Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Weakened pinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

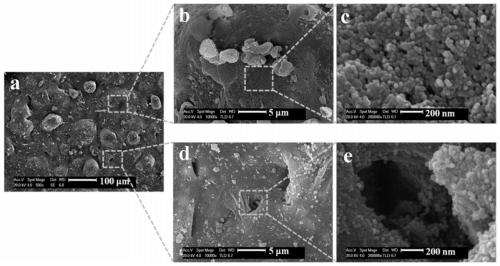

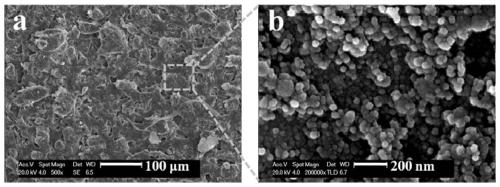

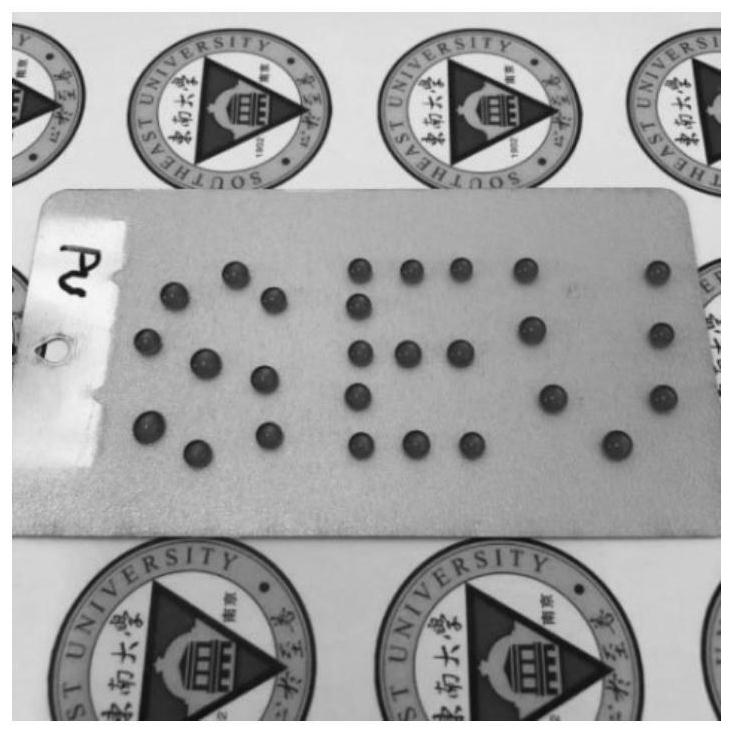

Super-wear-resistant and super-amphiphobic coating as well as preparation method and application thereof

ActiveCN110240849AImprove wear resistanceExcellent ice-phobic performanceLiquid surface applicatorsPolyurea/polyurethane coatingsWear resistantKitchen utensils

