Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8351 results about "Series production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Series production. The manufacture of a product or service by a group of operations sequenced so that all materials will be routed successively through each production state.

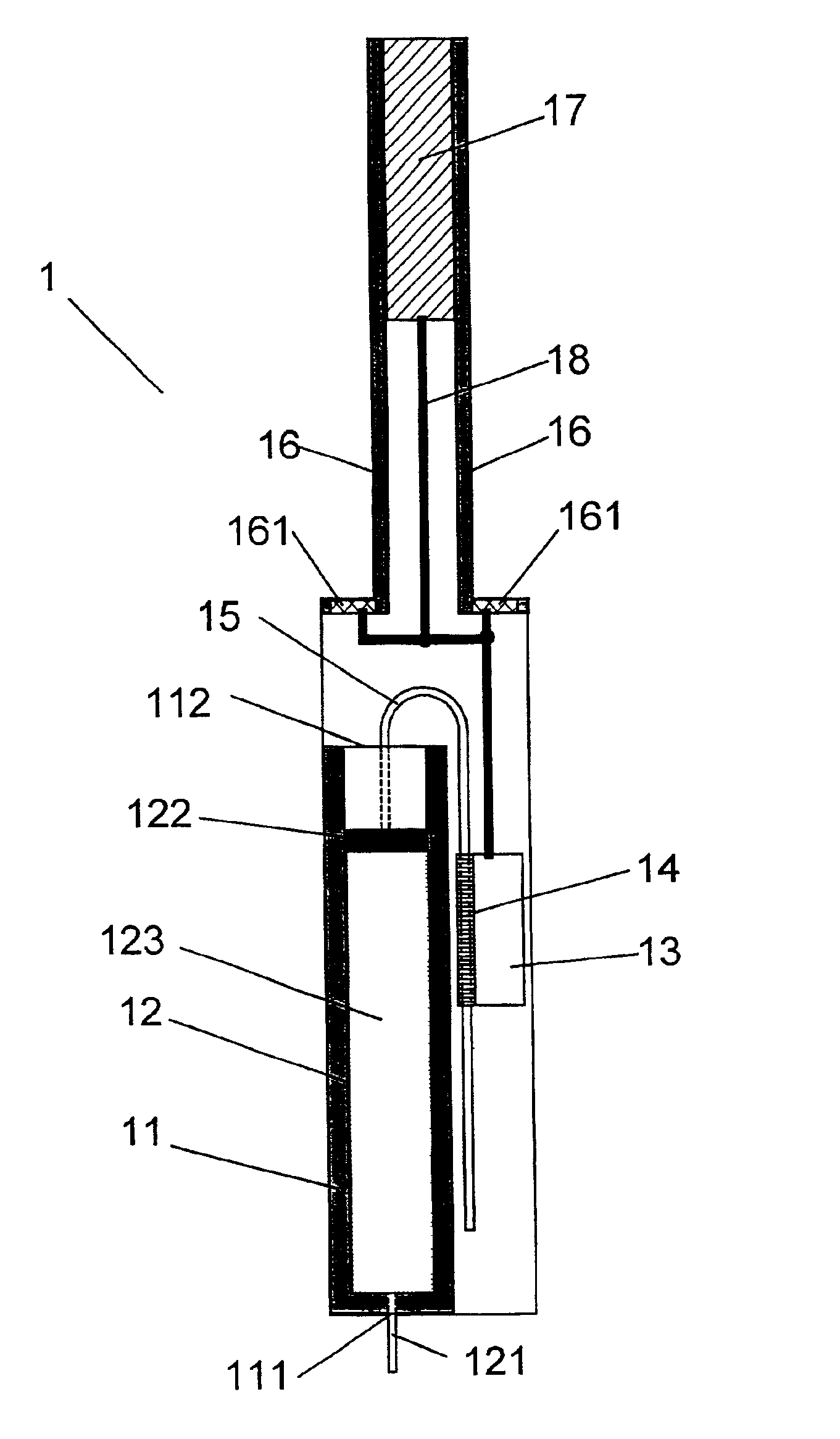

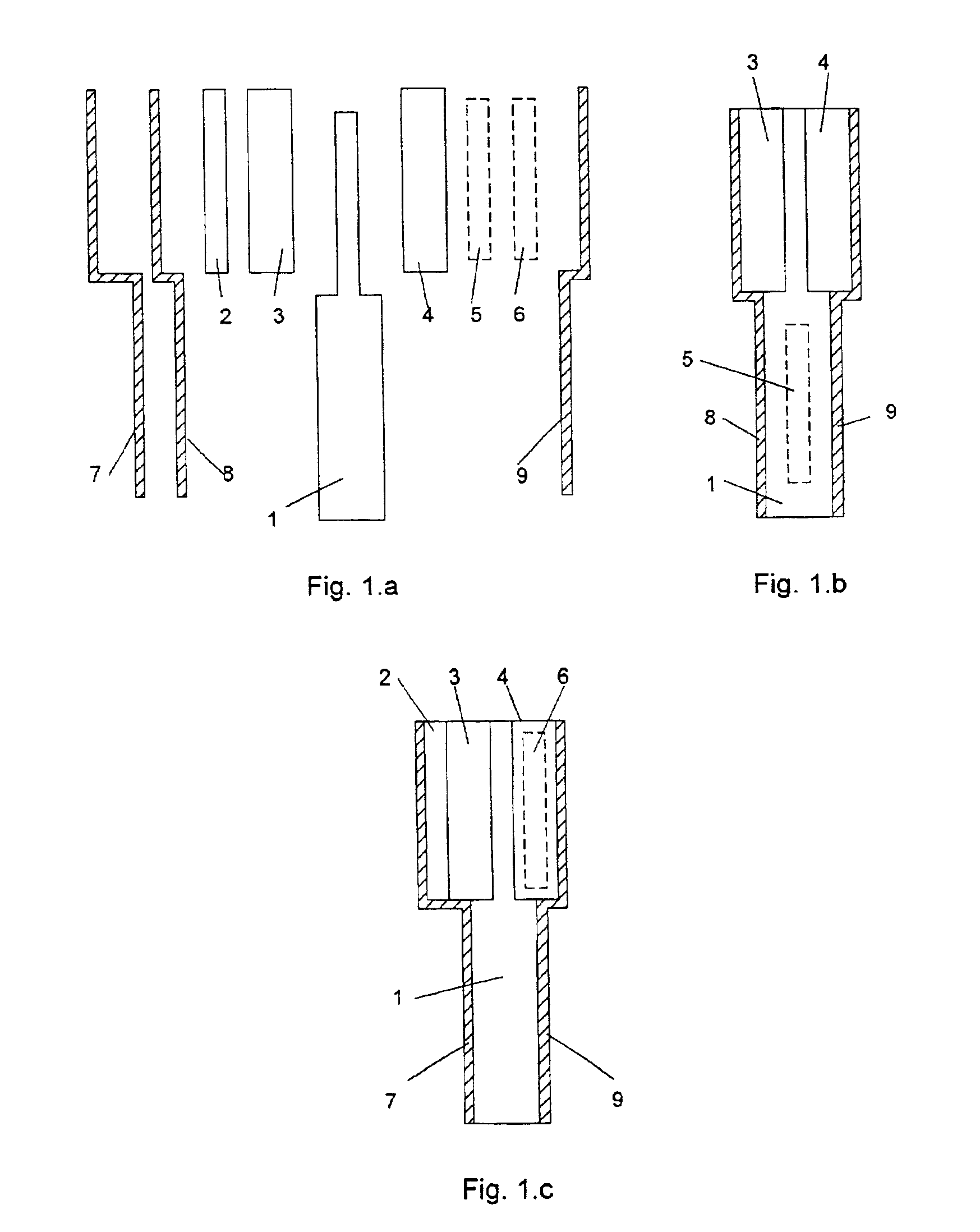

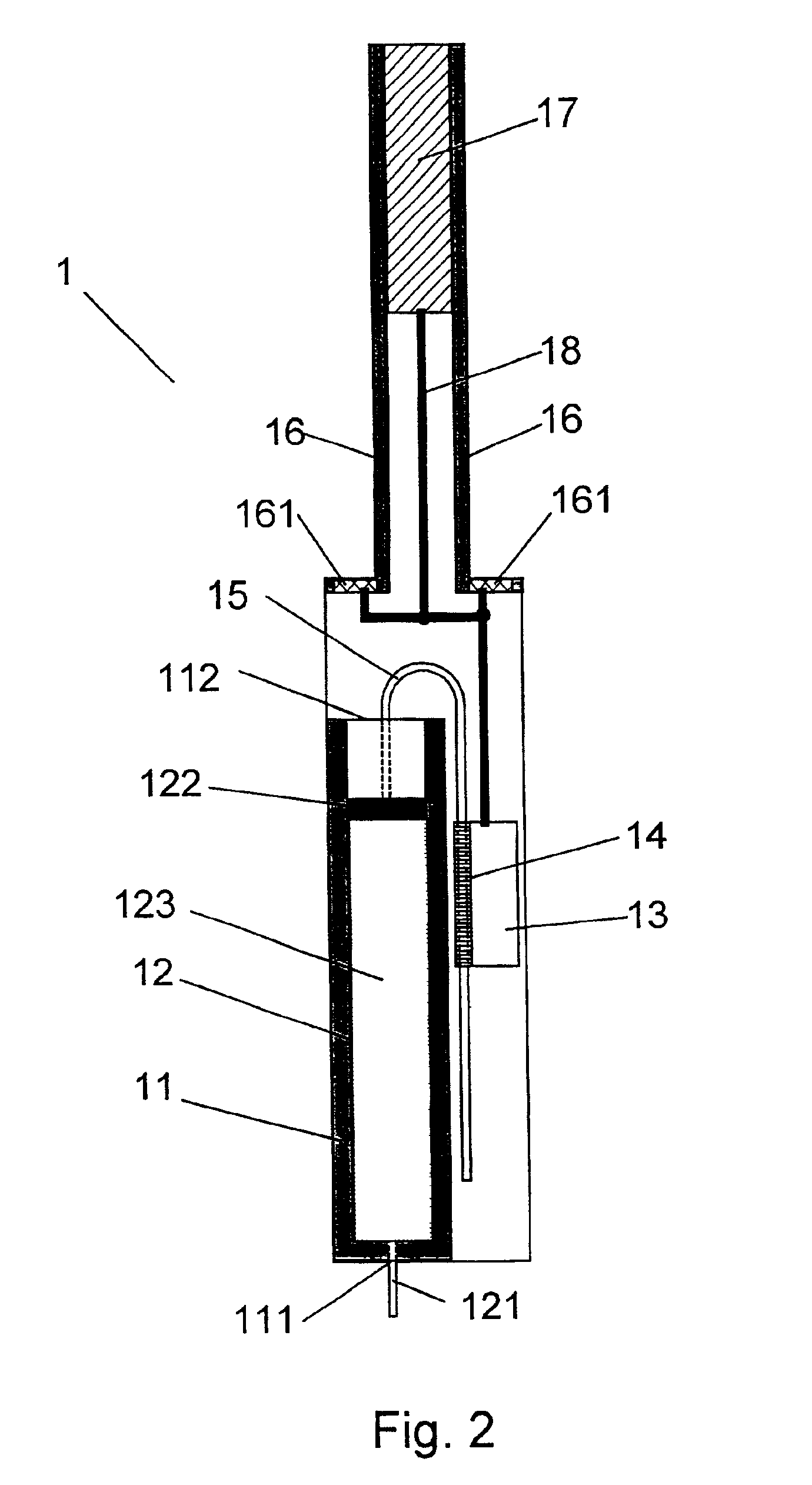

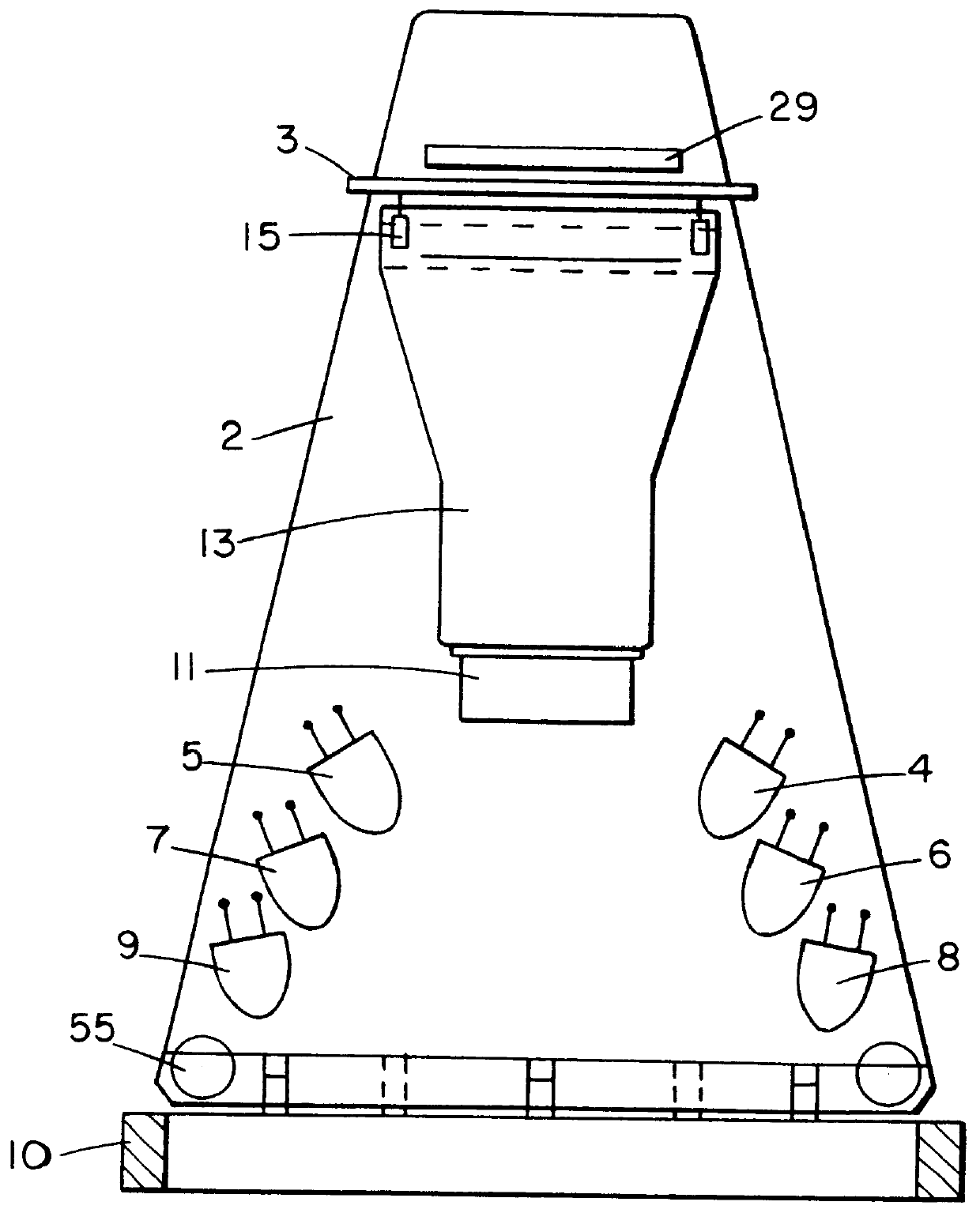

Medication delivery device with replaceable cooperating modules and a method of making same

InactiveUS6997911B2Easy to adjustAvoid repetitionJet injection syringesMedical devicesSpecific functionComputer module

The invention relates to: A medication delivery device and a method of making such a device. The object of the present invention is to provide a handy medication delivery device that may be easily adjusted to the different needs of a given user in different situations and to the different needs of different users, and which is economic from a production point of view. The problem is solved in that it comprises a basis module (1) and one or more replaceable modules (2, 3, 4, 5, 6), each of which is adapted to cooperate mechanically and / or electronically with the basis module to provide a specific function, and the basis module includes resources that are jointly used by the replaceable modules. This has the advantage of providing a rational concept for economically supplying high quality, mass-produced devices capable of being customized to individual users' needs for functionality by avoiding the duplication of key components. The invention may be used in injector type, medication pump type, inhaler or spray type devices for delivering a discrete dose or a continuous dose of a medication to a user.

Owner:NOVO NORDISK AS

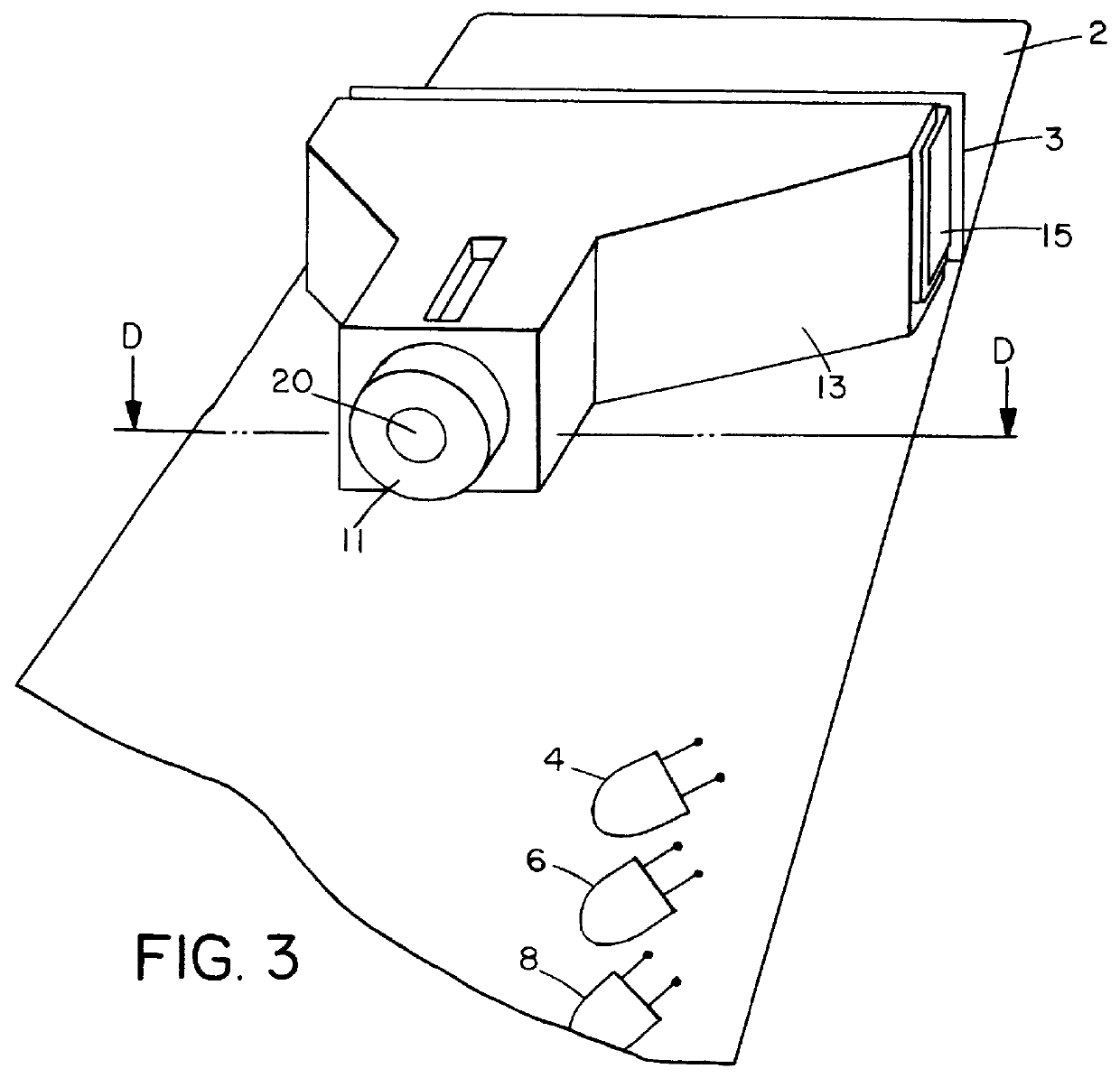

Optical scanning head

InactiveUSRE36528E1Add depthIncrease distanceVisual representatino by photographic printingPhotomechanical exposure apparatusOptical scannersBarcode

The [ornamental] design for a bar code Scanner using the Light Emitting Diode (LED), Optical Scanner assembly and Charge-Coupled Devices (CCD) capable of reading the barcode symbols at the variable distance, as shown and described. The optical passive elements for increasing the depth of field and method of fabricating the scanning head by mass-production techniques are also disclosed.

Owner:SYMBOL TECH INC

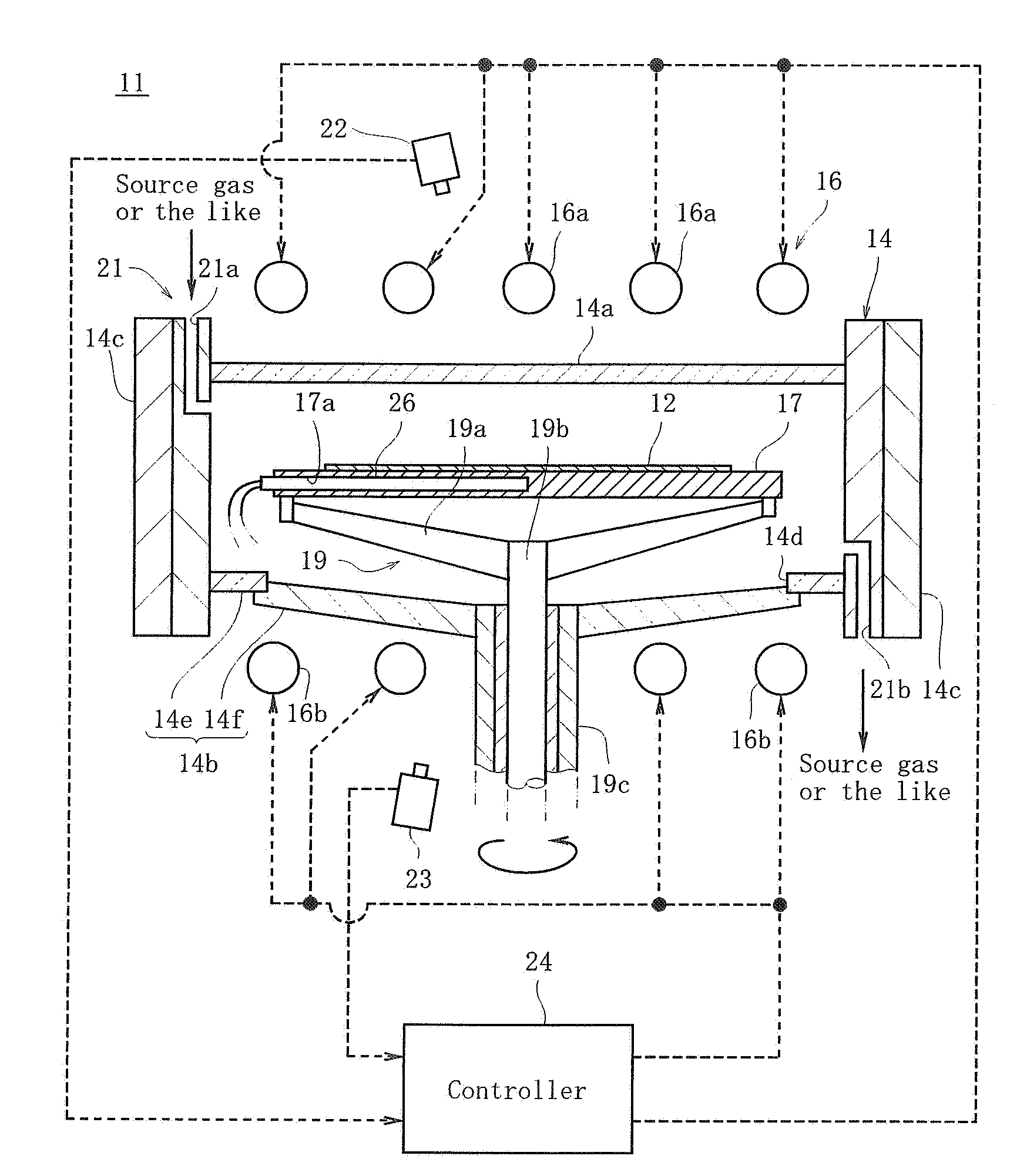

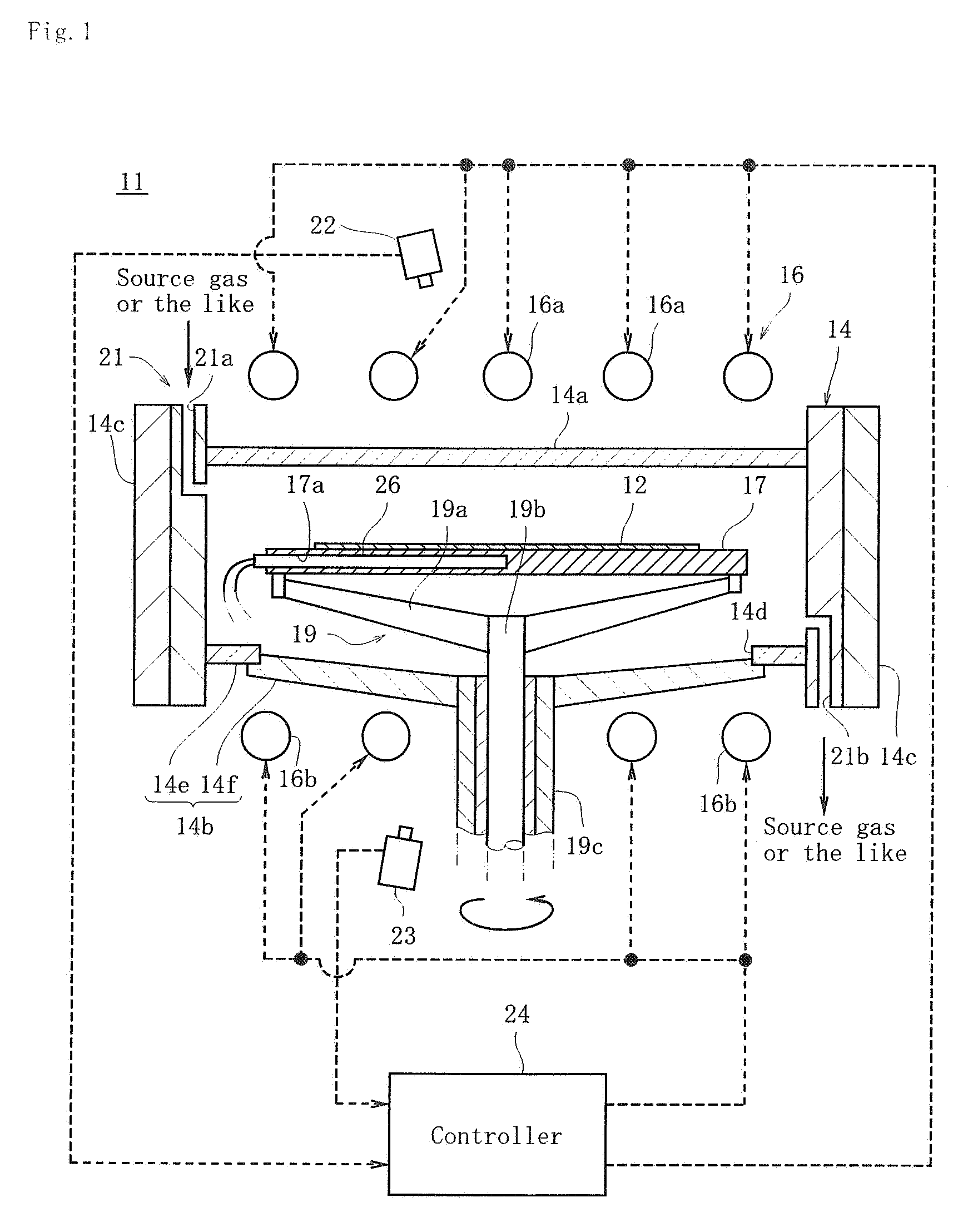

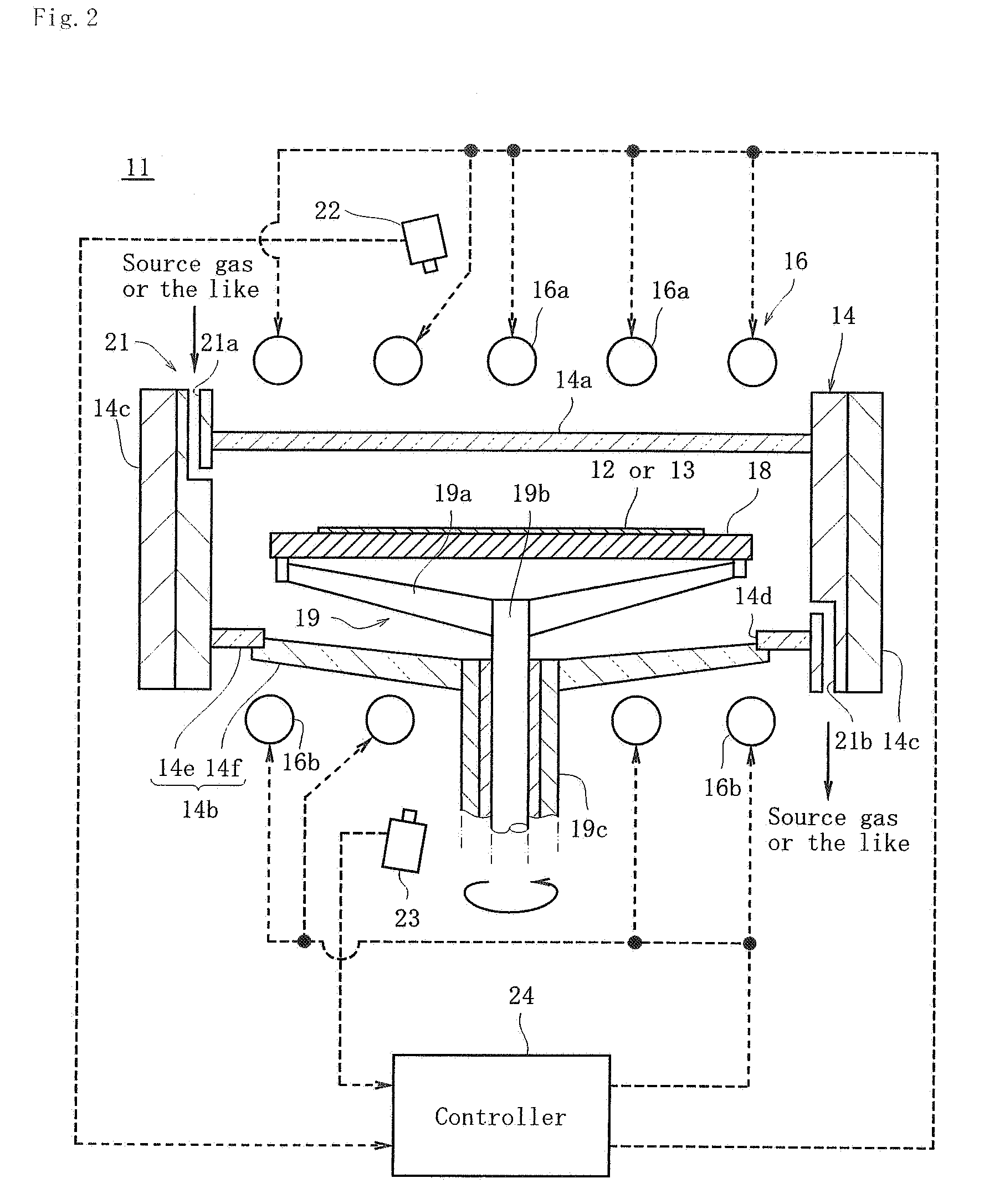

Temperature control method of epitaxial growth apparatus

ActiveUS7833348B2Accurate CalibrationQuality improvementPolycrystalline material growthThermometer testing/calibrationTemperature controlSusceptor

An object of the invention is to calibrate an upper pyrometer for indirectly measuring a substrate temperature at the time of epitaxial growth in a comparatively short time and with accuracy to thereby improve the quality of an epitaxial substrate.After calibrating an upper pyrometer by a thermocouple mounted to a temperature calibrating susceptor, a measured value of a lower pyrometer is adjusted to a calibrated value of the upper pyrometer. Then, a correlation line between substrate temperature indirectly measured by the upper pyrometer at the time of epitaxial growth onto a sample substrate and haze of a sample substrate measured immediately after epitaxial growth is set to indirectly measure a substrate temperature by the upper pyrometer at the time of epitaxial growth onto a mass-production substrate. Moreover, substrate temperature at the time of epitaxial growth onto the mass-production substrate is estimated by applying the haze of the mass-production substrate measured immediately after epitaxial growth to the correlation line and then a measured temperature of the upper pyrometer is adjusted to the estimated temperature.

