Mesothermal heat process method for improving hyperelasticity of NiTiV shape memory alloy

A heat treatment method and memory alloy technology, applied in the field of shape memory alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The selected components are Ni: 56.45 wt %; Ti: 42.88 t %; V: 0.67 wt %. , the phase transition point A f =-15 ℃ memory alloy wire, heat treatment at medium temperature according to Table 1. The test wire of NiTiV shape memory alloy with a length of 11 cm and a diameter of 1.19 mm was selected, and the medium temperature heat treatment process shown in Table 1 was adopted.

[0011] Table 1 Heat treatment process

[0012] Tab 1 The Heat Treatment Method

[0013]

[0014]

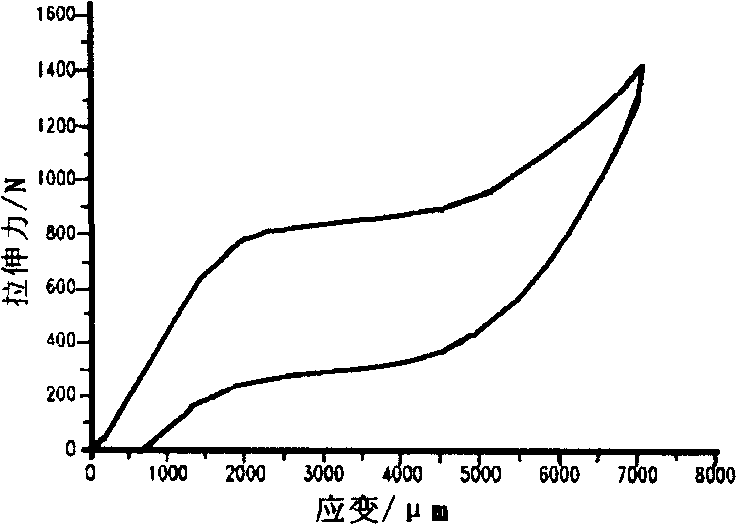

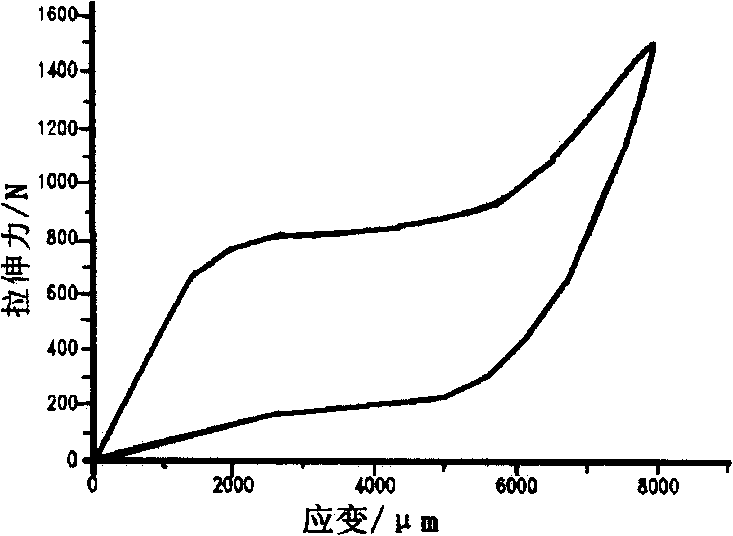

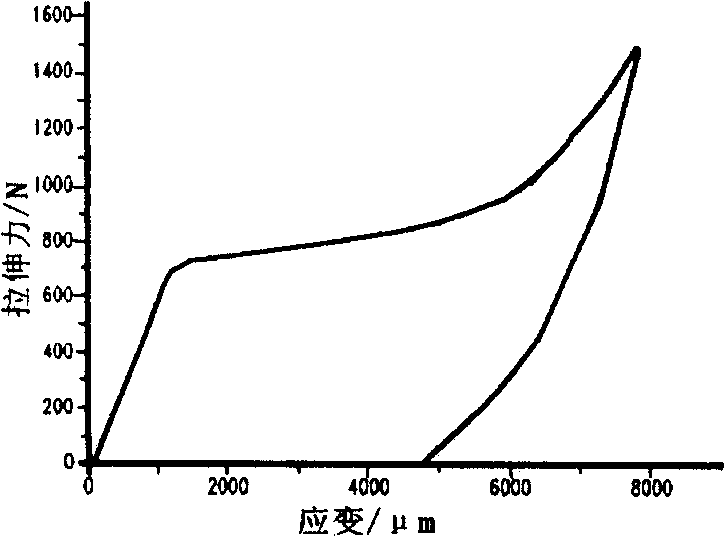

[0015] The NiTiV shape memory alloy wire treated at medium temperature was subjected to tensile test in WDW-10 microcomputer-controlled electronic universal tensile testing machine. Tensile tests yield different curves ( Figures 1 to 4 ), it can be seen from the curve that the superelasticity of the NiTiV shape memory alloy is significantly affected by the medium temperature heat treatment: at the medium temperature heat treatment temperature of 440 °C, the heat preservation for 20min shows ...

Embodiment 2

[0017] The selected components are: Ni: 55.5 wt %; Ti: 41.8 t %; V: 0.57 %. Phase transition point A f =-5℃ memory alloy wire. The NiTiV shape memory alloy wire subjected to the same medium temperature treatment as in Example 1 was subjected to a tensile test in a WDW-10 microcomputer-controlled electronic universal tensile testing machine. get as Figure 5 The curves shown, from Figure 5 It can be seen that the NiTiV shape memory alloy exhibits complete nonlinear superelasticity at the medium temperature heat treatment temperature of 440 °C for 20 min, and its superelasticity reaches the maximum value.

Embodiment 3

[0019] The selected components are Ni: 57.3 wt%; Ti: 43.4 t%; V: 0.73%. , the phase transition point A f = -35°C memory alloy wire, NiTiV shape memory alloy wire subjected to the same medium temperature treatment as in Example 1, and the tensile test was carried out on a WDW-10 microcomputer-controlled electronic universal tensile testing machine. get as Image 6 The curves shown, from Image 6 It can be seen that the NiTiV shape memory alloy exhibits complete nonlinear superelasticity at the medium temperature heat treatment temperature of 440 °C for 20 min, and its superelasticity reaches the maximum value.

[0020] The NiTiV shape memory alloy used for microstructure analysis was inlaid on an XQ-2 sample inlay machine, and the inlaid wire was polished and etched with an etchant (hydrofluoric acid:nitric acid=1:2.5). The corroded samples were observed under a microscope. According to the metallographic structure ( Figures 7 to 10 ), it can be seen that the NiTiV shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com