Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

357 results about "Sensing applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

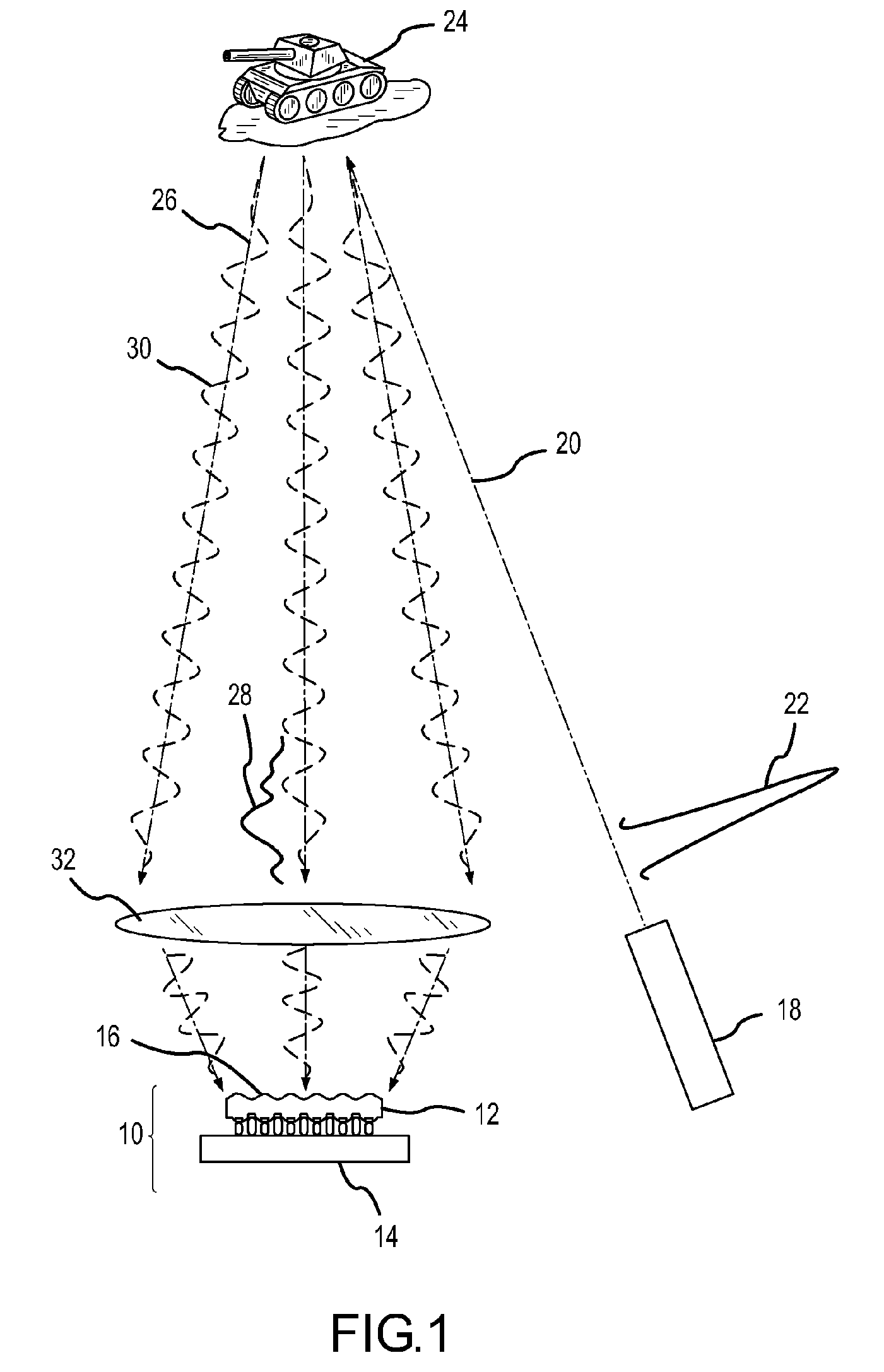

Method and system for transmitting terahertz pulses

InactiveUS7531803B2Improve performanceReduce lossRadiation pyrometryAbsorption/flicker/reflection spectroscopyGroup velocity dispersionSensing applications

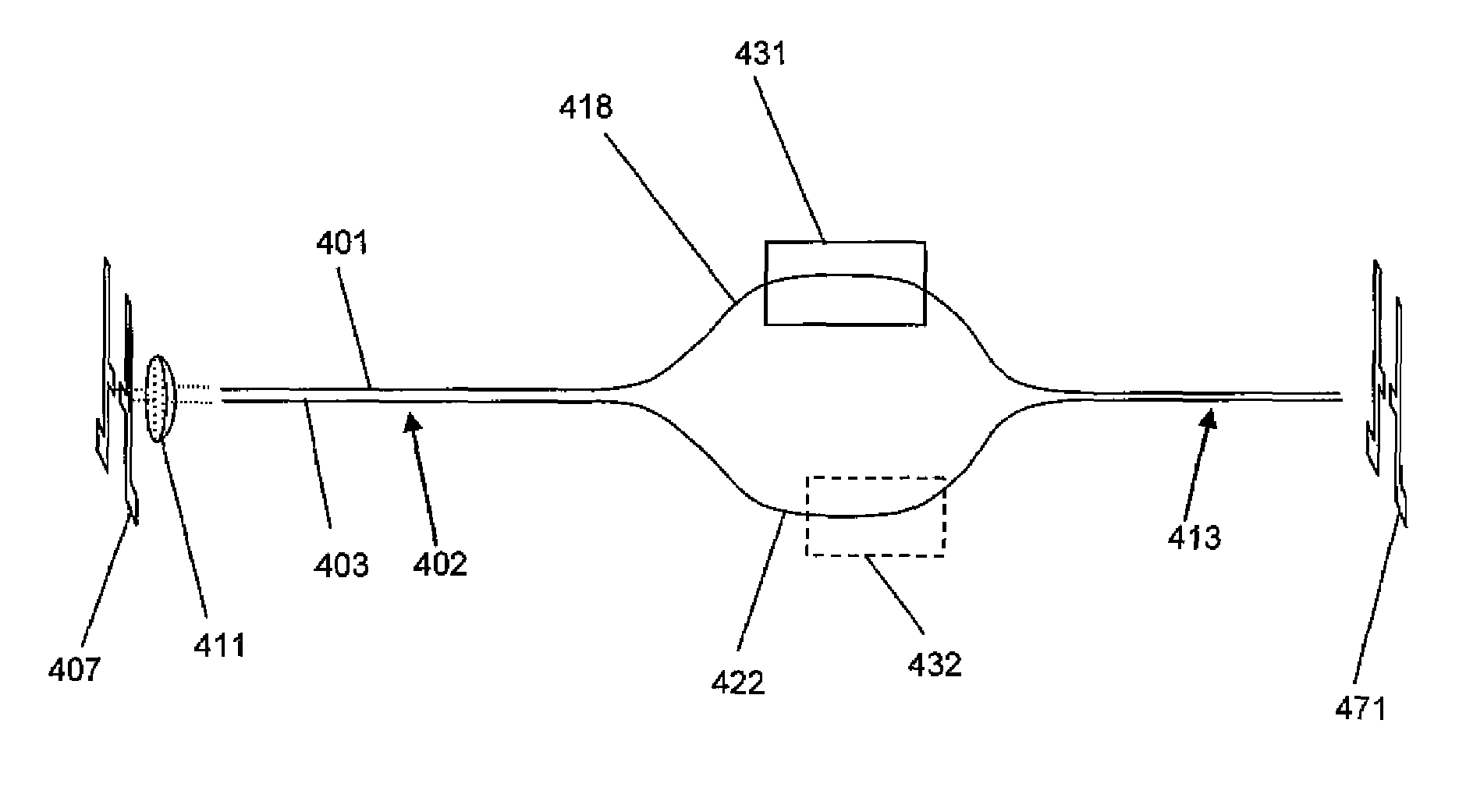

Systems for THz transmission using new types of THz waveguides with low loss, negligible group velocity dispersion and structural simplicity are described herein. The THz system incorporates the use of a waveguide with two or more substantially parallel conductive elements which may enable many new THz sensing applications. It is now possible to direct the THz pulse inside of containers or around corners, where line-of-sight optics are not practical. Moreover, the systems allow use of either radially polarized or linearly polarized THz antennas. The disclosed systems are compatible with existing terahertz generation and detection techniques.

Owner:RICE UNIV

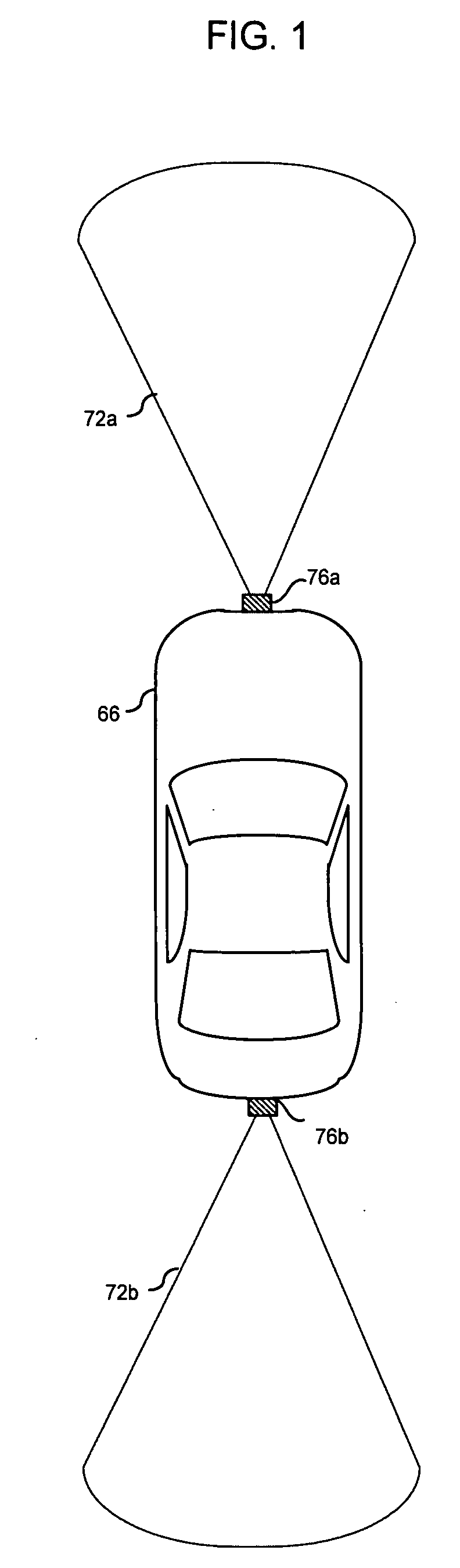

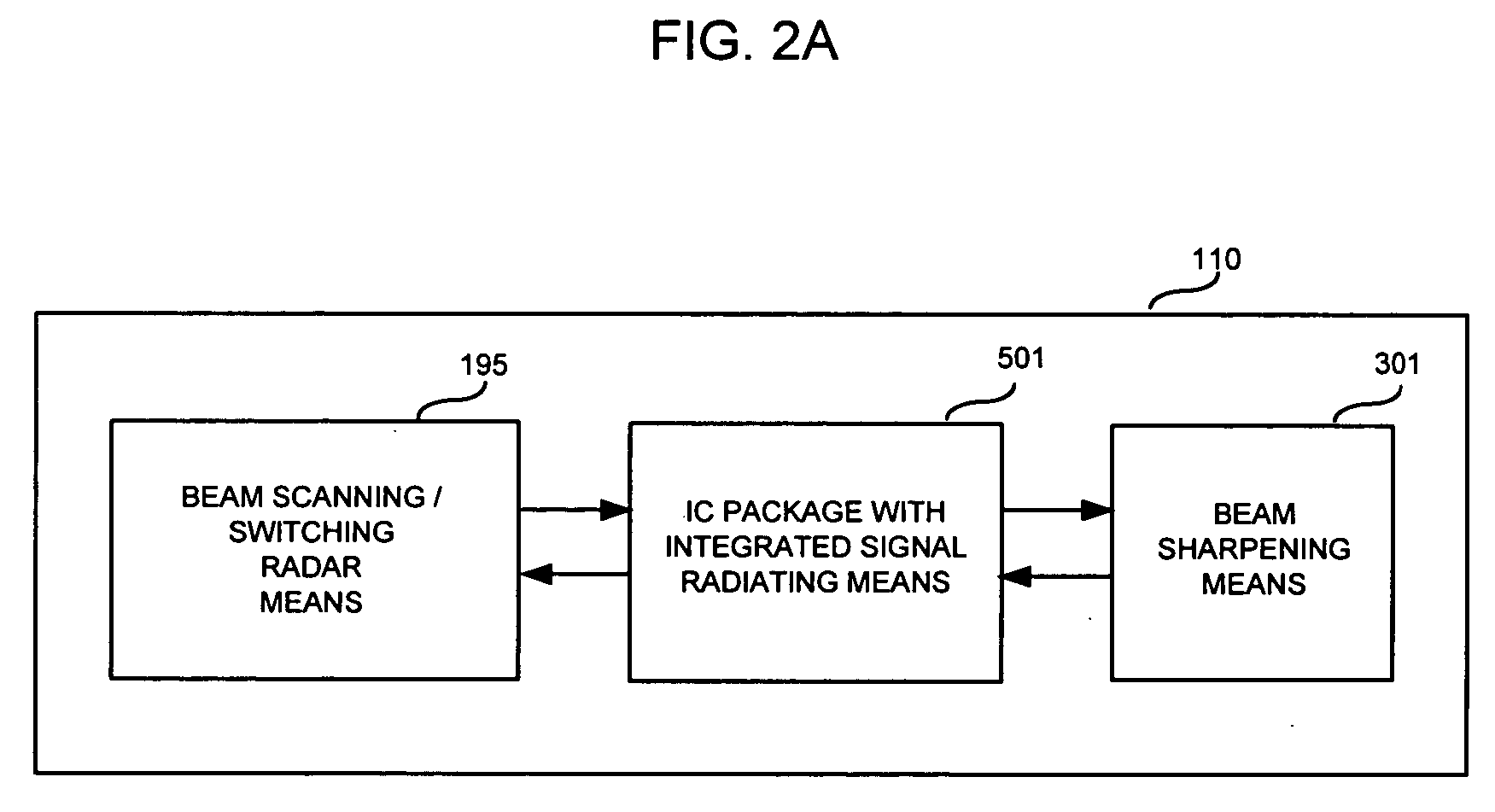

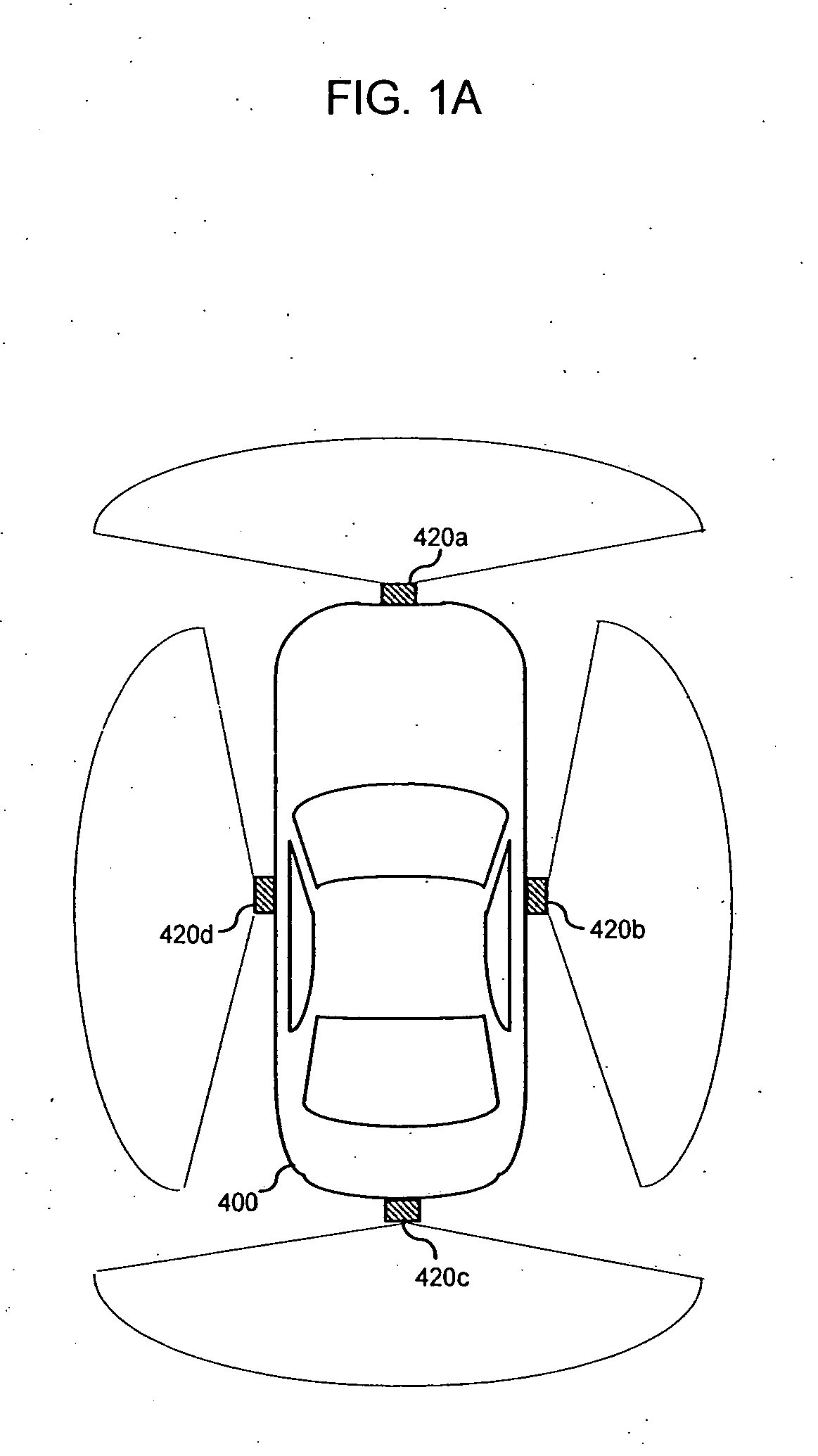

Method and apparatus for automotive radar sensor

InactiveUS20050225481A1Low costAdditional imaging capabilityAntenna adaptation in movable bodiesSolid-state devicesEngineeringWaveguide

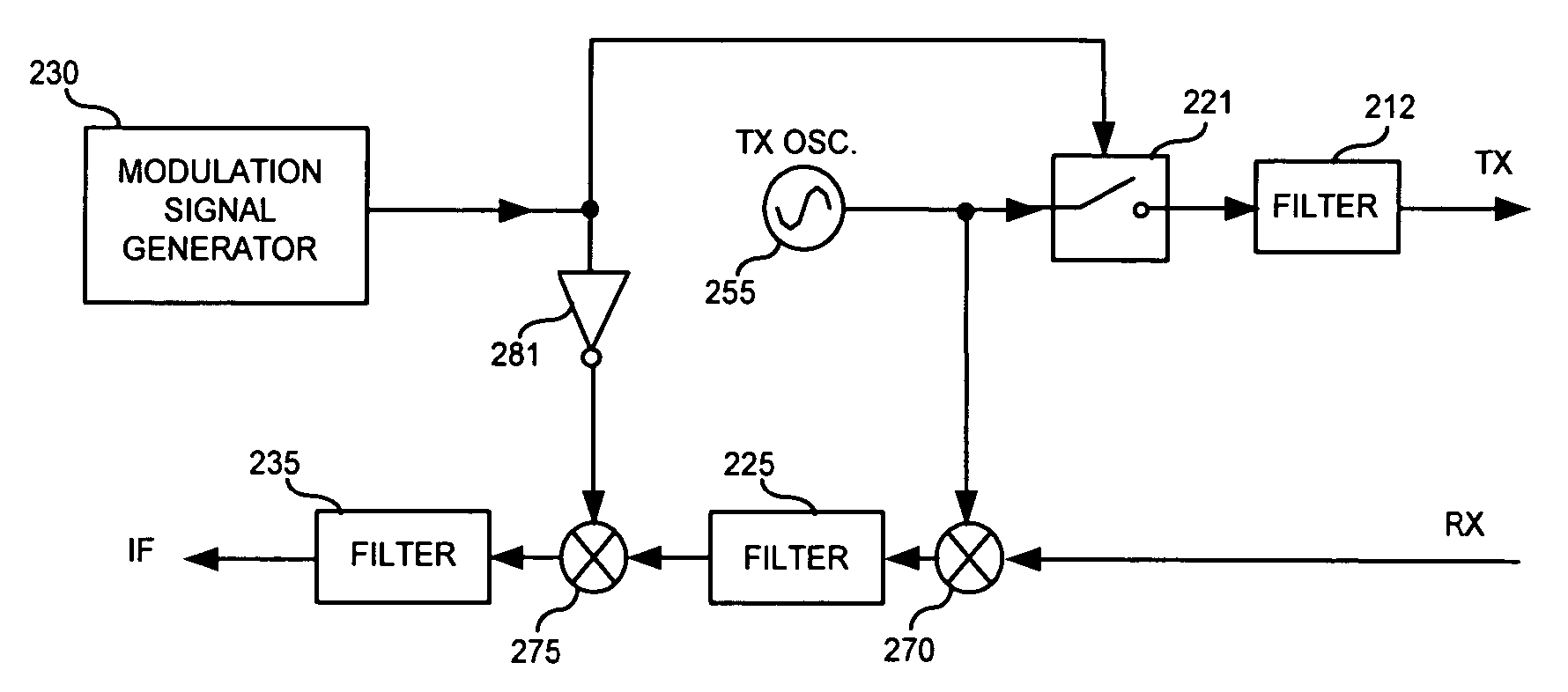

Methods and apparatus are presented which reduce the overall cost and increase the imaging capability for medium and long range automotive radar sensing applications through the combination of a high signal-to-noise ratio and wide dynamic range radar waveform and architecture, antenna arrangement, and a low cost packaging and interconnection method. In accordance with aspects of the present invention, one way a high signal-to-noise ratio and wide dynamic range imaging radar with reduced cost can be achieved is through the combination of a pulsed stepped-frequency-continuous-wave waveform and electrically beam-switched radar architecture, utilizing a planar package containing high-frequency integrated circuits as well as integrated high-frequency waveguide coupling ports, coupled to a multi-beam waveguide-fed twist-reflector narrow beam-width antenna. Other methods and apparatus are presented.