Owner:SUMCO CORP

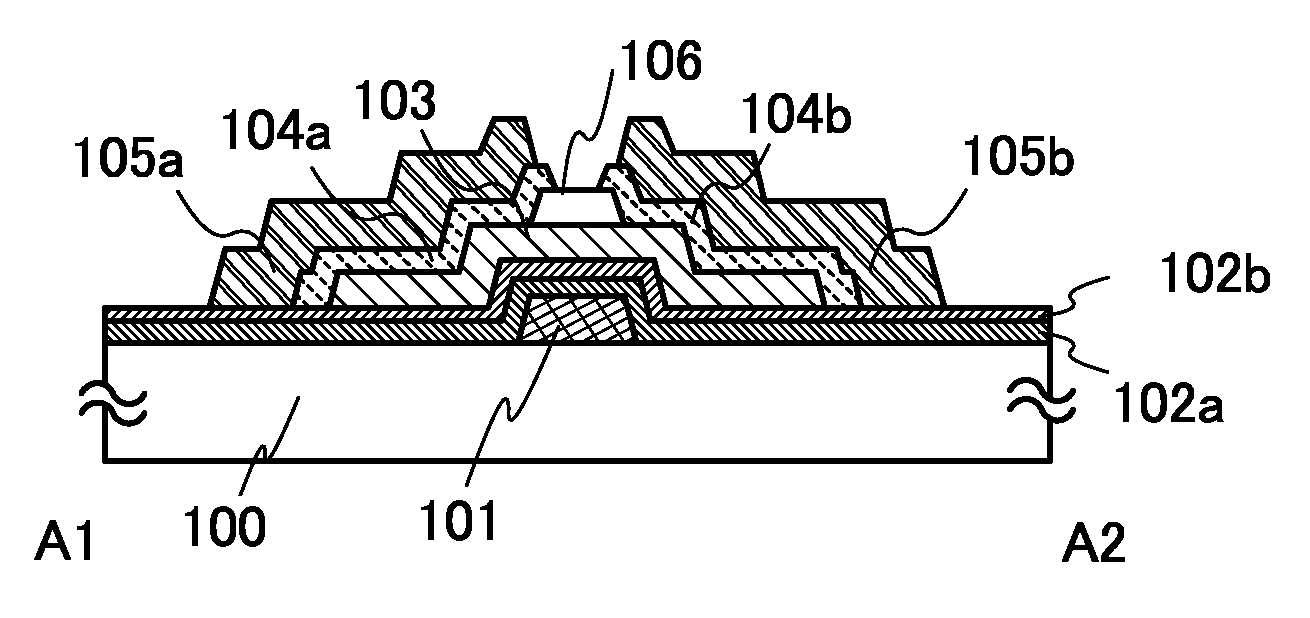

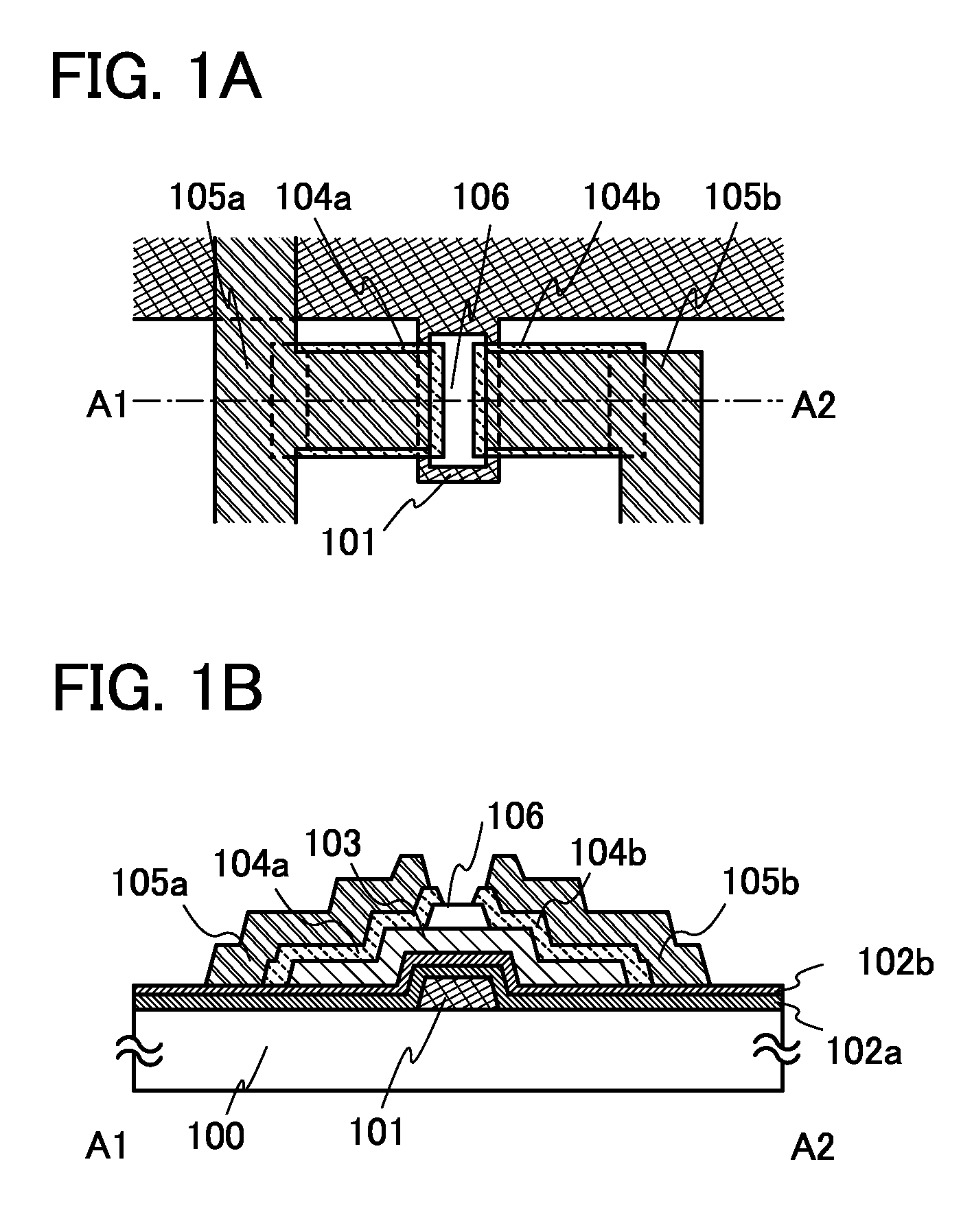

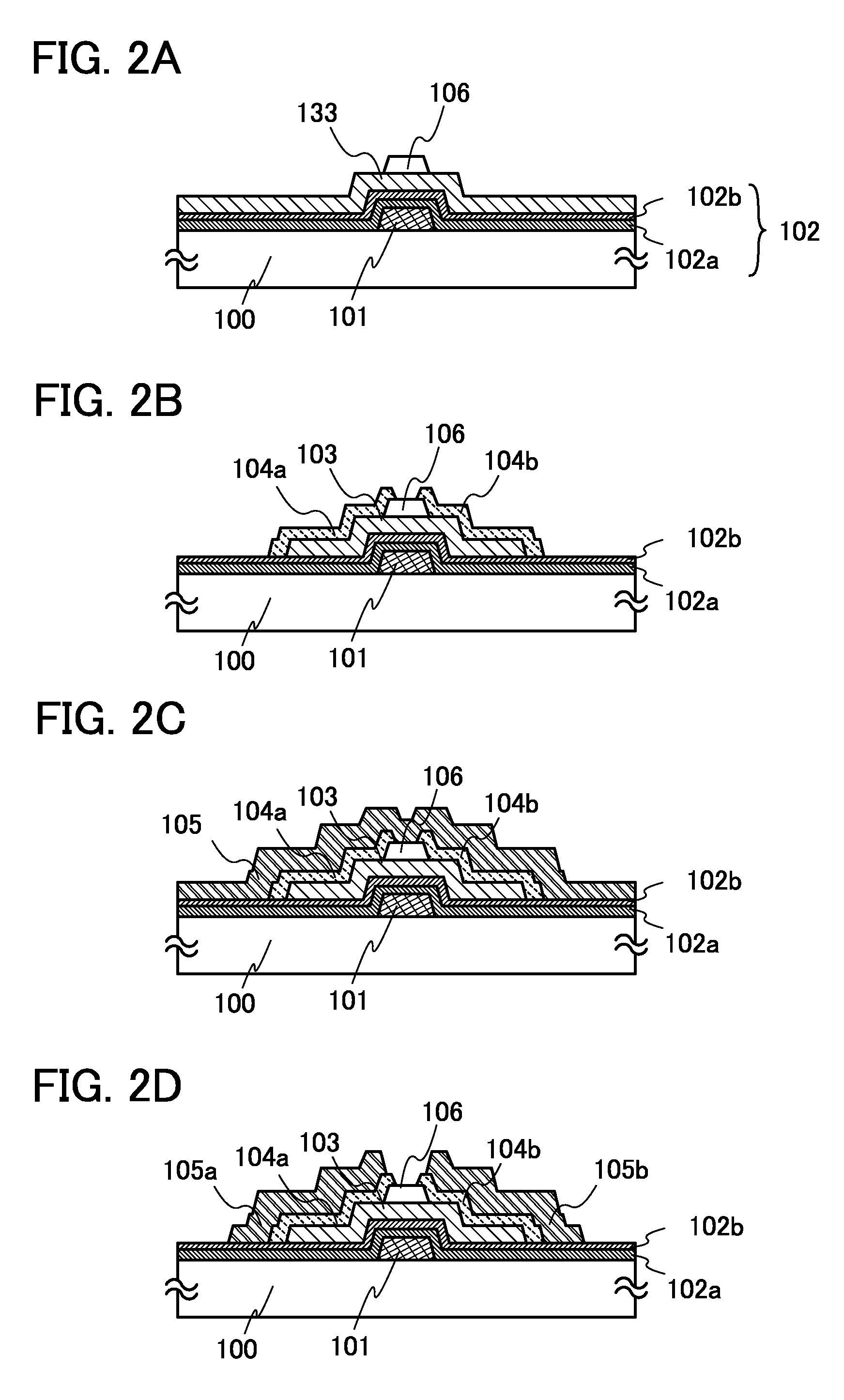

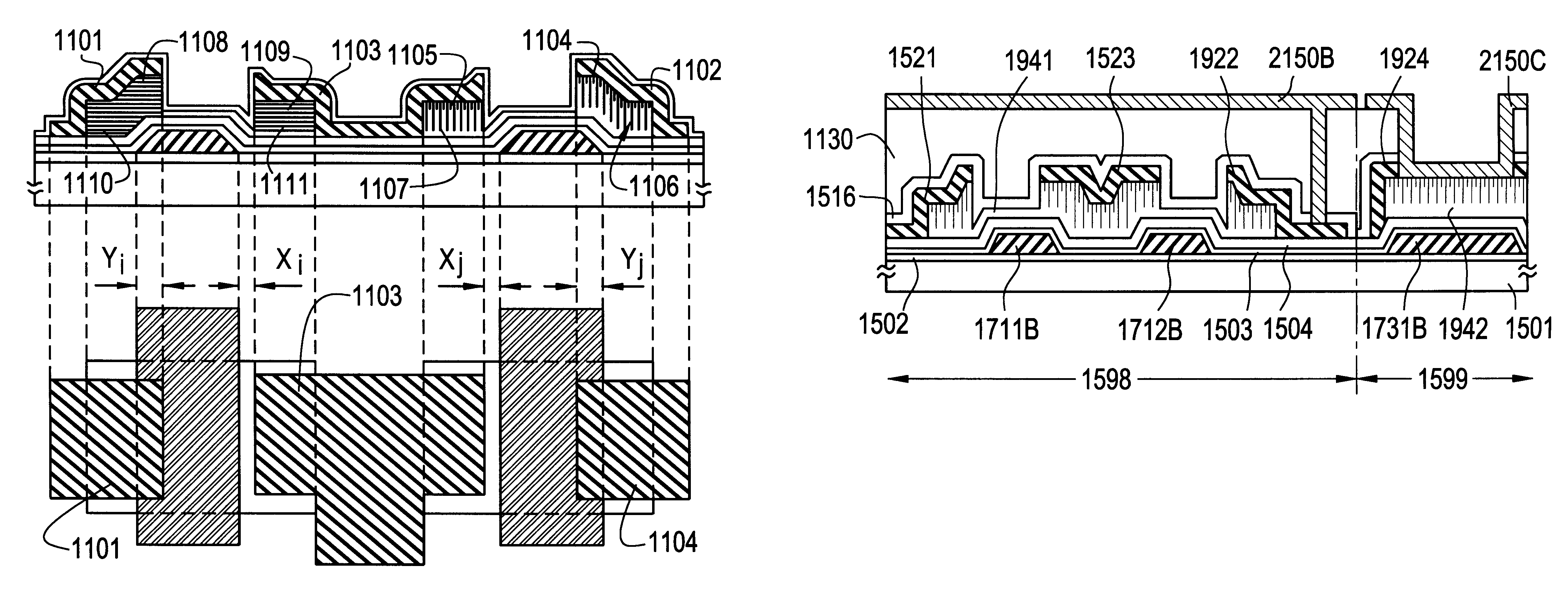

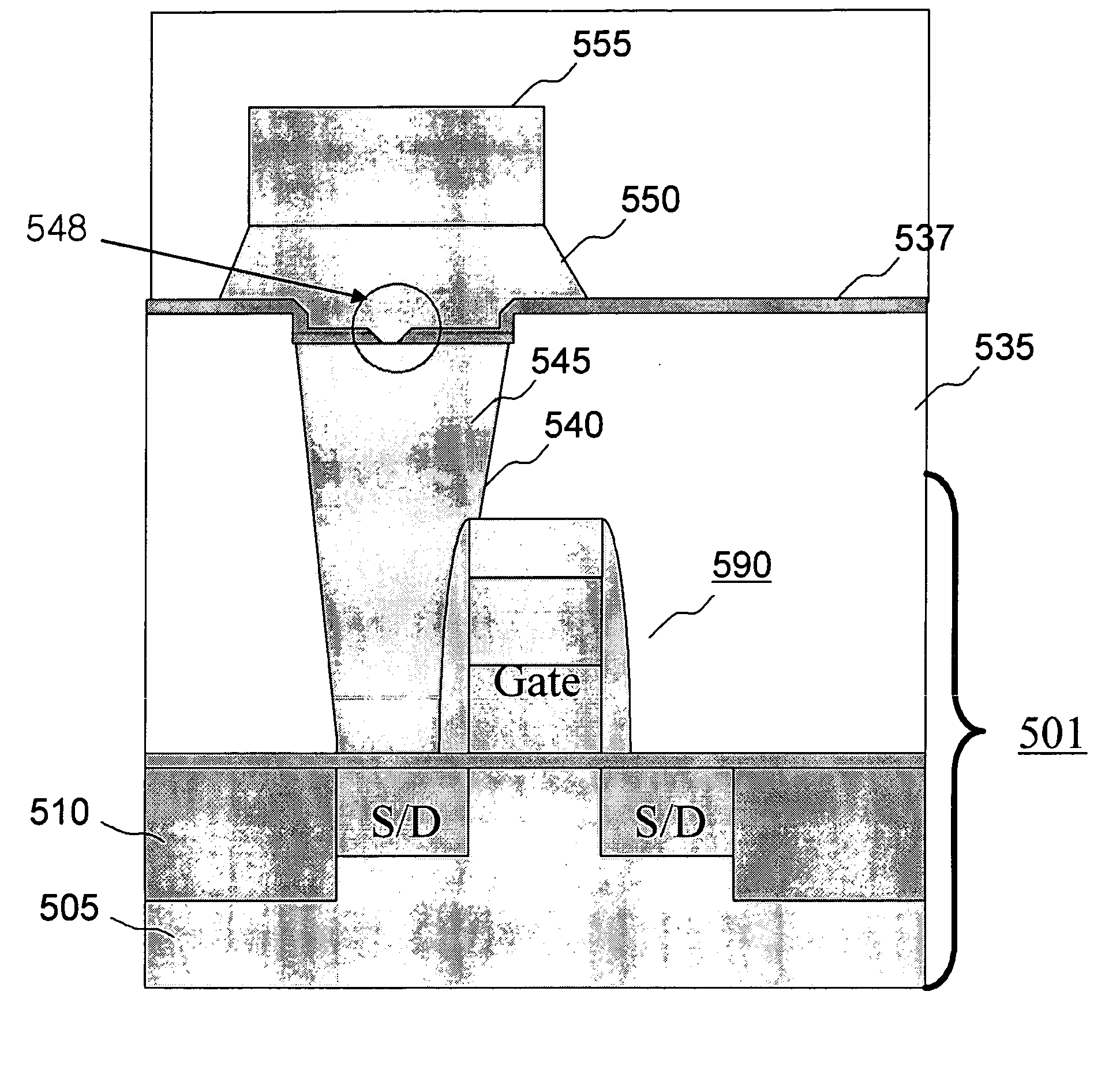

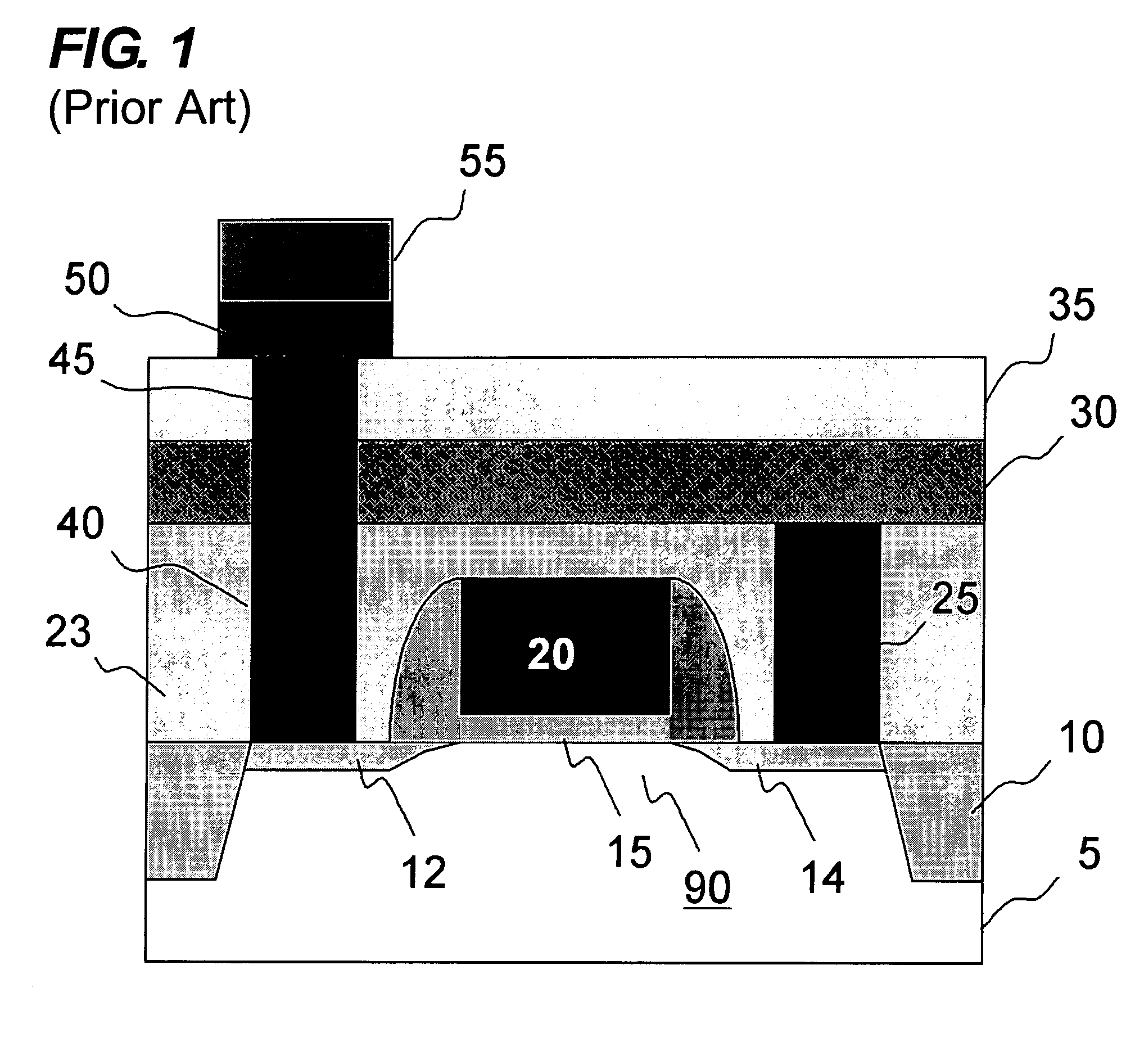

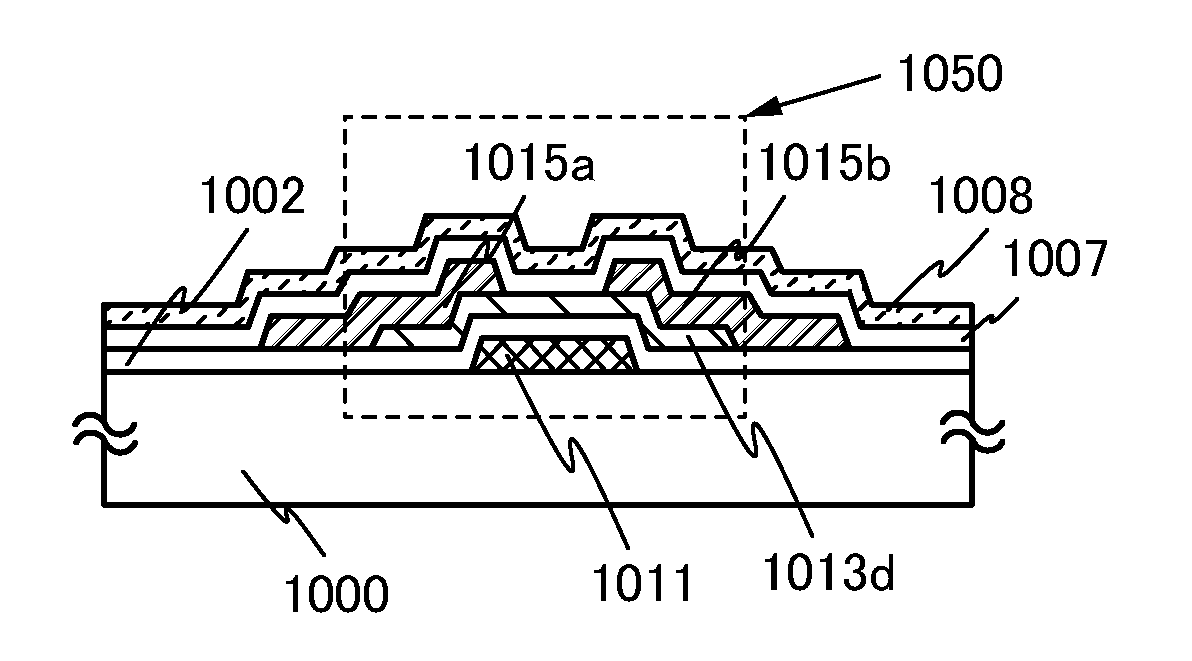

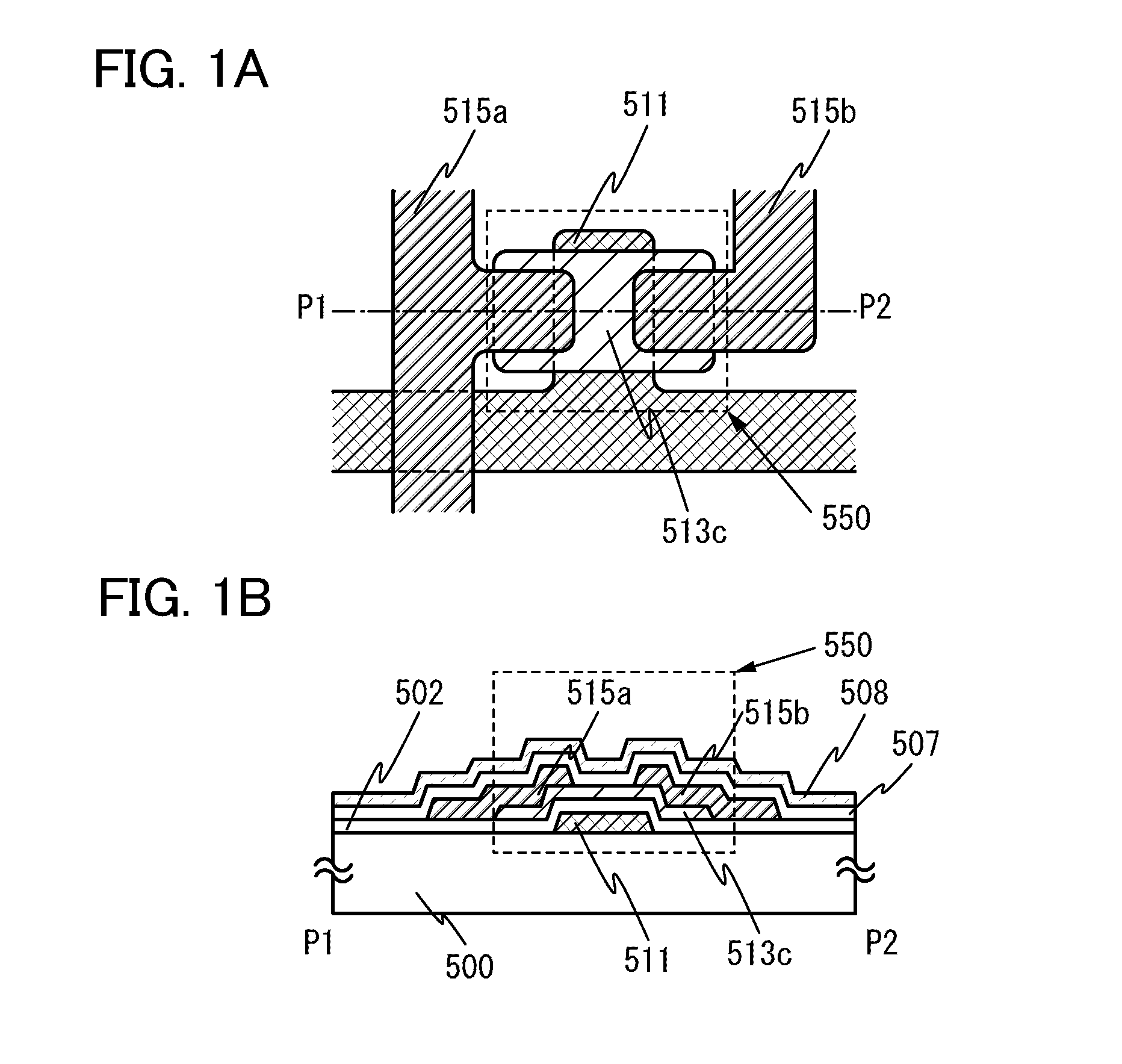

Semiconductor device and manufacturing method thereof

ActiveUS20100025677A1Small amount of photocurrentReduce parasitic capacitanceTransistorElectroluminescent light sourcesProduction rateCharge carrier

To provide a semiconductor device including a thin film transistor having excellent electric characteristics and high reliability and a manufacturing method of the semiconductor device with high mass productivity. The summary is that an inverted-staggered (bottom-gate) thin film transistor is included in which an oxide semiconductor film containing In, Ga, and Zn is used as a semiconductor layer, a channel protective layer is provided in a region that overlaps a channel formation region of the semiconductor layer, and a buffer layer is provided between the semiconductor layer and source and drain electrodes. An ohmic contact is formed by intentionally providing the buffer layer having a higher carrier concentration than the semiconductor layer between the semiconductor layer and the source and drain electrodes.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and fabrication method thereof

To provide a semiconductor device having high mass production performance and high reliability and reproducibility by simple fabrication steps, in a constitution of a semiconductor device of a bottom gate type formed by a semiconductor layer having a crystal structure, source and drain regions are constituted by a laminated layer structure comprising a first conductive layer (n+ layer), a second conductive layer (n- layer) having resistance higher than the first conductive layer and an intrinsic or a substantially intrinsic semiconductor layer (i layer) in which the n- layer functions as an LDD region and the i layer functions as an offset region in a film thickness direction.

Owner:SEMICON ENERGY LAB CO LTD

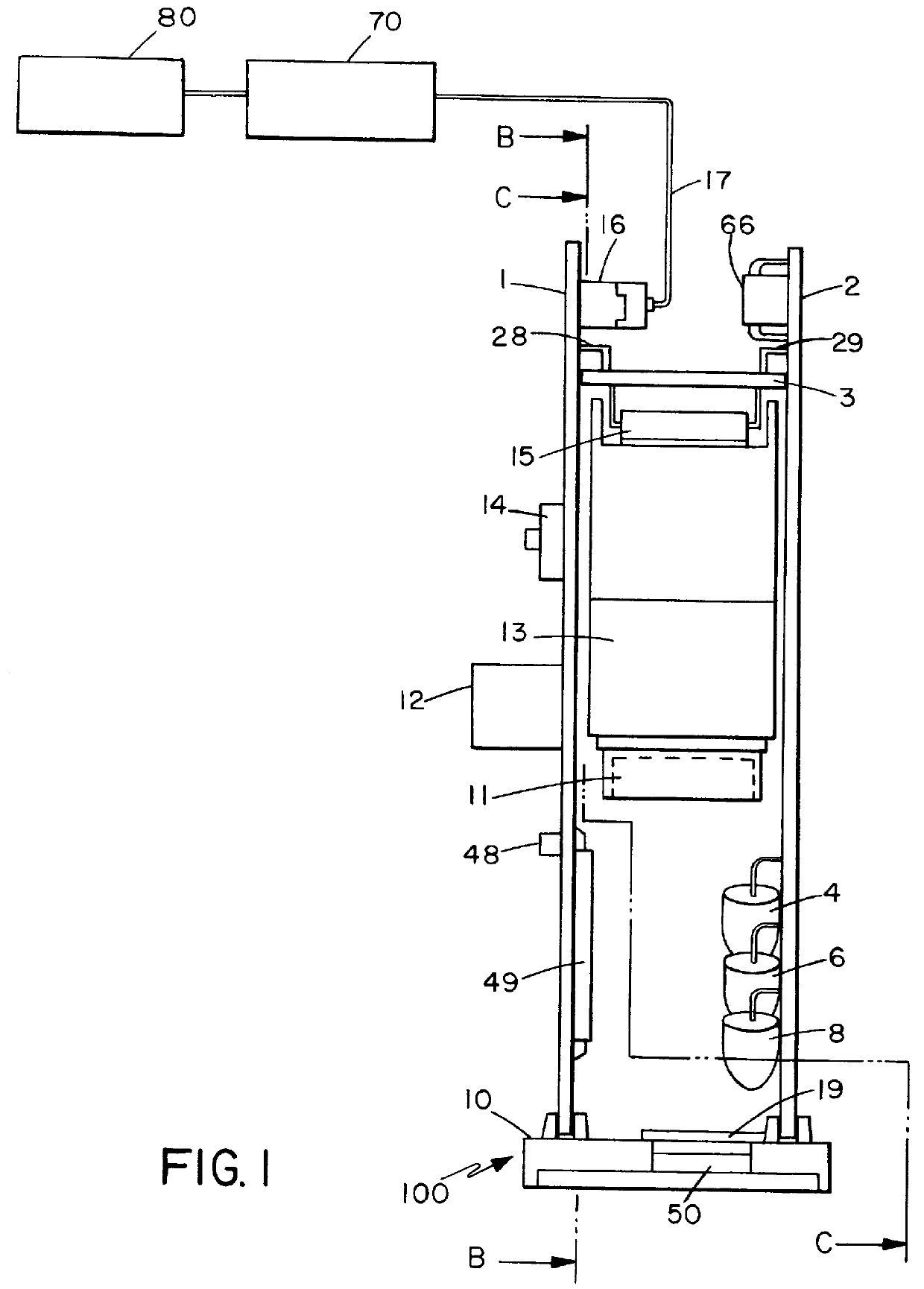

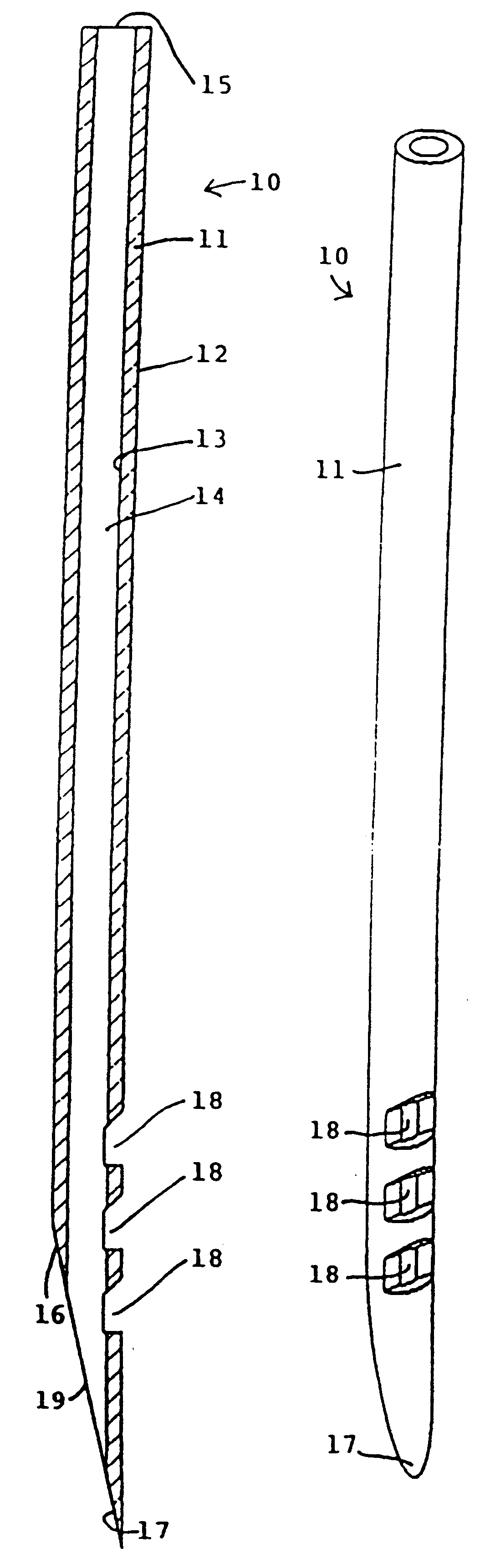

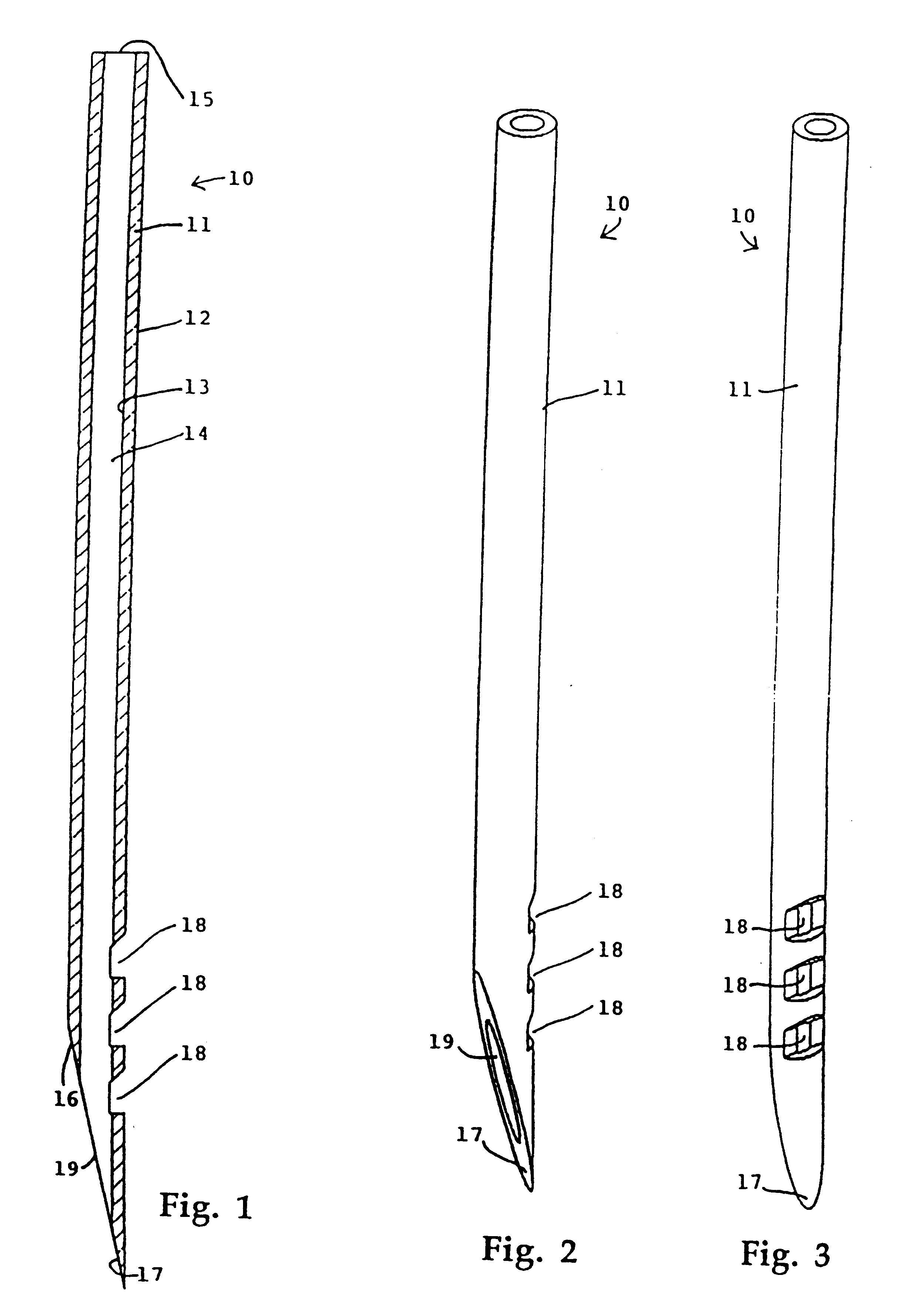

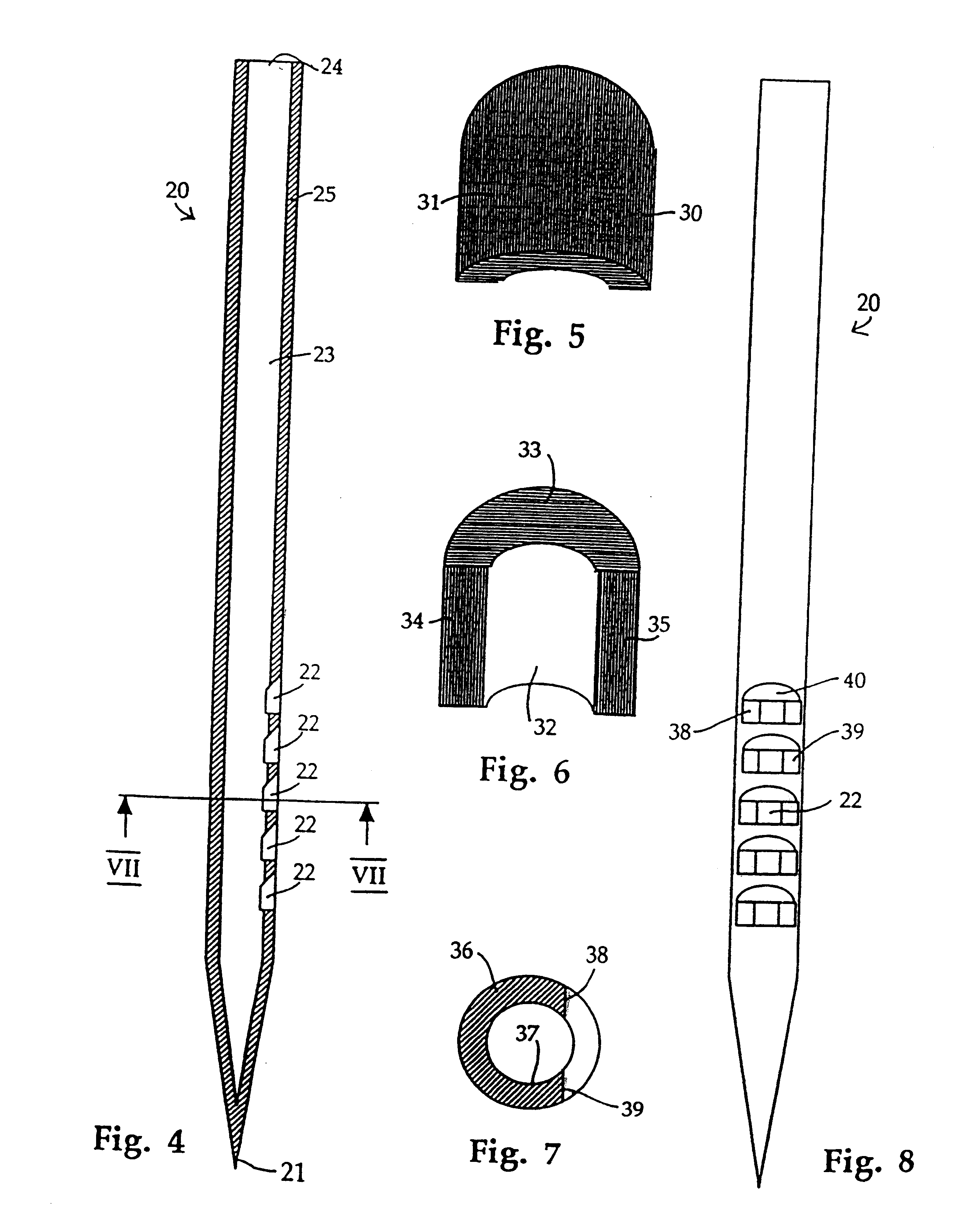

Needle and method for delivery of fluids

InactiveUS6346095B1Low costEasy to manufactureAutomatic syringesInfusion needlesBiomedical engineeringSeries production

A needle (10) for the delivery of a liquid to a subject comprises a shaft (11) having an internal surface defining a longitudinally extending internal bore open at one end (15) to receive a liquid supply, the other end (16) being sharpened for penetration of the skin of the subject. A plurality of apertures (18) are provided, each in the form of a cut extending across the external surface of the side of the shaft (11) at a sufficient depth to establish communication with the bore. The external aperture area is approximately three times greater than the internal aperture area, thereby ensuring that the liquid is delivered to a large surface area of tissue to improve absorption and eliminate fluctuations in the delivery rate. The needle (10) can be mass-produced by aligning a batch of shafts alongside one another and running a grinder across the surfaces of the shafts to create the apertures (18) in the entire batch of needles simultaneously.

Owner:ALKERMES PHARMA IRELAND LTD

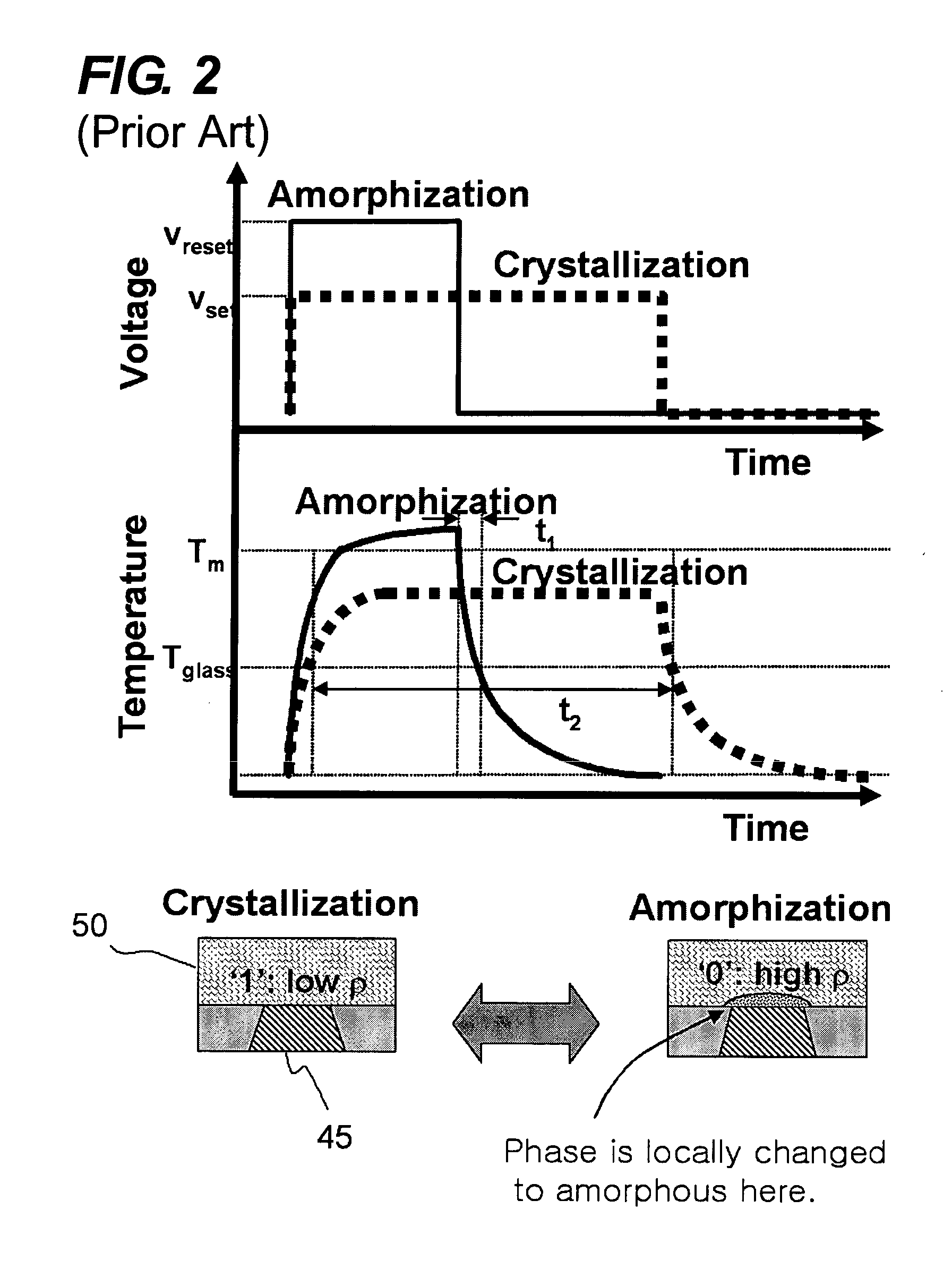

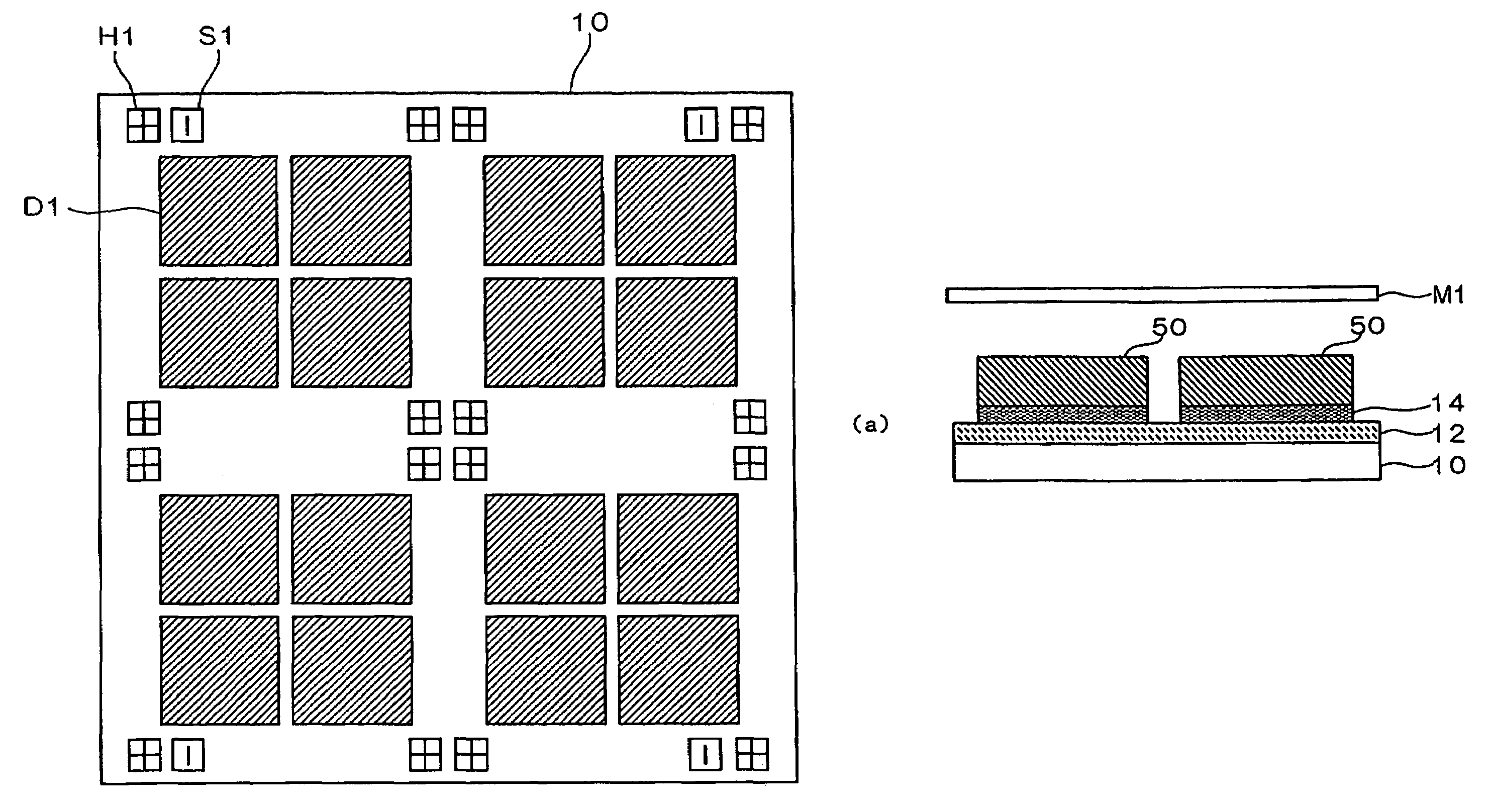

Phase-change memory device and manufacturing method thereof

InactiveUS20050018526A1Easy to manufactureHigh yield rateSolid-state devicesDigital storagePhase-change memoryDielectric layer

The present invention is to provide a phase change memory device having a new structure which can be easily manufactured by mass-production with a high yield rate, therefore, reducing the cost of process and providing reliable device characteristics, and a manufacturing method thereof. The present invention provides a phase-change memory device comprising: a lower dielectric layer; a lower electrode, at least a part of the lateral surface of the lower electrode being surrounded by the lower dielectric layer; a thin dielectric layer including a pore having smaller area than the top surface of the lower electrode, aligned to the top surface of the lower electrode and extending to the top surface of the lower electrode; and a phase-change resistor filling the pore and formed on the thin dielectric layer. In the proposed structure of the present invention, the pores or local damaged spots can provide a micro path of current and localize the phase-changing volume in the phase-change resistor. Thus, the phase-change memory device can be operated with very low power.