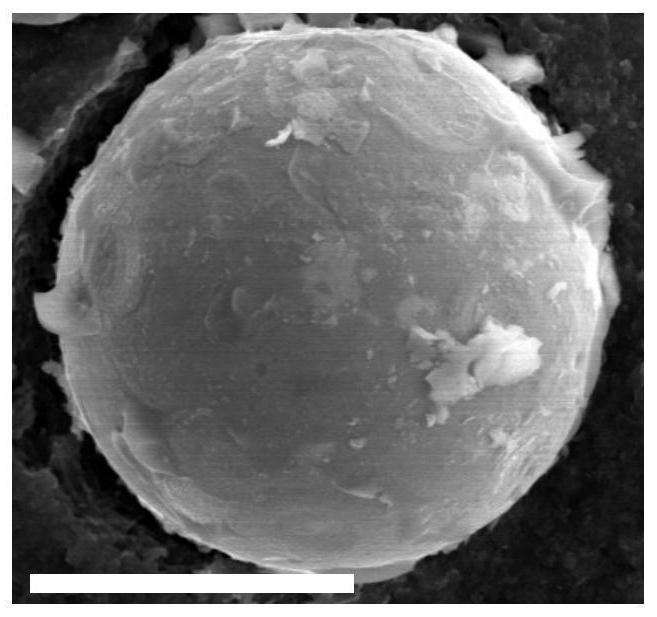

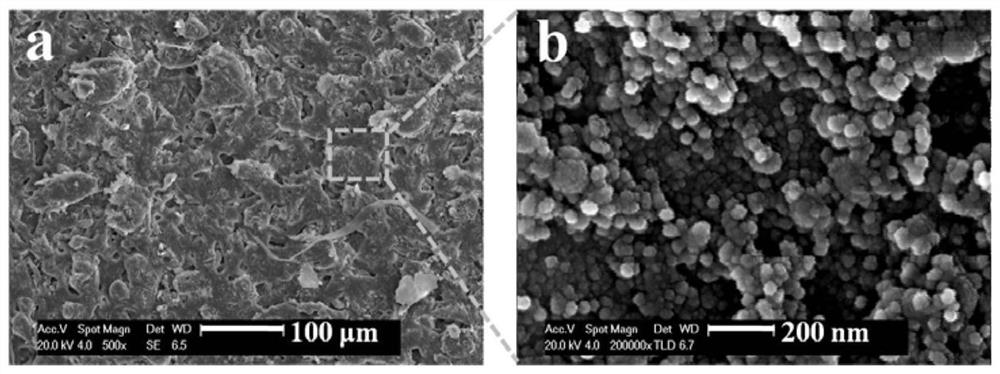

The invention relates to a super-wear-resistant and super-amphiphobic coating as well as a preparation method and application thereof, belonging to the technical field of coating preparation. The preparation process comprises the following steps: mixing resin powder, hydrophobic powder and an auxiliary agent, then putting the obtained mixture into a twin-screw mixer for melting and extruding, and then tabletting and crushing; grinding the crushed the sheets, and sieving to obtain a powder coating; dispersing aqueous silica sol into an aqueous solution, adding ammonia water for carrying out alkalization treatment, then adding the solution into an ethanol solution, mixing uniformly and then adding a hydrophobic modifier, stirring and standing to obtain a nano-super-amphiphobic coating; electrostatically spraying the powder coating to obtain a primer coating, and then spraying the nano-super-amphiphobic coating onto the surface of the primer coating to obtain the super-wear-resistant and super-amphiphobic coating. According to the preparation method provided by the invention, a large roughness surface structure is prepared by means of an electrostatic powder spraying process; due to the introduction of the functional finish coating, the super-amphiphobic coating with ultra-high wear resistance and anti-icing performance can be obtained; the super-wear-resistant and super-amphiphobic coating can be applied to preparation of kitchen utensils and equipment, inner walls of refrigeration equipment or outer walls of outdoor facilities in cold areas.

Owner:SOUTHEAST UNIV

Low carbon cold-rolled steel sheet for LED lead frame and production method thereof

