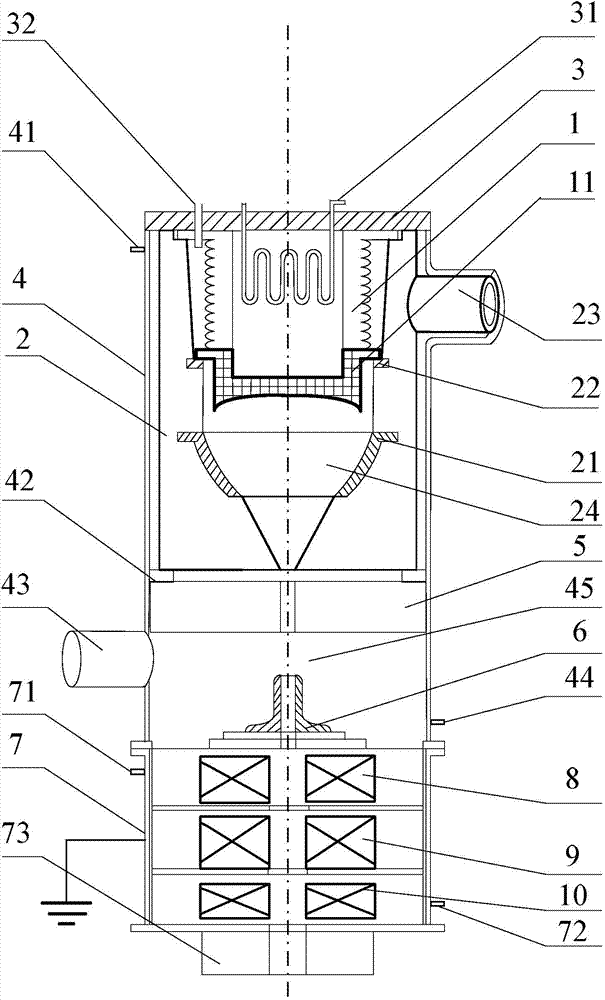

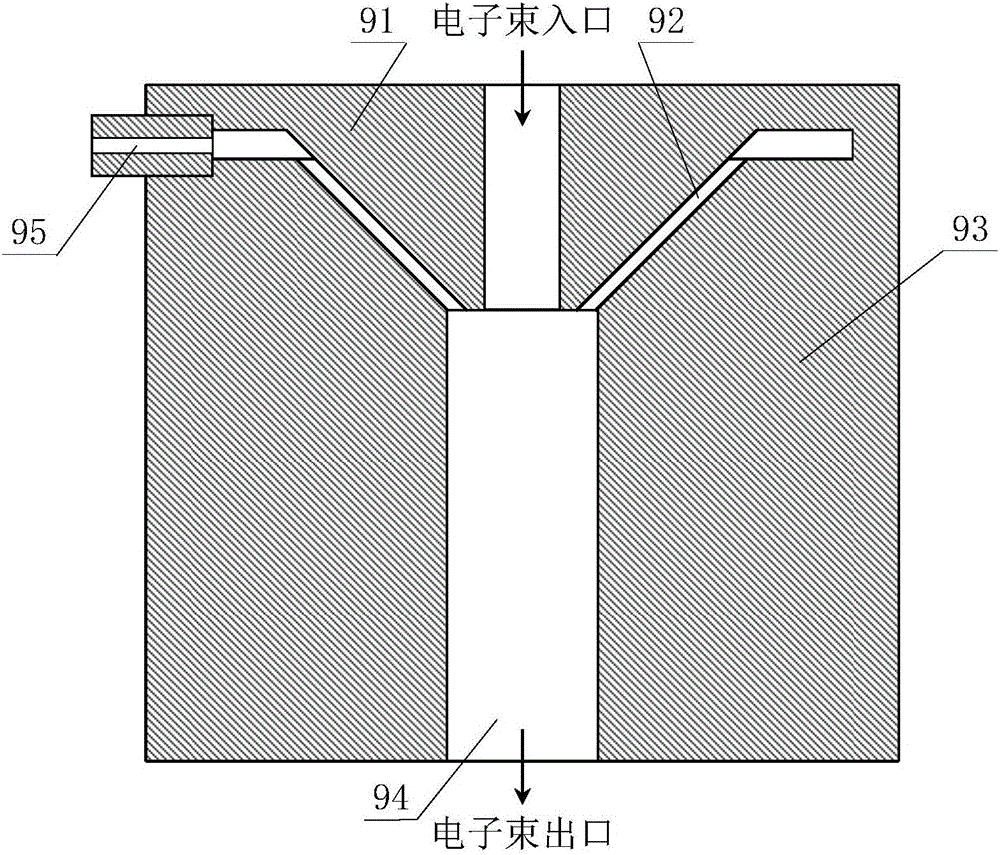

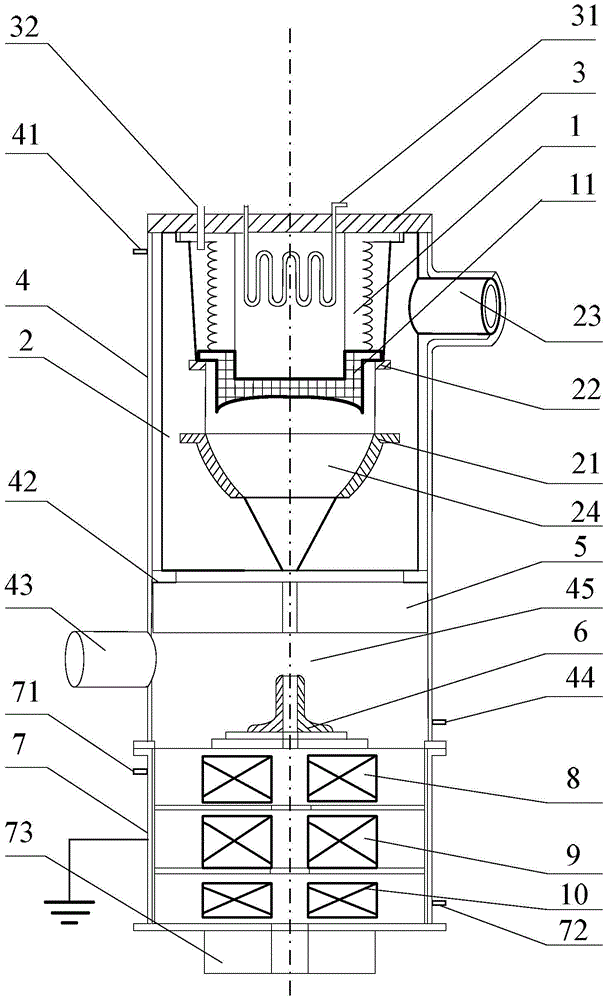

Electronic fun for atmospheric electron beam machining equipment

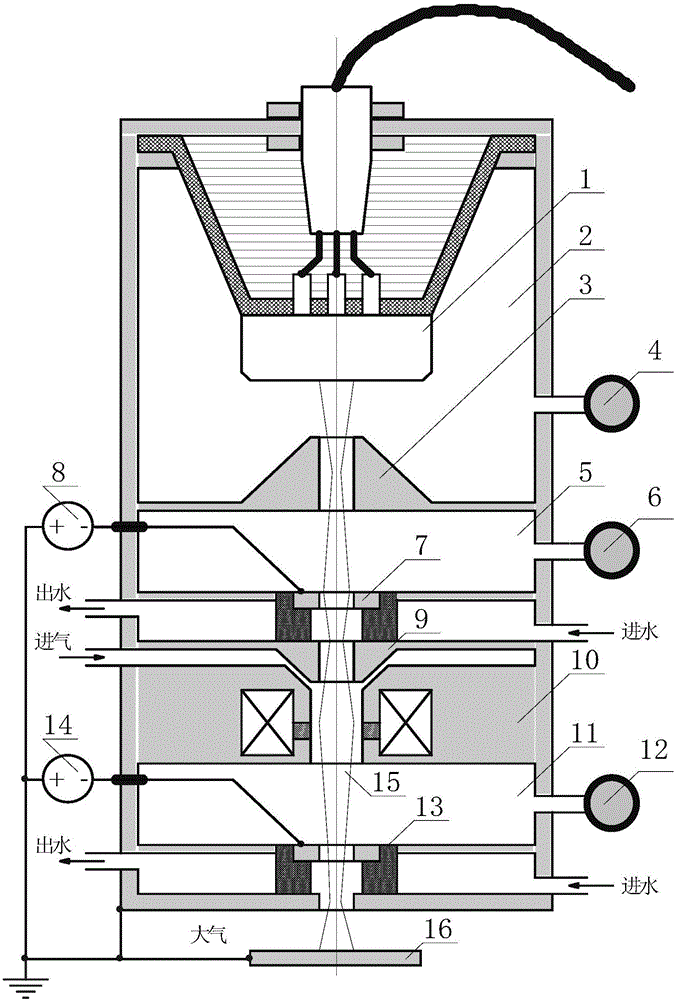

ActiveCN106024561AFast convergenceReduce energy lossElectric discharge tubesElectron beam machiningMachining process

The invention discloses an electronic fun for atmospheric electron beam machining equipment. The whole electronic fun is of an axisymmetric structure and comprises a first plasma window, a first vacuum cavity, a focusing device, a pneumatic window, a second plasma window, a second vacuum cavity, an anode, a third vacuum cavity and an electron beam generator from bottom to top. The combined structure that the first plasma window, the pneumatic window and the second plasma window are connected in series is adopted, an electron beam flying path with the extremely large vacuum gradient is formed in the electronic gun, the energy loss and energy density reduction amount of an electron beam are reduced, and therefore two main key technical problems existing in the electron beam machining process of the electron beam machining equipment in the atmosphere environment are solved.