Owner:LEE HEON

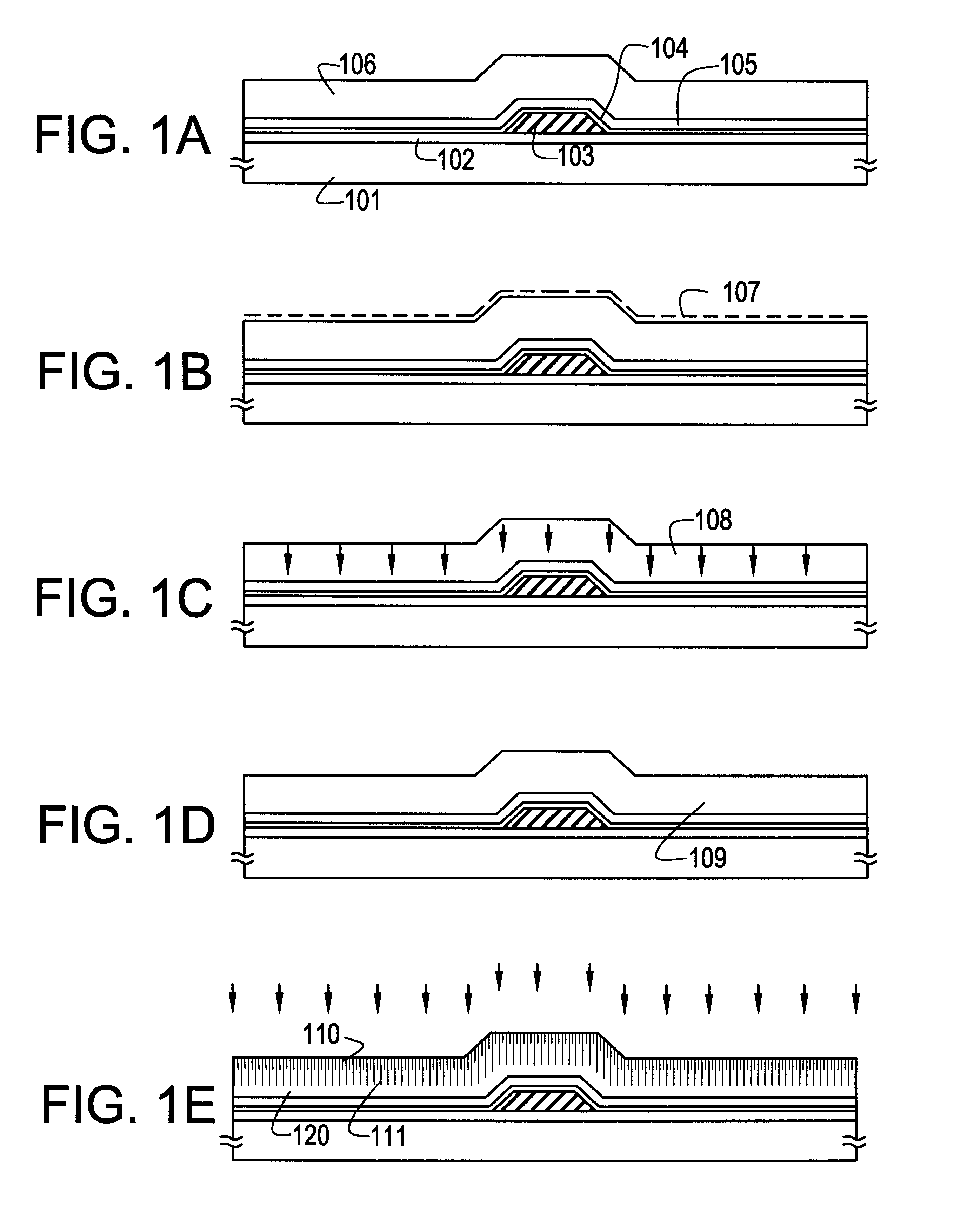

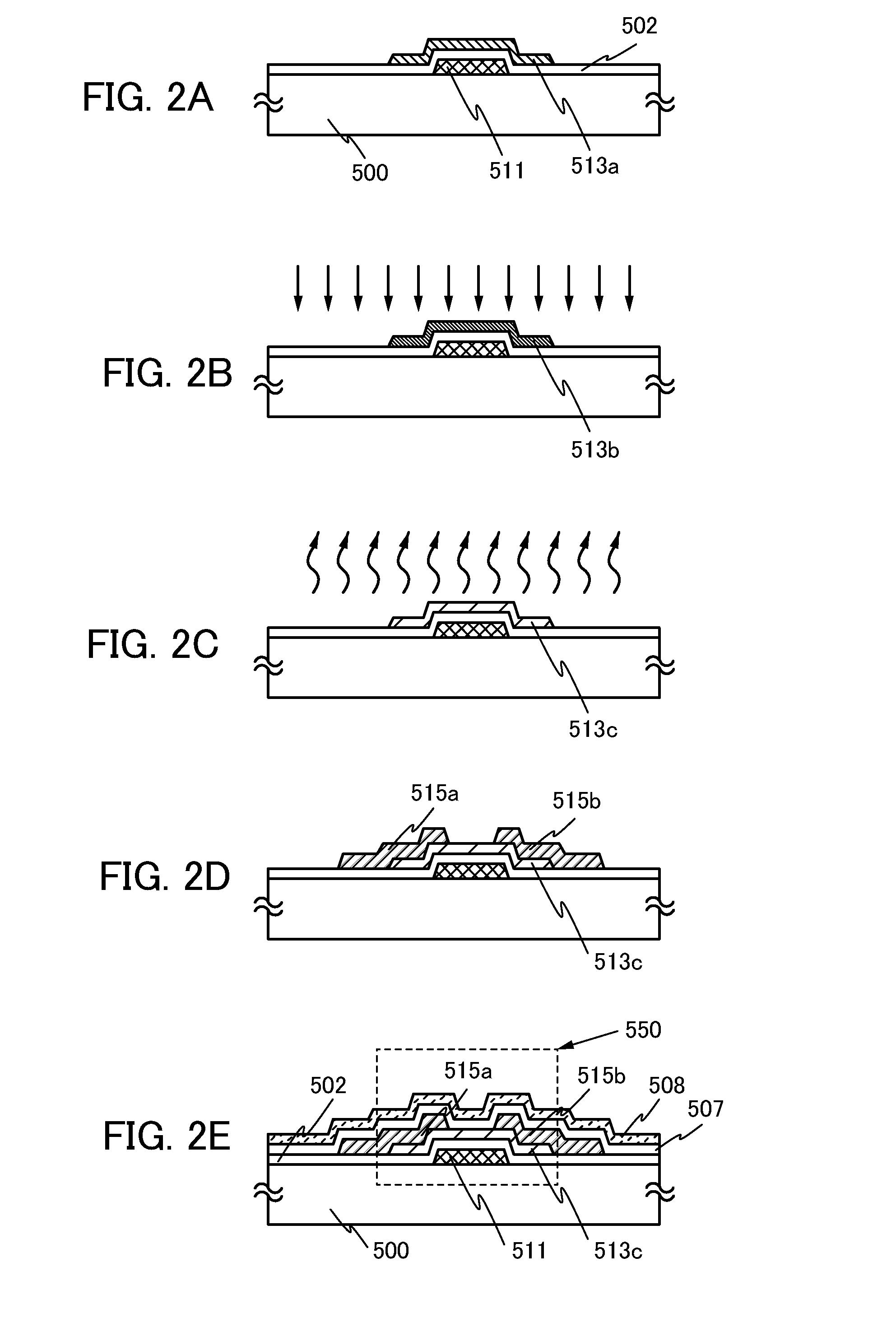

Method for fabricating semiconductor device, and electro-optical device, integrated circuit and electronic apparatus including the semiconductor device

InactiveUS7547589B2High resolutionDecrease productivityTransistorOther printing matterProduction rateEngineering

The invention provides a technique that enables formation of minute patterns on an uneven substrate in volume production without reducing productivity. The method for fabricating a semiconductor device includes: first patterning a semiconductor film on a substrate to form element regions, each of which will be provided with a source / drain region and a channel region, second forming a gate insulating film covering segments of the patterned semiconductor film in the respective element regions, third forming gate electrodes on the gate insulating film at predetermined positions, and fourth forming the source / drain region and the channel region in each element region. At least the gate electrodes are formed by a process including an exposure step through a holographic exposure mask in the third step, and by a process including an exposure step through a projection exposure mask, the element regions are formed in the first step, and the source / drain regions and the channel regions are formed in the fourth step.

Owner:SEIKO EPSON CORP

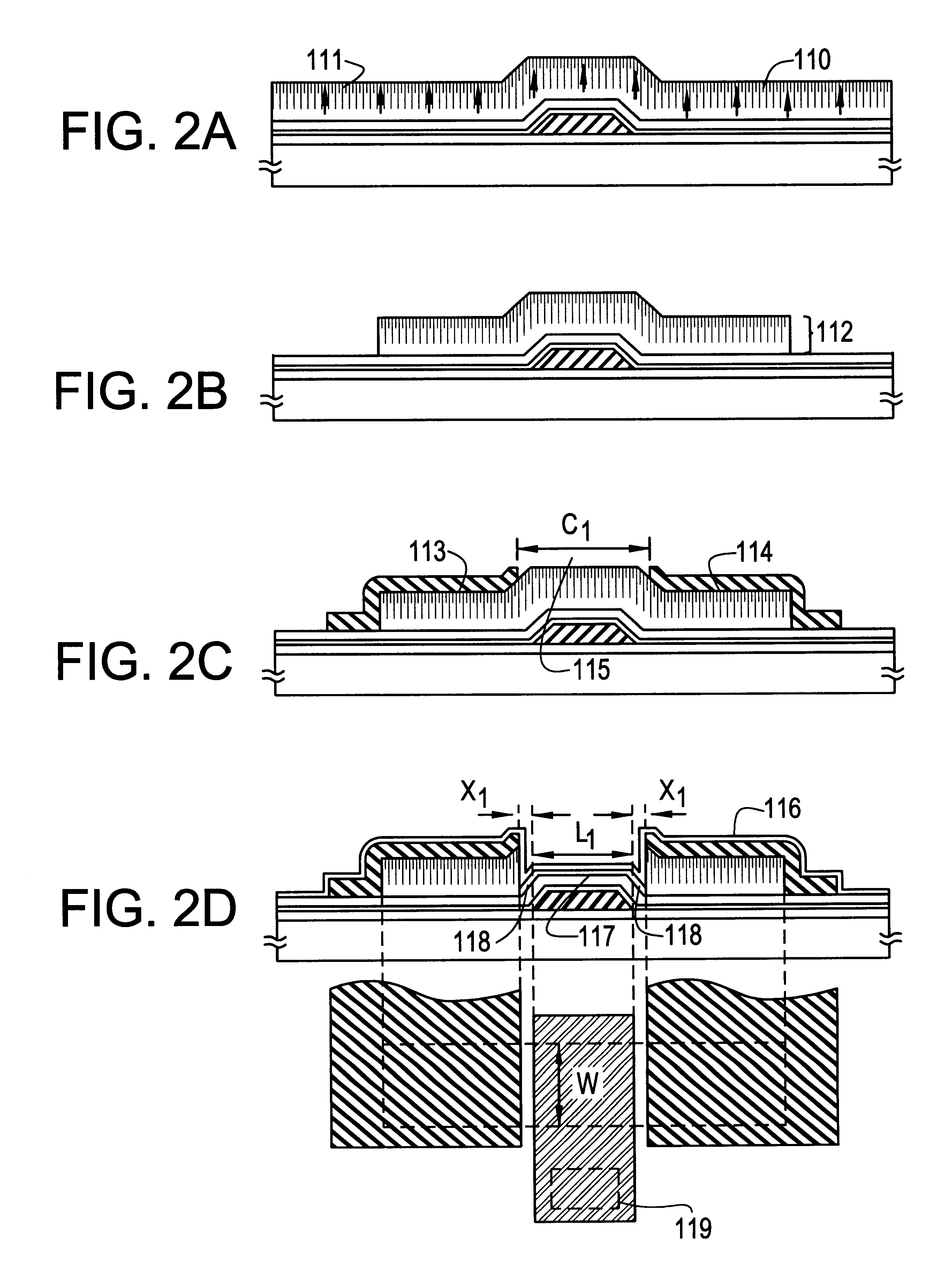

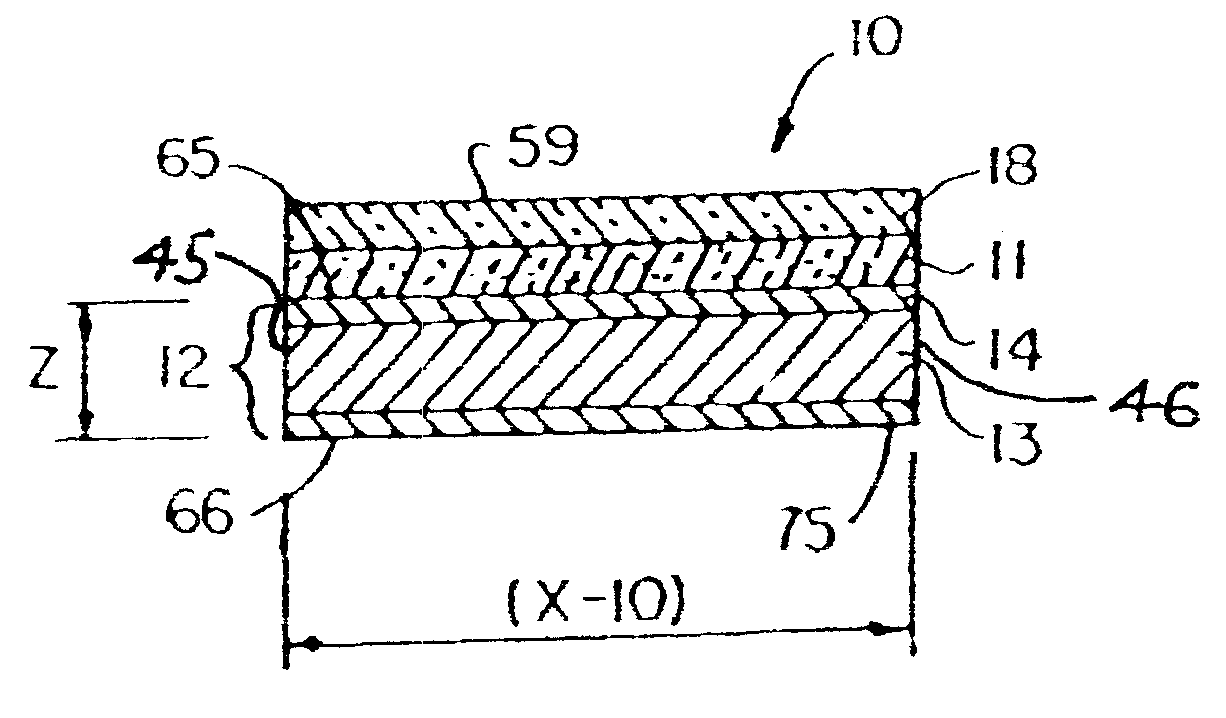

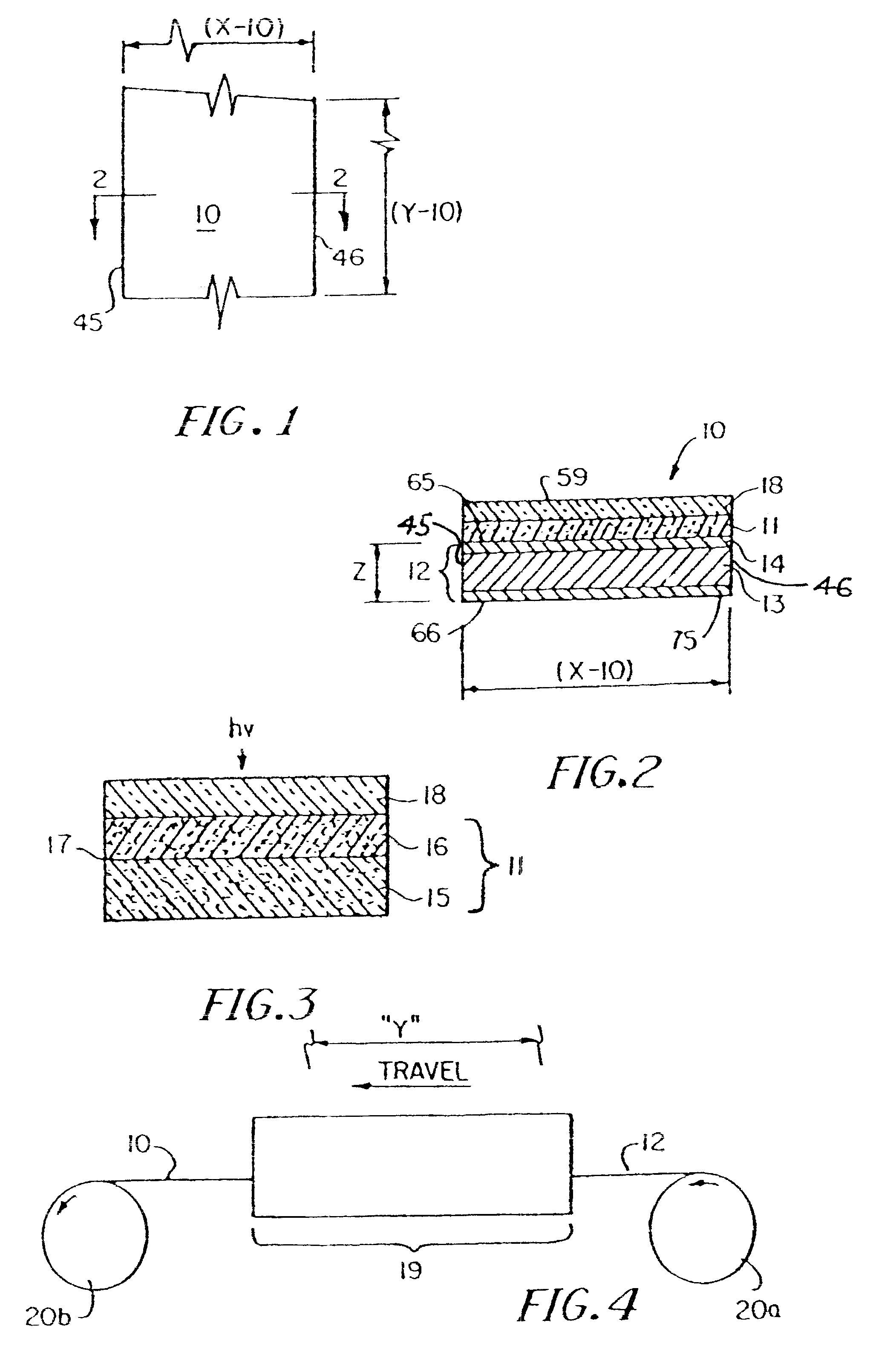

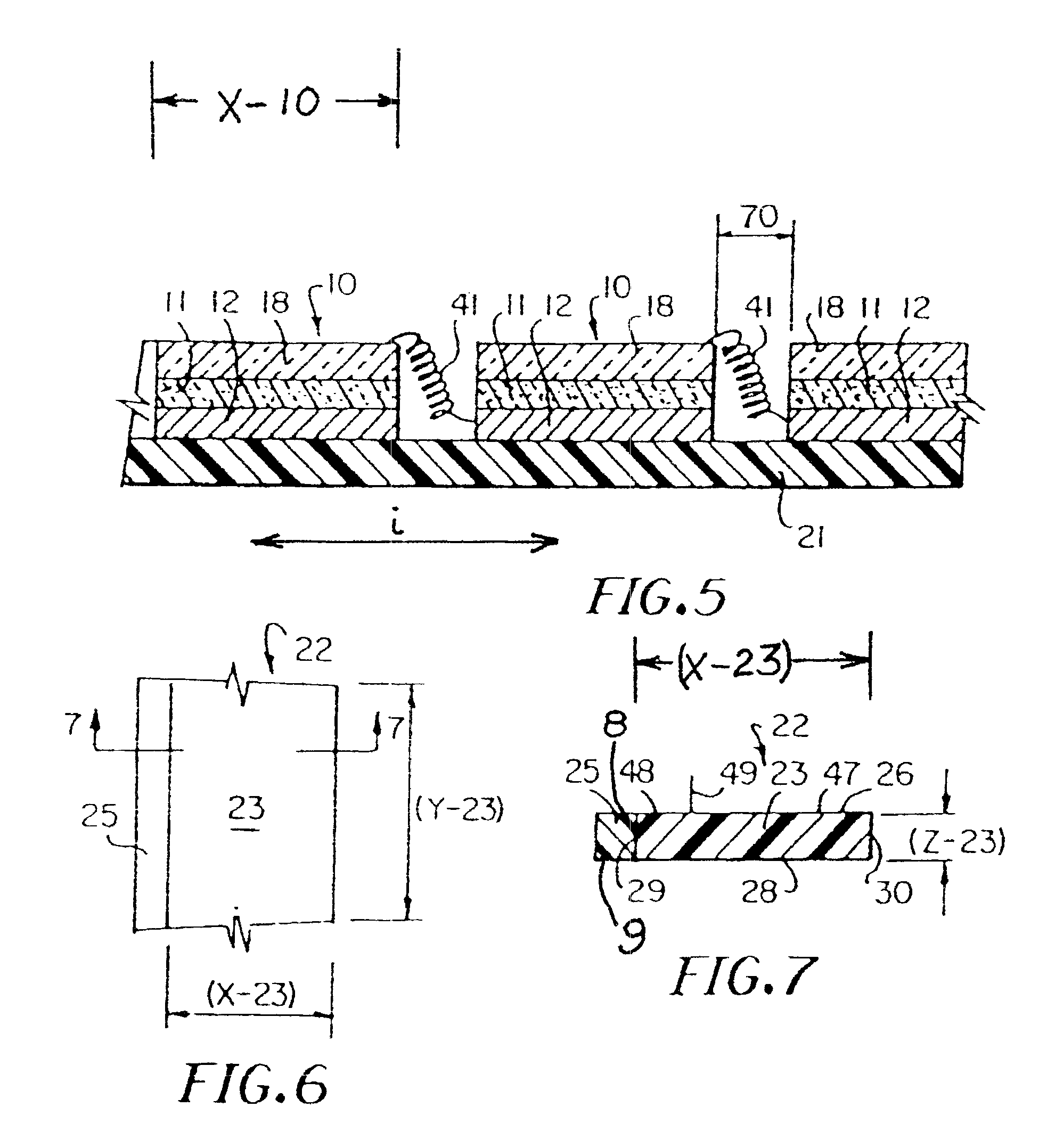

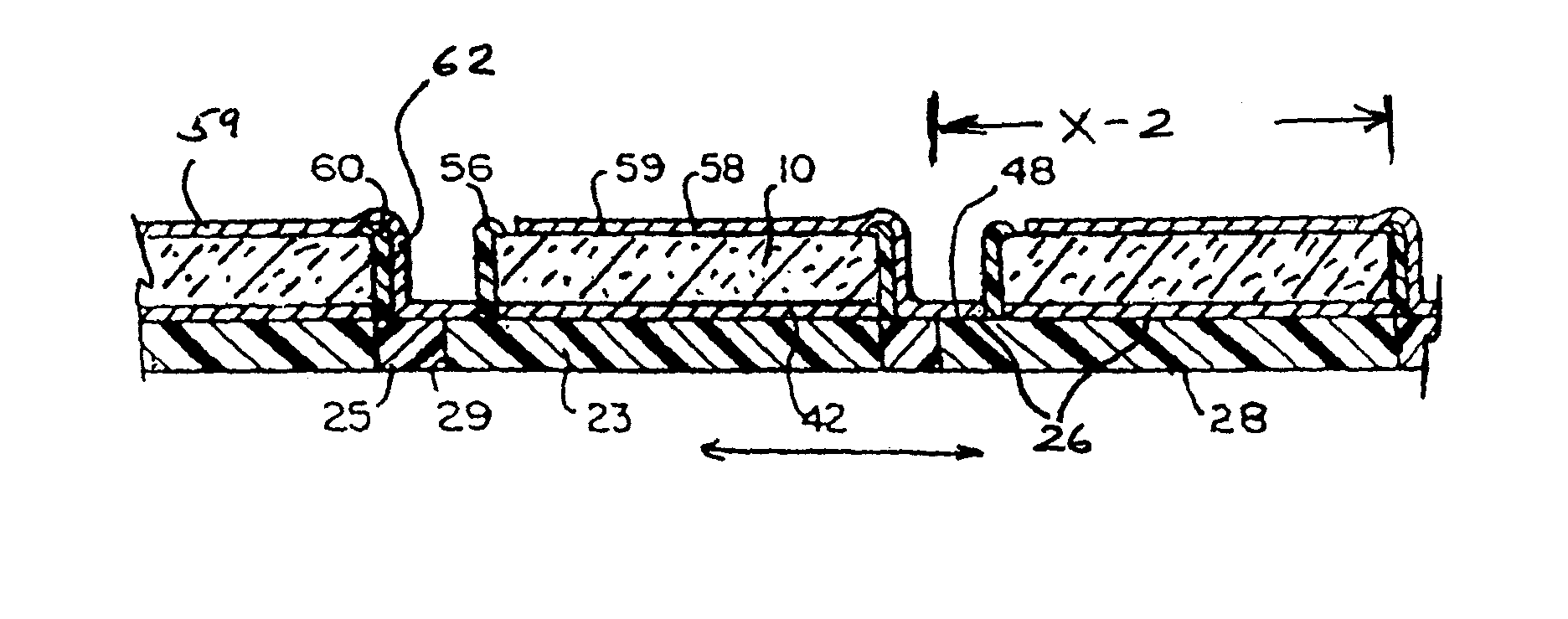

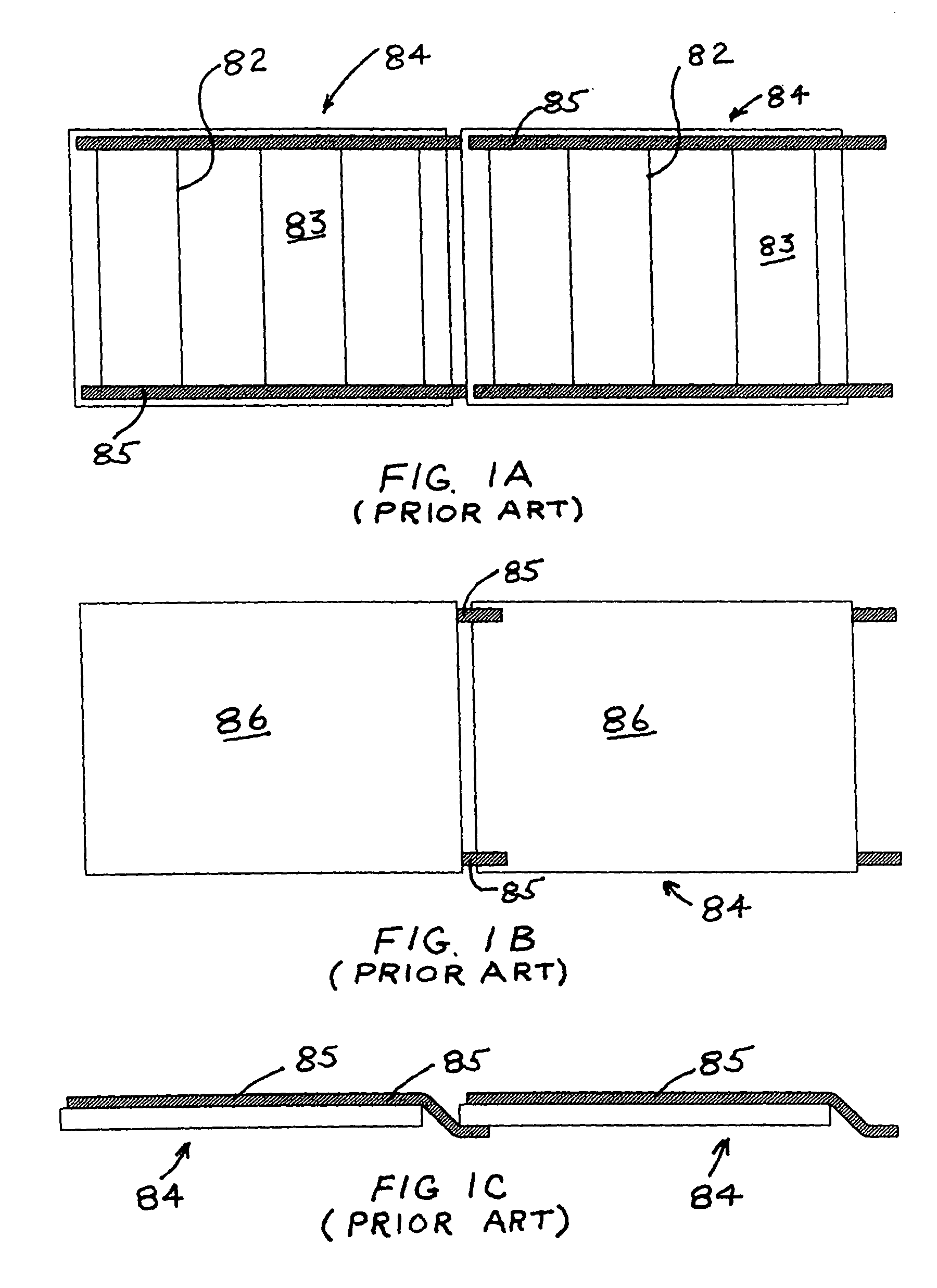

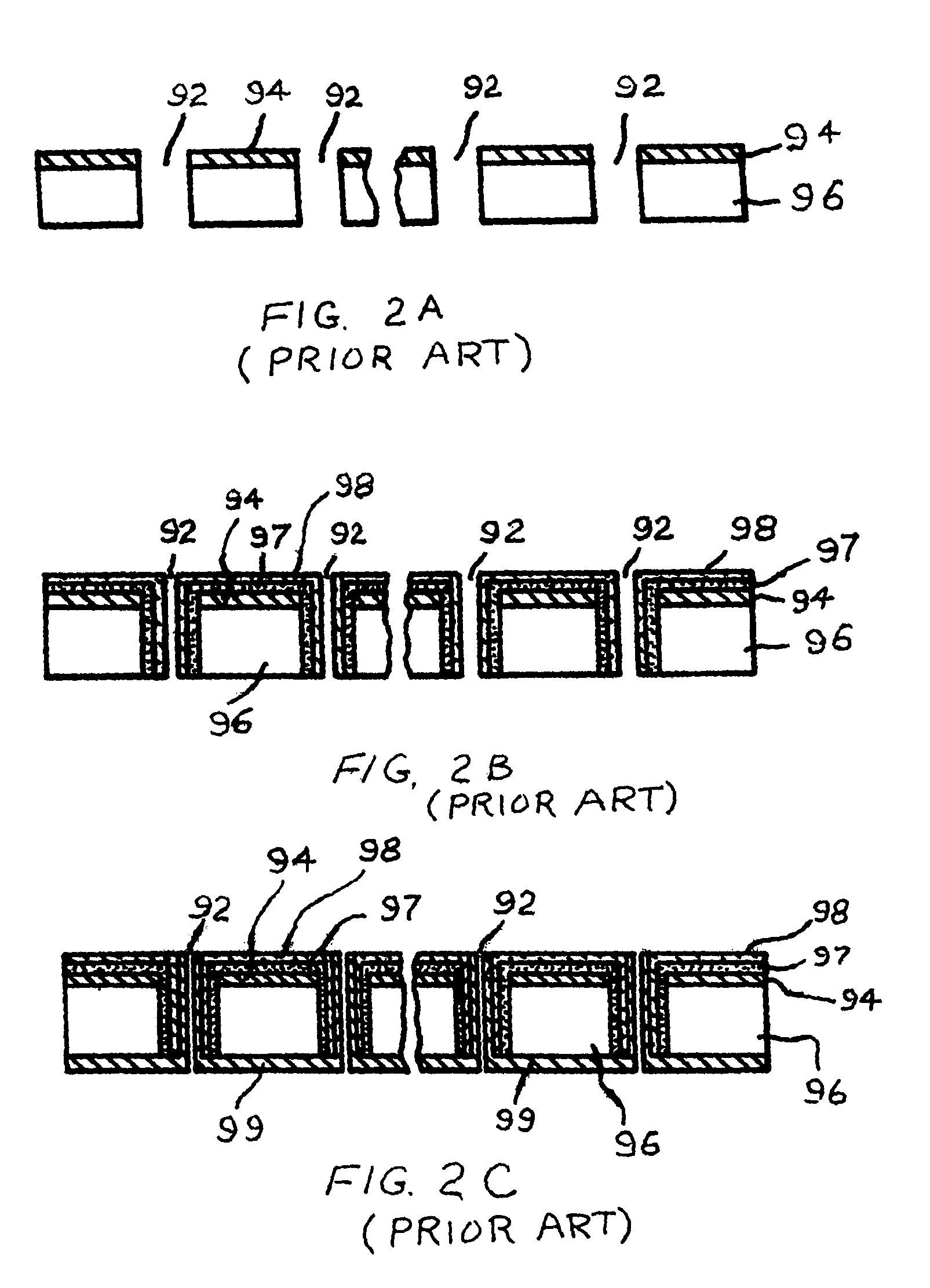

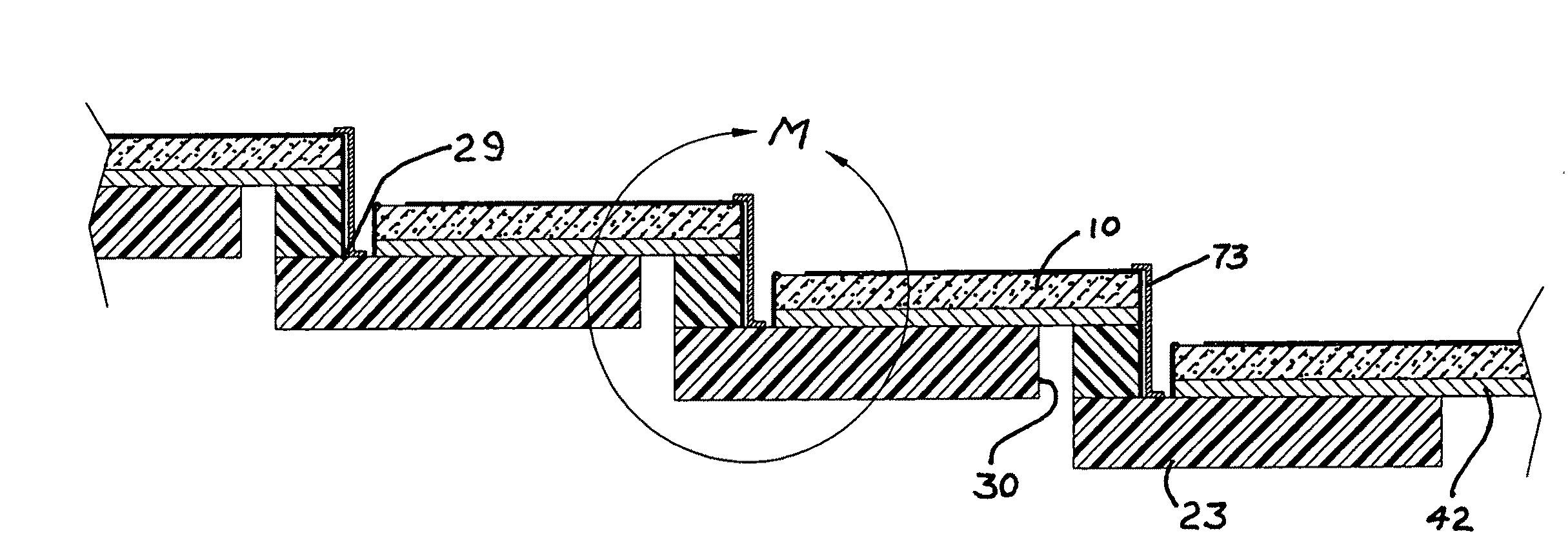

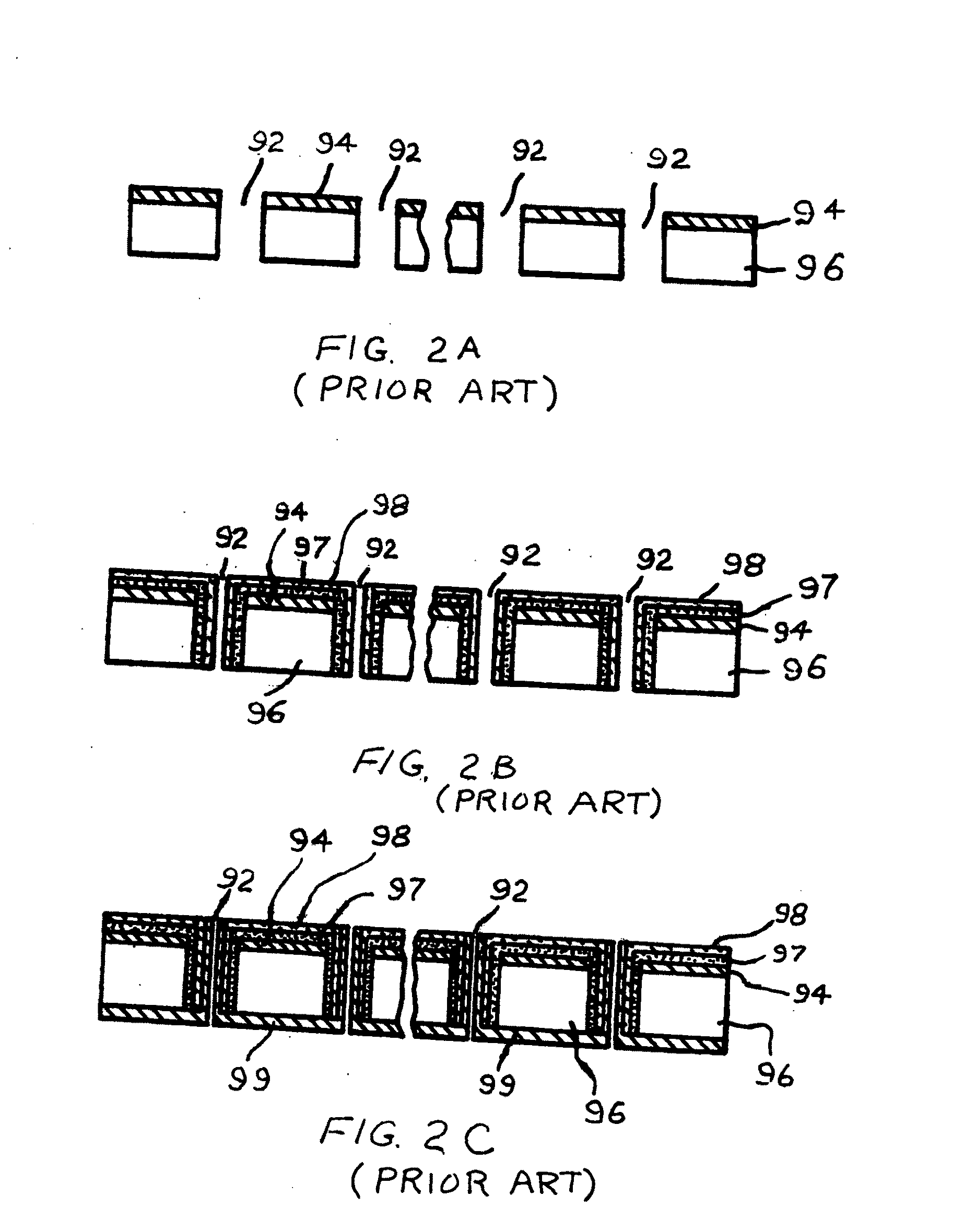

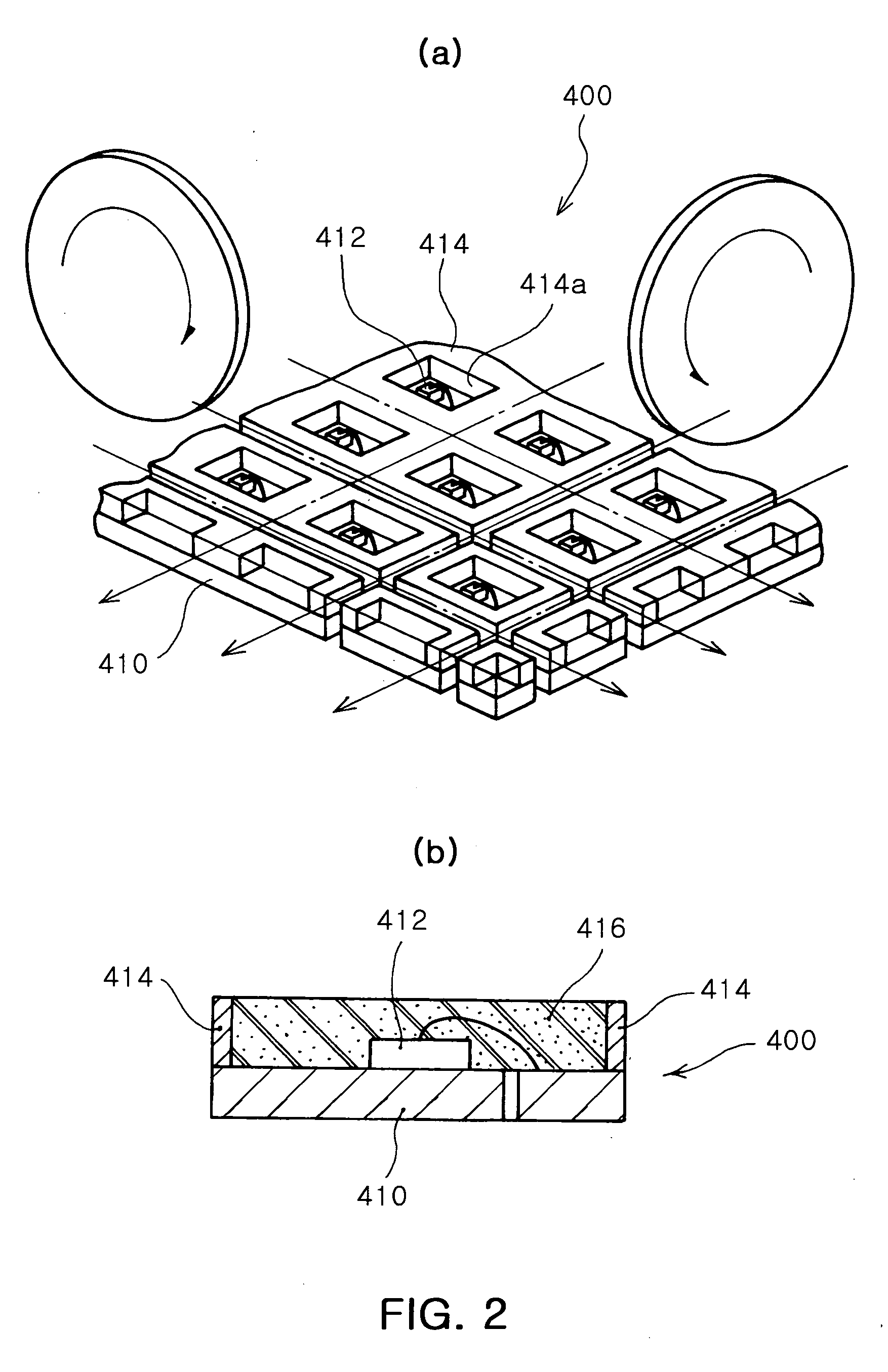

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS6459032B1Eliminate deficienciesCheap productionPV power plantsSolid-state devicesMaterial removalEngineering

