Flux-cored wire for welding of titanium-steel dissimilar metal sheet and preparation method of flux-cored wire

A technology for welding dissimilar metals and sheets, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., it can solve the problem that titanium steel cannot be welded butt joint, etc., to facilitate mass production, less alloying elements, Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

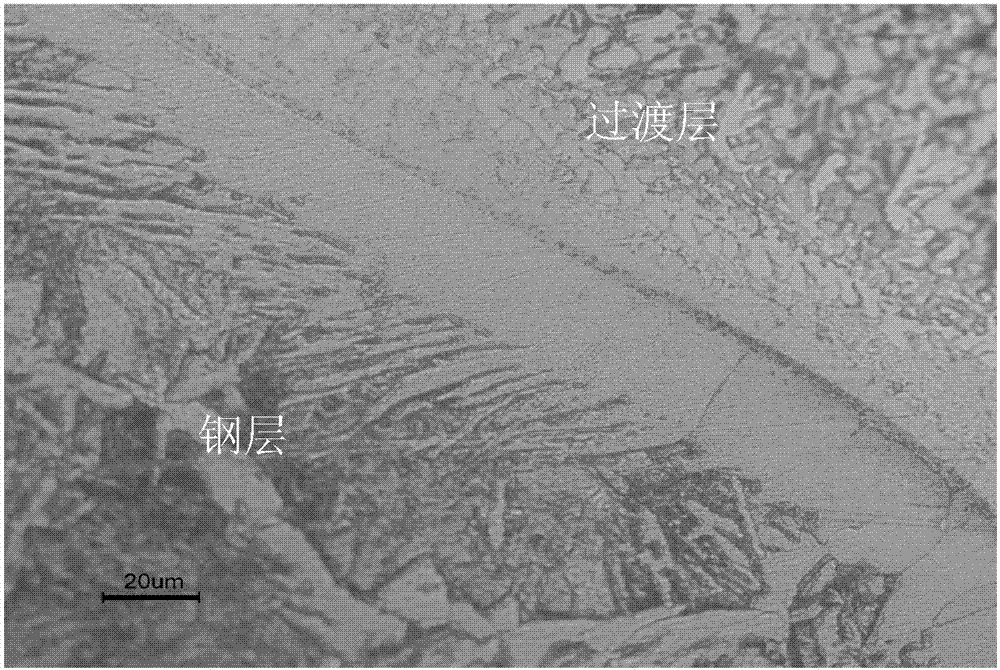

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned titanium-steel dissimilar metal sheet welding flux-cored wire, the specific steps are as follows:

[0030] Step 1: Weigh 60% to 80% of V powder and 20% to 40% of Ni powder respectively by mass percentage, and the sum of the mass percentages of the above components is 100%;

[0031] Step 2: Put the V powder and Ni powder weighed in step 1 into a ball mill, and after ball milling for 8 hours, obtain a uniformly mixed drug core powder; heat it in a vacuum heating furnace with a vacuum degree of 0.1 Pa and a heating temperature of 200 ℃-300℃, heat preservation time 3h-5h, remove the crystal water in the medicine powder, and obtain the medicine core powder;

[0032] Step 3: Wrap the flux core powder prepared in step 2 in the copper tape through the flux cored wire making machine. The diameter of the first drawing abrasive tool is 2.6mm. Wipe clean with alcohol;

[0033] Step 4: After the first process of drawing is completed, t...

Embodiment 1

[0036] Step 1: Weigh 60% V powder and 40% Ni powder respectively according to requirements, and the sum of the mass percentages of the above components is 100%;

[0037] Step 2: Put the V powder and Ni powder weighed in step 1 into a ball mill, and ball mill for 8 hours to obtain a uniformly mixed drug core powder; heat it in a vacuum heating furnace with a vacuum degree of 0.1 Pa and a heating temperature of 200°C , heat preservation time 3h, remove the crystal water in the medicine powder, obtain medicine core powder;

[0038] Step 3: Wrap the flux core powder prepared in step 2 in the copper tape through the flux cored wire making machine, the filling amount is controlled at 15%. Before a process, the copper strip is wiped clean with alcohol;

[0039] Step 4: After the first process of drawing is completed, the hole diameter of the abrasive tool is changed to 2.3mm, 2.0mm, 1.8mm, 1.6mm, 1.42mm, 1.34mm, 1.28mm, 1.24mm, and finally the flux cored wire is drawn to the diamete...

Embodiment 2

[0044] Step 1: Weigh 70% V powder and 30% Ni powder respectively according to requirements, and the sum of the mass percentages of the above components is 100%;

[0045] Step 2: Put the V powder and Ni powder weighed in step 1 into a ball mill, and ball mill for 8 hours to obtain a uniformly mixed drug core powder; heat it in a vacuum heating furnace with a vacuum degree of 0.1Pa and a heating temperature of 250°C , the holding time is 3.5h, the crystal water in the medicine powder is removed, and the medicine core powder is obtained;

[0046] Step 3: Wrap the flux core powder prepared in step 2 in the copper tape through the flux cored wire making machine, the filling amount is controlled at 18%. Before a process, the copper strip is wiped clean with alcohol;

[0047]Step 4: After the first process of drawing is completed, the hole diameter of the abrasive tool is changed to 2.3mm, 2.0mm, 1.8mm, 1.6mm, 1.42mm, 1.34mm, 1.28mm, 1.24mm, and finally the flux cored wire is drawn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com