Faraday cup sensing device used in electron beam processing beam quality test

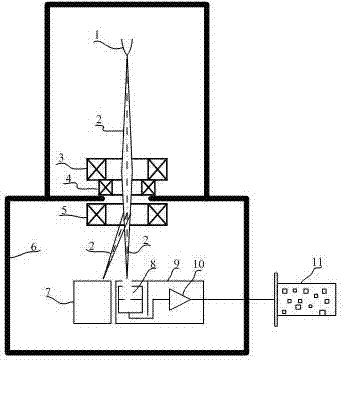

A technology of electron beam processing and Faraday cylinder, which is applied in measurement devices, radiation measurement, X/γ/cosmic radiation measurement and other directions to achieve the effects of reducing electromagnetic interference, shortening cables and improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

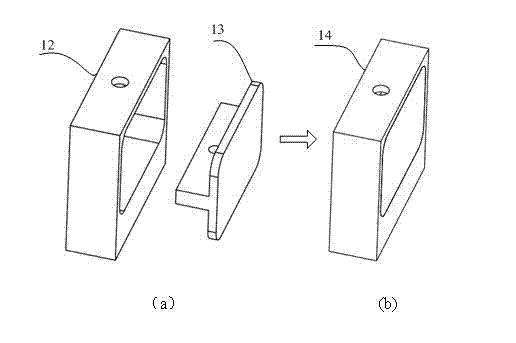

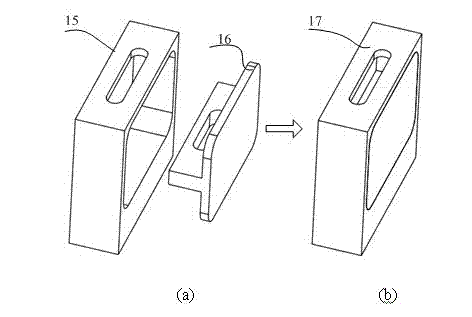

[0028] combine figure 2 , image 3 and Figure 4 . see figure 2 , the hole collecting electrode 14 of the electron beam is composed of the hole collecting electrode outer collector 12 and the hole collecting electrode inner collector 13 (the size and distance are selected and adjusted according to the needs of the actual test), the material is H62 brass, the hole collecting electrode A hole with a diameter of 2mm is placed on the center of the upper surface of the outer collector 12, and a hole with a diameter of 1.5mm is placed at the center of the inner collector 13 of the hole collecting electrode. The axes of the two holes are on the same axis, and the upper surfaces of the two holes are apart from each other. 6mm, the size of the electrode cavity is 18×12×2mm, except for the bottom wall thickness of the electrode is 5mm, the rest is 1mm, and the threaded hole M2×3mm is placed at the center of the bottom of the hole collecting electrode 14, which is used to fix the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com