This invention comprises deposition of thin film photovoltaic junctions on conductive foil substrates which can be heat treated following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is produced in a continuous roll-to-roll fashion. The conductive foil supported photovoltaic junction is then laminated to the interconnection substrate structure and conductive connections are deposited to complete the module or array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials since it does not have to endure high temperature exposure. Furthermore, the photovoltaic junction and its conductive foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

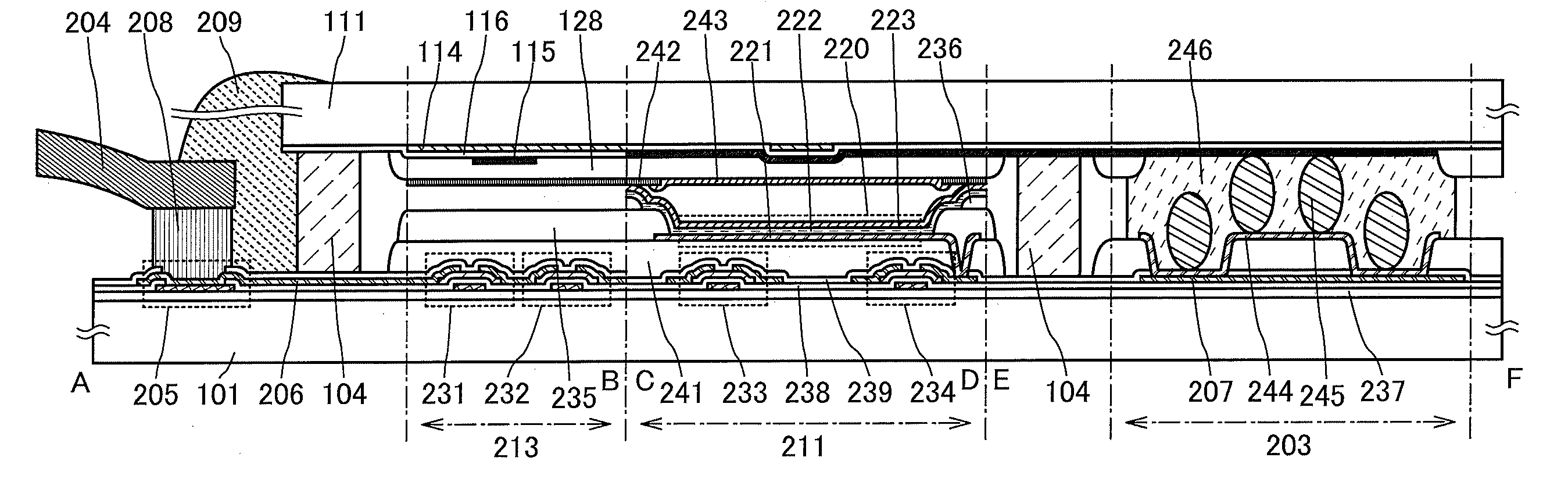

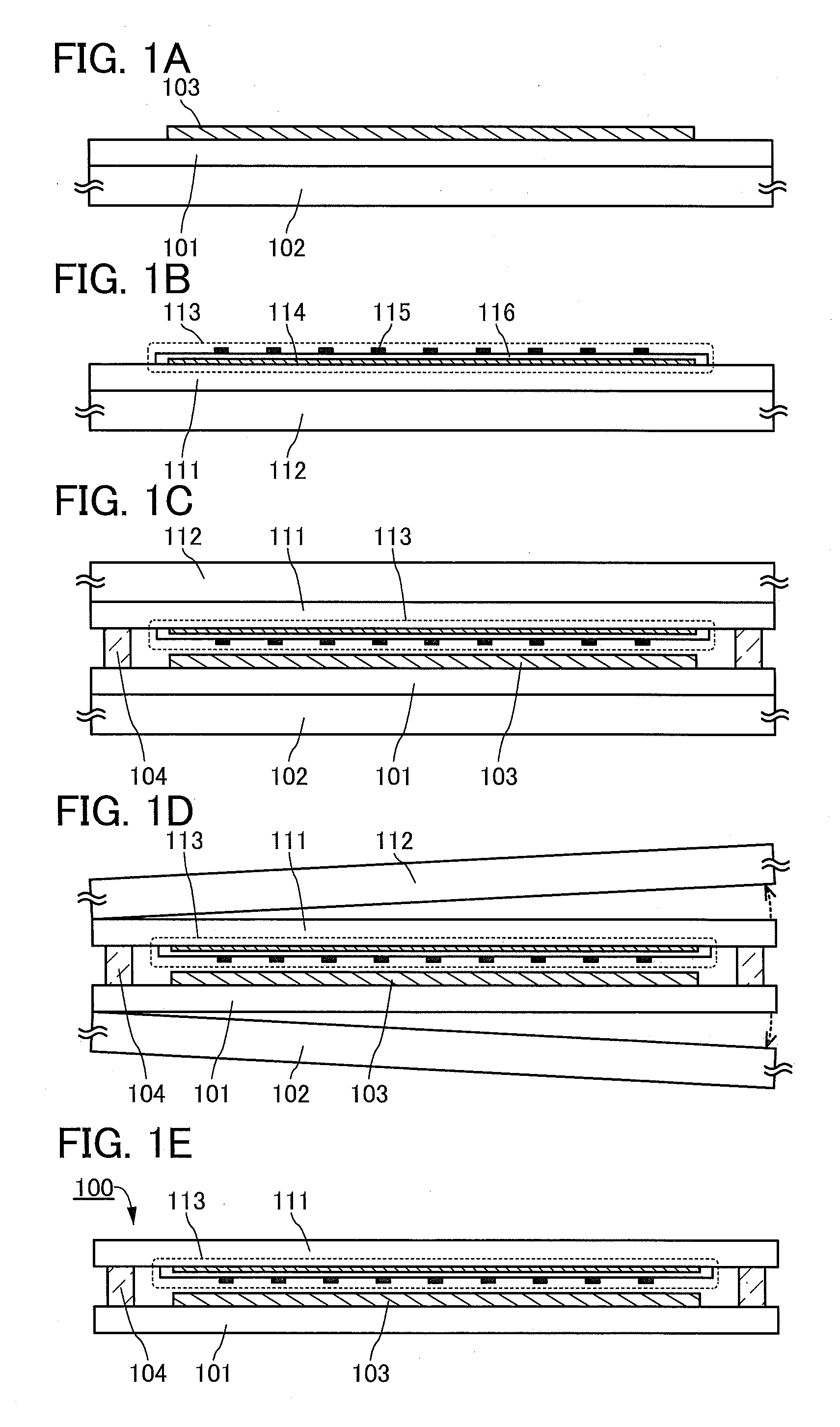

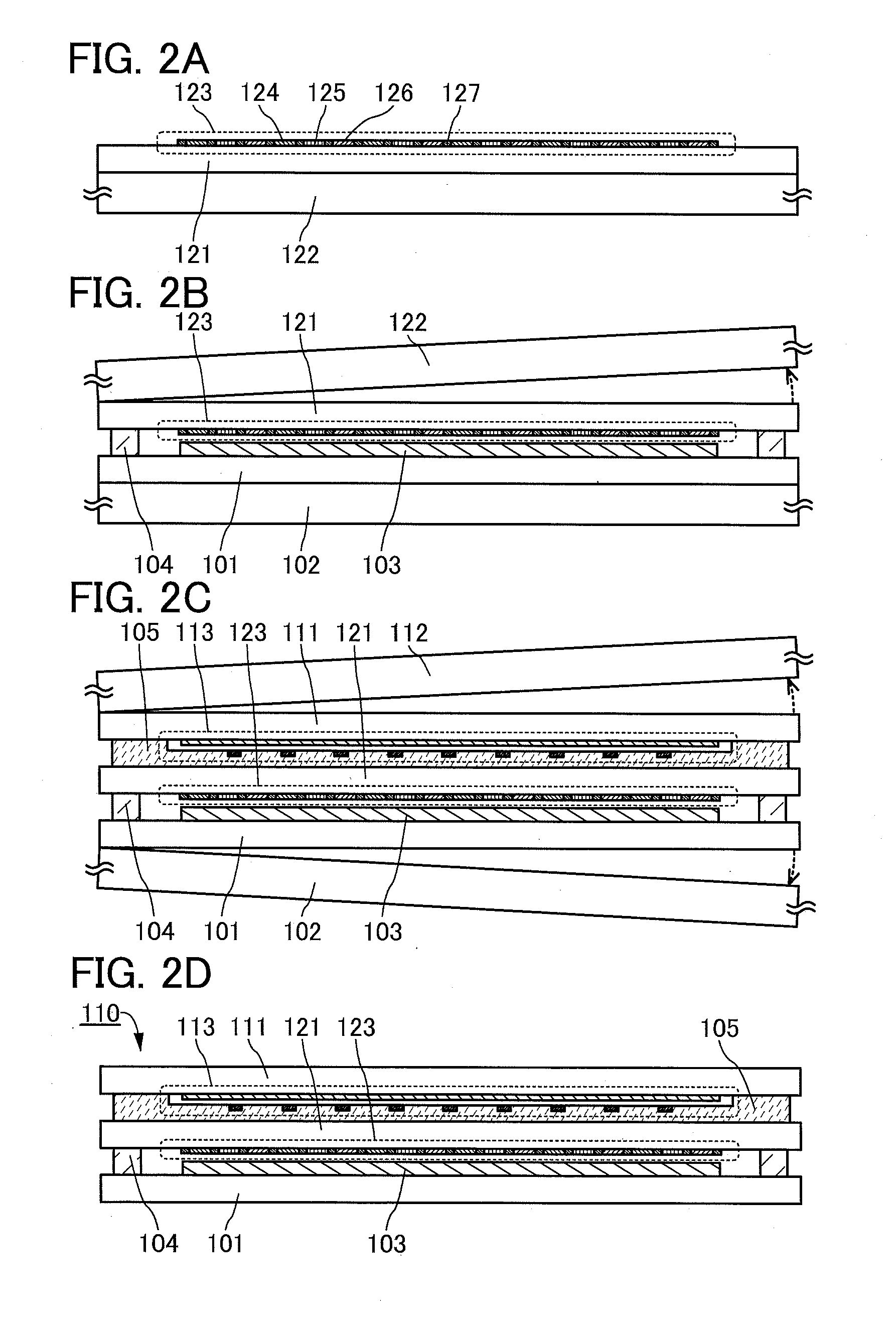

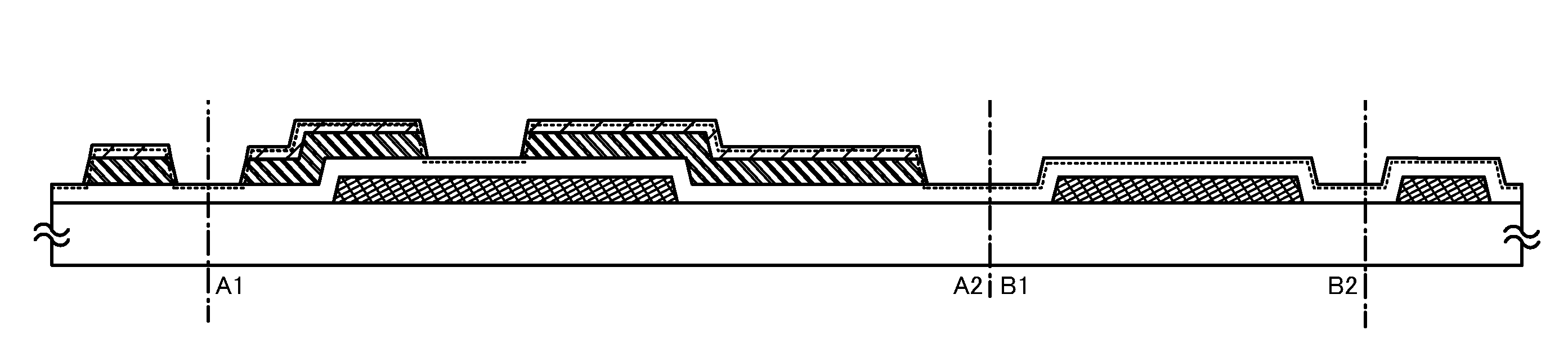

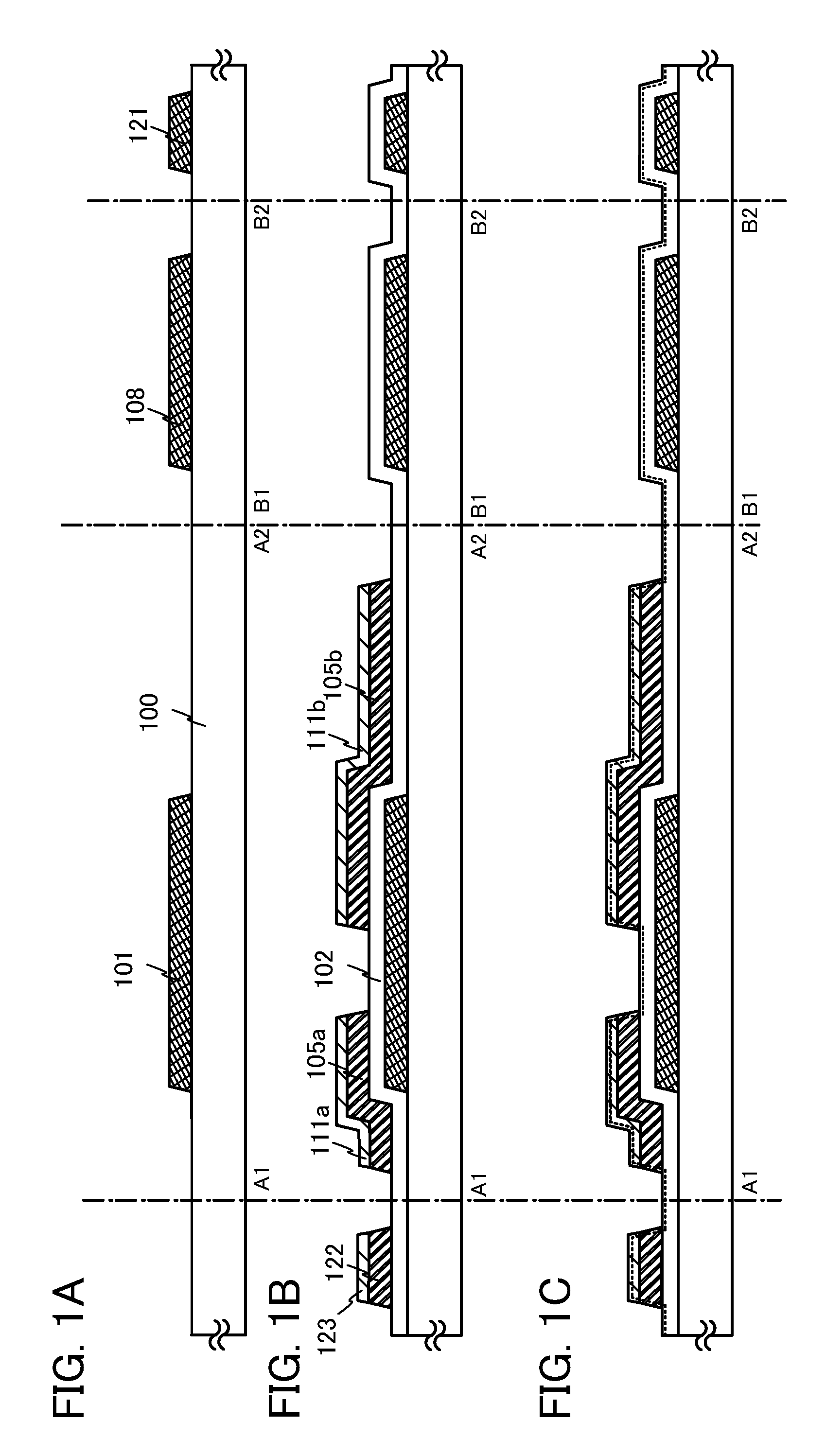

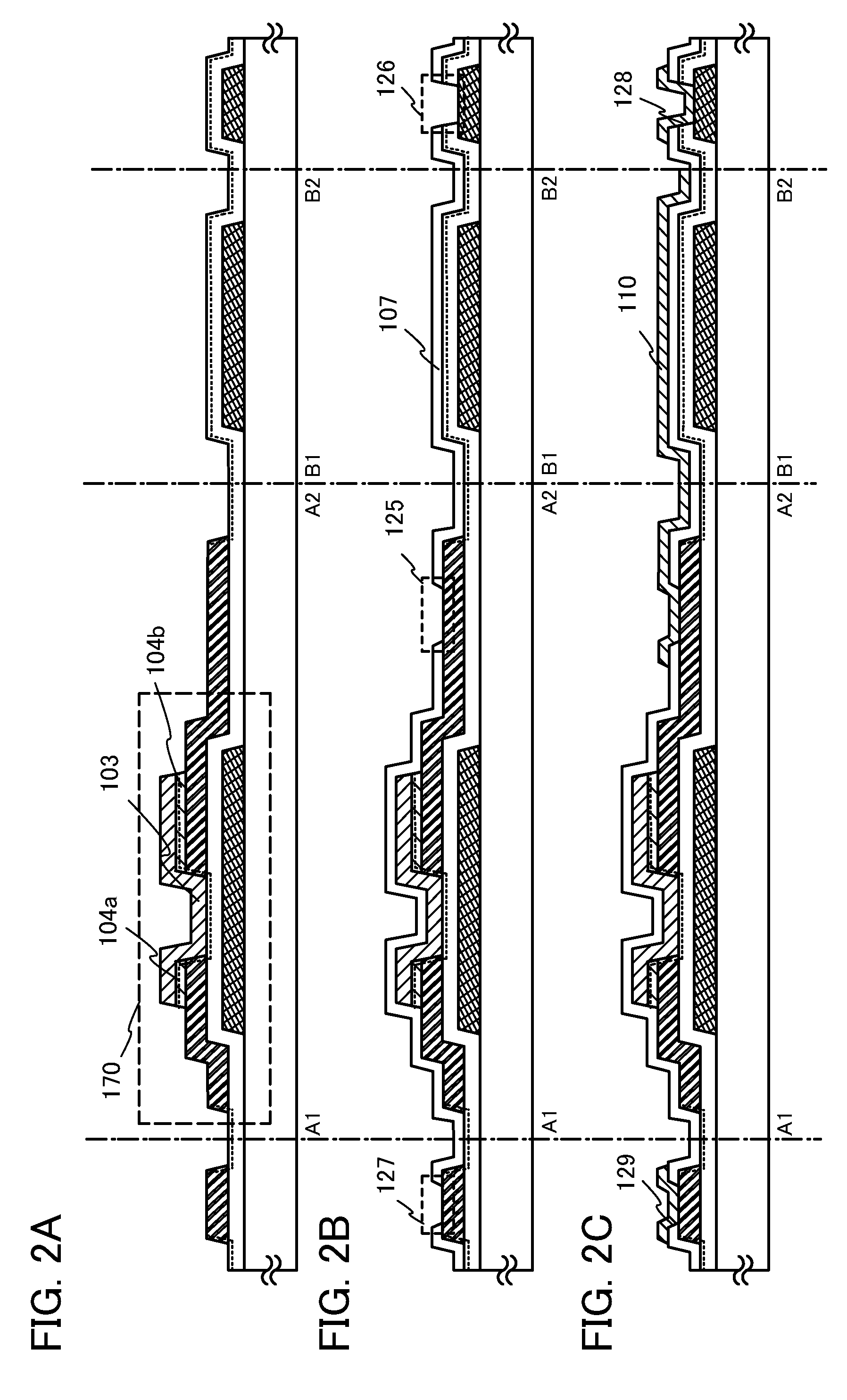

Display Device and Method for Manufacturing Display Device

ActiveUS20140014960A1Reduce thicknessImprove batch productivitySolid-state devicesSemiconductor/solid-state device manufacturingProduction rateDisplay device

The thickness of a display device including a touch sensor is reduced. Alternatively, the thickness of a display device having high display quality is reduced. Alternatively, a method for manufacturing a display device with high mass productivity is provided. Alternatively, a display device having high reliability is provided. Stacked substrates in each of which a sufficiently thin substrate and a relatively thick support substrate are stacked are used as substrates. One surface of the thin substrate of one of the stacked substrates is provided with a layer including a touch sensor, and one surface of the thin substrate of the other stacked substrate is provided with a layer including a display element. After the two stacked substrates are attacked to each other so that the touch sensor and the display element face each other, the support substrate and the thin substrate of each stacked substrate are separated from each other.

Owner:SEMICON ENERGY LAB CO LTD

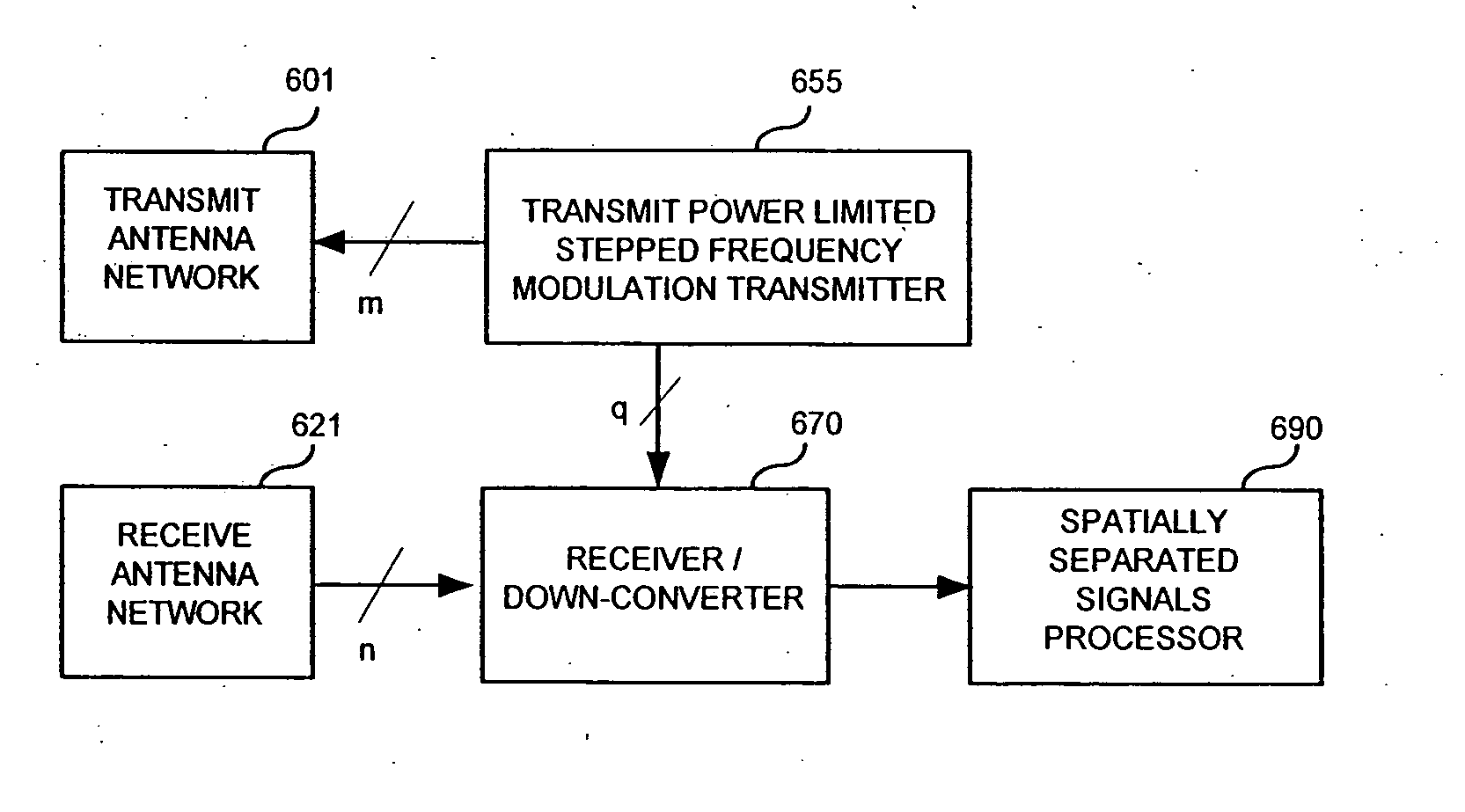

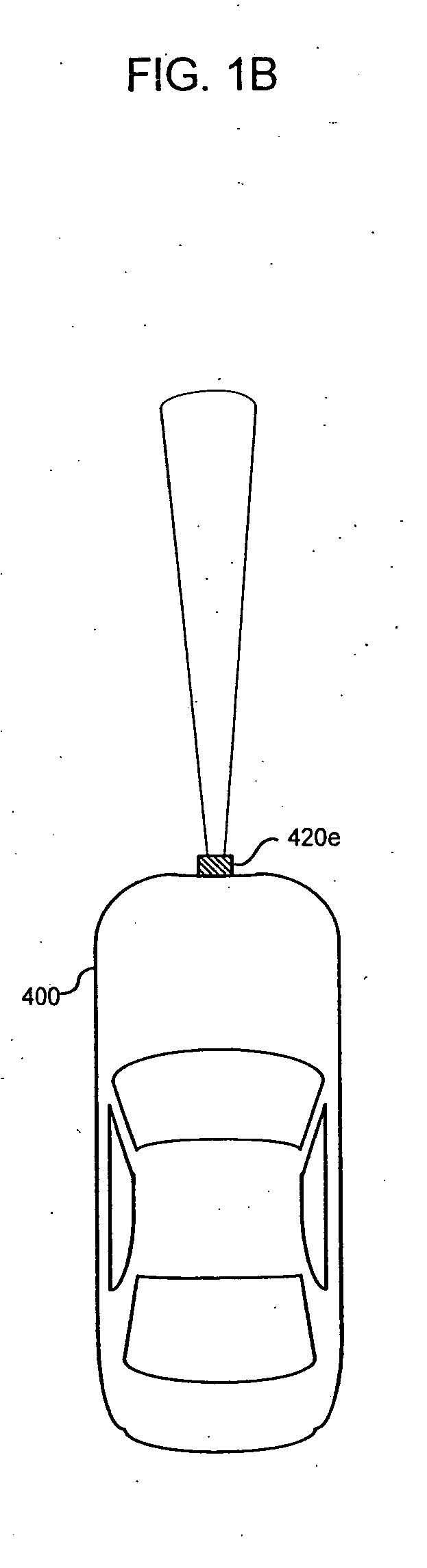

Methods and apparatus for automotive radar sensors

InactiveUS20060262007A1Reduce system costReduce in quantityRadio wave reradiation/reflectionIntermediate frequencyTransmitted power

Methods and apparatus are presented that reduce the overall system cost for automotive radar sensing applications through reduction of the number of the radar sensors required. In accordance with aspects of the present invention, one way sensor count reduction can be achieved is through the combination of target range, direction, and velocity determination capability with wide angular field of view coverage within a single sensor unit. One embodiment combines a transmit-pulsed, linearly stepped frequency modulated, transmit power limited radar architecture with a spatially separated receiver antenna array, intermediate frequency down-conversion, and a digital multi-zone monopulse (DMM) signal processing technique for high-resolution target range, velocity, and azimuth angle determination and fast update rate capability in a low cost, mass-production-capable design.

Owner:CLARIANT TECH

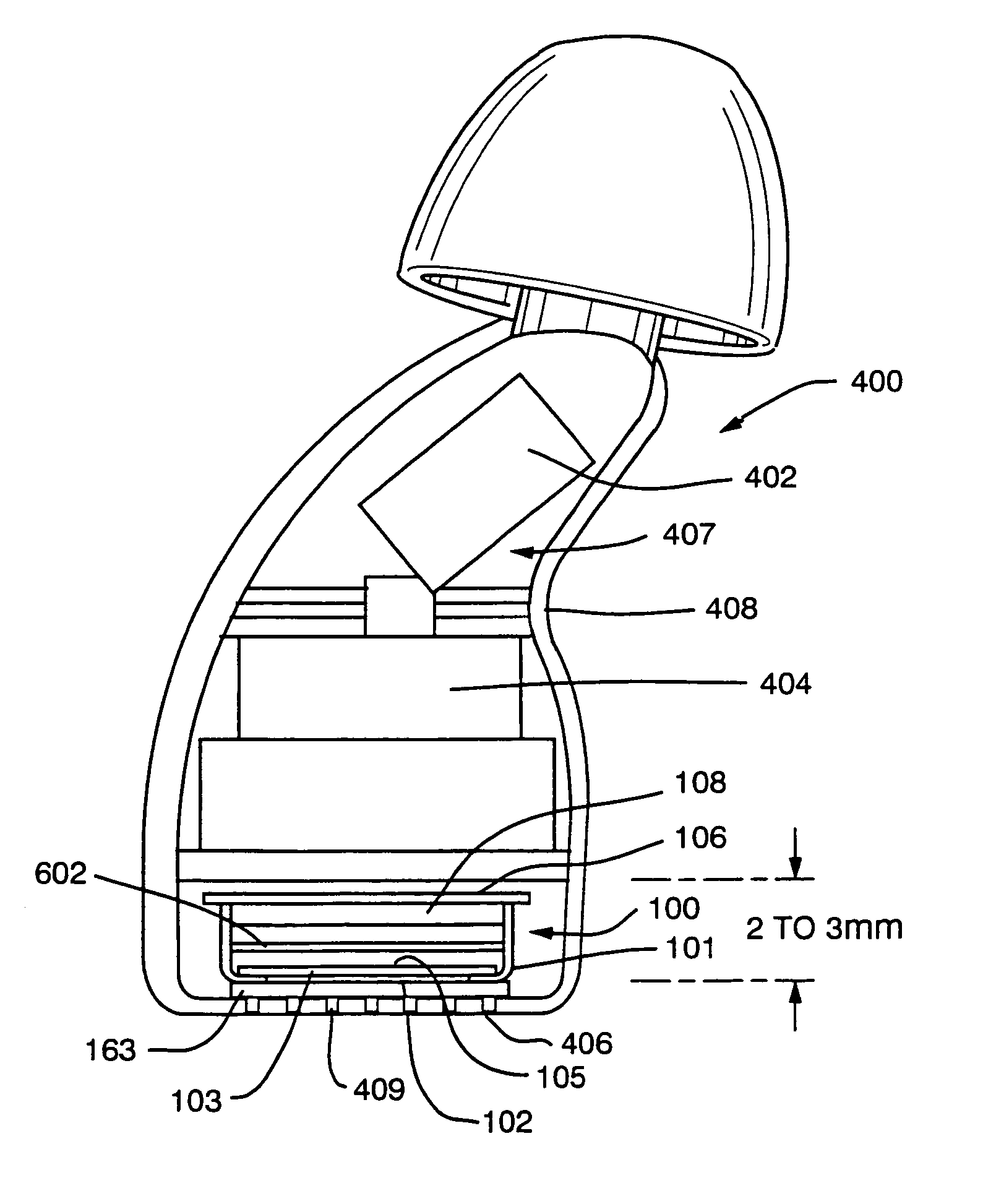

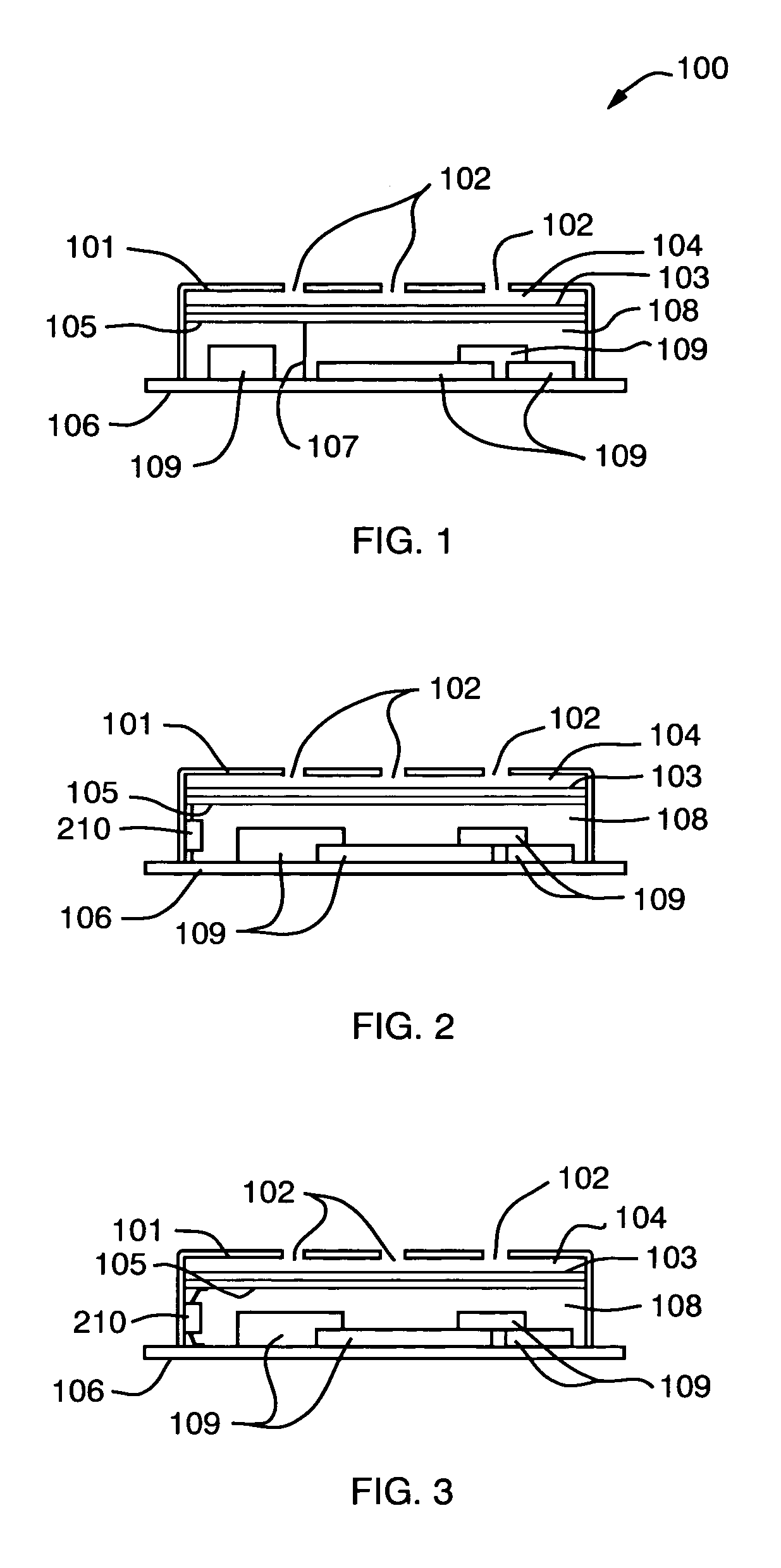

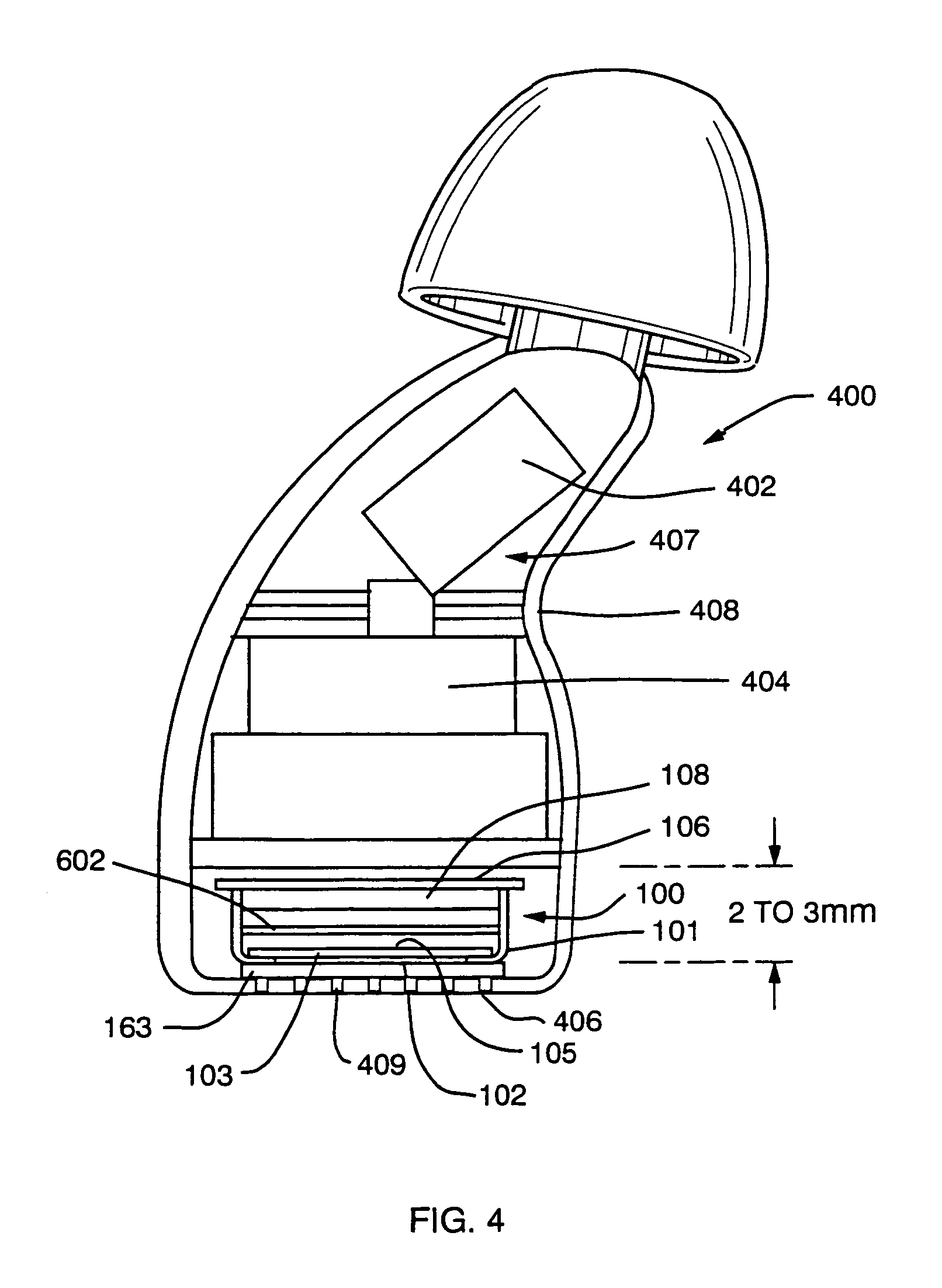

Hearing aid with large diaphragm microphone element including a printed circuit board

InactiveUS7003127B1Low costImprove performanceElectrostatic transducersHearing aids housingLow noiseElectrical connection

A disposable-type hearing aid uses a relatively large single diaphragm or a large single diaphragm subdivided into a plurality of smaller active diaphragm areas obtained using a grate-like back support plate with ridges which contact and divide the diaphragm into the several smaller active diaphragm areas. The diaphragm and a backplate are enclosed in a metal housing and are disposed proximal and parallel to a shell-like hearing aid enclosure having sound inlets. The metal housing is closed at an end opposite the sound inlets by a printed circuit board (PCB) forming an acoustical seal for a back volume of the microphone. The PCB also carries substantially all the electronic components for the hearing aid thereon. The PCB has a ground plane in contact with the housing whereby the PCB also acts as an EMI shield. An electrical connection is formed in various ways between the back support plate and the PCB during assembly of the metal housing and components with the PCB. Mass production of disposable hearing aids with large diaphragms and relatively low noise levels is thus possible using this invention.

