Preparation method for high-performance low-modulus medical titanium alloy three-dimensional metal part

A technology for metal parts and titanium alloys is applied in the field of preparation of high-performance and low-modulus medical titanium alloy three-dimensional metal parts, achieving the effects of broad application prospects, fully controllable internal structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

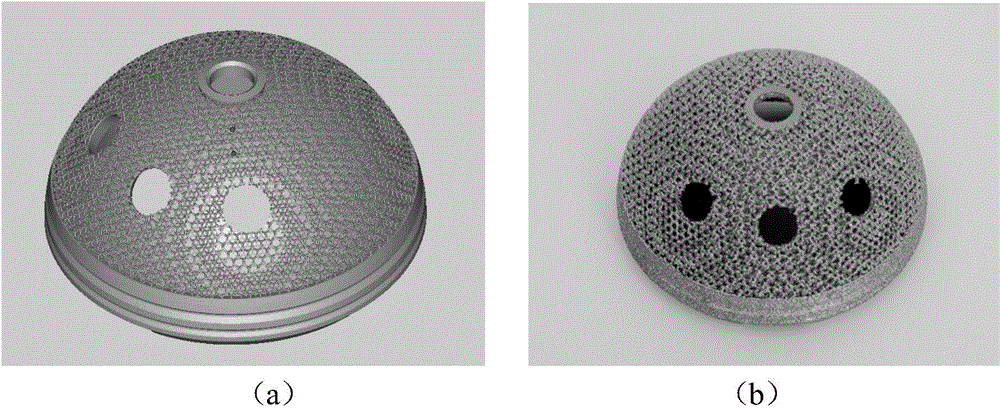

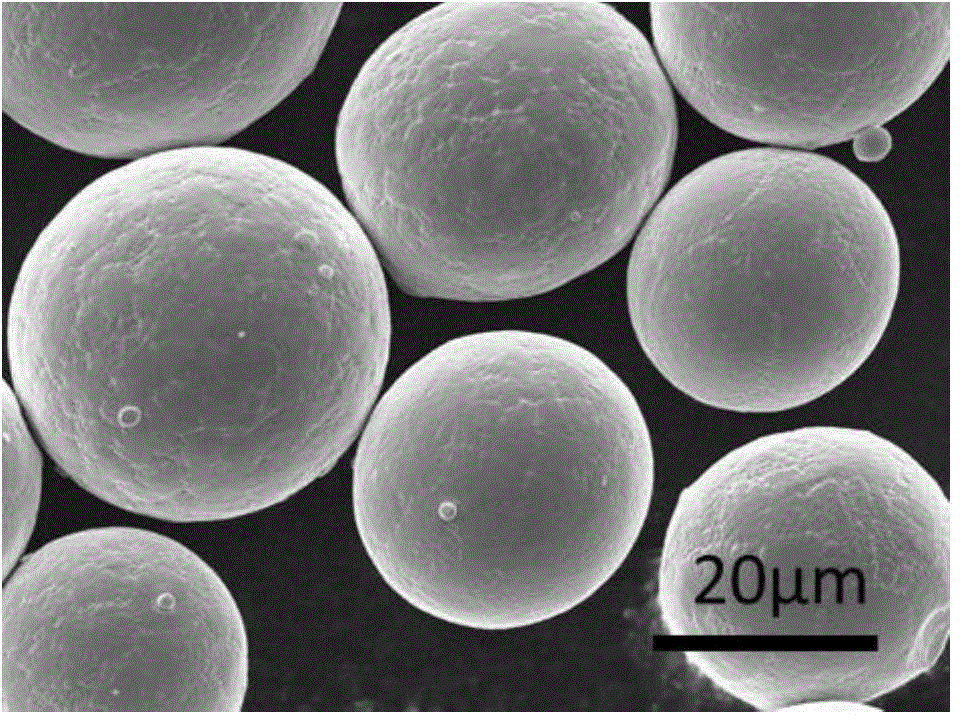

[0043] Such as figure 1 As shown in (a), CAD software was used to design a low modulus medical titanium alloy acetabular cup model with a wall thickness of 3 mm. Low modulus titanium alloy Ti-24Nb-4Zr-8Sn (wt.%) alloy powder ( figure 2 , powder diameter is 50-80μm) as raw material, using Arcam A1 electron beam melting equipment to prepare Ti-24Nb-4Zr-8Sn alloy acetabular cup model, substrate preheating temperature is 500 ℃, electron beam scanning speed is 500-600mm / s, the electron beam current is 18-25mA, and the component is prepared at a distance of 6mm above the substrate, and the final Ti-24Nb-4Zr-8Sn alloy acetabular cup is as follows: figure 1 (b) shown.

