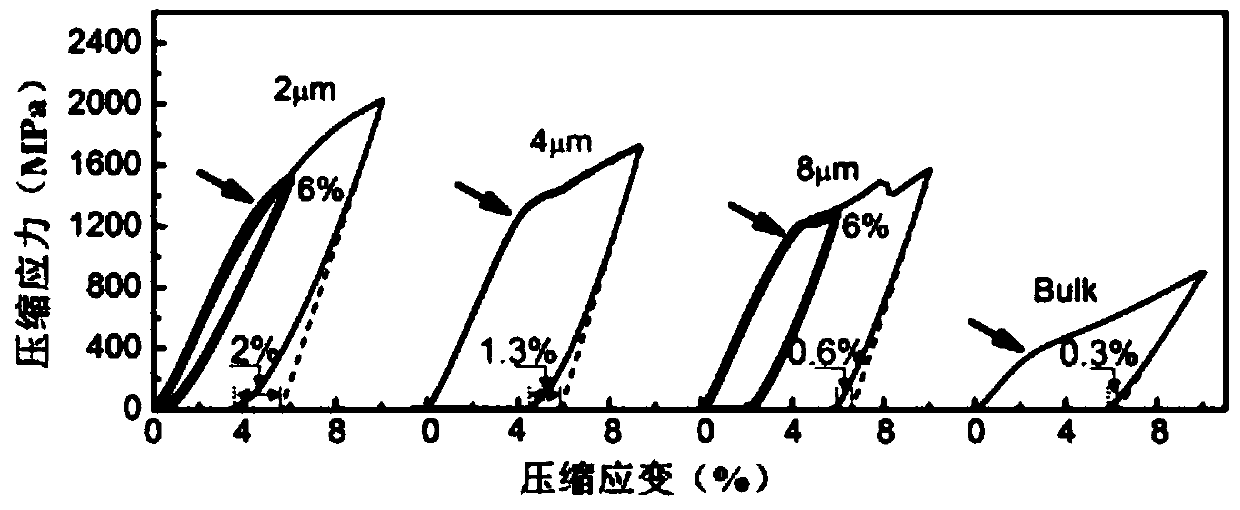

Method for improving super-elasticity of beta titanium alloy

A β-titanium alloy and superelastic technology, which is applied in the field of nanomaterial preparation, can solve the problems of inconspicuous superelastic behavior, achieve the effects of reducing pinning, reducing dislocation opening, and improving superelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Taking the Ti-10V-2Fe-3Al alloy as an example, for other β-titanium alloys with shape memory, the purpose of reducing size and improving superelasticity can be achieved by selecting the orientation of martensitic phase transformation and adjusting the sample size range through calculation.

[0040] Step 1. Calculate the phase transformation strain generated when the Ti-10V-2Fe-3Al alloy is transformed from the downward β phase to martensite at different positions, and select the orientation grains that are beneficial to the martensitic transformation;

[0041] Specifically: for the Ti-10V-2Fe-3Al alloy, the β phase undergoes transformation to the α″ martensite phase under the action of an external force. The β phase maintains an orientation relationship with the α″ martensite:[100] α″ / / [100] β , [010] α″ / / [101] β and [001] α″ / / [110] β , the martensitic transformation is along three principal axes ([100] α″ , [010] α″ and [001] α″ ) will produce η 1 =-7.1%, η...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com