Mfg. method of assembly set with electronic component and mfg. method for related products

A technology of electronic components and manufacturing methods, which is applied to the direction of assembling printed circuits containing printed electrical components, electrical components, electrical components, etc., which can solve problems such as low productivity, short circuit, poor contact, etc., achieve high productivity and reduce damage , powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

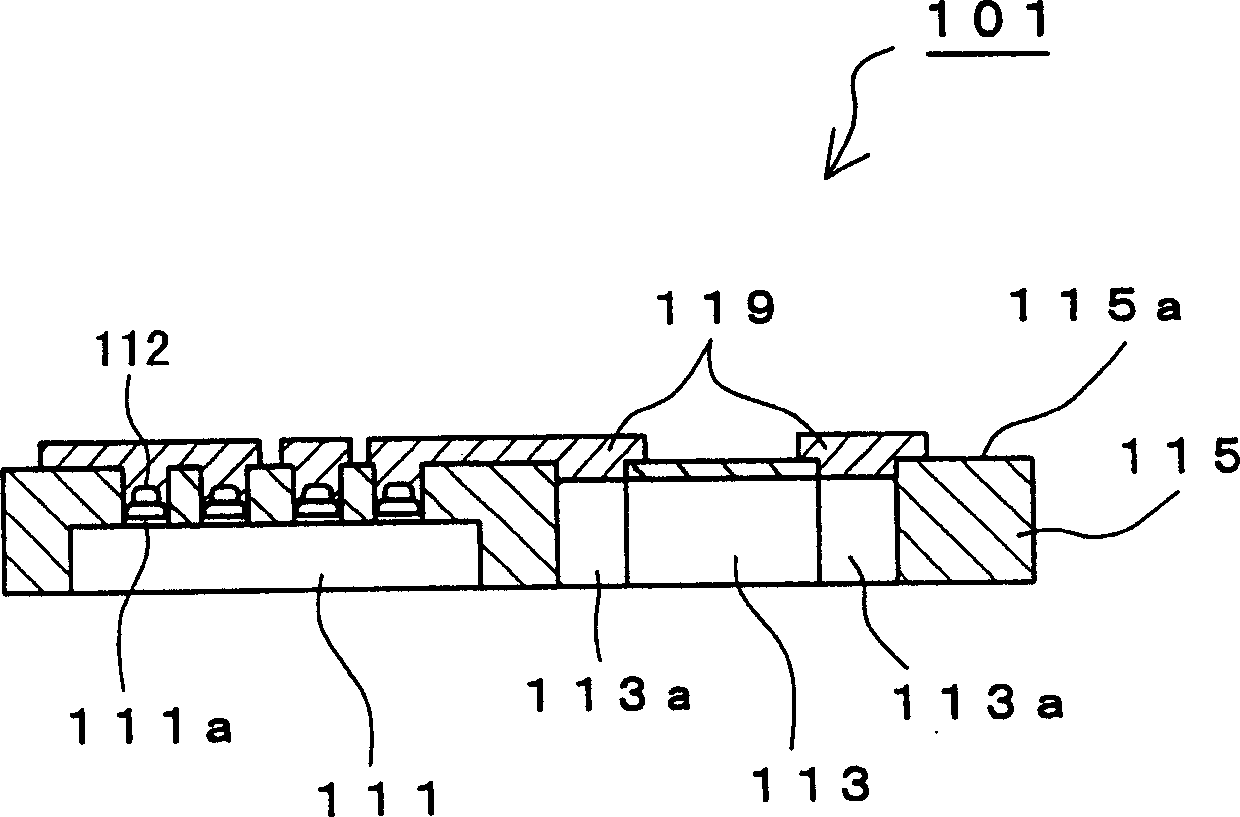

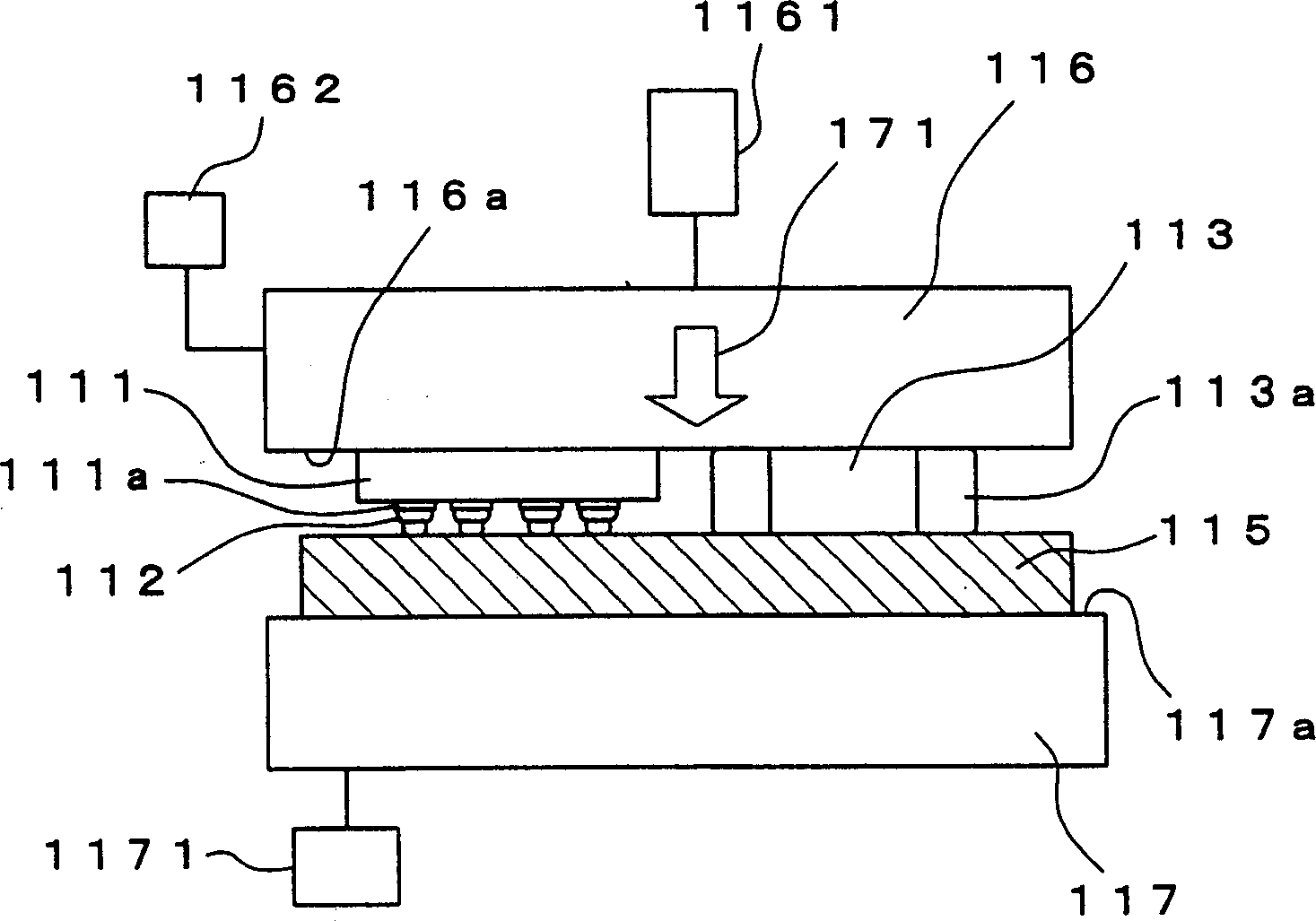

[0061] First, a manufacturing method for the electronic component mounted package 101 will be described. The process of mounting the semiconductor element 111 and the passive element 113 as electronic components into the substrate 115 includes a process of embedding the electronic components into the sheet-shaped substrate 115 from which electrodes 112 and 113a, and a process of forming a circuit pattern 119 electrically connected to the exposed electrodes 112 and 113. The description here exemplifies the case of forming a sheet module having the semiconductor element 111 and the passive element 113 embedded in a thermoplastic substrate as an example of the substrate 115 .

[0062] The thermoplastic base is preferably, for example, polyethylene terephthalate, polyvinyl chloride, polycarbonate, acrylonitrile butadiene styrene, thermoplastic polyimide or such material having electrically insulating properties, and The base thickness is 10μm-2.000mm. The thickness of the thermo...

no. 2 example

[0082] Figure 7 Shown is a sheet-shaped module corresponding to a component mounted with electronic components, which has a through hole 118 as a hole penetrating through a processed surface 115a of a thermoplastic sheet base 115 and a back surface 115d opposite to the processed surface 115a, and can be connected with figure 1 The illustrated assembly 101 mounted with electronic components compares the film capacitor 120 . The through hole 118 is formed by punching a hole in the thickness direction of the thermoplastic substrate 115 using a laser, a particle beam, or an electron beam. When the circuit pattern 119 is formed, a conductive material is provided to the inner outer surface of the through hole 118 or inside the through hole 118 at the same time. Thus, the electrical connection between the processed face 115a and the rear face 115d is achieved via the via hole 118 by at least one of conductive sputtering, vapor deposition, filling of a conductive material, and the ...