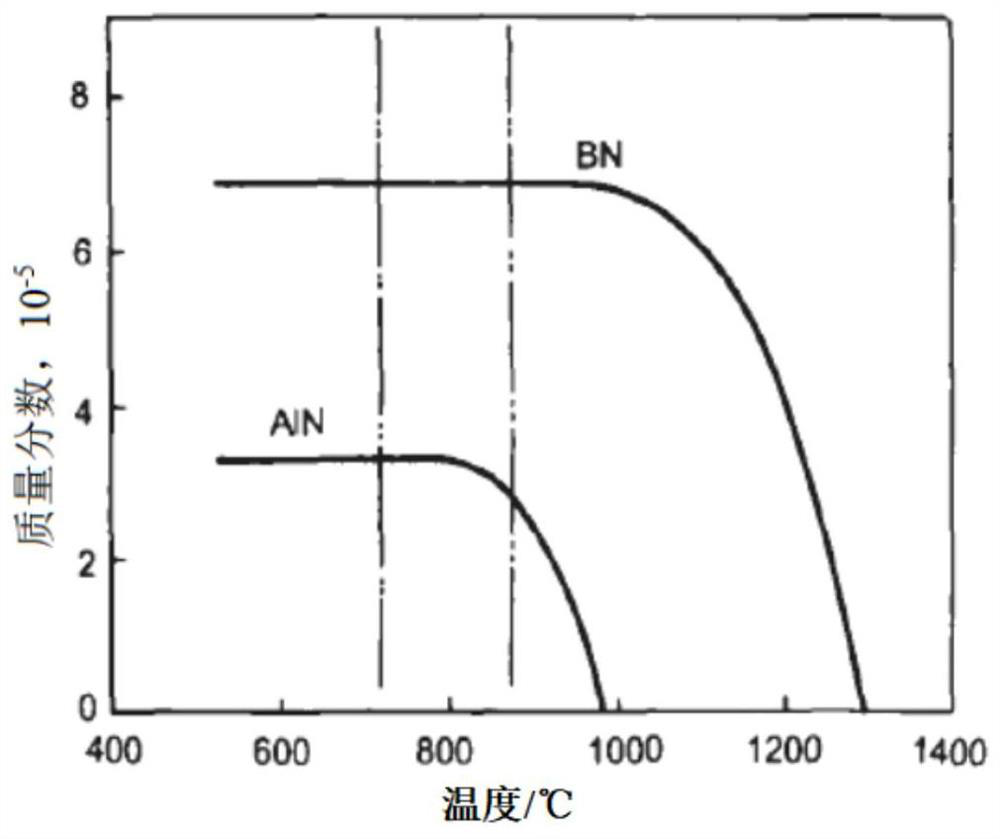

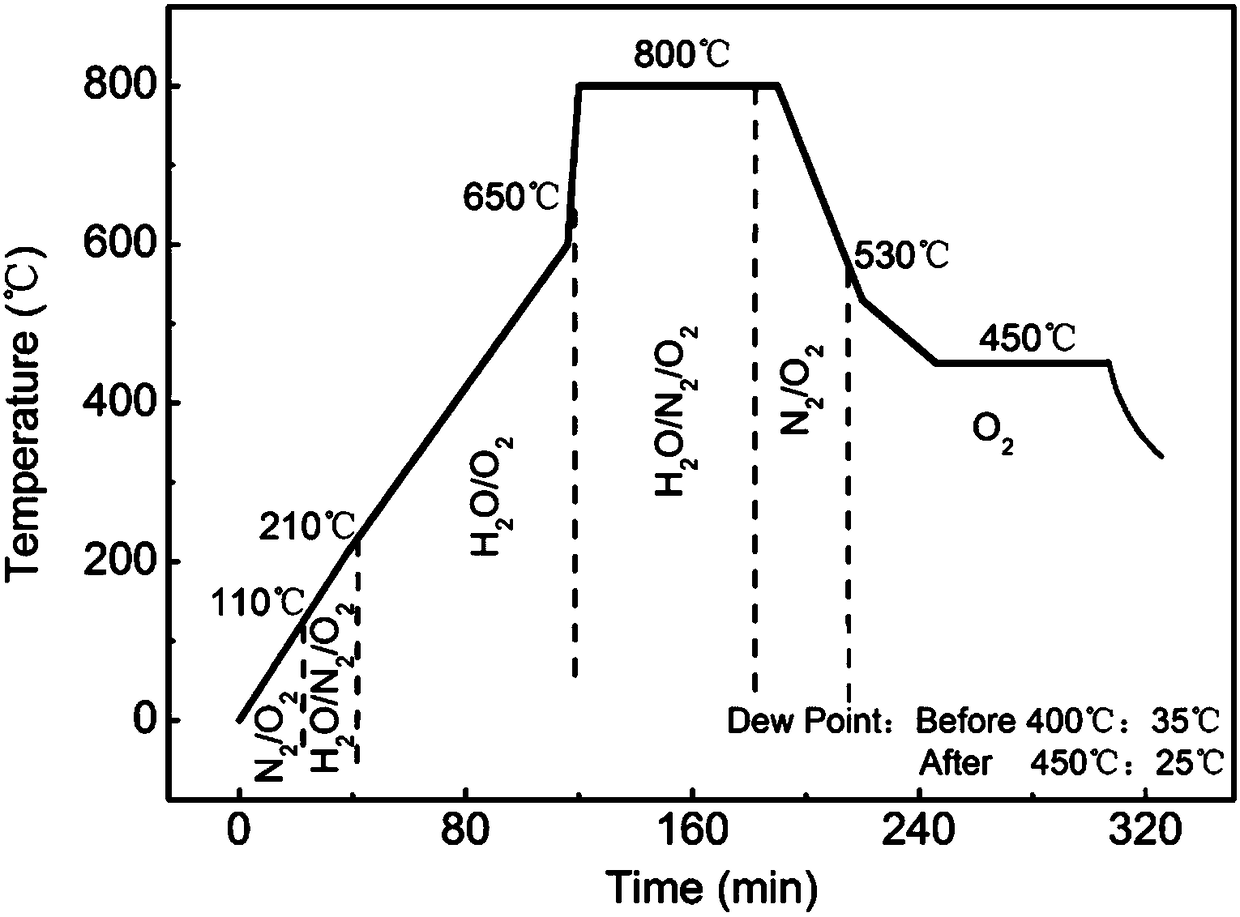

The invention relates to a low carbon cold-rolled steel sheet for a LED lead frame and a production method thereof, and mainly solves the technical problems that the low carbon cold-rolled steel sheet for the LED lead frame in prior art has nonuniform hardness, high surface roughness and bad aging-resistance. The production method comprises the following steps: smelting according to components, molten iron desulphurization, complex top-bottom blowing converter smelting, argon blowing from bottom of a ladle, protective casting with argon blowing in whole course, heating in a slab heating furnace, rough rolling, finish rolling, reeling for obtaining a hot-rolled steel coil, uncoiling, pickling, cold rolling, annealing in a vertical type continuous annealing furnace, flattening, and reeling for obtaining a finished product with a thickness of 0.4-0.5mm; the finishing temperature of the finish rolling is 860-900 DEG C, the reeling temperature of the hot rolling is 620-660 DEG C, the cold rolling reduction is 75-85%, the temperature scope of a soaking zone of the vertical type continuous annealing furnace for a band steel in hard rolled state after cold rolling is 710-730 DEG C, the soaking time for the band steel in the vertical type continuous annealing furnace is 105-120 s, and temper elongation is 1.0-1.4%. The low carbon cold-rolled steel sheet is mainly used for the LED lead frame.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

