Phase type photon sieve

A photon sieve and phase-type technology, applied in the direction of diffraction grating, etc., can solve the problems of low diffraction efficiency, weakening the focus, and affecting practicality, etc., and achieve the effects of excellent diffraction efficiency, improved resolution, and improved competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

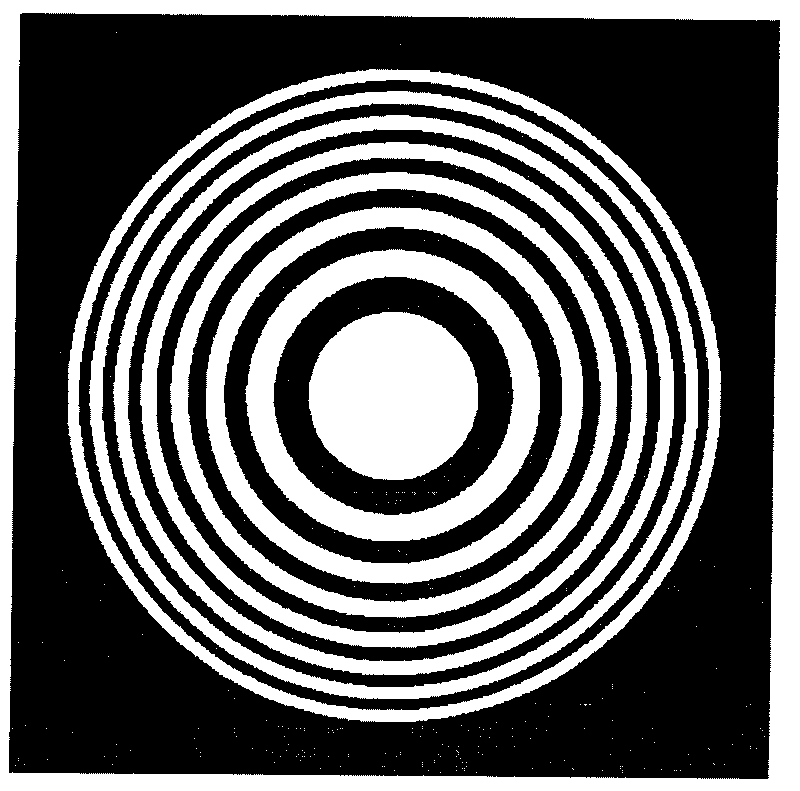

[0020] Such as figure 1 Shown is a schematic diagram of the structure of a Fresnel zone plate. In this specific embodiment, the wavelength of the incident light source is 355 nm, the diameter of the zone plate is 1 mm, and the focal length is 10 mm. Record N as the number of bands, then N=D 2 / λ×f=281; record r n is the radius of each ring, then f is the focal length, λ is the wavelength, n is the serial number of the zone plate, N is the total number of zones of the zone plate, and the value range of n is less than or equal to N; the diagram only shows the first 16 zones, and so on . The radii of the first 16 rings are r 1 ...r 16 = 60.42μm, 85.44μm, 104.64μm, 120.83μm, 135.09μm, 147.99μm, 159.84μm, 170.88μm, 181.25μm, 191.05μm, 200.37μm, 209.28μm, 217.83μm, 223.062μm, 26.032μm, 26 The difference between the radii of two adjacent rings is the width of the ring, which is denoted as w n , then the width of the annulus is 25.02 μm, 19.20 μm, 16.19 μm, 14.16 μm, 12.90 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com