no. 3 example

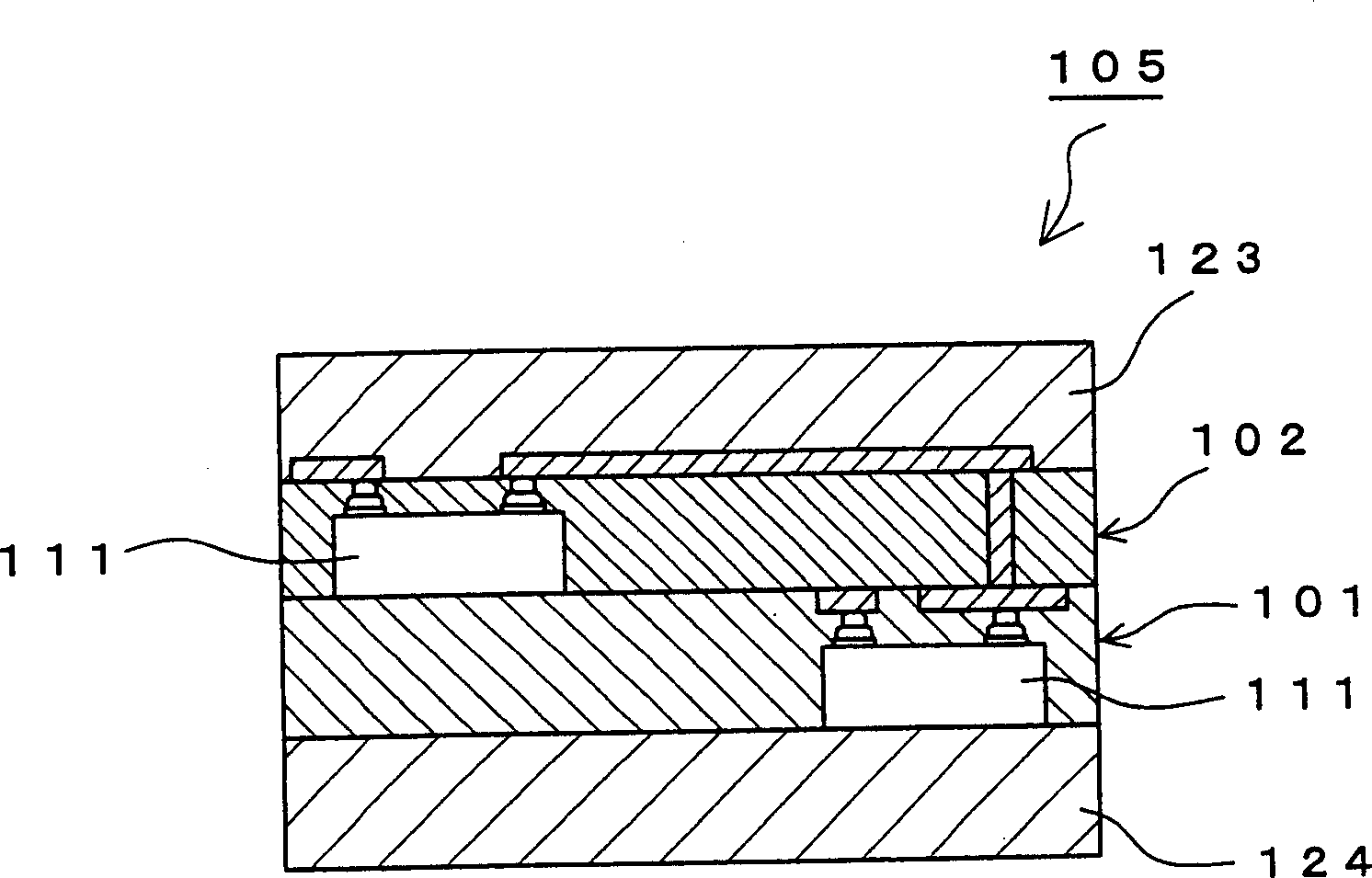

[0086] The electronic component mounted assembly 101 in the above first embodiment and the electronic component mounted assembly 102 in the above second embodiment are stacked in the thickness direction of the electronic component mounted assemblies 101 and 102, and by covering the The sheet-shaped protective materials 123 and 124 of the electronic component mounted components 101 and 102 are rolled to the electronic component mounted components 101 and 102, thereby manufacturing such as figure 2 A finished product 105 is shown with electronic components installed. The electronic component-mounted package 102 included in the electronic component-mounted finished product 105 of this third embodiment has no circuit pattern 119 formed on the back surface 115d. The electronic component-mounted assemblies 101 and 102 are aligned with each other such that the through hole 128 formed in the electronic component-mounted assembly 102 is electrically connected to the circuit pattern 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com