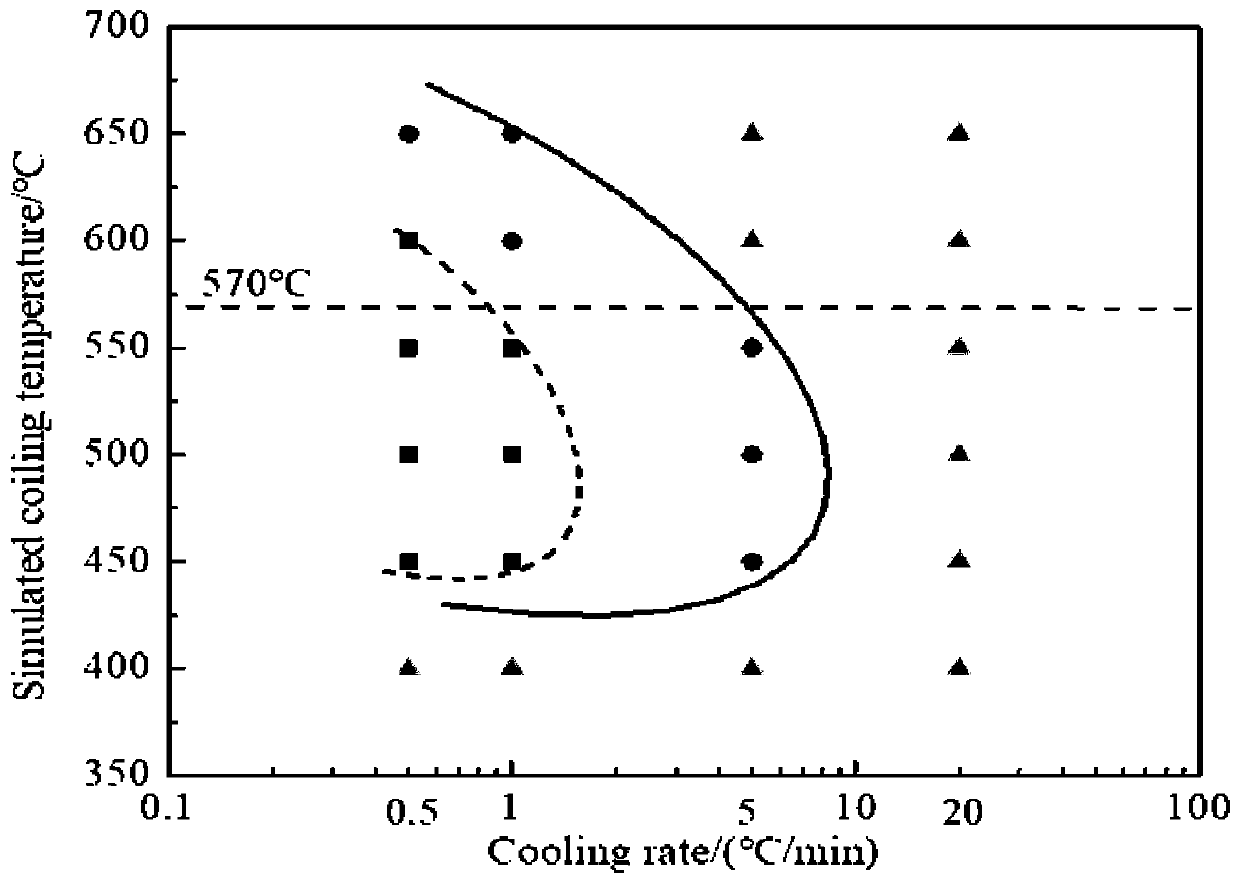

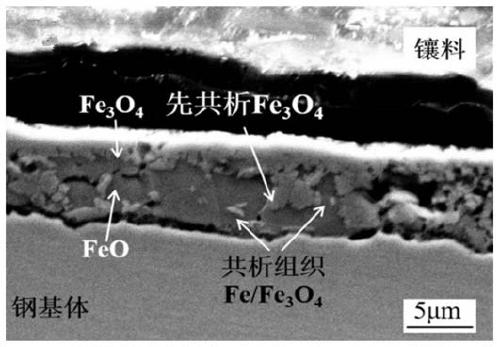

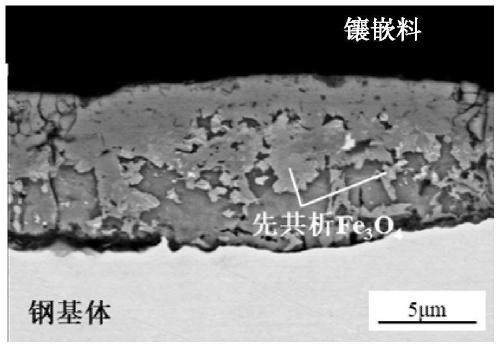

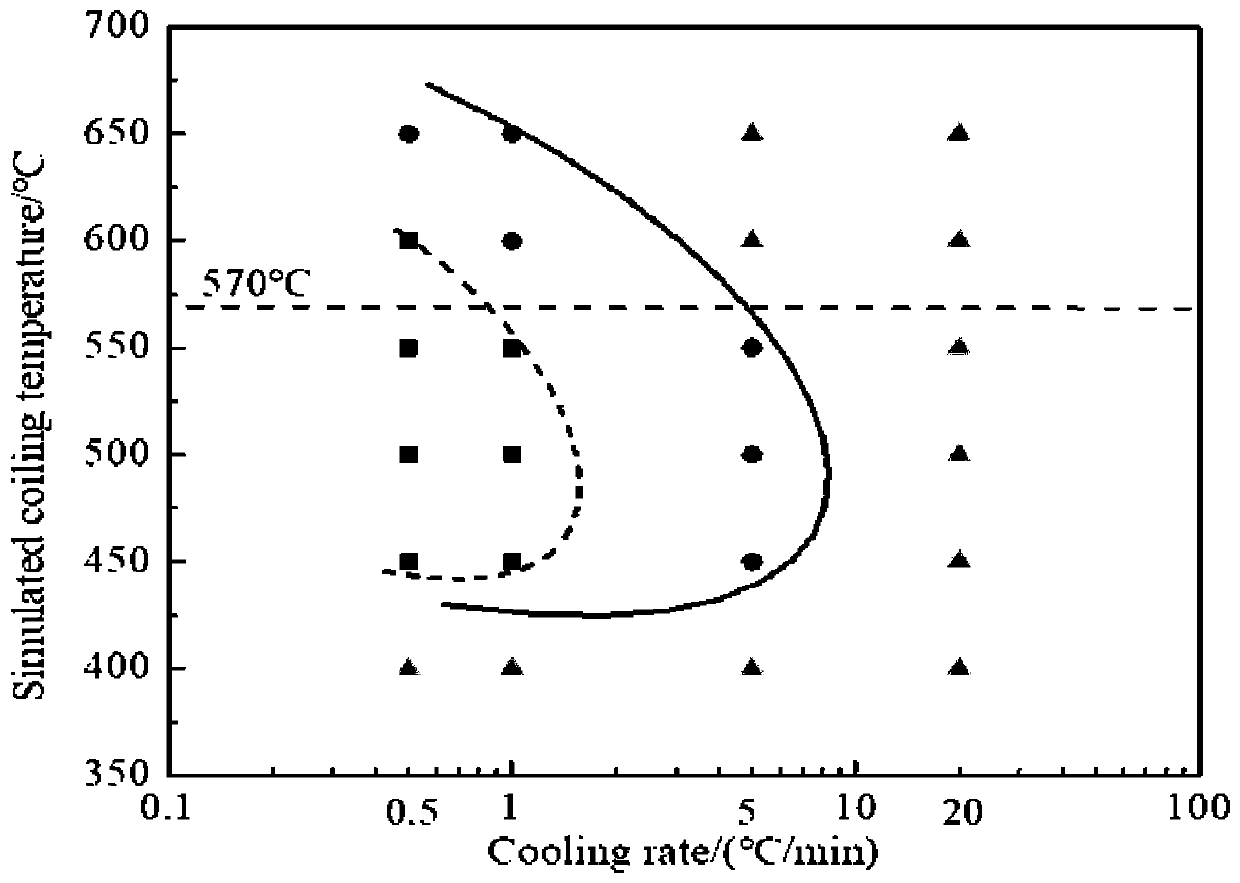

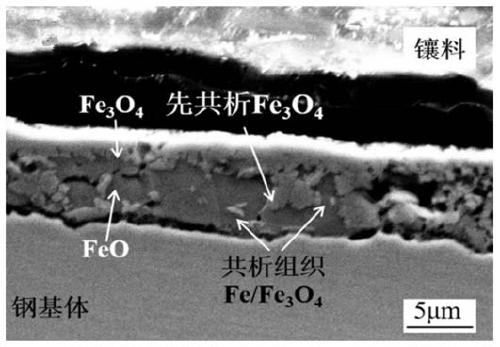

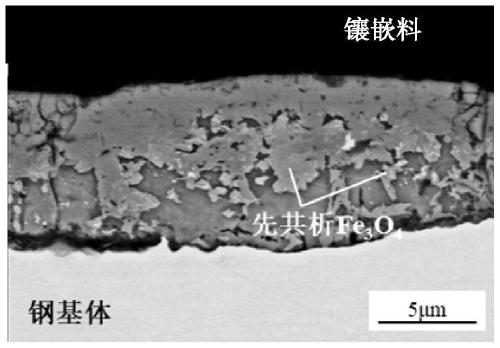

Automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and preparation method of automobile beam steel plate

The invention relates to an automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and a preparation method of the automobile beam steel plate. The steel plate comprises, by mass, 0.03 to 0.12% of C, 0.05 to 0.60% of Si, 0.2 to 1.0% of Cr, 1.0 to 2.5% of Mn, not greater than 0.015% of S, not greater than 0.025% of P, 0.015 to 0.045% of Als, 0.07 to 0.15% of Ti, 0.02 to0.08% of Nb, and the balance being Fe and impurities that are unavoidable during smelting. During preparation, a steel billet adopting the above chemical composition proportion is subjected to reasonable process design, so as to prevent the pickling preparation process from replacing the original process, reduce the thickness of the scale, and obtain the scale complex structure of Fe3O4, FeO and eutectoid Fe3O4 coexisting with alpha-Fe, so that the surface quality of the steel plate is significantly improved, and the requirements of the use of pickling-free direct stamping or roll forming andeliminate the pickling process can be met, production efficiency is improved, environmental pollution is reduced and production cost is reduced.

