Photonic sensor particles and fabrication methods

a technology of photonic sensors and fabrication methods, applied in the field of sensing, can solve the problems of many of the components required by such microscopic devices that cannot be fabricated using conventional lithographic tools, and achieve the effect of improving the quality of the finished produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

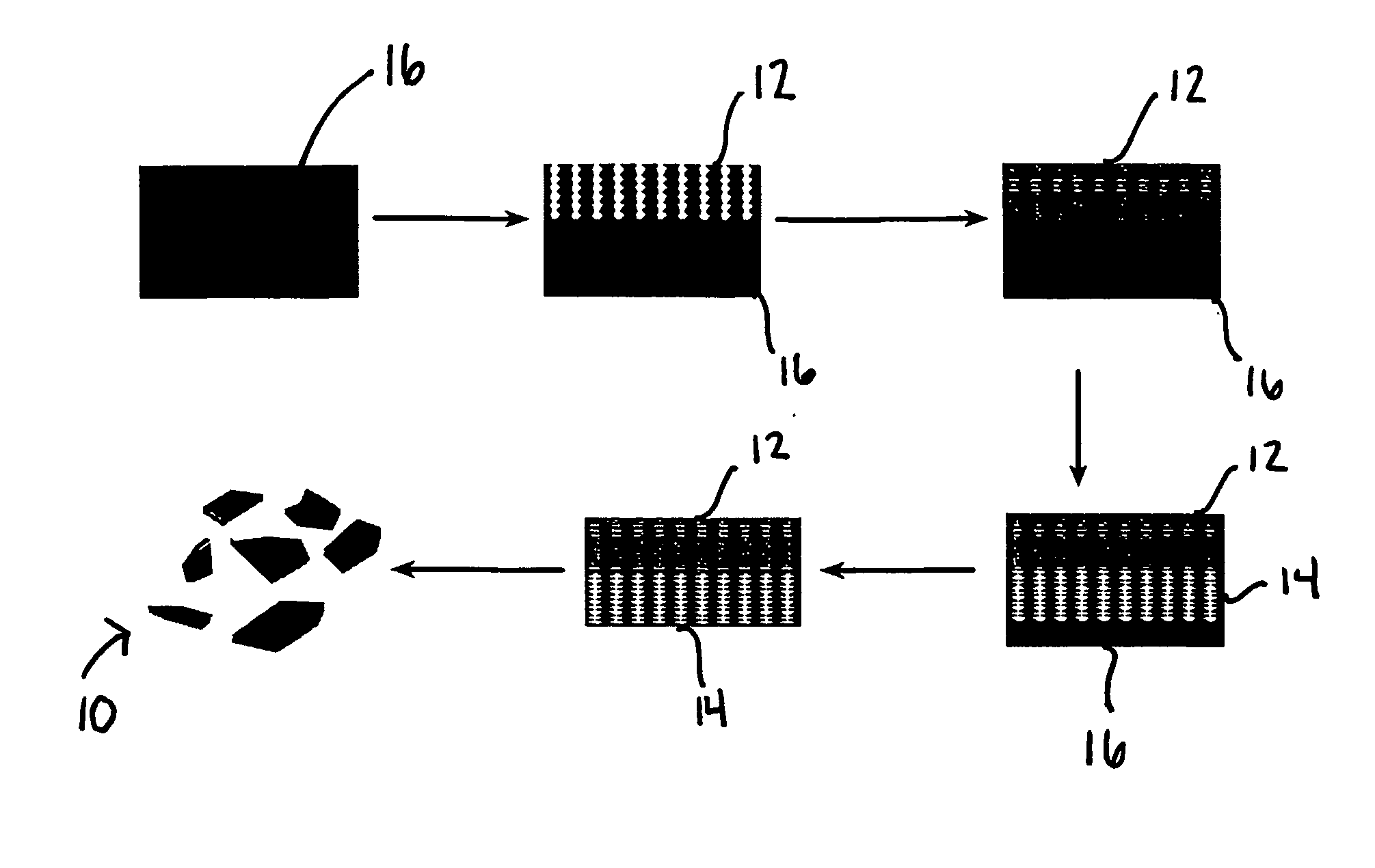

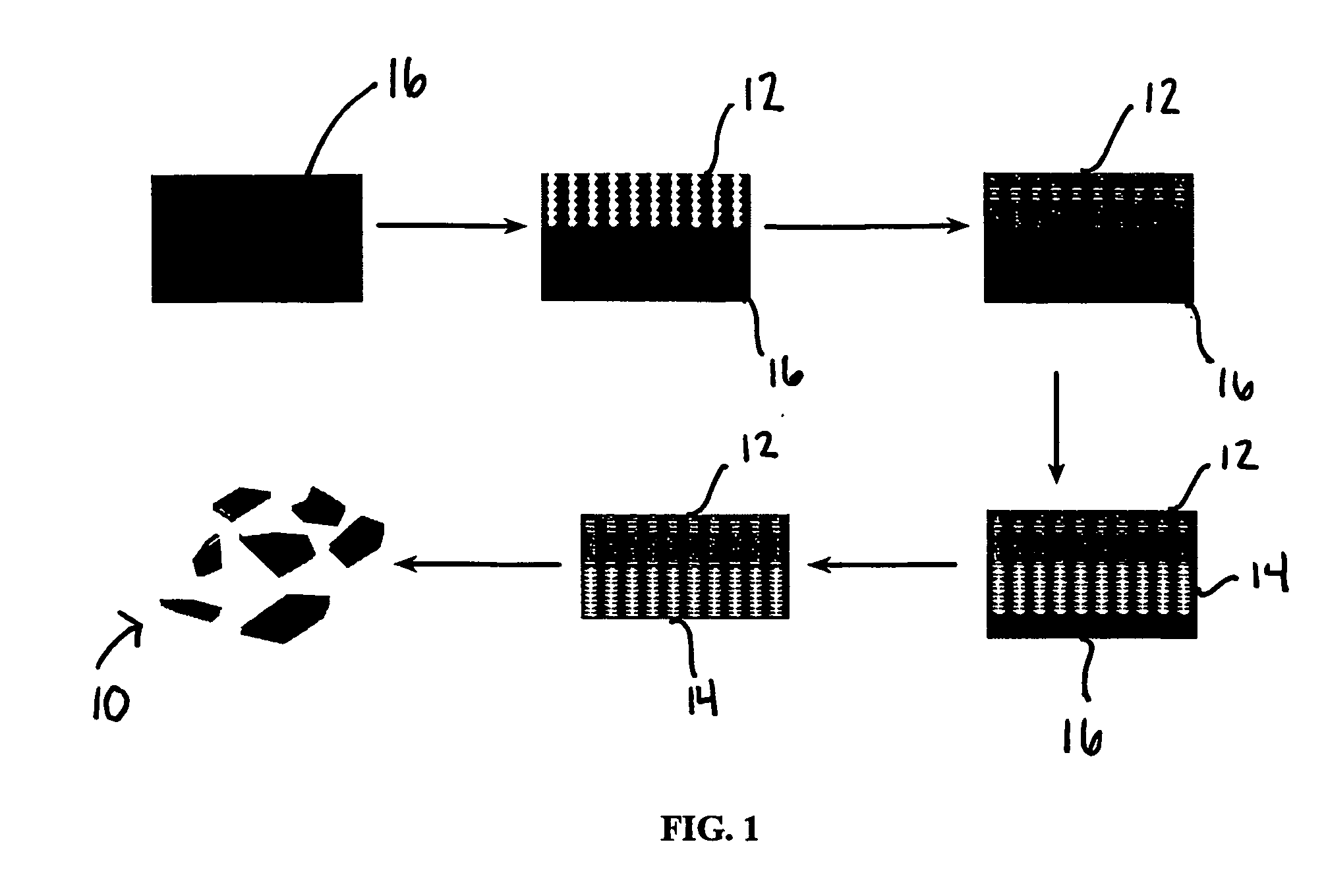

[0009] The invention is related to optical particles, use of optical particles in sensing applications, and methods of fabricating optical particles. It is contemplated that the chemically asymmetric optical particles have applications in high throughput screening, drug discovery, biomedical implants, information display, optical switching, and chemical and biological sensor fields. In one embodiment, a processed substrate is provided having two opposing surfaces, such as, for example, a top surface and a bottom surface, with different surface affinities and different optical signatures, with a first optical structure formed on the top surface, and a second optical structure formed on the bottom surface. While the opposing surfaces are discussed as top and bottom surfaces herein for purposes of convention, the invention contemplates use of any two opposite sides, referred to herein as oppositely.

