Automatic setting method and system for focusing currents on workpiece surface of electron beam processing equipment

A technology of electron beam processing and focusing current, which is applied in the direction of electron beam welding equipment, metal processing equipment, welding equipment, etc., and can solve the problem of low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

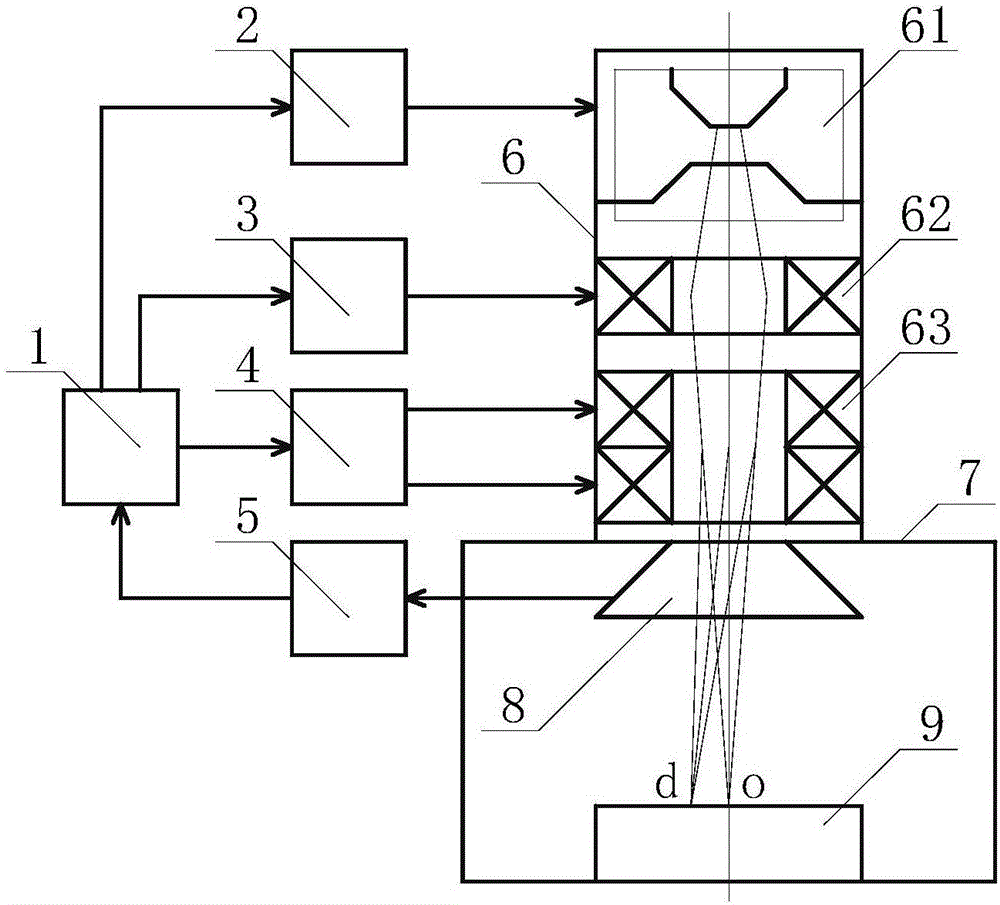

[0032] An automatic tuning system for focusing current on the workpiece surface of electron beam processing equipment, such as figure 1 As shown, it consists of central control unit 1, electron beam generator power supply 2, focusing power supply 3, bias sweep power supply 4, transmitter 5, electron gun 6, vacuum working chamber 7 and secondary electron collector 8.

[0033] Central control unit 1: undertakes the control and monitoring of the entire equipment, has the function of digital setting and digital sampling for the operating parameters of the electron beam processing equipment, and configures the program to realize the automatic adjustment of the focusing current.

[0034] Electron beam generator power supply 2: including the cathode heating power supply of the electron beam generator 61, the electron beam accelerating high voltage power supply and the electron beam control grid bias power supply. The central control unit 1 is connected to the electron beam generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com