[0044] In this example, the prepared Ti-24Nb-4Zr-8Sn alloy acetabular cup is subjected to hot isostatic pressing, the process is as follows: the temperature is 920° C., the pressure is 120 MPa, and the holding time is 3 hours.

[0045] In this example, the prepared Ti-24Nb-4Zr-8Sn alloy acetabular cup is subjected...

Embodiment 2

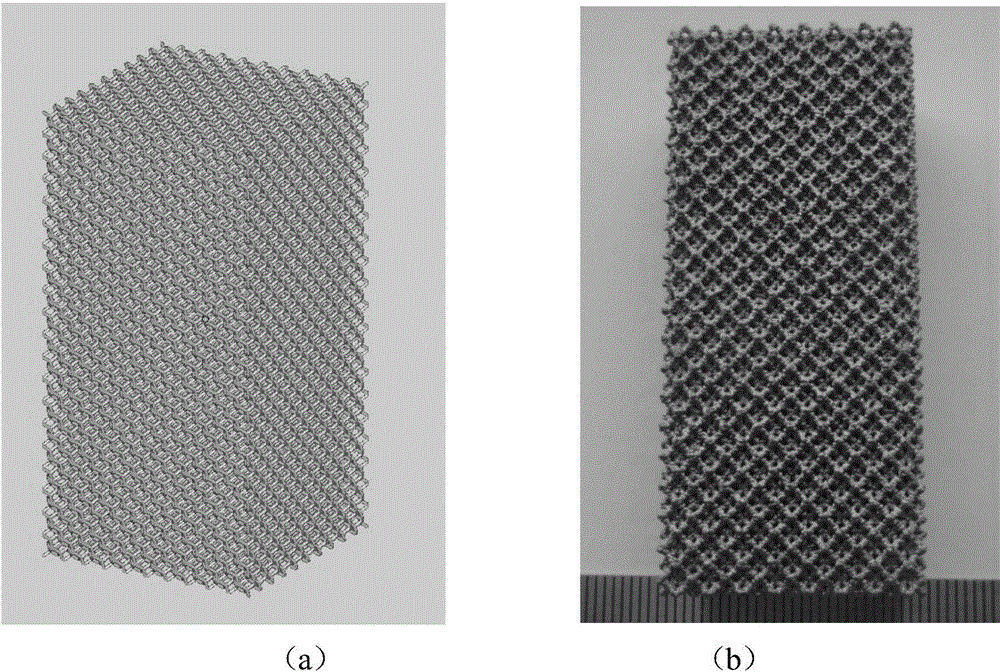

[0050] Such as image 3 As shown in (a), the porous material model is designed by using CAD software, and its cell type is a rhombic dodecahedron with a porosity of 80%. Using Ti-24Nb-4Zr-8Sn (wt.%) alloy powder as raw material ( figure 2 , the powder diameter is 50-80 μm), the Ti-24Nb-4Zr-8Sn alloy porous material was prepared by Arcam A1 electron beam melting equipment, the substrate preheating temperature was 500°C, the electron beam scanning speed was 700-800m / s, and the electron beam The current is 1-10mA, and the components are prepared at a distance of 5mm from the substrate. The final Ti-24Nb-4Zr-8Sn alloy porous material is as follows: image 3 (b) shown.

[0051] In this example, the prepared Ti-24Nb-4Zr-8Sn alloy porous material is subjected to two-step heat treatment:

[0052] (1) Solid solution treatment in the β single-phase region. Using a vacuum heat treatment furnace, the prepared Ti-24Nb-4Zr-8Sn alloy porous material was kept at 700°C for 0.5h, and cooled...

Embodiment 3

[0056] Such as Figure 4 As shown in (a), CAD software is used to design the model of the femoral head support nail, and the unit hole type of the porous part is a rhombic dodecahedron with a porosity of 70%. Using Ti-20Nb-5Zr (wt.%) alloy powder as raw material (powder diameter is 40-70 μm), using Arcam A1 electron beam melting equipment to prepare Ti-20Nb-5Zr femoral head support nail, the substrate preheating temperature is 550 °C , the scanning speed of the electron beam is 500-600m / s, the current of the electron beam is 5-15mA, the component is prepared at a distance of 8mm from the substrate, and the finally prepared Ti-22Nb-5Zr alloy femoral head support nail is as follows: Figure 4 (b) shown.

[0057] In this embodiment, the prepared Ti-20Nb-5Zr alloy femoral head support nail is subjected to two-step heat treatment:

[0058] (1) Solid solution treatment in the β single-phase region. Using a vacuum heat treatment furnace, the prepared Ti-20Nb-5Zr alloy femoral head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com