Automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and preparation method of automobile beam steel plate

A technology for automobile girders and tensile strength, which is applied in the field of metallurgy, and can solve problems such as increasing the difficulty of descaling, thicker oxide scales, and high deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

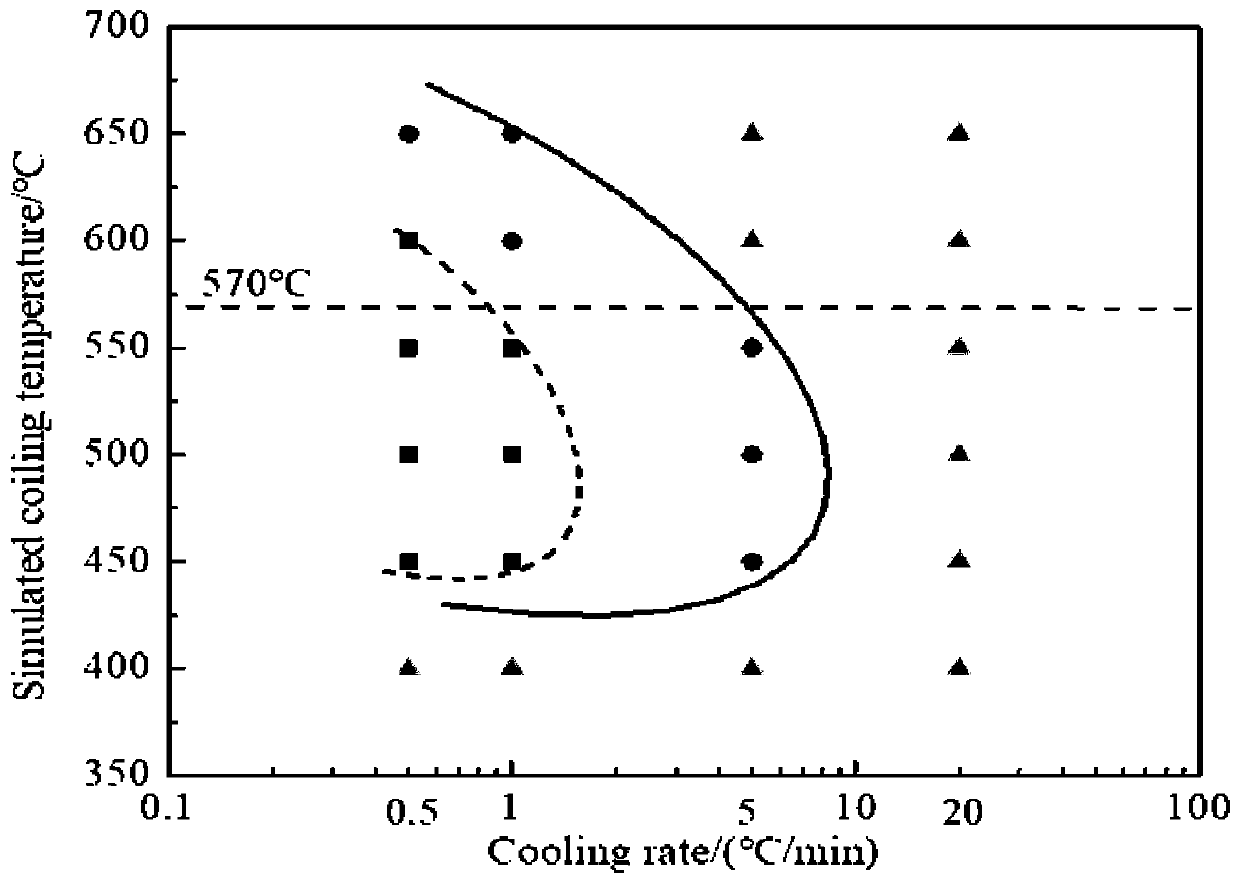

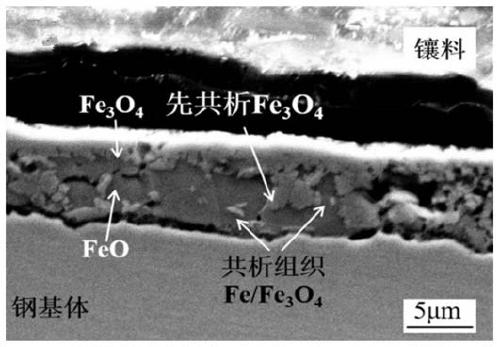

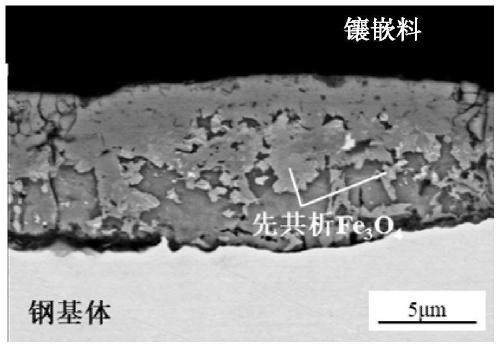

Method used

Image

Examples

Embodiment 1

[0033] Preparation of thick gauge automobile frame steel with a tensile strength of 750MPa and a thickness specification of 6mm:

[0034] Heat the slab with a thickness of 230mm to 1200°C and hold it for 240min. The chemical composition of the slab is: C: 0.03, Si: 0.05%, Mn: 1.0%, S: 0.015%, P: 0.025%, Als : 0.015%, Cr: 0.2%, Ti: 0.07%, Nb: 0.02%, and the rest are Fe and unavoidable impurities during smelting. Rough rolling is carried out on the steel slab after being released from the furnace, the rolling temperature is 1130°C, and the rolling is carried out for 5 passes to obtain an intermediate slab with a thickness of 34 mm; the rough rolled intermediate slab is subjected to finish rolling, and the finishing rolling passes are 7 passes. The finish rolling entrance temperature is 1050°C, the finish rolling temperature is 890°C, and the rolling speed of the F7 stand is 8m / s to obtain a 6mm thick strip. The descaling water pressure for heating furnace descaling, rough rolli...

Embodiment 2

[0036] Preparation of thick gauge automobile frame steel with a tensile strength of 750MPa and a thickness specification of 6mm:

