Preparation method for radioactivity TiNi alloy bracket without fringe effect

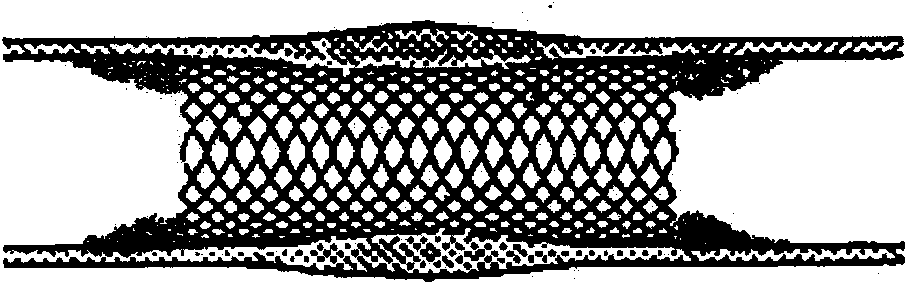

An edge effect and radioactive technology, applied in radiation therapy, stents, medical science, etc., can solve the problems of uneven dose, high restenosis rate at the edge of the stent, weak ray penetration, etc., to achieve suppression of edge effects, excellent super The effect of elasticity and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

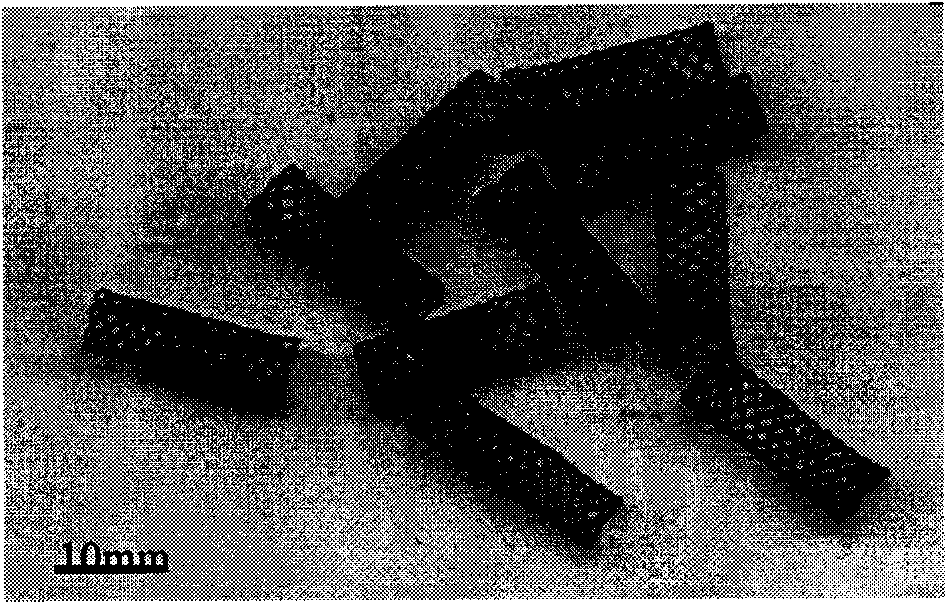

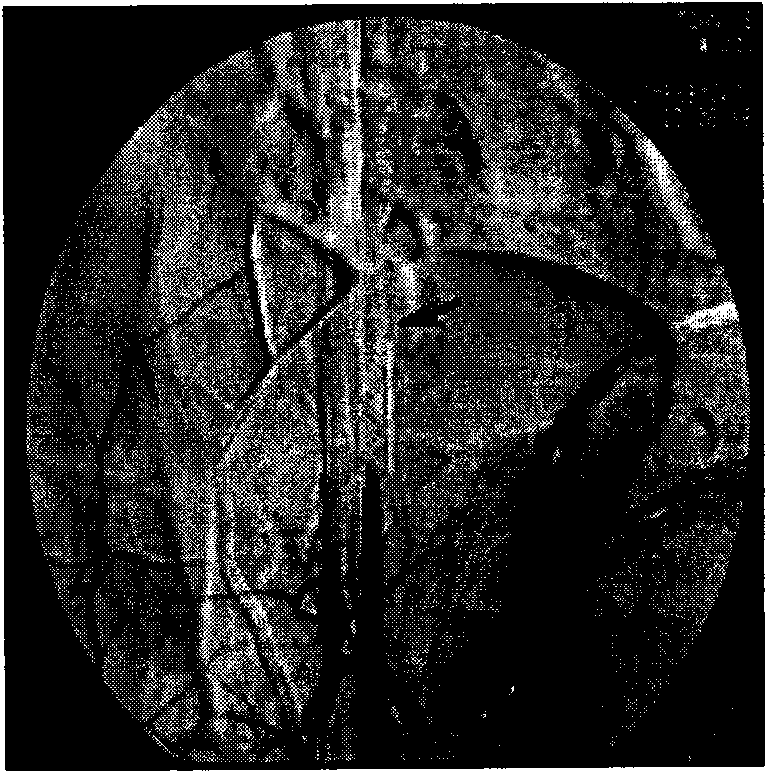

[0008] Embodiment 1: The method for preparing the radioactive TiNi alloy stent without edge effect in this embodiment is realized by the following steps: 1. Take 50.6% Ni, 0.032% C, 0.003% H, 0.045% O, 0.040% by atomic percentage % Fe and the remainder of Ti are mixed, and then melted in a water-cooled copper crucible vacuum induction melting furnace to obtain ingots; 2. Clean the surface of the ingot, and then homogenize it at a temperature of 750-850°C for 8-24 hours. Then, the billet is forged at a temperature of 800°C, and then hot-rolled at a temperature of 650-800°C, and then turned into a bar with a diameter of 1.5cm at a temperature of 650-800°C. Then, under the condition of temperature of 700°C and pass deformation of 10%, it is hot-drawn into a hot-drawn wire with a diameter of 2mm, then sand blasted, and then cold-drawn to a diameter of 0.24mm under the condition of a pass deformation of 10%. Cold-drawn wire, and finally cold-drawn into a cold-drawn wire with a diam...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 2, the homogenization treatment is performed at a temperature of 800° C. for 12 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the temperature of the hot rolling treatment in step 2 is 700°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com