Owner:HIMPP

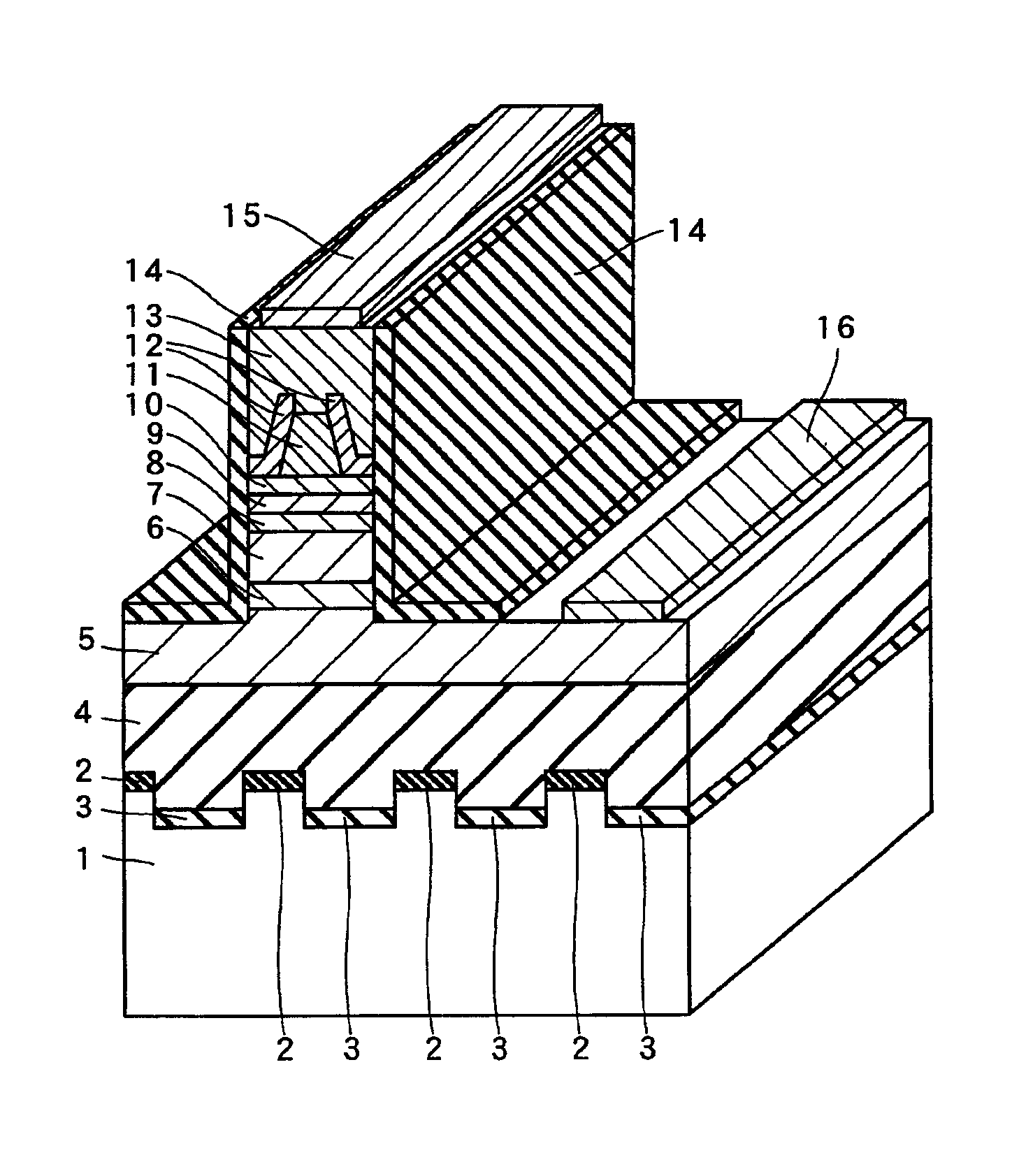

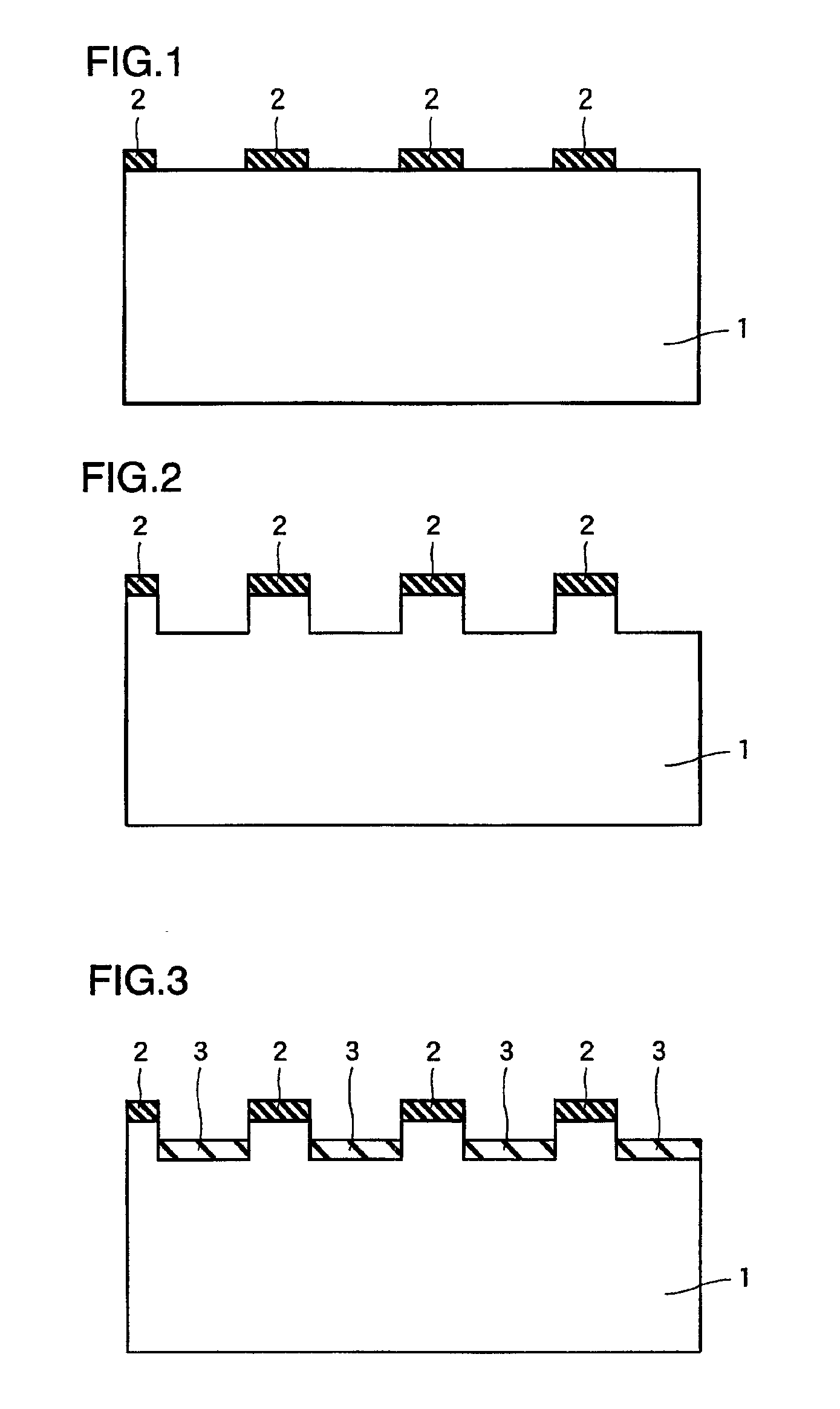

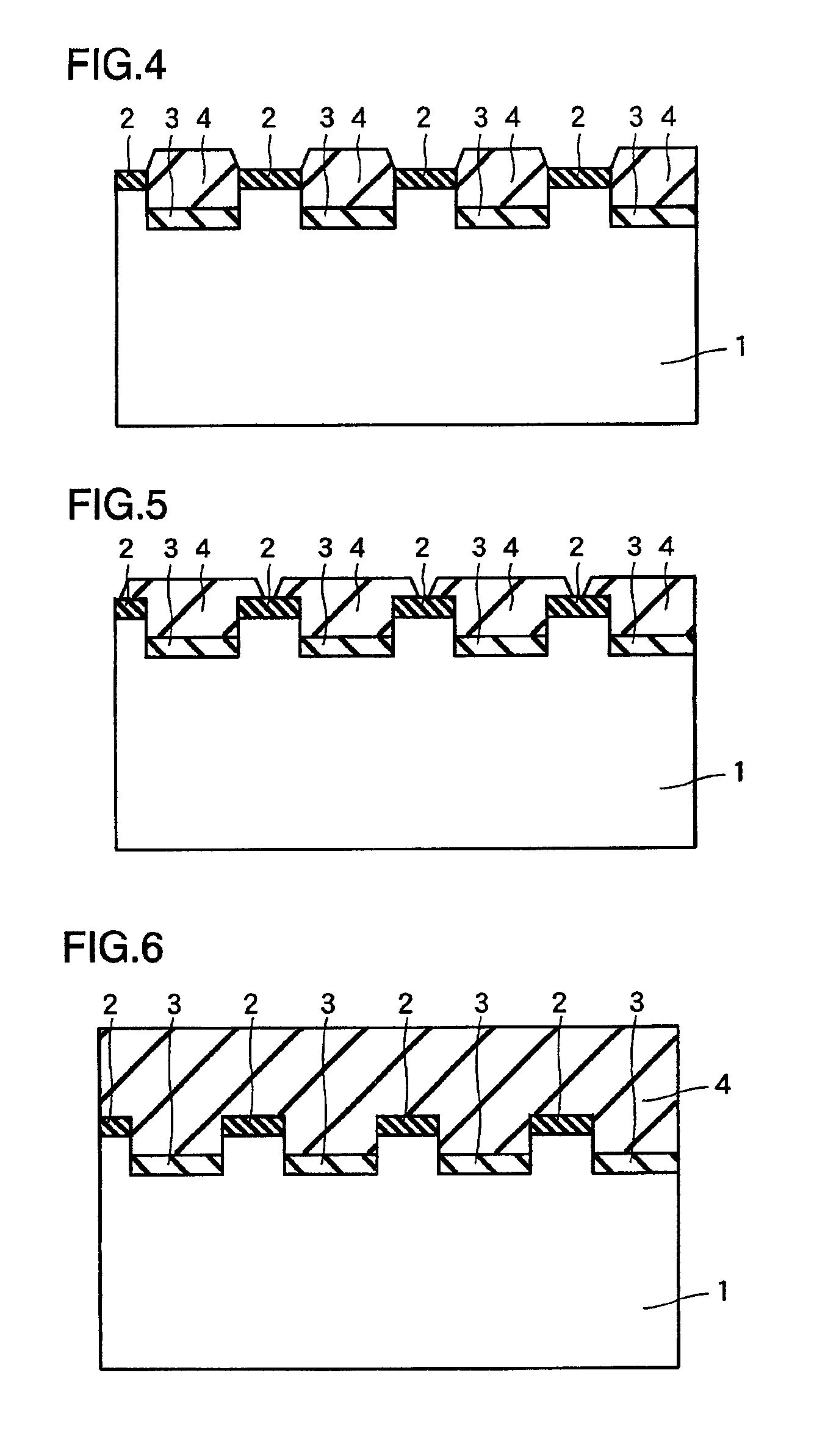

Nitride-based semiconductor element and method of forming nitride-based semiconductor

InactiveUS6994751B2Improve batch productivityExcellent element characteristicOptical wave guidancePolycrystalline material growthProduction rateDislocation

A nitride-based semiconductor element having superior mass productivity and excellent element characteristics is obtained. This nitride-based semiconductor element comprises a substrate comprising a surface having projection portions, a mask layer formed to be in contact with only the projection portions of the surface of the substrate, a first nitride-based semiconductor layer formed on recess portions of the substrate and the mask layer and a nitride-based semiconductor element layer, formed on the first nitride-based semiconductor layer, having an element region. Thus, the first nitride-based semiconductor layer having low dislocation density is readily formed on the projection portions of the substrate and the mask layer through the mask layer serving for selective growth. When the nitride-based semiconductor element layer having the element region is grown on the first nitride-based semiconductor layer having low dislocation density, a nitride-based semiconductor element having excellent element characteristics can be readily obtained. The first nitride-based semiconductor layer is formed through only single growth on the substrate, whereby a nitride-based semiconductor element having excellent mass productivity is obtained.

Owner:LEDVANCE GMBH

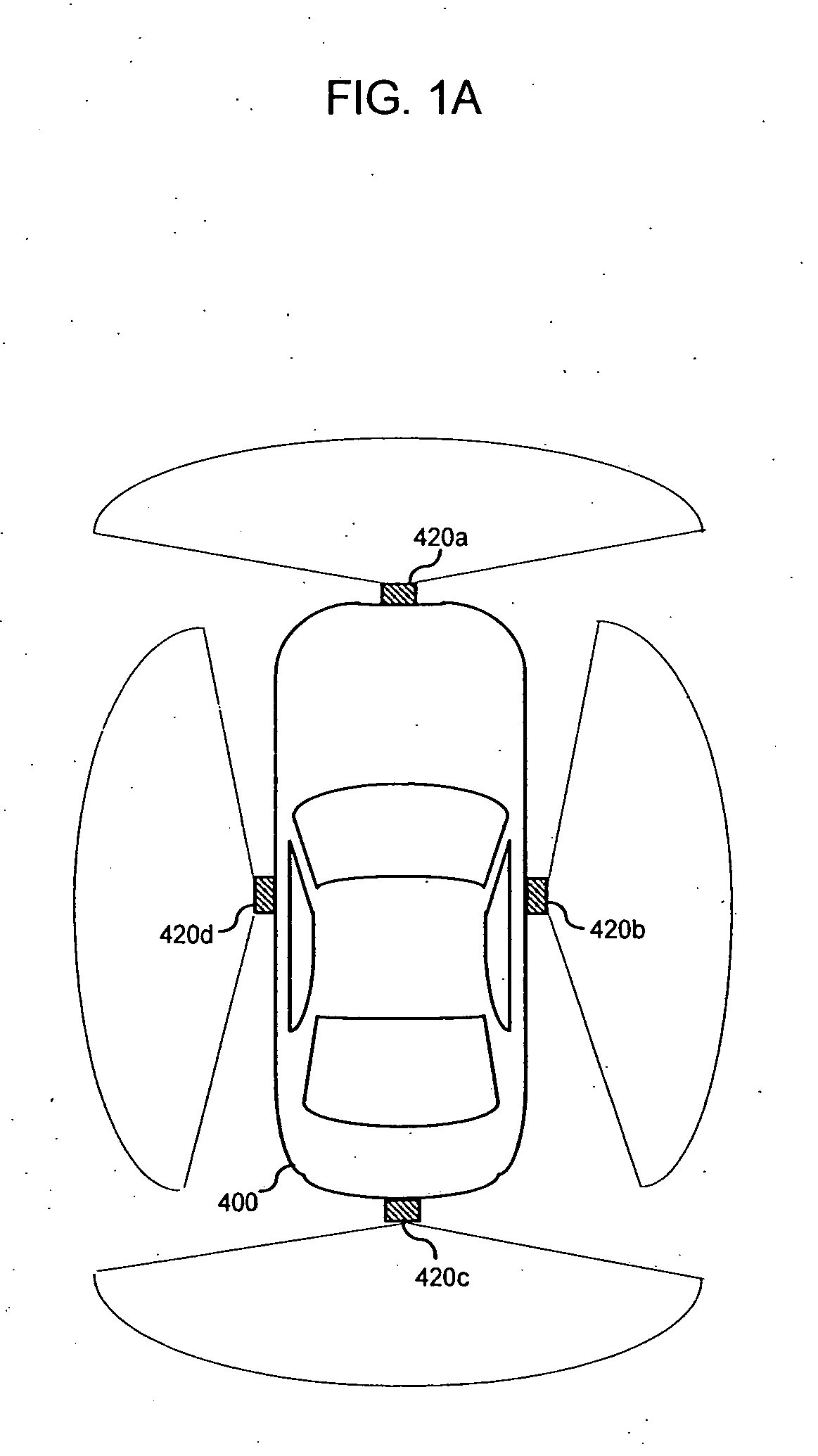

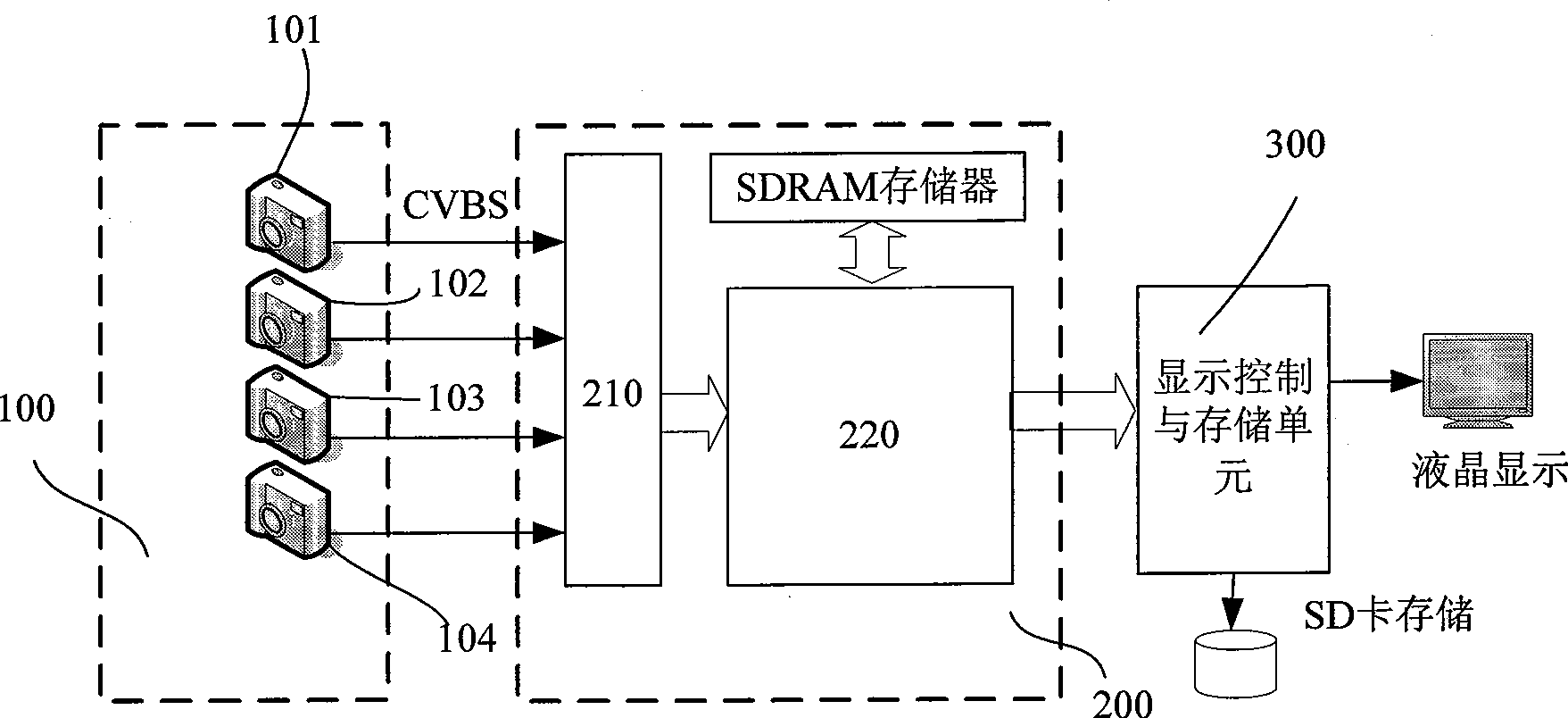

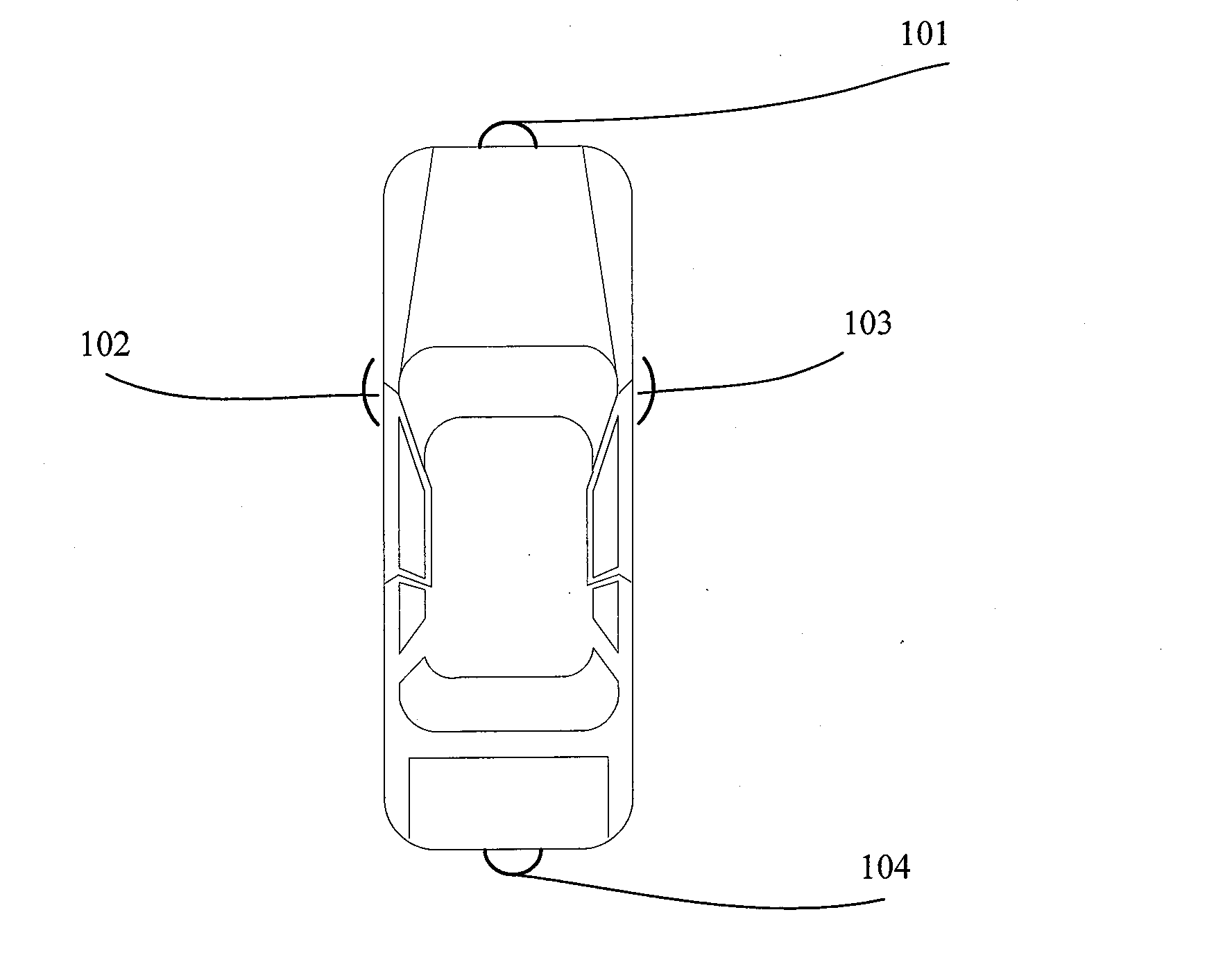

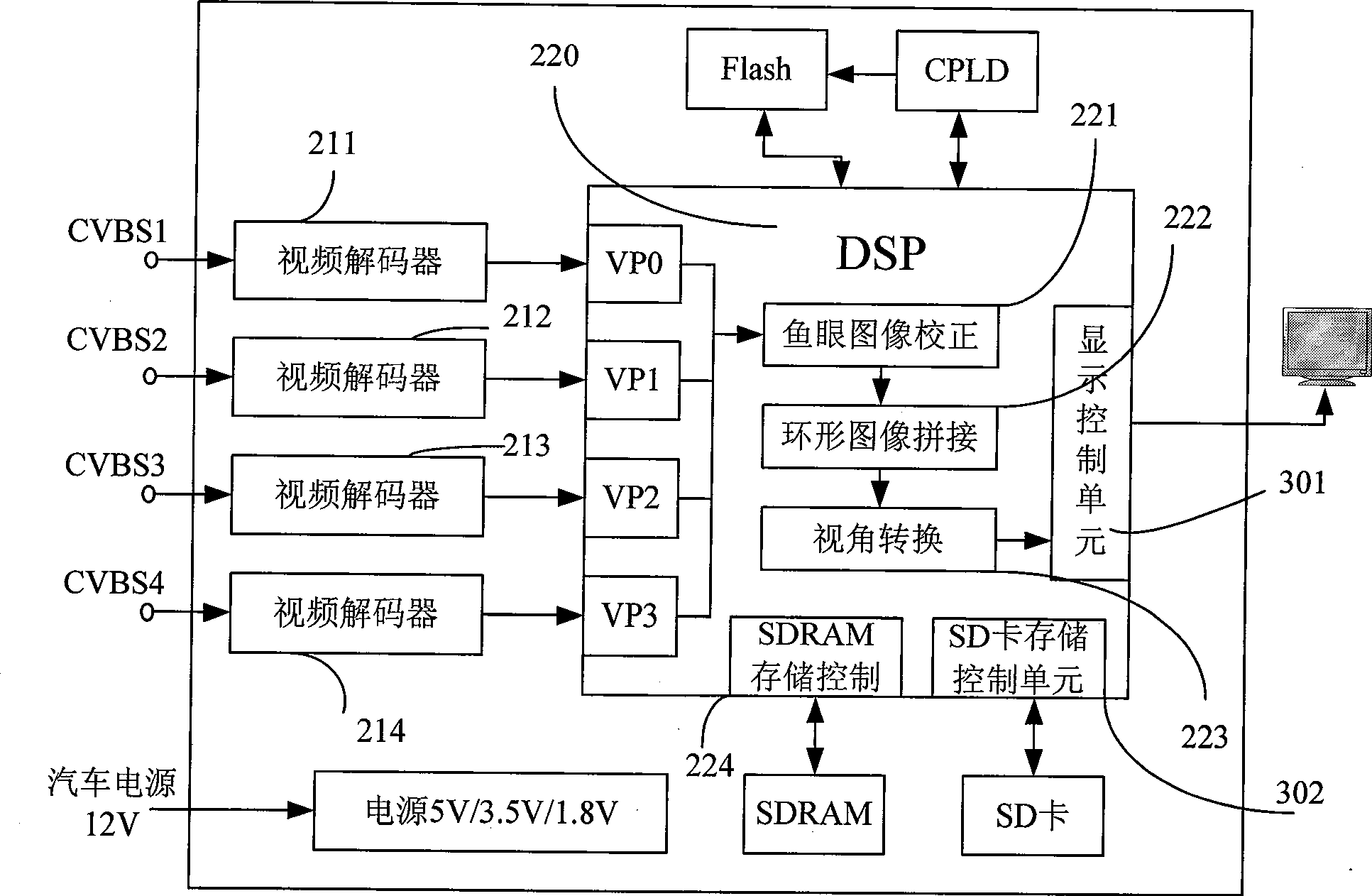

Method for synthesizing 360 DEG ring-shaped video of vehicle assistant drive

InactiveCN101442618ALow costSuitable for mass productionTelevision system detailsColor television detailsBlind zoneDriver/operator

The invention discloses a method for synthesizing annular video of 360 degrees for assistant drive of a vehicle. The method adopts a video acquisition unit, an annular video synthesis unit and a display control and storage unit, and has the characteristics of reliable stability, low cost and suitable batch production. The method can acquire video signals in real time for four super-wide-angle fish-eye cameras arranged at front, back, left and right of the vehicle, carries out treatment of fish-eye image correction, annular image mosaic and vision angle conversion on four channels of the video signals through a video decoding unit and a video synthesizing control unit to generate a panoramic displayed plan view of 360 degrees, achieves multiple display modes through the display control and storage unit, and can selectively store correlated video information. The method can provide surrounding scenes for a driver, and eliminate vision blind area thereof, and is favorable for the driver to achieve safe and accurate vehicle driving operations. The method is used for assistant drive for sedans, business vehicles and heavy trucks of various grades, and passenger coaches of different types.