Owner:GHZ TR CORP

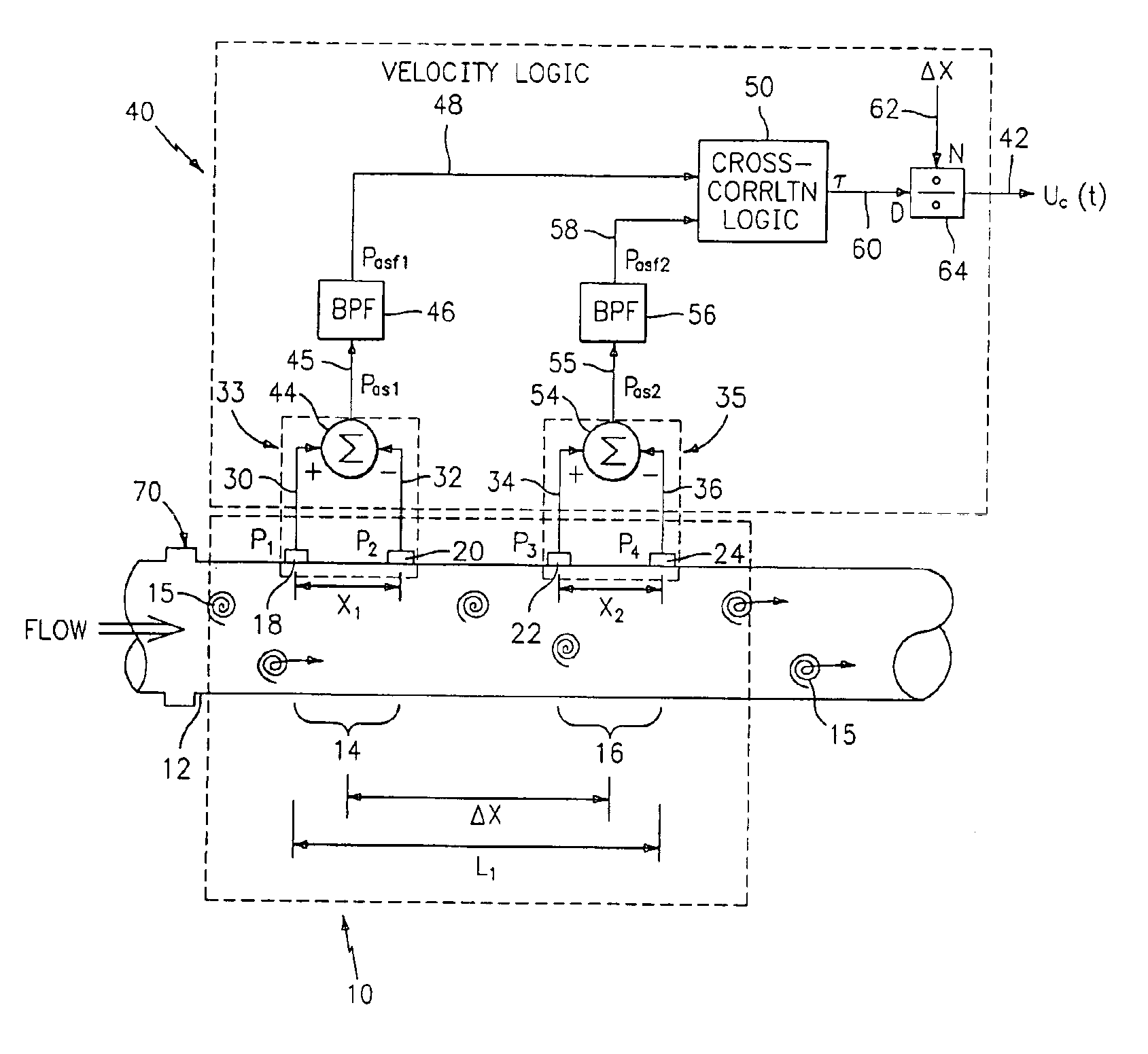

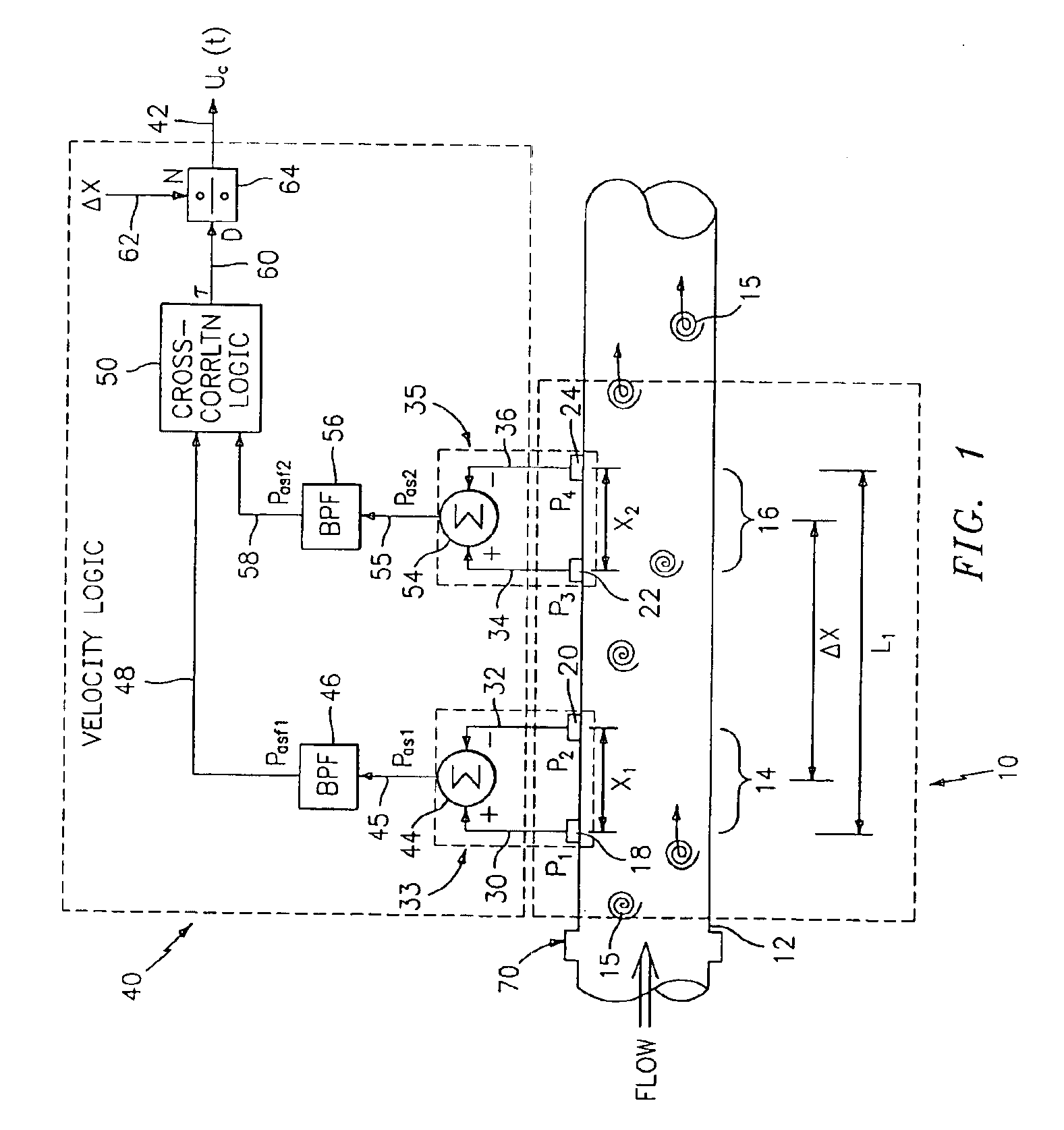

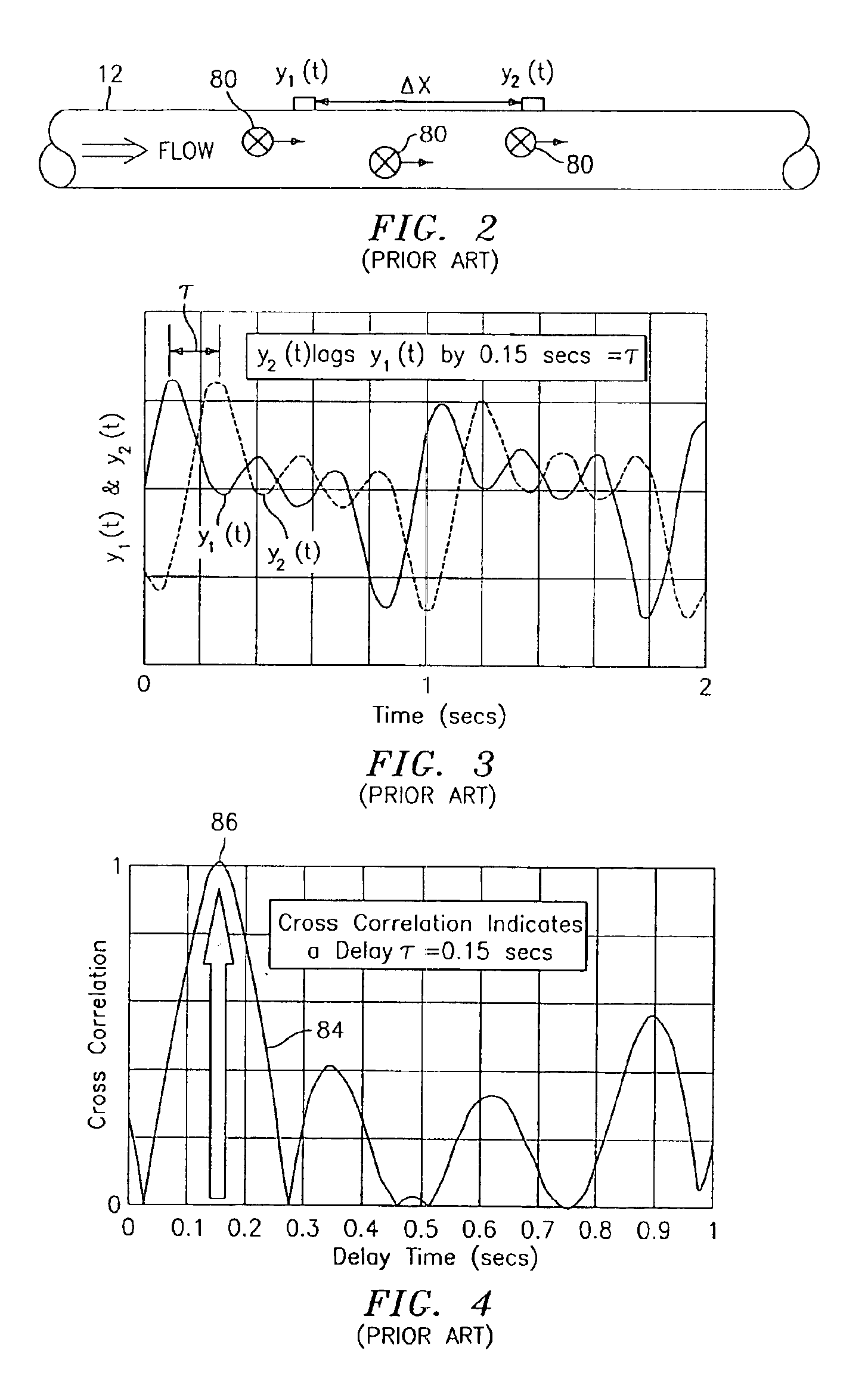

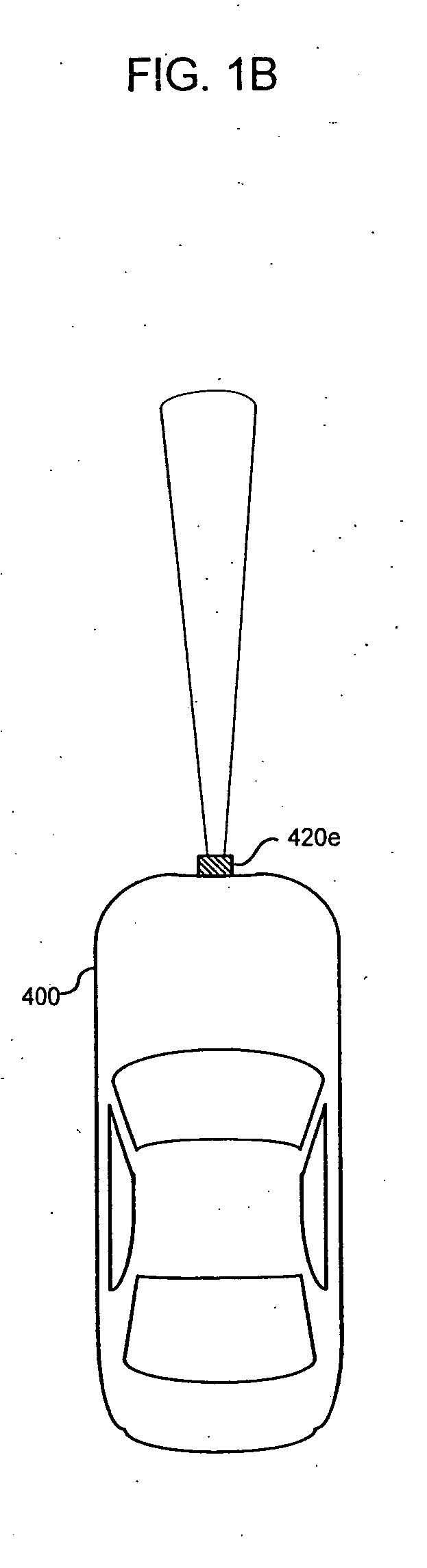

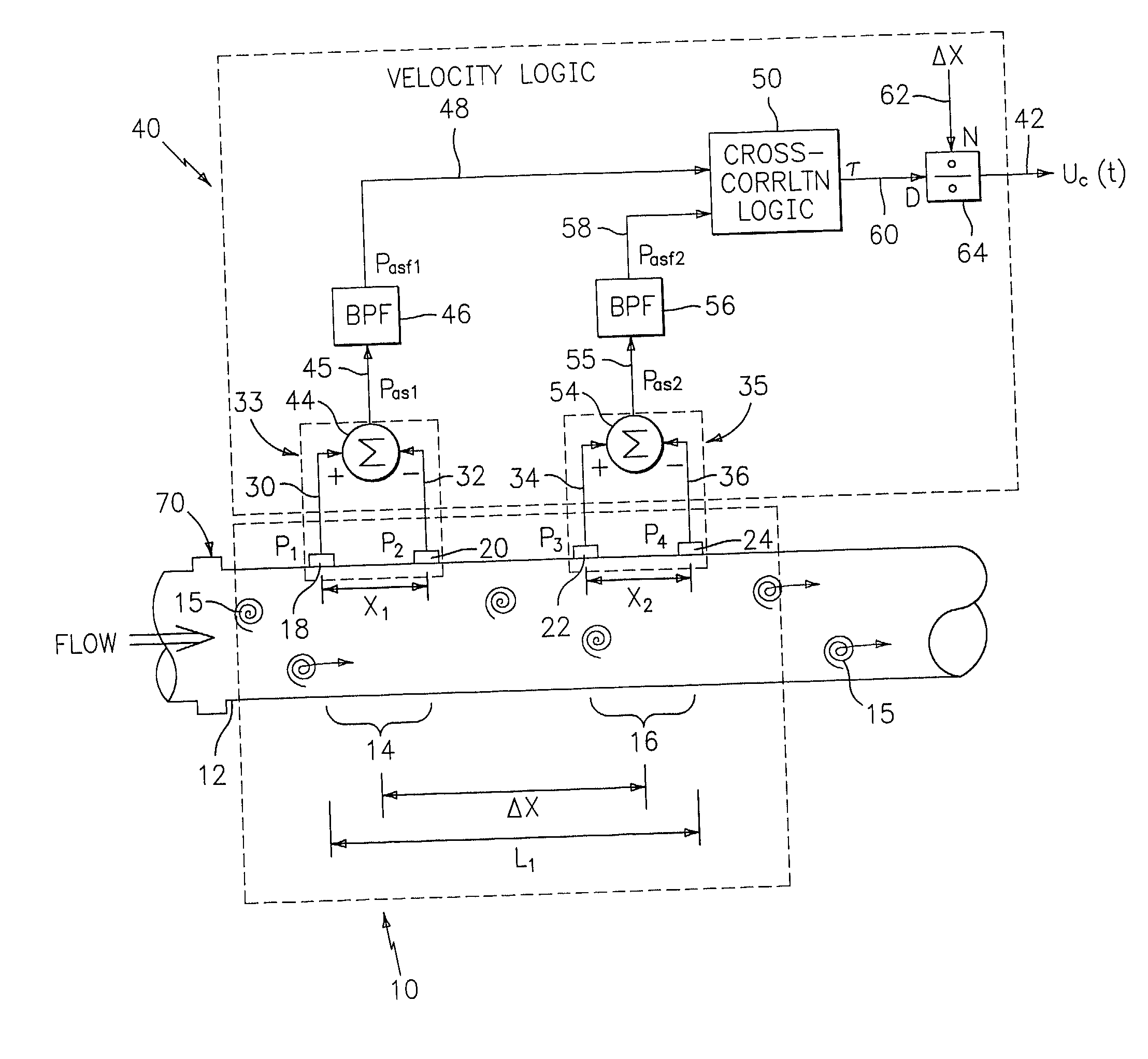

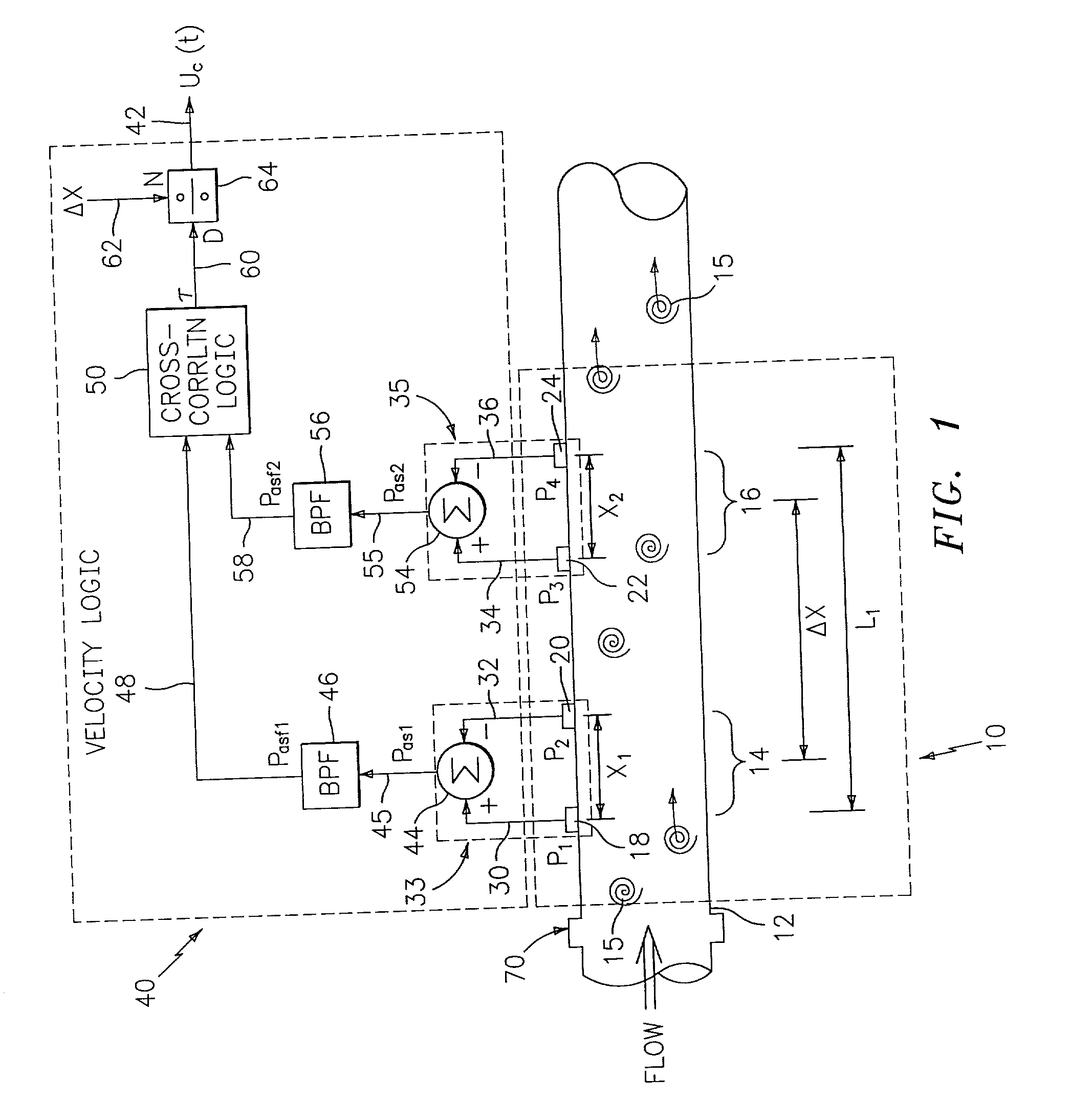

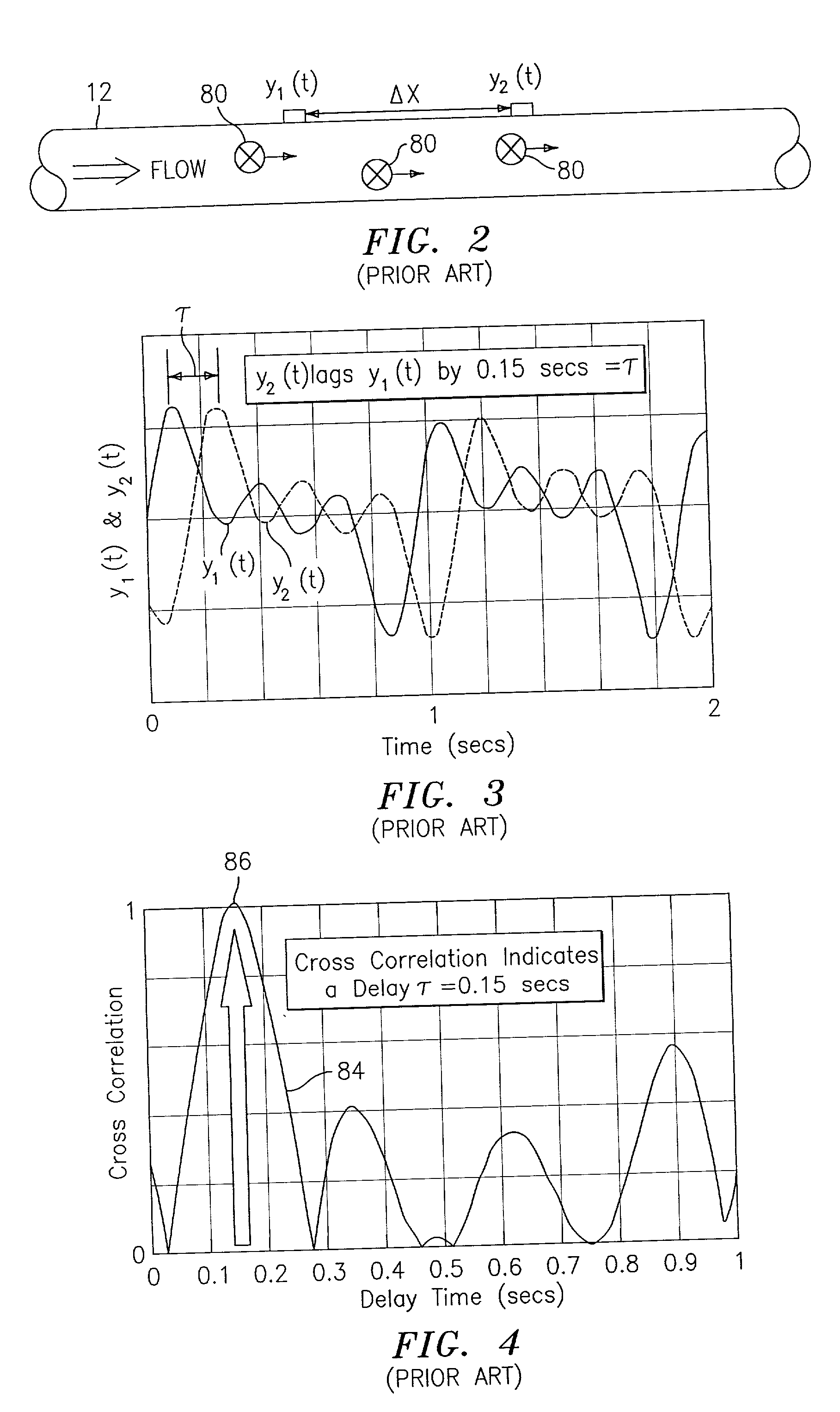

Flow rate measurement for industrial sensing applications using unsteady pressures

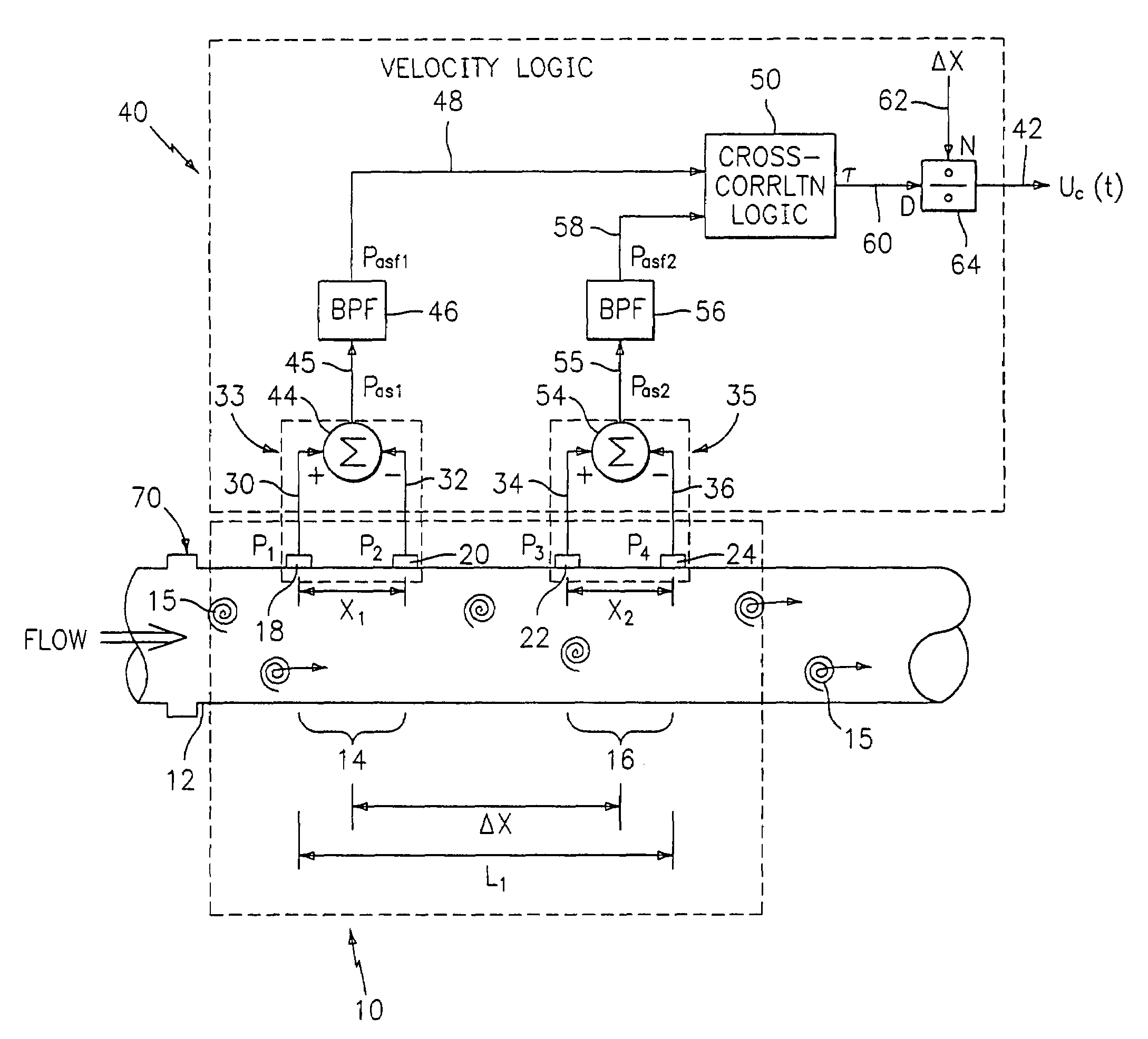

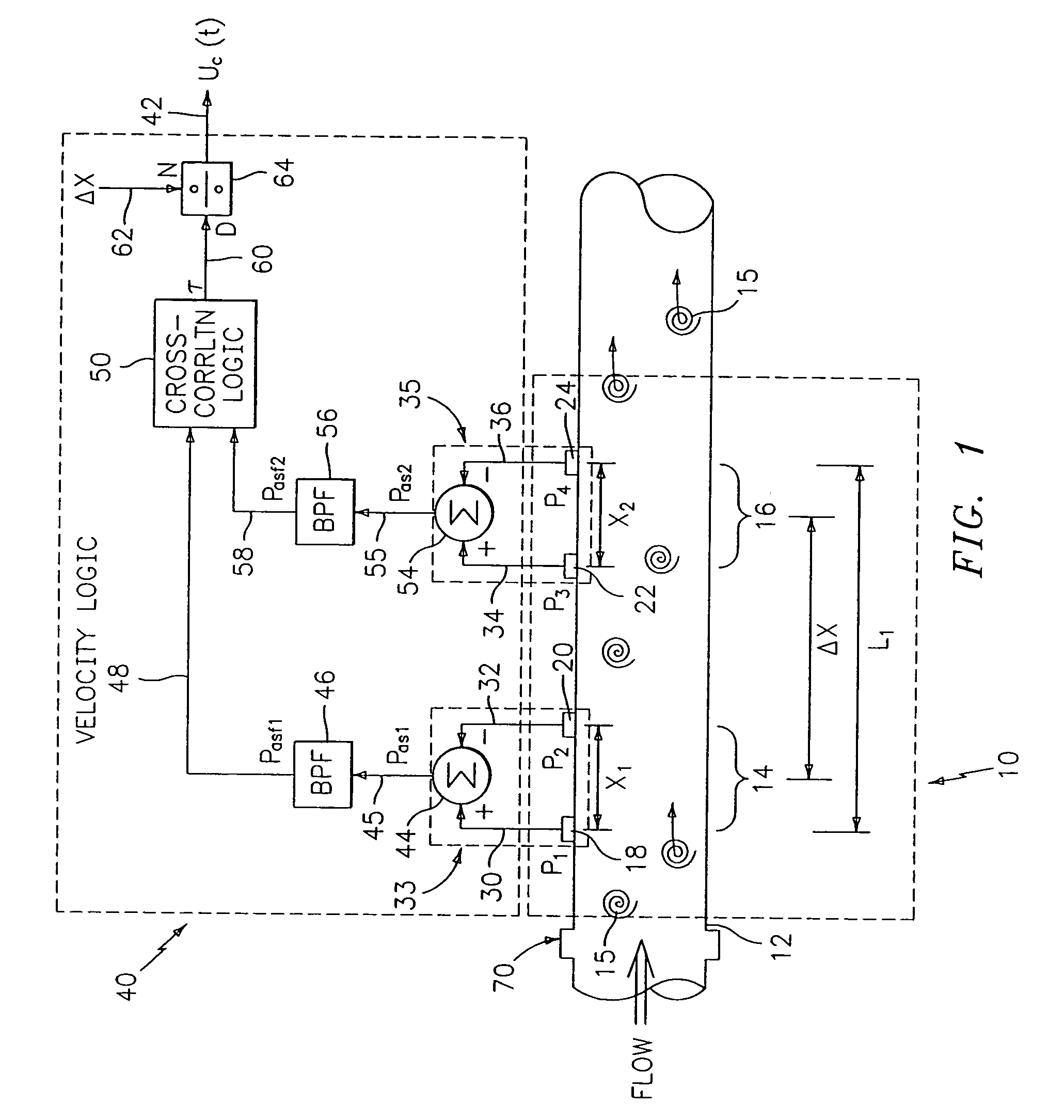

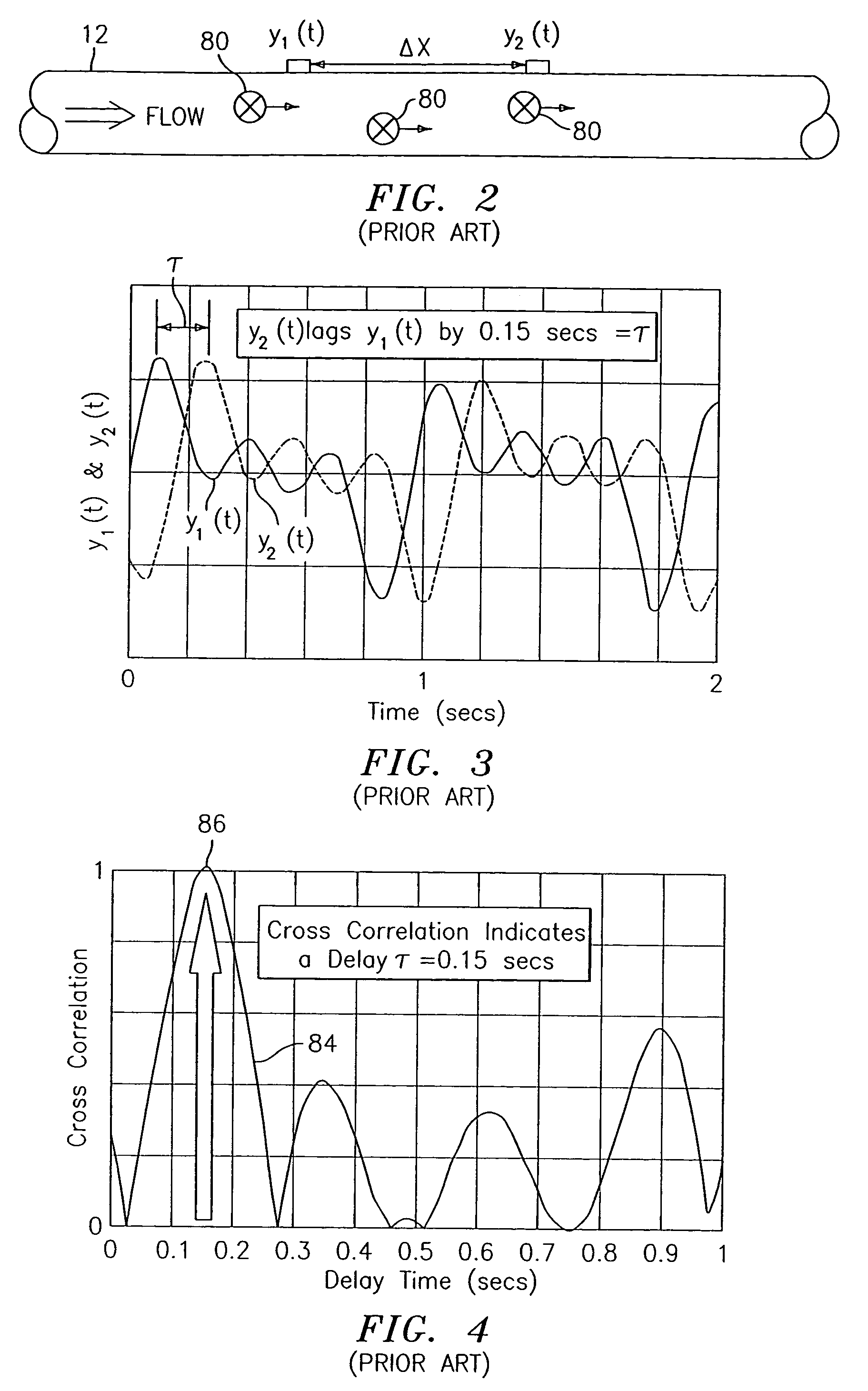

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance ΔX apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35 filters out acoustic pressure disturbances Pacoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances Pvortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals Pas1,Pas2 to band pass filters 46,56 that filter out high frequency signals. The Pvortical -dominated filtered signals Pasf1,Pasf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay τ between the two sensing locations 14,16 which is divided into the distance ΔX to obtain a convection velocity Uc(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

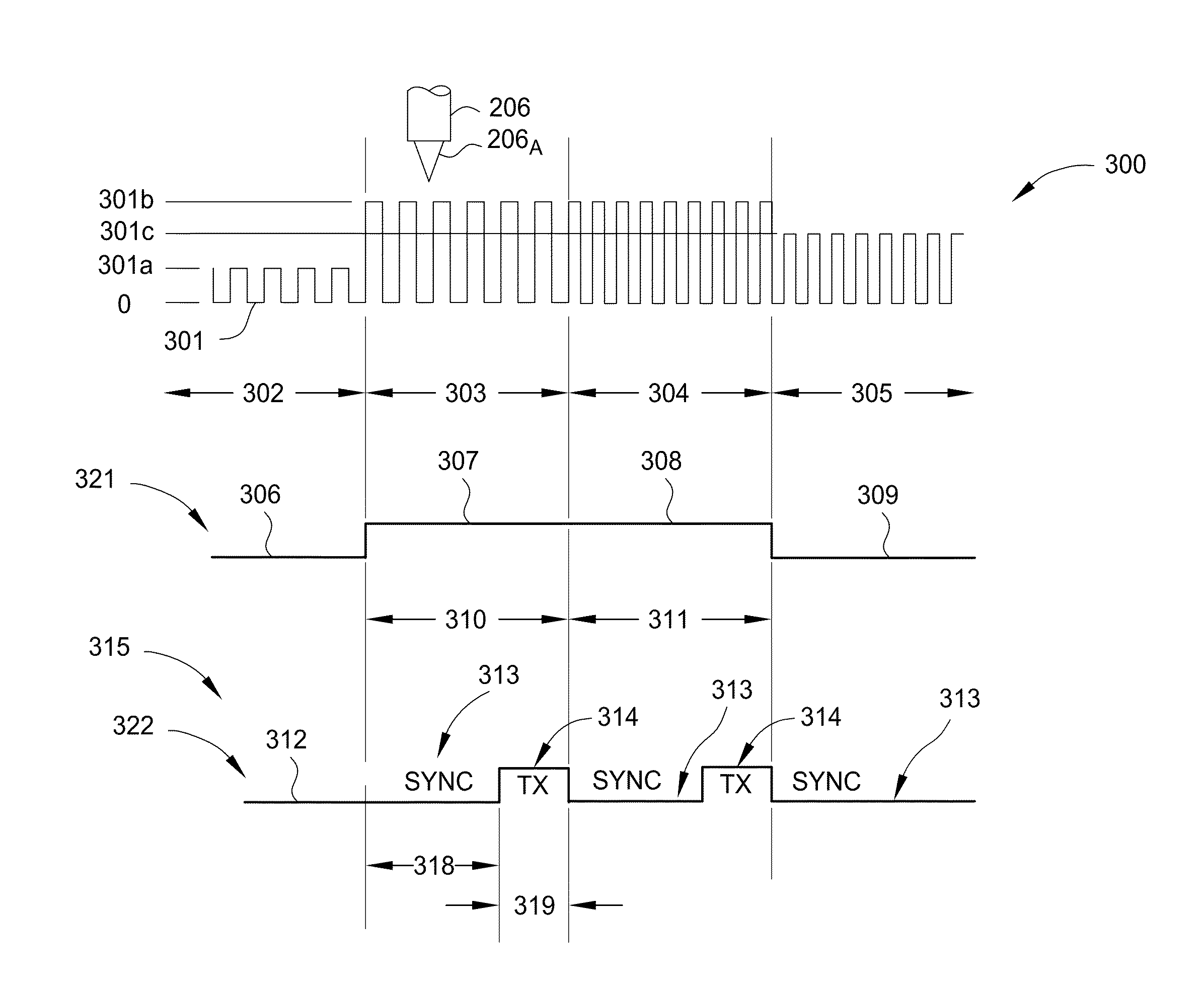

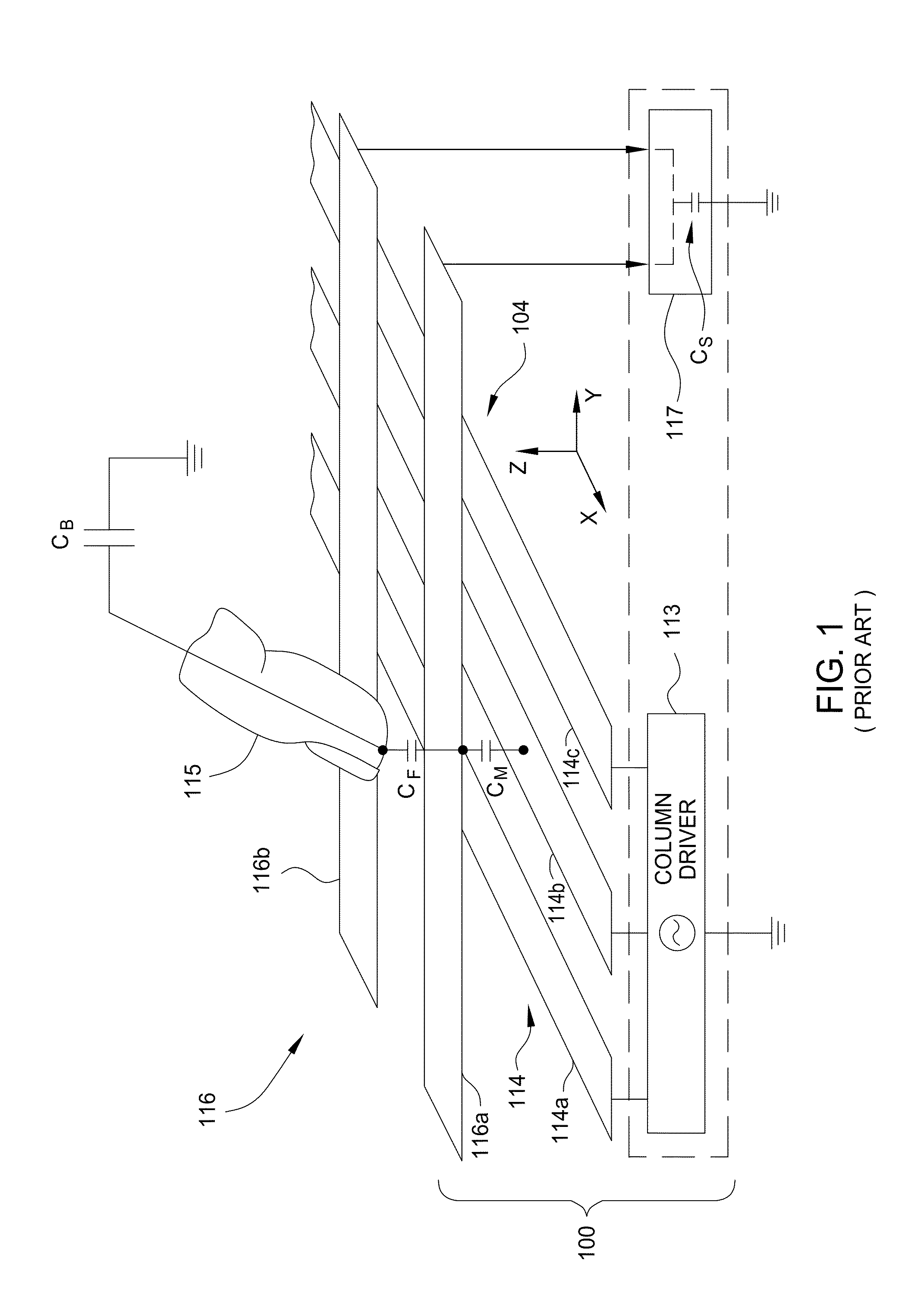

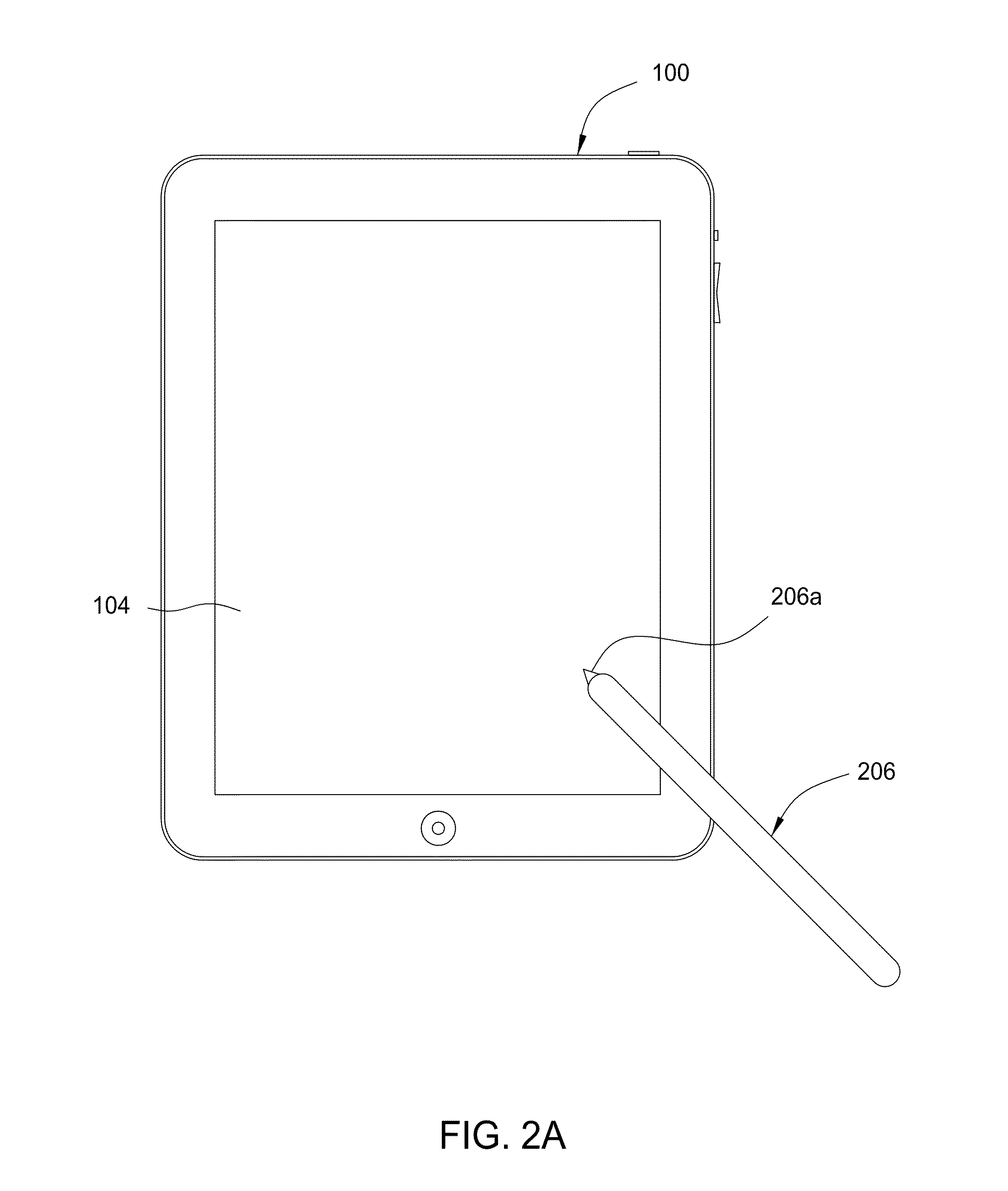

Active stylus for touch sensing applications

ActiveUS20140176495A1Quality improvementInput/output processes for data processingTouch SensesSensing applications

Embodiments relate generally to control devices, such as human interface devices, configured for use with a touch-screen containing device. More specifically, the present invention relates to methods and various apparatus that are used to actively control the interaction of a handheld device, such as a stylus pen, with a touch-screen containing device. Embodiments of the invention provide a universal handheld device that is able to provide input to any type of capacitive sensing touch-screen containing device, regardless of the manufacturer or, in some embodiments, without knowledge of the touch-screen containing device manufacturer's specific capacitive touch-sensing detection techniques.

Owner:LOGITECH EURO SA

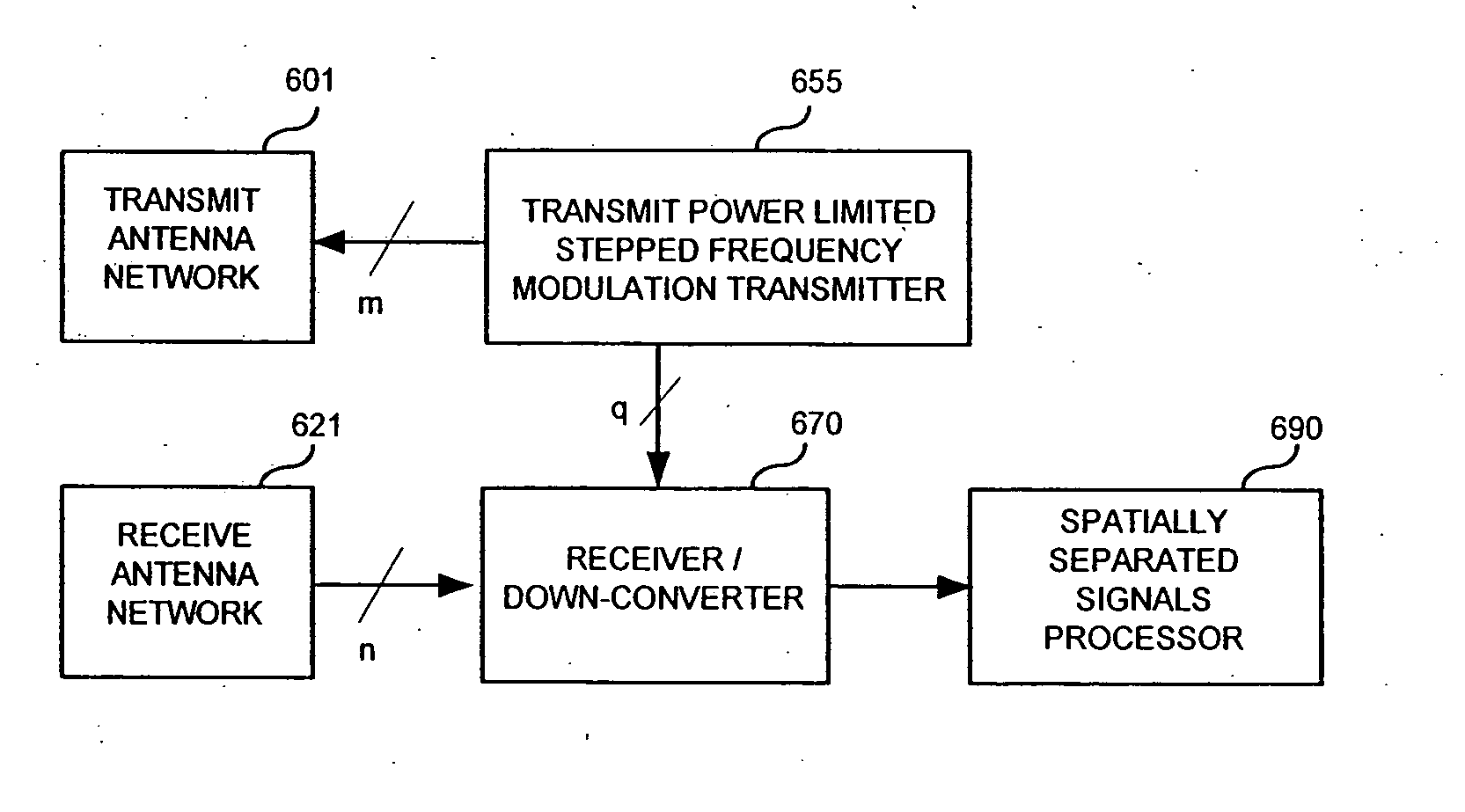

Methods and apparatus for automotive radar sensors

InactiveUS20060262007A1Reduce system costReduce in quantityRadio wave reradiation/reflectionIntermediate frequencyTransmitted power

Methods and apparatus are presented that reduce the overall system cost for automotive radar sensing applications through reduction of the number of the radar sensors required. In accordance with aspects of the present invention, one way sensor count reduction can be achieved is through the combination of target range, direction, and velocity determination capability with wide angular field of view coverage within a single sensor unit. One embodiment combines a transmit-pulsed, linearly stepped frequency modulated, transmit power limited radar architecture with a spatially separated receiver antenna array, intermediate frequency down-conversion, and a digital multi-zone monopulse (DMM) signal processing technique for high-resolution target range, velocity, and azimuth angle determination and fast update rate capability in a low cost, mass-production-capable design.