Owner:GUILIN THD TECH CO LTD

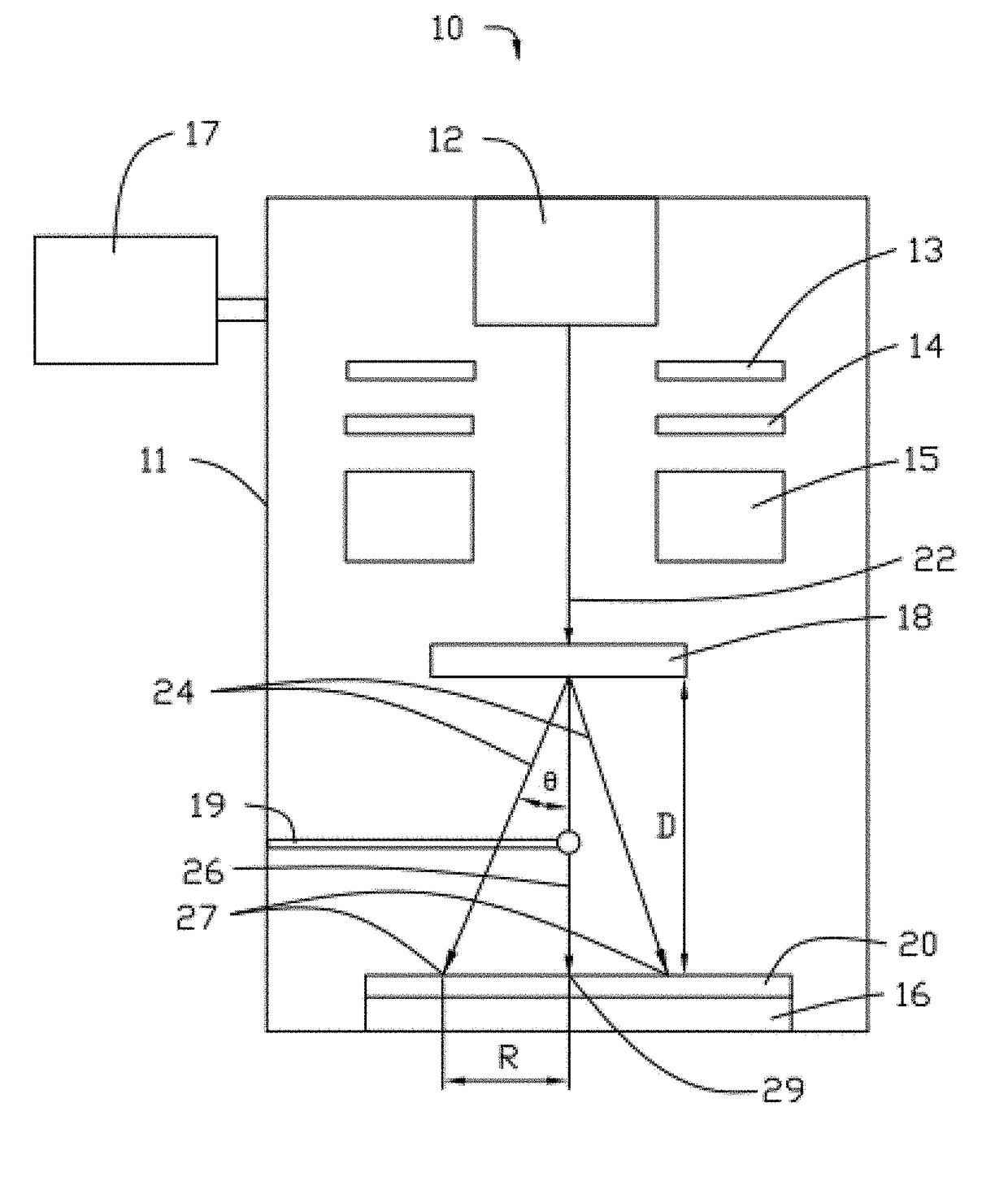

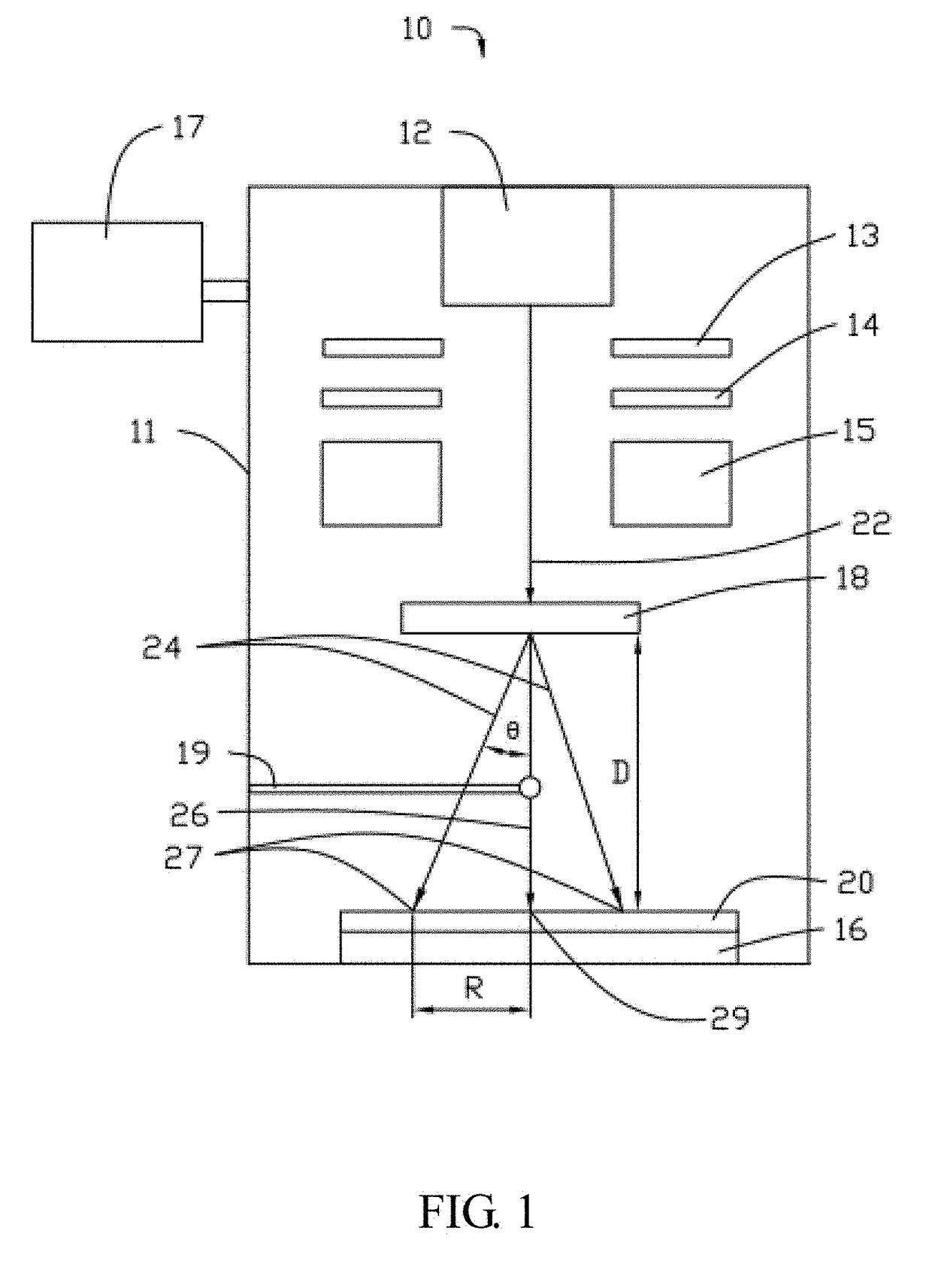

Electronic beam machining system

ActiveUS20170358424A1Low efficiencyLow costElectric discharge tubesGrapheneElectron beam machiningMachining system

The disclosure relates to an electronic beam machining system. The system includes a vacuum chamber; an electron gun located in the vacuum chamber and used to emit electron beam; a holder located in the vacuum chamber and used to fix an object; a control computer; and a diffraction unit located in the vacuum chamber; the diffraction unit includes a two-dimensional nanomaterial; the electron beam transmits the two-dimensional nanomaterial to form a transmission electron beam and a plurality of diffraction electron beams; the transmission electron beam and the plurality of diffraction electron beams radiate the object to form a transmission spot and a plurality of diffraction spots.