Owner:葛晨阳

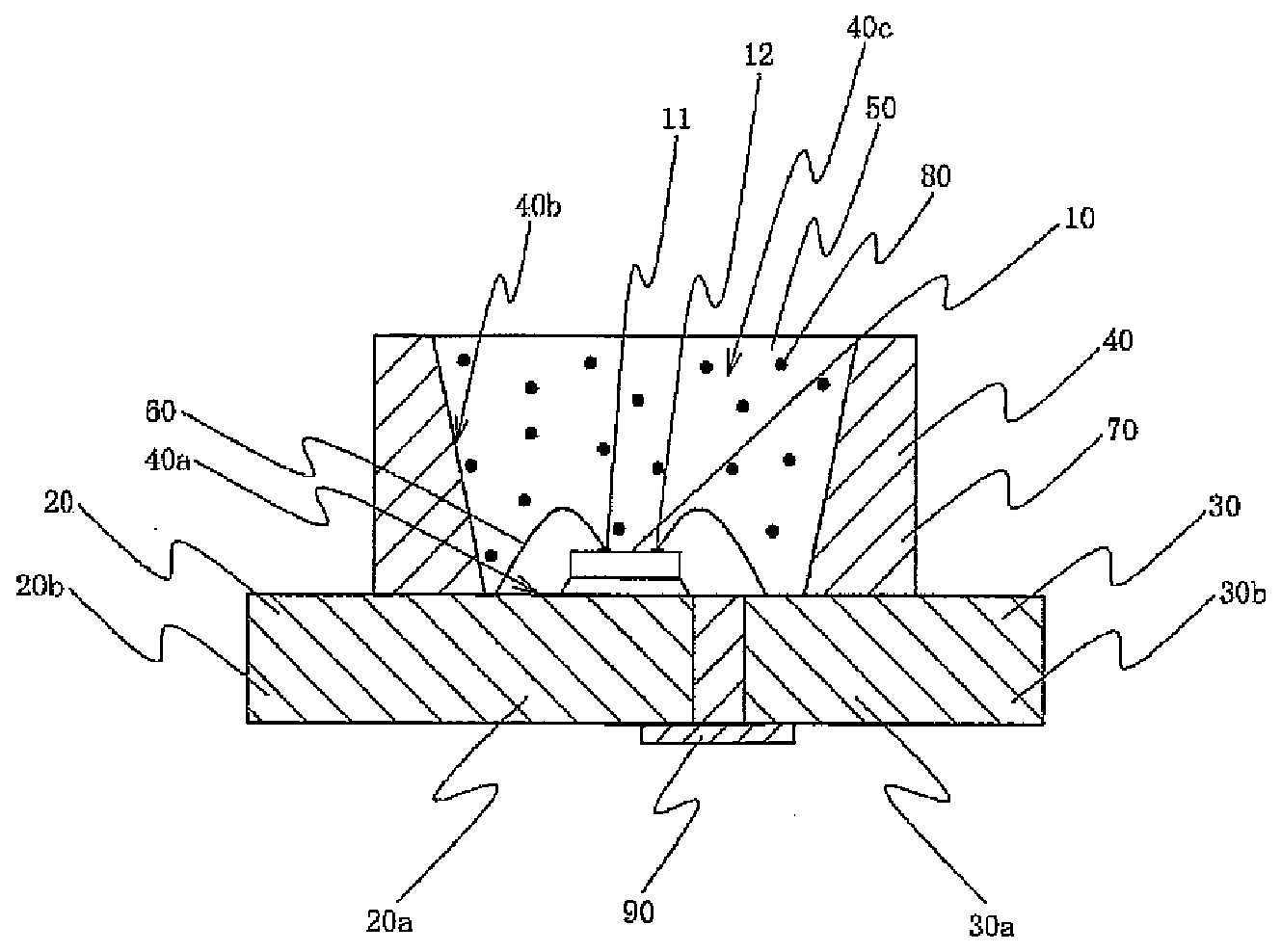

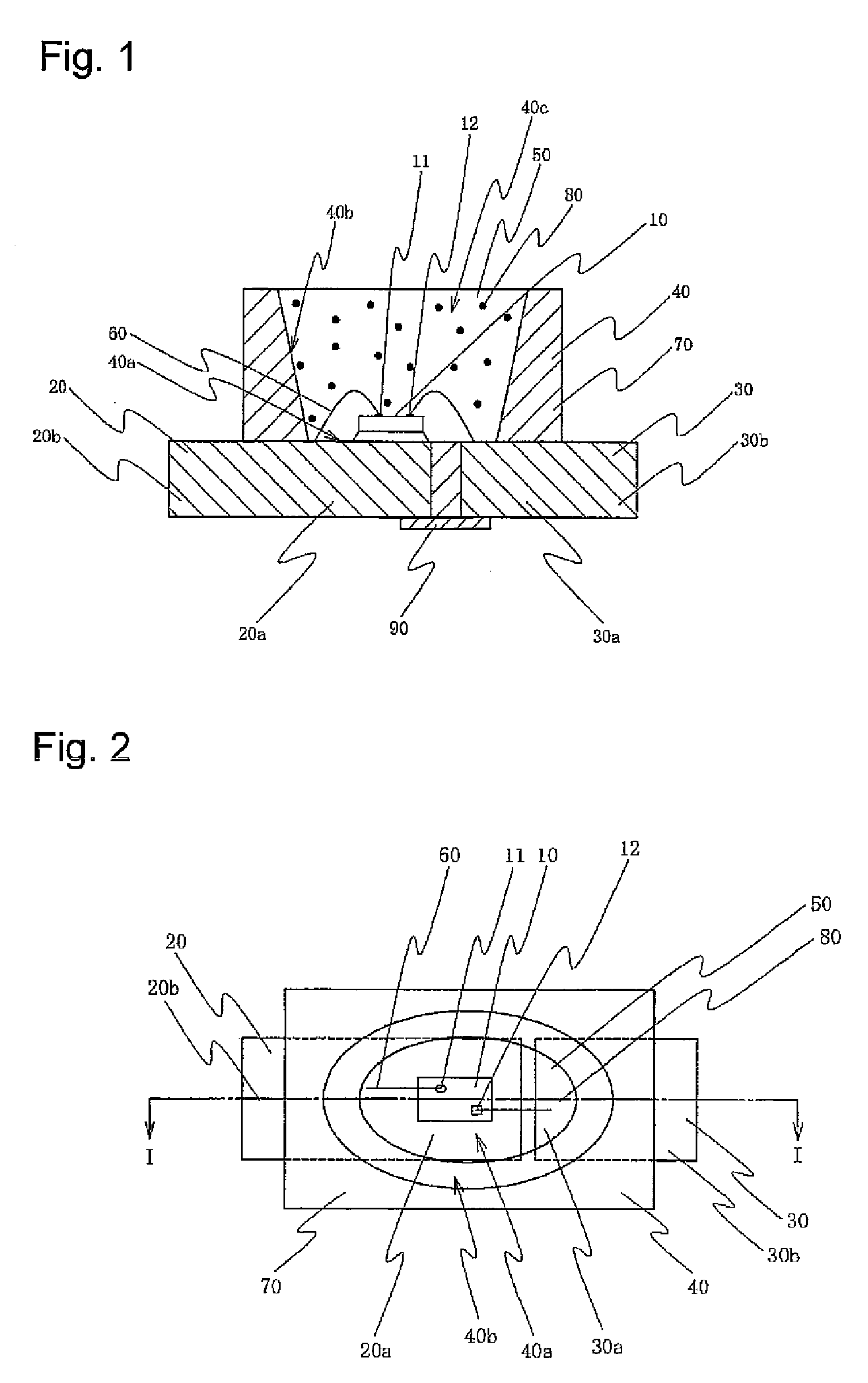

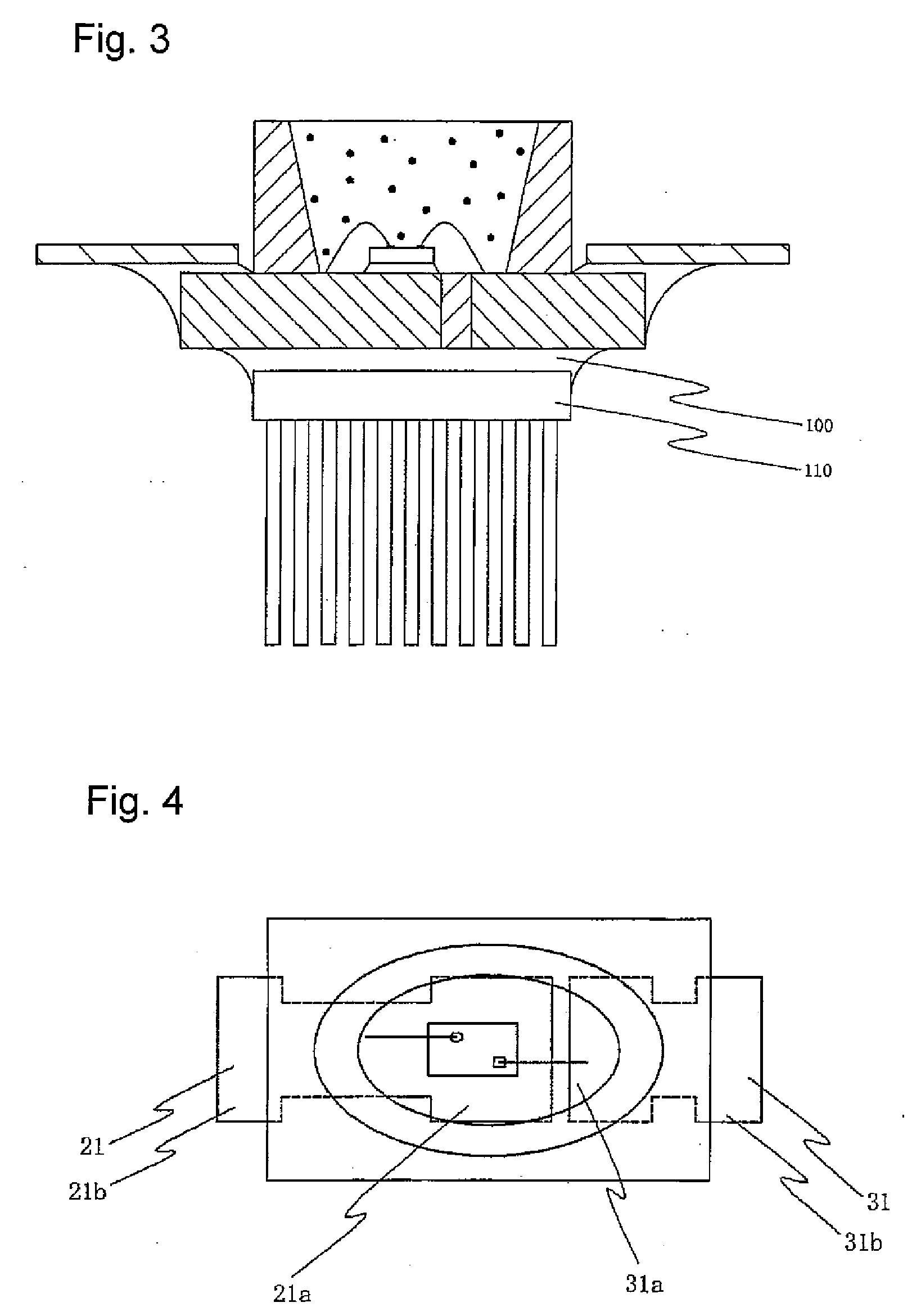

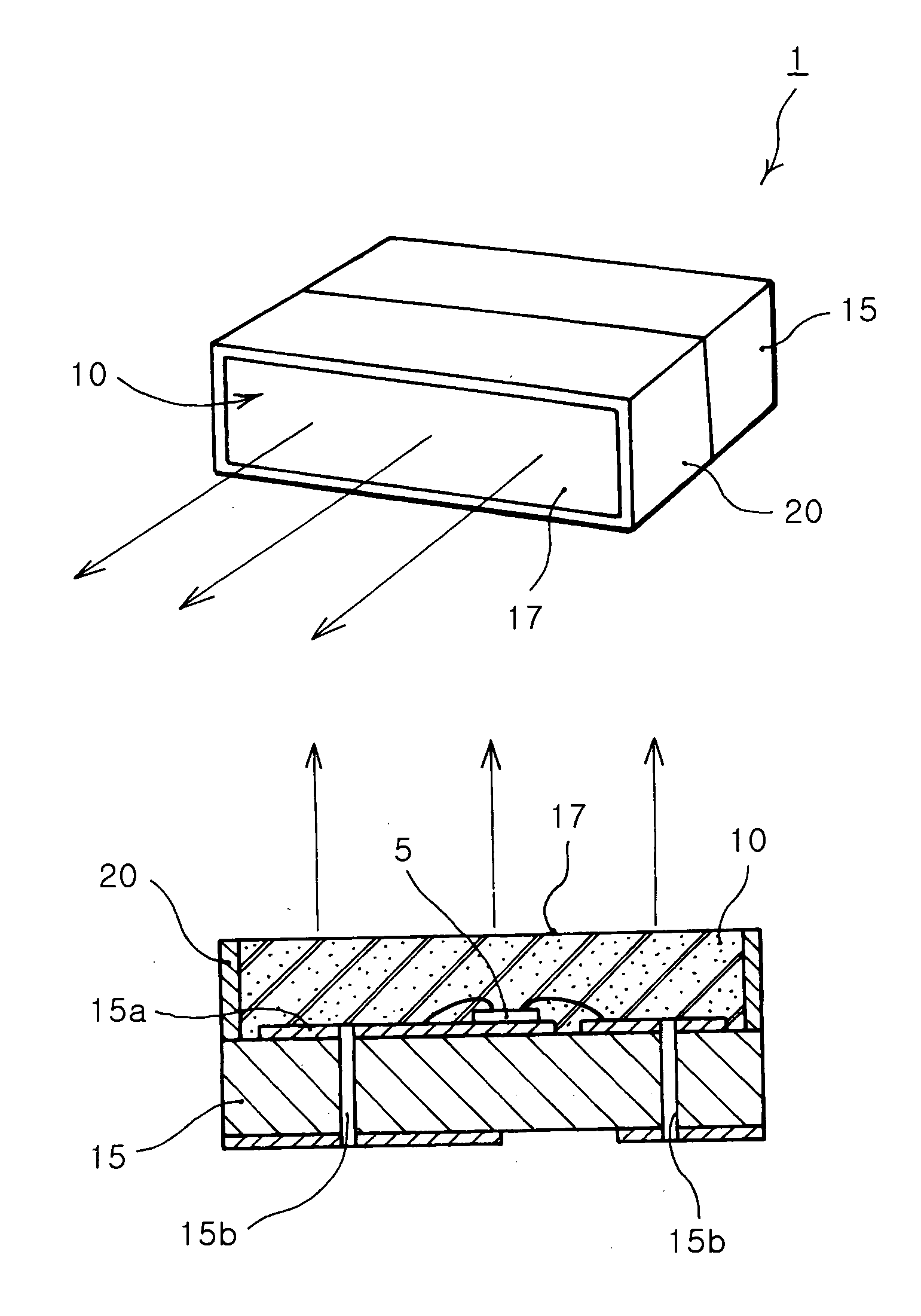

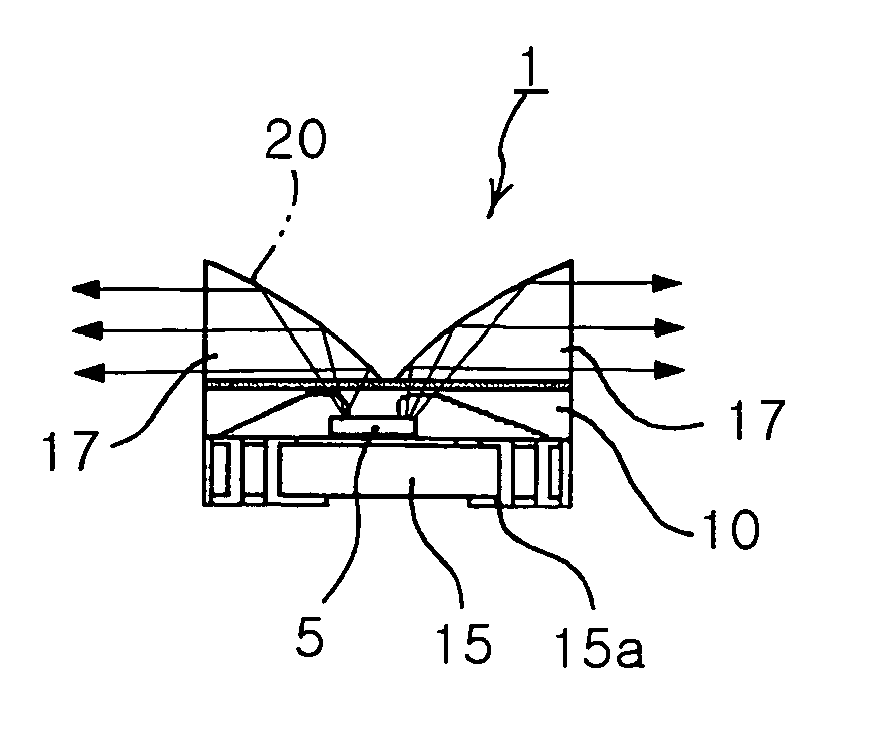

Resin molding, surface mounted light emitting apparatus and methods for manufacturing the same

ActiveUS20090050925A1Easy to useSuitable for mass productionSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyShell molding

The present invention provides a surface mounted light emitting apparatus which has long service life and favorable property for mass production, and a molding used in the surface mounted light emitting apparatus.The surface mounted light emitting apparatus comprises the light emitting device 10 based on GaN which emits blue light, the first resin molding 40 which integrally molds the first lead 20 whereon the light emitting device 10 is mounted and the second lead 30 which is electrically connected to the light emitting device 10, and the second resin molding 50 which contains YAG fluorescent material and covers the light emitting device 10. The first resin molding 40 has the recess 40c comprising the bottom surface 40a and the side surface 40b formed therein, and the second resin molding 50 is placed in the recess 40c. The first resin molding 40 is formed from a thermosetting resin such as epoxy resin by the transfer molding process, and the second resin molding 50 is formed from a thermosetting resin such as silicone resin.

Owner:NICHIA CORP

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS7732243B2Eliminate deficienciesFacilitate electrical interconnectionPV power plantsSolid-state devicesPolymer substrateMaterial removal

Owner:SOLANNEX

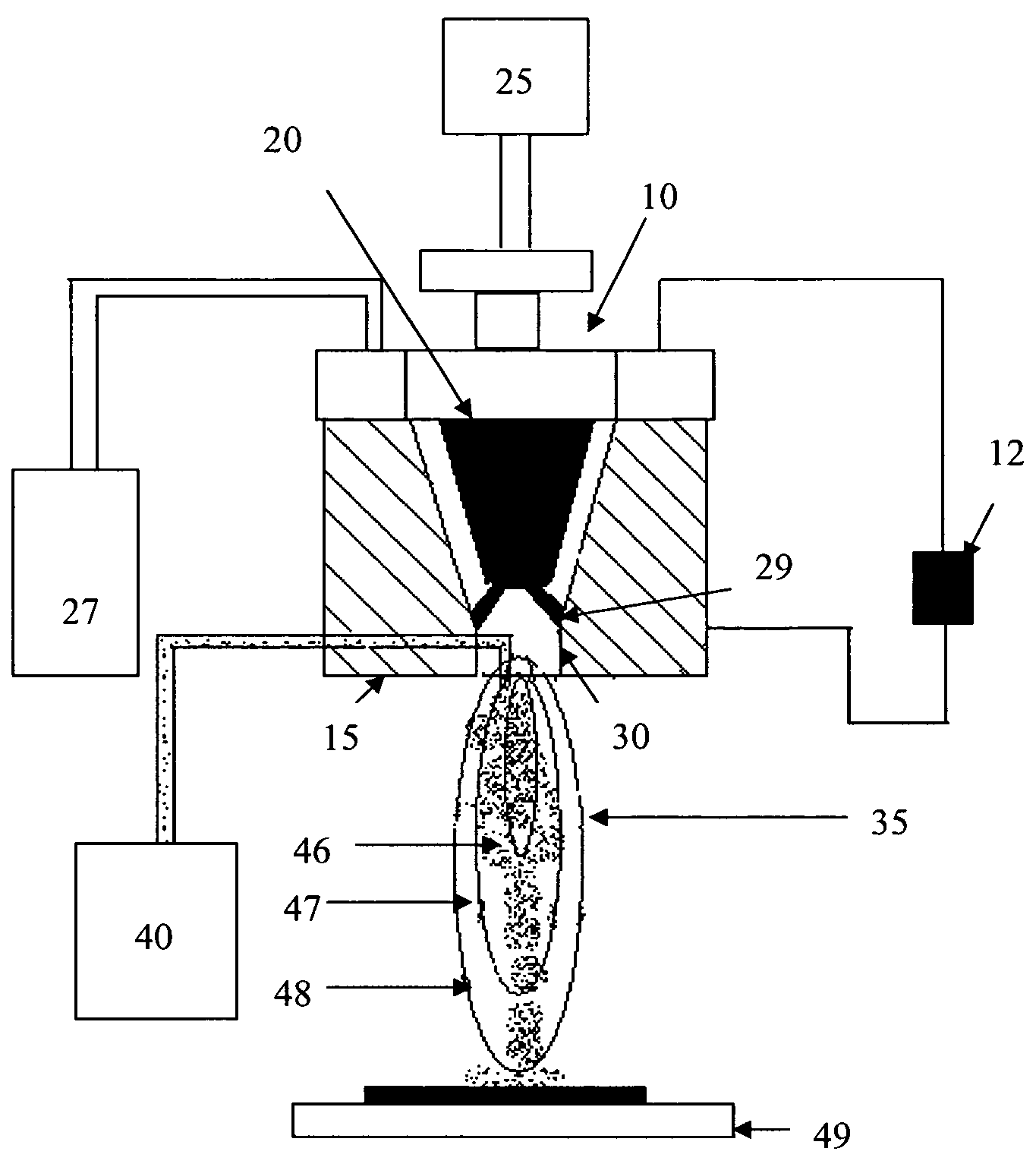

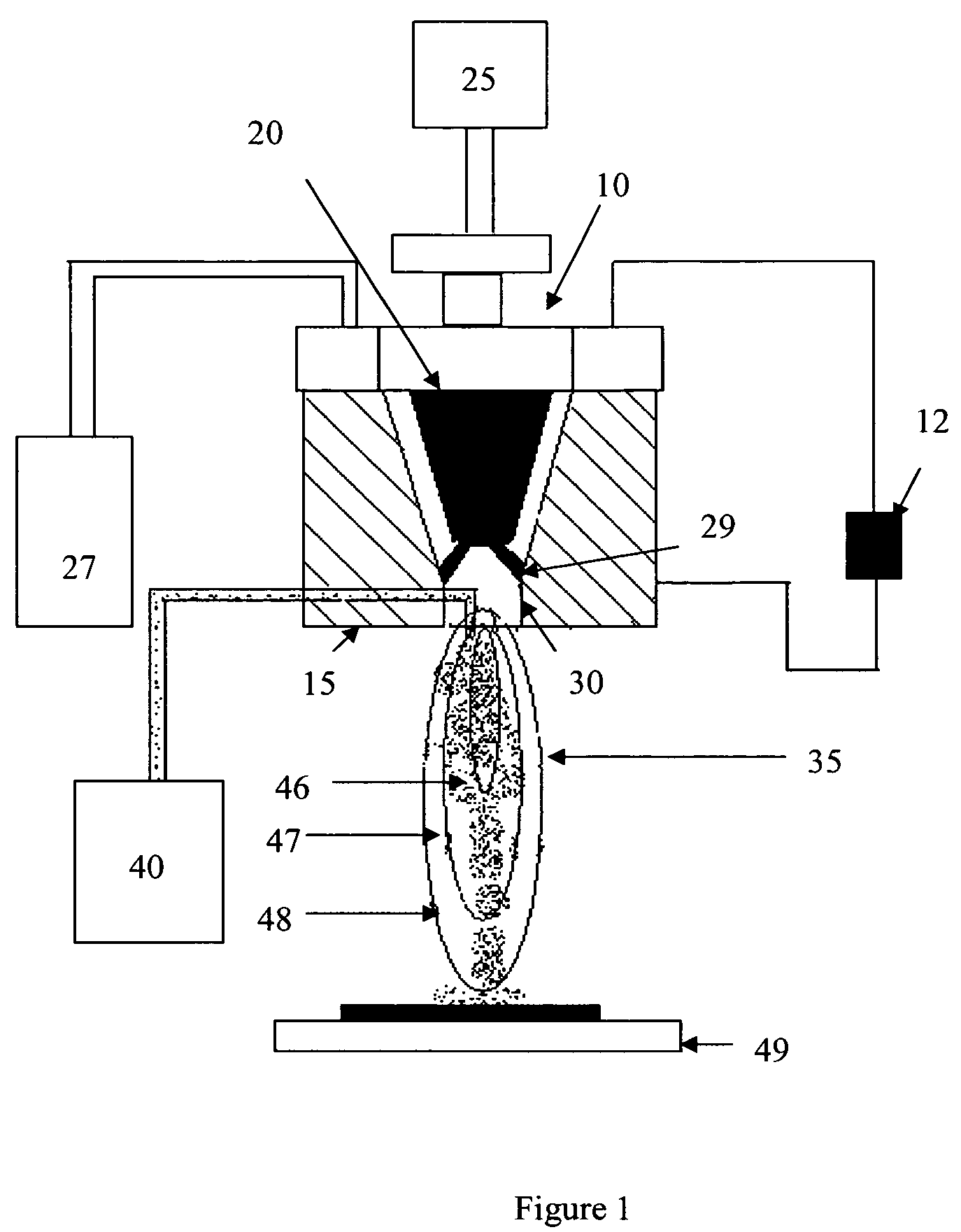

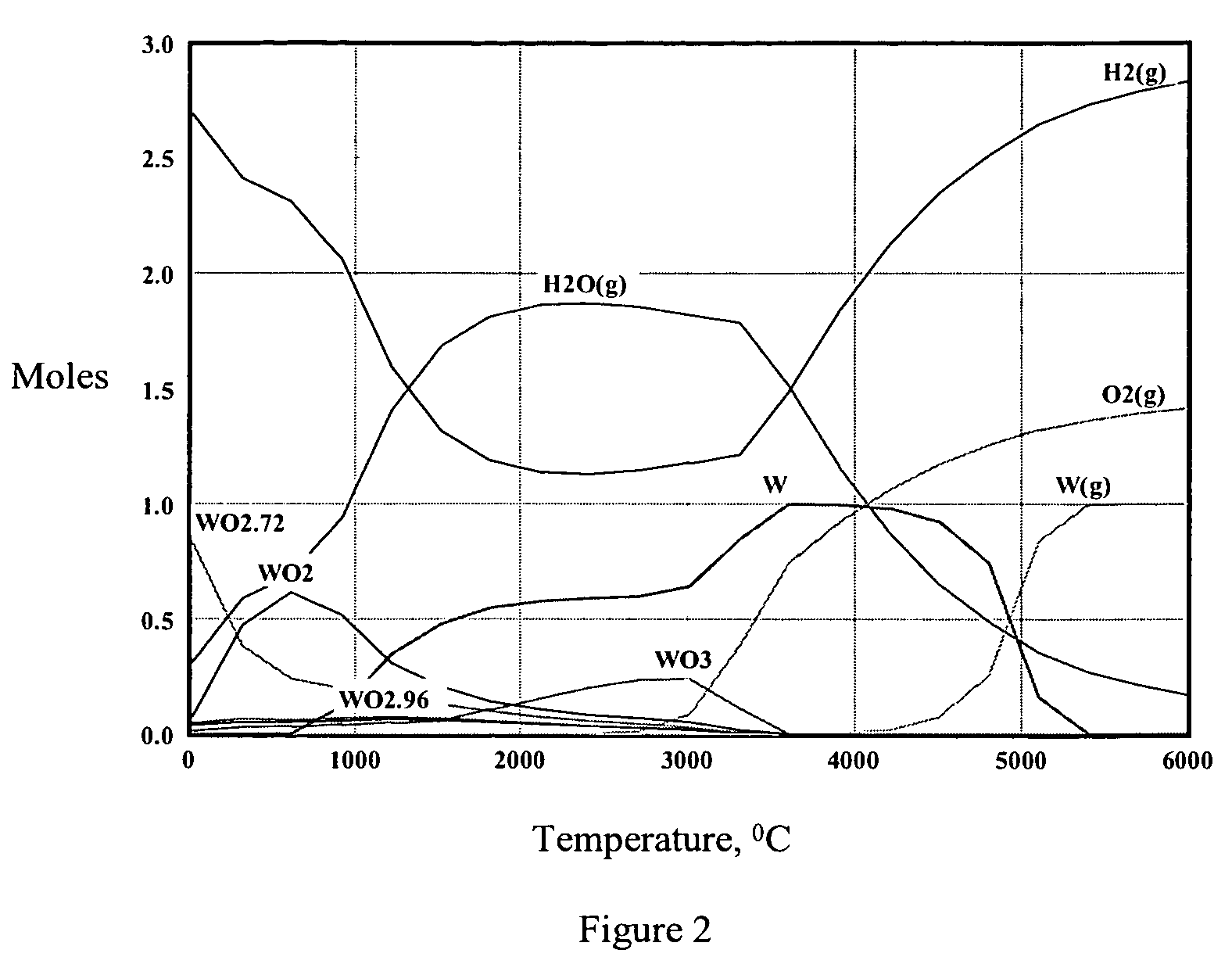

Nano powders, components and coatings by plasma technique

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

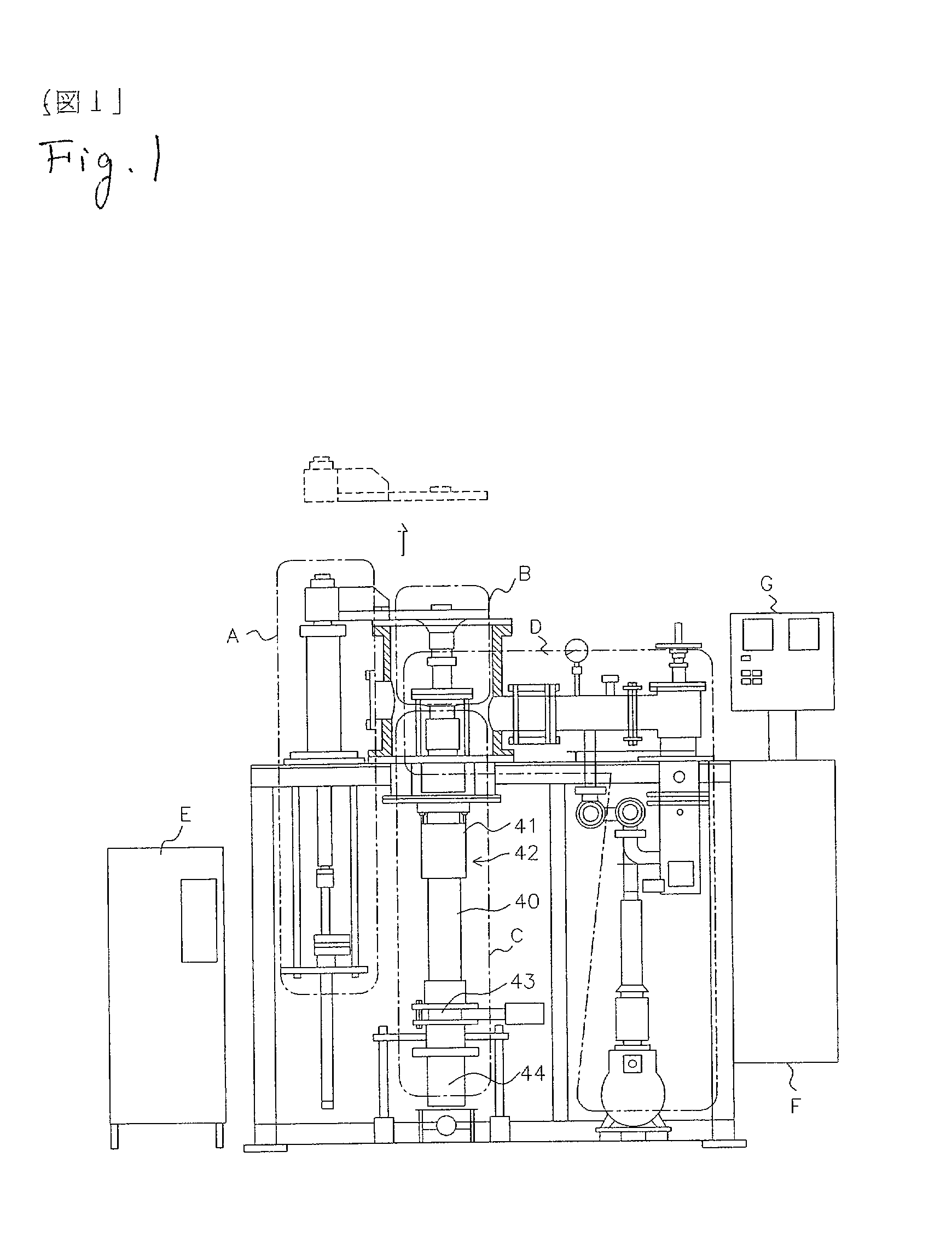

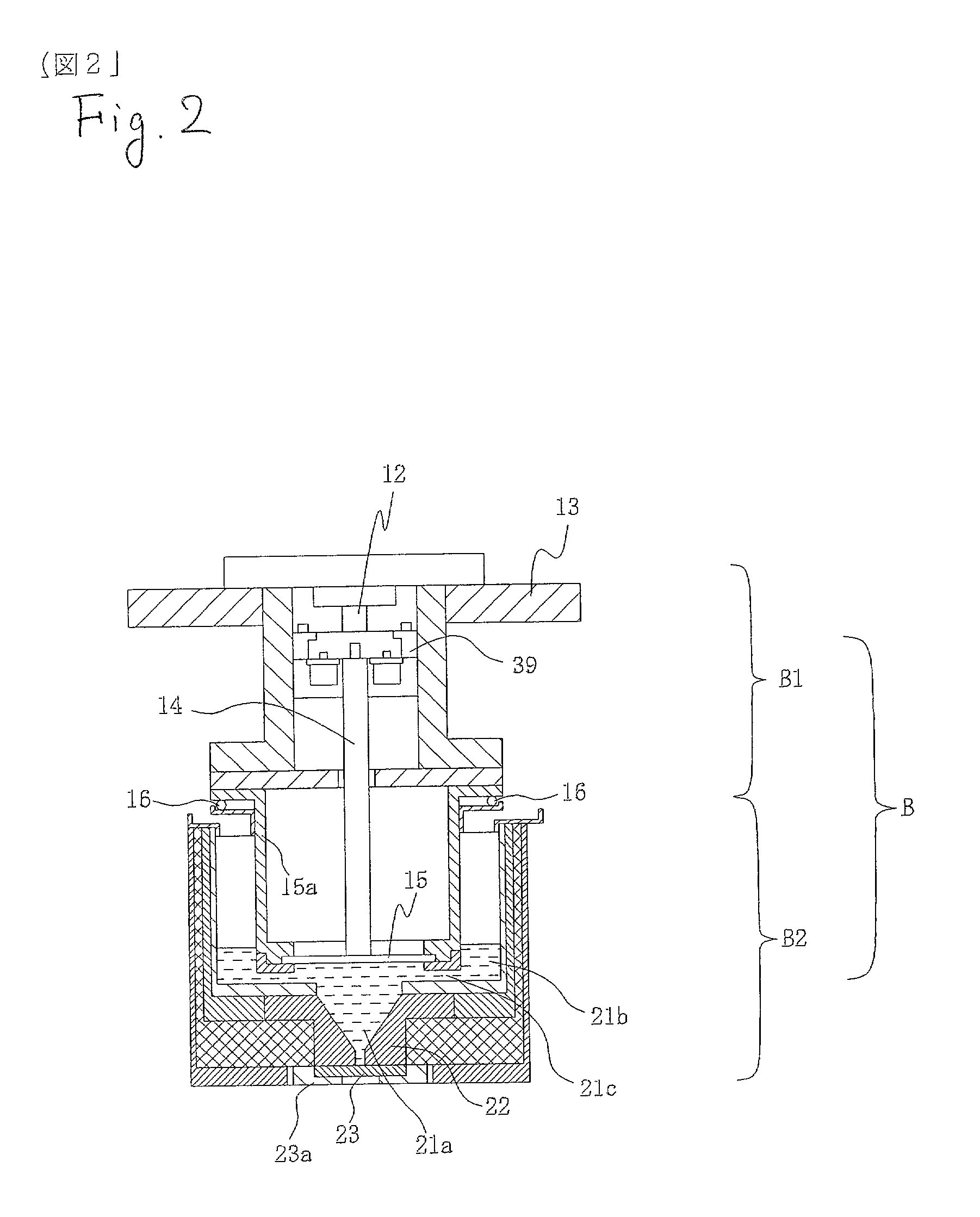

Production apparatus of monodisperse particle and production process of monodisperse particle and monodisperse particle produced by the process

InactiveUS20020089100A1Highly multi-purpose monodisperse particle industrially and cheaplyEasy to controlTransportation and packagingMetal-working apparatusMetallurgySlurry

It is the object to provide a production process of monodisperse particle in which monodisperse particle with uniform particle size (particle diameter) can be stably mass-produced, and monodisperse particle produced by this process, and its production apparatus. The supply pipe diameter deltaf is set to be greater than the orifice diameter deltao and the internal and external pressure of the slurry retention part b is controlled, and this allows to facilitate supply of the slurry through the supply pipe (21c), and continuously and efficiently supply the slurry, and then to produce monodisperse particle with uniform particle size (particle diameter).

Owner:KAWASAKI CORP KK

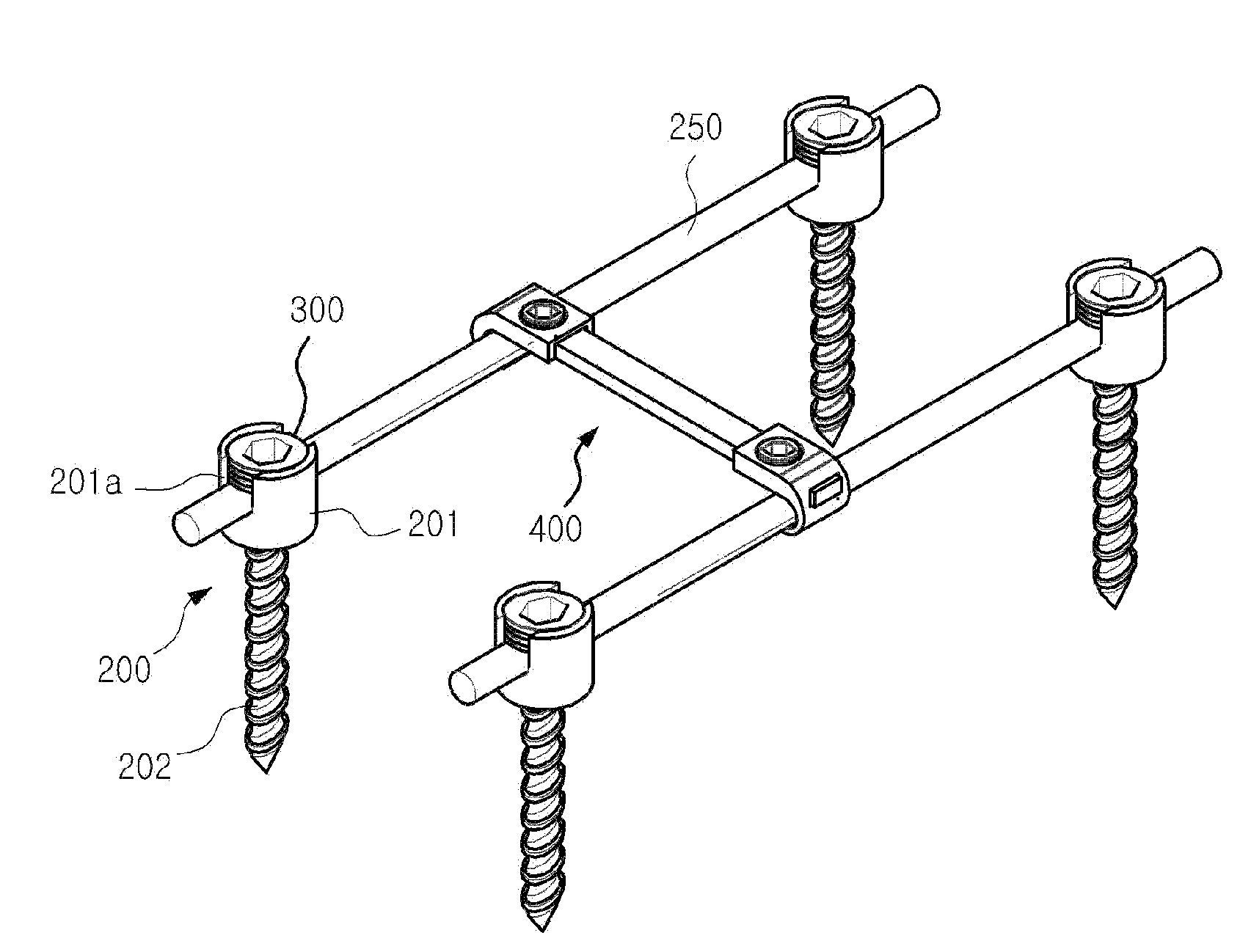

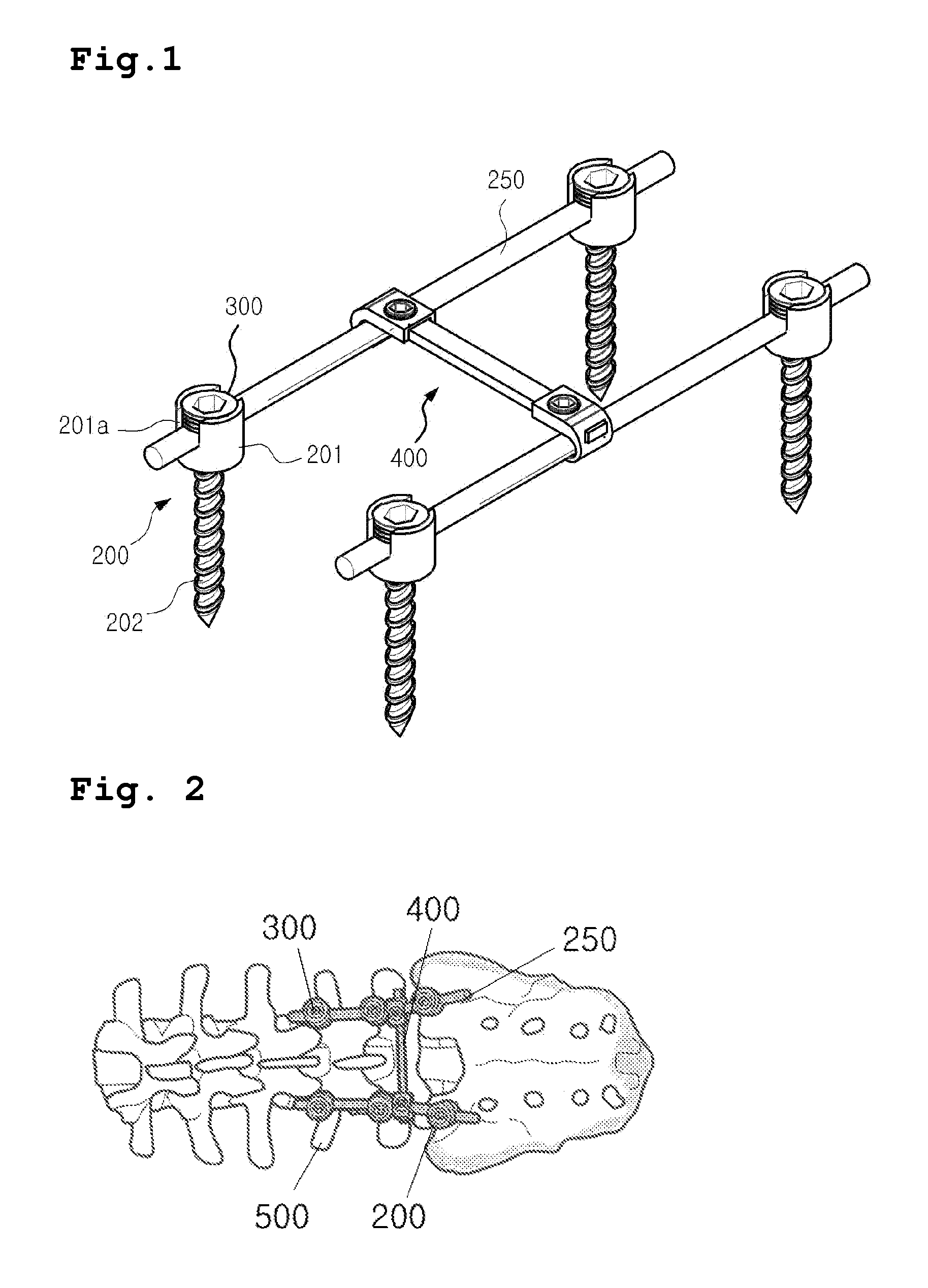

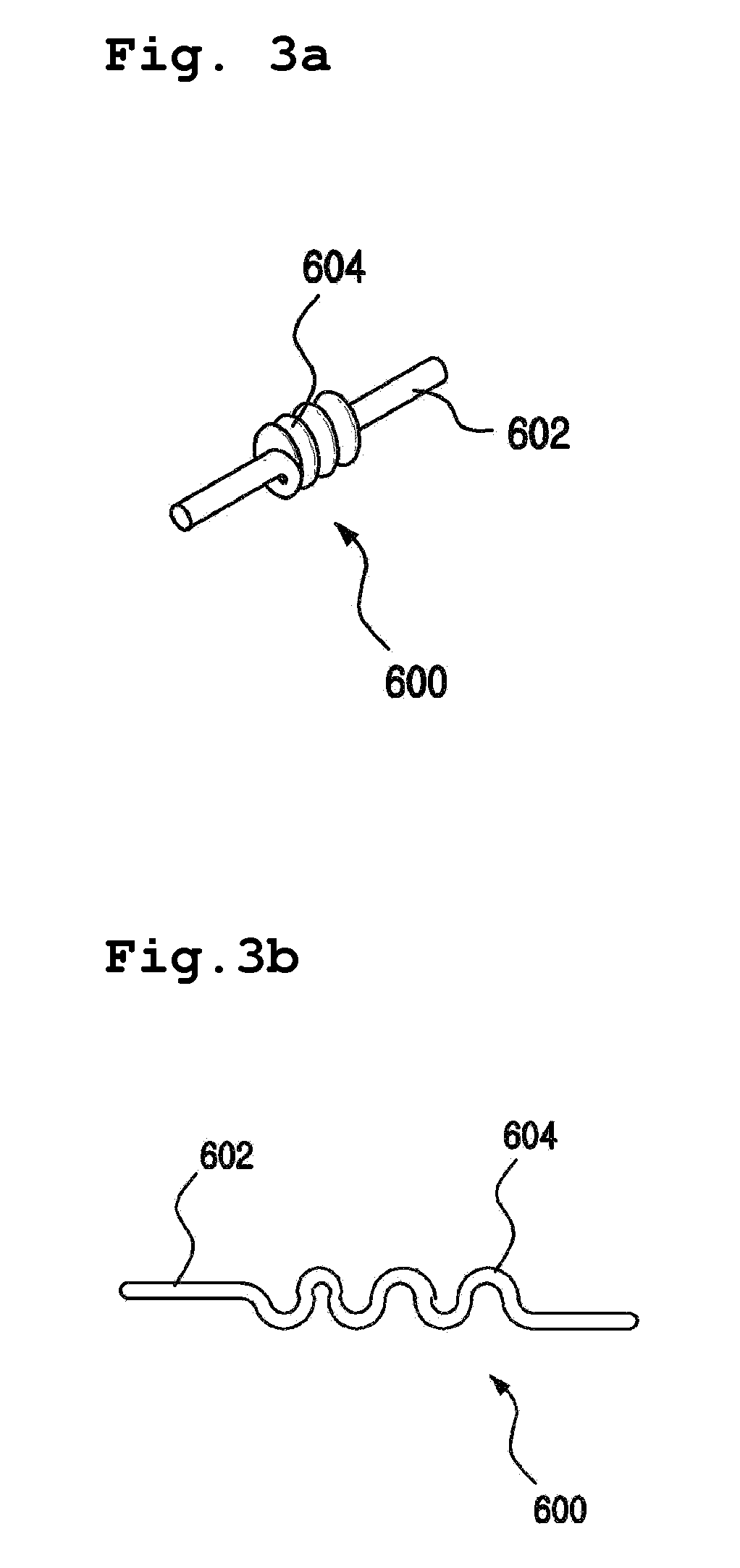

Flexible rod manufacturing apparatus and method for a spinal fixation and the flexible rod manufactured through the same

ActiveUS20080065071A1Easy to fixInternal osteosythesisJoint implantsManufactured apparatusEngineering

The present invention relates to a rod capable of securely connecting pedicle screws in a pedicle screw system for correcting a damaged or transformed spine and a method and an apparatus for fabricating the same and, more particularly, to a flexible pedicle rod with superelasticity in order to provide a flexibility to a fixation between spine segments and a method and an apparatus capable of fabrication the same in mass production. The apparatus according to the present invention comprises a body; an X- and Y-axis moving element mounted on a top surface of the body, the X- and Y-axis moving element simultaneously moving in X-axis and Y-axis directions to wind a material at an angle of 90 degrees; a magazine mounted on the X- and Y-axis moving element to load a material; a material withdrawing element for withdrawing materials one by one from the magazine; and a material molding element mounted on the X- and Y-axis moving element, the material molding element gripping both ends of the material withdrawn from the material withdrawing element and rotating to mold a portion of the material in a spring shape.