Owner:CLARIANT TECH

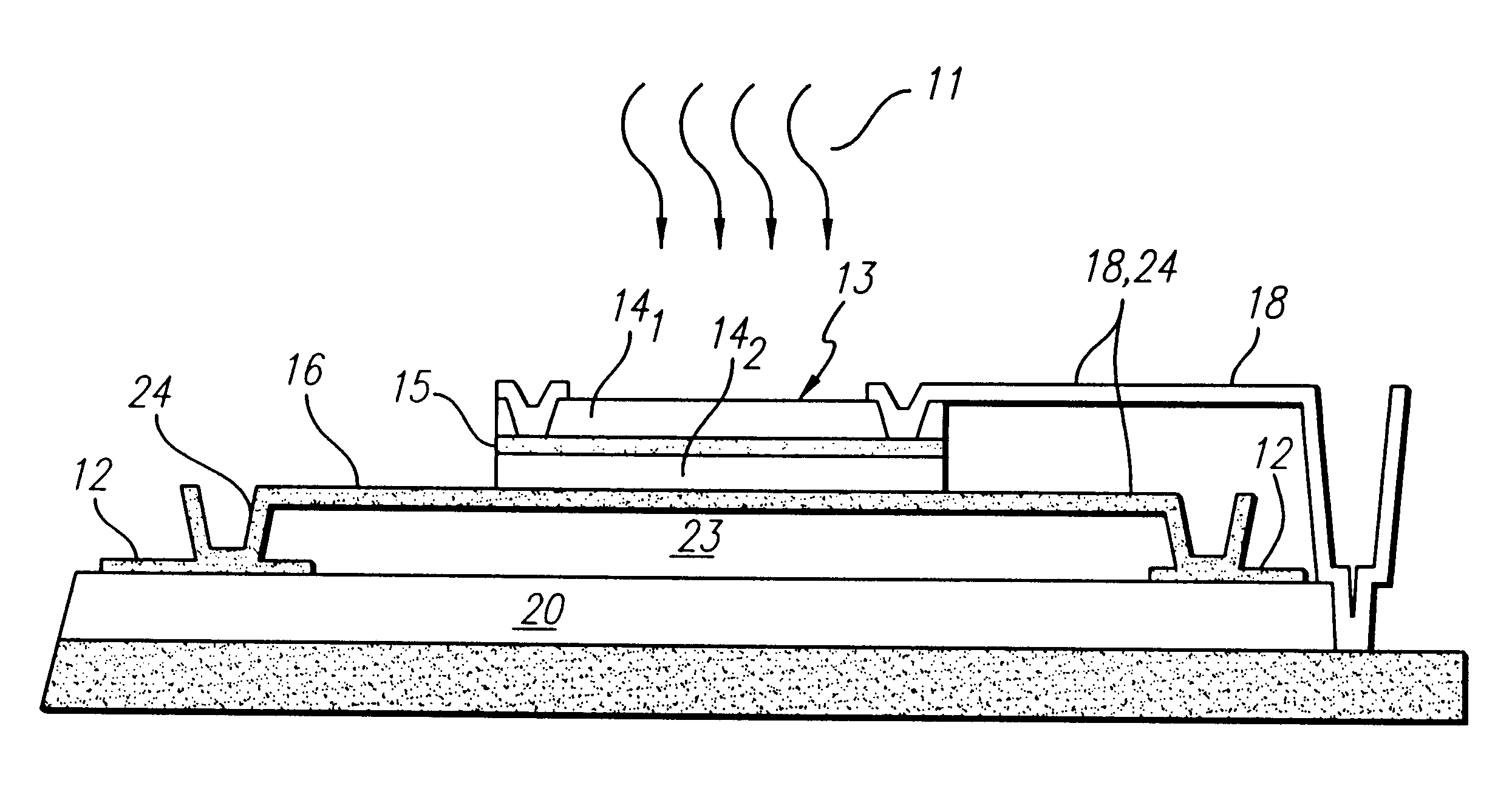

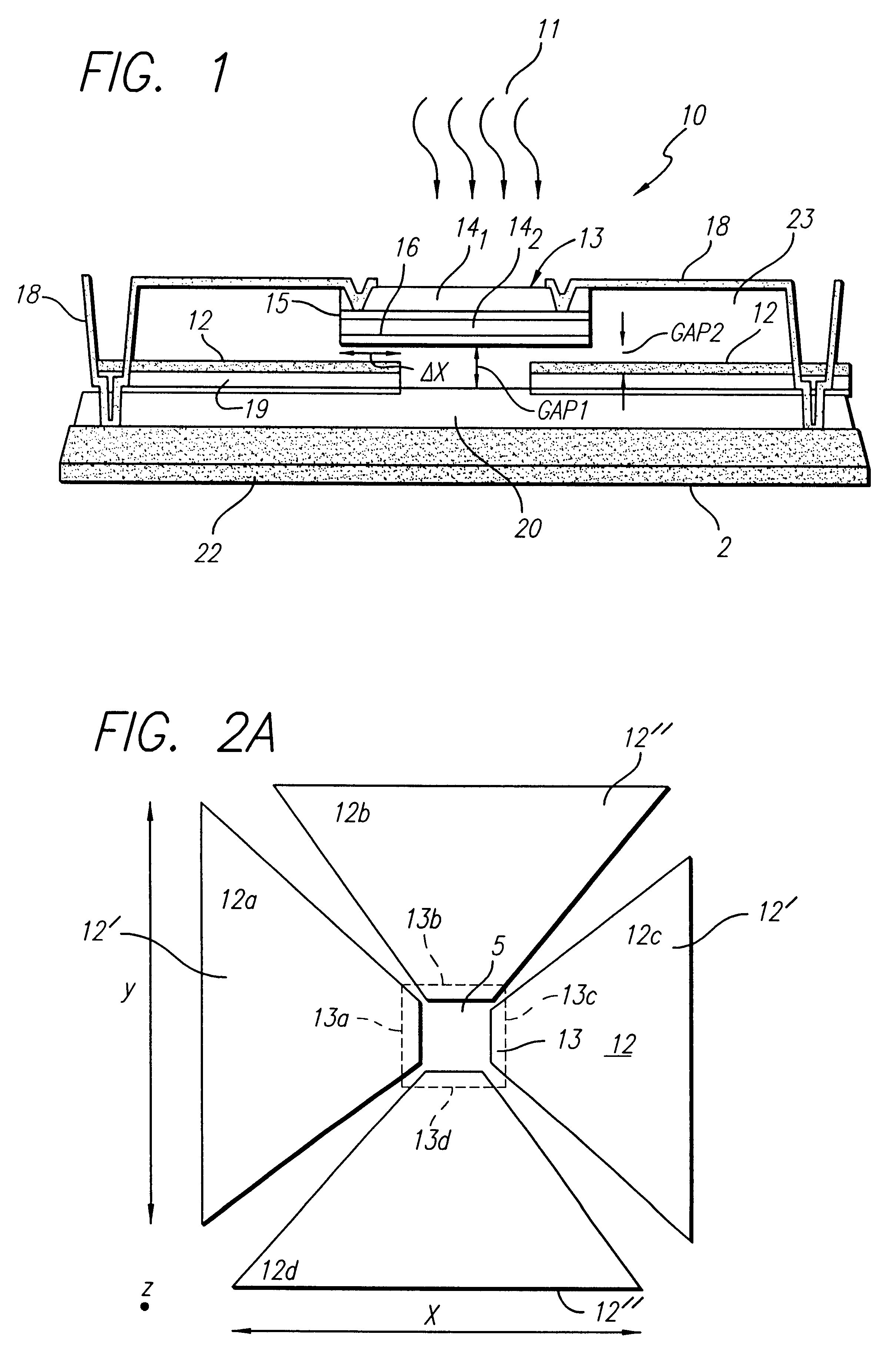

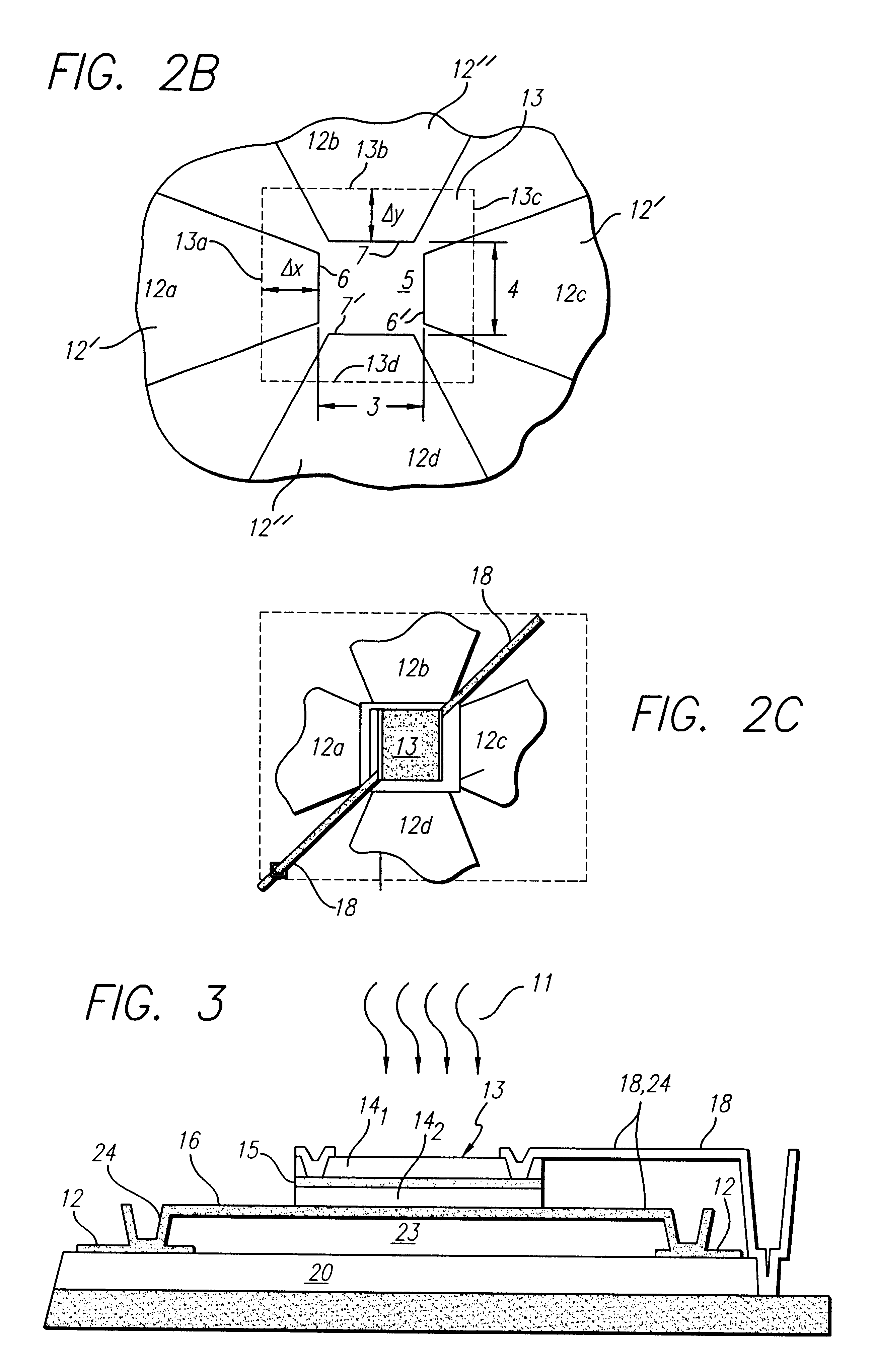

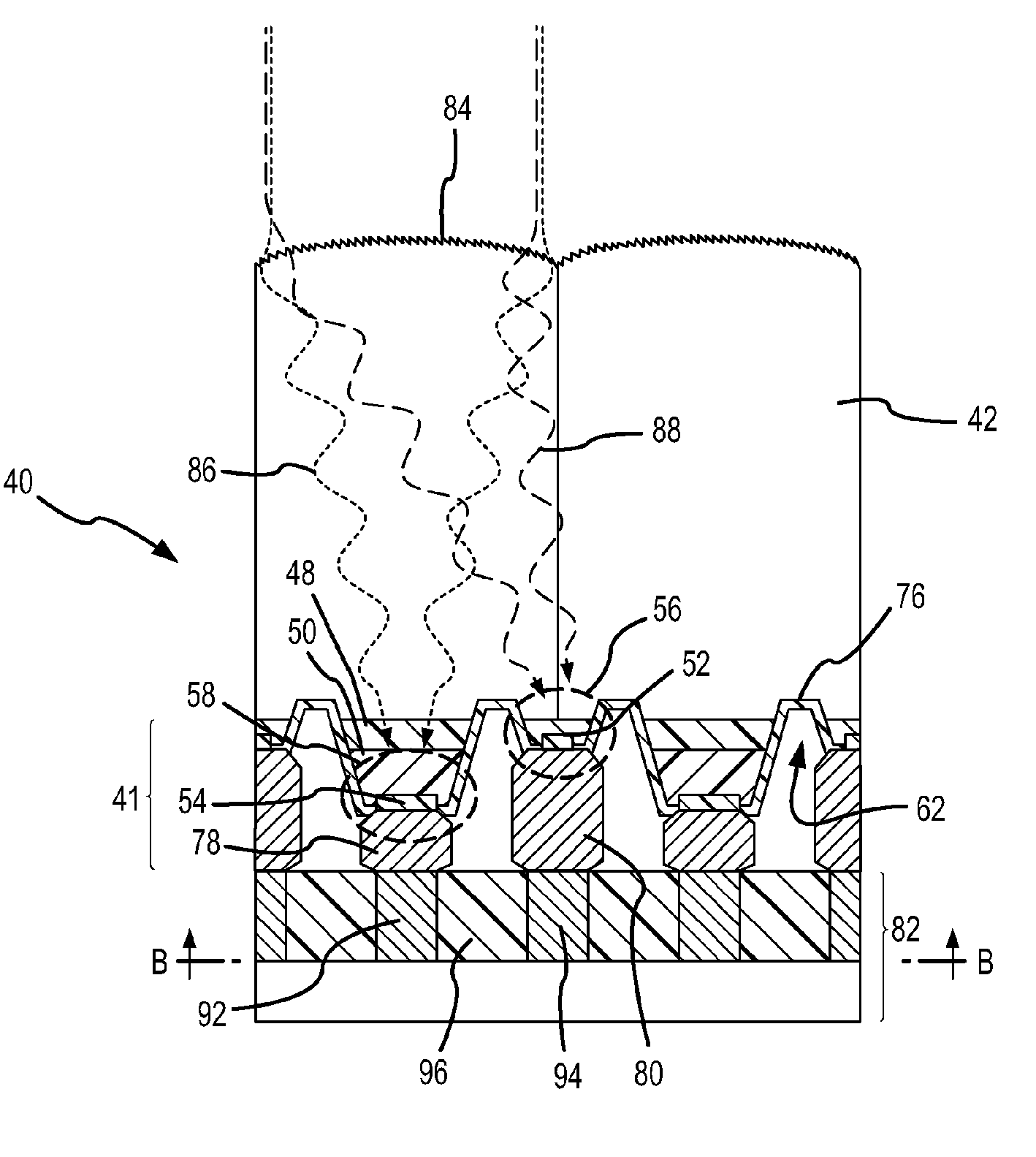

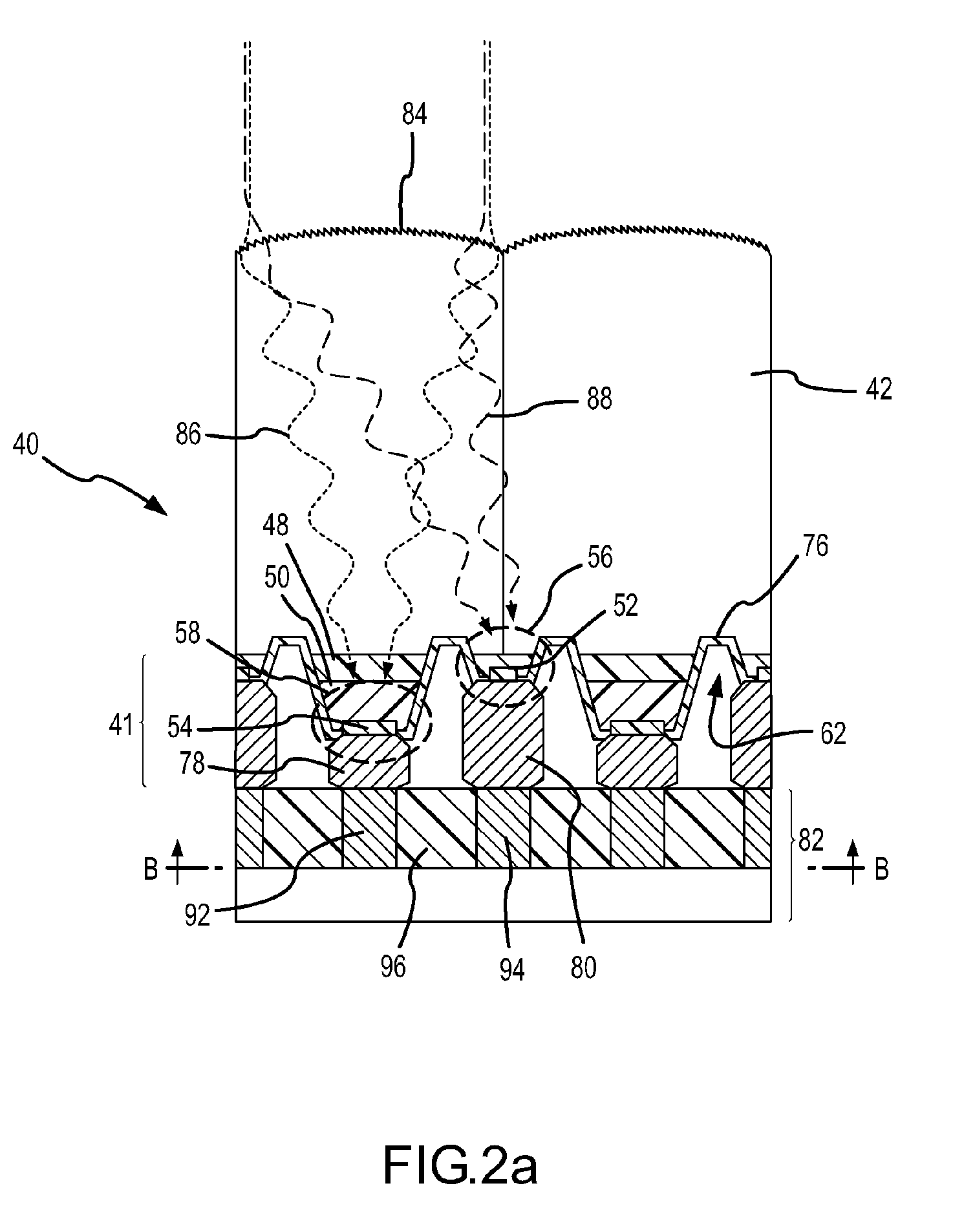

Architecture and method of coupling electromagnetic energy to thermal detectors

InactiveUS6329655B1Antenna supports/mountingsSolid-state devicesSensing applicationsElectromagnetic shielding

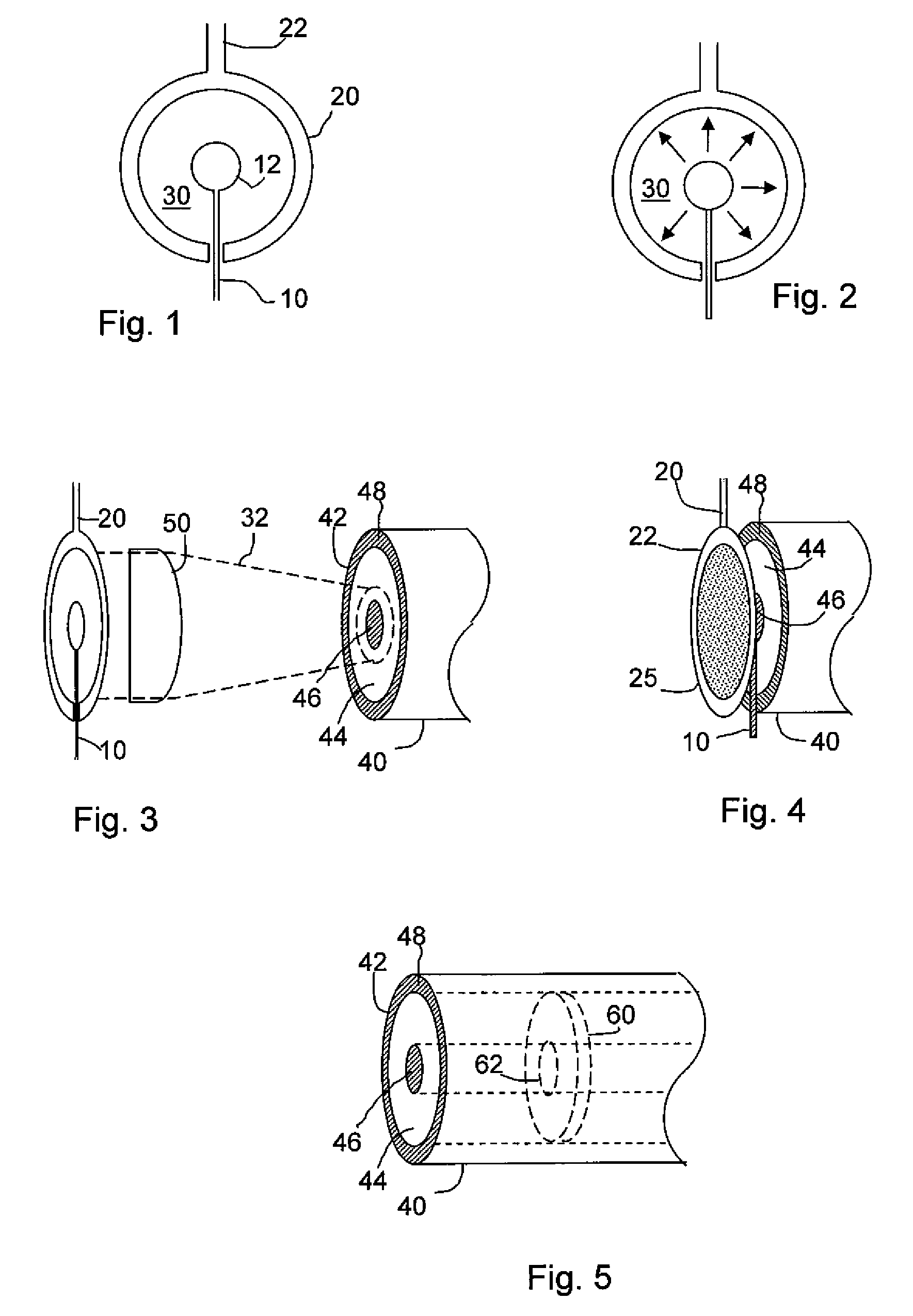

A radiation sensor. The inventive sensor has a two-level detector structure formed on a substrate in which a thermal detector element is suspended over the substrate as a microbridge structure. A receiver of electromagnetic radiation is provided on the same side of the substrate in a manner that efficiently couples the radiation field to the thermal detector element. The thermal detector element has a sandwich structure including a heater metal layer, a dielectric layer, and a thin film thermo-resistive material. The thermal detector element is suspended out of physical contact with the receiver. In one embodiment, the receiver is an antenna having a crossed bowtie configuration that efficiently couples the radiation field to the detector element. The inventive radiation sensors are especially useful for mm-wave and microwave sensing applications. The sensor can be used individually or in linear or two-dimensional arrays thereof. The invention also is directed to a method of fabricating such a radiation sensor.

Owner:HRL LAB +1

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance .DELTA.X apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X.sub.1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X.sub.2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35 filters out acoustic pressure disturbances P.sub.acoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances P.sub.vortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals P.sub.as1,P.sub.as2 to band pass filters 46,56 that filter out high frequency signals. The P.sub.vortical -dominated filtered signals P.sub.asf1,P.sub.asf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay .tau. between the two sensing locations 14,16 which is divided into the distance .DELTA.X to obtain a convection velocity U.sub.c(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

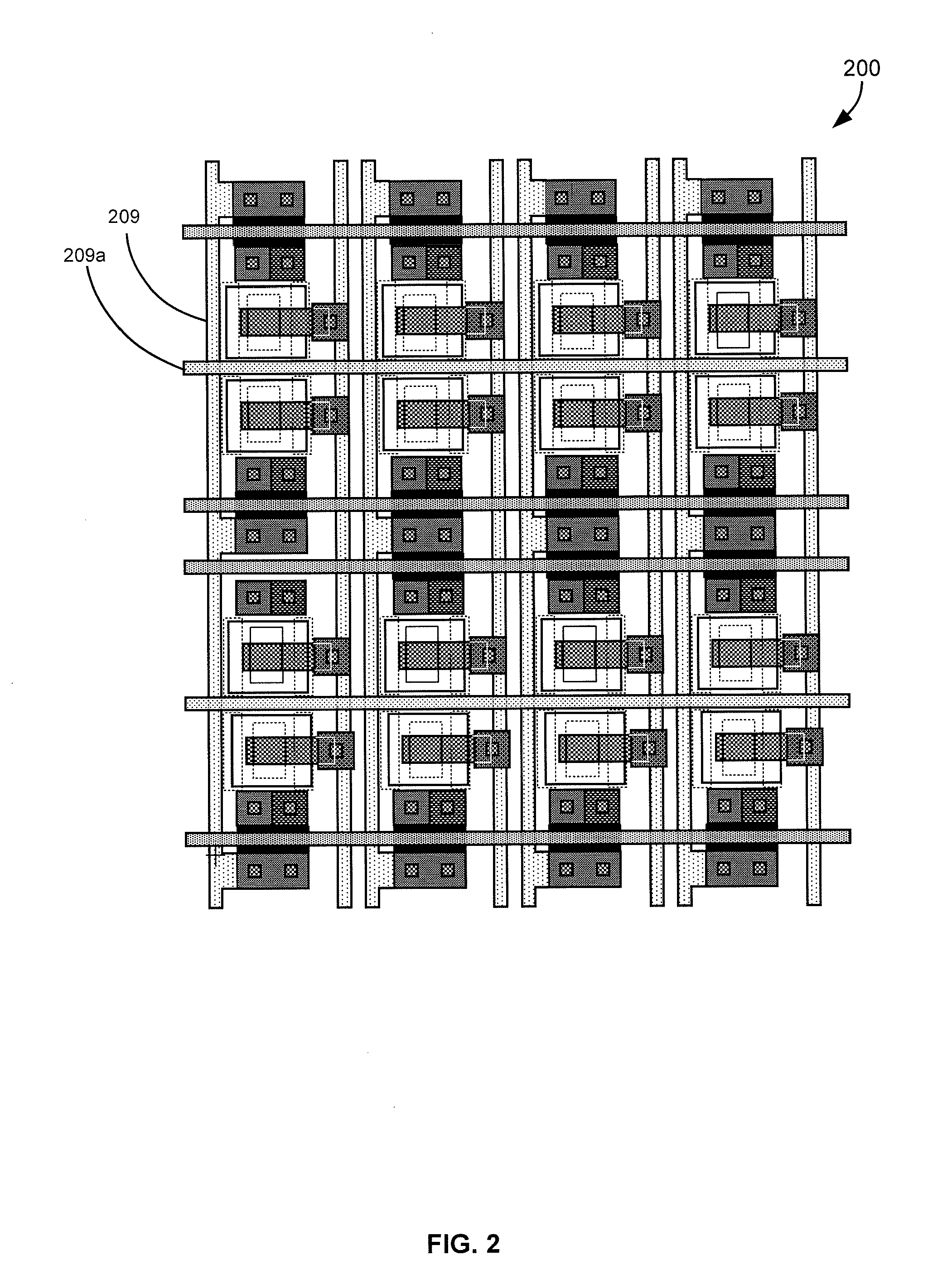

Multimode focal plane array with electrically isolated commons for independent sub-array biasing

InactiveUS20070076481A1Improve fill factorPossible to useRadiation pyrometrySolid-state devicesCMOSPhotovoltaic detectors

In a multimode FPA, all of the FPA's conducting layers including all of the absorbing layers are patterned to form electrically isolated commons for at least two, and in some instances all of the photodetector sub-arrays, to support independent mode biasing of the photodetectors. Because the commons are electrically isolated, the bias voltages are not constrained by the CMOS design rules. The commons can accommodate large bias amplitude differences and different temporal bias profiles to address a wide range of multimode sensing applications.

Owner:TELEDYNE SCI & IMAGING

Flow rate measurement for industrial sensing applications using unsteady pressures

Flow rate measurement system includes two measurement regions 14,16 located an average axial distance ΔX apart along the pipe 12, the first measurement region 14 having two unsteady pressure sensors 18,20, located a distance X1 apart, and the second measurement region 16, having two other unsteady pressure sensors 22,24, located a distance X2 apart, each capable of measuring the unsteady pressure in the pipe 12. Signals from each pair of pressure sensors 18,20 and 22,24 are differenced by summers 44,54, respectively, to form spatial wavelength filters 33,35, respectively. Each spatial filter 33,35filters out acoustic pressure disturbances Pacoustic and other long wavelength pressure disturbances in the pipe 12 and passes short-wavelength low-frequency vortical pressure disturbances Pvortical associated with the vortical flow field 15. The spatial filters 33,35 provide signals Pas1,Pas2 to band pass filters 46,56 that filter out high frequency signals. The Pvortical-dominated filtered signals Pasf1,Pasf2 from the two regions 14,16 are cross-correlated by Cross-Correlation Logic 50 to determine a time delay τ between the two sensing locations 14,16 which is divided into the distance ΔX to obtain a convection velocity Uc(t) that is related to an average flow rate of the fluid (i.e., one or more liquids and / or gases) flowing in the pipe 12. The invention may also be configured to detect the velocity of any desired inhomogeneous pressure field in the flow. The invention may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