Owner:TSINGHUA UNIV +1

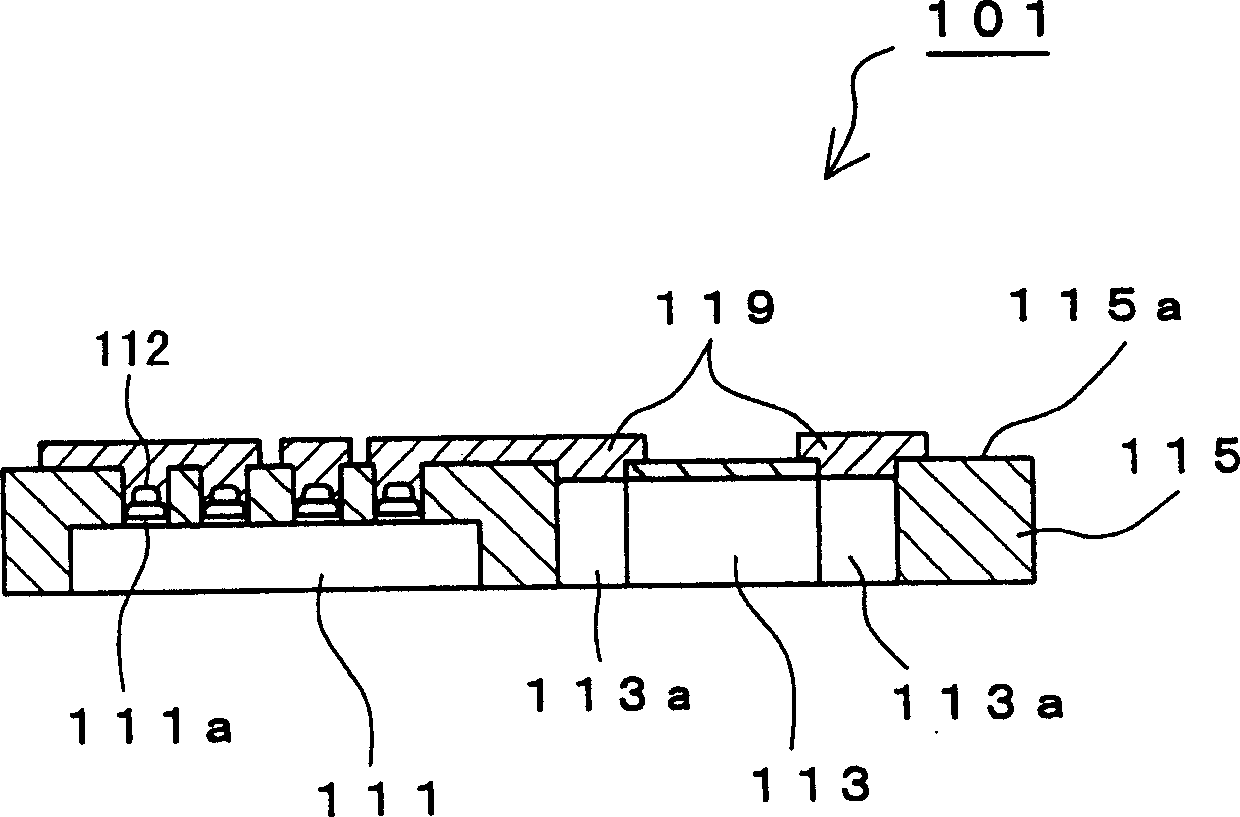

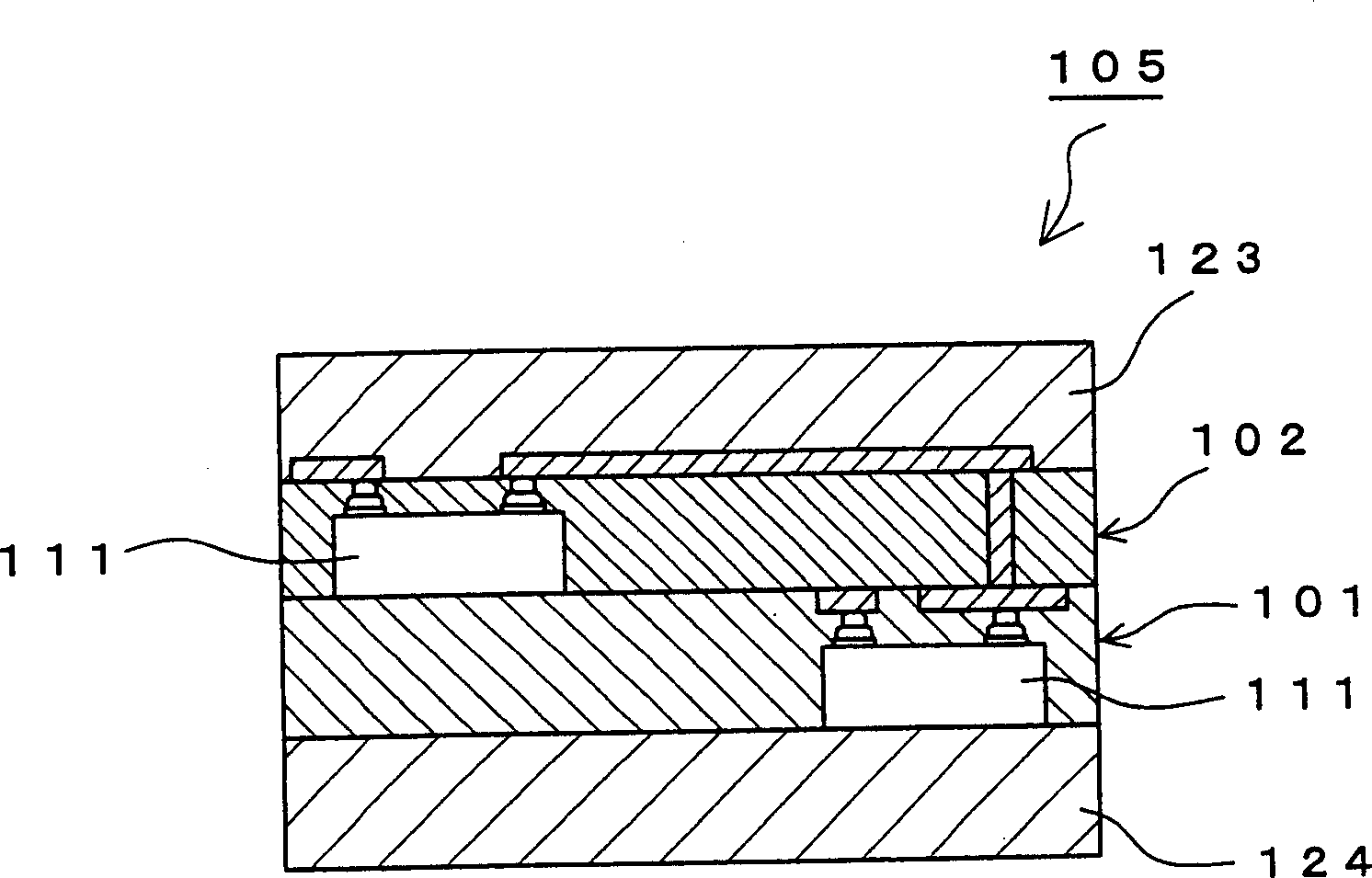

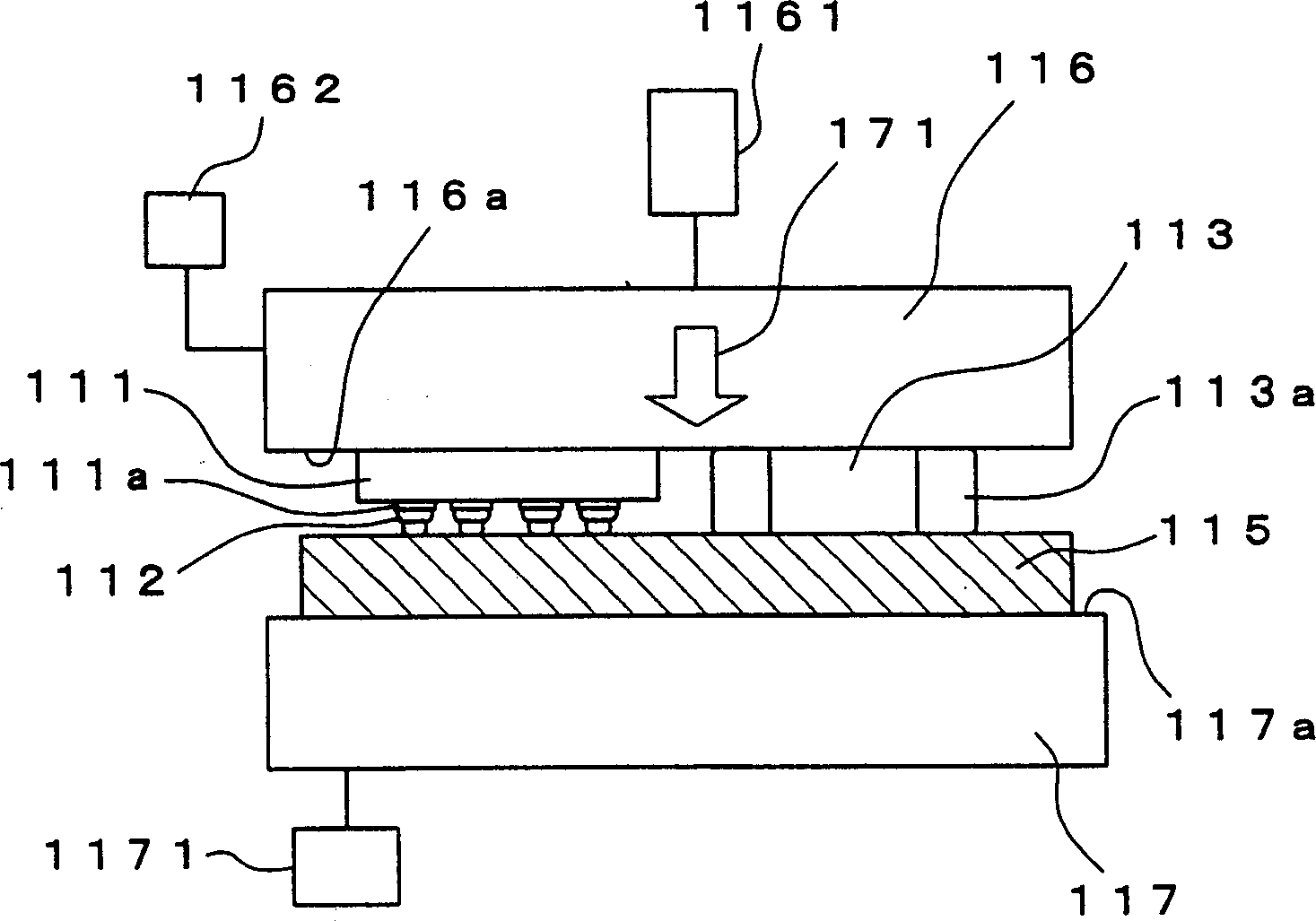

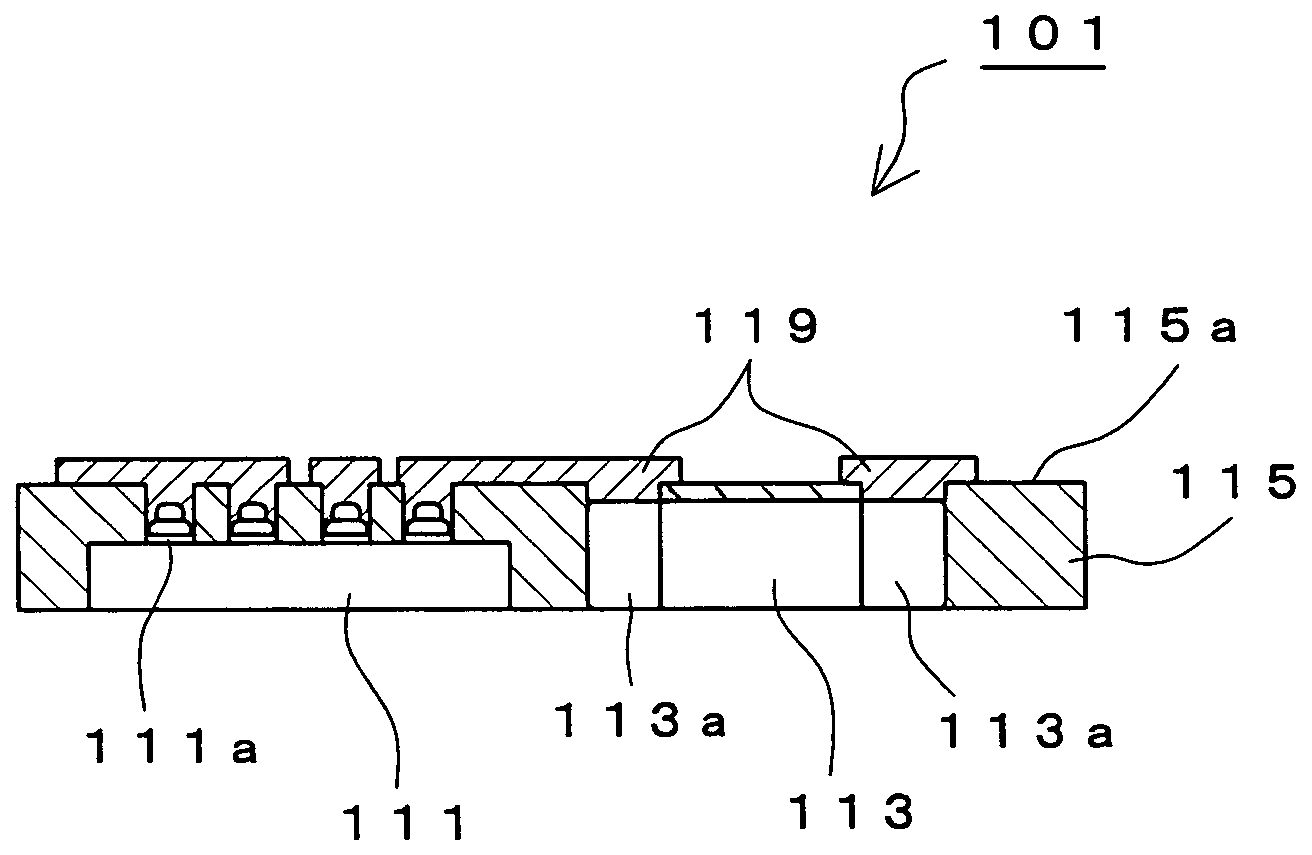

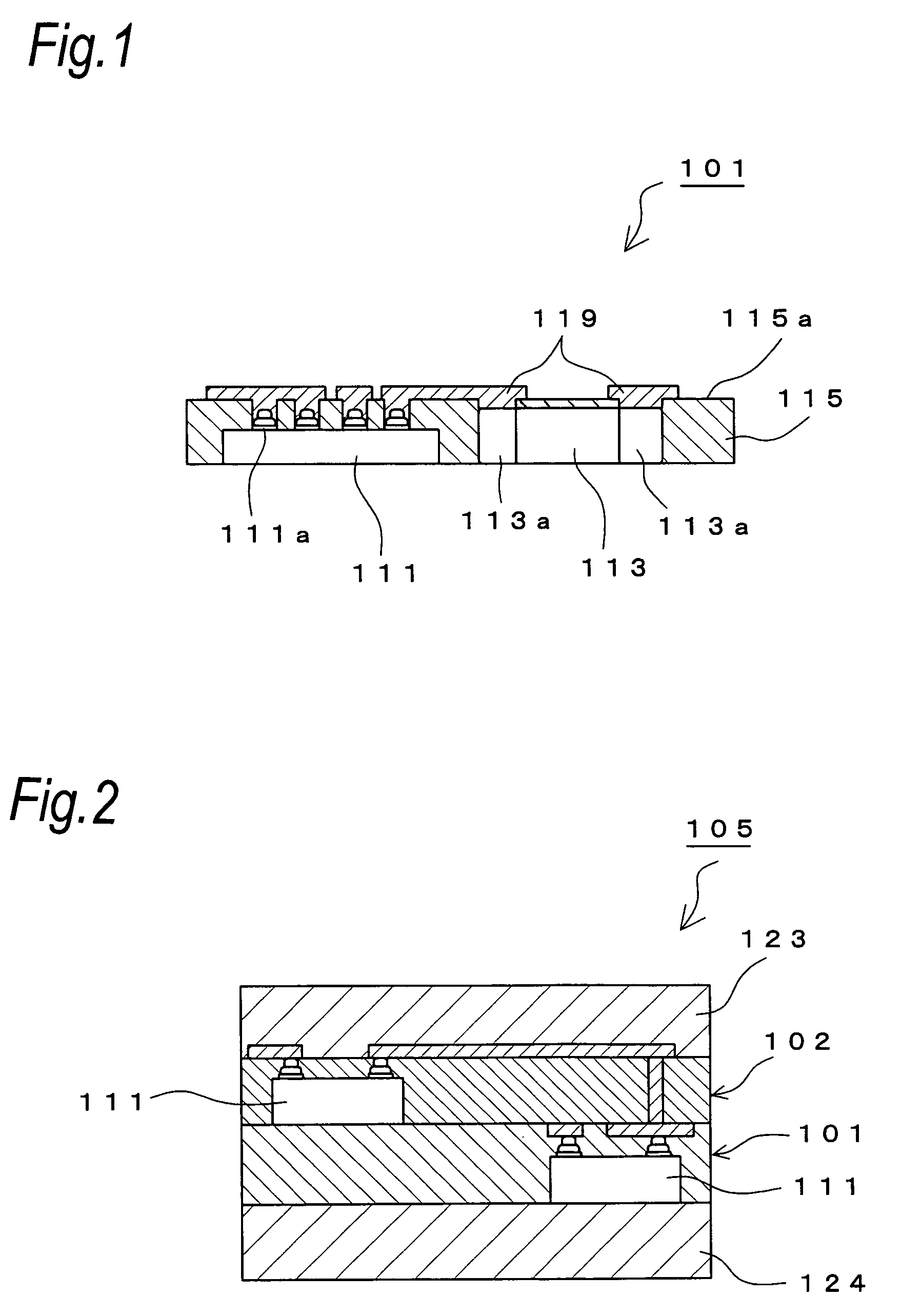

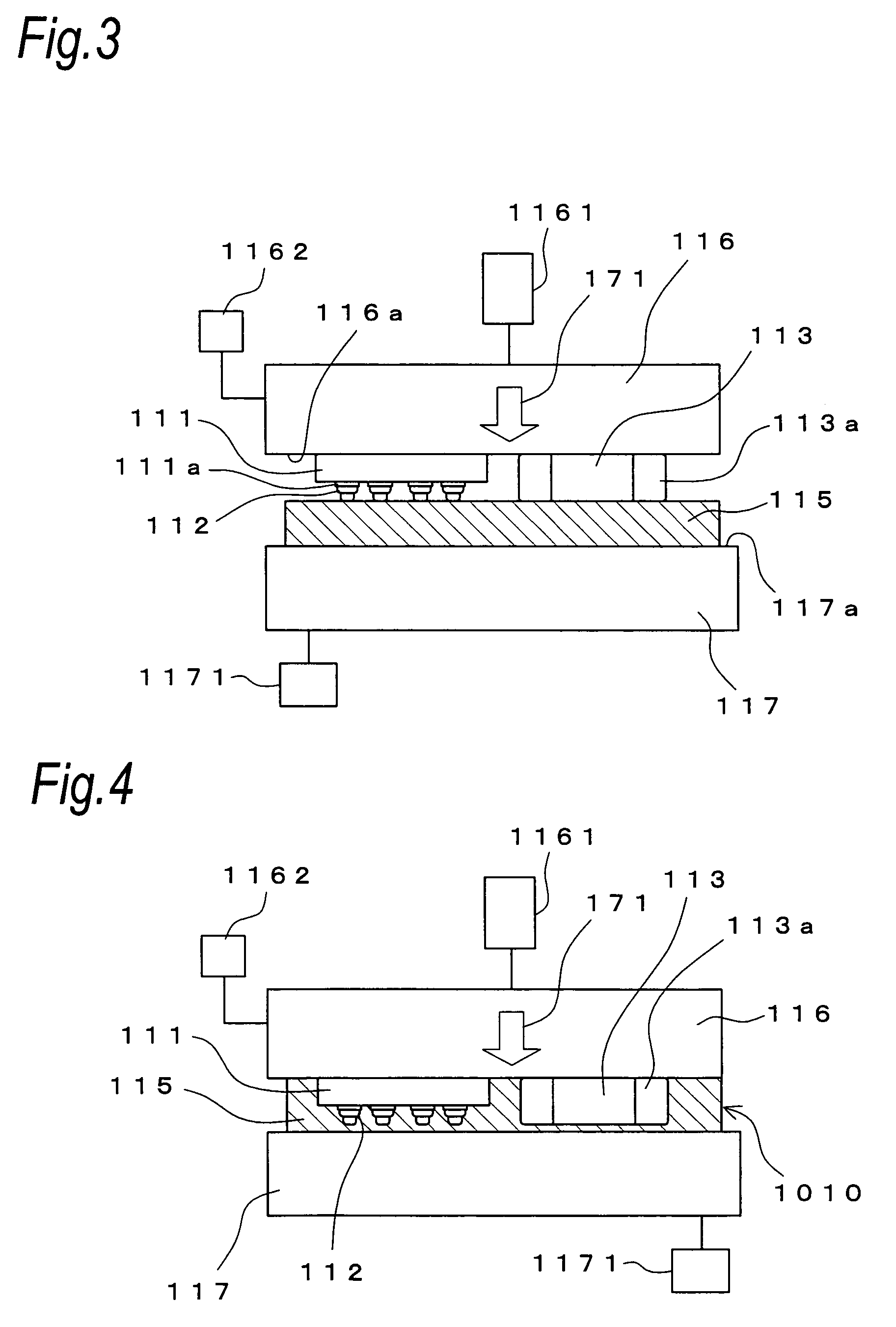

Mfg. method of assembly set with electronic component and mfg. method for related products

InactiveCN1499596AFunctionalSmall sizePrinted circuit assemblingSemiconductor/solid-state device detailsProduction rateElectron beam machining

A semiconductor element ( 111 ) with electrodes ( 112 ), and a passive element ( 113 ) with electrodes ( 113 a) are embedded in a thermoplastic sheet base ( 115 ), which is then subjected to laser beam machining, electron beam machining or ion beam machining to expose electrodes ( 112 and 113 a). Thereafter, a circuit pattern ( 119 ) is formed by formation of a thin film or printing of a conductive adhesive. Exposing the electrodes by laser beam machining or the like can be carried out in a short period of time and also by local treatment, thereby reducing damage to the base.