Owner:PARK KYUNG WOO

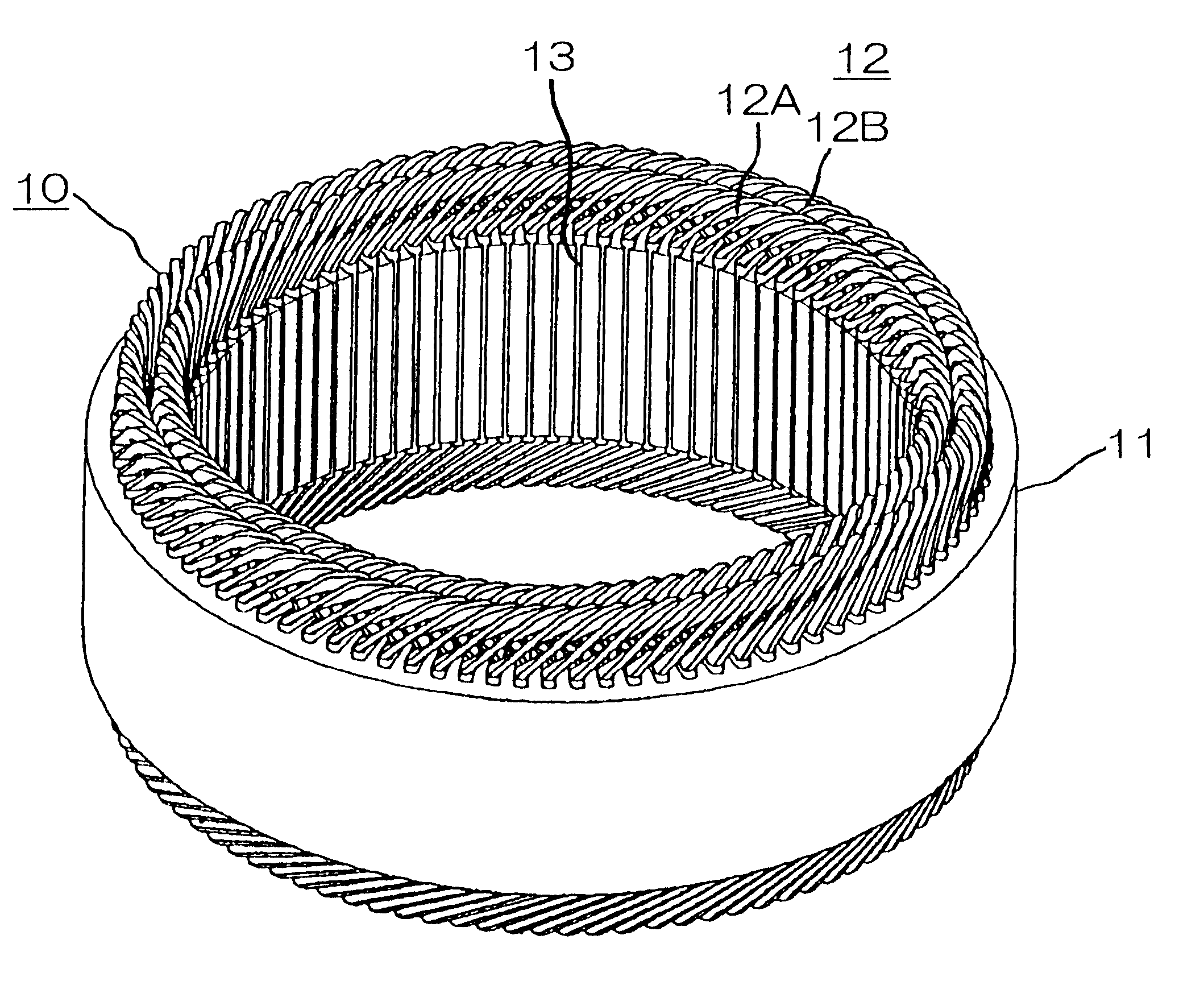

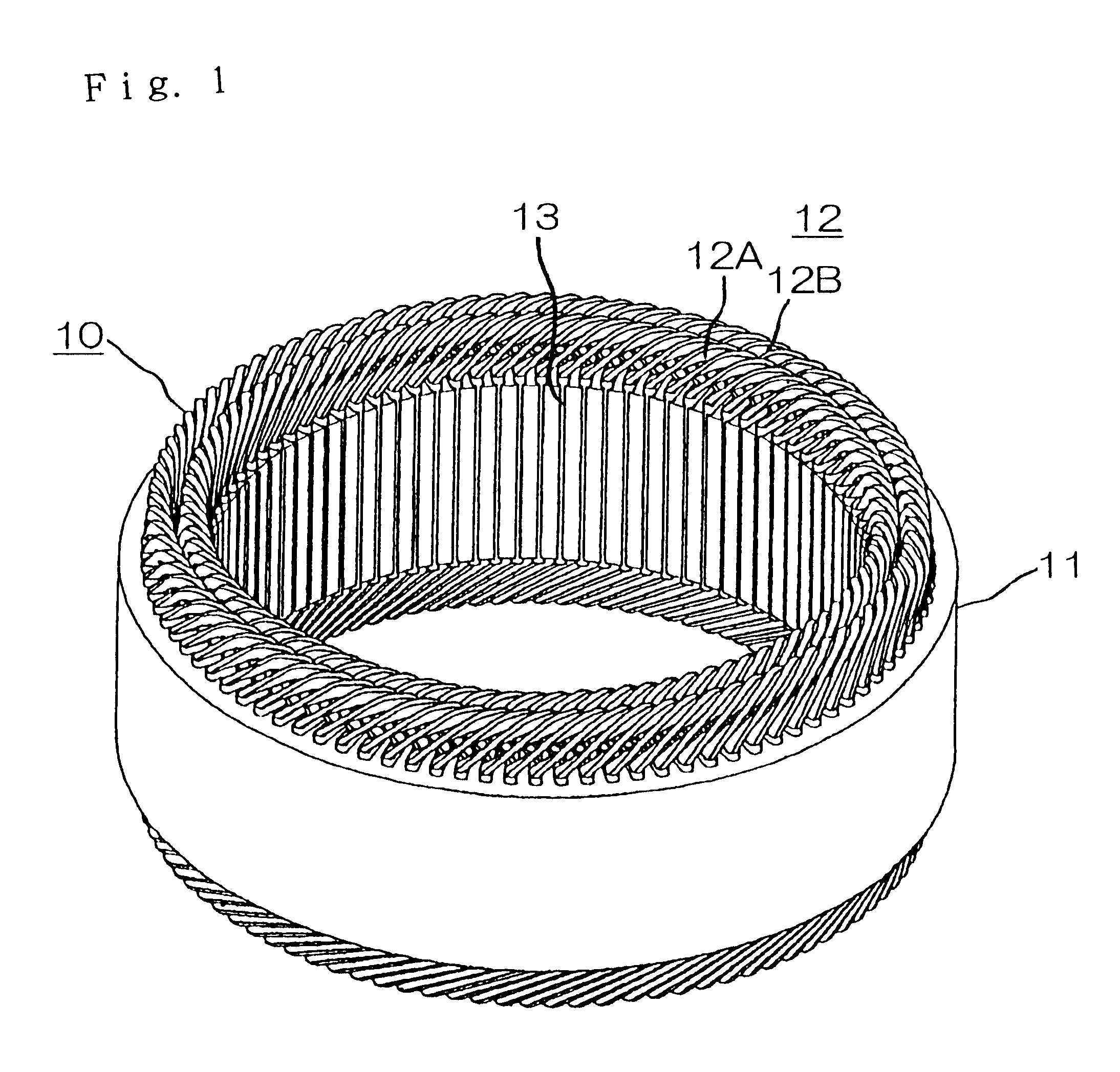

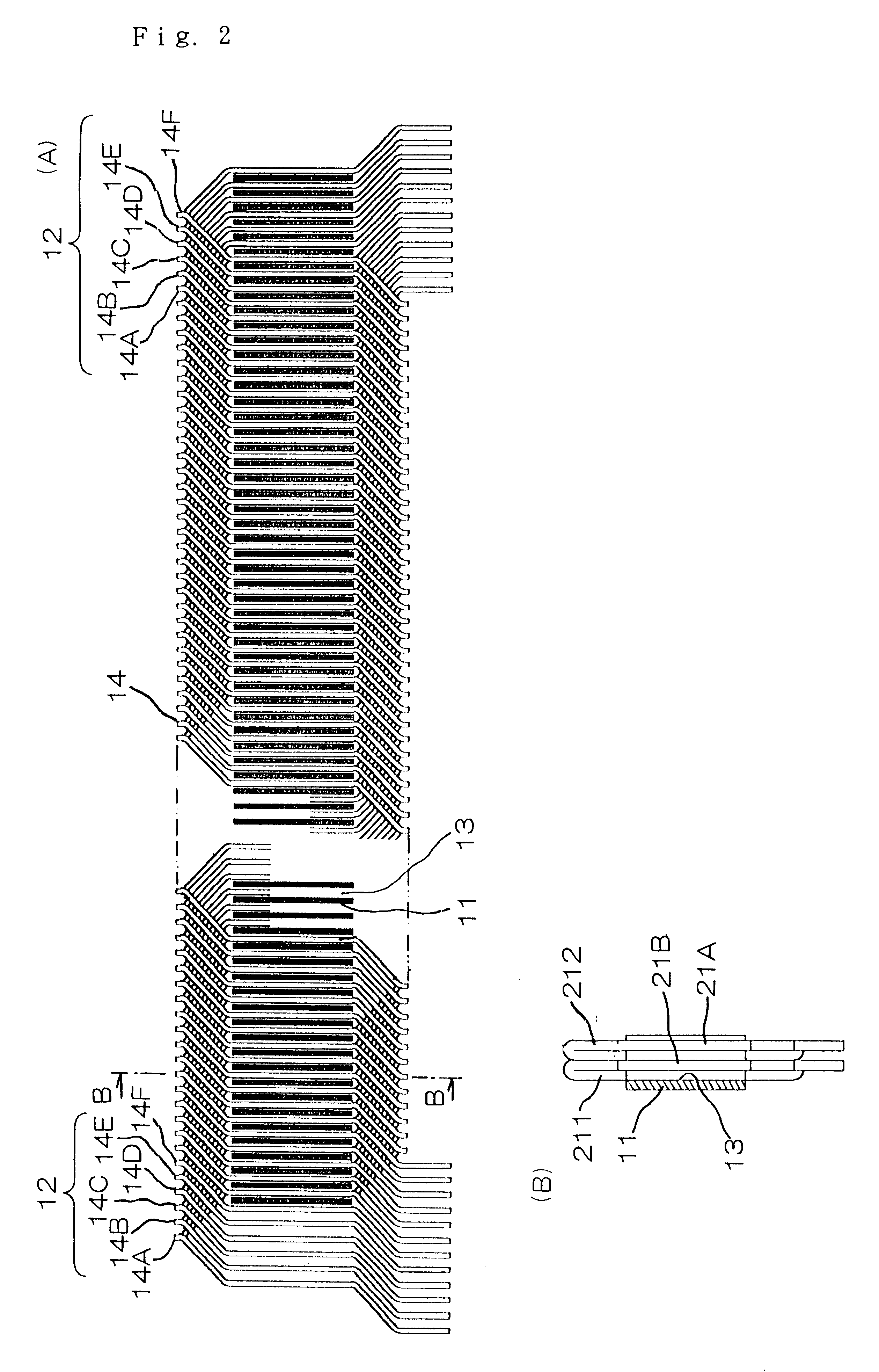

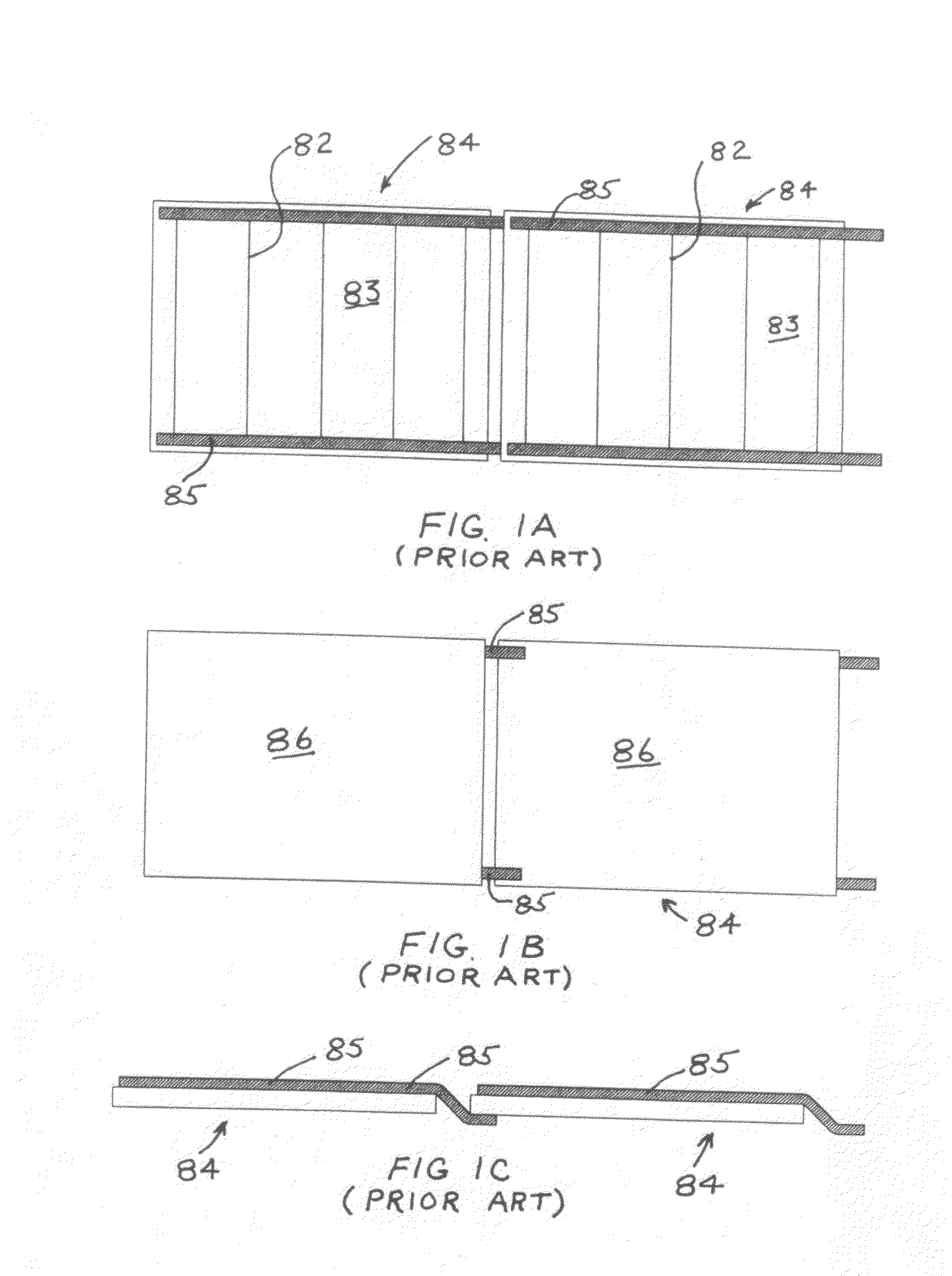

Coil assembly of rotating electrical machinery and method for producing the same, and stator of rotating electric machinery using the same coil assembly

InactiveUS6376961B2Synchronous generatorsMagnetic circuit stationary partsElectric machineryElectrical and Electronics engineering

The invention provides a coil member of rotating electrical machinery, by which improvements in the mass production and downsizing thereof are enabled, which is a coil assembly for rotating electrical machinery, consisting of a plurality of coil combinations mounted at iron core slots, wherein the respective coil combinations 14 are inserted into slots at pitches equivalent to an appointed number of slots, and are formed of an integral coil member 21 in which the first and the second linear portions 21A and 21B alternately disposed at the inner layer side and the outer layer side in the slots, and the first and the second turning portions 21C and 21D for connecting the first and second linear portions 21A and 21B adjacent to each other outward of one end side and outward of the other end side in the lengthwise direction of the slots are integrated together. And, the first linear portion 21A of the appointed coil member 211 thereof, and the second linear portion 21B of another coil member 211 are laminated and disposed in the same slots.

Owner:MITSUBISHI ELECTRIC CORP

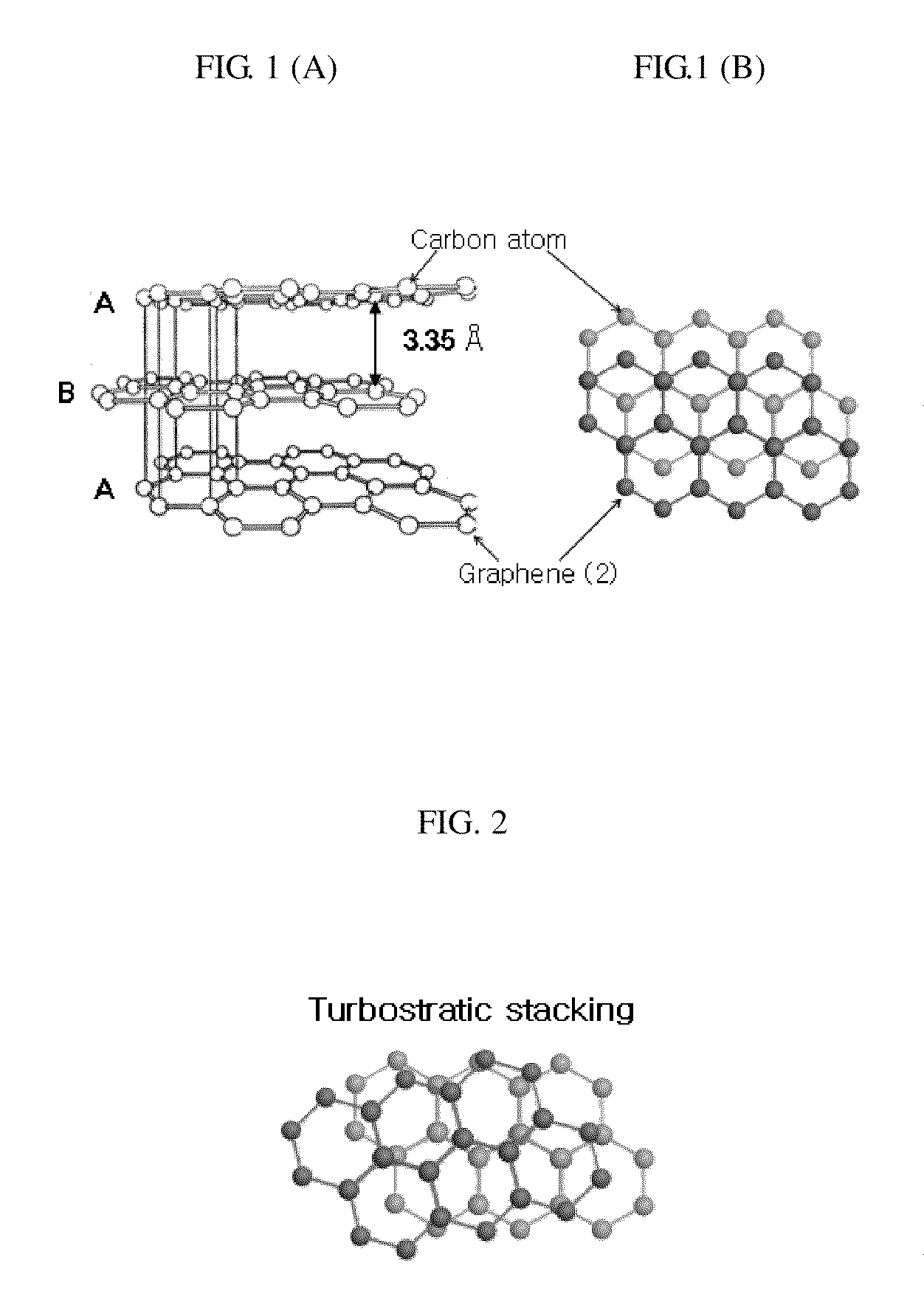

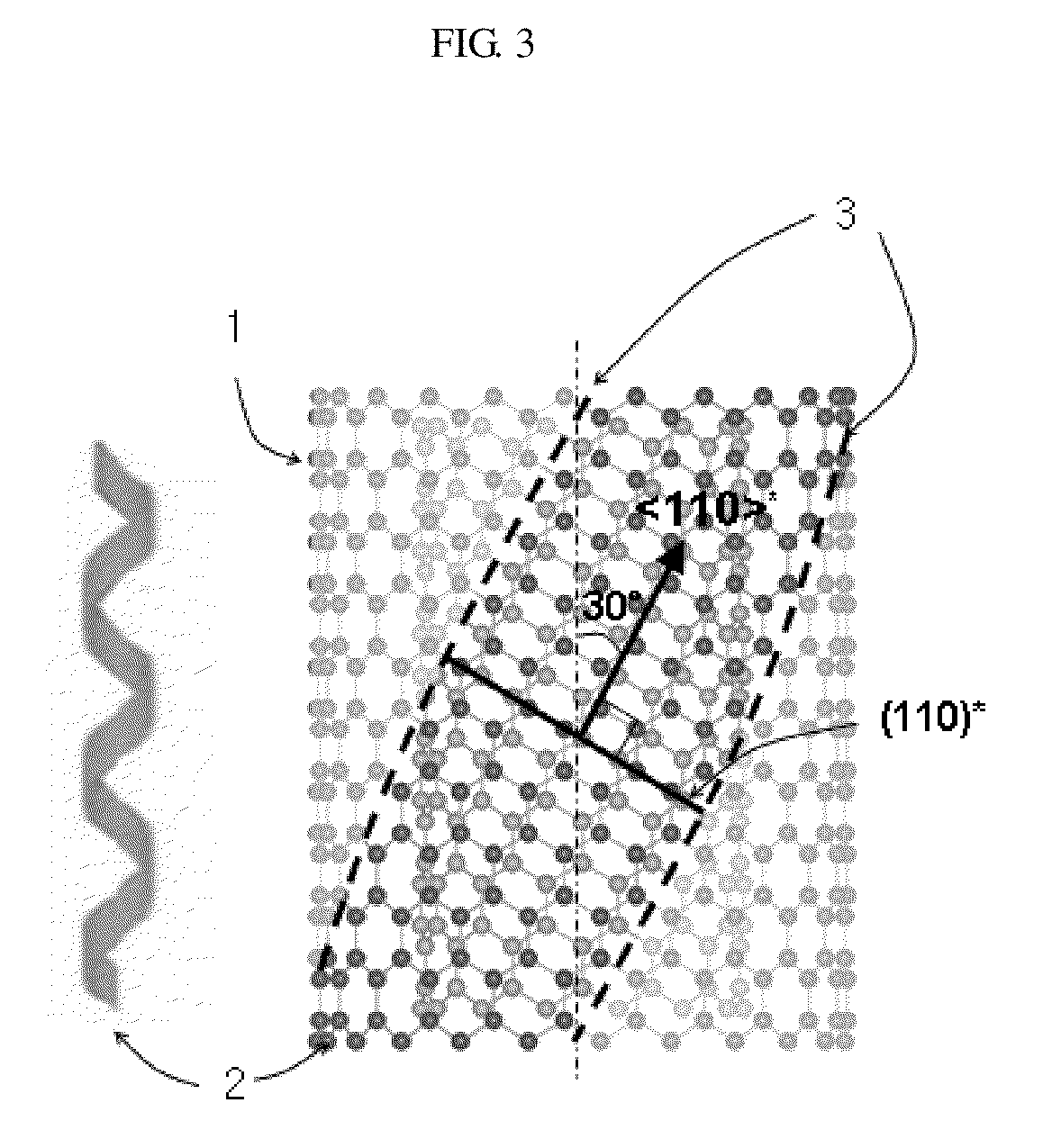

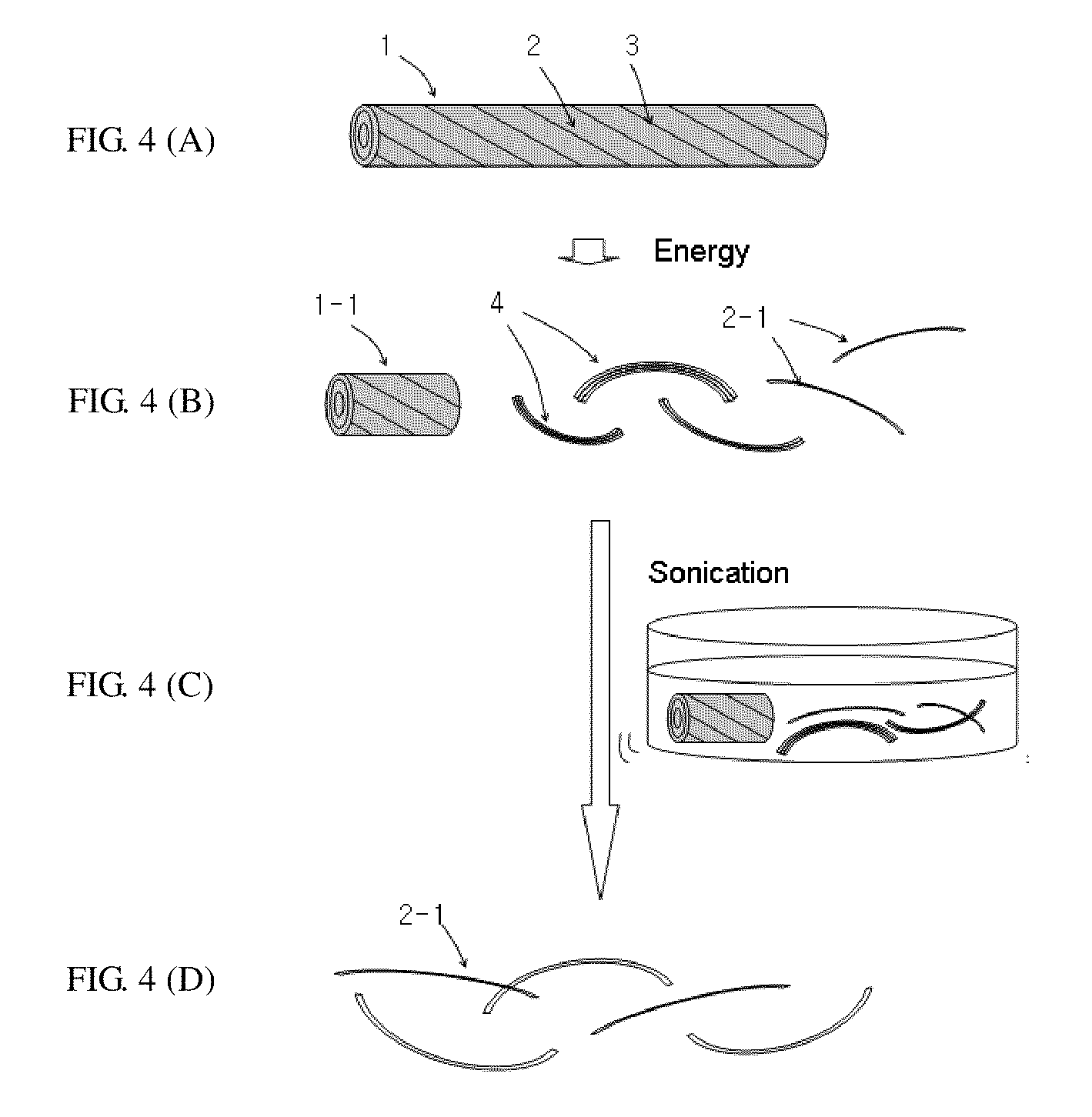

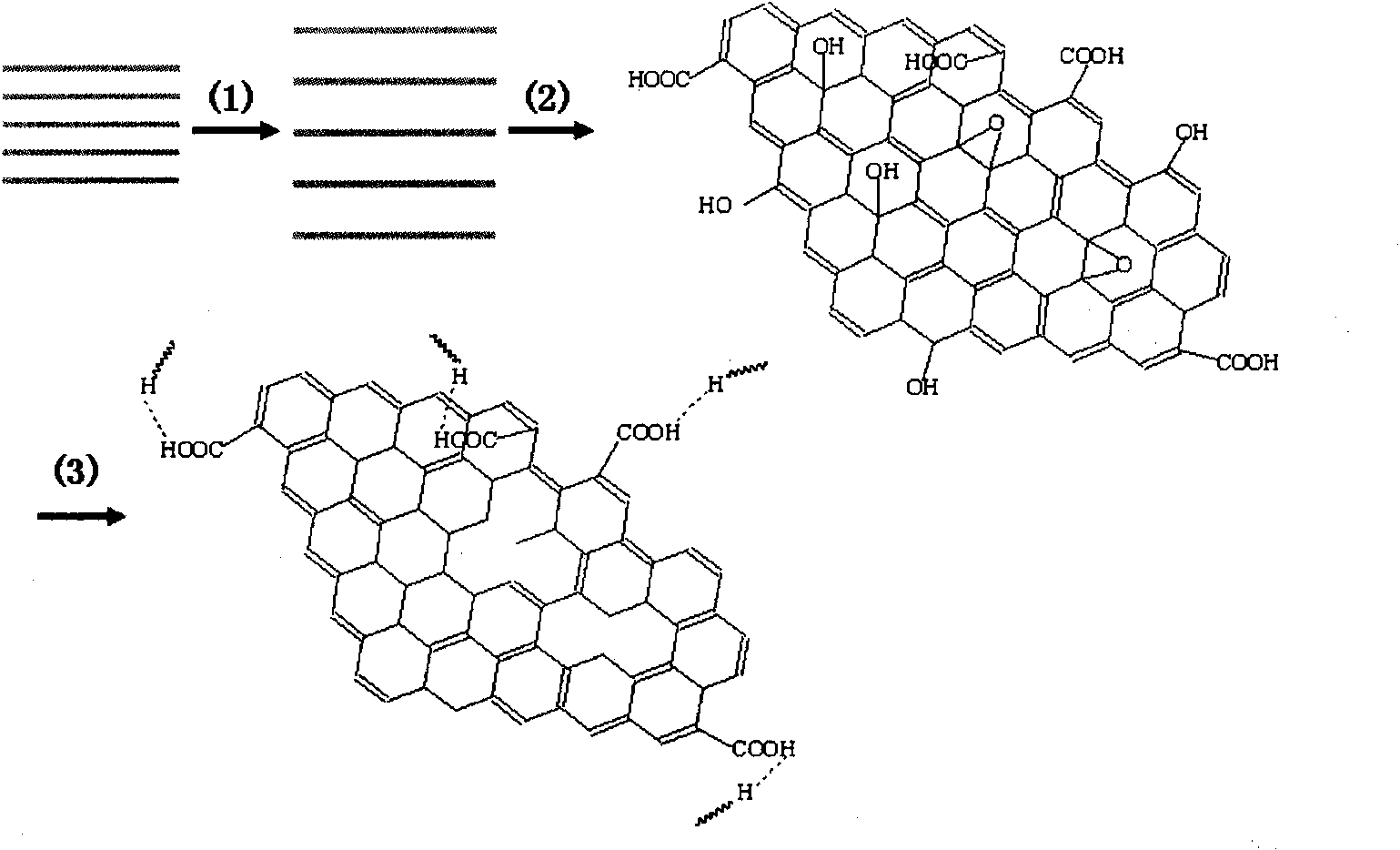

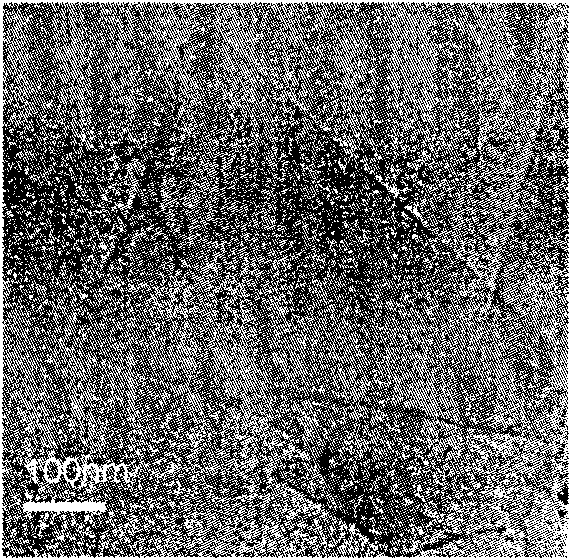

Method for preparing graphene ribbons

Disclosed is a method for fabricating graphene ribbons, comprising: preparing a graphitic material comprising stacked graphene helices; and cutting the graphitic material in a short form by applying energy to the graphitic material; and simultaneously or afterward, decomposing the graphitic material into short graphene ribbons. This method provides a mass production route to graphene ribbons.

Owner:KOREA INST OF SCI & TECH

Semiconductor device and method for manufacturing the same

ActiveUS20100065838A1Small currentHigh on-off ratioTransistorSolid-state devicesProduction rateSemiconductor package

An object is to provide a semiconductor device including a thin film transistor with excellent electrical characteristics and high reliability and a method for manufacturing the semiconductor device with high mass productivity. A main point is to form a low-resistance oxide semiconductor layer as a source or drain region after forming a drain or source electrode layer over a gate insulating layer and to form an oxide semiconductor film thereover as a semiconductor layer. It is preferable that an oxygen-excess oxide semiconductor layer be used as a semiconductor layer and an oxygen-deficient oxide semiconductor layer be used as a source region and a drain region.

Owner:SEMICON ENERGY LAB CO LTD

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20080314433A1Minimization requirementsIncrease volumePV power plantsPhotovoltaic energy generationPolymer substrateMaterial removal

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

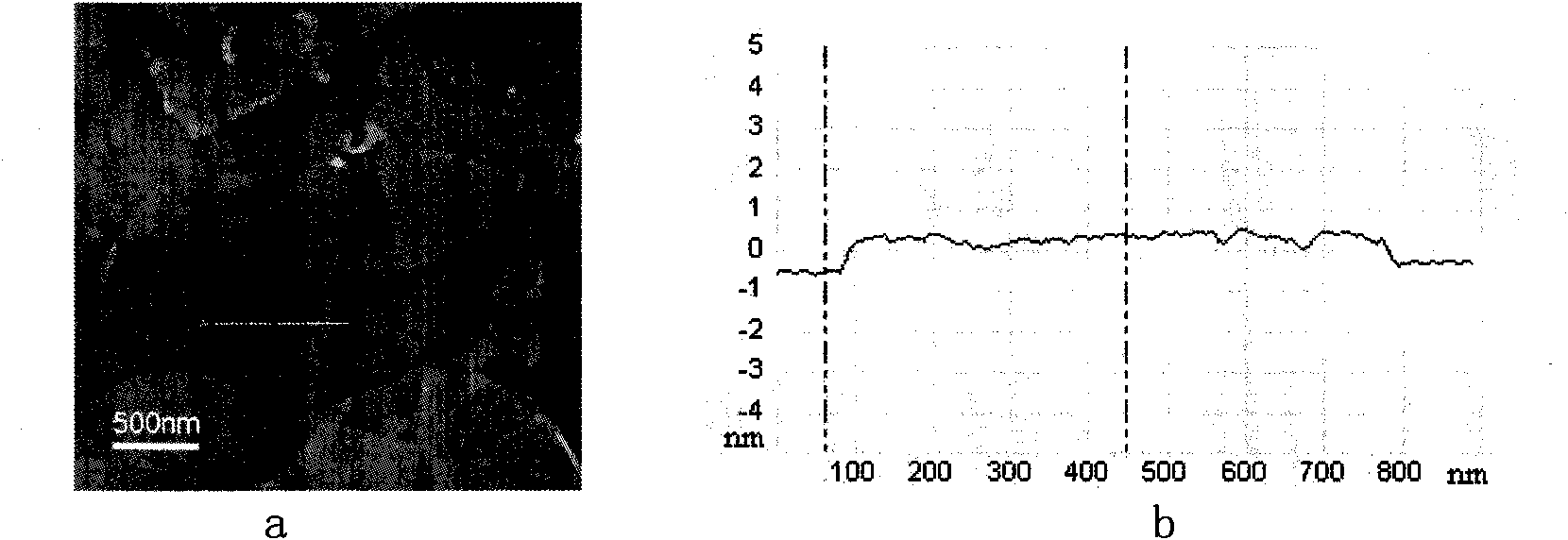

Preparation method of graphene based on ascorbic acid

ActiveCN101602504AEase of mass productionShort reaction timeNanostructure manufactureMaterials scienceReducing agent

The invention relates to a preparation method of graphene based on ascorbic acid, belonging to the technical field of nano materials. The preparation method comprises the following steps: preparing brown graphite suspending liquid; preparing luminous yellow graphite diluent; preparing graphite oxide solid; dispersing graphite oxide into deionized water, separating graphene oxide by ultrasonic separation treatment for 1 hour and preparing graphene oxide solution; and fully mixing the graphene oxide solution and ascorbic acid water solution, stewing and obtaining the graphene solution. The preparation adopts the ascorbic acid as a reducing agent, shortens reaction time under the condition that no stabilizing agent is added, obtains single-layer grapheme with the thickness of 0.8 to 1.2nm and is beneficial to batch production of the grapheme.