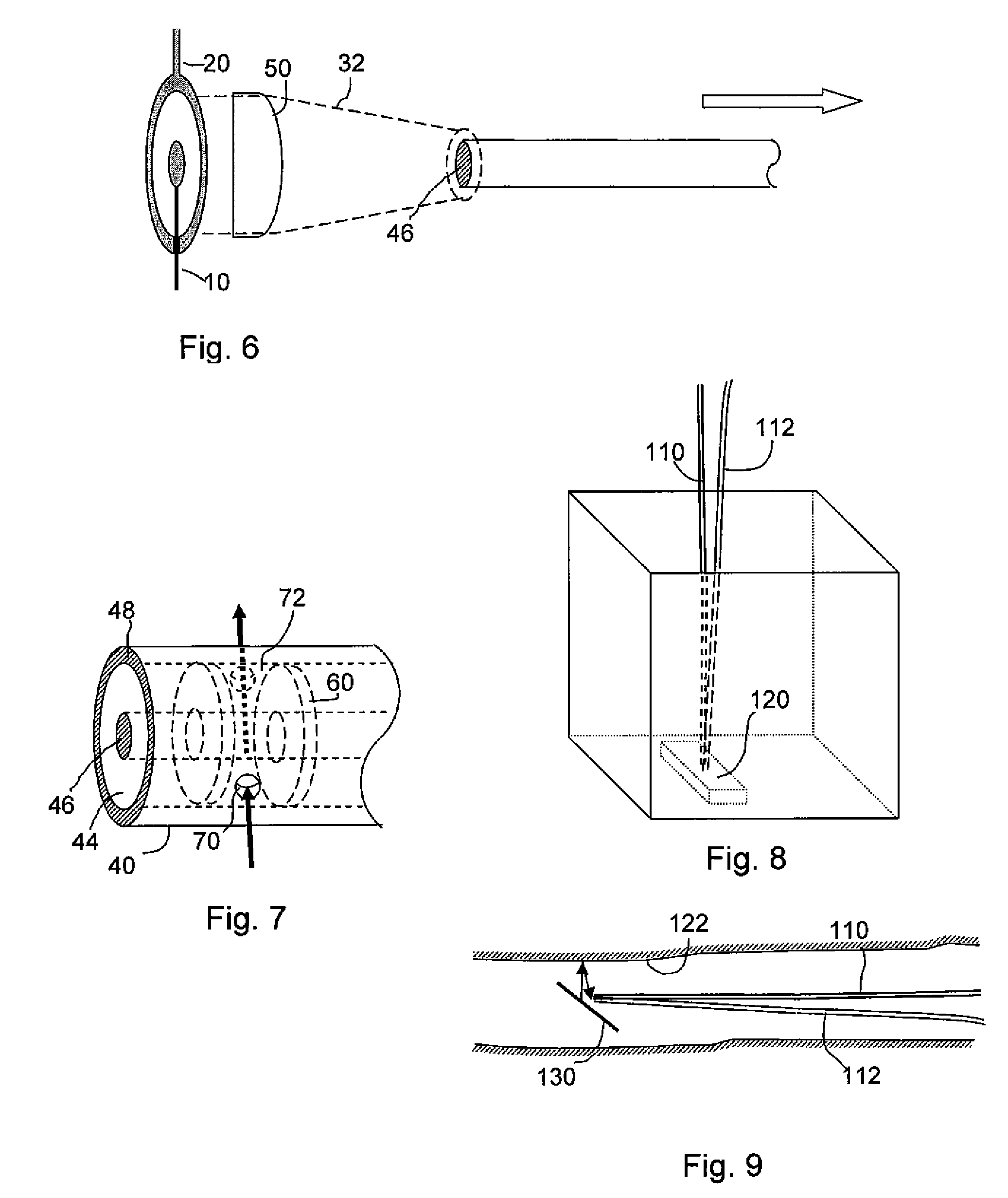

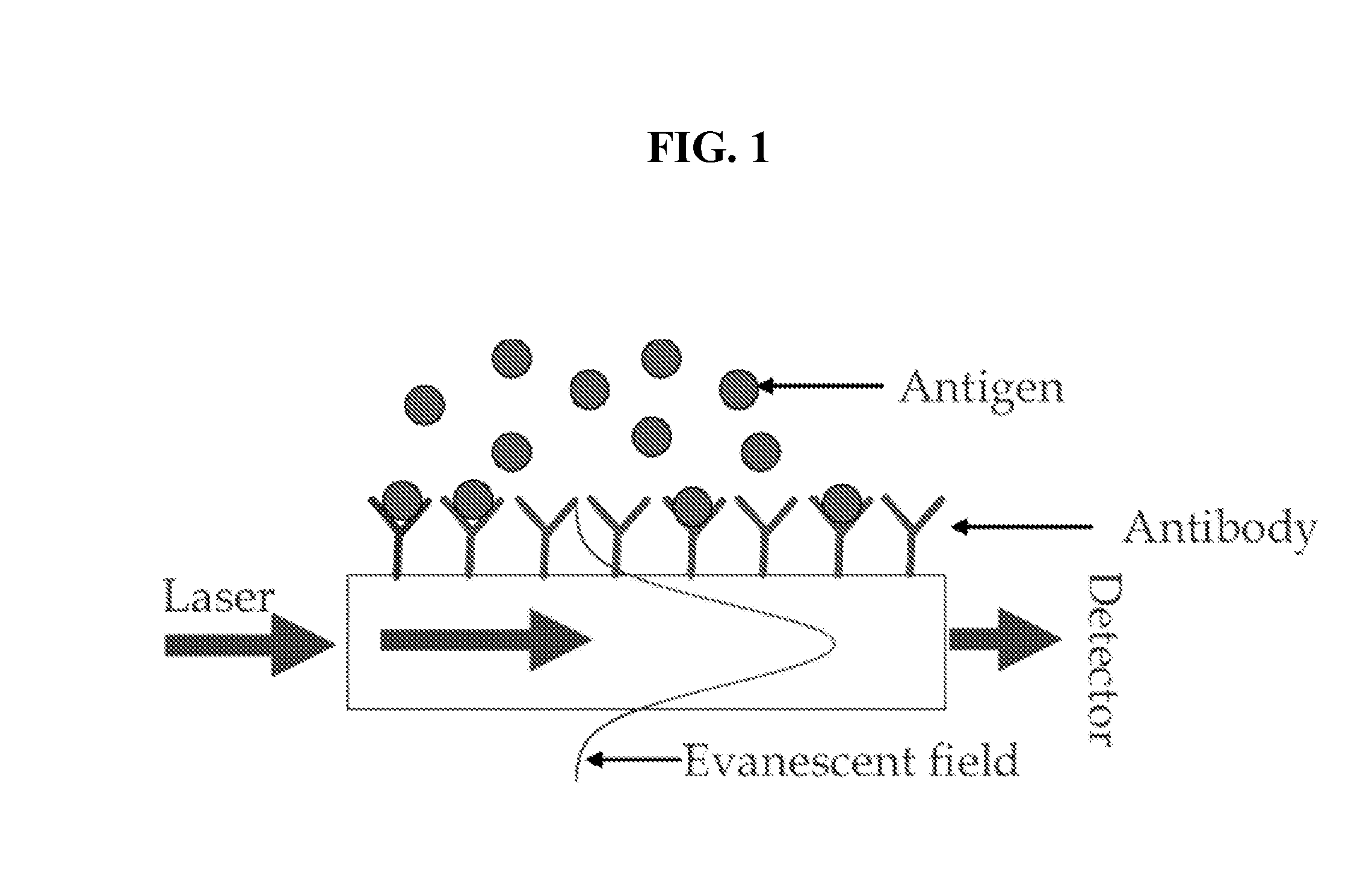

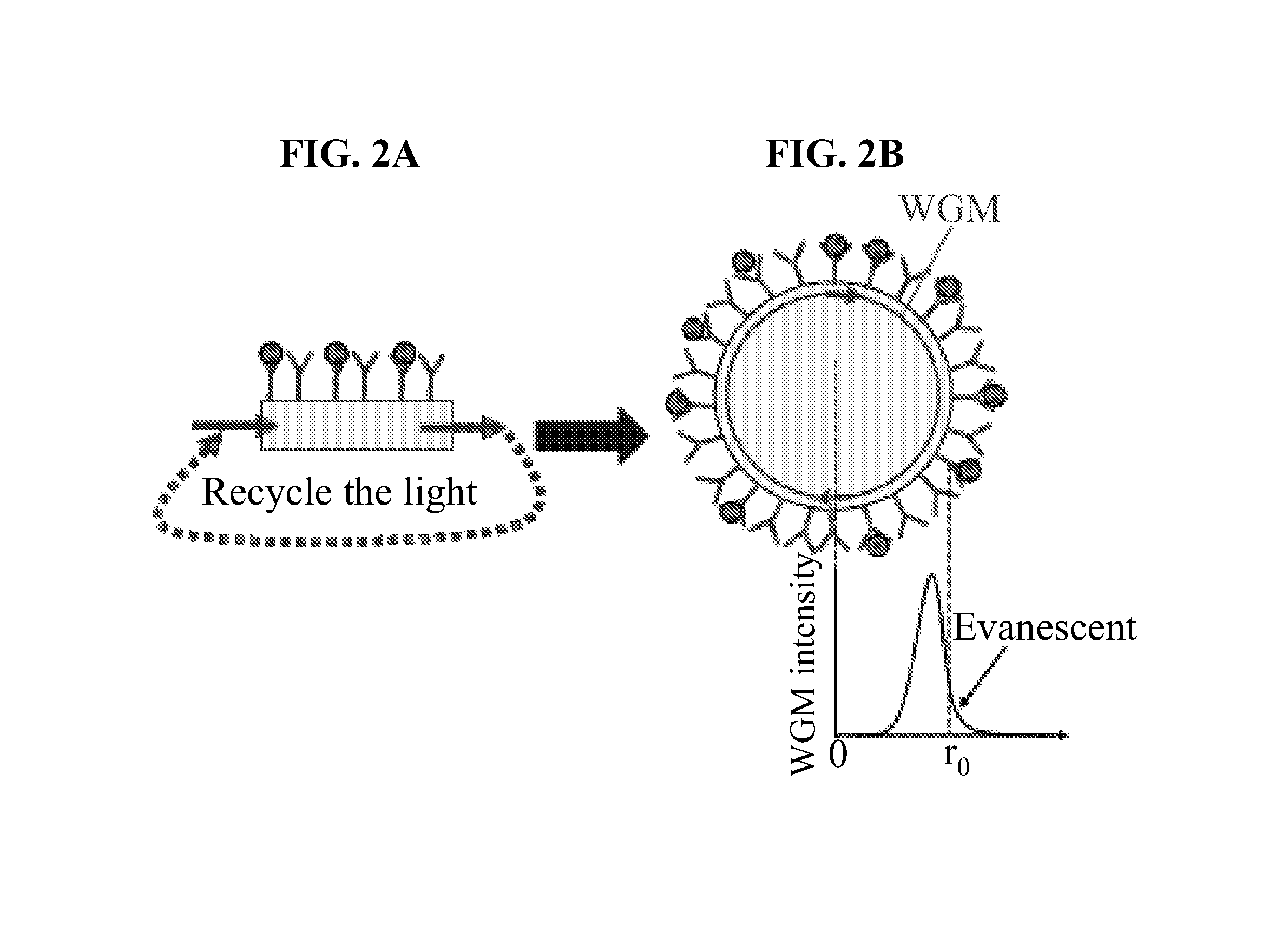

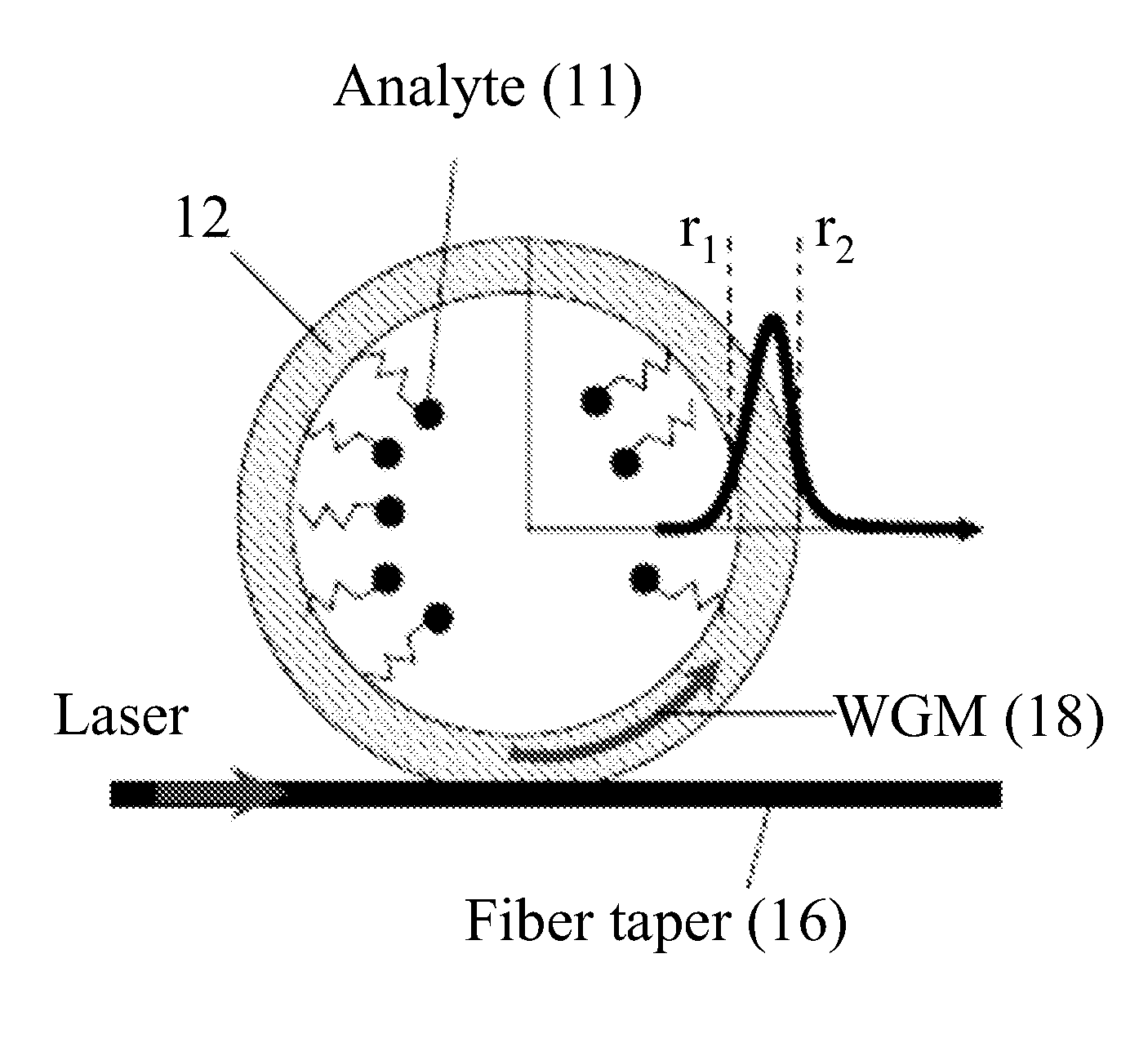

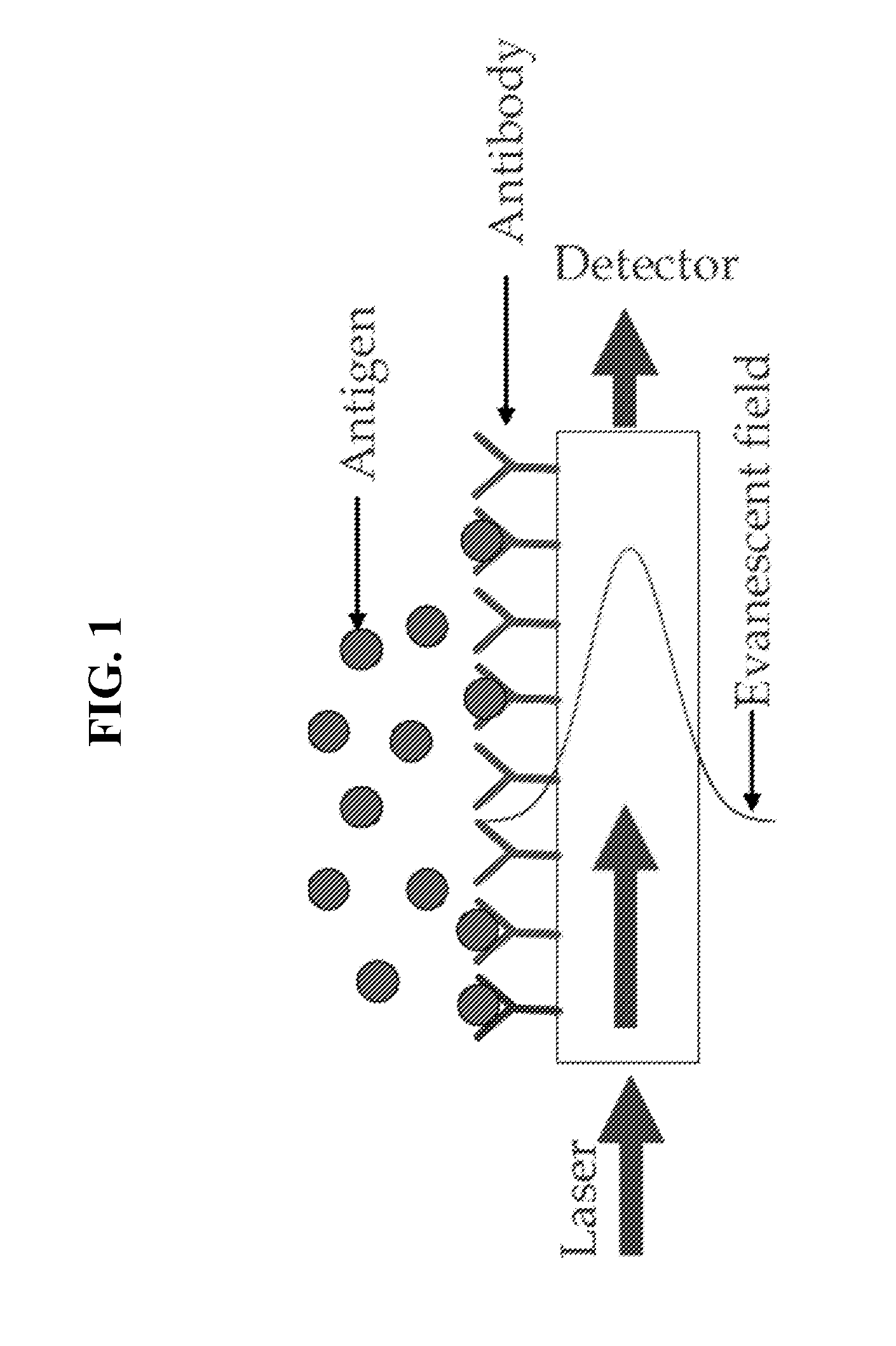

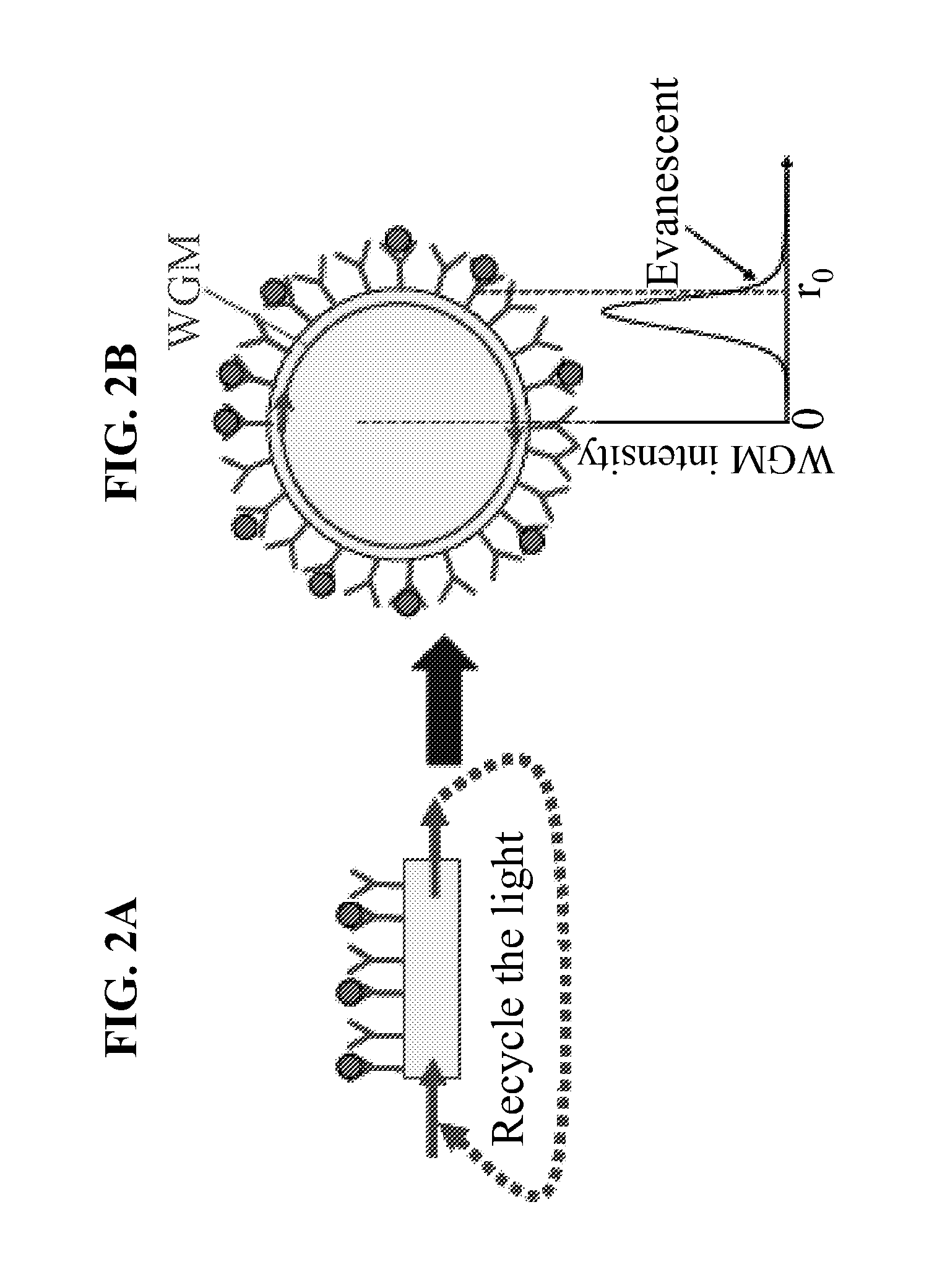

Hollow Core Optical Ring Resonator Sensor, Sensing Methods, and Methods of Fabrication

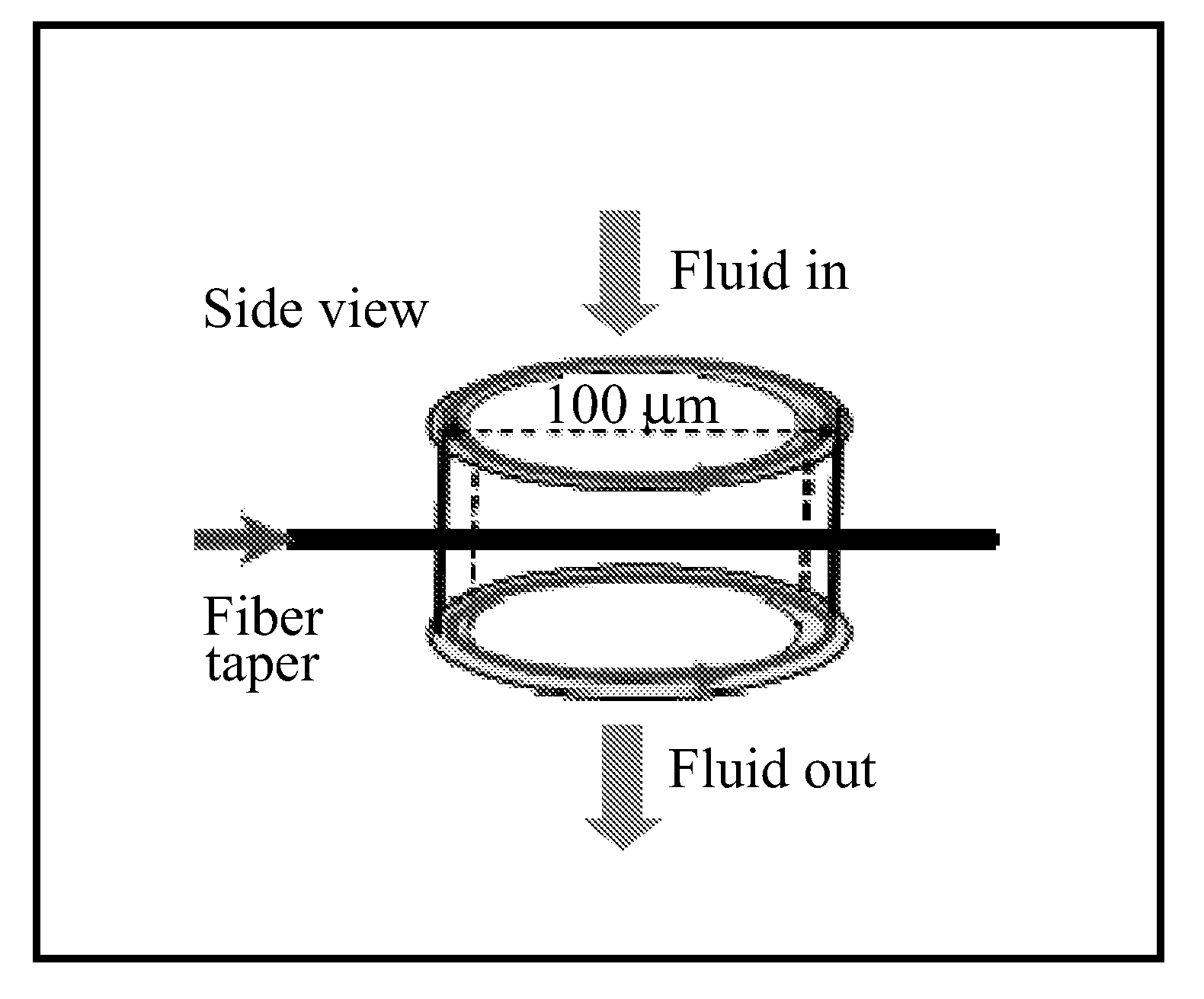

InactiveUS20070237460A1High sensitivityLow sample consumptionMaterial analysis by optical meansCoupling light guidesTarget analysisWhispering gallery

The present invention is directed to hollow core optical ring resonators (HCORRs), methods of fabricating HCORRs, and methods of using HCORRs in sensing applications. In particular, the evanescent field and whispering gallery modes of the HCORRs may be used to detect a target analyte within the hollow core of the HCORR. Other features of the present invention include utilizing the HCORR as part of a multiplex sensing device, including using the HCORR in capillary electrophoresis and chromatography applications.

Owner:UNIVERSITY OF MISSOURI

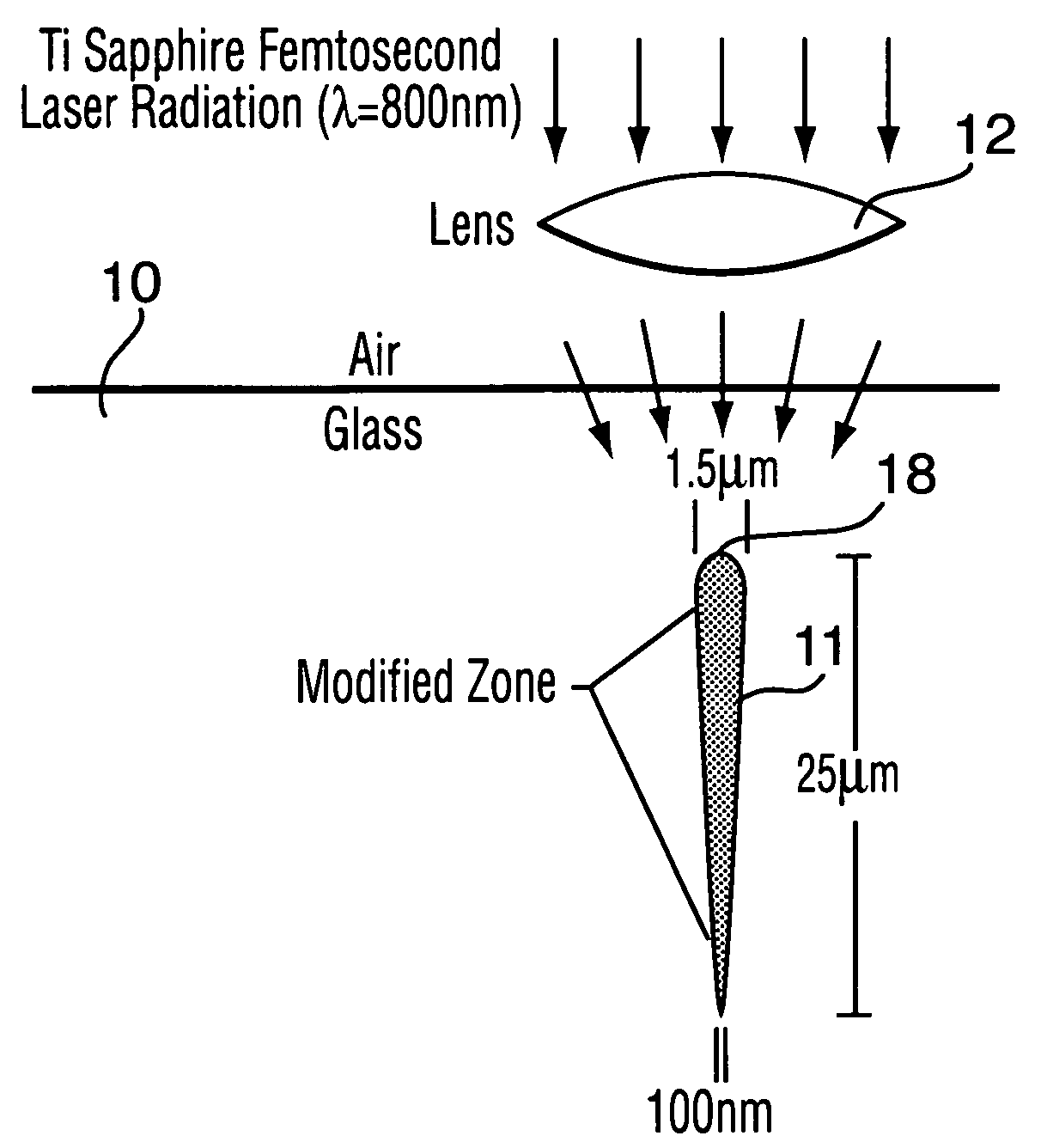

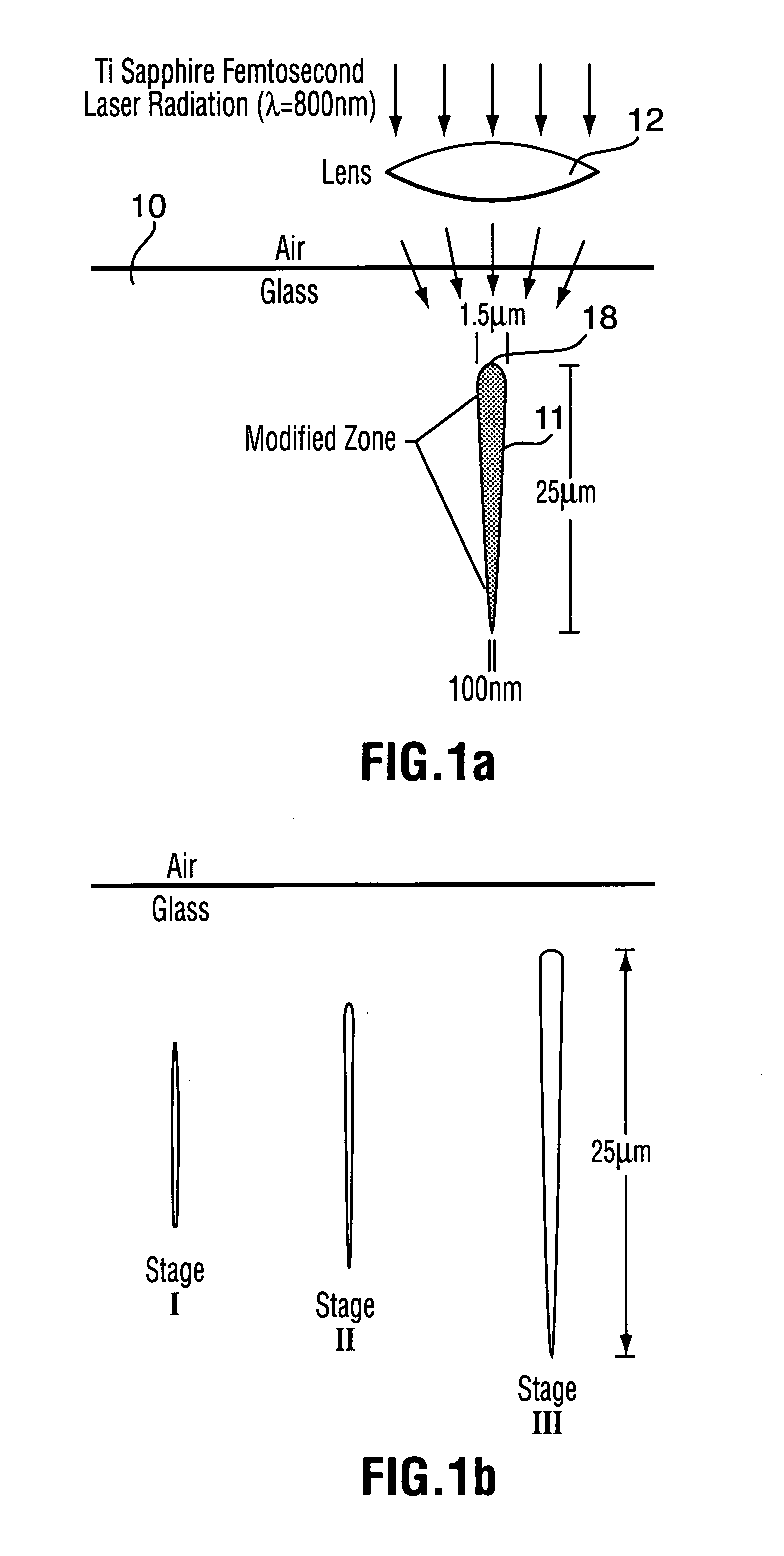

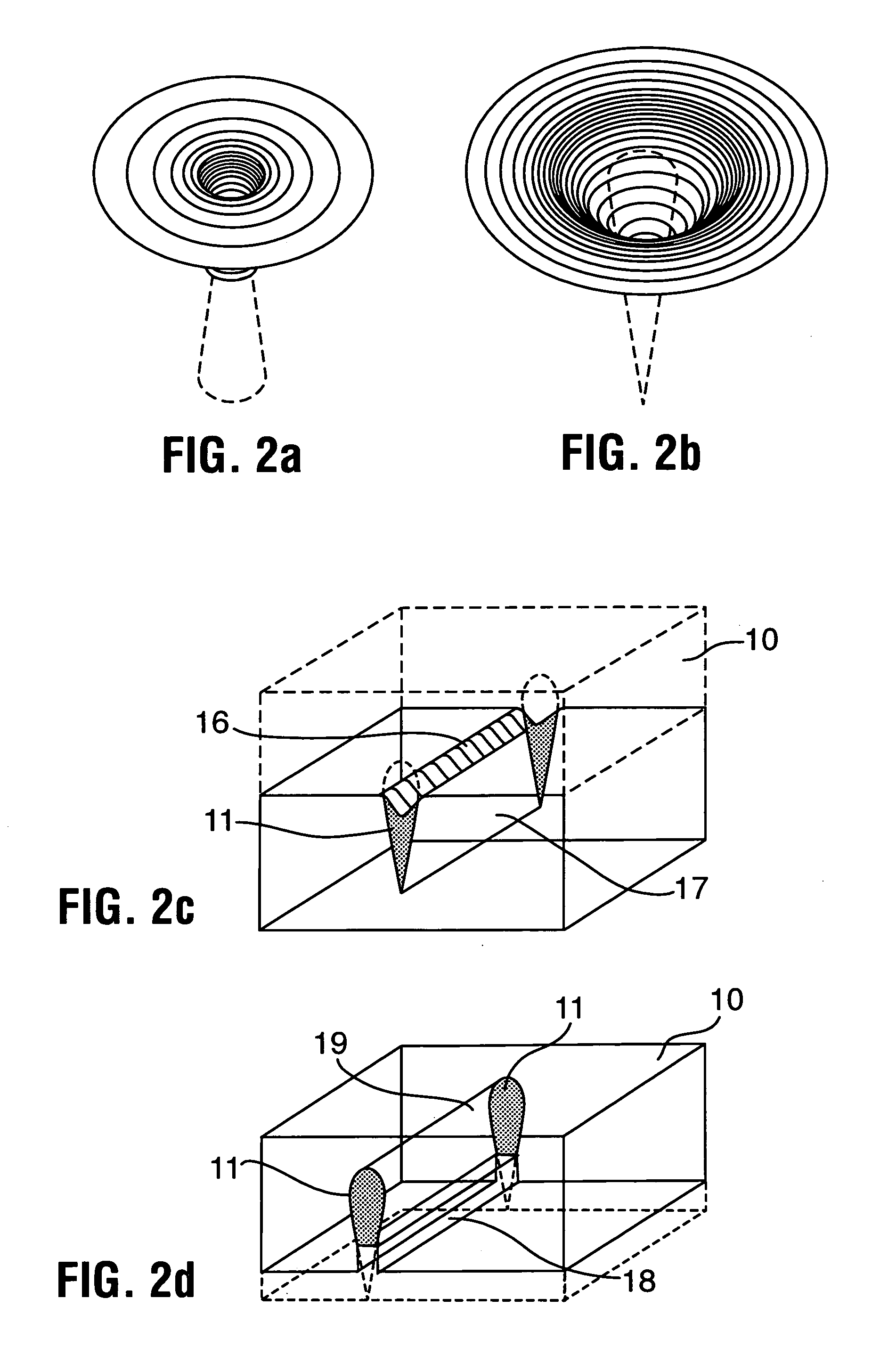

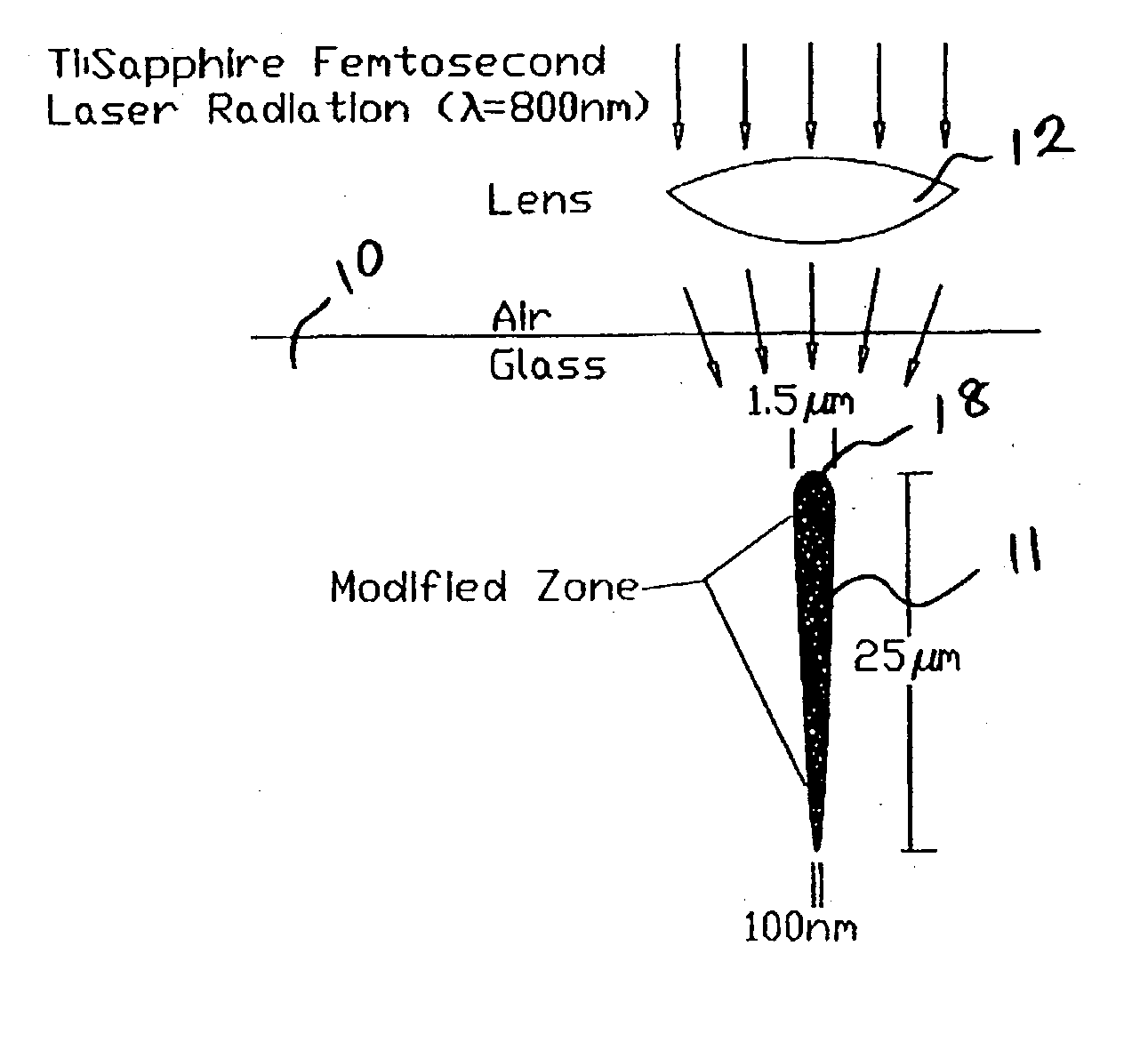

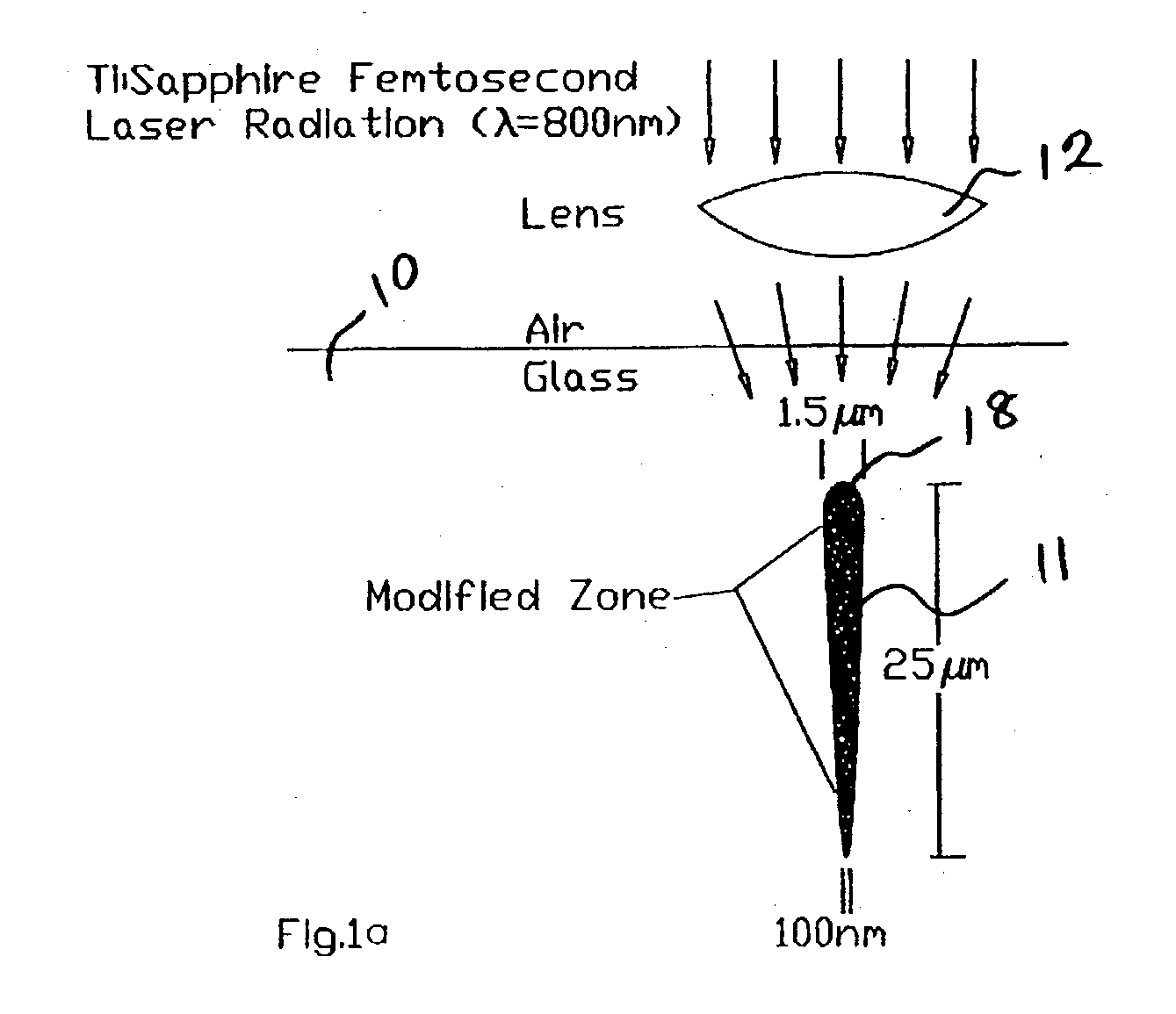

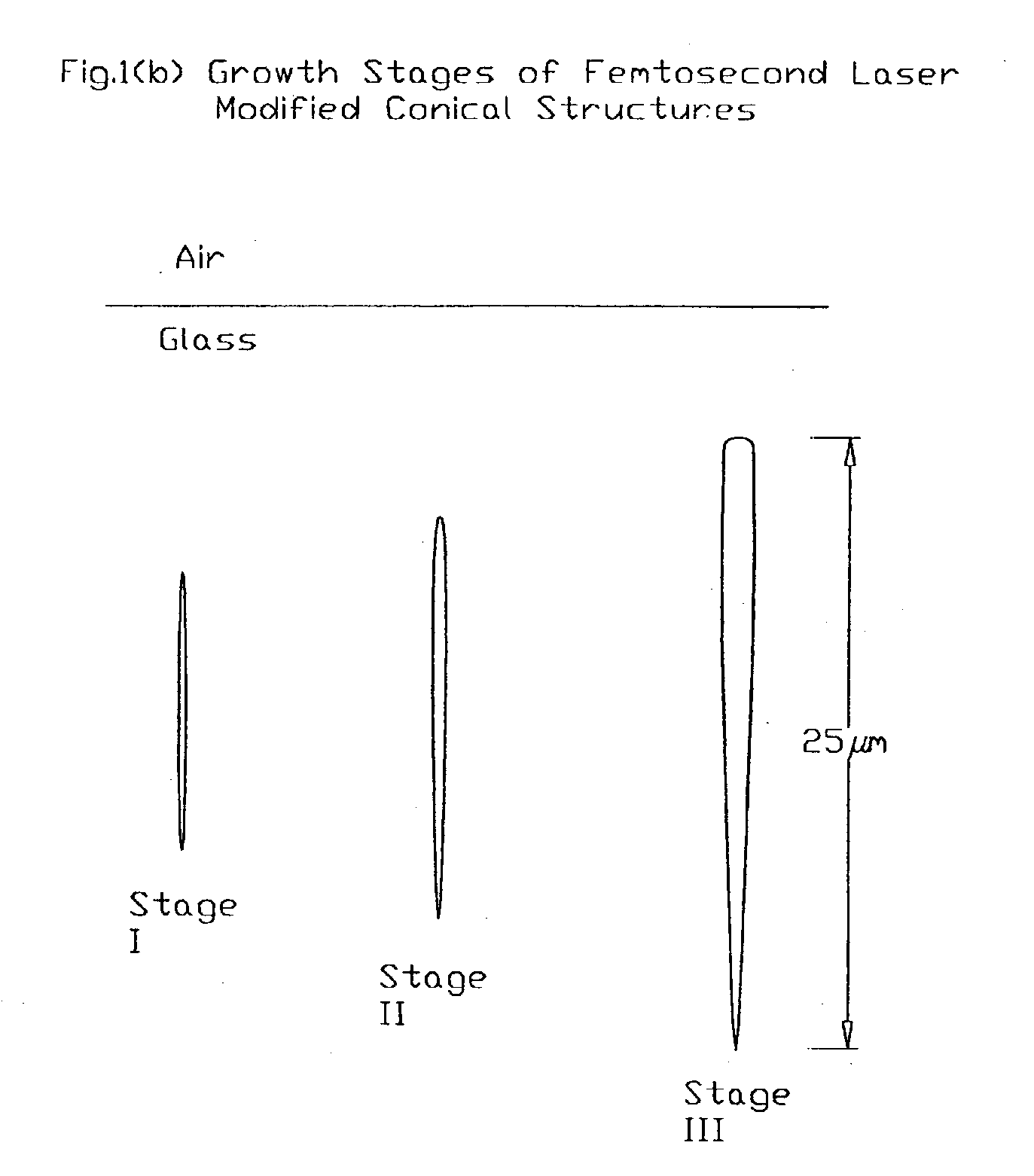

Method of fabricating sub-micron structures in transparent dielectric materials

A sub-micron structure is fabricated in a transparent dielectric material by focusing femtosecond laser pulses into the dielectric to create a highly tapered modified zone with modified etch properties. The dielectric material is then selectively etched into the modified zone from the direction of the narrow end of the tapered zone so that as the selective etching proceeds longitudinally into the modified zone, the progressively increasing width of the modified zone compensates for lateral etching occurring closer to the narrow end so as to produce steep-walled holes. The unetched portion of the modified zone produced by translating the laser beam close to and parallel to the bottom surface of the dielectric can serve as an optical waveguide to collect light from or deliver light to the etched channel which can contain various biological, optical, or chemical materials for sensing applications.