Owner:PANASONIC CORP

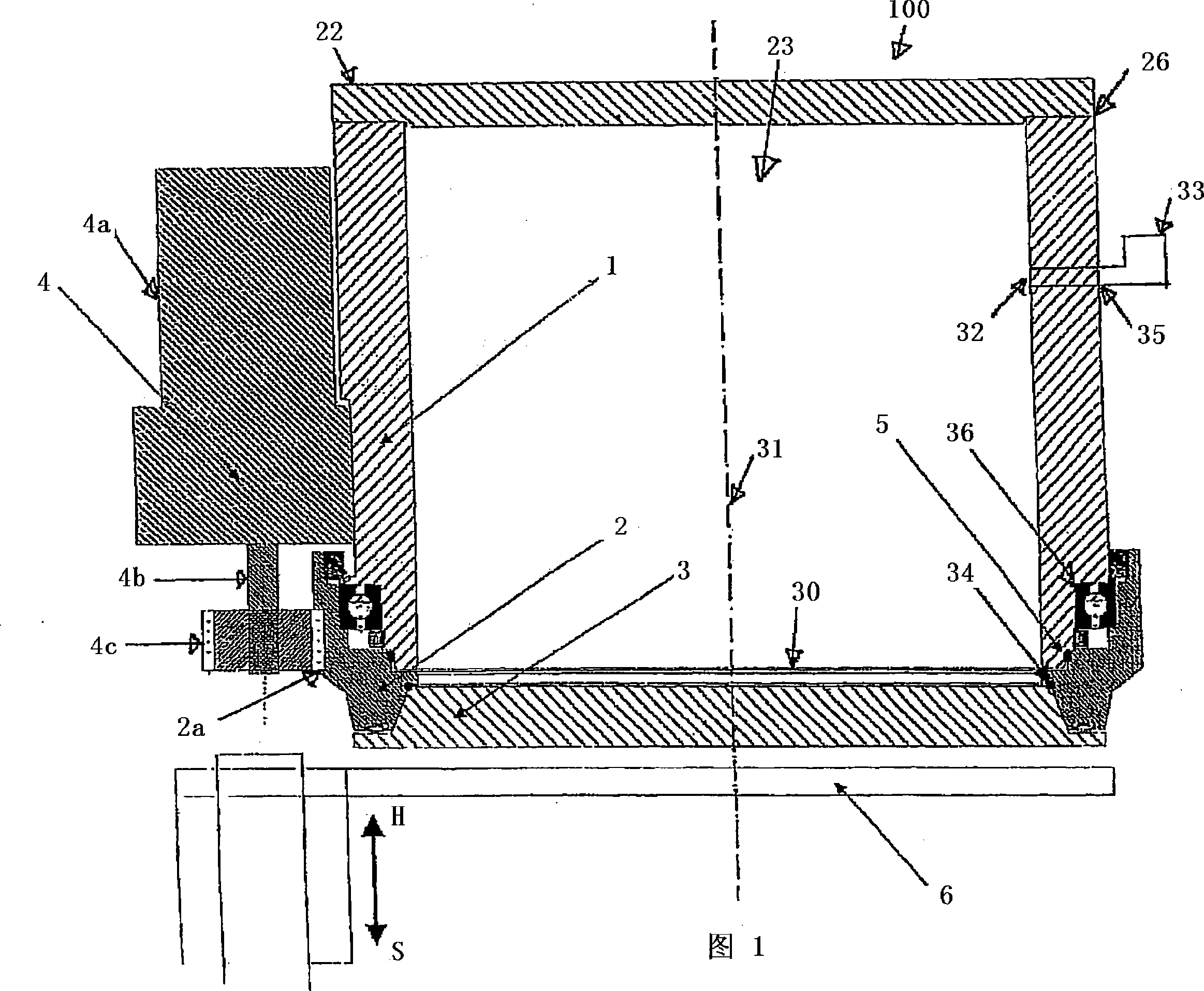

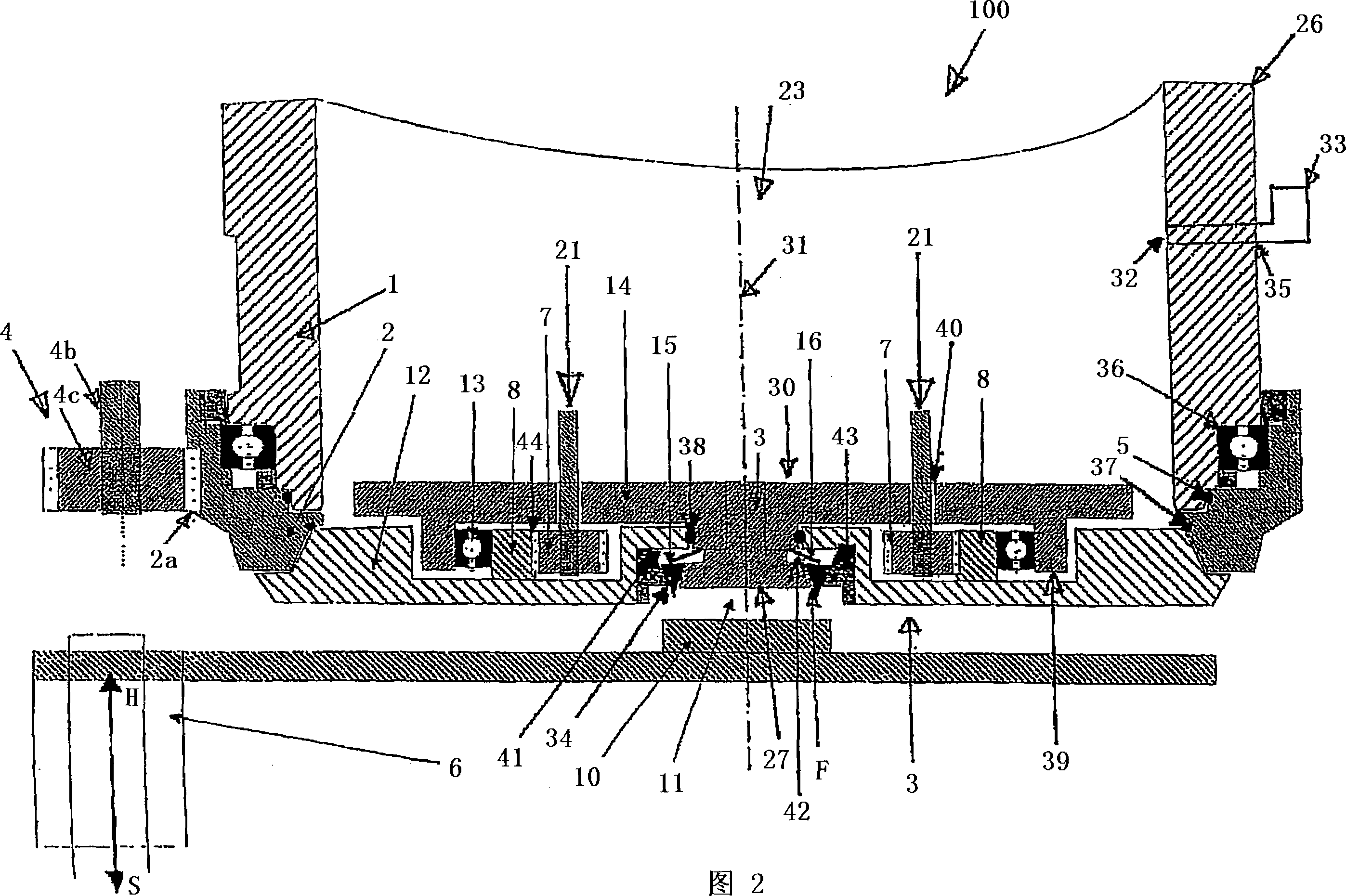

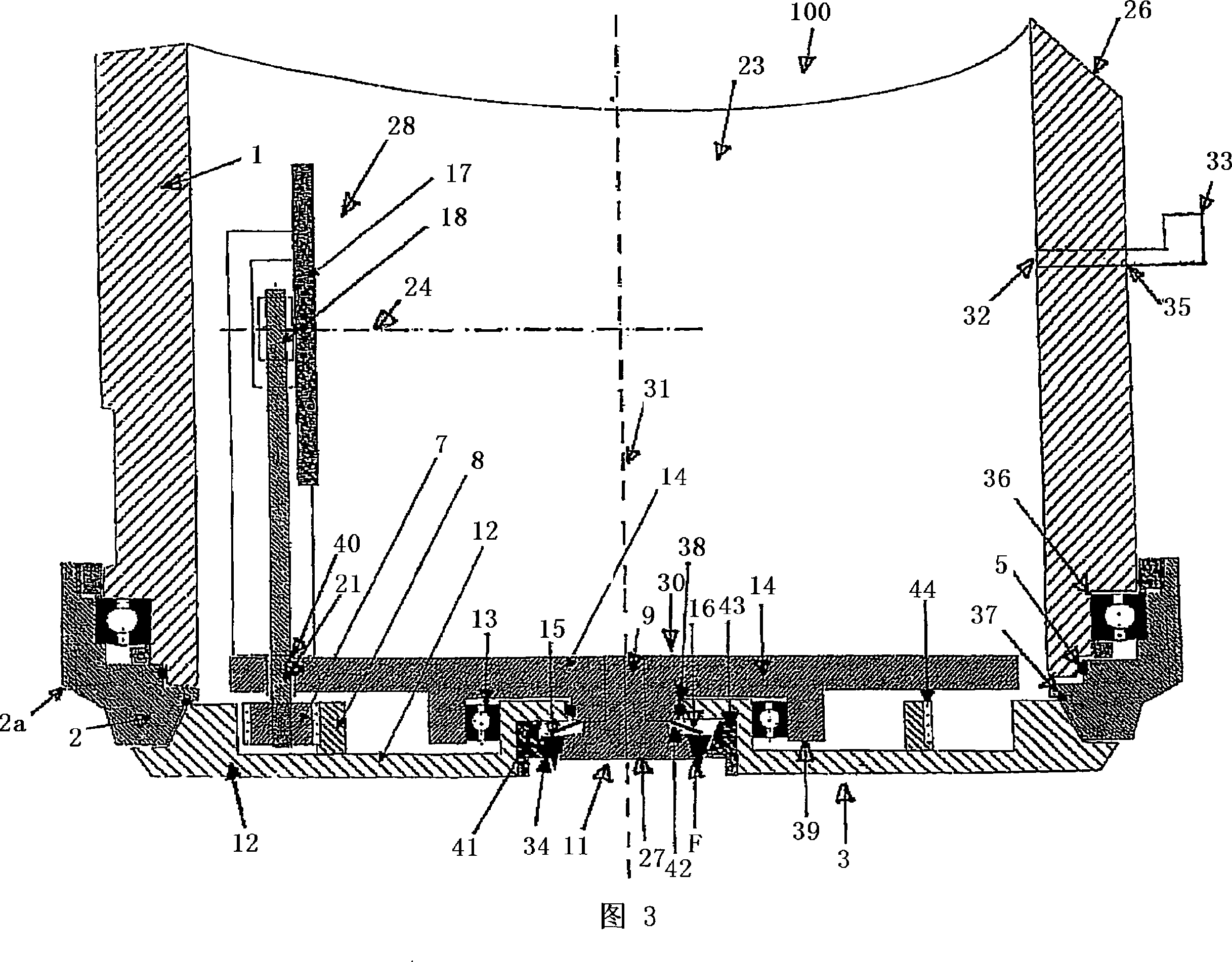

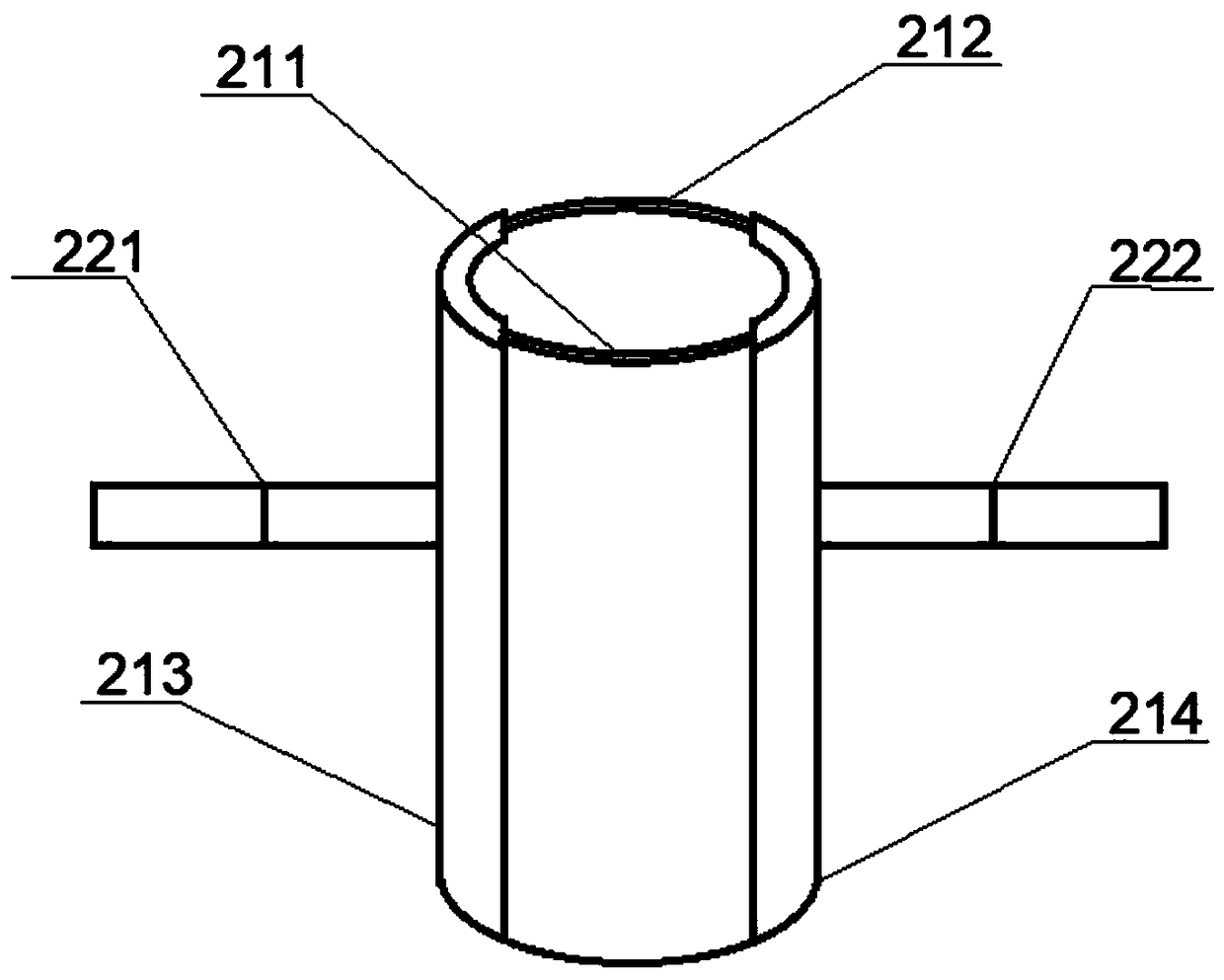

Chamber assembly for application in electron beam machining

InactiveCN101096062AEfficient processingElectron beam welding apparatusElectron beam machiningElectron

The invention discloses a chamber assembly for application in electron beam machining. The said chamber assembly is used to perform electron beam welding on the workpiece in vacuo, comrprising a shell for defining a chamber space, including at least one intake / outtake hole, and a circular ring, wherein the circular ring encloses along the intake / outtake hole and is torred above the shell to make it rotate along the shaft corresponding to intake / outtake hole, and a chamber cover connected with the circular ring and for capping the intake / outtake hole and the chamber cover rotates together with the circular ring corresponding to intake / outtake hole.

Owner:ALL WELDING TECH

Electron beam welding anti-magnetic-interference device

ActiveCN108746976ATrajectory stabilizationImprove welding precisionElectron beam welding apparatusElectron beam machiningMachining process

The invention belongs to the field of welding and particularly relates to a one-gun multi-beam electron beam welding anti-magnetic-interference device. The one-gun multi-beam electron beam welding anti-magnetic-interference device comprises a detection part, a shielding part and a control part. With the adoption of the one-gun multi-beam electron beam welding anti-magnetic-interference device, a structure of a shielding case can be adjusted according to the complexity degree of electronic beam machining and the intensity of an environmental magnetic field, and an electric push rod is controlled to extend and retractso as to allow silicon steel sheets on the inner layers and the outer layers to be nested and combined into a single-layer structure or a multi-layer structure, so that the different shielding requirements are achieved, it is guaranteed that the track is stable in the electronic beam machining process, and the welding accuracy is high.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

