Light emitting diode package with metal reflective layer and method of manufacturing the same

a technology of light-emitting diodes and reflective layers, which is applied in the direction of basic electric elements, electrical equipment, semiconductor devices, etc., can solve the problems of limiting automated manufacturing and mass production, low uniformity, and rather mediocre color development, so as to minimize irregular color distribution, small size, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

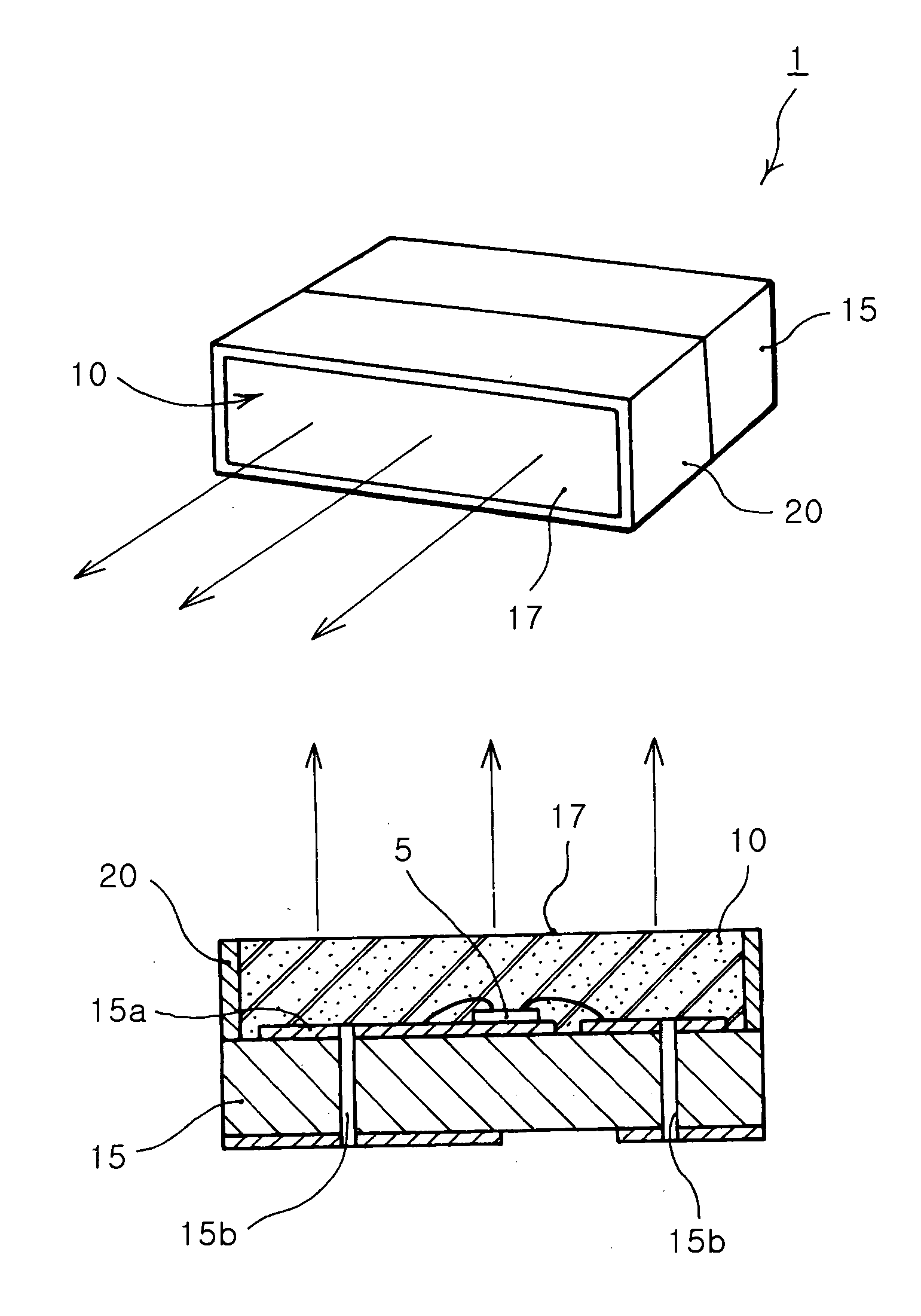

[0027] As shown in FIG. 4, an LED package 1 having a metal reflective layer according to the present invention is for emitting light from an LED chip 5 in one direction of an encapsulant 10.

[0028] Light is emitted through a light transmitting surface 17 which is preferably in front and in parallel with a plane where the LED chip 5 is disposed.

[0029] The LED package 1 having a metal reflective layer according to the present invention has a substrate with electrodes 15a and 15b formed thereon. The substrate 15 may preferably be a Printed Circuit Board (PCB) or a ceramic substrate having pattern electrodes 15a and vertical electrodes 15b such as vias.

[0030] In addition, an LED chip 5 is electrically connected to the electrode 15a and mounted on the substrate 15. The LED chip 5 may be a horizontal type with all of its electric terminals formed only on an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com