Chamber assembly for application in electron beam machining

A technology of electron beam processing and chamber body, applied in electron beam welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

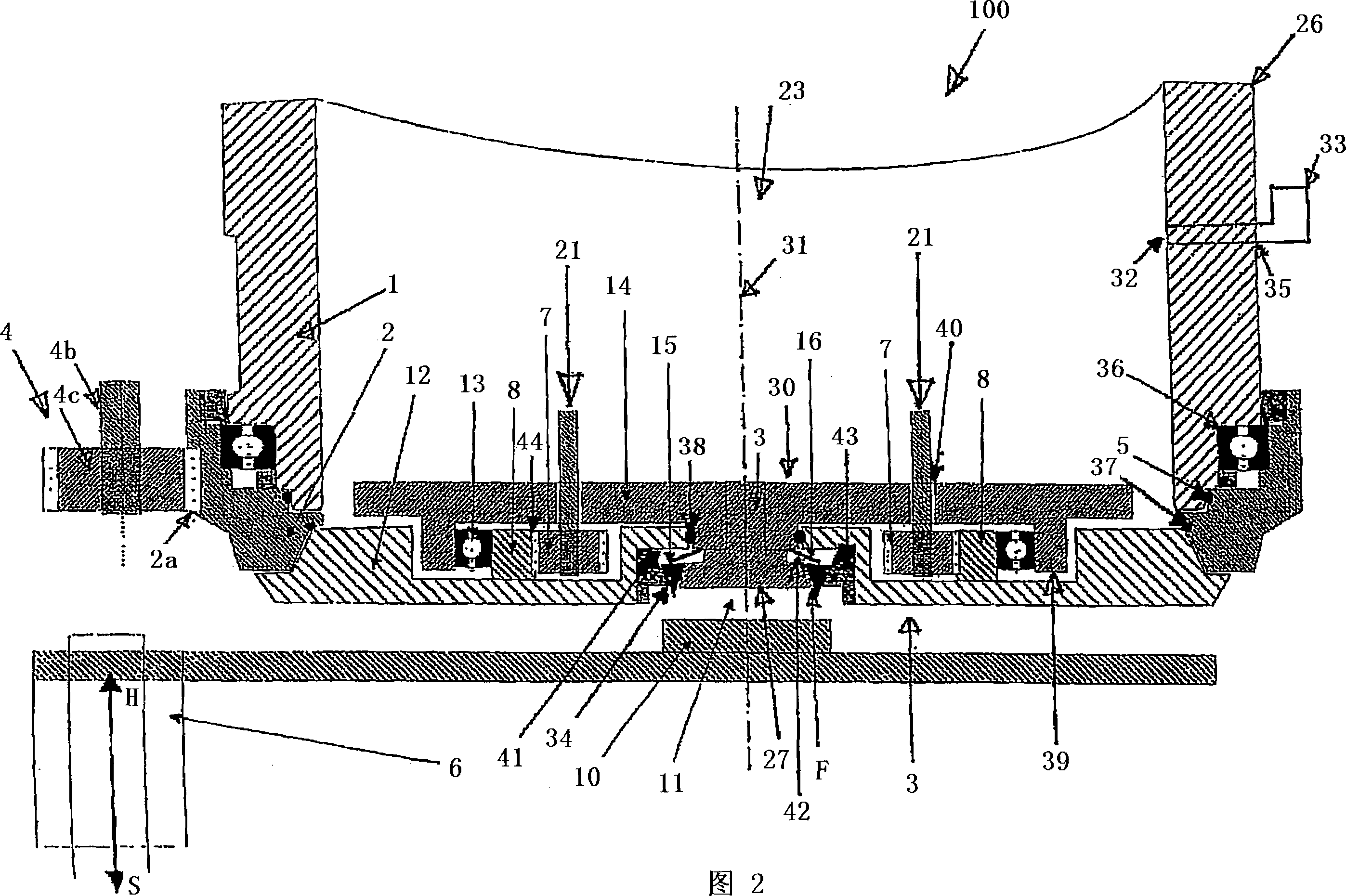