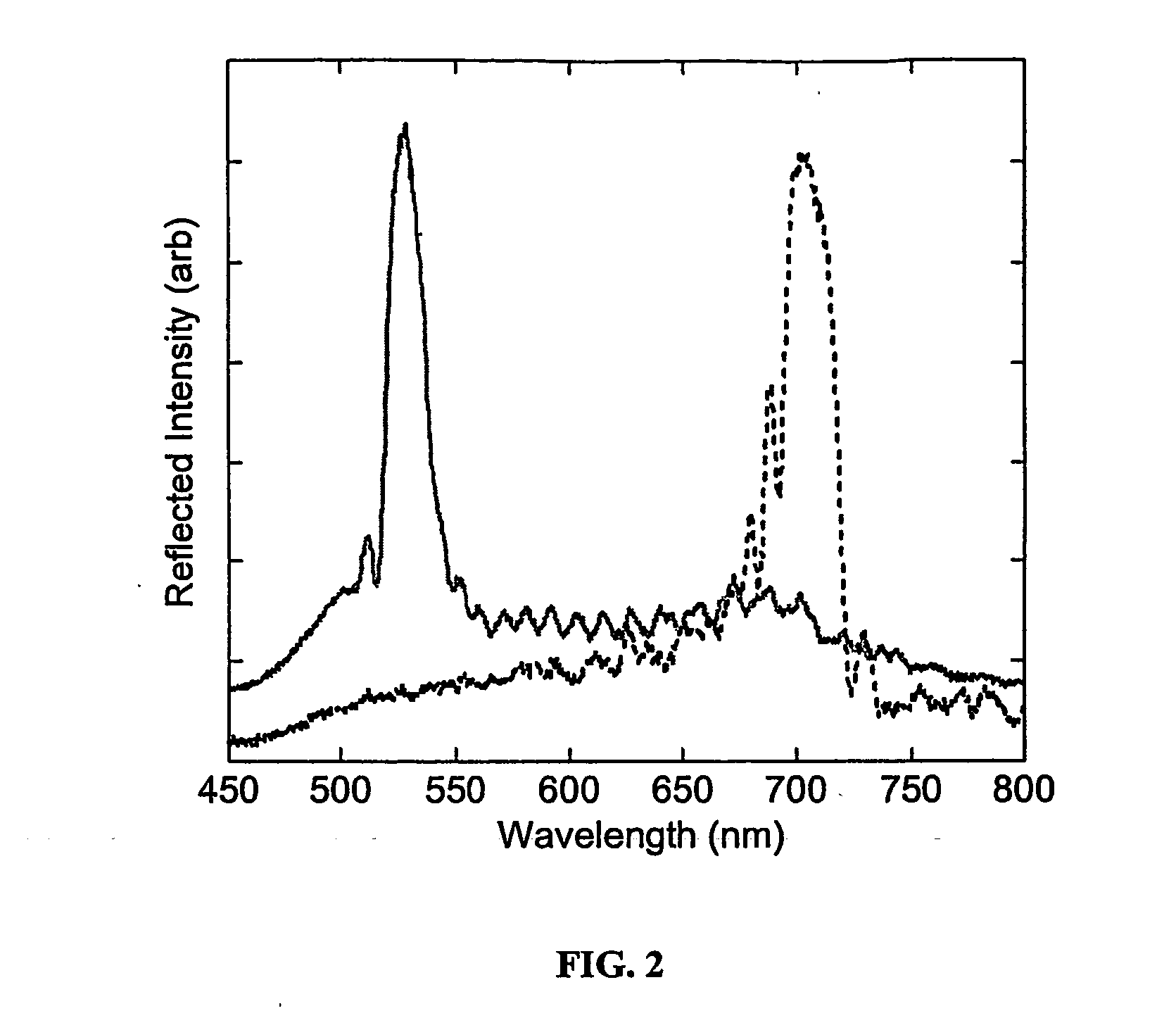

[0010] The top and bottom surfaces are chemically and optically asymmetric. At least on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com