Electron beam surface rapid shaping method based on vectorized control

ActiveCN111331237AIncrease flexibilityIncrease diversityElectron beam welding apparatusElectron beam machiningElectron bunches

An electron beam surface rapid shaping method based on vectorized control comprises the following steps that a surface shaping figure and a corresponding vector path are designed, numeric treatment isconducted on the surface shaping figure, numeric figure data are obtained and transmitted to an electron beam machining device for control, and then electron beam surface rapid shaping is achieved. According to the electron beam surface rapid shaping method based on vectorized control, the design figure undergoes numeric treatment, rapid design of multiple kinds of figures is achieved through intersection of data points, the figures are transmitted to an electron beam welding machine for control in a data manner, and electron beam surface rapid shaping of different types of patterns, shapes,arrays, intersections and the like is achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Magnetic shielding system for electron beam welding

ActiveCN108746975ATrajectory stabilizationImprove welding precisionElectron beam welding apparatusElectron beam machiningElectromagnetic shielding

The invention belongs to the field of welding, and particularly relates to a magnetic shielding system for electron beam welding. The magnetic shielding system comprises a detecting portion, a shielding cover body and a control portion. The structure of a shielding cover can be adjusted according to the complexity degree of electron beam processing and the intensity of an environmental magnetic field, and an electric ejector rod is controlled to enable inner and outer layer silicon steel sheets to be nested and combined into a single layer structure or a multi-layer structure, so that different shielding requirements are met, a stable trajectory is ensured during electron beam processing, and welding precision is high.