[0037]Heat the slab with a thickness of 210mm to 1300°C and hold it for 180min. The chemical composition of the slab is: C: 0.12%, Si: 0.60%, Mn: 2.5%, S: 0.010%, P: 0.020%, Als: 0.045%, Cr: 1.0%, Ti: 0.15%, Nb: 0.08%, and the rest are Fe and unavoidable impurities during smelting. Rough rolling is carried out on the steel slab after being released from the furnace, the rolling temperature is 1180°C, and rolling is carried out for 5 passes to obtain an intermediate slab with a thickness of 48 mm; the rough rolled intermediate slab is subjected to finish rolling, and the finishing rolling passes are 7 passes. The finish rolling entrance temperature is 1050°C, the finish rolling temperature is 850°C, and the rolling speed of the F7 stand is 7m / s to obtain a 6mm thick strip. The descaling water pressure for heating furnace descaling, rough rolling de...

Embodiment 3

[0039] Preparation of thick gauge automobile frame steel with a tensile strength of 750MPa and a thickness specification of 8mm:

[0040] Heat the slab with a thickness of 230mm to 1250°C and hold it for 200min. The chemical composition of the slab is: C: 0.05%, Si: 0.05%, Mn: 1.5%, S: ≤0.015%, P: ≤0.025 %, Als: 0.025%, Cr: 0.2%, Ti: 0.09%, Nb: 0.03%, and the rest are Fe and unavoidable impurities during smelting. The steel slab after being released from the furnace is subjected to rough rolling at a starting temperature of 1130°C for 5 passes to obtain an intermediate slab with a thickness of 52mm; the rough rolled intermediate slab is subjected to finish rolling with 7 passes. The finish rolling entrance temperature is 1040°C, the finish rolling temperature is 880°C, and the rolling speed of the F7 stand is 6m / s to obtain a strip with a thickness of 8mm. The descaling water pressure for heating furnace descaling, rough rolling descaling and finishing rolling descaling is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com