Owner:NORTHEASTERN UNIV

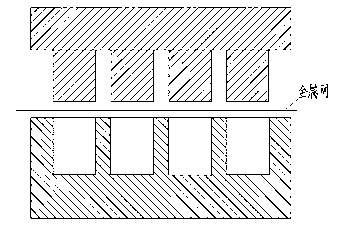

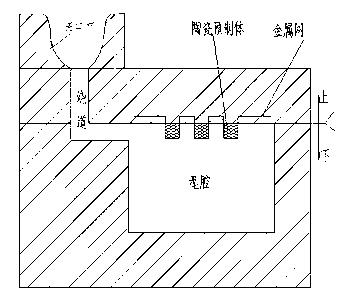

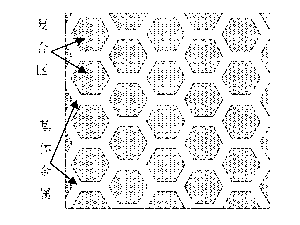

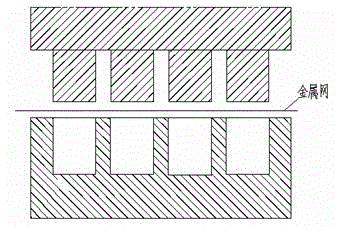

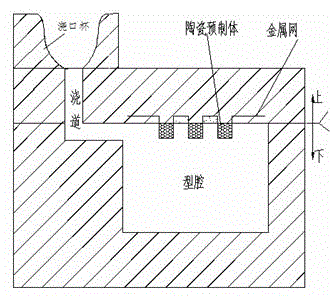

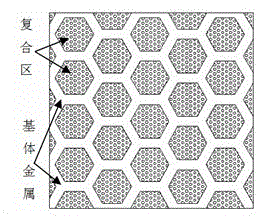

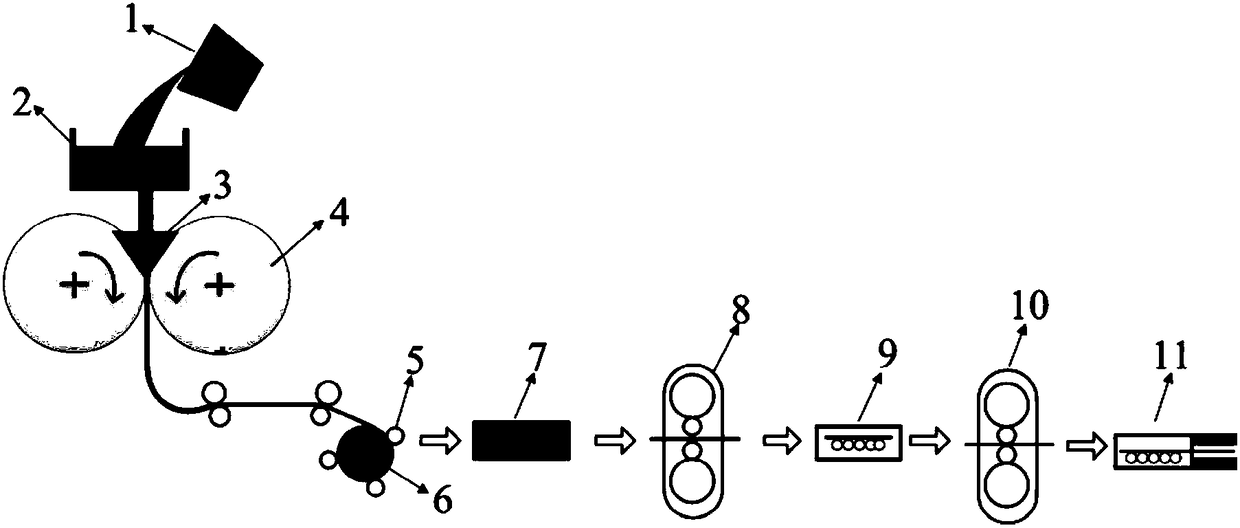

Preparation method of quincuncial pile network distribution ceramic/metal composite material

ActiveCN103343301ALow requirements for production equipmentSimple production processMetal meshShadow effect

The invention relates to a preparation method of a quincuncial pile network distribution ceramic / metal composite material, and belongs to the technical field of metal-based composite material. A plurality of grooves are formed in a metal mesh through pressing. Then, ceramic particles are filled in the grooves of the metal mesh, and a sand casting mould is prepared according to the shape of the quincuncial pile network distribution ceramic / metal composite material to be prepared. The metal mesh filled with the ceramic particles is arranged on the upper surface of the mould cavity of the sand casting mould. Then a smelt metal substrate is poured in the sand casting mould. After the metal substrate is cooled, the metal substrate is stripped from the sand casting mould, and then the product is obtained. The preparation method can be used for effectively solving the problem on manufacturing a prefabricated body of ceramic particles and ensuring the uniform distribution of the ceramic particles in the metal substrate. All recombination regions are not connected with one another, and also can play a role of macroscopical shadow effect so as to strengthen the abrasion resistance, so that the abrasion of the metal substrate can be avoided, and the falling problem of a surface composite material can be solved effectively.