Owner:NAT RES COUNCIL OF CANADA

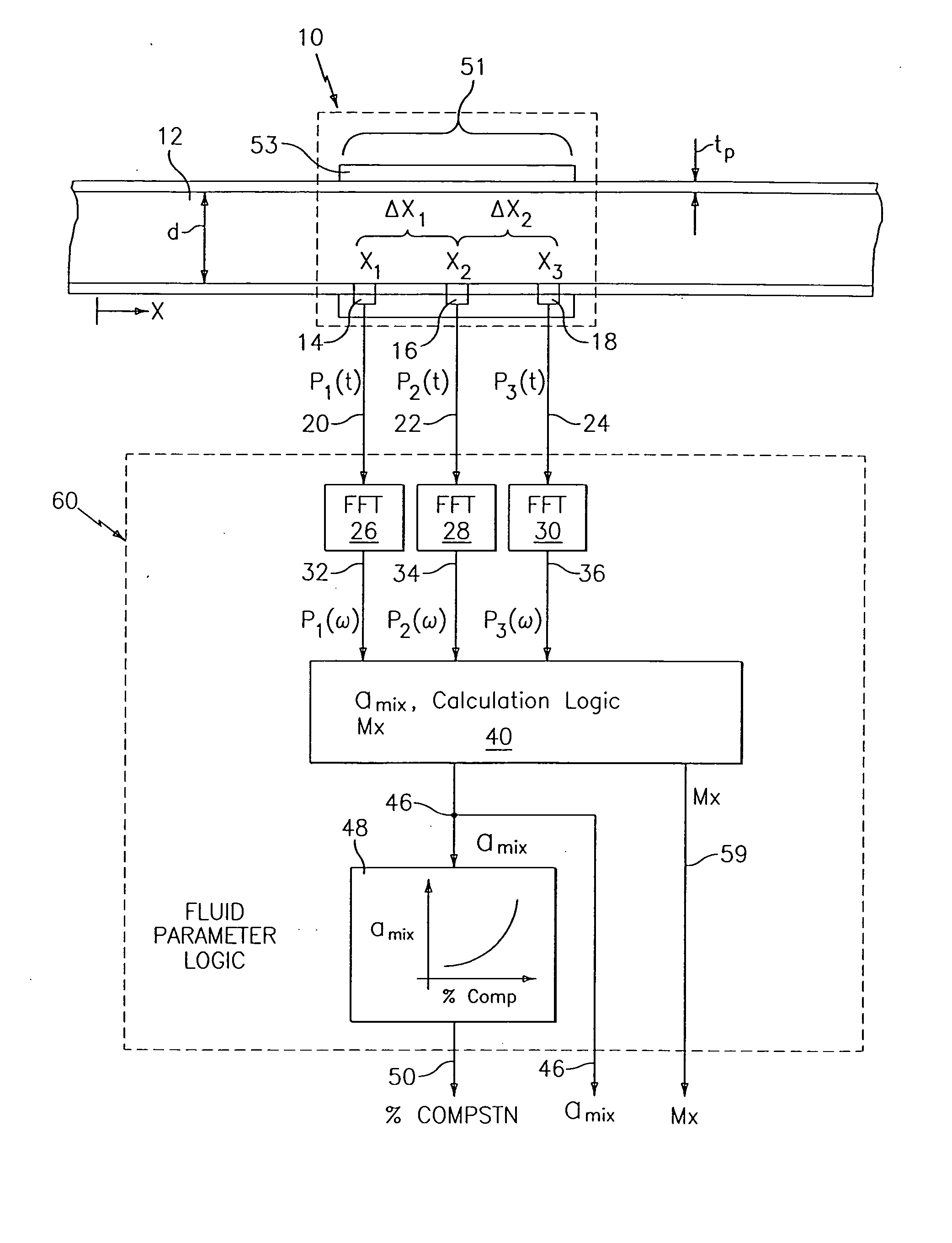

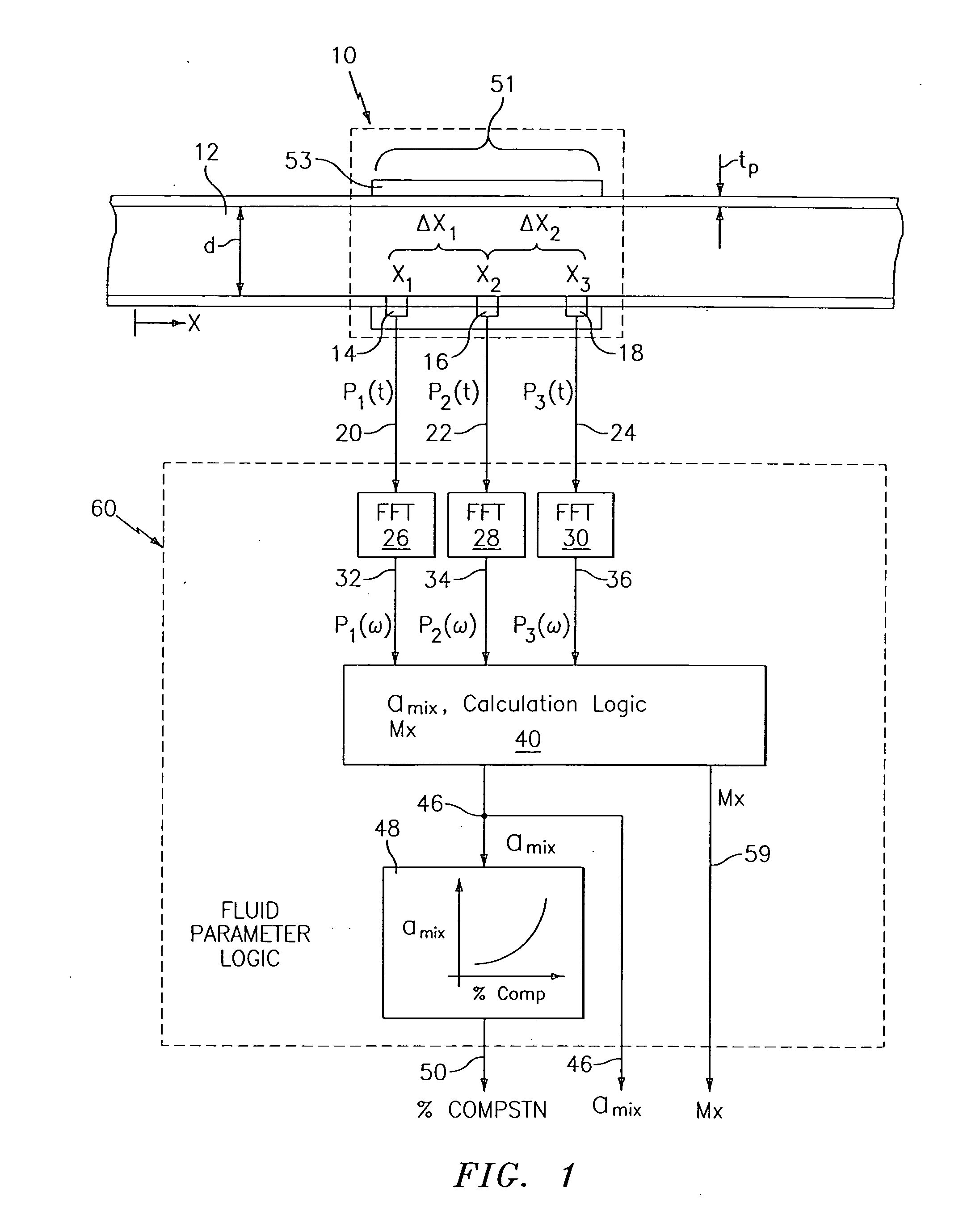

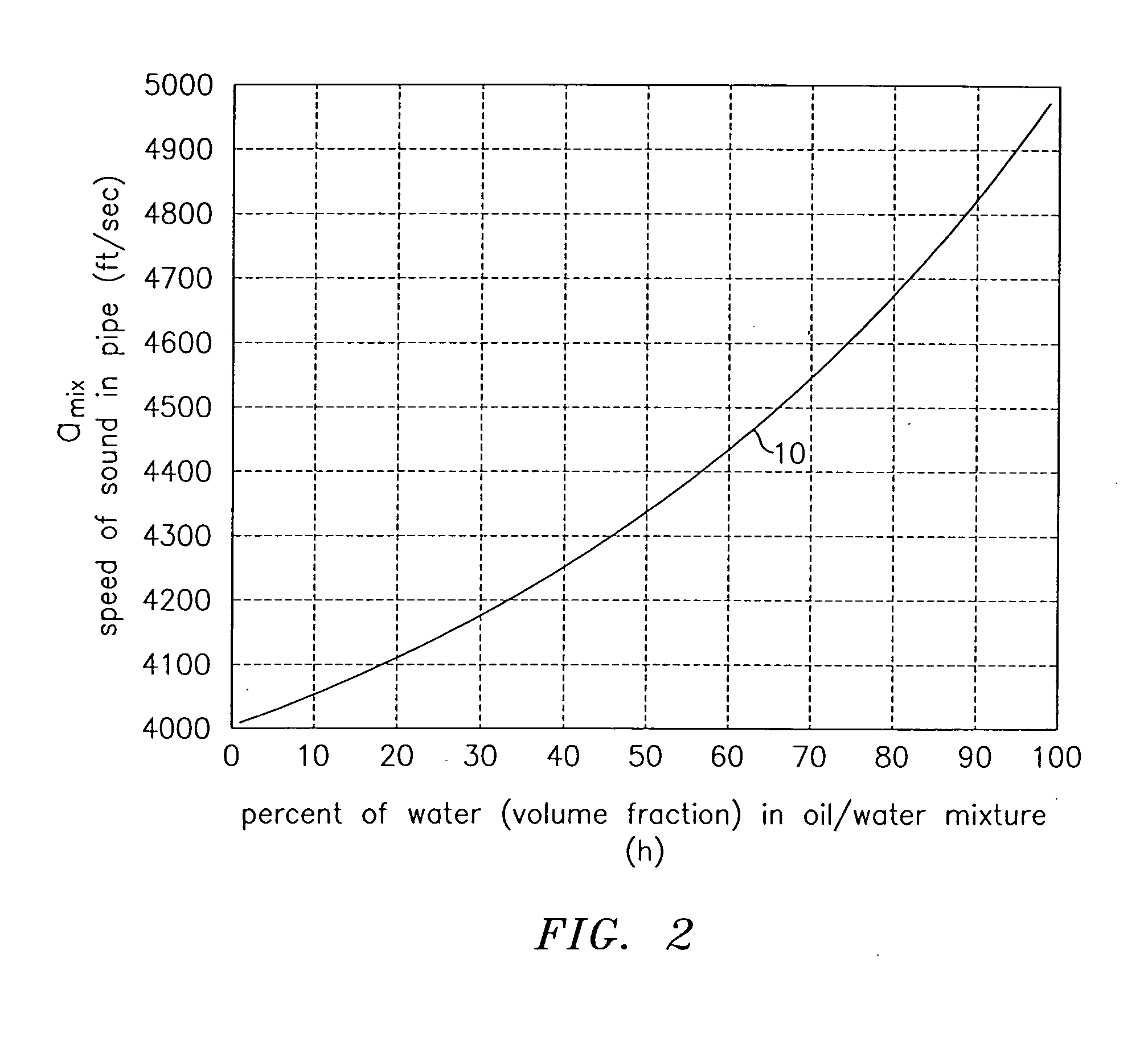

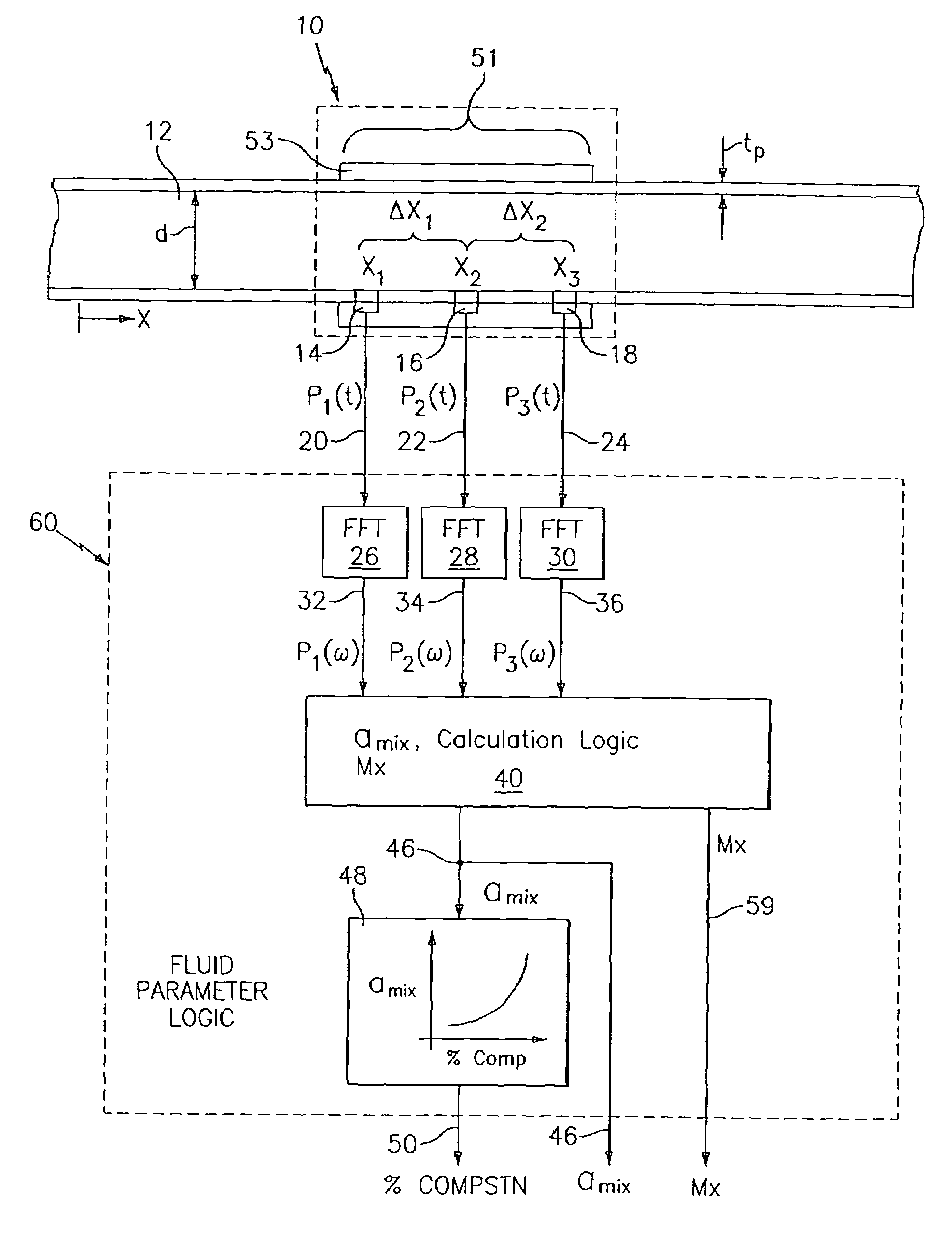

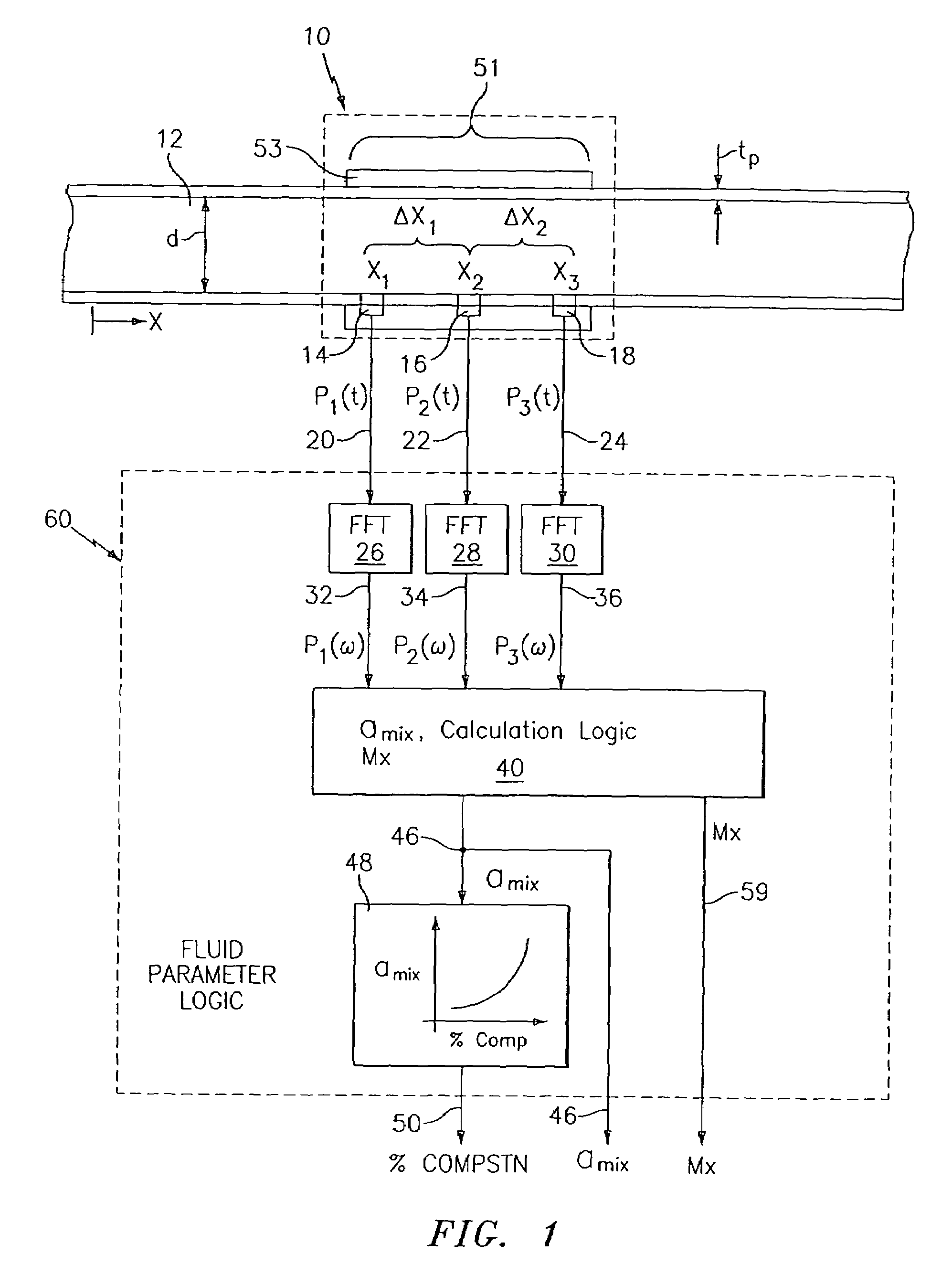

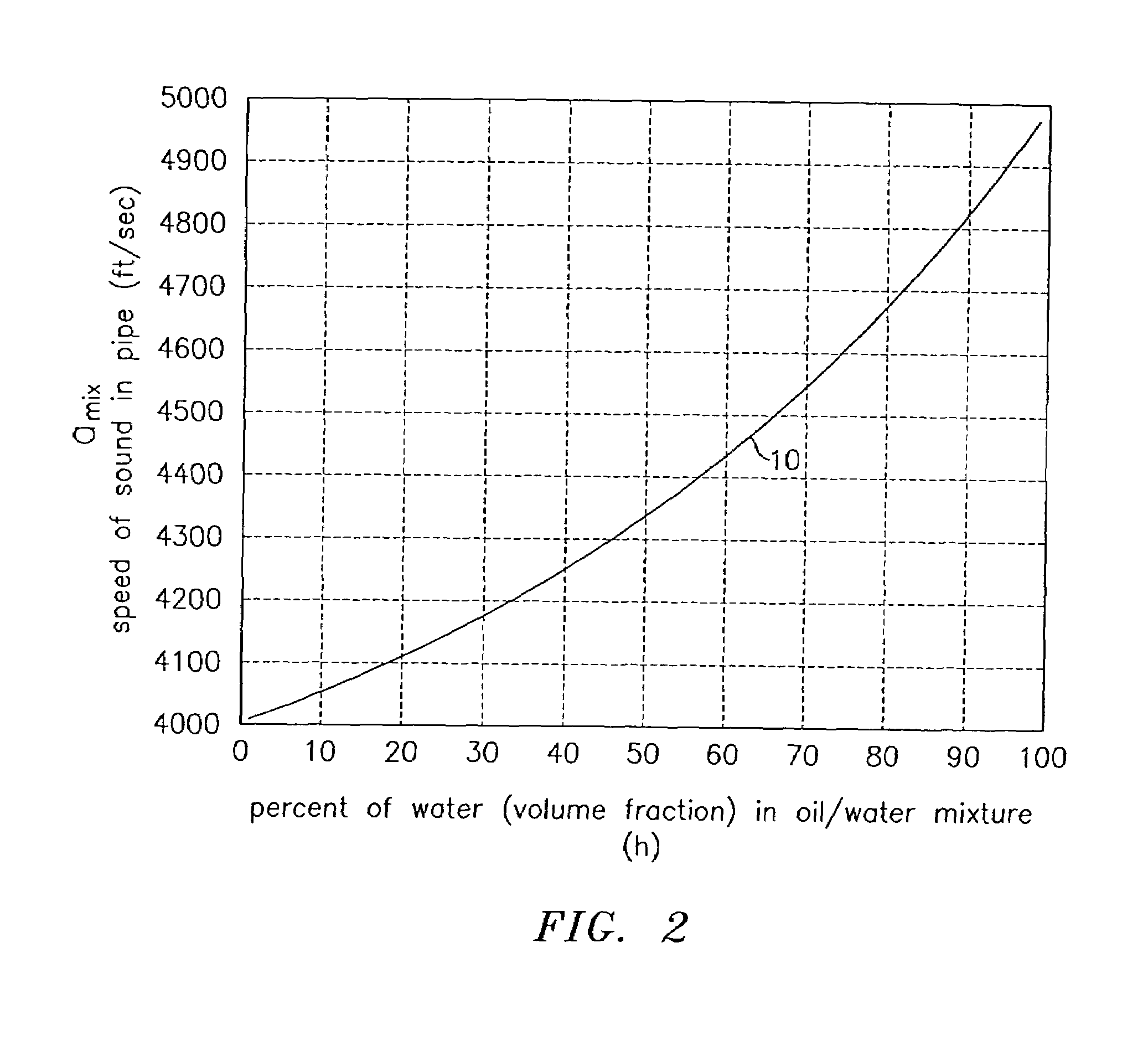

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS20050000289A1Less sensitiveImprove measurement reliabilityVibration measurement in solidsVibration measurement in fluidEngineeringOpto electronic