Owner:上海碳源汇谷新材料科技有限公司

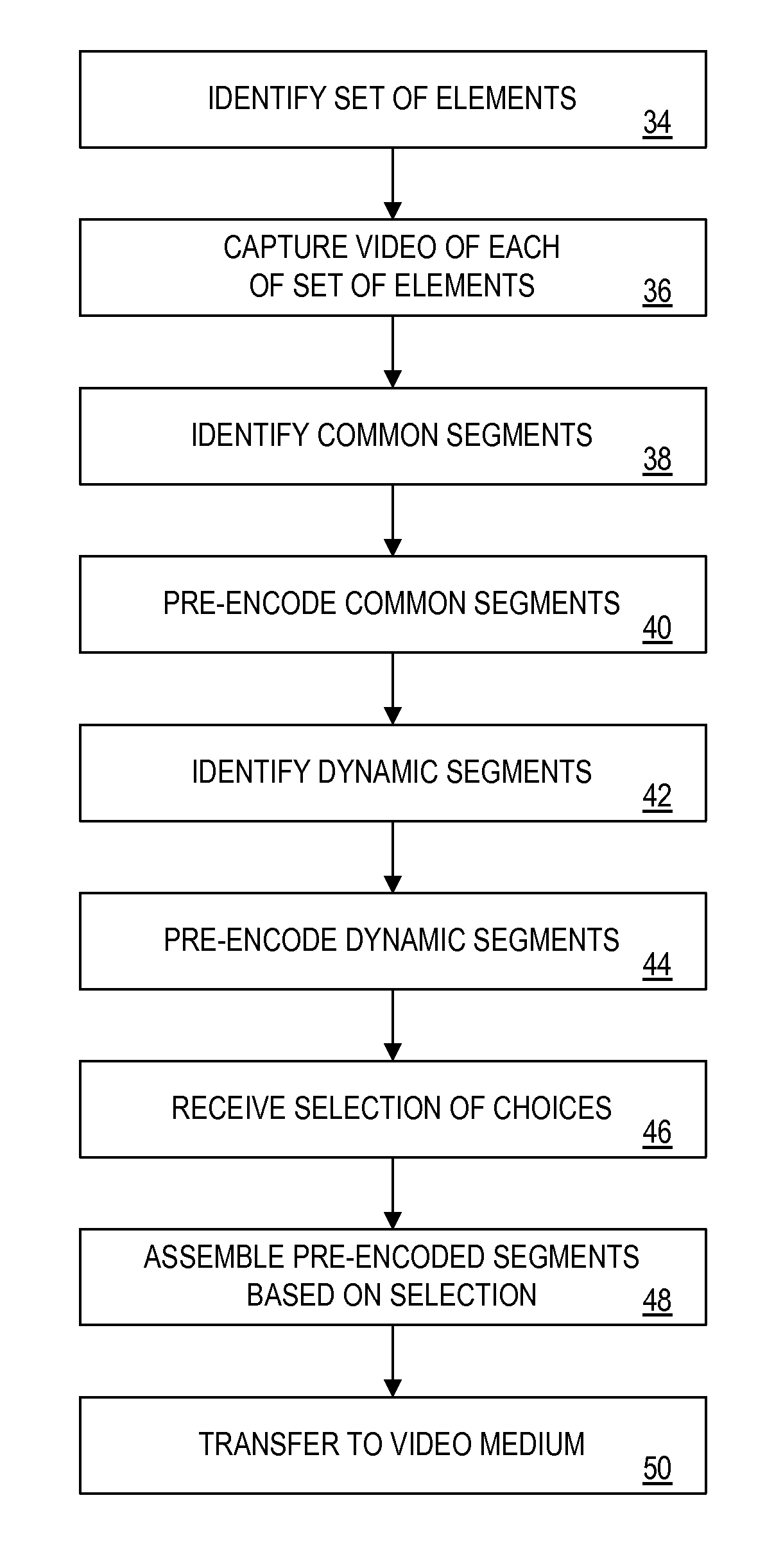

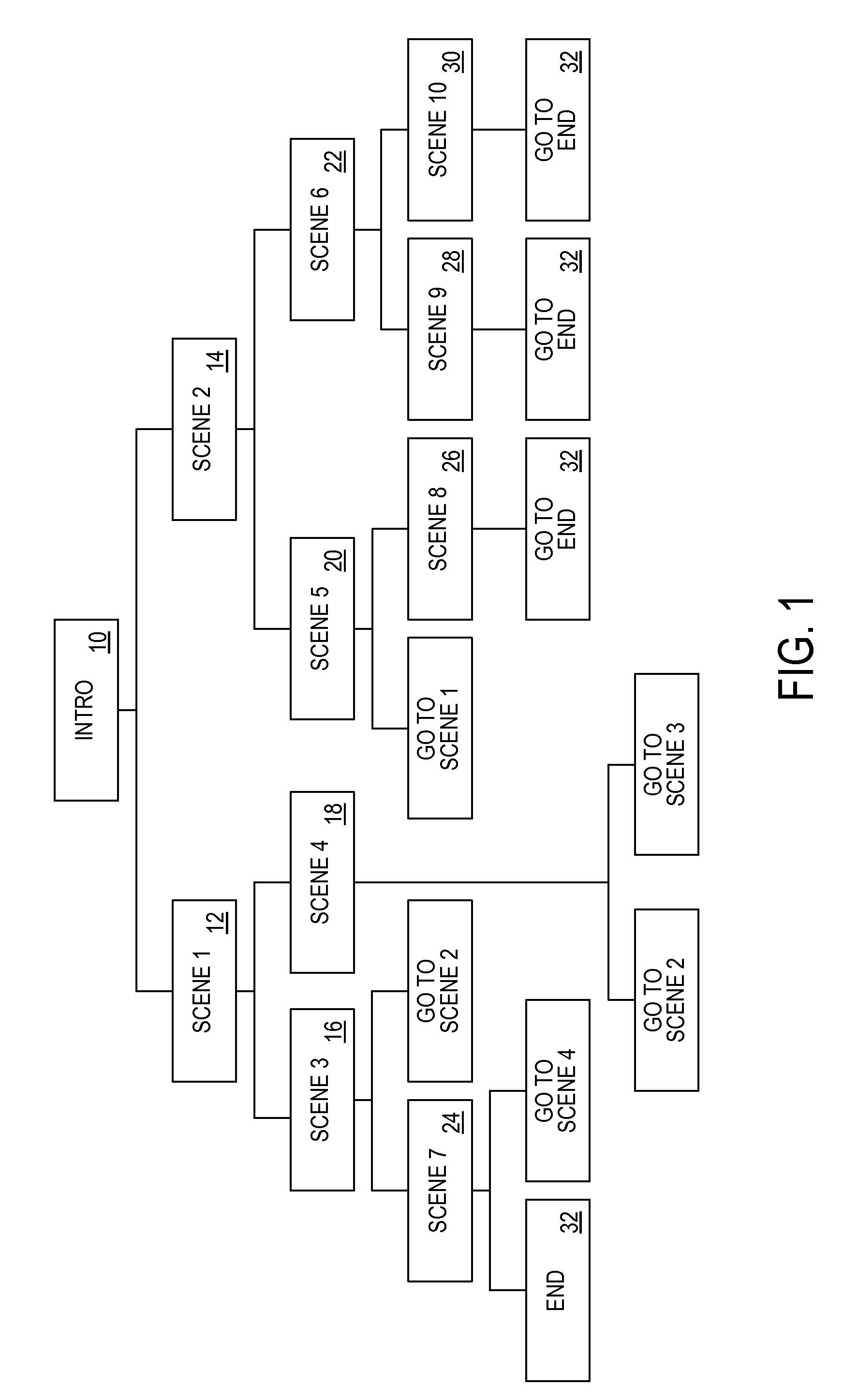

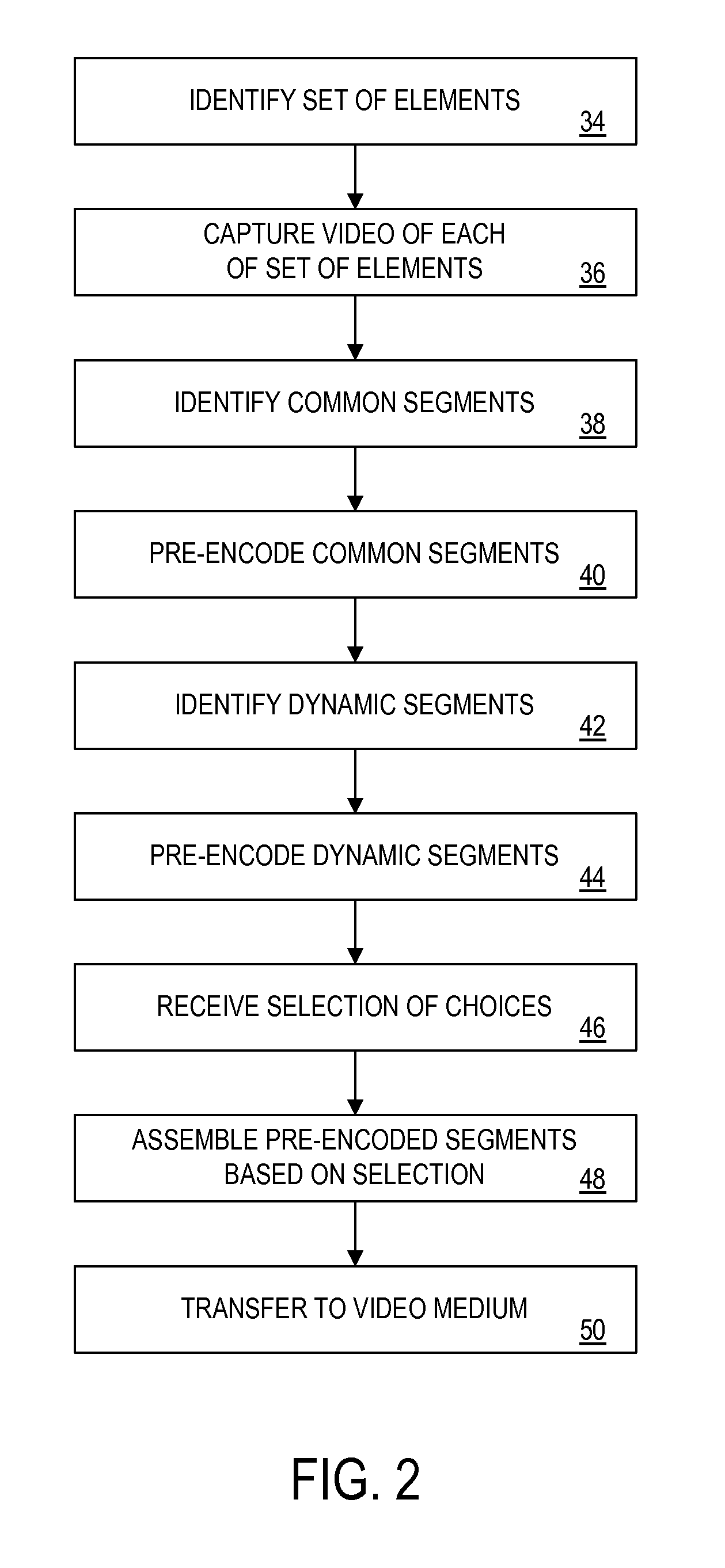

Efficient customized media creation through pre-encoding of common elements

InactiveUS20070011718A1Analogue secracy/subscription systemsTwo-way working systemsComputer graphics (images)Common element

A video clip containing certain customizable portions may be mass produced such that each copy of the video clip may be unique relative to the other copies. This customization is effectuated by pre-encoding the common elements and any reusable dynamic elements. Then, as the video clip is produced, the pre-encoded elements are combined to form the customized video clip.

Owner:IGT

Semiconductor device and manufacturing method thereof

ActiveUS20110215331A1Improve reliabilityReduce power consumptionTransistorStatic indicating devicesDevice materialEngineering

An object of the present invention to provide a highly reliable semiconductor device. Another object is to provide a manufacturing method of a highly reliable semiconductor device. Still another object is to provide a semiconductor device having low power consumption. Yet another object is to provide a manufacturing method of a semiconductor device having low power consumption. Furthermore, another object is to provide a semiconductor device which can be manufactured with high mass productivity. Another object is to provide a manufacturing method of a semiconductor device which can be manufactured with high mass productivity. An impurity remaining in an oxide semiconductor layer is removed so that the oxide semiconductor layer is purified to have an extremely high purity. Specifically, after adding a halogen element into the oxide semiconductor layer, heat treatment is performed to remove an impurity from the oxide semiconductor layer. The halogen element is preferably fluorine.

Owner:SEMICON ENERGY LAB CO LTD

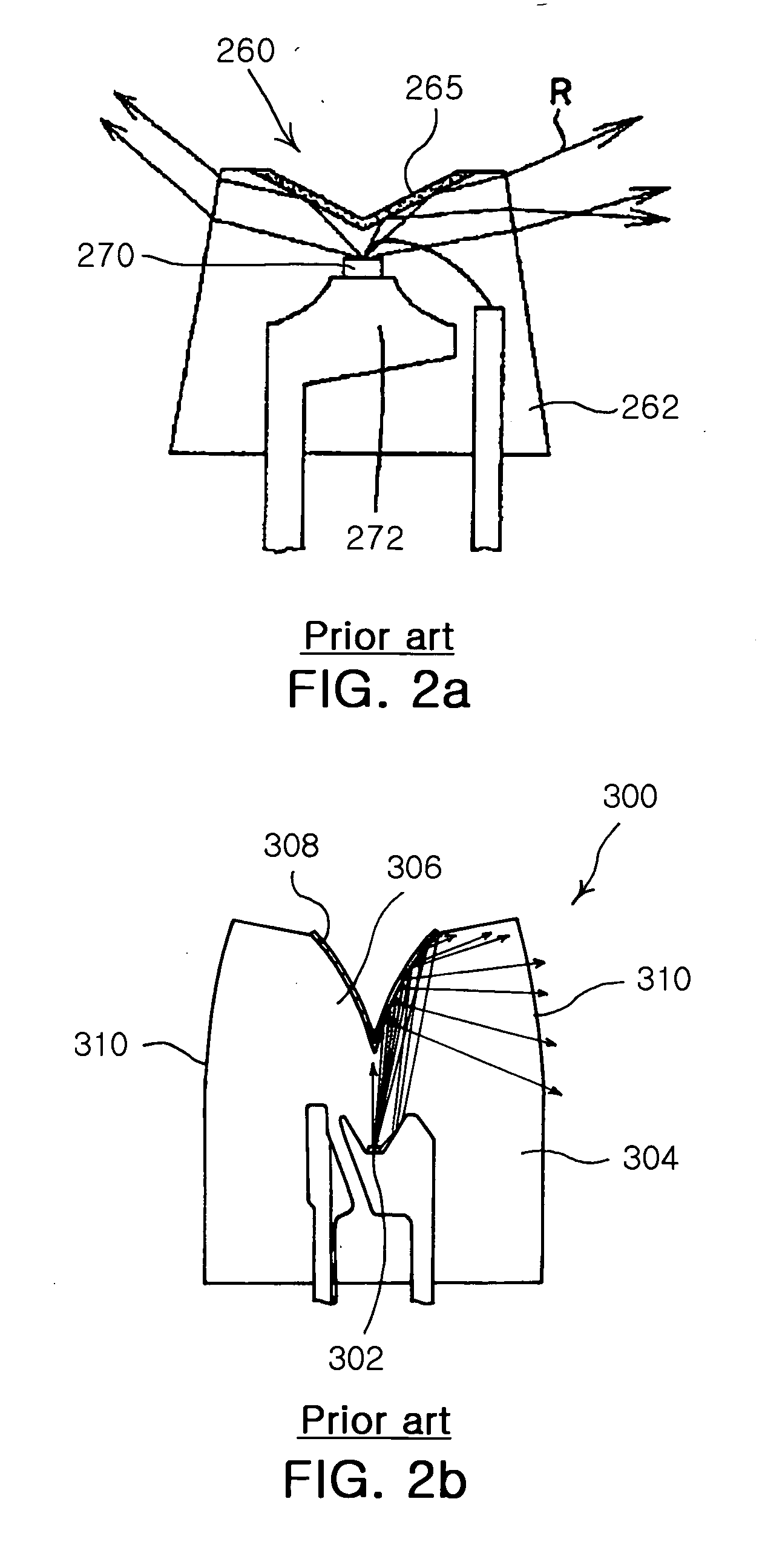

Light emitting diode package with metal reflective layer and method of manufacturing the same

InactiveUS20060284207A1Easy to manufactureSmall sizeSolid-state devicesSemiconductor devicesTransfer moldingEngineering

The invention relates to an LED package having a metal reflective layer for focusing and emitting light through a side of the package, and a manufacturing method of the same. The LED package includes a substrate with an electrode formed thereon, a light emitting diode chip disposed on the substrate, and an encapsulant covering the LED chip and the substrate to protect the LED chip. The LED package also includes a metal reflective layer surrounding side surfaces of the encapsulant to form a light transmitting surface on a top surface of the encapsulant. The invention minimizes light loss, improves luminance, can be mass-produced as a PCB type, and adopts EMC transfer molding to minimize irregular color distribution, thereby improving optical quality.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

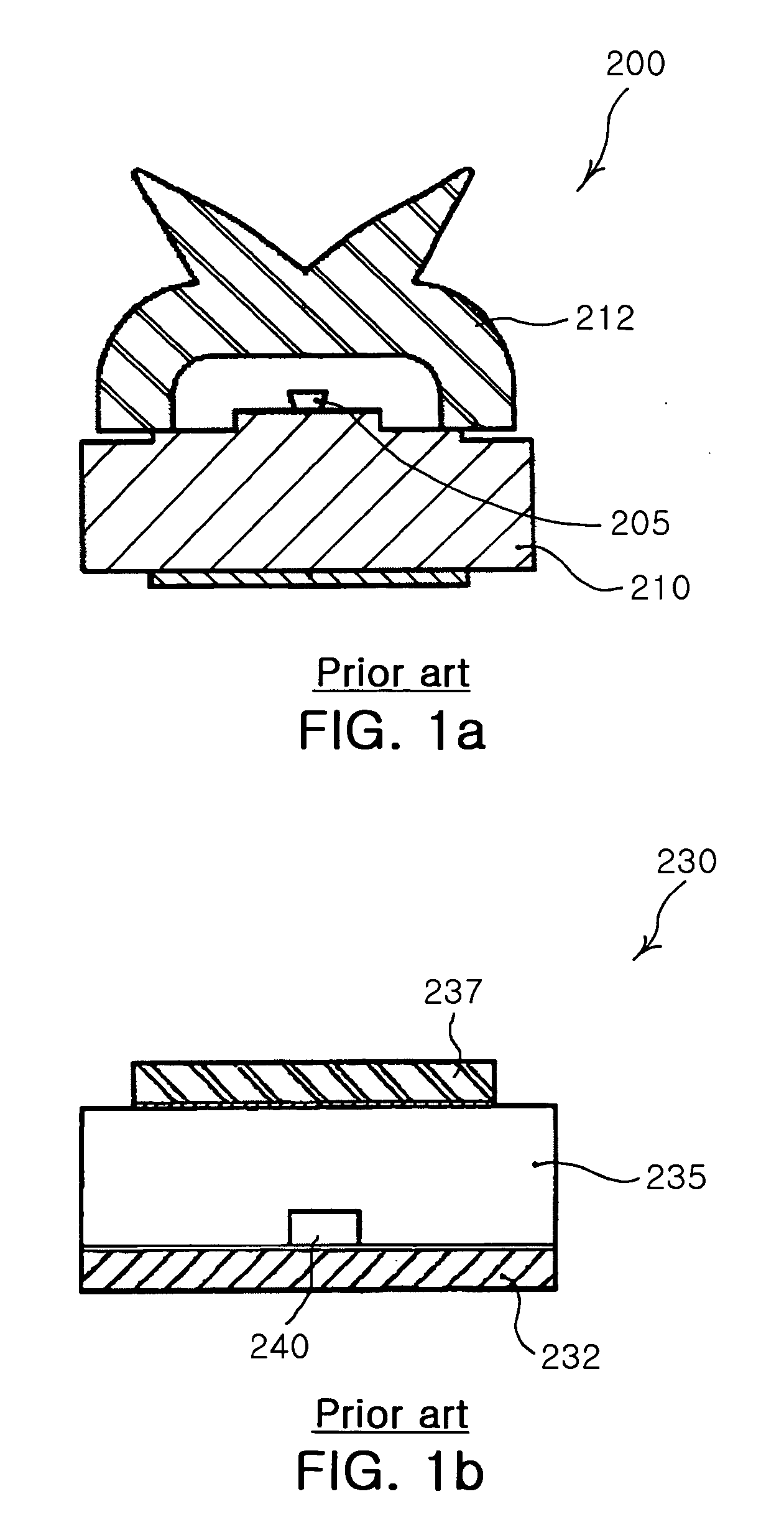

Side-emitting LED package and method of manufacturing the same

InactiveUS20060273337A1Effective reflectionEasy to manufactureSolid-state devicesSemiconductor devicesChip sizeEngineering

The invention relates to a side-emitting LED package and a manufacturing method thereof. The side-emitting LED package includes a substrate with an electrode formed thereon, and a light source disposed on the substrate and electrically connected to the electrode. The side-emitting LED package also includes a molded part having an upper surface with a center thereof depressed concavely, covering and protecting the substrate and the light source, and a reflection layer covering an entire upper surface of the molded part to reflect light sideward from the molded part which forms a light transmitting surface. The package is not restricted in the shape of the molded part and is not affected by the LED chip size, enabling a compact structure. The invention can also process a substrate by a PCB process, enabling mass-production.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

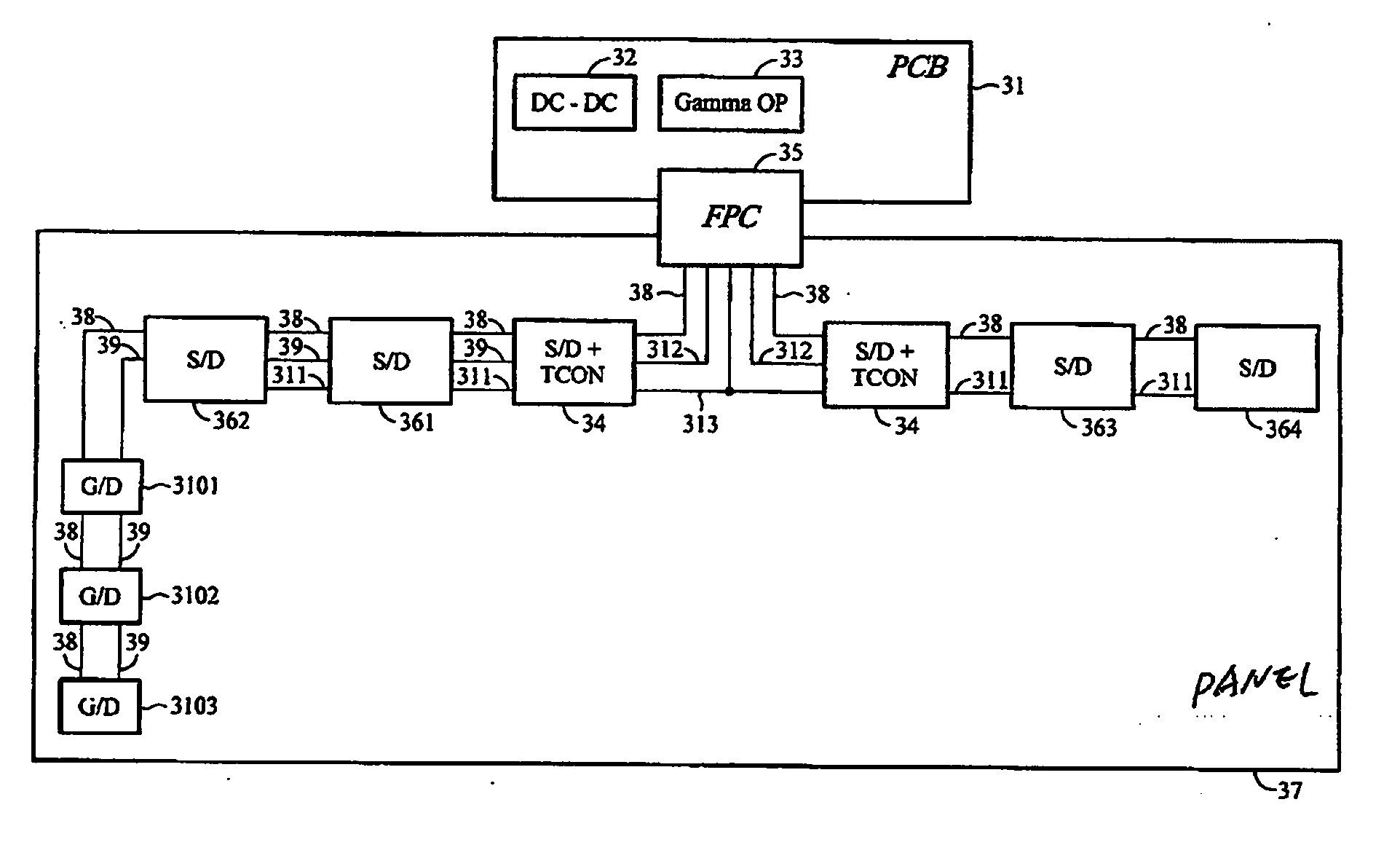

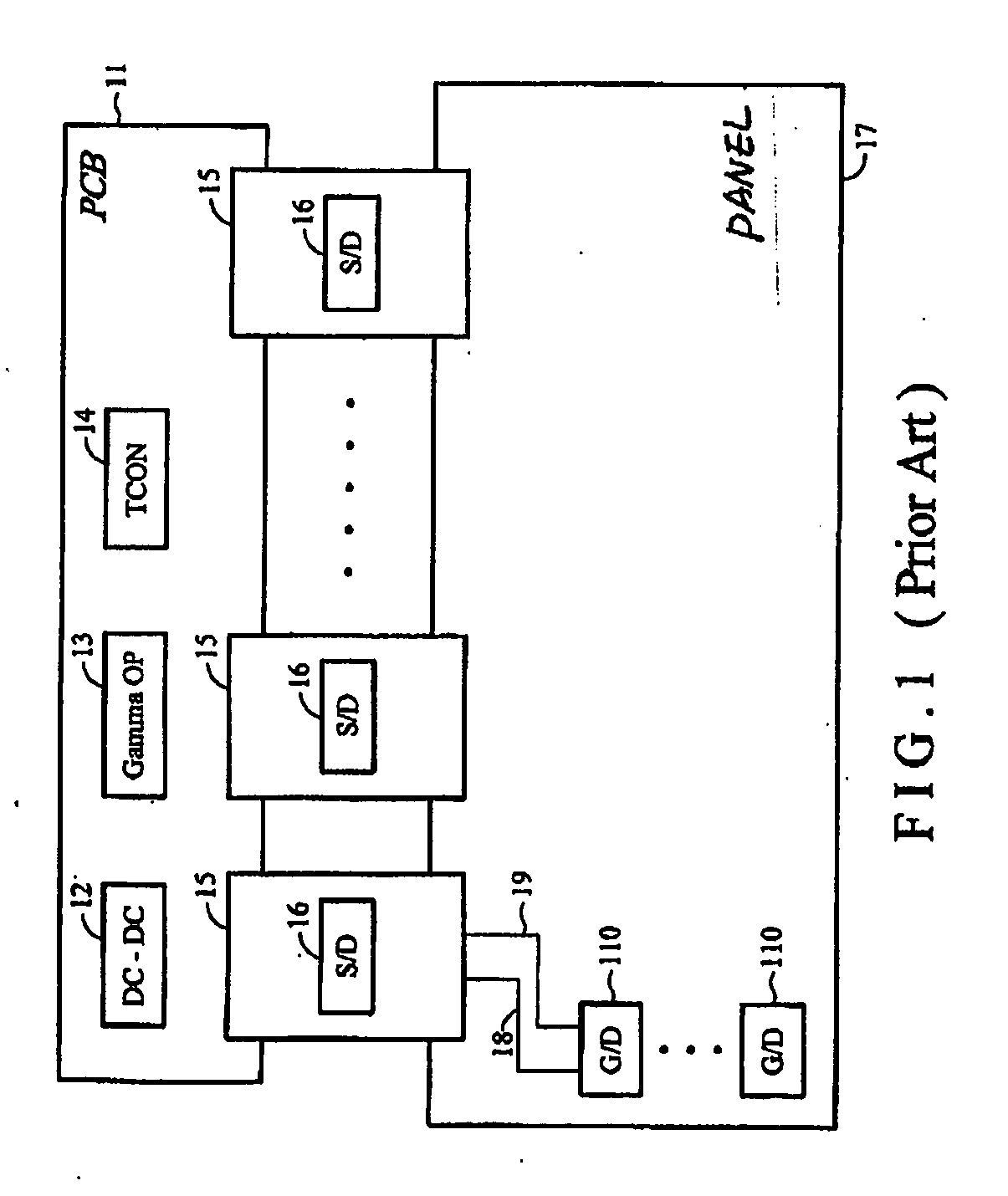

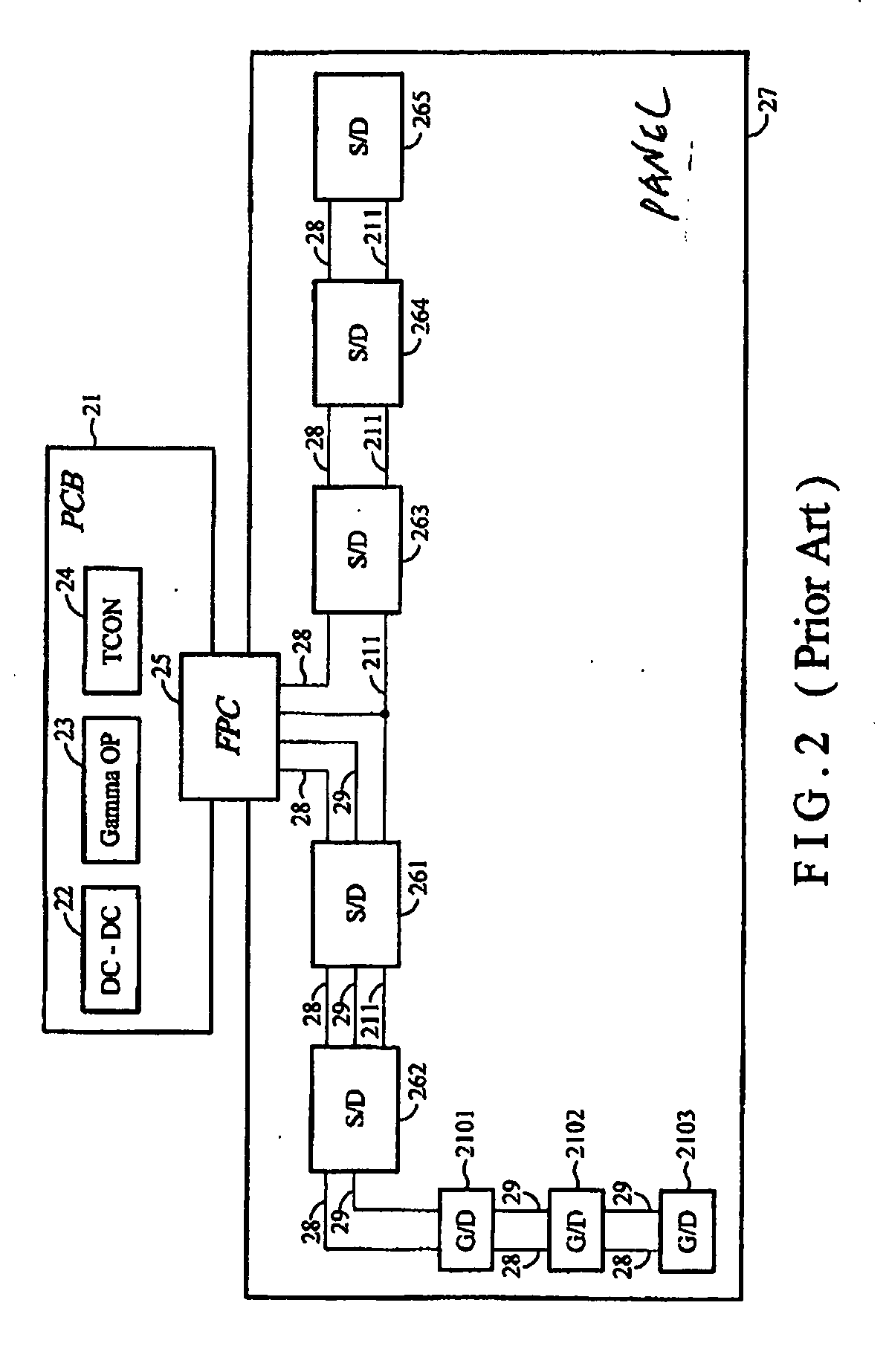

WOA panel architecture

InactiveUS20060232579A1Low costSmall sizeCathode-ray tube indicatorsInput/output processes for data processingSpatial correlationLiquid-crystal display

The present invention provides solutions to simplify and reduce the resources needed for manufacturing liquid crystal display modules. Failure of mid-process steps during mass production can result in significant costs. According to certain embodiments of the present invention, a WOA display panel architecture requires fewer LCM resources or has no PCB. Although the COG process and WOA method provide higher reliability in temporary LCD production, the costs associated with the space required for wires on the PCB or display panel for larger panel sizes remains expensive. Larger panel sizes also requires an increased number of driver ICs to construct a flat display panel. Similarly, the number of wires connecting each driver IC to a timing controller IC, gamma operational amplifier IC and DC-to-DC converter IC creates spacing problems that translate into higher production costs. These problems can be solved by certain embodiments of the present invention.

Owner:HIMAX TECH LTD

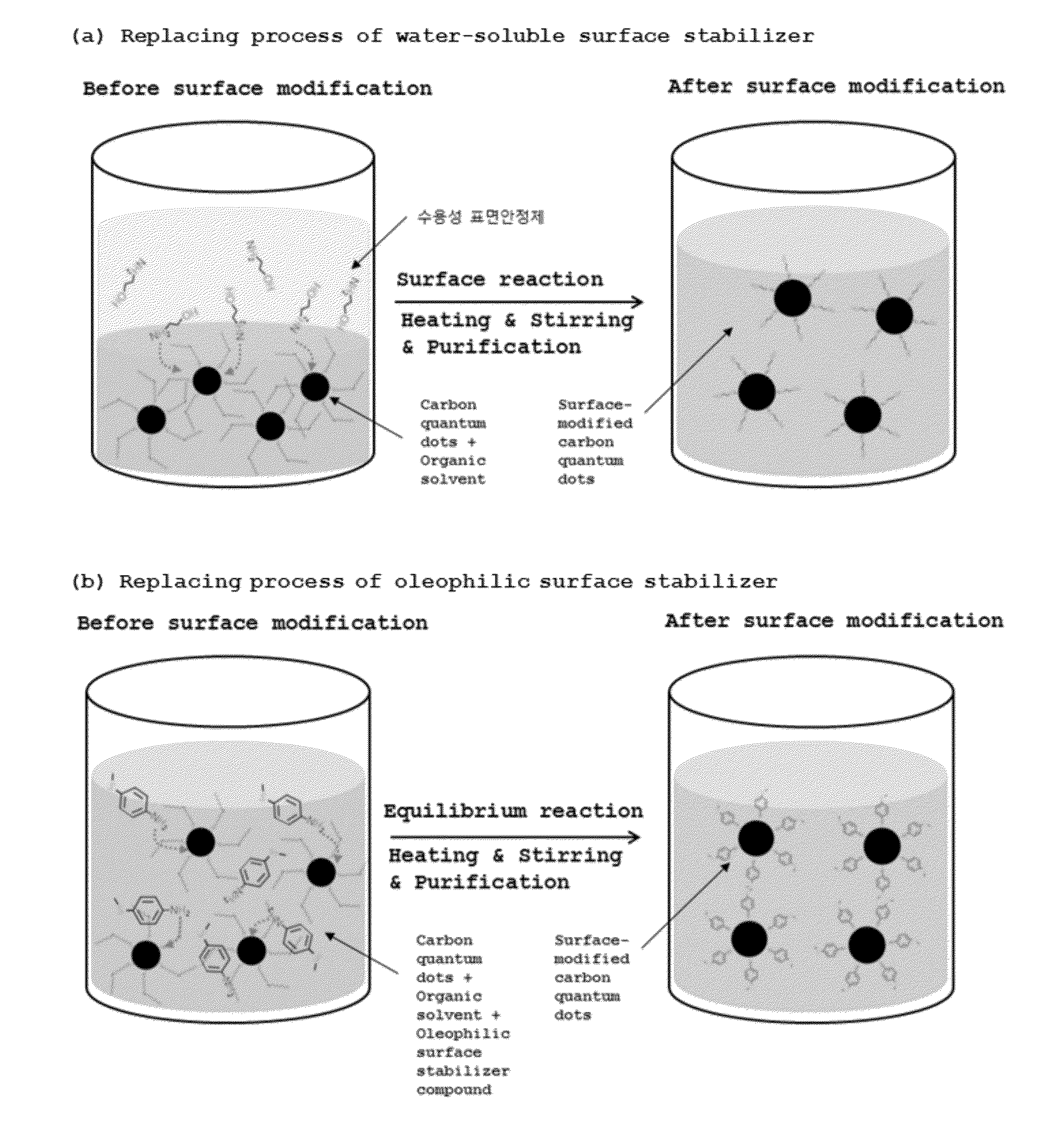

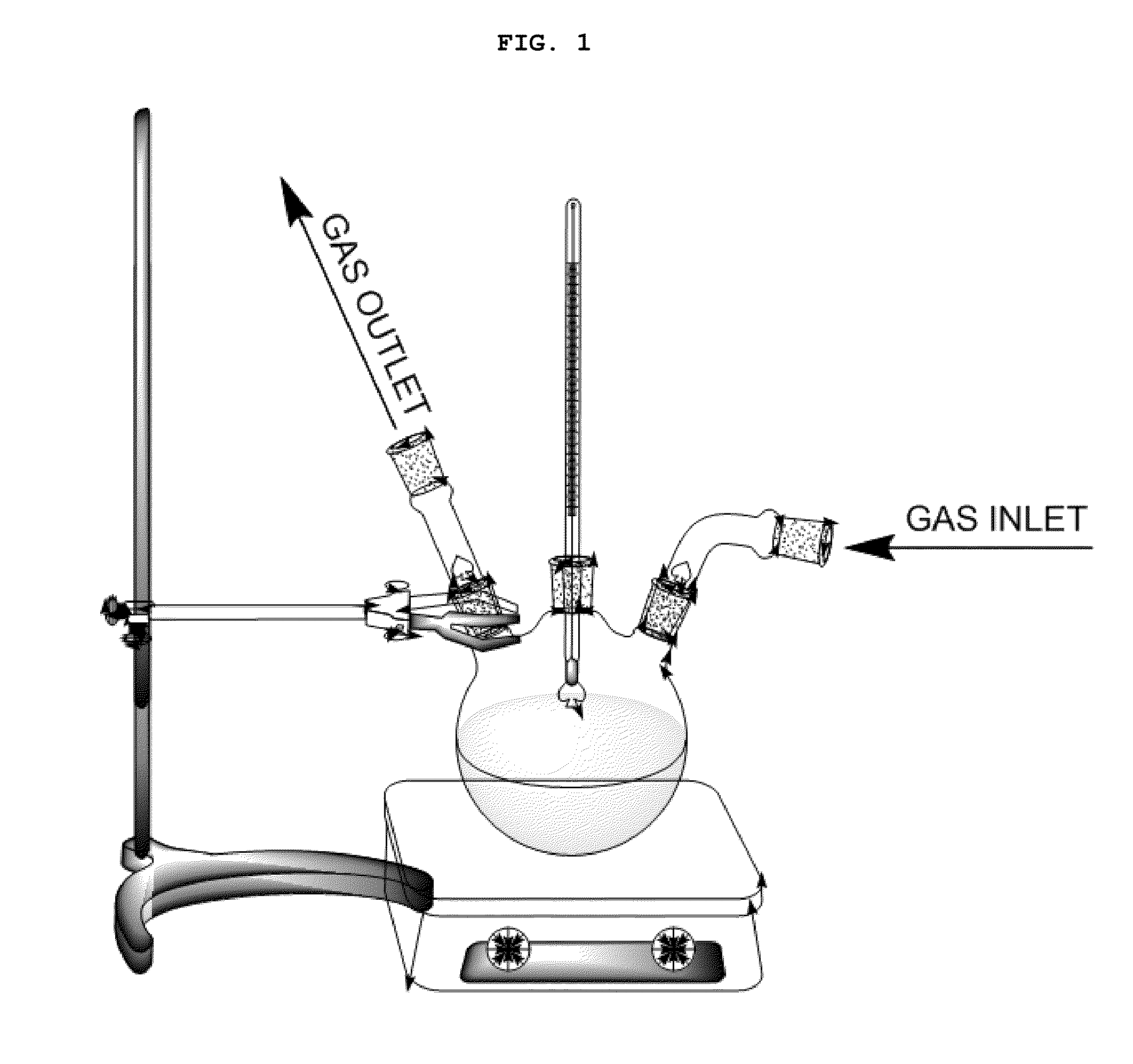

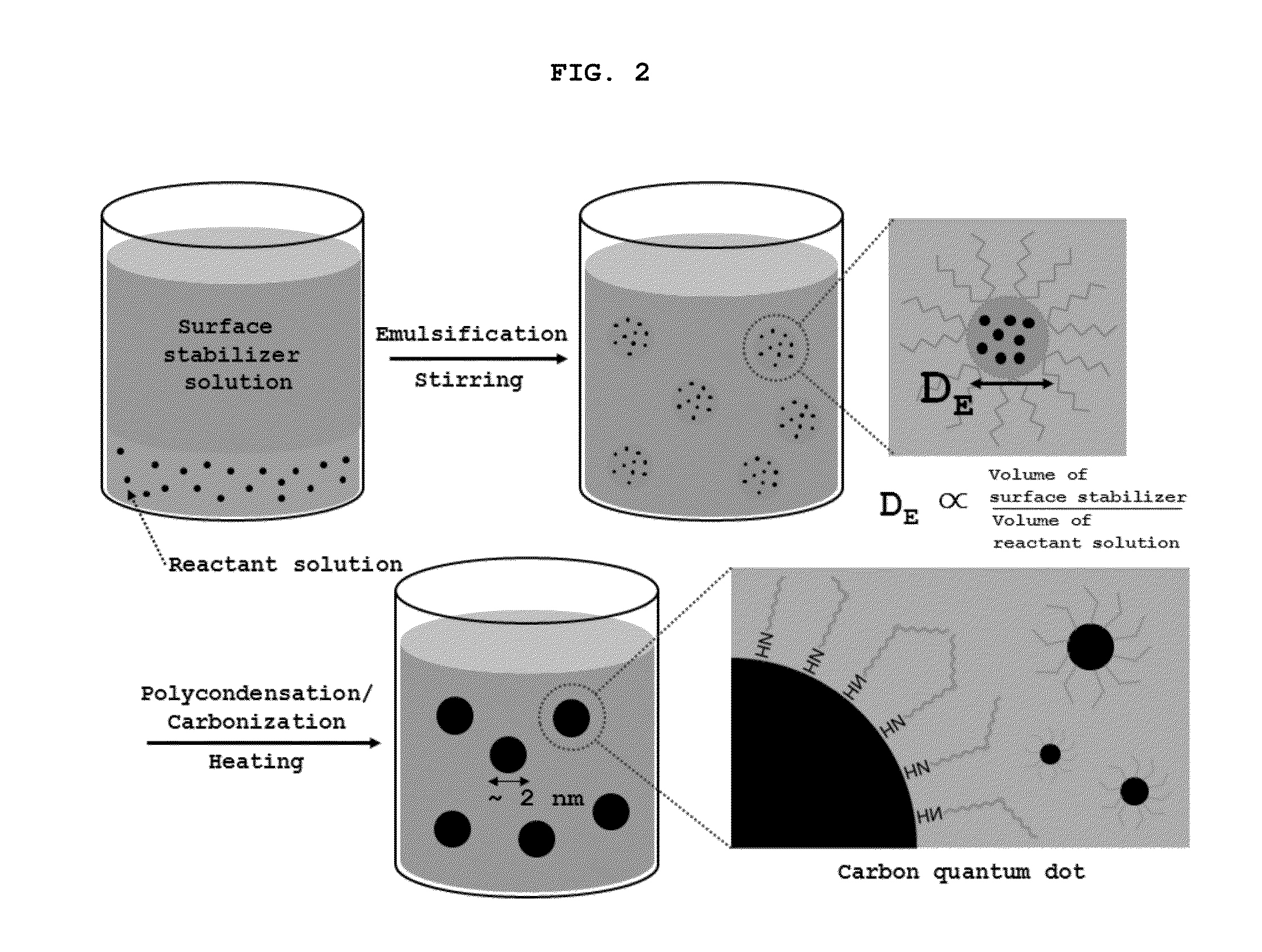

Process for preparing carbon quantum dots using emulsion

InactiveUS20150361334A1High reaction yieldEffective controlOrganic chemistryNano-carbonQuantum yieldEmulsion

The present invention provides a process for preparing carbon quantum dots having uniform size by using emulsion, and a process for doping the inside of the carbon structure with other element or replacing the surface with a surface stabilizer having a specific chemical functional group different from existing stabilizers in order to control the properties of the carbon quantum dots. The process for preparing the carbon quantum dots according to the present invention makes a mass production possible and the process thereof is simple. Furthermore, the process is easy to control the size of the quantum dots and the reaction yield rate of the method is excellent. In addition, according to the present invention, it is possible to synthesize carbon quantum dots having uniform size and superior quantum yield rate and it makes it possible to embody the color as equivalent to existing molecular chromophores or heavy metal quantum dots by changing the structure of the chromophore.

Owner:POSTECH ACAD IND FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com