Owner:KUNMING UNIV OF SCI & TECH

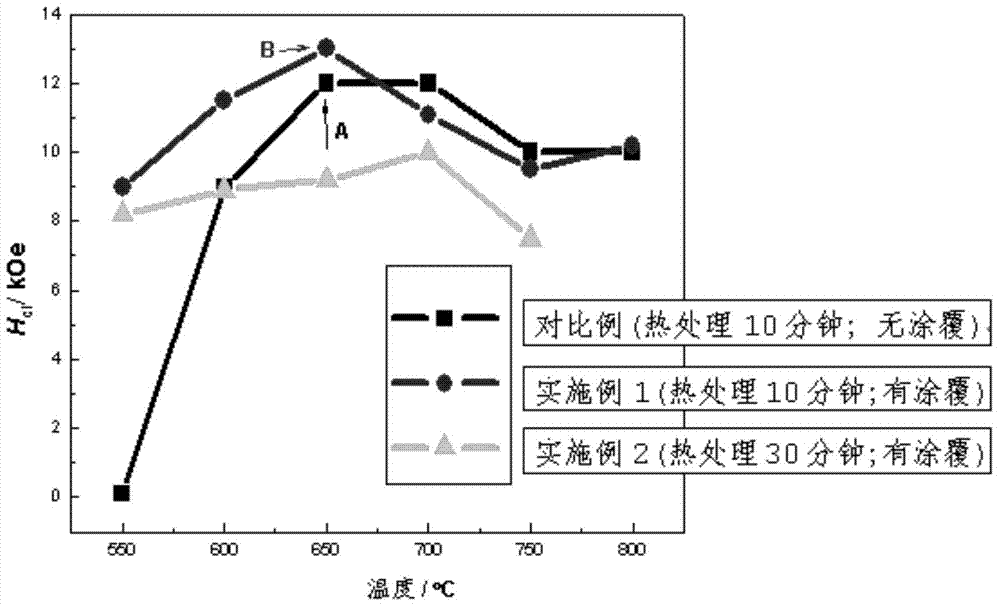

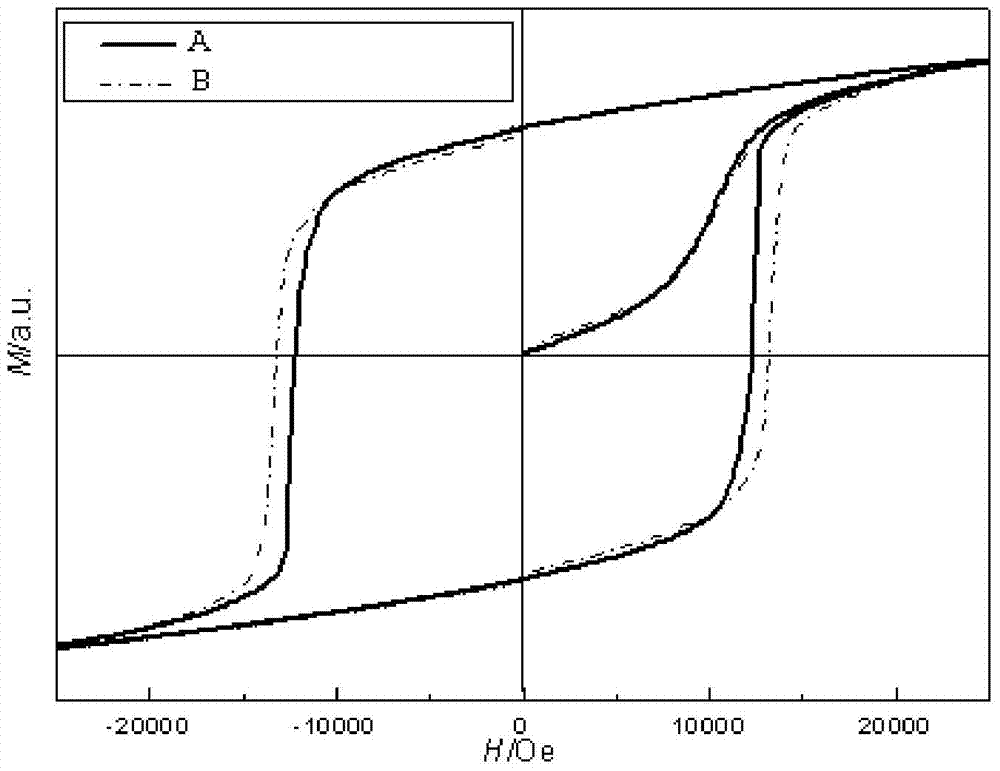

Method for improving coercive force of neodymium iron boron quick-quenching nanocrystalline magnetic powder

ActiveCN104707990AWeaken the exchange coupling effectImprove coercive forceMagnetic materialsAlloySolvent

The invention provides a method for improving coercive force of neodymium iron boron quick-quenching nanocrystalline magnetic powder. The method comprises the following steps that a, powder suspension liquid with low-melting-point alloy is prepared, and the weight ratio of the powder to a solvent is 1:1 to 1:10; b, the neodymium iron boron quick-quenching nanocrystalline magnetic powder prepared through a common method and the suspension liquid are mixed to be fully stirred, the powder in the suspension liquid evenly covers the particle periphery of the neodymium iron boron quick-quenching nanocrystalline magnetic powder, and the neodymium iron boron quick-quenching nanocrystalline magnetic powder is filtered out and dried in a vacuum manner; c, under the vacuum or atmosphere condition, heat treatment is carried out on the neodymium iron boron quick-quenching nanocrystalline magnetic powder treated in the step b, and the heat treatment is carried out for 5 minutes to 30 minutes at the temperature of 500 DEG C to 800 DEG C; and d, water quenching or oil quenching rapid cooling treatment is carried out on the neodymium iron boron quick-quenching nanocrystalline magnetic powder obtained after heat treatment. Through the method, the coercive force of the obtained magnetic powder is improved, and magnetizing becomes easy.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Martensitic steel strip and manufacturing method thereof