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

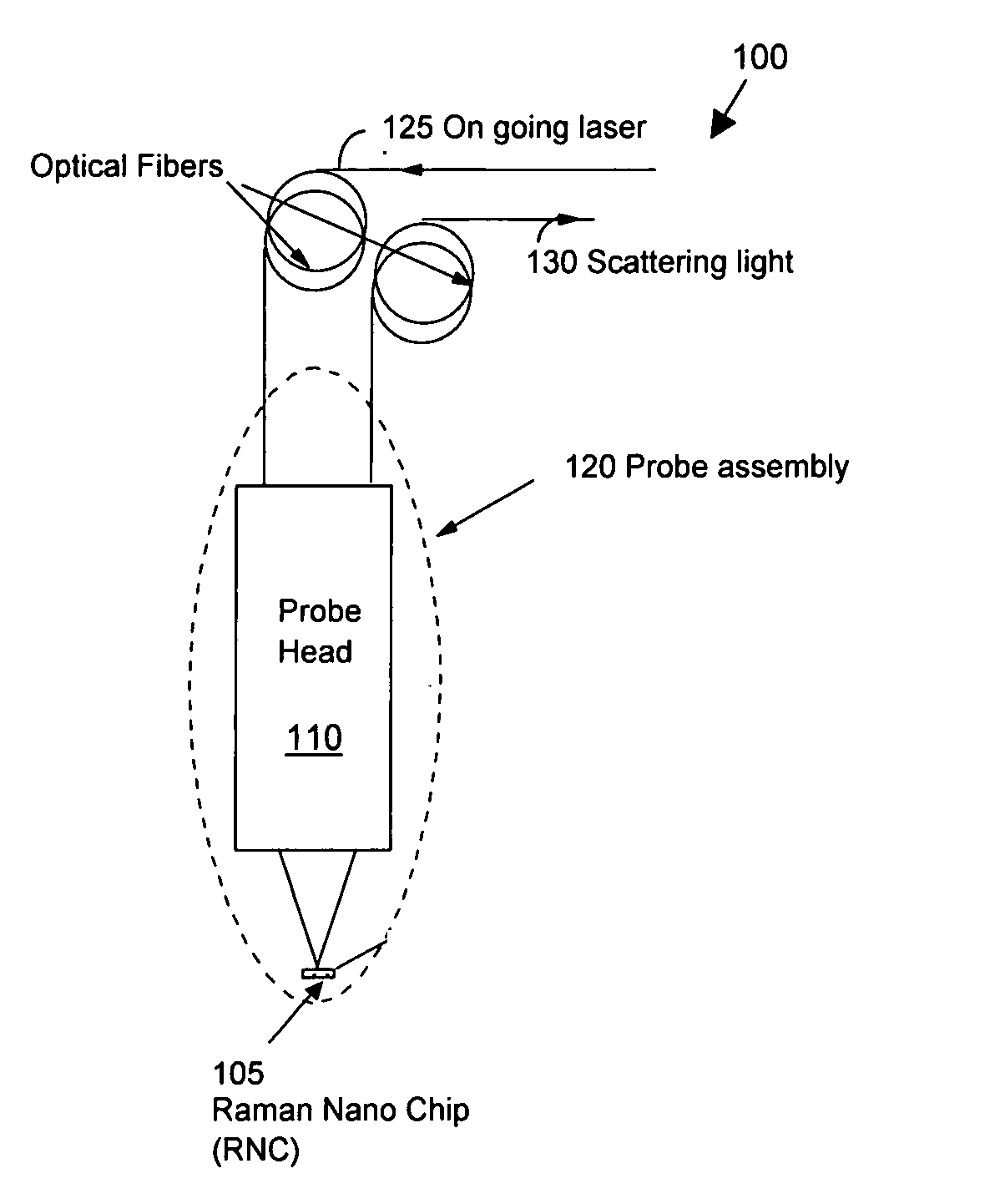

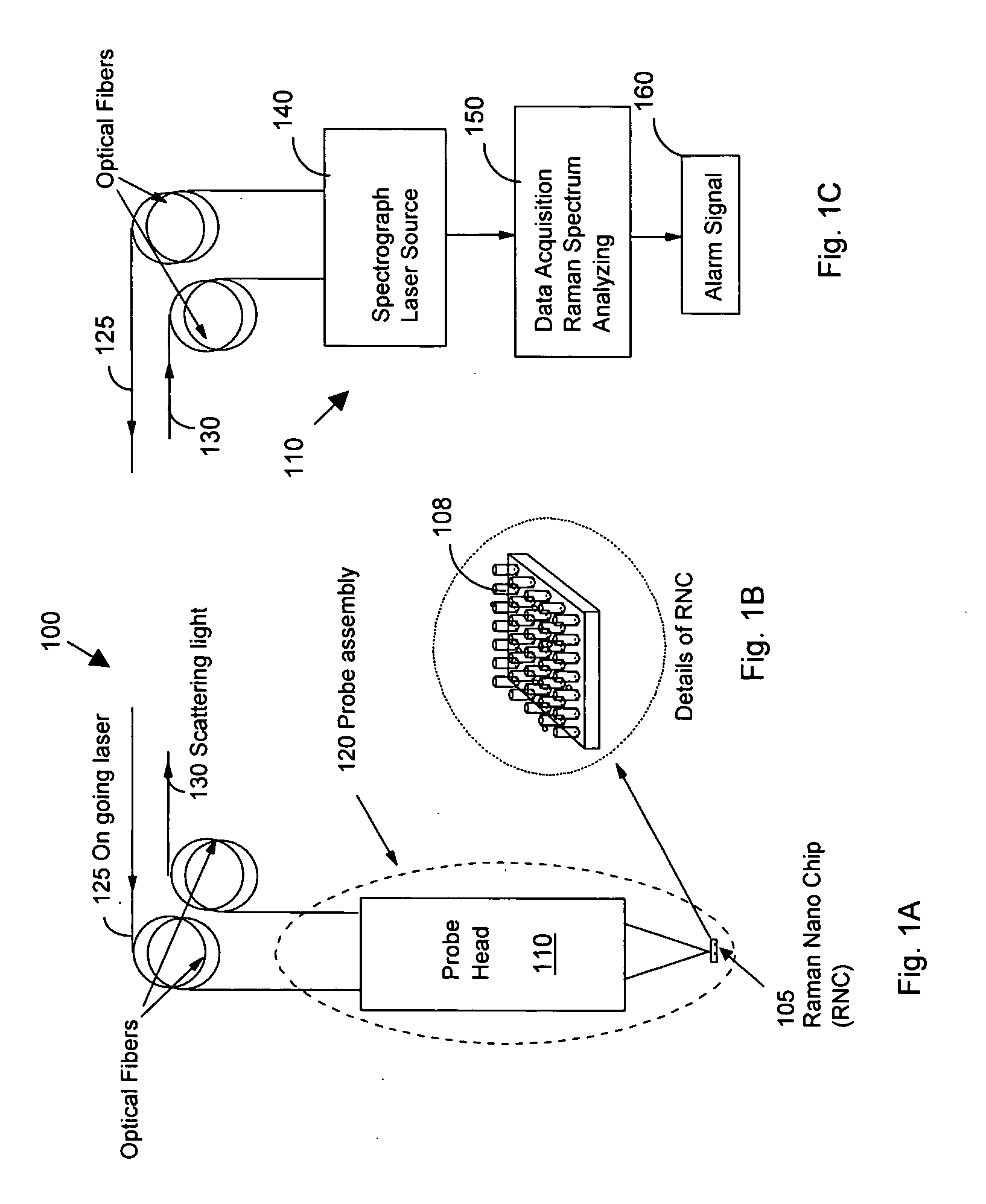

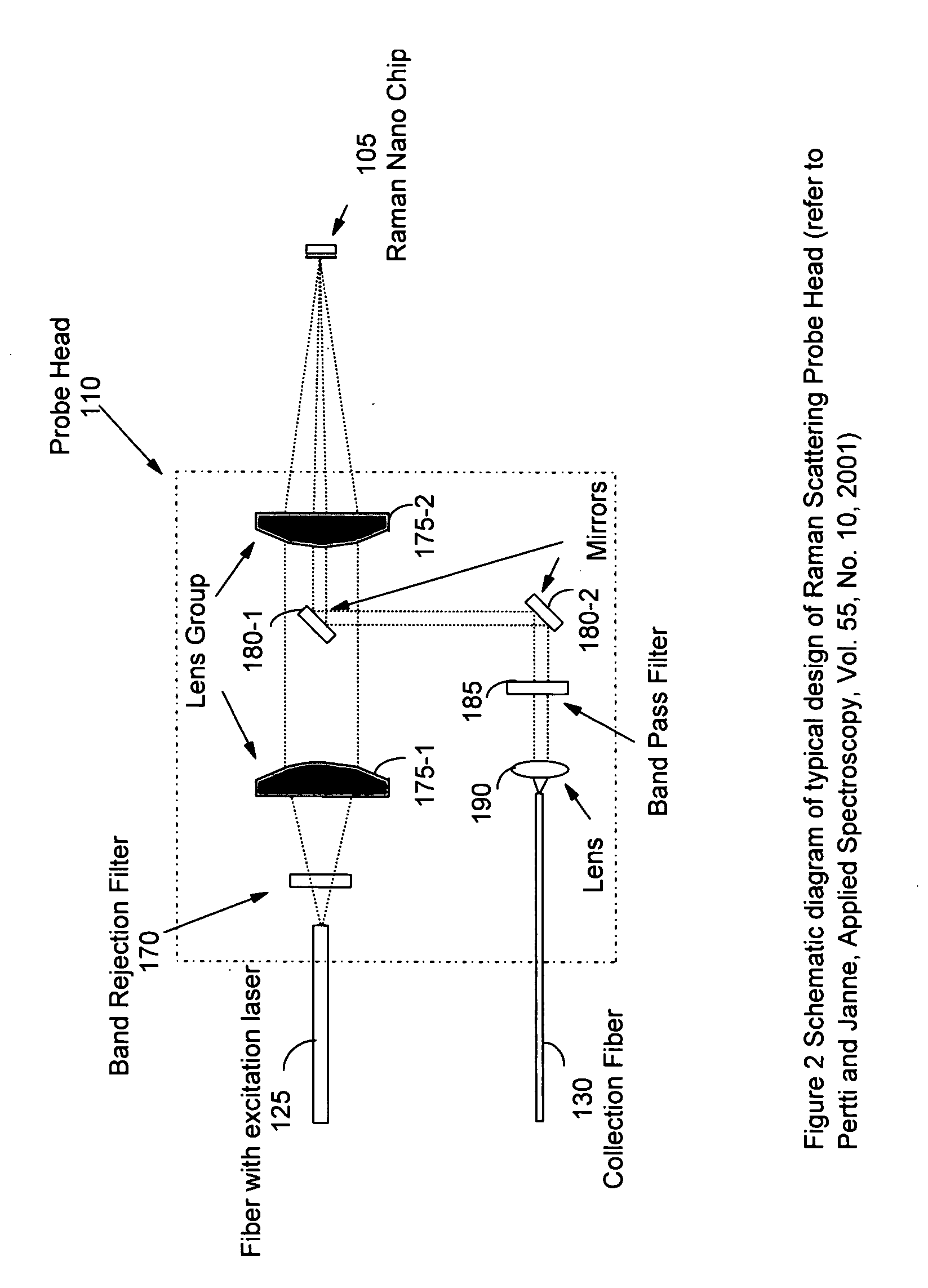

Applications of Raman scattering probes

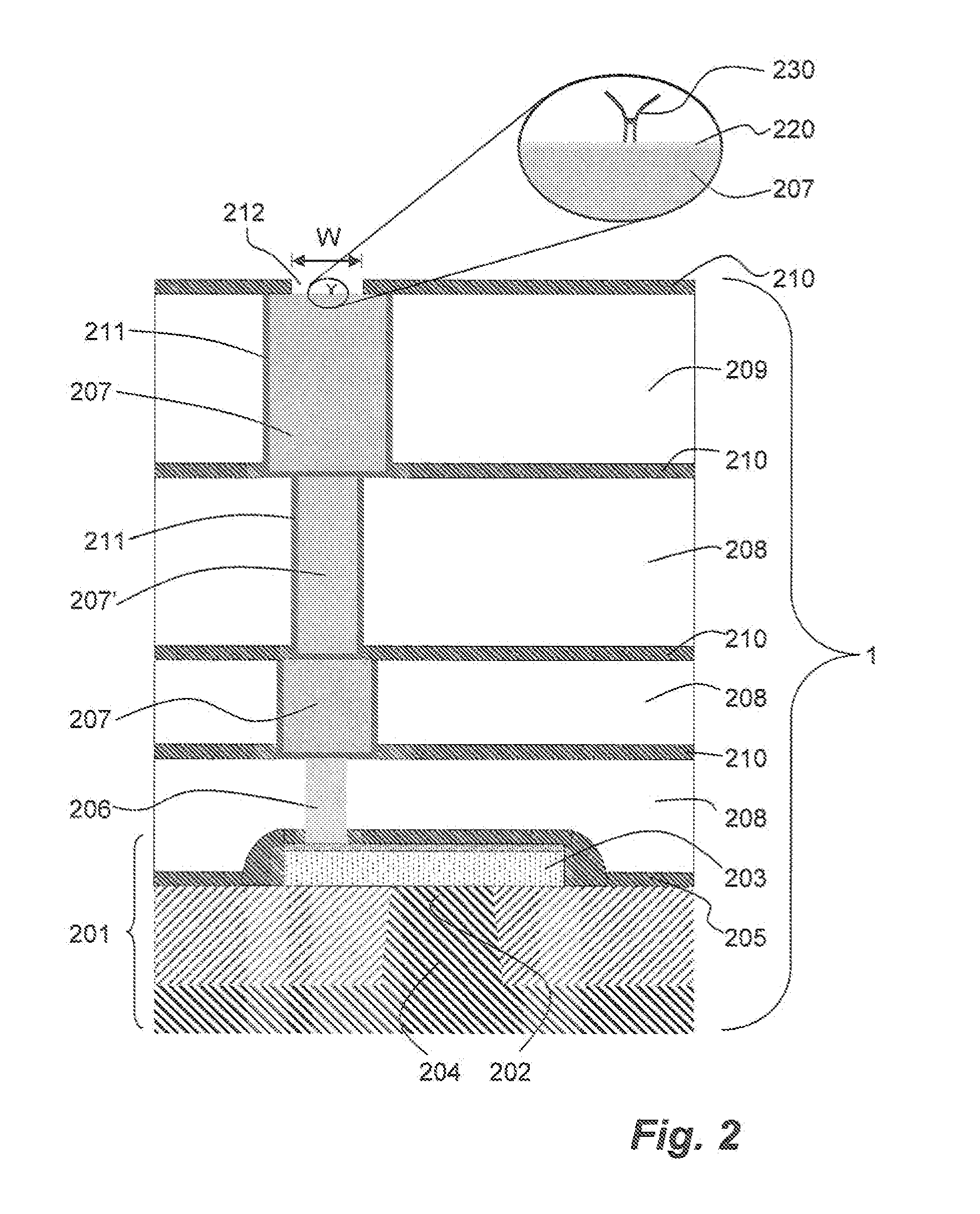

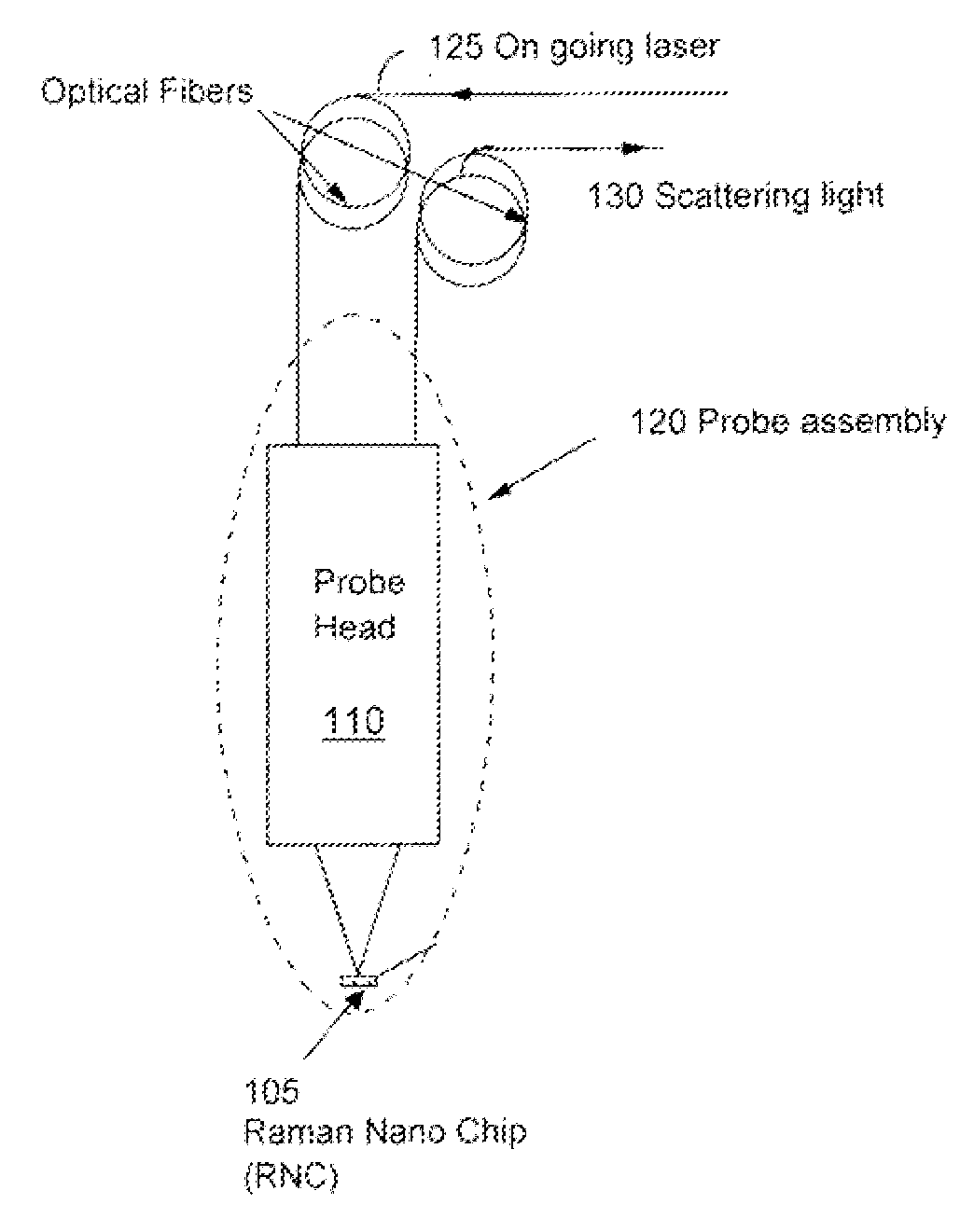

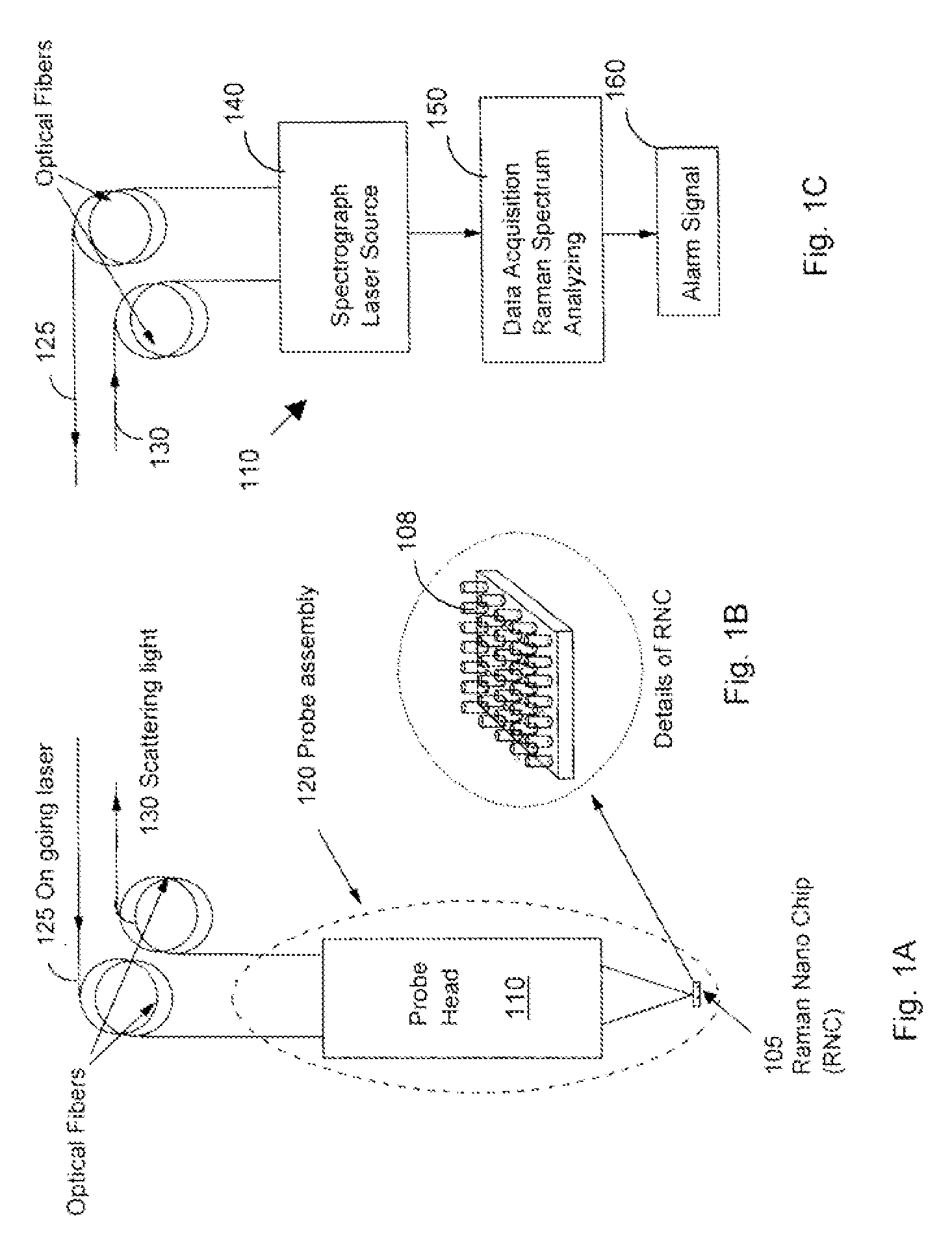

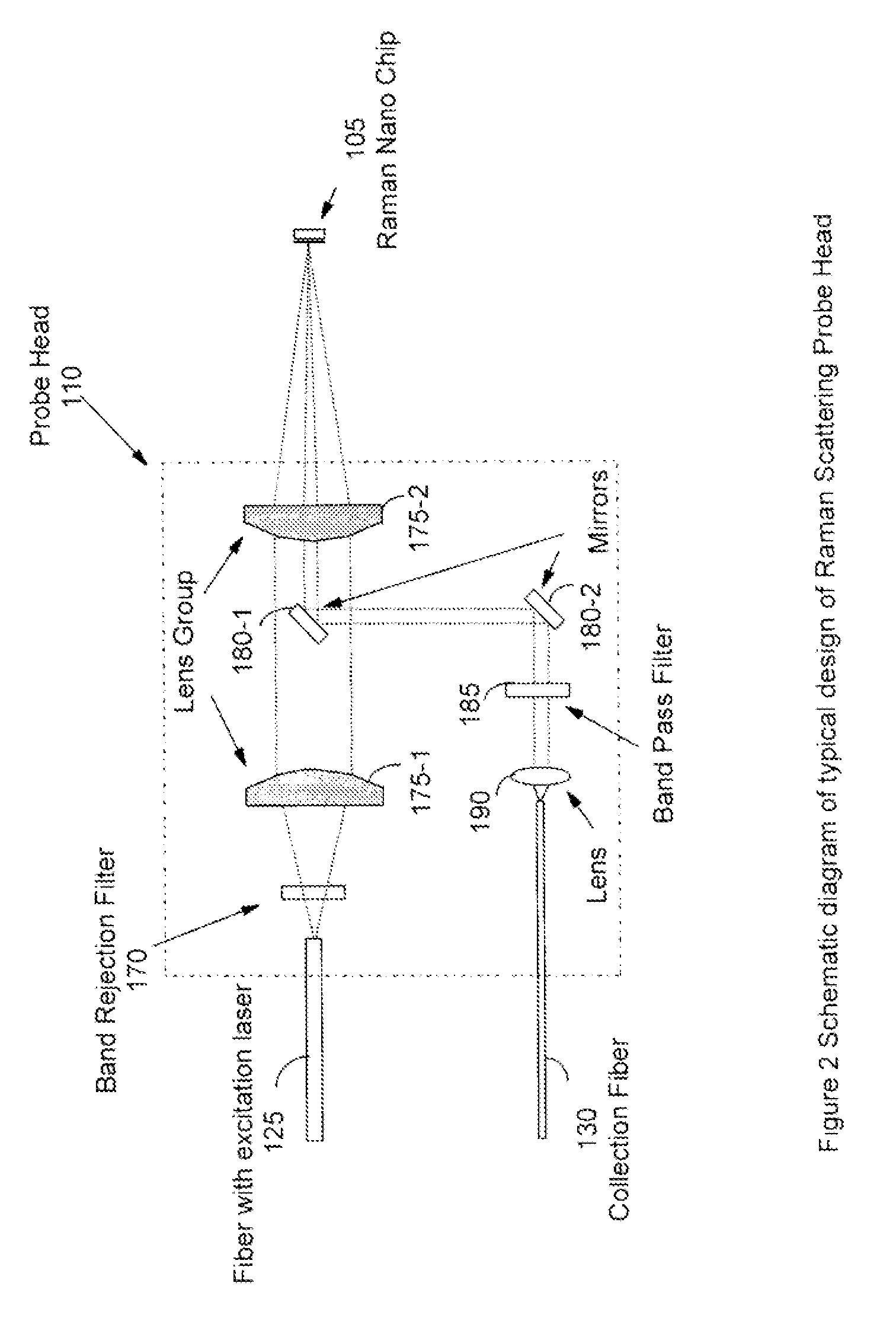

InactiveUS20050206892A1Wide applicationExpected can be lowRadiation pyrometryRaman scatteringHomeland securityNanostructure

New and improved applications of Raman Scattering are disclosed. These applications may be implemented with or without using an enhanced nano-structured surface that is trademarked as the RamanNanoChip™ disclosed in a pending patent. As a RamanNanoChip™ provides much higher sensitivity in SERS compared with conventional enhance surface, broader scopes of applications are now enabled and can be practically implemented as now disclosed in this application. Furthermore, a wide range of applications is achievable as new and improved Raman sensing applications. By applying the analysis of Raman scattering spectrum, applications can be carried out to identify unknown chemical compositions to perform the tasks of homeland security; food, drug and drinking materials safety; early disease diagnosis; environmental monitoring; industrial process monitoring, precious metal and gem authentications, etc.

Owner:OPTOTRACE TECH

Method of fabricating sub-micron structures in transparent dielectric materials

A sub-micron structure is fabricated in a transparent dielectric material by focusing femtosecond laser pulses into the dielectric to create a highly tapered modified zone with modified etch properties. The dielectric material is then selectively etched into the modified zone from the direction of the narrow end of the tapered zone so that as the selective etching proceeds longitudinally into the modified zone, the progressively increasing width of the modified zone compensates for lateral etching occurring closer to the narrow end so as to produce steep-walled holes. The unetched portion of the modified zone produced by translating the laser beam close to and parallel to the bottom surface of the dielectric can serve as an optical waveguide to collect light from or deliver light to the etched channel which can contain various biological, optical, or chemical materials for sensing applications.

Owner:NAT RES COUNCIL OF CANADA

Hybrid sensor array

InactiveUS20120028820A1Add dimensionLow costTransistorDetection of fluid at leakage pointBio moleculesAnalyte

The present invention provides devices, methods and systems to selectively detect the binding of a molecular species to a biomolecule. In its olfactory sensing application, the hybrid sensor arrays of the present invention provide a high dimensional signature of odorants present that is also readily reversible, together enabling the identification and localization of a source analyte in the presence of the background odorant landscape inherent in a real-world setting.

Owner:NANOSENSE

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS6988411B2Less sensitive to static shifts (or errors) in sensingImprove measurement reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringSound pressure

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

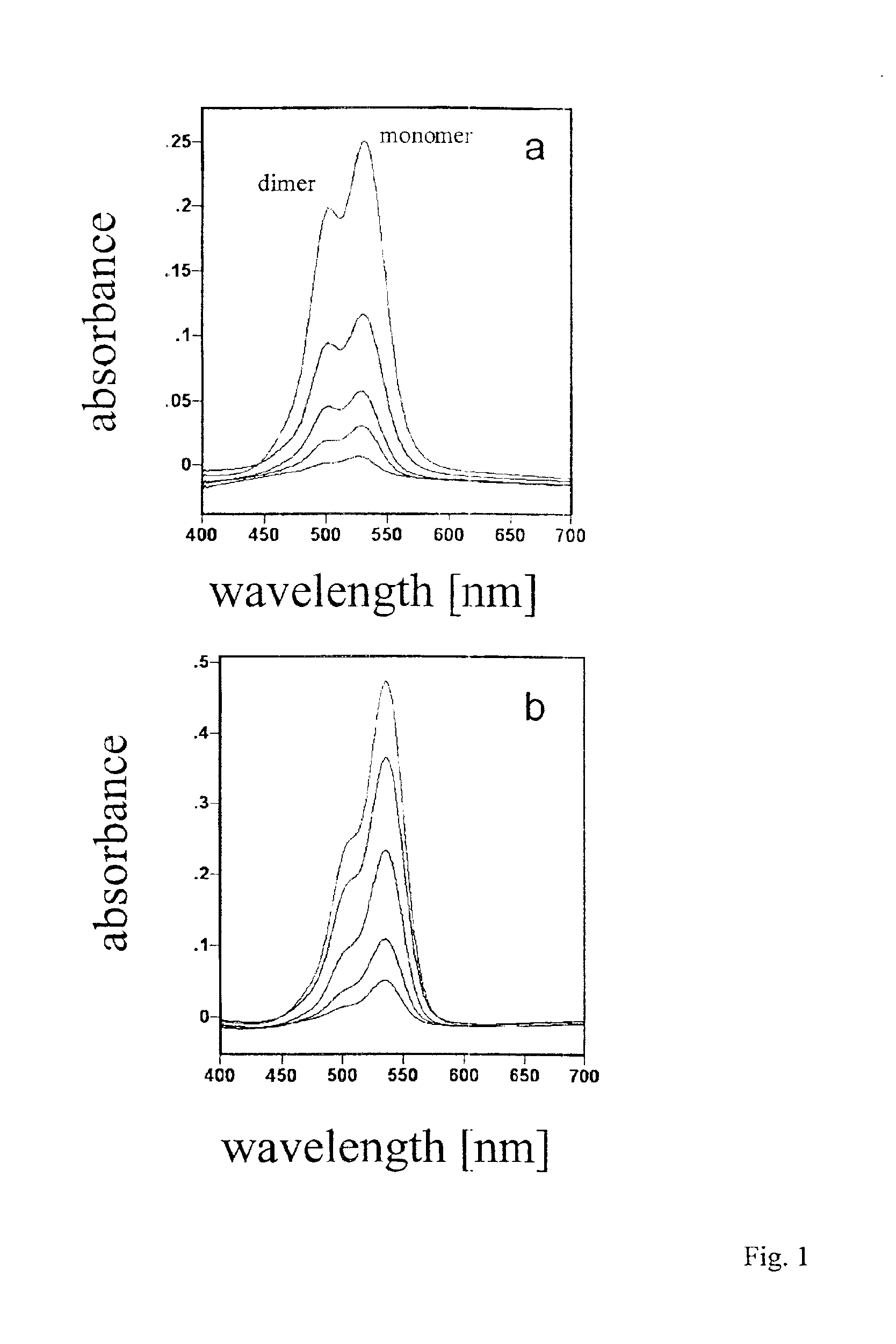

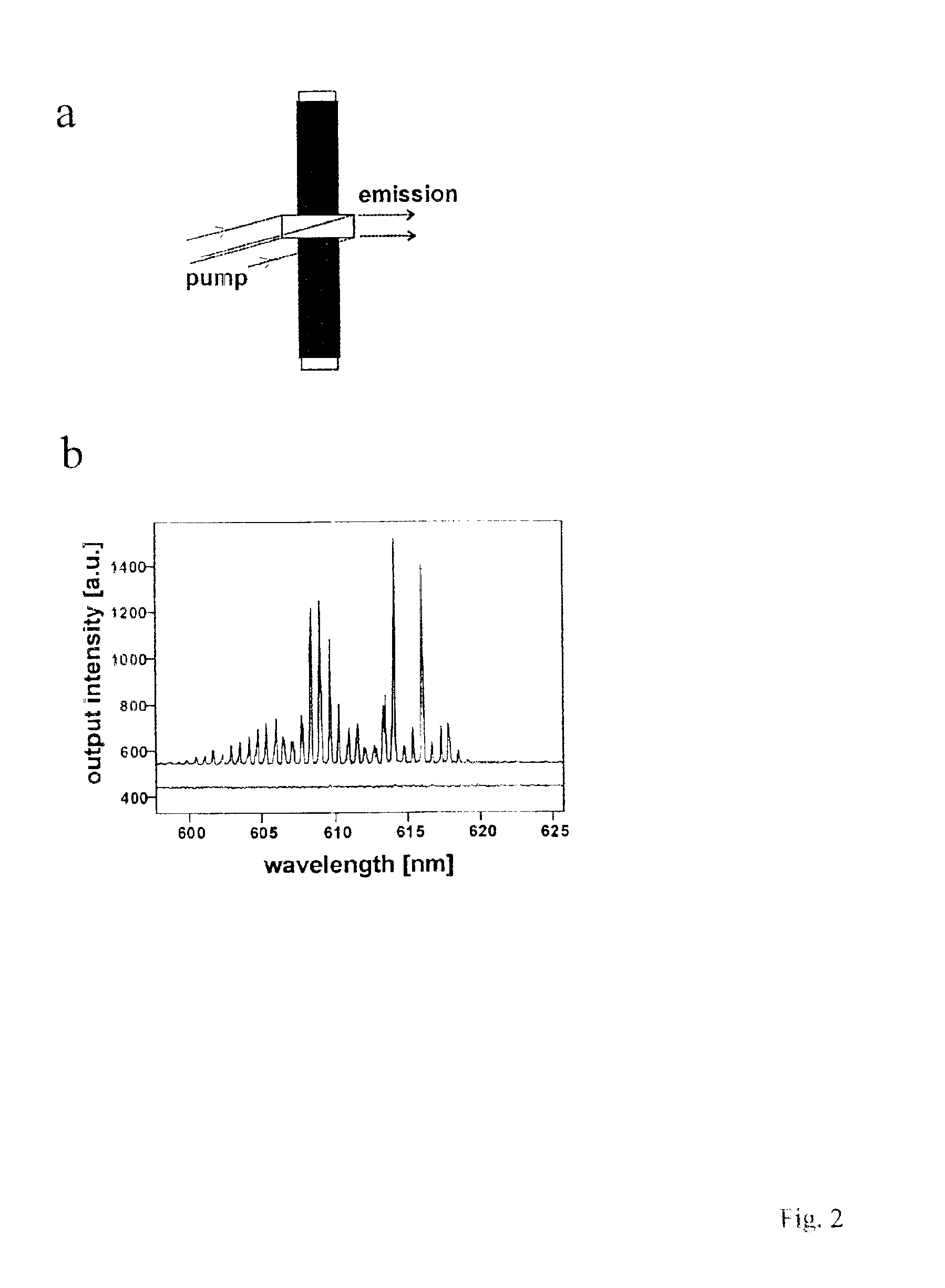

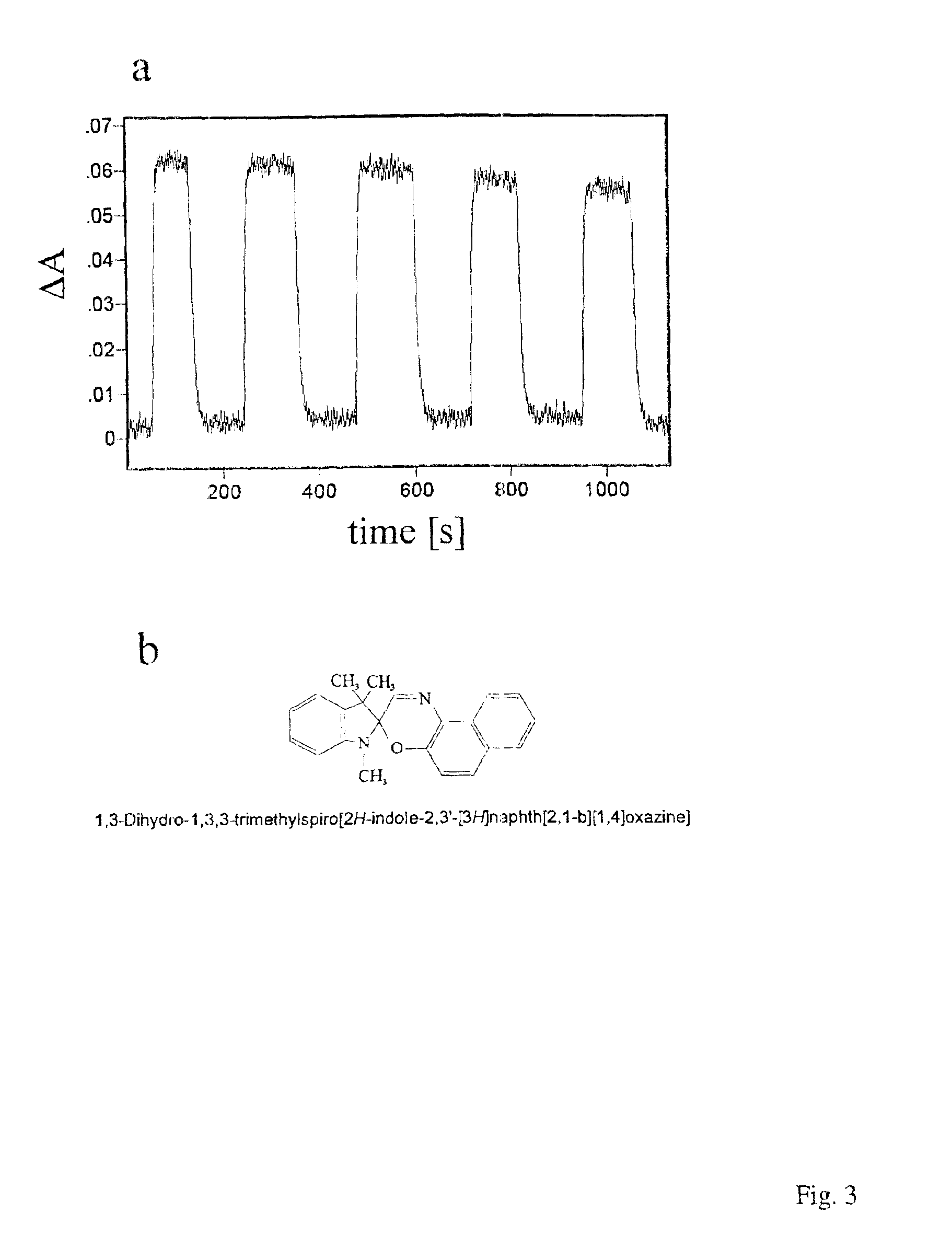

Inorganic/block copolymer-dye composites and dye doped mesoporous materials for optical and sensing applications

InactiveUS6952436B2High dye doping concentrationEnhancing dye dispersionActive medium materialOptical light guidesFiberMesoporous material

A method for preparing transparent mesostructured inorganic / block-copolymer composites or inorganic porous solids containing optically responsive species with selective optical, optoelectronic, and sensing properties resulting therefrom. Mesoscopically organized inorganic / block copolymer composites doped with dyes or complexes are prepared for use as optical hosts, chemical / physical / biological sensors, photochromic materials, optical waveguides, tunable solid-state lasers, or optoelectronic devices. The materials can be processed into a variety of different shapes, such as films, fibers, monoliths, for novel optical and sensing applications.

Owner:RGT UNIV OF CALIFORNIA

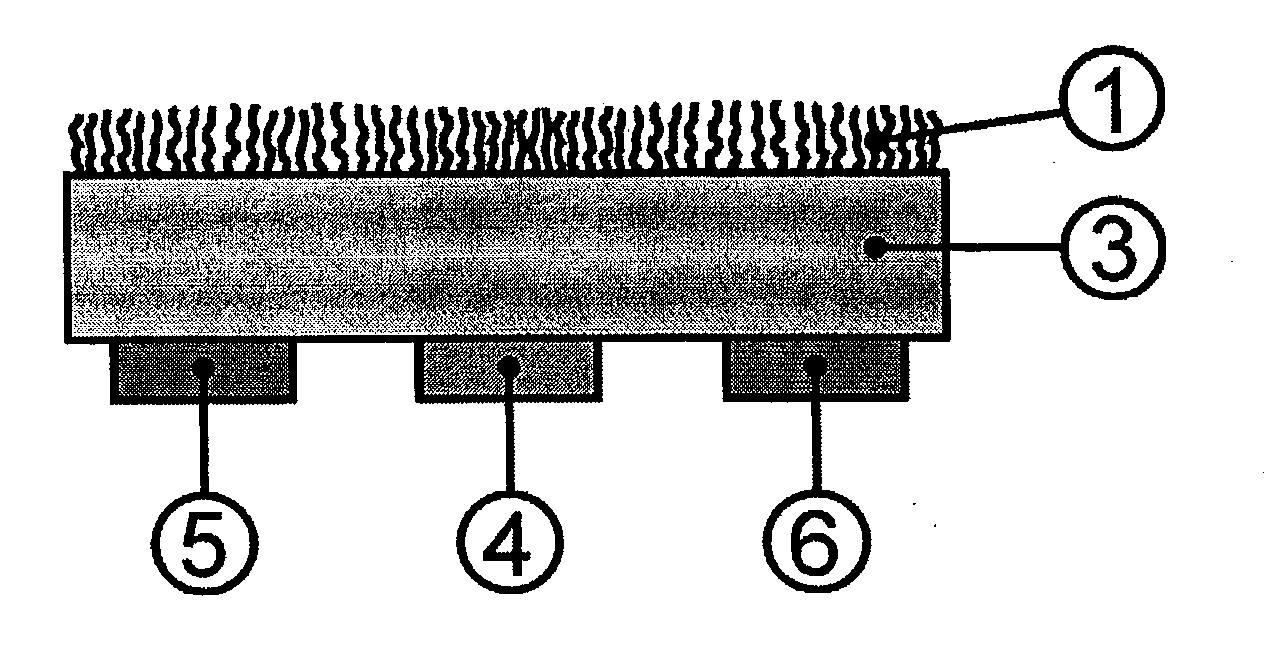

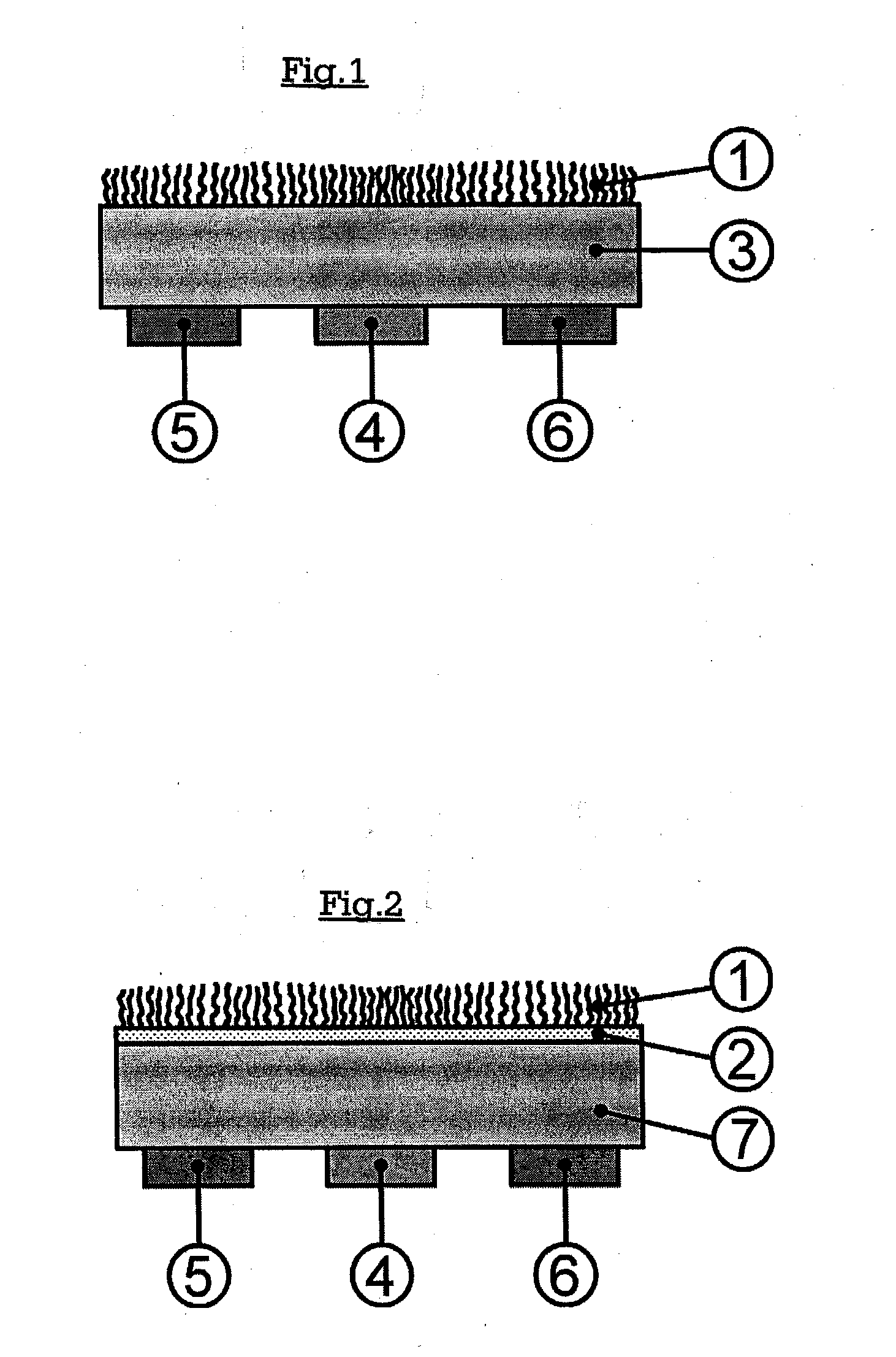

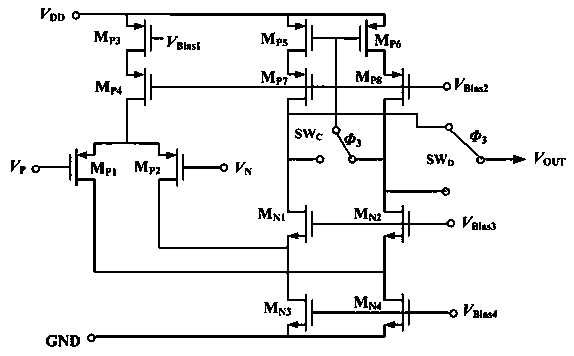

Molecularly controlled dual gated field effect transistor for sensing applications

A sensing device and method of making and using the sensing device. The device comprises a sensing gate layer of multifunctional organic sensing molecules having at least one functional group that binds to the semiconductor layer and at least another functional group that serves as a sensor. The device further comprises a semiconductor channel layer, a drain electrode, a source electrode, and a biasing gate. The source and drain electrodes and biasing gate are situated on the same side of the device and simultaneously on the opposite side of the sensing gate layer. The sensing gate layer may be directly in contact with the intermediate layer or the semiconductor channel layer.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

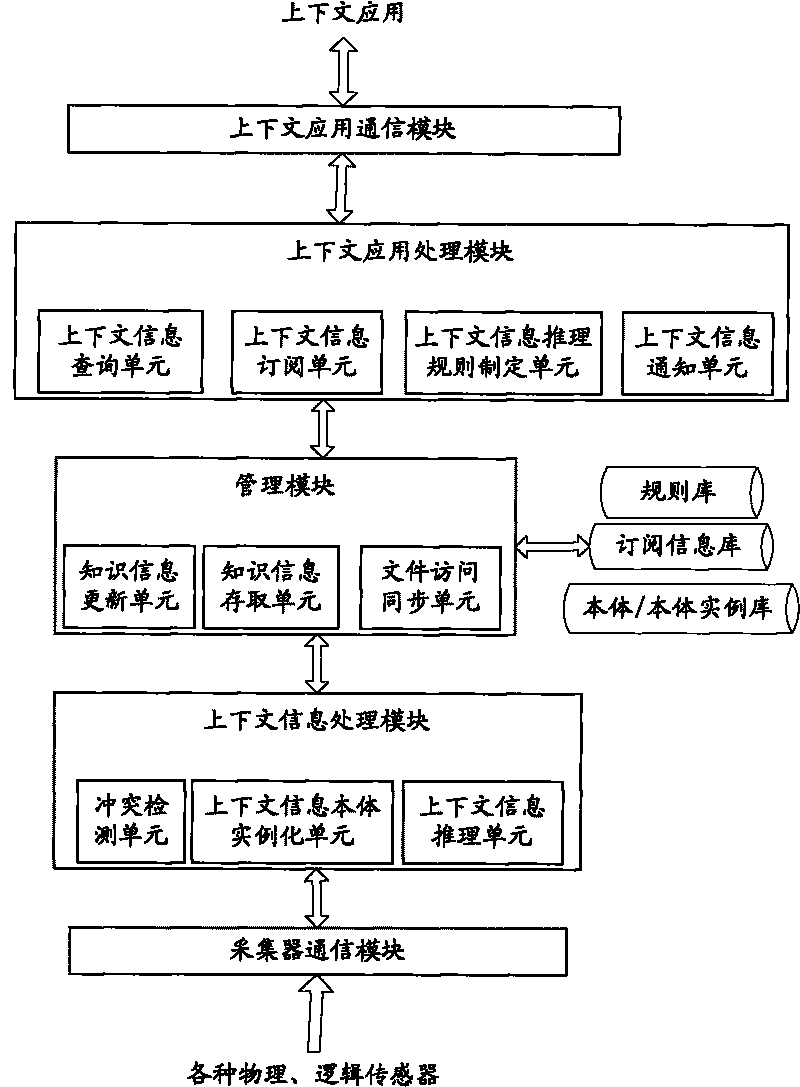

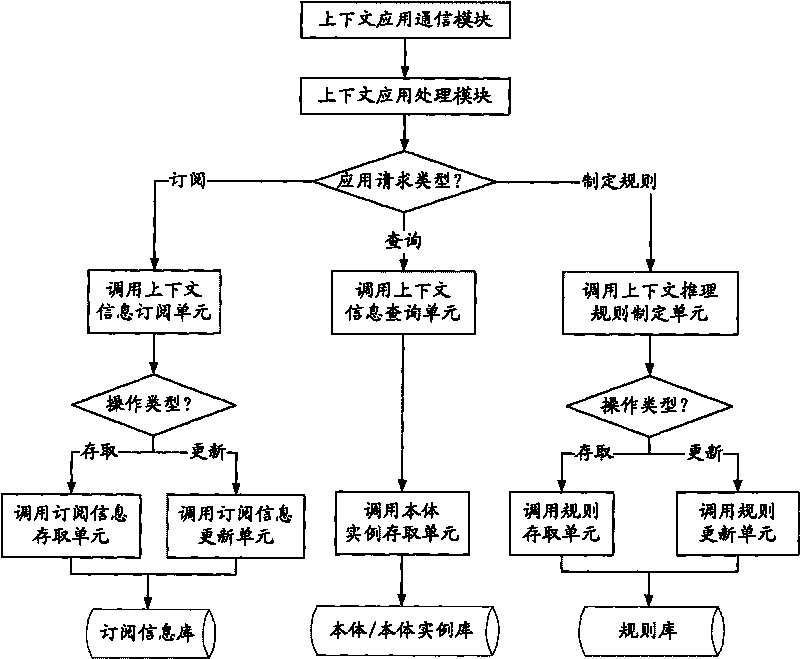

Context sensing application platform based on main body and work method thereof

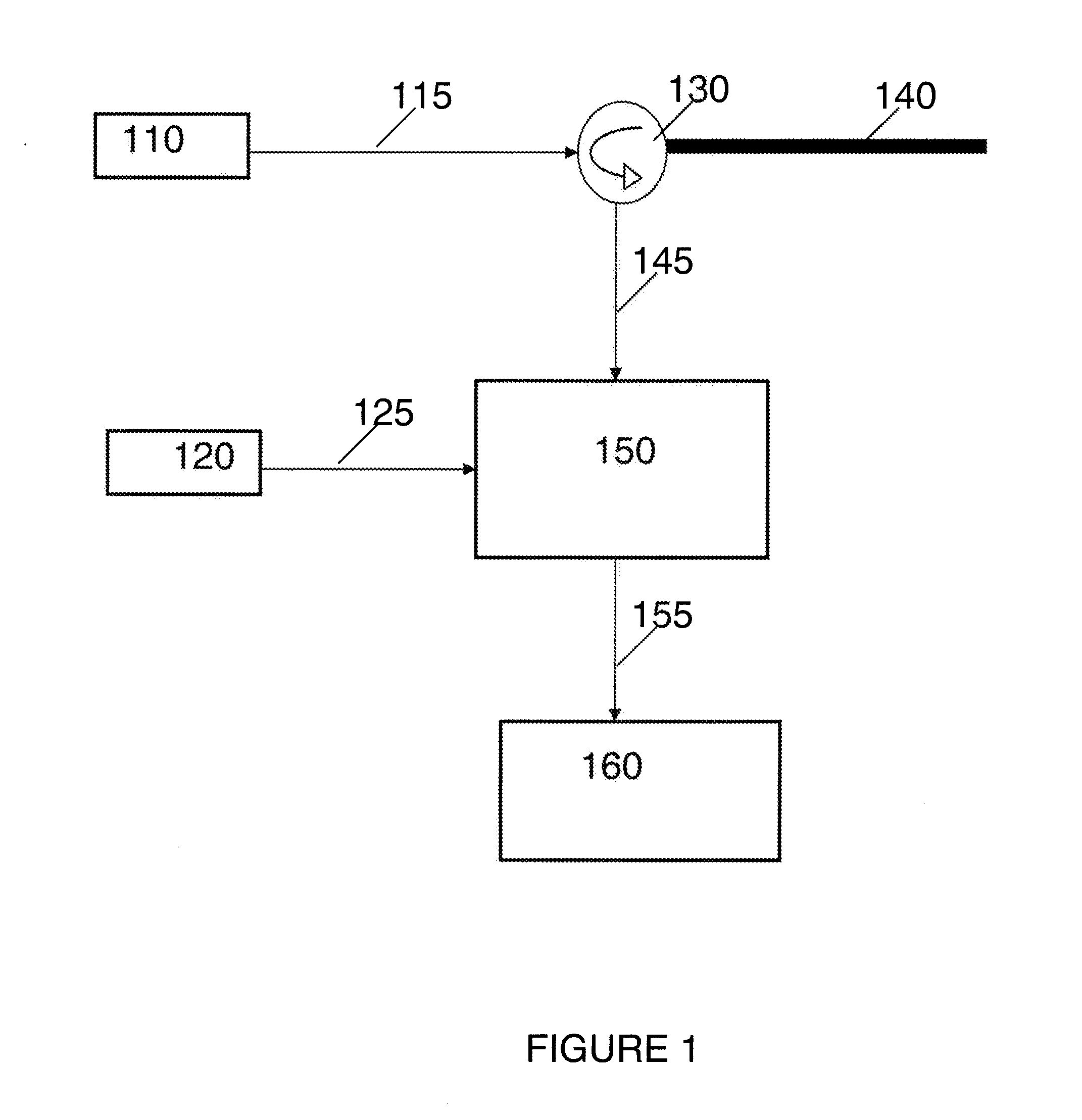

InactiveCN101694629AAchieve mutual transparencyMultiprogramming arrangementsSpecial data processing applicationsInformation repositoryInformation processing

Disclosed is a context sensing application platform based on main body and a work method thereof, wherein the creation core of the invention is to supply a general-purpose processing model for obtaining context information, wherein the processing model comprises a gatherer communication module, a context information processing module, a management module, a knowledge information base, a context application processing module and a context sensing application platform of the context application processing module, when the application platform is supplied for sensing the context application, two mutually-independent and mutually-coordinated context information processing flows are proposed on how to use the context information processing steps, are mutually transparent, and share knowledge information through a synchronous control mechanism. The two processing flows are both on the basis of the context sensing and application platform of the invention, cover each flow of the context information processing, and reach knowledge sharing. The invention uses a main body to describe the context information, and reaches the universal share of knowledge information in the calculating field.

