Energy controlling method in electronic beam machining

A technology of electron beam processing and energy control, which is applied in the direction of electron beam welding equipment, metal processing equipment, manufacturing tools, etc., and can solve problems such as no energy density control method is given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Energy density control of a single scanning trajectory through the number of points

[0051] In this embodiment, a single scanning track is controlled by the number of scanning points along the length direction of the scanning track, and the energy density is controlled at different positions of the scanning track.

[0052] use as figure 1 The scanning track shown requires that the energy density of the electron beam is uniformly distributed along the length of the scanning track. According to the above requirements, it is preliminarily determined that the scanning points are evenly distributed along the length direction of the scanning track, and the number of scanning points in one scanning cycle is 660.

[0053] The surface of the workpiece is divided into discrete points, and 50×50 points are divided, that is, both M and N are equal to 50 in the energy density distribution matrix. Using the aforementioned energy density calculation method, the energy de...

Embodiment 2

[0055] Embodiment 2: Energy density control of a single scanning track through beam current

[0056] In this embodiment, energy density is controlled at different positions of the scanning track by controlling the beam current along the length direction of the scanning track for a single scanning track.

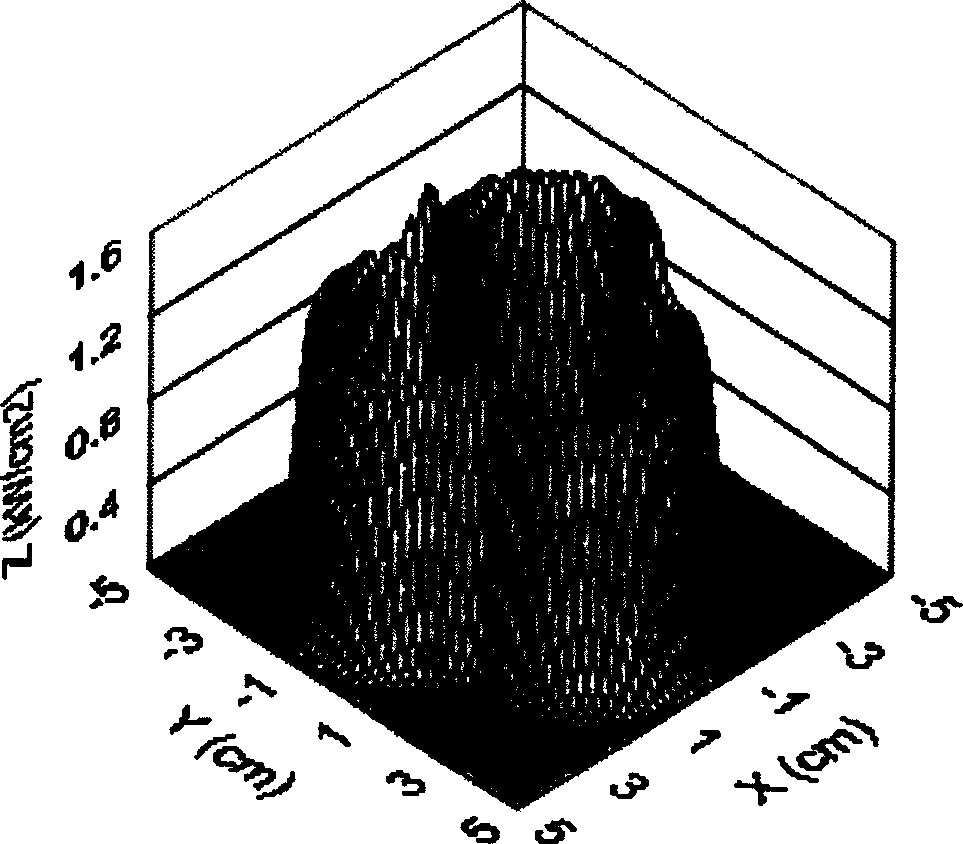

[0057] use as Figure 4 The scanning trajectory shown requires the electron beam energy density distribution as Figure 5 As shown, it varies uniformly along the length of the scanning track. According to the above requirements, the scanning points are uniformly distributed along the length direction of the scanning track, and the beam current value changes uniformly at different positions of the scanning track. The number of scanning points in one scanning cycle is 500.

