Preparation method of titanium alloy pin fin tube by adopting electron beams

A titanium alloy needle and electron beam technology, applied in electron beam welding equipment, metal processing equipment, welding equipment, etc., can solve the problems that titanium alloy pin-fin tubes cannot be prepared, reduce the tube bundle diameter ratio, and weld defects, etc., and achieve Reliable preparation, reduced tube bundle diameter ratio, and compact tube bundle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

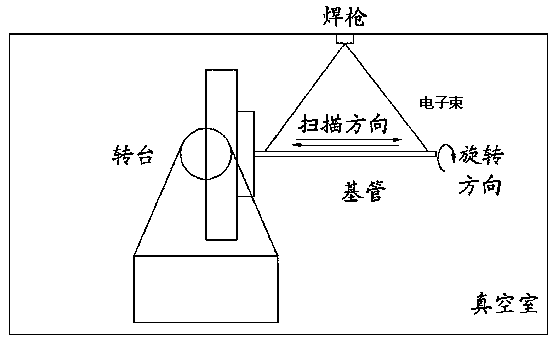

[0020] Such as figure 1 Shown, a kind of titanium alloy pin-fin tube electron beam preparation method comprises the following steps:

[0021] Step 1. Cleaning: Pickling the base pipe to be processed to remove the surface oxide film until the metallic luster is revealed, rinse the base pipe with water, and then clean the part to be welded with acetone or alcohol;

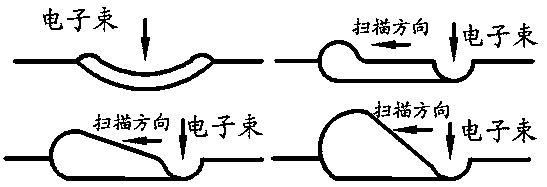

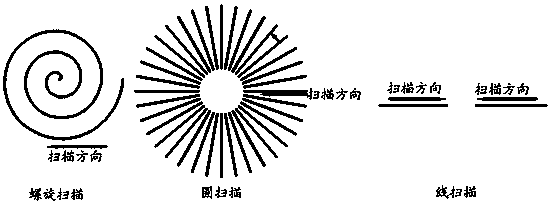

[0022] Step 2. Preparation: put the substrate tube to be processed together with the tooling into the area to be welded. For electron beam processing, it needs to be placed in a vacuum chamber and vacuumized; processing: for electron beam processing, when the vacuum degree reaches 5×10 -4 At mbar, start the welding process, use surface focus or upper focus, line scan, circular scan or helical scan, scan frequency 0-1000Hz, scan amplitude 0-5mm, manufacturing scan speed 0.1-5m / s, welding voltage 60- 150KV, beam current 1-20mA, electron beam focus radius 0.2-1mm, the base tube rotates on the tooling at a linear speed ...

Embodiment 1

[0024] Example 1 Titanium Alloy Helical Scanning

[0025] Pickle the Ti31 base pipe to be processed to remove the surface oxide film until the metallic luster is revealed, rinse with water, and then clean the part to be welded with acetone or alcohol;

[0026] Put the substrate tube to be processed into the area to be welded together with the tooling. For electron beam processing, it needs to be placed in a vacuum chamber and vacuumized; when the vacuum degree reaches 5×10 -4 At mbar, start welding, use surface focus, helical scanning, scanning frequency 1000Hz, scanning amplitude 1mm, manufacturing scanning speed 0.1m / s, welding voltage 150KV, beam current 2.5mA, electron beam focus radius 0.3mm, welding torch distance from workpiece The distance is 500mm.

[0027] After the processing is completed, the heat treatment furnace is used for vacuum stress relief annealing treatment, and the vacuum degree is 5×10 -3 Pa, temperature 450°C, time 30min. After heat treatment, the re...

Embodiment 2

[0028] Example 2 Titanium Alloy Linear Scanning

[0029] Pickle the Ti31 base pipe to be processed to remove the surface oxide film until the metallic luster is revealed, rinse with water, and then clean the part to be welded with acetone or alcohol;

[0030] Put the substrate tube to be processed into the area to be welded together with the tooling. For electron beam processing, it needs to be placed in a vacuum chamber and vacuumized; when the vacuum degree reaches 5×10 -4 At mbar, start welding, use surface focus, linear scanning, one-way scanning from both ends to the center, scanning frequency 1000Hz, scanning amplitude 10mm, manufacturing scanning speed 5m / s, welding voltage 90KV, beam current 20mA, electron beam focal radius 0.3mm, the distance between the welding torch and the workpiece is 1000mm.

[0031] After the processing is completed, the heat treatment furnace is used for vacuum stress relief annealing treatment, and the vacuum degree is 5×10 -3 Pa, temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com