Owner:BEIJING UNIV OF POSTS & TELECOMM

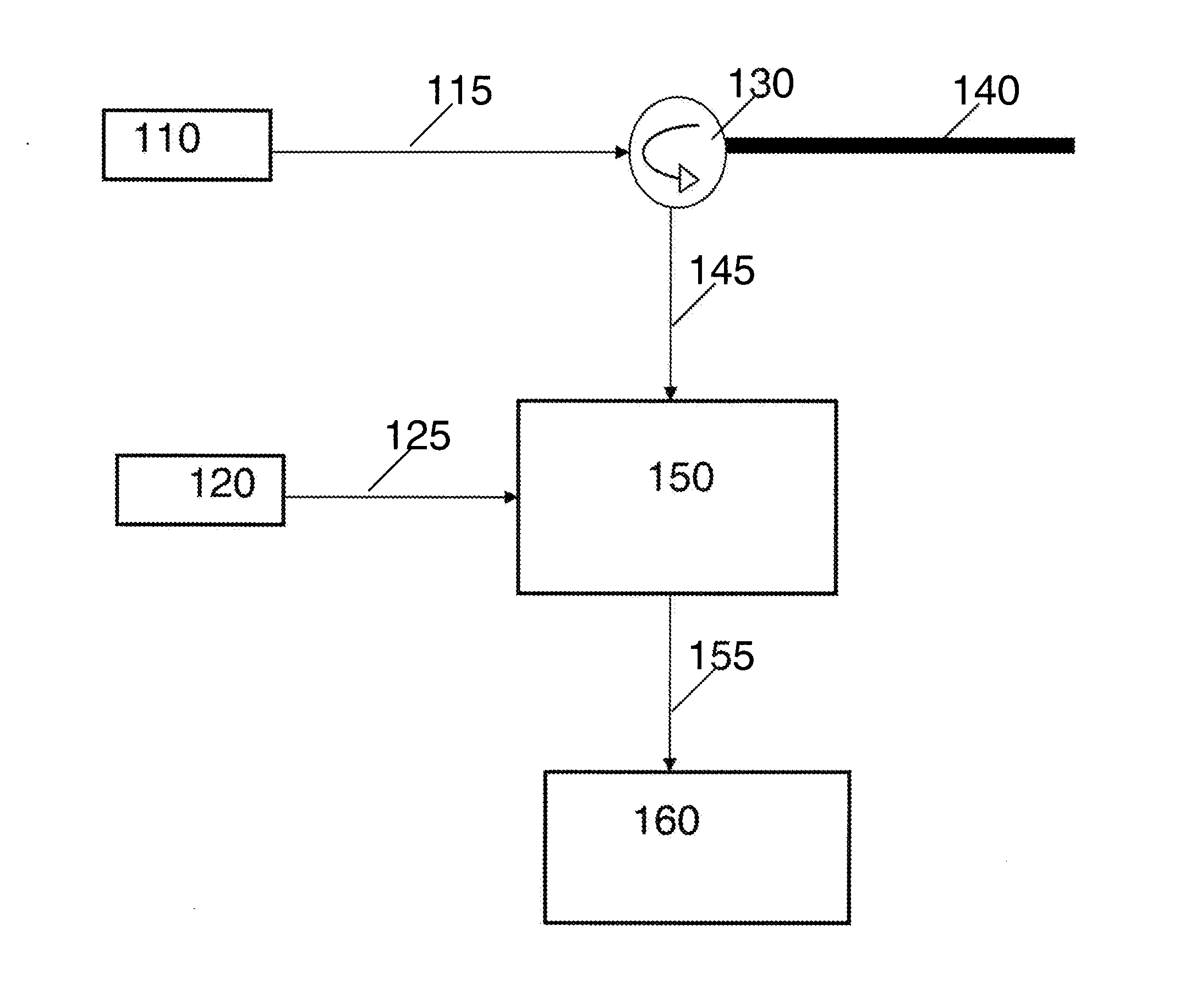

System and method for using coherently locked optical oscillator with brillouin frequency offset for fiber-optics-based distributed temperature and strain sensing applications

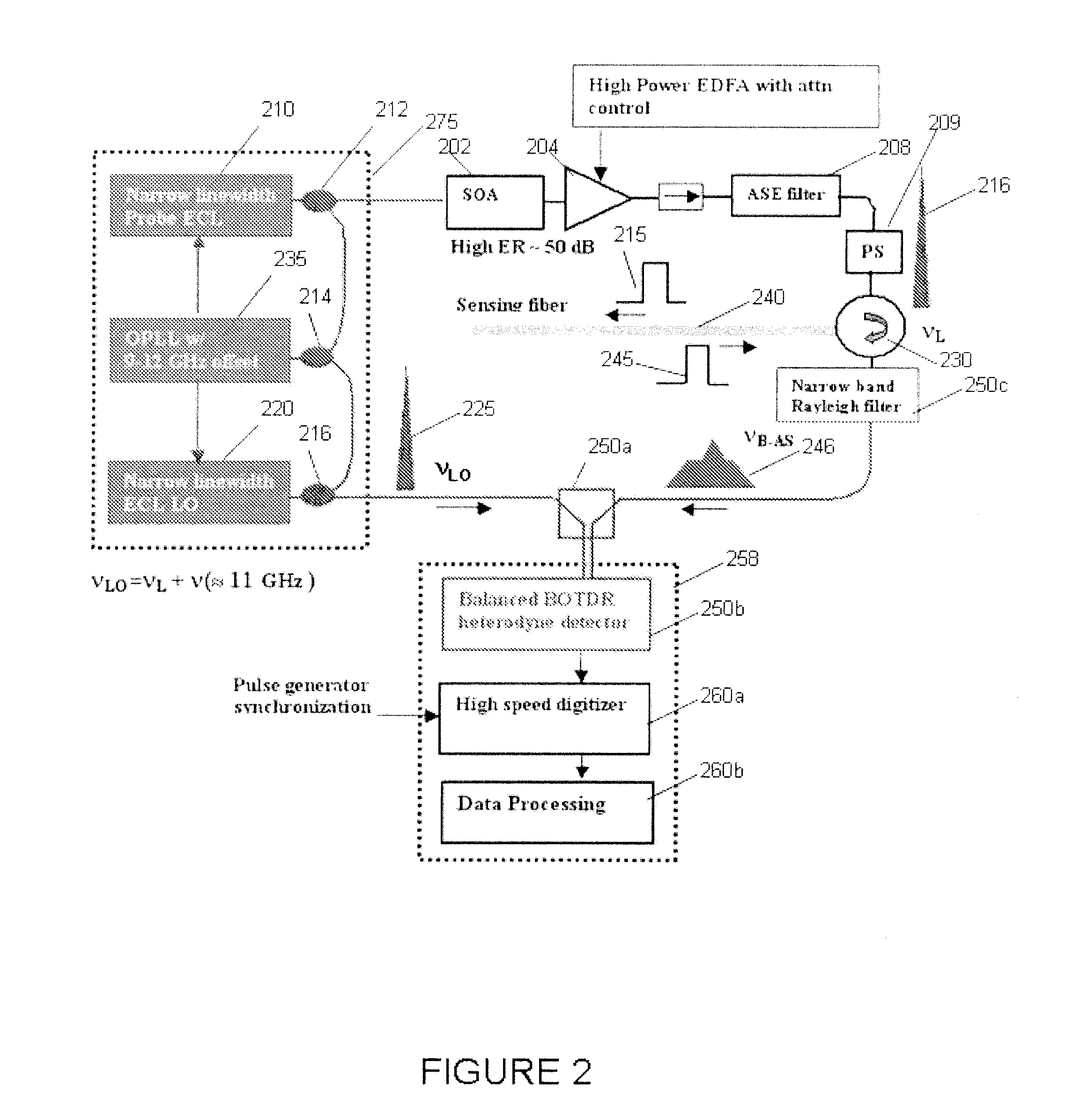

InactiveUS20110090936A1Efficient detectionReduce frequencyThermometer detailsForce measurement by measuring optical property variationExternal cavity laserLine width

Systems and methods are disclosed for distributed temperature and strain sensing along a length of an infrastructure. Two optical sources, such as, external cavity lasers with a narrow linewidth, are used for launching a probe signal into a sensing fiber coupled to the infrastructure, and for producing a local oscillation signal, respectively. The optical sources are coherently locked with a predefined frequency offset with respect to each other, the predefined frequency offset being in the order of the Brillouin frequency shift. The optical sources are included in an optical phase lock loop (OPLL) system. A balanced heterodyne receiver for narrow band detection at radio frequency (RF) bandwidth receives an optical signal generated by coherent mixing of a backscattered probe signal with the Brillouin frequency shift and the local oscillation signal, and produces an output indicative of one or both of a measured temperature and a measured strain.

Owner:REDFERN INTEGRATED OPTICS

Device having self-assembled-monolayer

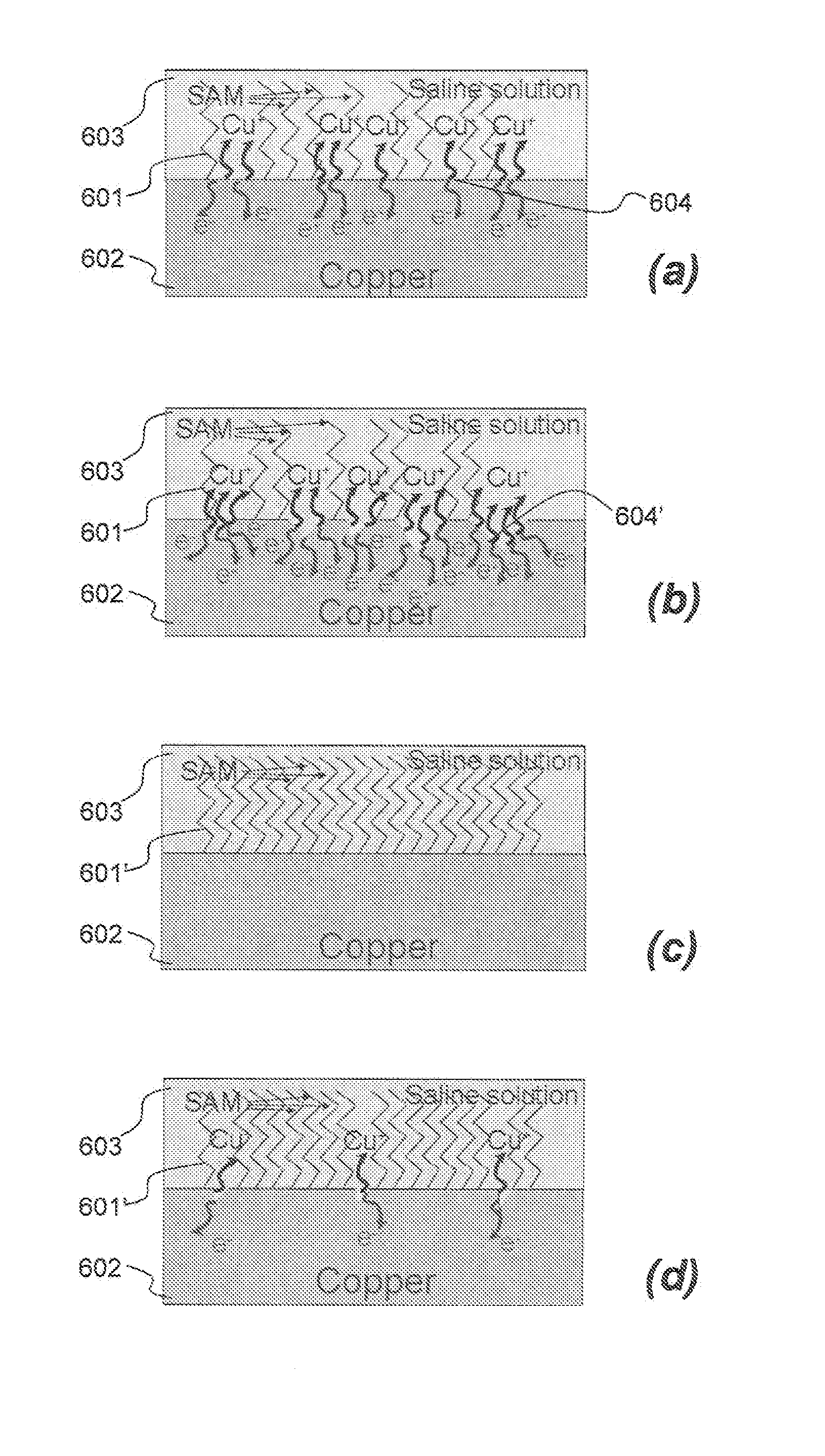

InactiveUS20120088315A1Avoid inhibitionEffective corrosion inhibitionComponent separationBiological material analysisSelf-assembled monolayerSensing applications

A device for bio-sensing applications is disclosed, comprising a substrate such as a semiconductor chip having Cu electrodes thereon, and a self assembled monolayer bonded to at least one of the Cu electrodes, wherein molecules of the self-assembled monolayer comprise a head group which bonds to Cu, a carbon-comprising chain comprising a chain of at least 12 C atoms, and a terminal group which is hydrophilic and for binding a bio-receptor. The terminal group is hydrophilic to allow binding to the bio-receptor, and inclusion of the carbon-comprising chain, limits or avoids corrosion of the copper. Also disclosed is a method of providing such a device, activating the terminal group and coupling a bio-receptor to the activated terminal group. Disclosure further extends to use of such a device for bio-sensing applications.

Owner:NXP BV

Trace chemical optical probe

Owner:EXCELLENT CAPACITY LTD

Blockchain-based safety excitation method and system in crowd sensing application

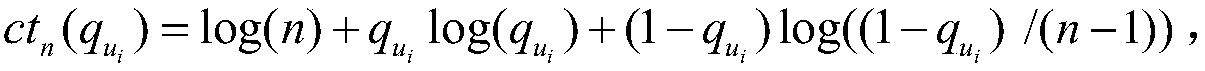

ActiveCN108055119AAvoid Collusion AttacksAvoid safety hazardsCryptographic attack countermeasuresThird partySensing applications

The invention relates to a blockchain-based safety excitation method and system in a crowd sensing application. In the method, a user side and a server side, as both transaction parties of a blockchain, carry out transaction. The method comprises the following steps that: 1, a server releases a perception task to the user side; 2, after executing and completing the perception task, the user side uploads perception data to the server; 3, a miner in the blockchain verifies quality of the perception data and sends the quality of the perception data to the server; and 4, the server pays the remuneration to the user side according to the quality of the perception data. Further, after obtaining the quality of the perception data, the miner quantifies an effective contribution of the quality of the perception data by utilizing a mutual information principle and sends the effective contribution to the server, and then the server gives the corresponding remuneration to the user side according to the effective contribution. According to the invention, safety excitation in the crowd sensing application is implemented by adopting a distributed architecture of blockchain safety, a collusion attack initiated by a perception platform can be effectively prevented, and potential safety hazards which a credible third party faces are overcome.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

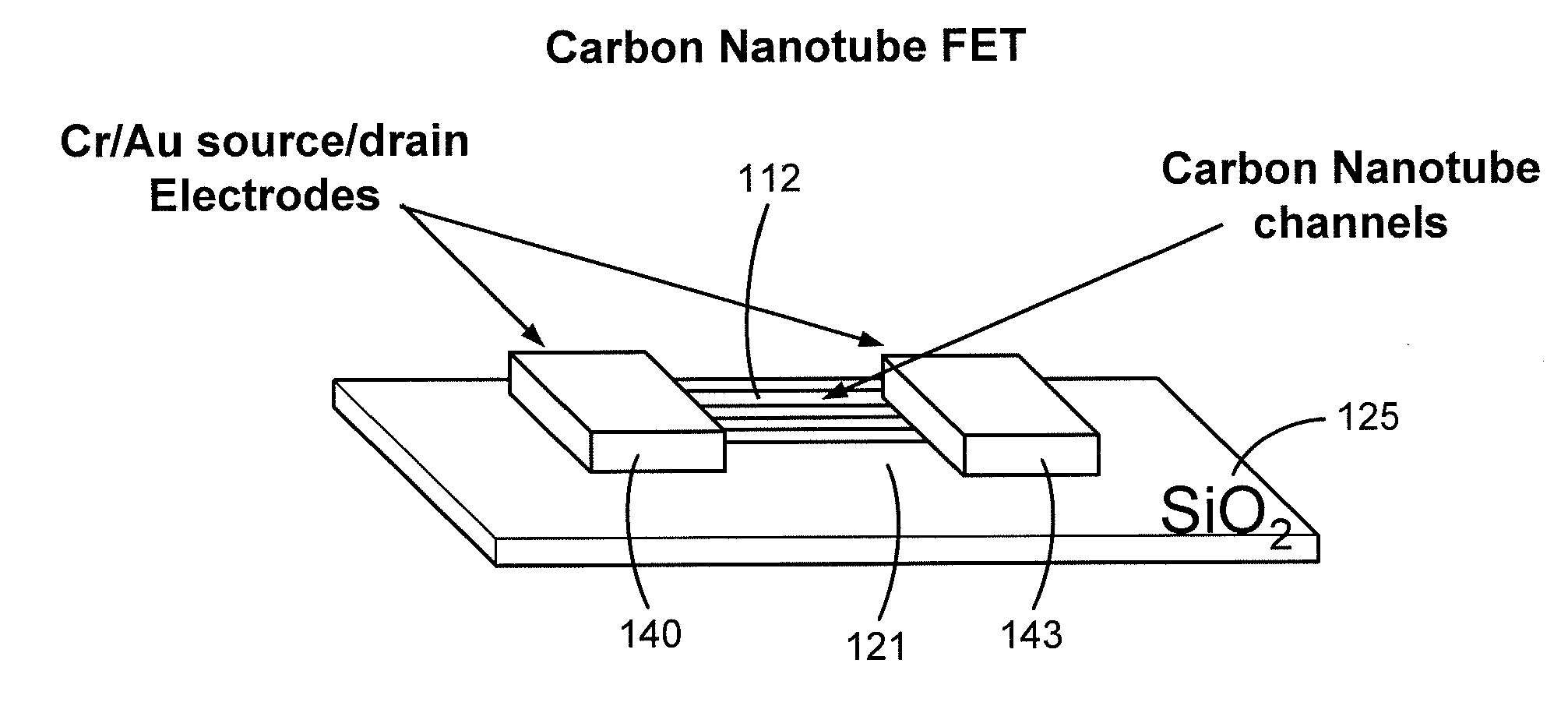

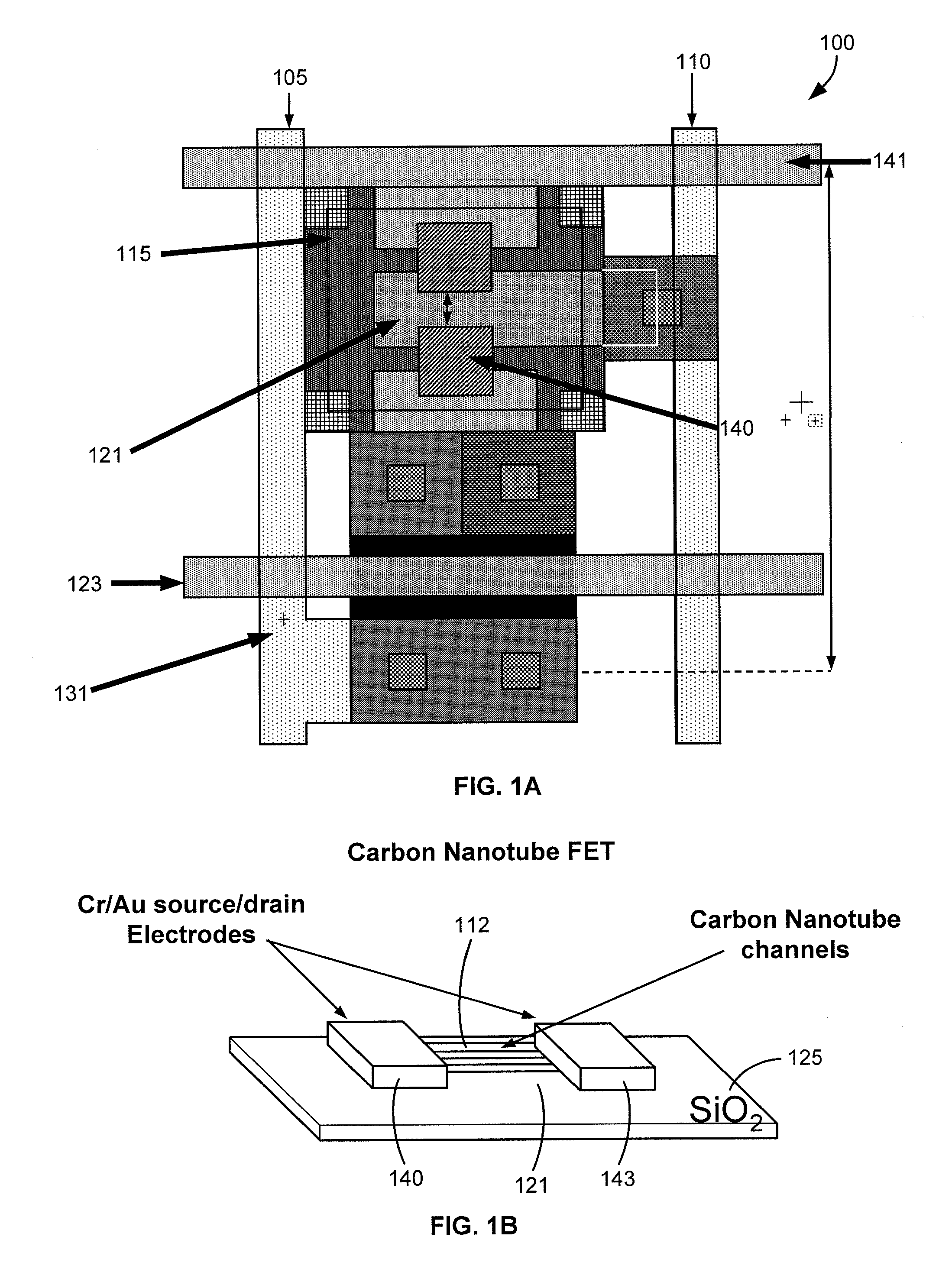

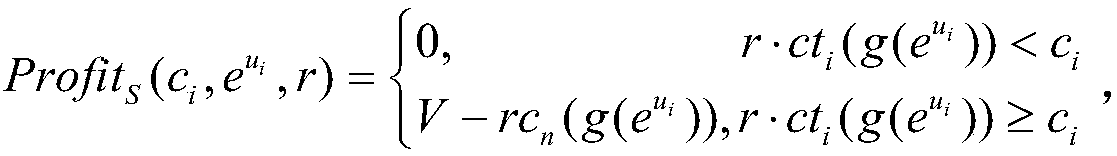

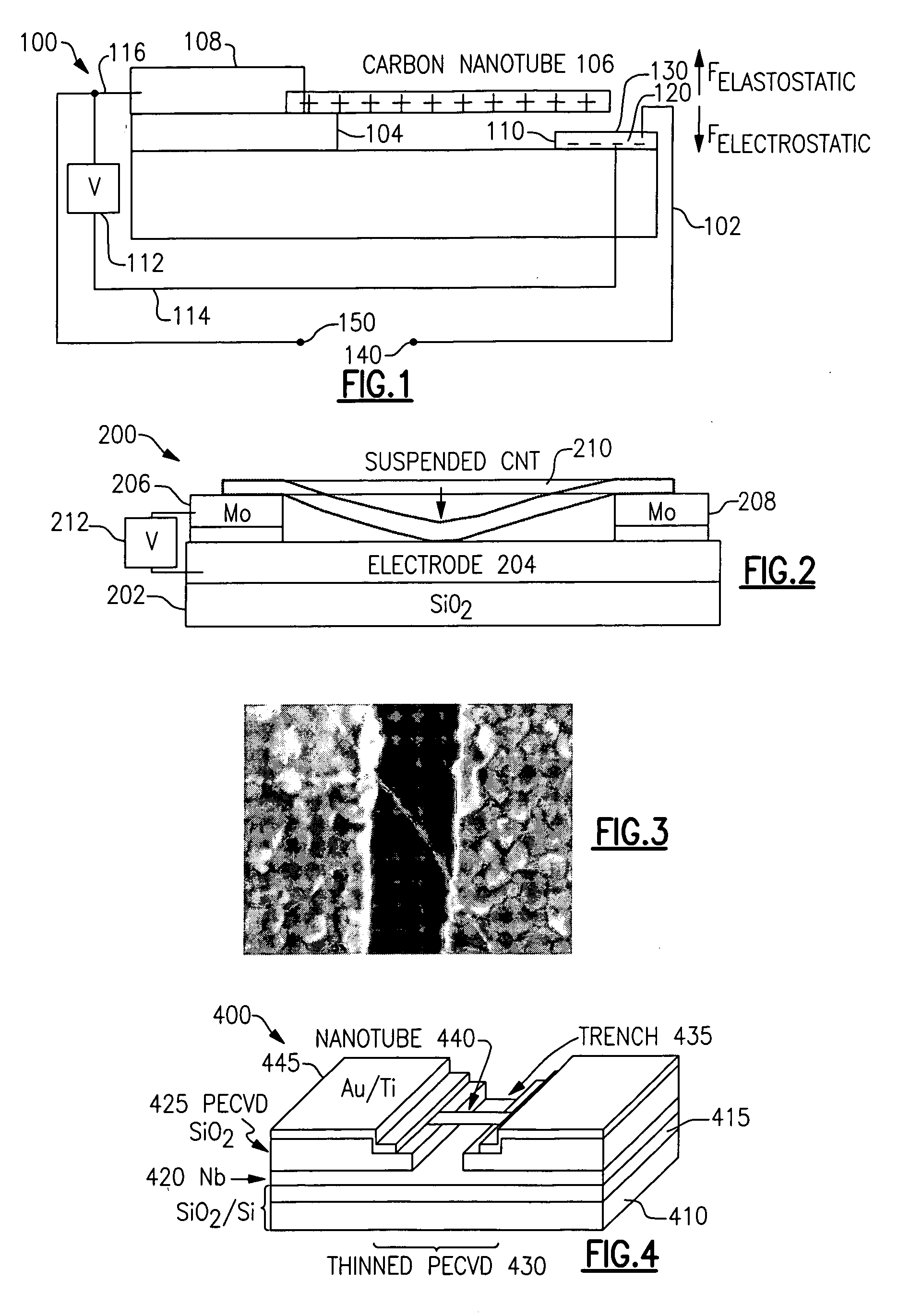

Carbon nanotube switches for memory, RF communications and sensing applications, and methods of making the same

InactiveUS20080233744A1Electrostatic/electro-adhesion relaysNanoelectromechanical switchesElectrical connectionEngineering

Switches having an in situ grown carbon nanotube as an element thereof, and methods of fabricating such switches. A carbon nanotube is grown in situ in mechanical connection with a conductive substrate, such as a heavily doped silicon wafer or an SOI wafer. The carbon nanotube is electrically connected at one location to a terminal. At another location of the carbon nanotube there is situated a pull electrode that can be used to electrostatically displace the carbon nanotube so that it selectively makes contact with either the pull electrode or with a contact electrode. Connection to the pull electrode is sufficient to operate the device as a simple switch, while connection to a contact electrode is useful to operate the device in a manner analogous to a relay. In various embodiments, the devices disclosed are useful as at least switches for various signals, multi-state memory, computational devices, and multiplexers.

Owner:CALIFORNIA INST OF TECH

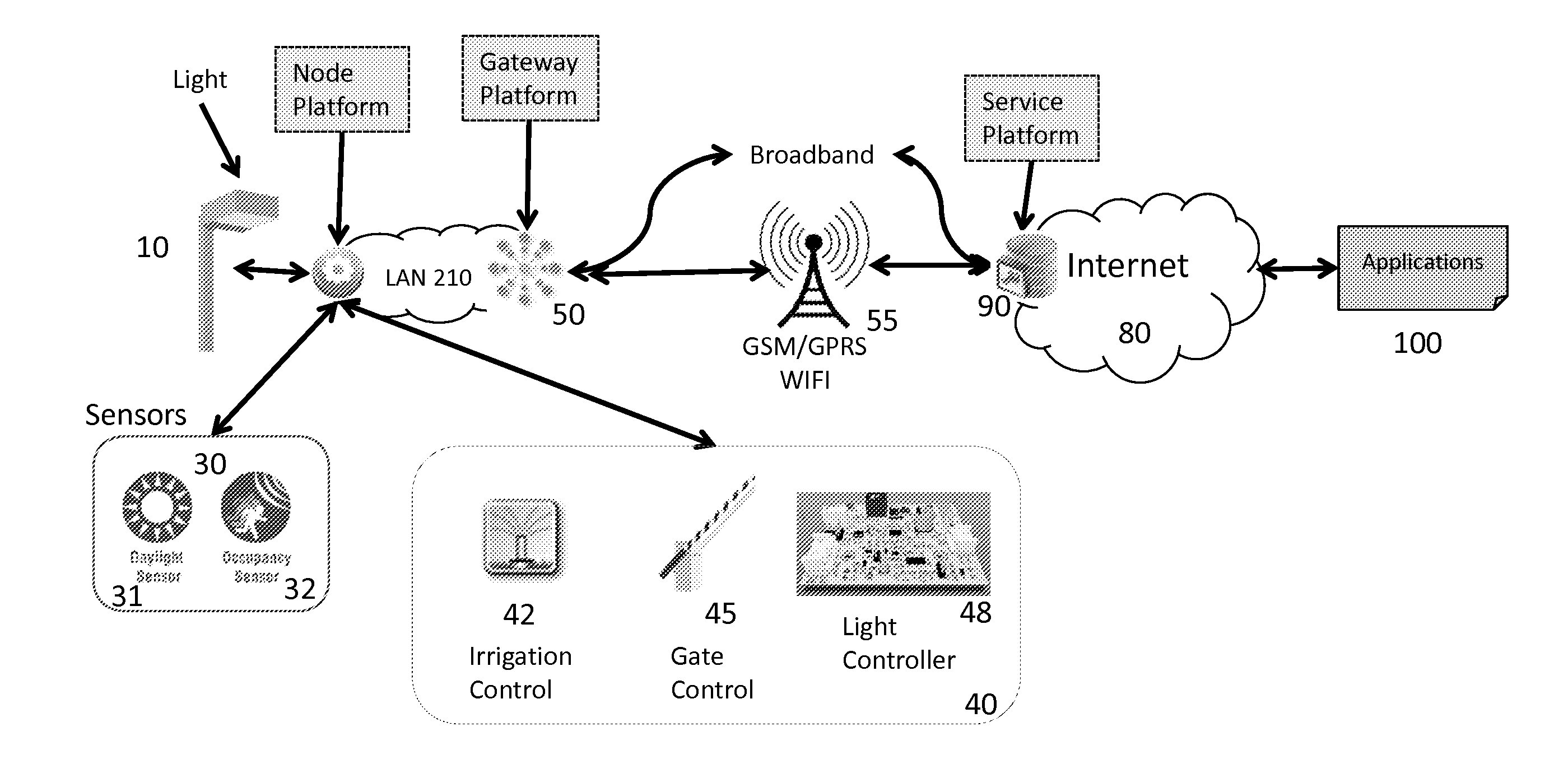

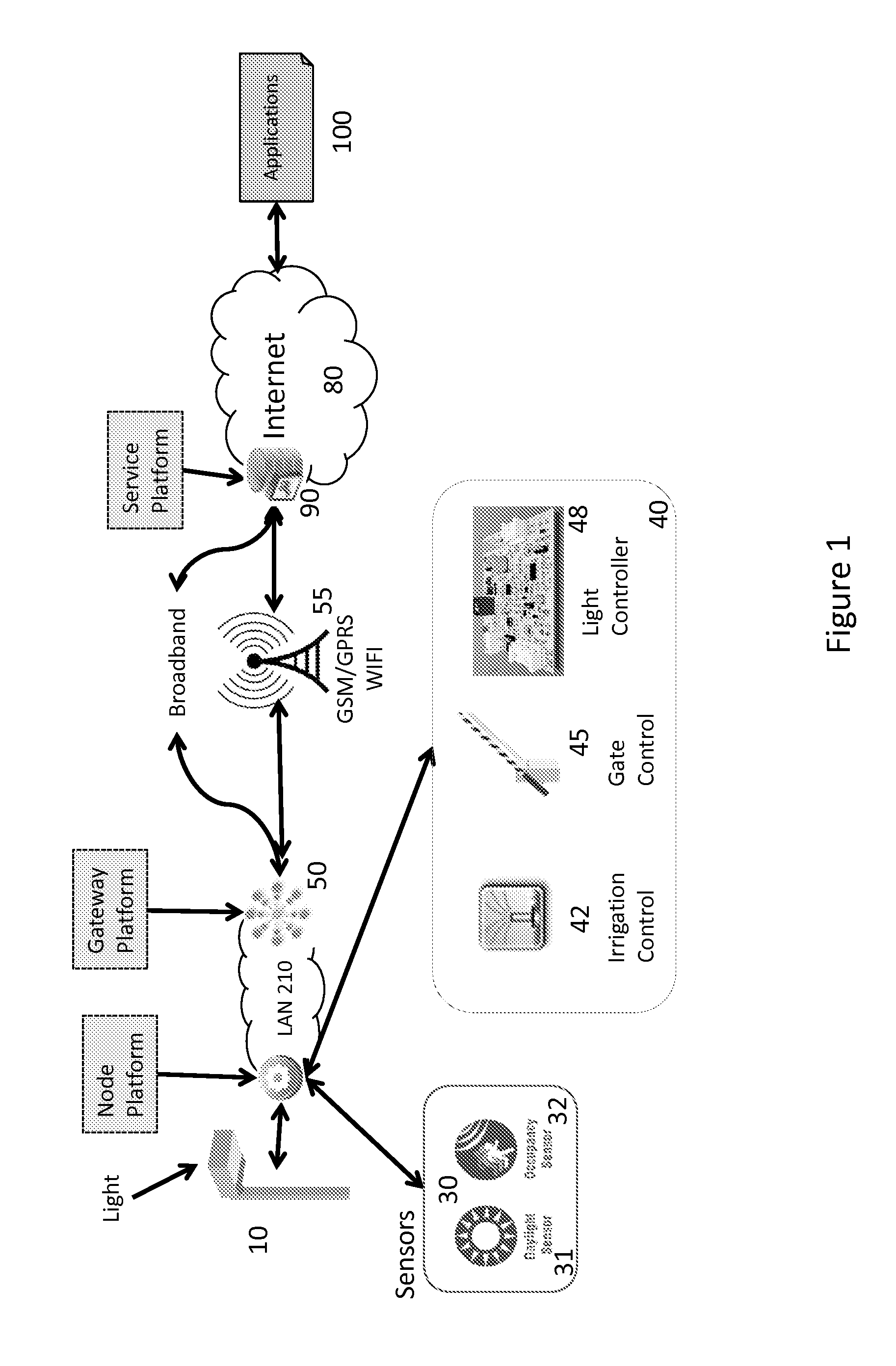

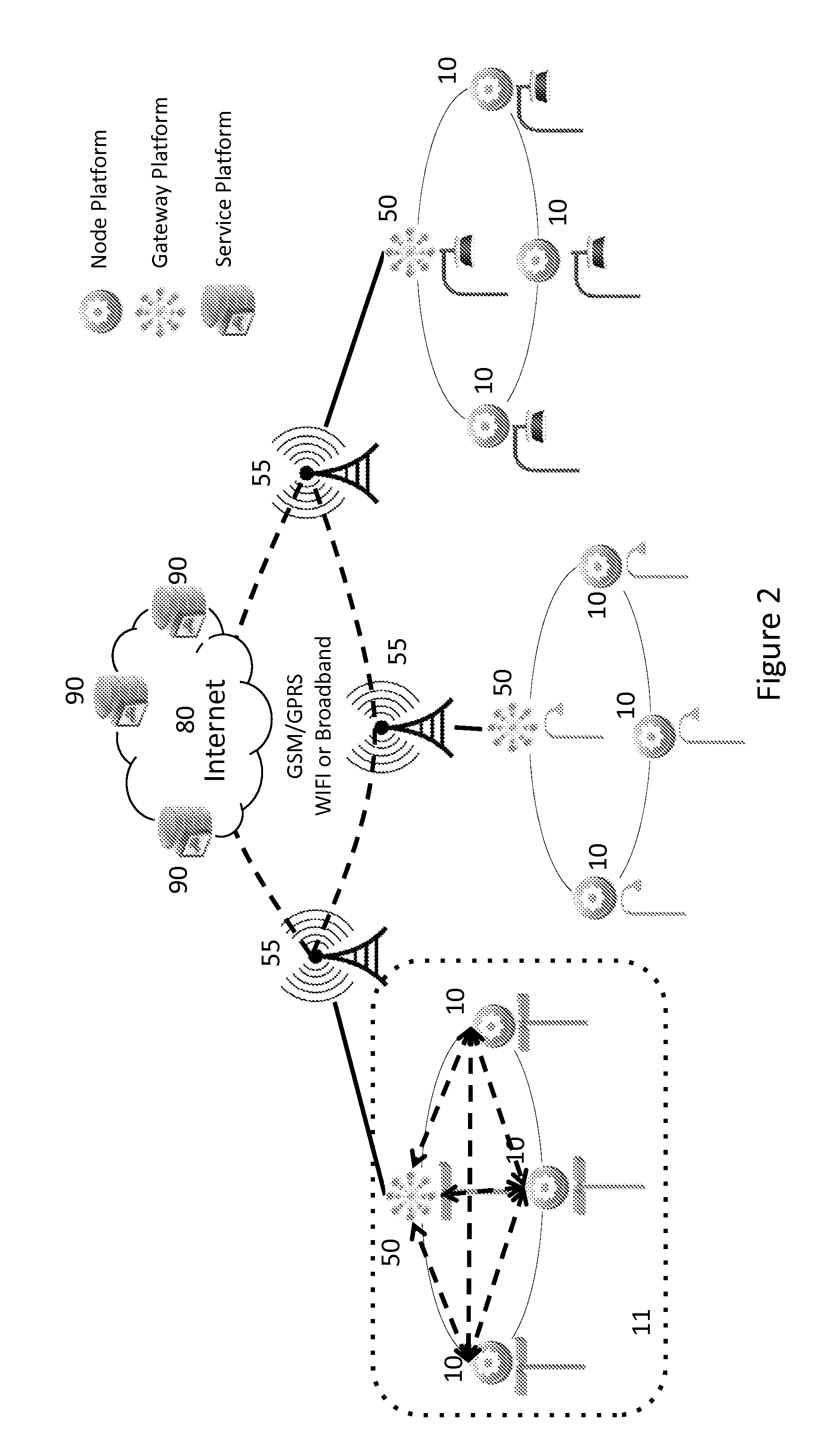

Networked lighting infrastructure for sensing applications

ActiveUS20140084795A1High replacement costConvenient lightingWave amplification devicesElectroluminescent light sourcesSensing applicationsLighting system

A network using existing streetlights is described. Each street light becomes a node in the network, and each includes a power terminal for receiving electrical power, a light source coupled to the power terminal, a processor coupled to the power terminal, a network interface coupled between the processor and the network of lighting systems, and a sensor coupled to the processor for detecting a condition at the node, and in response providing information about that condition to the processor.

