Low-cost X65 pipeline steel based on magnesium treatment, and manufacturing method thereof

A manufacturing method and low-cost technology, applied in the field of iron-based alloys, can solve the problem of high manufacturing cost of X65 pipeline steel, achieve good lattice mismatch relationship, refine grains, and promote precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

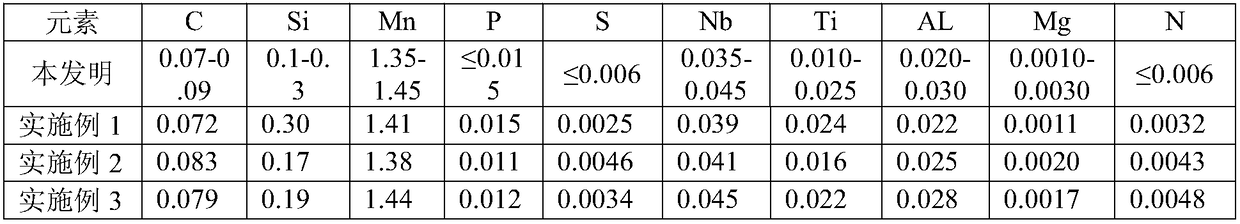

[0041] The present invention will be further described below in conjunction with Embodiments 1-3; the molten iron ladle capacity for containing molten iron in the embodiment of the present invention is 250 tons. Table 1 is the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is iron and unavoidable impurities.

[0042] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0043]

[0044] The molten steel that meets the chemical composition requirements is obtained through converter smelting. The molten steel is treated with Ar blowing in the refining process of the refining furnace. The RH furnace is subjected to vacuum circulation degassing treatment and fine-tuning of the composition, and then the slab is continuously cast to obtain the continuous casting slab; the thickness of the continuous casting slab The length is 210-230mm, the width is 900-160...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com