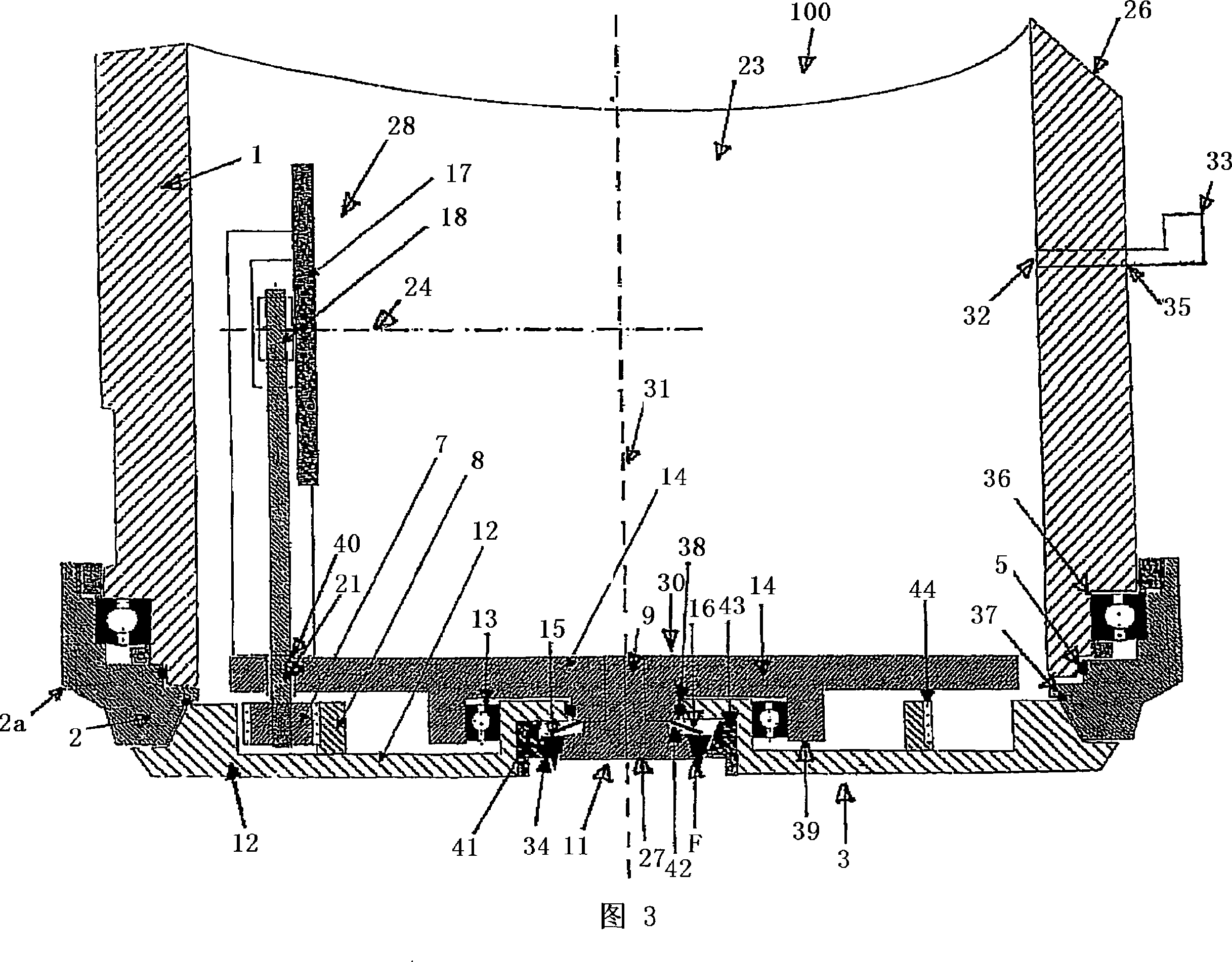

[0047] Some methods for electron beam processing, such as electron beam generators, deflection coils, etc., that can be installed near or in the housing of the chamber are not described in the drawings.