Owner:JIANGSU JINGYI ELECTRICAL APPLICANCE

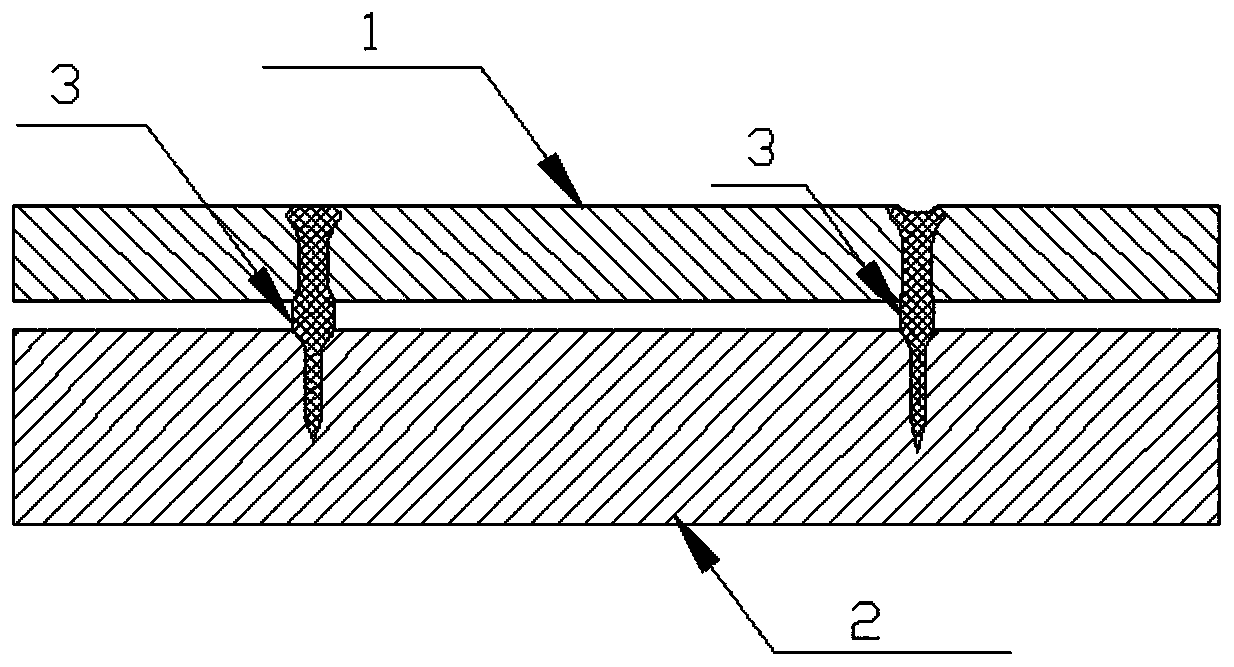

Double-layer board with turbulent flow column structure for cooling and vacuum electron beam machining method

InactiveCN110560876AFast preparationEfficient preparationElectron beam welding apparatusElectron beam machiningEngineering

The invention discloses a double-layer board with a turbulent flow column structure for cooling and a vacuum electron beam machining method and relates to the technical field of double-layer boards with cooling structures. Double-layer boards with the thickness being 0.1-10 mm are assembled together according to the set gaps; the assembled double-layer boards are conveyed into a vacuum electron beam vacuum chamber and fastened to a working table; vacuumizing is carried out until the vacuum degree is superior to 7*(10-4) Pa; electron beam surface focusing or defocusing is carried out, a machining path and parameters are edited, and the electron beam machining parameters are set to the proper range; according to the preset procedure, electron beam machining of the turbulent flow column structure for cooling between the double-layer boards is carried out on the designated portion, it is ensured that the upper board achieves penetration, and the lower board has a certain penetration depth,and metal molten on the upper board flows down and makes contact with the lower board to form the turbulent flow column structure; and after machining is completed, standing is carried out for 10-30minutes, a vacuum chamber is inflated, and the machined double-layer board is taken out. According to the double-layer board, the characteristic of the large penetration depth of high-vacuum electronbeam machining is utilized, and rapid machining of the turbulent flow column structure for cooling among the double-layer boards with different thicknesses and different gaps can be achieved.

Owner:NANCHANG HANGKONG UNIVERSITY

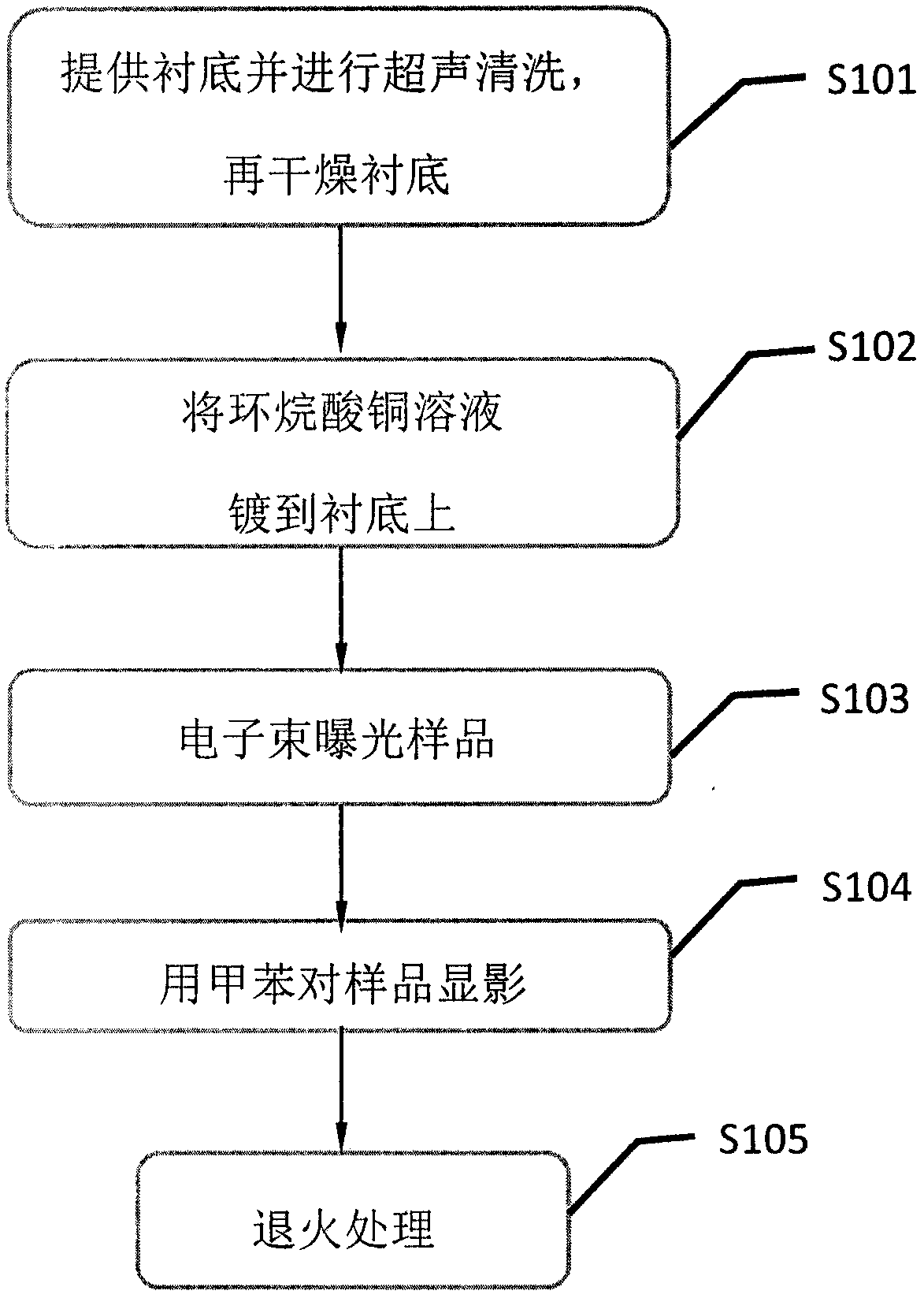

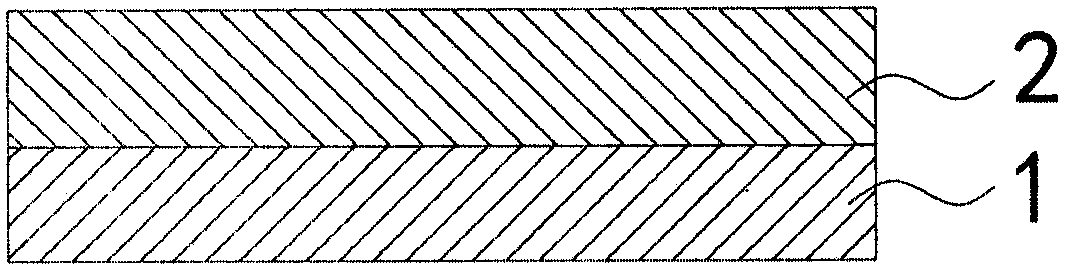

Method for processing copper-graphene composite nanometer pattern through electron beams

InactiveCN109765760ASmall feature sizeImprove mechanical propertiesNanotechnologyPhotomechanical exposure apparatusElectron beam machiningCopper naphthenate

The invention discloses a method for processing a copper-graphene composite nanometer pattern through electron beams. The method comprises the steps: firstly, a layer of copper naphthenate thin film is rotatably smeared on a provided substrate; a sample is exposed through an electron beam exposure technology and developed, and then a preset copper naphthenate nanometer pattern is obtained; and then the sample is annealed to obtain the nanometer pattern of a copper-graphene composite material. The defect that traditional micronano processing cannot manufacture the composite material nanostructure pattern with the extremely small feature size is overcome, and meanwhile, metal deposition is not needed, so that the production cost is lowered.