Owner:VERIZON PATENT & LICENSING INC

Hollow core optical ring resonator sensor, sensing methods, and methods of fabrication

InactiveUS7693369B2High sensitivityReduce consumptionMaterial analysis by optical meansCoupling light guidesTarget analysisWhispering gallery

The present invention is directed to hollow core optical ring resonators (HCORRs), methods of fabricating HCORRs, and methods of using HCORRs in sensing applications. In particular, the evanescent field and whispering gallery modes of the HCORRs may be used to detect a target analyte within the hollow core of the HCORR. Other features of the present invention include utilizing the HCORR as part of a multiplex sensing device, including using the HCORR in capillary electrophoresis and chromatography applications.

Owner:UNIVERSITY OF MISSOURI

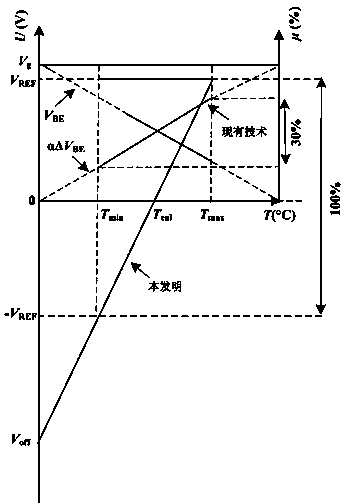

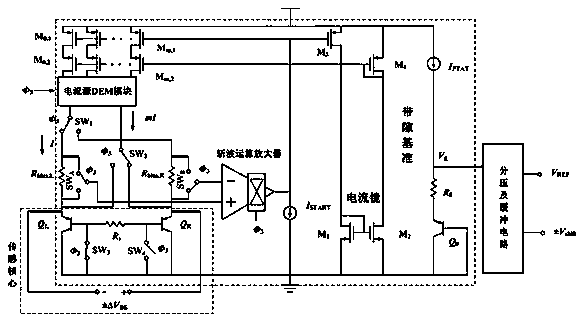

Temperature conversion method and a low-power high-precision integrated temperature sensor

ActiveCN104390715ASimple structureReduce power consumptionThermometers using electric/magnetic elementsUsing electrical meansCapacitanceEngineering

The invention relates to a temperature conversion method and a low-power high-precision integrated temperature sensor. The low-power high-precision integrated temperature sensor is composed of a band gap reference circuit with a sensing core, a positive and negative synchronous switch capacitor integral circuit, a current source and a sampling capacitor dynamic element matching module, a clock generating circuit, a divider and buffer circuit and a fully differential analog-to-digital converter. The sensing core circuit in the traditional technology and the band gap reference circuit are combined and integrated, so that the circuit structure is simplified; the current source dynamic element matching module is arranged and thus a base-emitter junction voltage difference in proportion to the absolute temperature is generated, wherein the polarity of the voltage difference changes alternately; with the novel positive and negative synchronous switch capacitor integral circuit, the improved temperature conversion function is completed and the dynamic range utilization rate of the analog-to-digital converter is improved; dynamic element matching is carried out on the sampling capacitor, thereby improving the integral accuracy; and the analog-to-digital converter is used for carrying out quantization processing on an effective temperature signal to provide a digital output. Therefore, the temperature error and circuit power consumption of the sensor can be effectively reduced; and the method and the sensor are suitable for the low-power high-precision temperature sensing application.

Owner:沈阳恒久安泰环保与节能科技有限公司

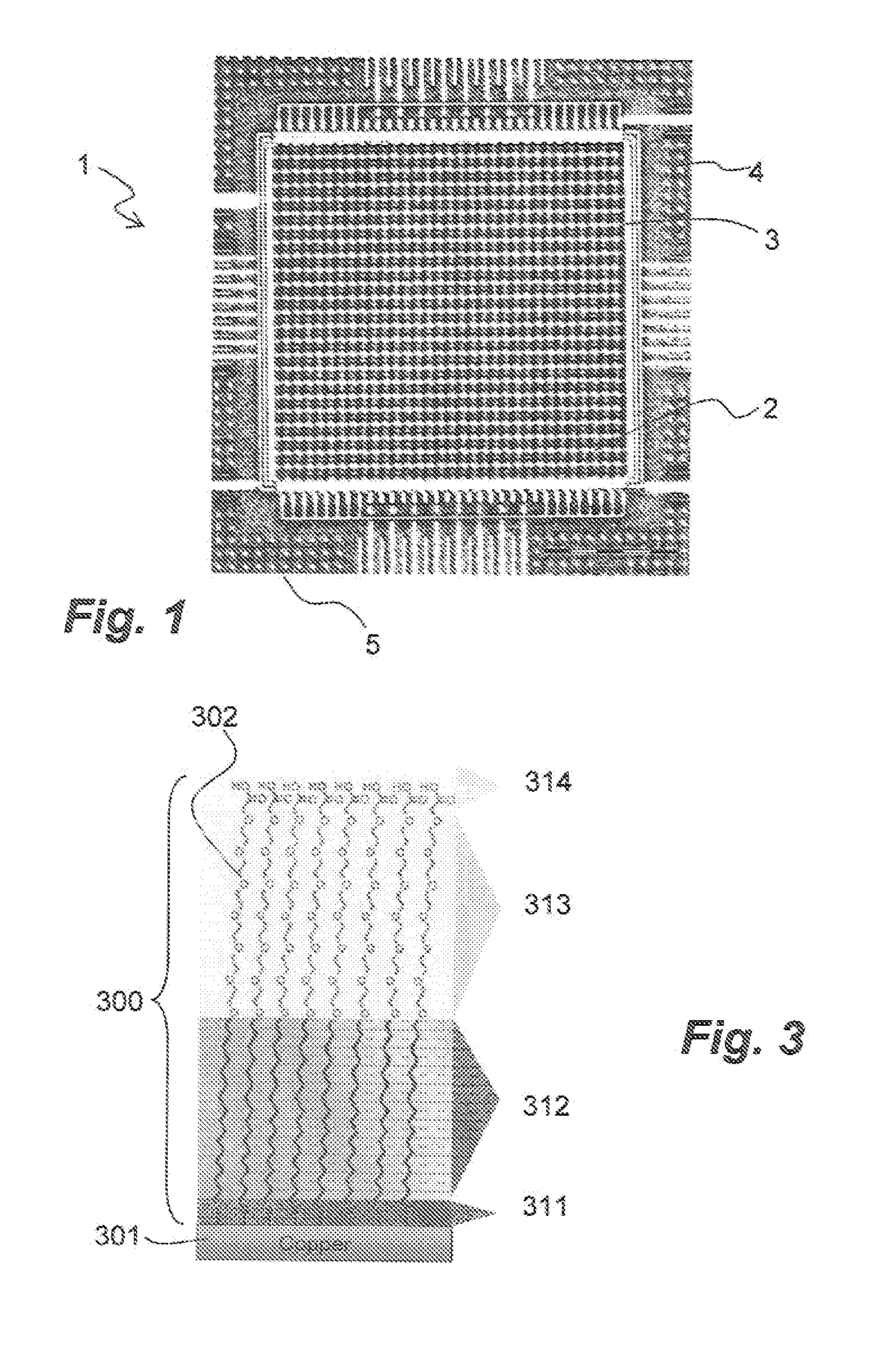

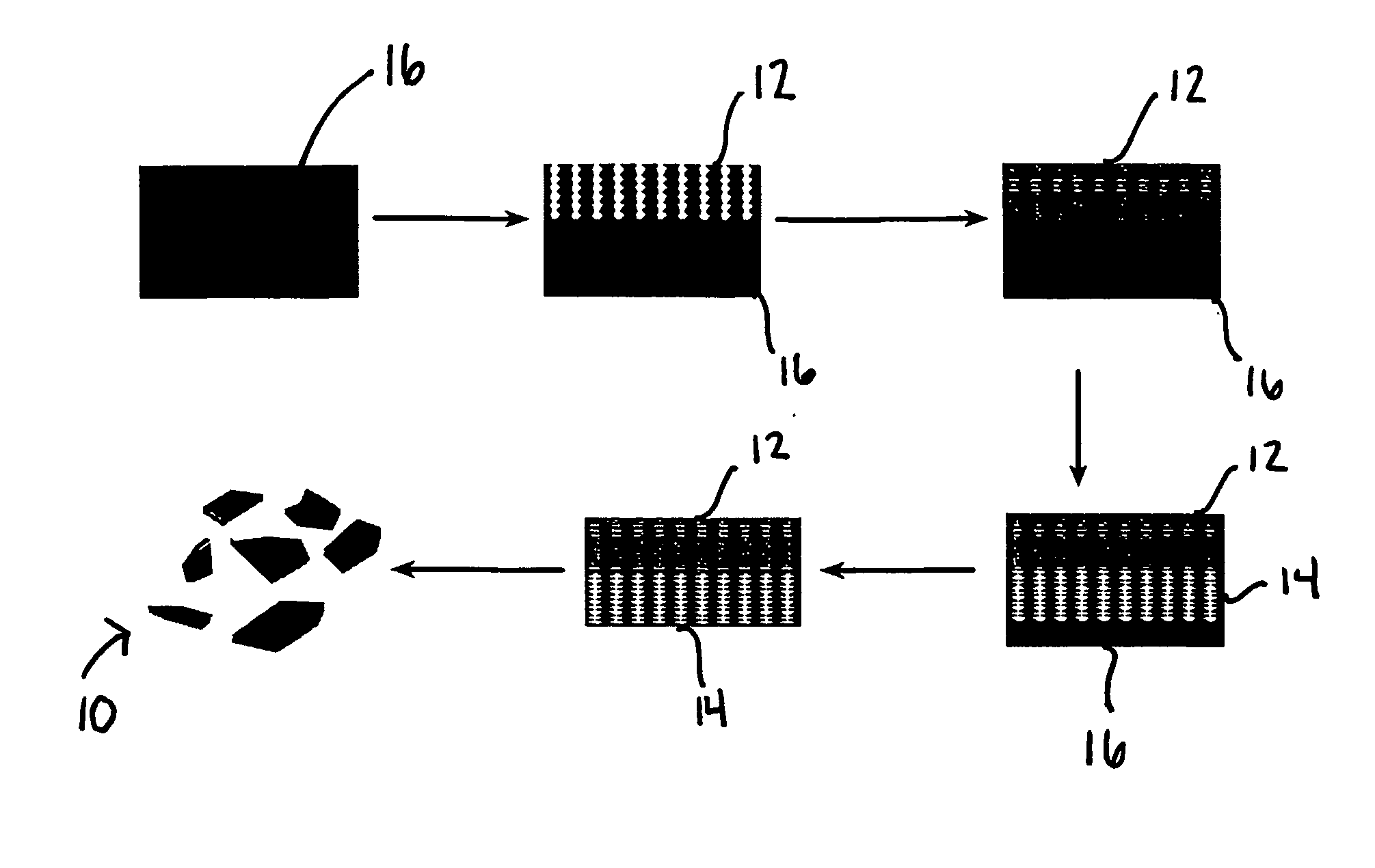

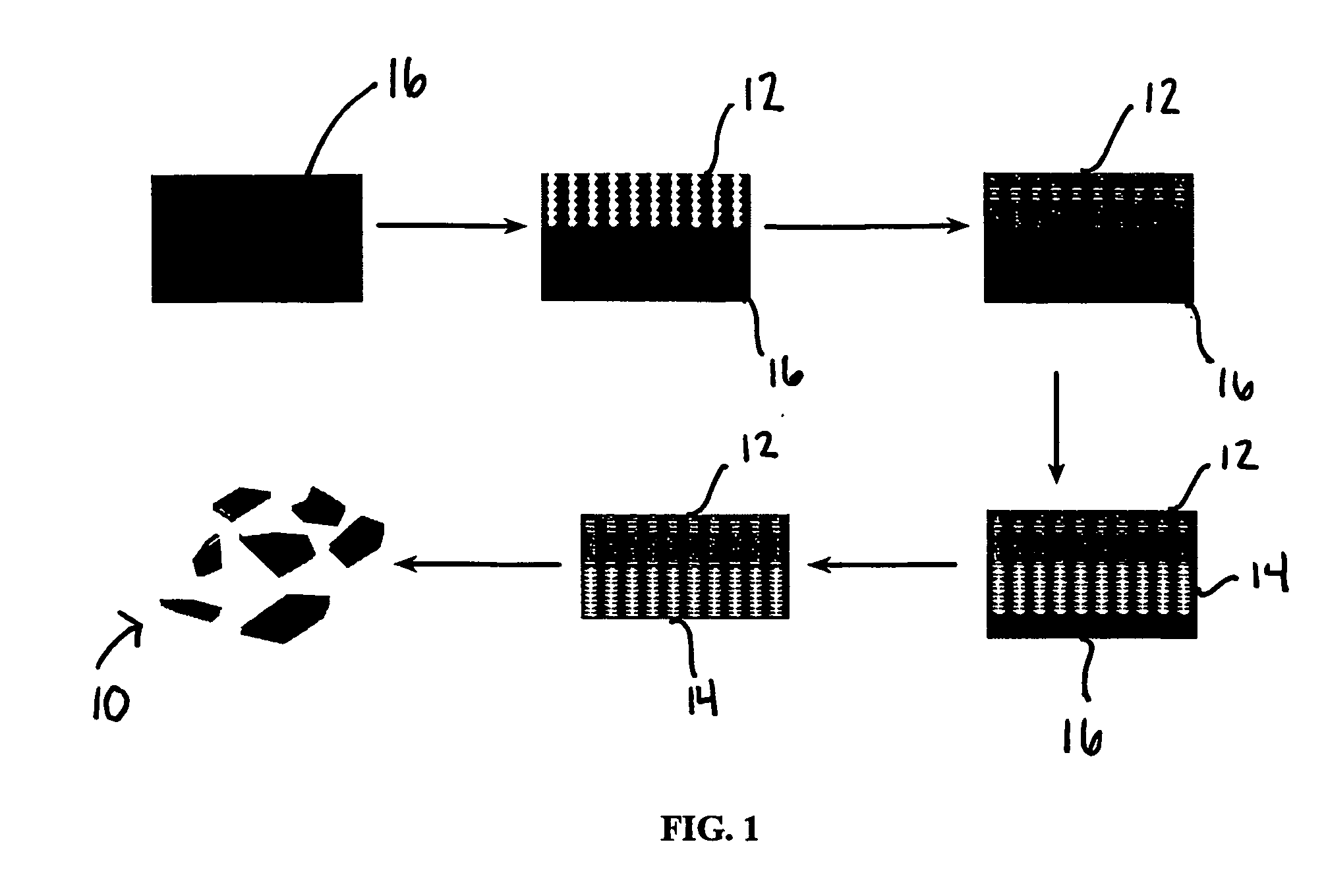

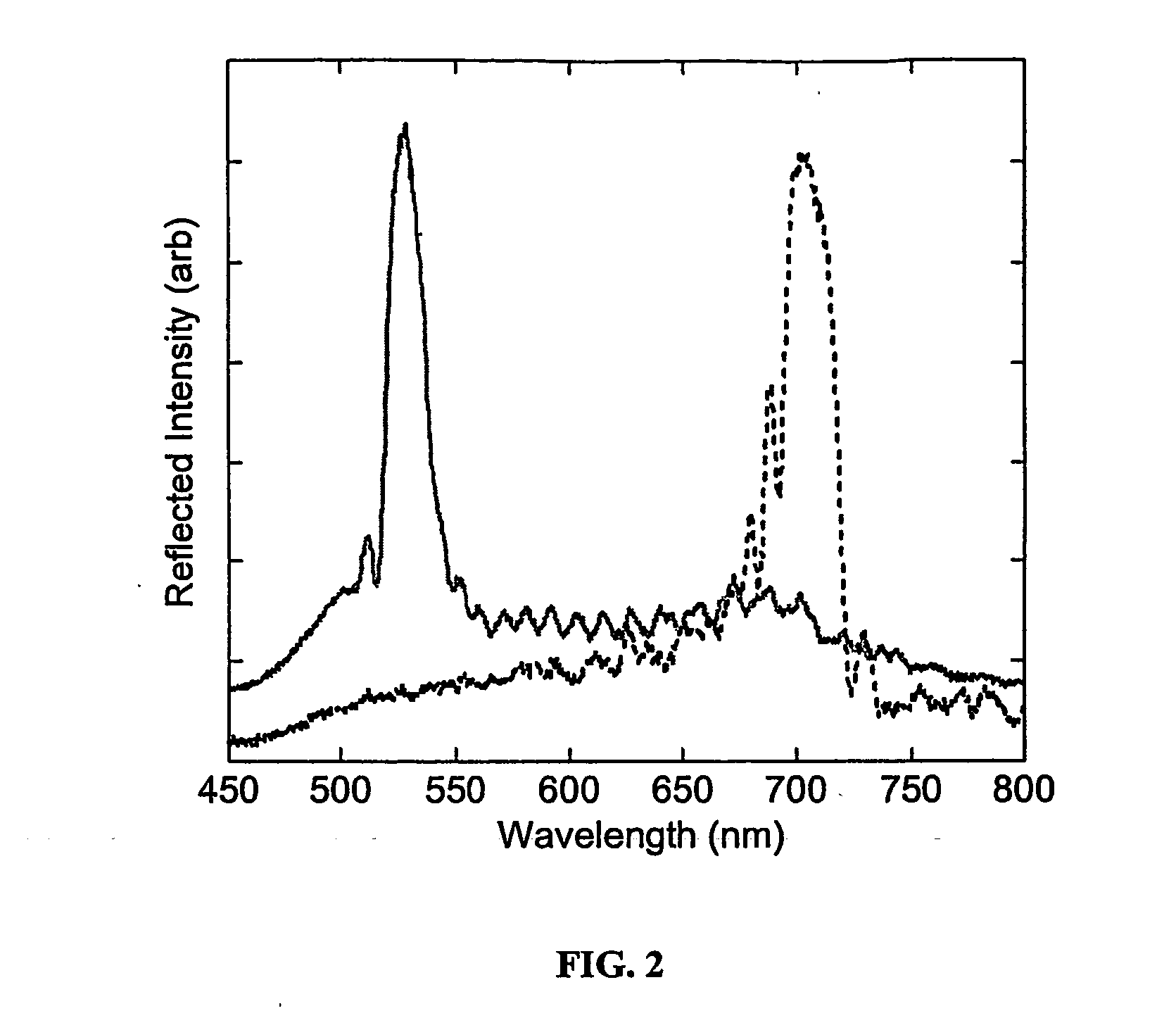

Photonic sensor particles and fabrication methods

The invention is related to optical particles (10), use of optical particles in sensing applications, and methods of fabricating optical particles that can target a desired analyte. The invention is also related to the self assembly of individual optical particles. An advantage of the invention is that it includes self-assembling individual photonic crystal sensors onto a target. In an embodiment of the invention, a processed sensor structure having two generally opposing surfaces is provided, wherein each of the opposing surfaces have different surface affinities, with a first optical structure formed on one of the opposing surfaces, and a second optical structure formed on the other of the opposing surfaces. The chemically and optically asymmetric opposing surfaces will spontaneously align at an organic liquid / water interface. Changes in the optical response of at least one of the opposing surfaces indicate the presence of a particular analyte for sensing applications.

Owner:RGT UNIV OF CALIFORNIA

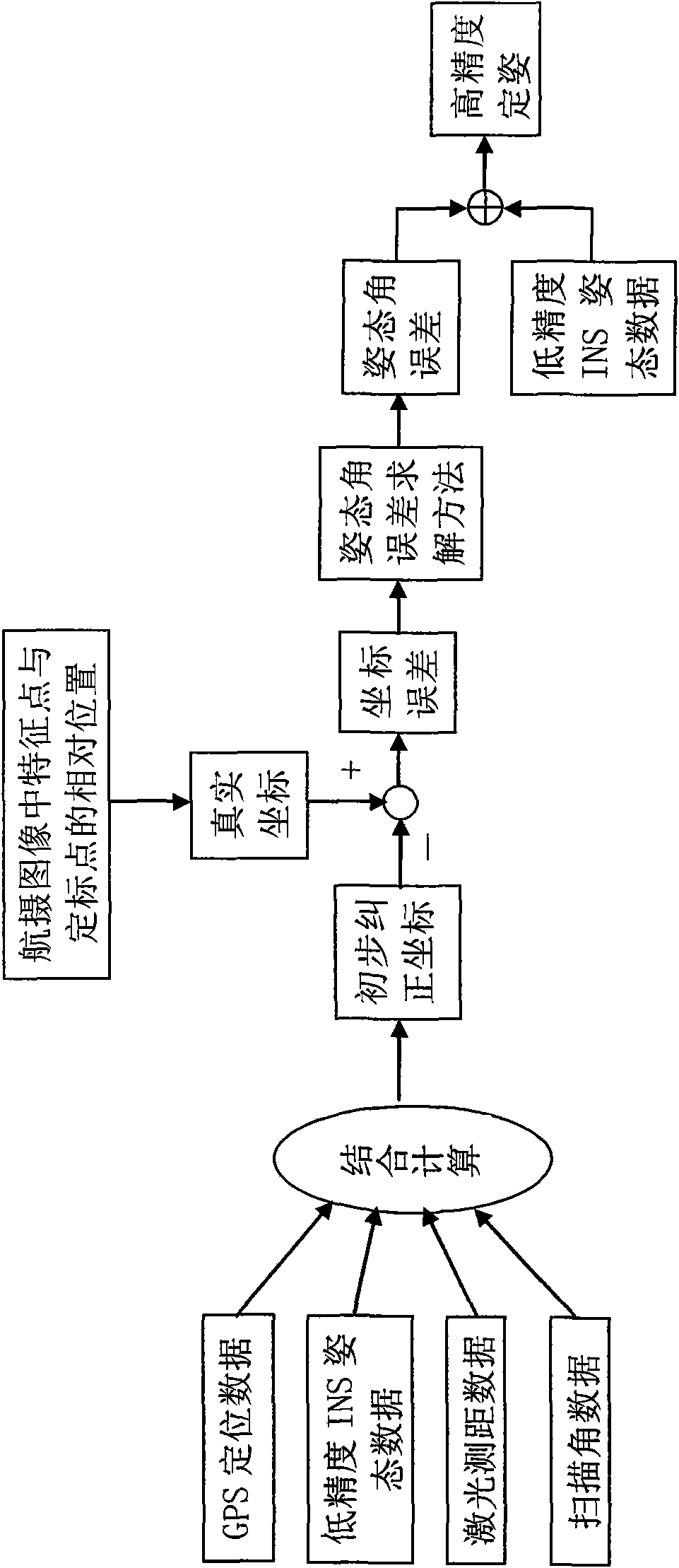

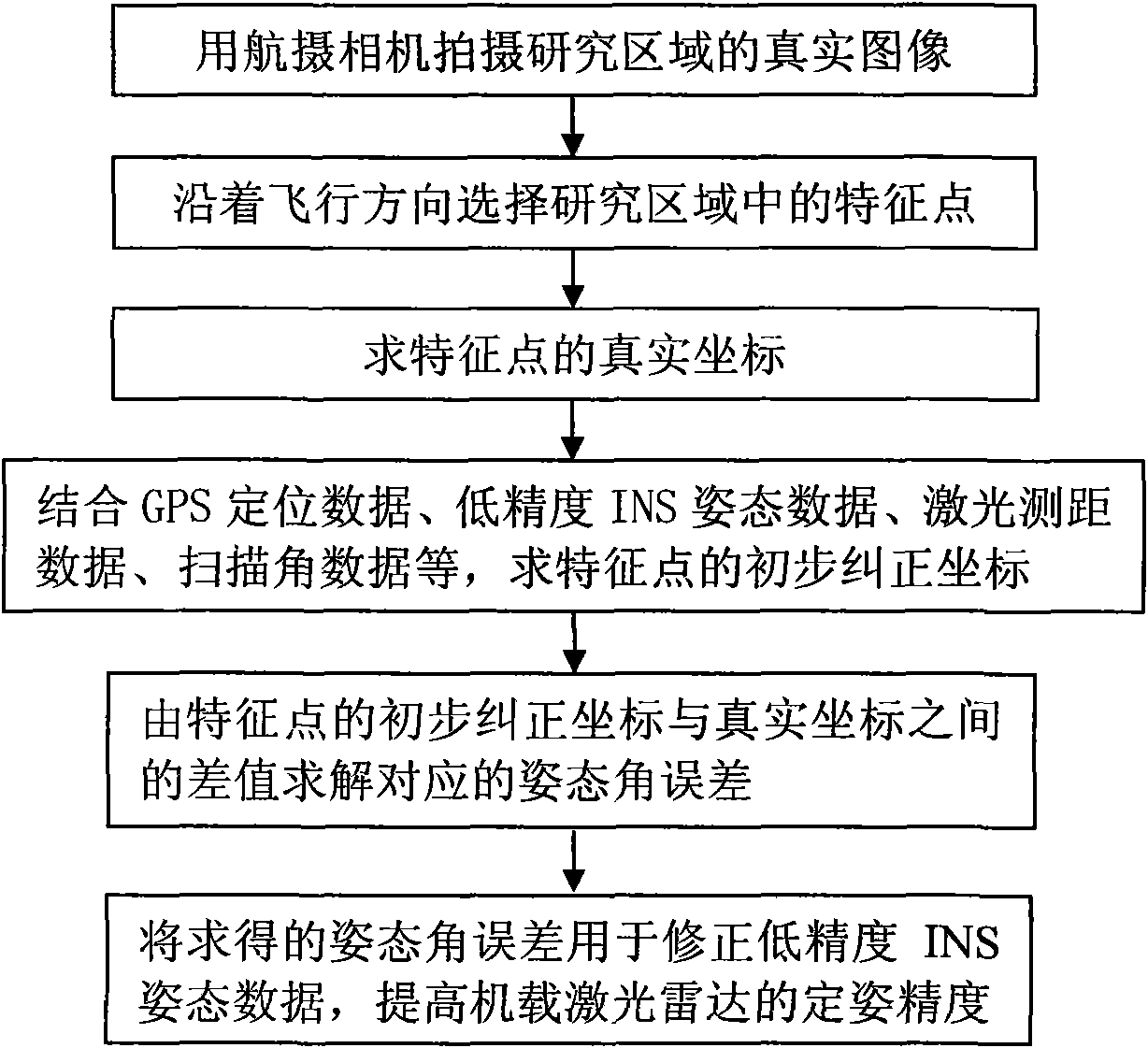

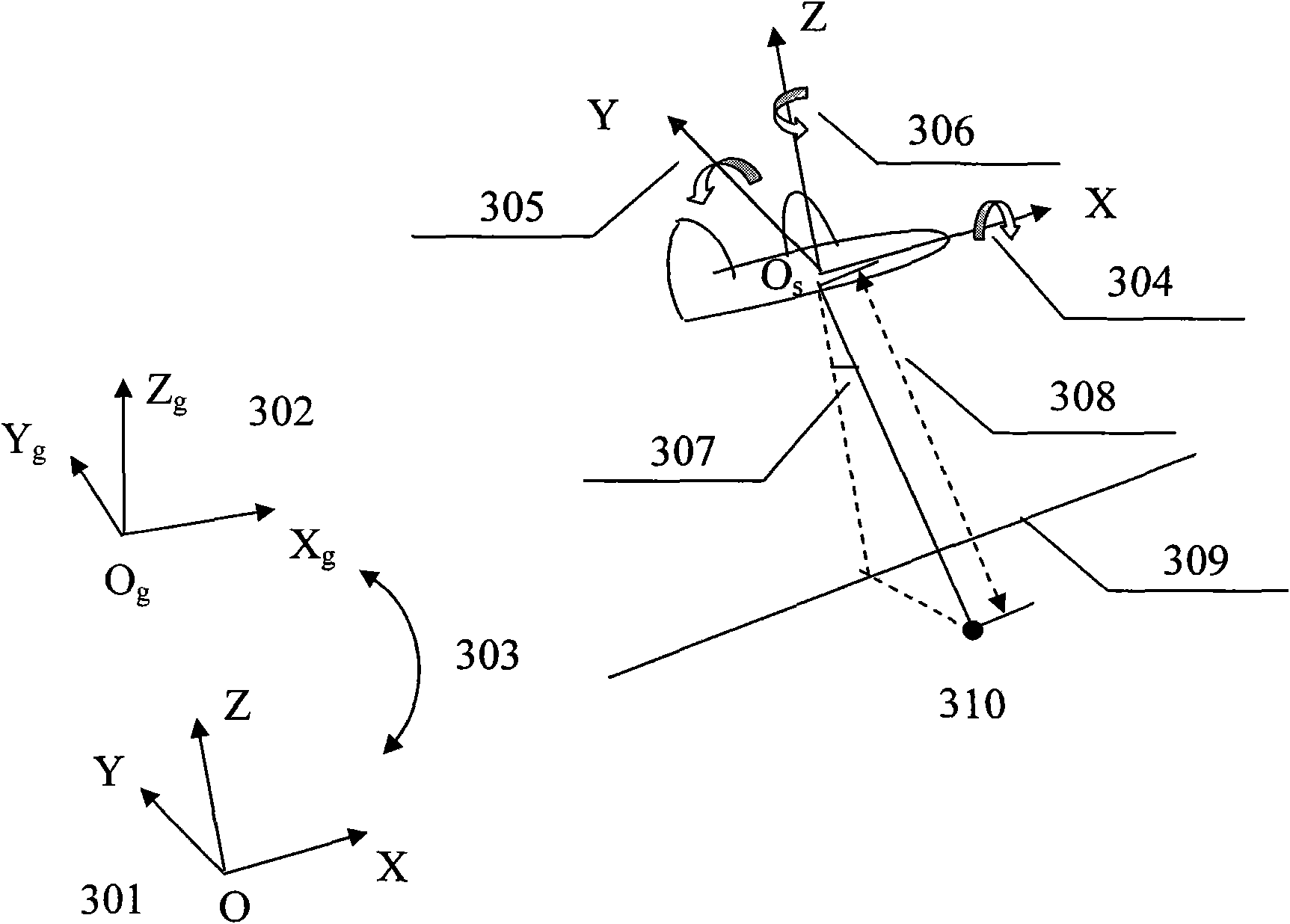

Method for improving attitude determination precision of airborne laser radar

InactiveCN101609149AThe requirements for measurement accuracy are not highImprove attitude accuracyPhotogrammetry/videogrammetryElectromagnetic wave reradiationAviationLaser ranging

The invention discloses a method for improving attitude determination precision of an airborne laser radar by solving three attitude angle errors through two-dimensional coordinate errors of feature points on a geodetic coordinate system under the condition of selecting an INS with low cost and low precision. The method is characterized in that the method combines three-dimensional initial correction coordinates of GPS positioning data, INS attitude determination data, laser distance measurement data, scanning angle data and other feature points on the geodetic coordinate system, solves the attitude angle errors by differences between the initial correction coordinates of the feature points in the two-dimensional direction of the geodetic coordinate system and real coordinates according to the mapping relation between the coordinate errors of laser footprints on the geodetic coordinate system and the attitude angle errors, and utilizes the solved attitude angle errors to amend the INS attitude data with low precision, thereby improving the attitude determination precision of the airborne laser radar. The method can greatly reduce system cost and amend the attitude angle errors with high frequency, thereby being applicable to the situations of platform attitude frequent change in light and small aerial remote sensing applications.

Owner:BEIHANG UNIV

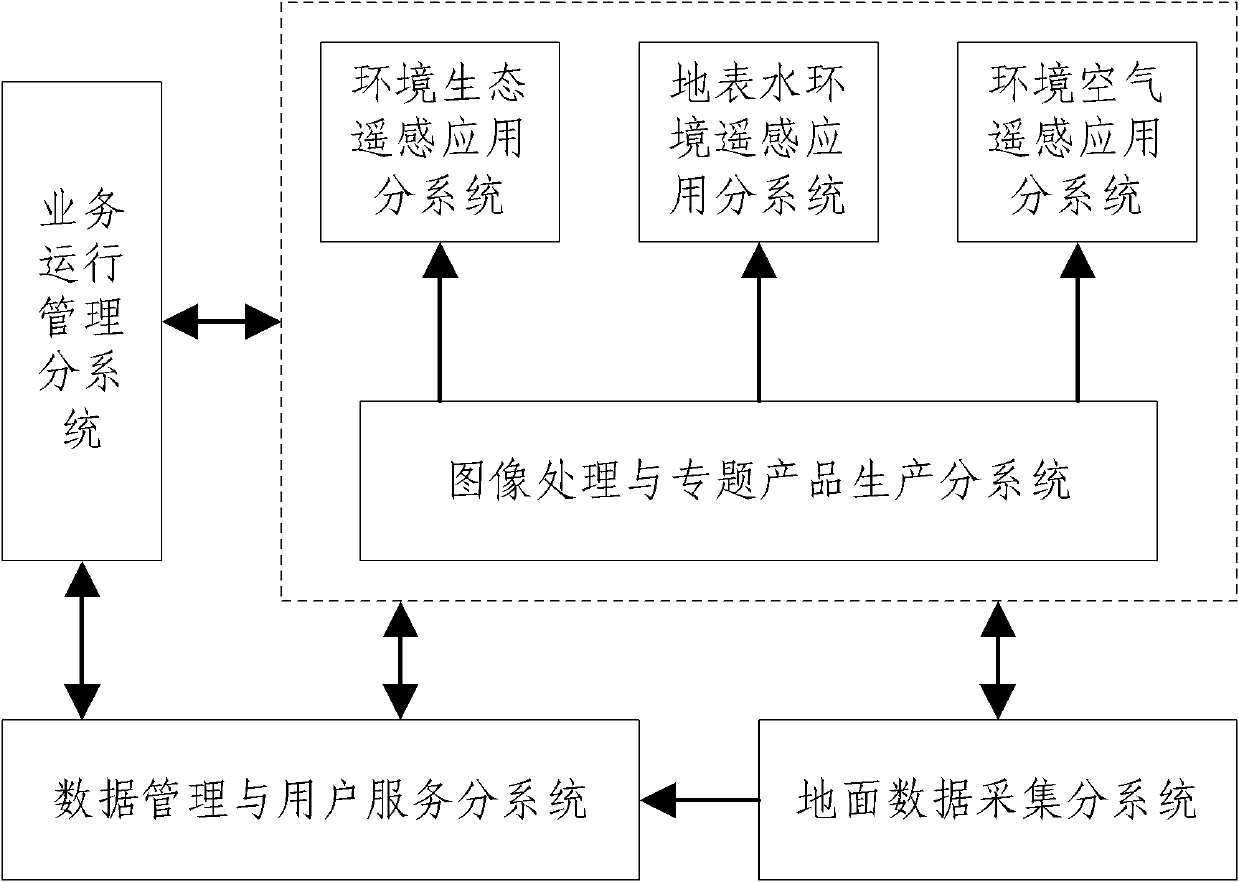

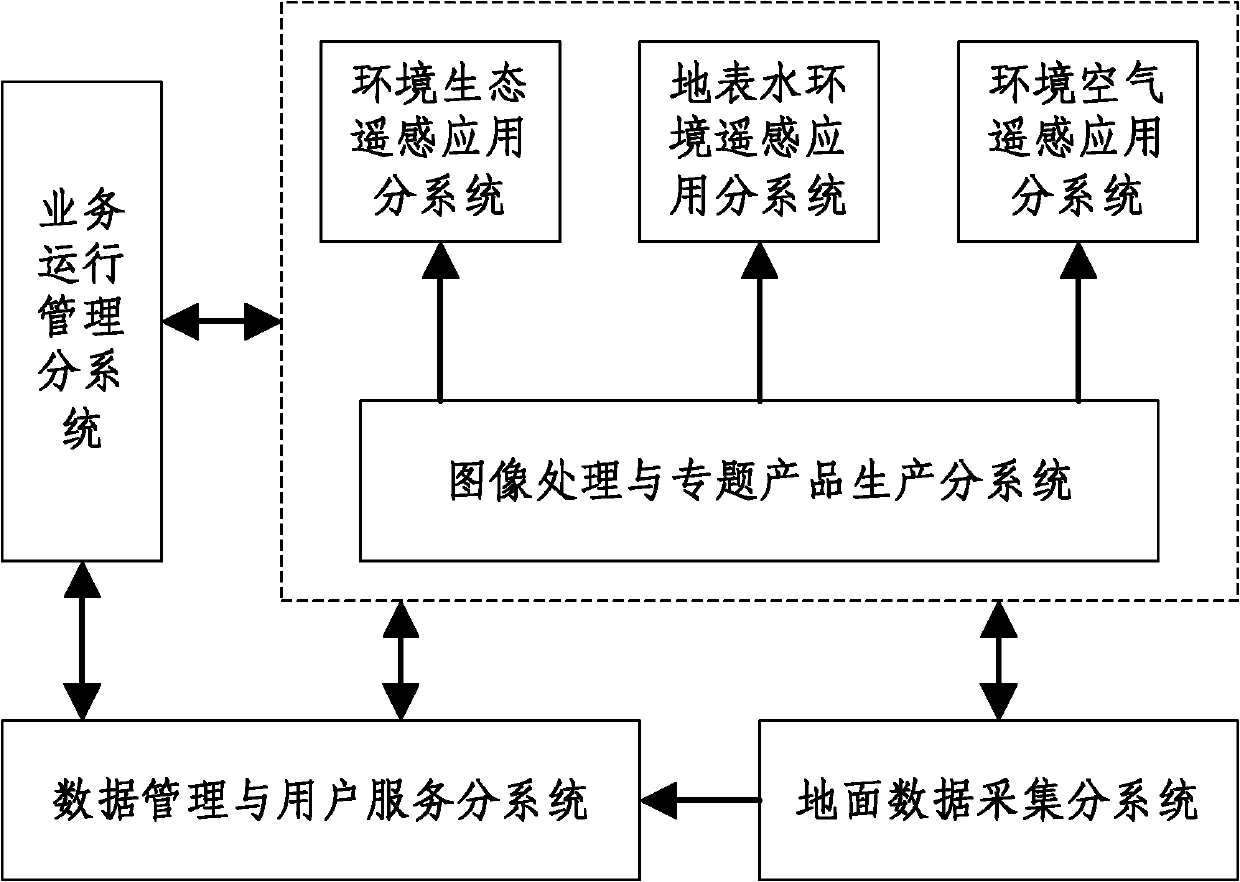

Environment remote sensing application system

InactiveCN102169557AImprove effective useRealize automated productionInstrumentsData acquisitionRemote sensing application

The invention discloses an environment remote sensing application system, which comprises a business operation and management subsystem, an image processing and special product production subsystem, a data management and subscriber service subsystem, an environment ecology remote sensing application subsystem, a surface water environment remote sensing application subsystem, an environment air remote sensing application subsystem, and a ground data acquisition subsystem. In the invention, environment spatial data resources for supporting environment satellite remote sensing monitoring businesses are built, and the automatic processing of environment satellite data and automatic production of special data products are realized, the operation of environment remote sensing monitoring and a task-driven business model integrating business requirement, task schedule formulation and task execution are achieved, and the processing and application capability of environment satellite data is formed, therefore, the problems of lag construction and poor operation capability of a satellite application system are solved, the effective utilization of a satellite is comprehensively promoted, and the operation of environment remote sensing monitoring businesses is supported.

Owner:王桥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com