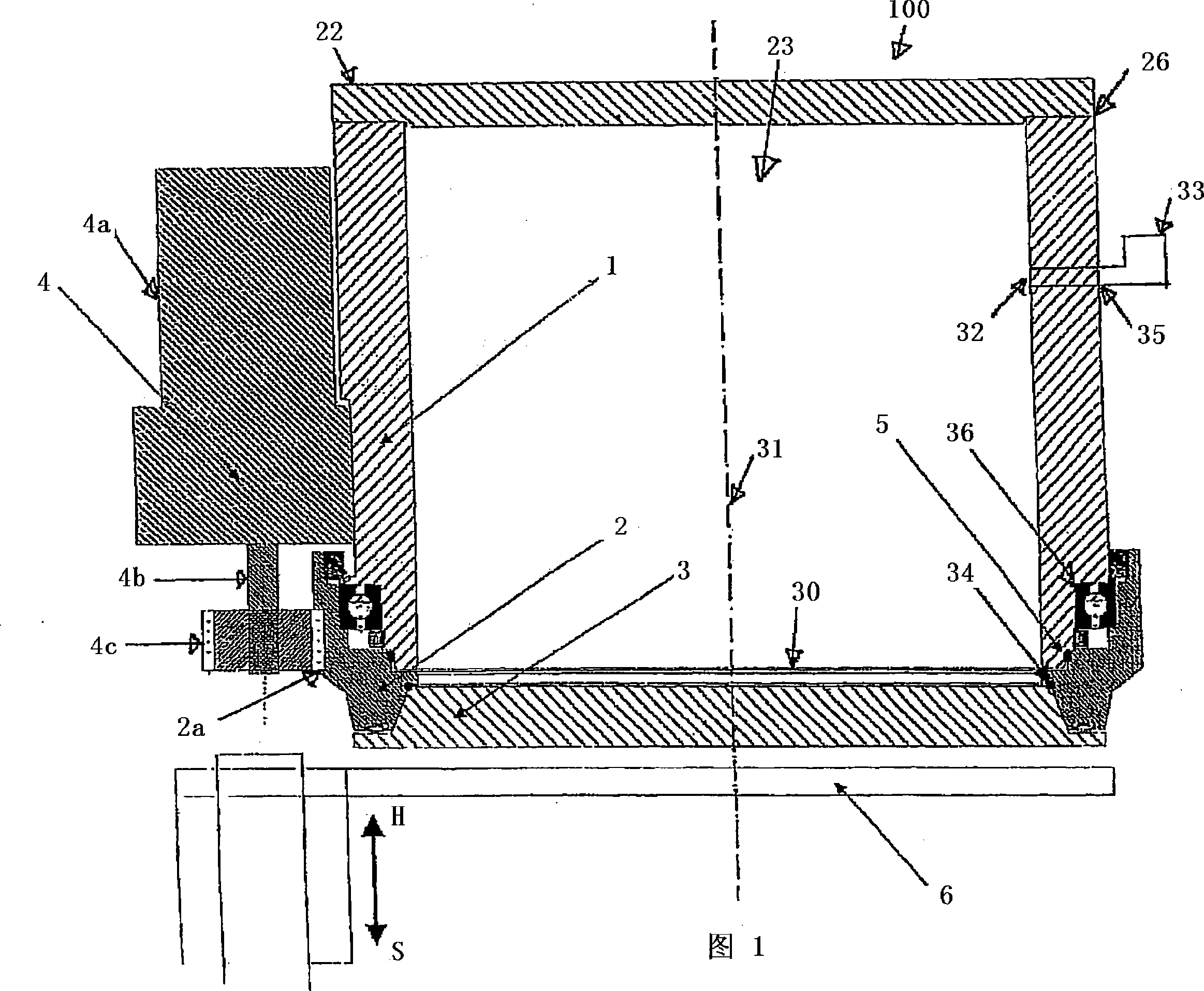

[0048]Figure 1 shows the first embodiment of the chamber device 100. According to the first embodiment, the chamber device includes a chamber housing 26, which defines a chamber space 23. Electron beam processing can be carried out in the chamber space, such as vacuum electron beam workpiece welding. In this embodiment, the chamber housing 26 includes a cylindrical chamber wall 1, a cover 22, and a feeding / outlet hole 30. The cylindrical axis of the chamber wall 1 defines the longitudinal axis of the chamber space 23. The cover 22 forms the upper boundary of the chamber space 23 in the longitudinal direction. A feed / out hole 30 is formed on the bottom surface of the chamber body shell 26 in the longitudinal direction, the shape of which is circular, and the diameter is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com