Owner:杭州欧克液压科技有限公司

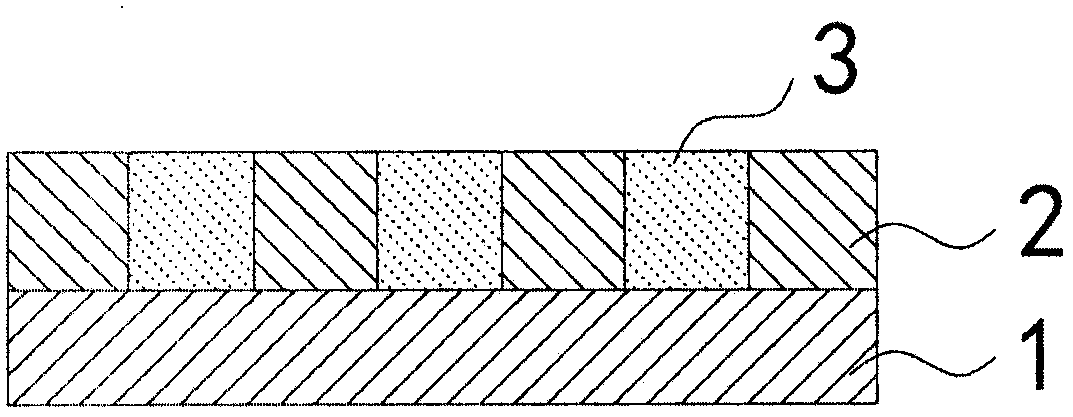

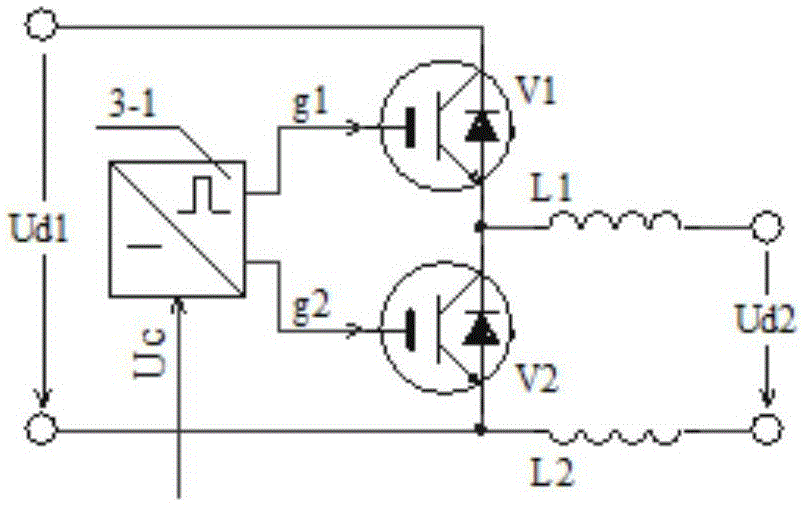

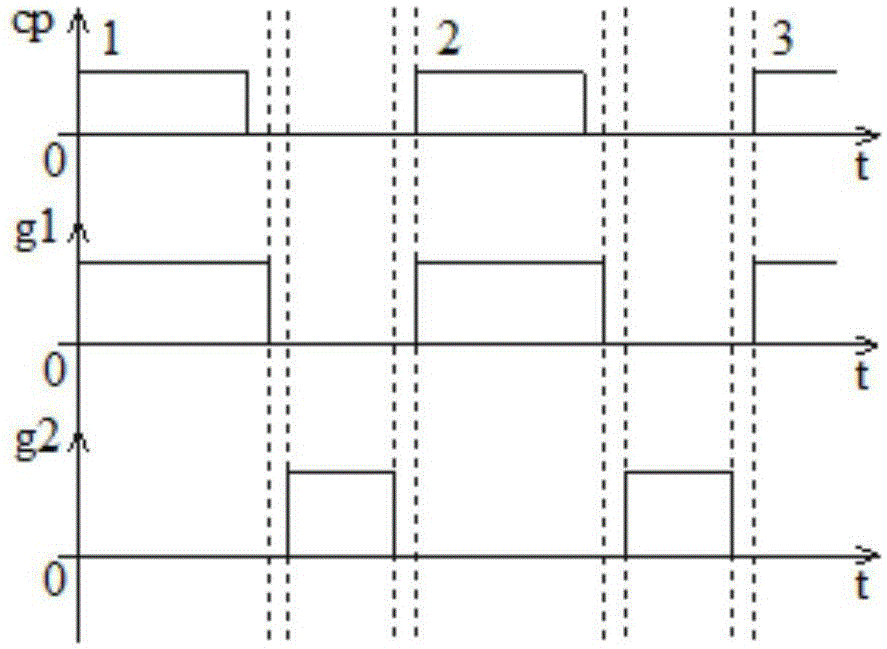

Electron beam processing equipment precision acceleration power supply device and control method thereof

InactiveCN105141169AAvoid short passthroughFast adjustmentAc-ac conversionElectricityHigh voltage igbt

The present invention relates to an electron beam processing equipment precision acceleration power supply device and a control method thereof. The electron beam processing equipment precision acceleration power supply device comprises an incoming line filter, a low voltage rectification filtering unit, a DC-DC conversion unit, an inverter unit, a high voltage unit and a regulator, the input end of the incoming line filter is connected with an external power grid, and the output end of the incoming line filter, the low voltage rectification filtering unit, the DC-DC conversion unit, the inverter unit and the input end of the high voltage unit are connected in series orderly, and the high voltage output end of the high voltage unit outputs a high voltage and is electrically connected with the cathode of an electronic gun. A high voltage feedback signal U outputted by the signal end of the high voltage unit is sent to the second input end of the regulator, the first input end of the regulator inputs a high voltage given signal U*, and the output end of the regulator is connected with the signal end of the DC-DC conversion unit. Relative to the prior art, the electron beam processing equipment precision acceleration power supply device and the control method thereof of the present invention utilize a synchronous Buck circuit to regulate the voltage, thereby solving the problem that a light load current generates a peak pulse voltage interruptedly.

Owner:GUILIN THD TECH CO LTD

A high-voltage gas discharge electron gun device

ActiveCN104505325BExtend cathode lifeMove fastElectric discharge tubesElectron beam machiningCold cathode

The invention provides an electronic gun device for high-voltage gas discharge. The electronic gun device comprises a cathode insulator, a high-voltage insulator, a sealing top cover, a first section of gun shell, an insulating trap, an anode, a second section of gun shell, a first focusing coil, a second focusing coil and a deflection scanning coil, wherein the cathode insulator, the high-voltage insulator, the sealing top cover, the insulating trap and the anode are positioned in the first section of gun shell; the first focusing coil, the second focusing coil and the deflection scanning coil are positioned in the second section of gun shell; the cathode insulator, the high-voltage insulator, the insulating trap, the anode, the first focusing coil, the second focusing coil and the deflection scanning coil are coaxial and are sequentially distributed along the axis from top to bottom. According to the electronic gun device for the high-voltage discharge, the cathode life can be greatly prolonged, which is conductive to expanding the application field of a cold cathode electron beam machining technology.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Intelligent magnetic shielding device

ActiveCN108990402AStable Magnetic Shielding PerformanceTrajectory stabilizationShielding materialsShielding efficiency measurementElectron beam machiningEngineering

The invention belongs to the welding field, in particular to an intelligent magnetic shielding device for electron beam welding. The device includes a detection unit, a shield part and a control part,The structure of the shielding cover can be adjusted according to the complexity of the electron beam machining and the intensity of the ambient magnetic field, and the expansion and contraction of the electric ejector rod can be controlled to make the inner and outer silicon steel sheets be nested and combined into a single-layer structure or a multi-layer structure, so as to realize different shielding requirements, thereby ensuring stable track and high welding precision when the electron beam machining is carried out.

Owner:YANGZHOUSRKLE INDAL

Manufacturing method for electronic component-mounted component, manufacturing method for electronic component-mounted completed product with the electronic component-mounted component, and electronic component-mounted completed product

InactiveUS7084008B2High-productivity and inexpensiveReduce thicknessSemiconductor/solid-state device detailsPrinted electric component incorporationElectron beam machiningAdhesive

A semiconductor element (111) with electrodes (112), and a passive element (113) with electrodes (113a) are embedded in a thermoplastic sheet base (115), which is then subjected to laser beam machining, electron beam machining or ion beam machining to expose electrodes (112 and 113a). Thereafter, a circuit pattern (119) is formed by formation of a thin film or printing of a conductive adhesive. Exposing the electrodes by laser beam machining or the like can be carried out in a short period of time and also by local treatment, thereby reducing damage to the base.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com