[0058] The surface of the workpiece is divided into discrete points, and 50×50 points are divided. Continuously changing beam current: in one cycle of the scanning trajectory, the beam current gradually ...

Embodiment 3

[0059] Example 3: Energy density control of two scanning trajectories through the number of points

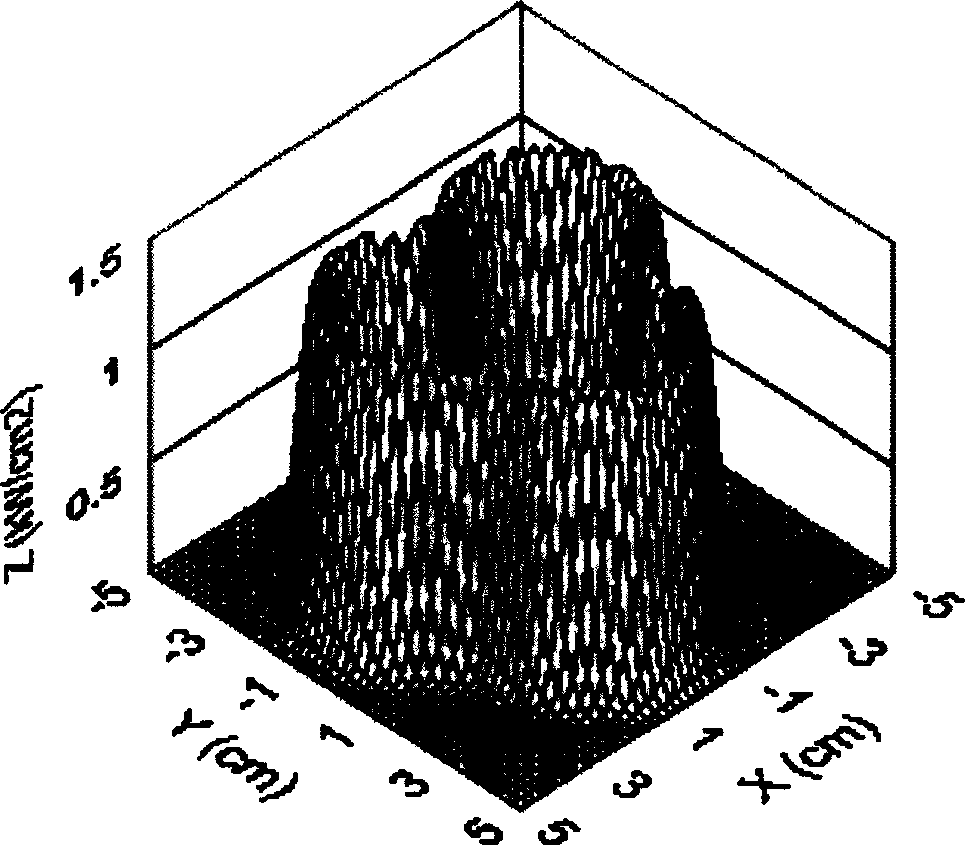

[0060] The scanning trajectory of the electron beam is in the form of two concentric circles, such as Figure 6 As shown, and requires the energy density of the small circle to be lower than that of the large circle.

[0061] Preliminarily determine the number of small circle scanning points: 200, the number of large circle scanning points: 350, divide the surface of the workpiece into discrete points, and divide 50×50 points. Using the aforementioned energy density calculation method, the obtained energy density distribution shows that the energy density of the small circle is slightly higher than that of the large circle, which does not meet the requirements, so it is necessary to reduce the number of points of the small circle or increase the number of points of the large circle. Now reduce the number of small dots to 150 and keep the number of big dots unchanged, then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com