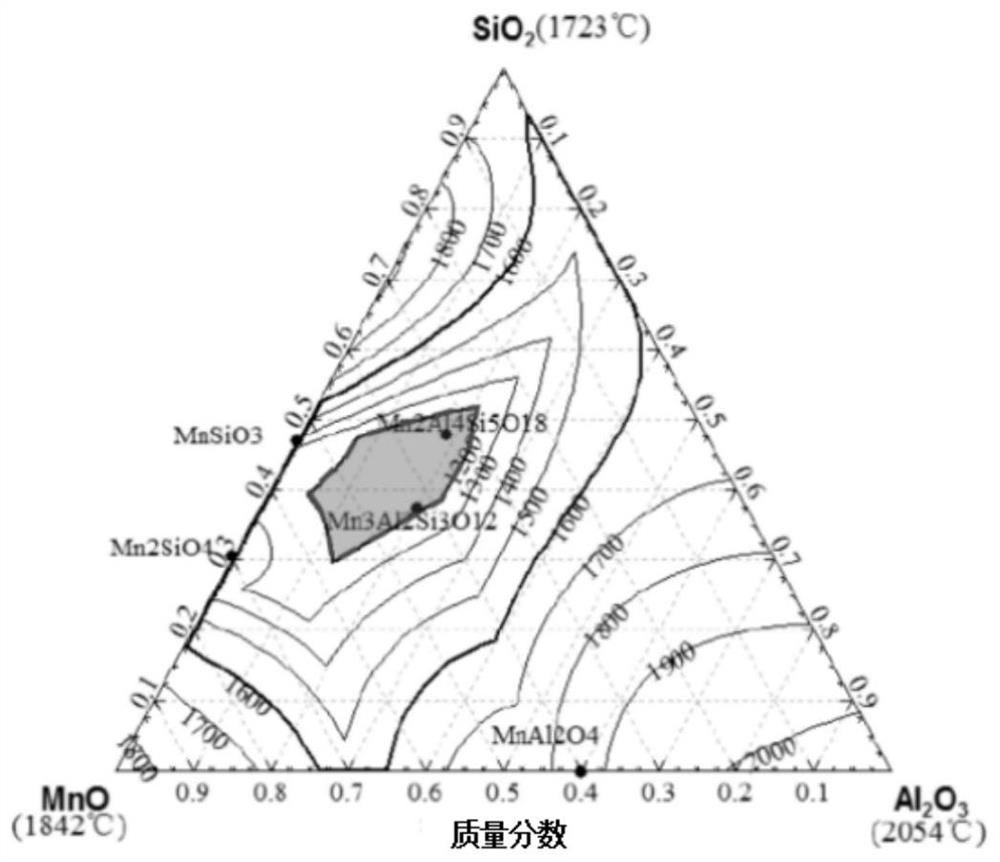

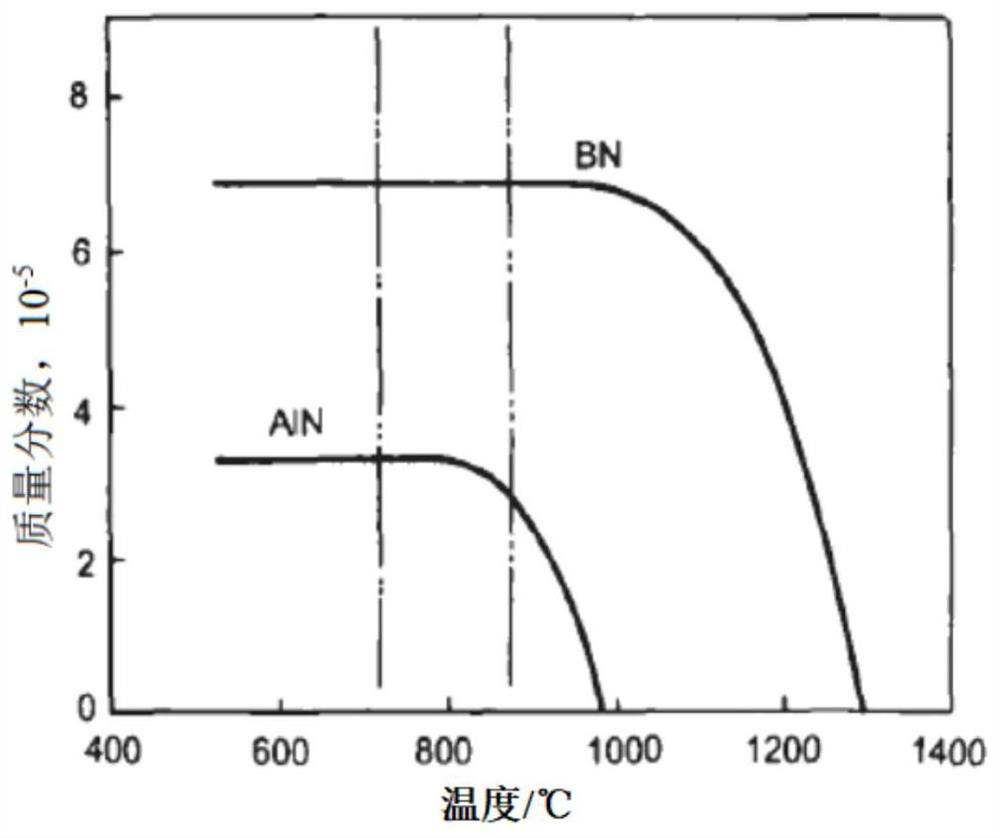

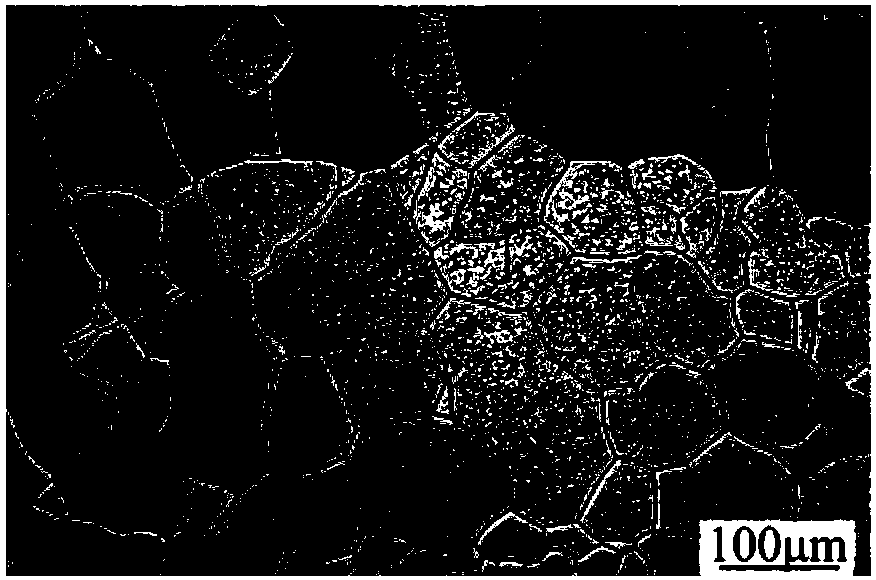

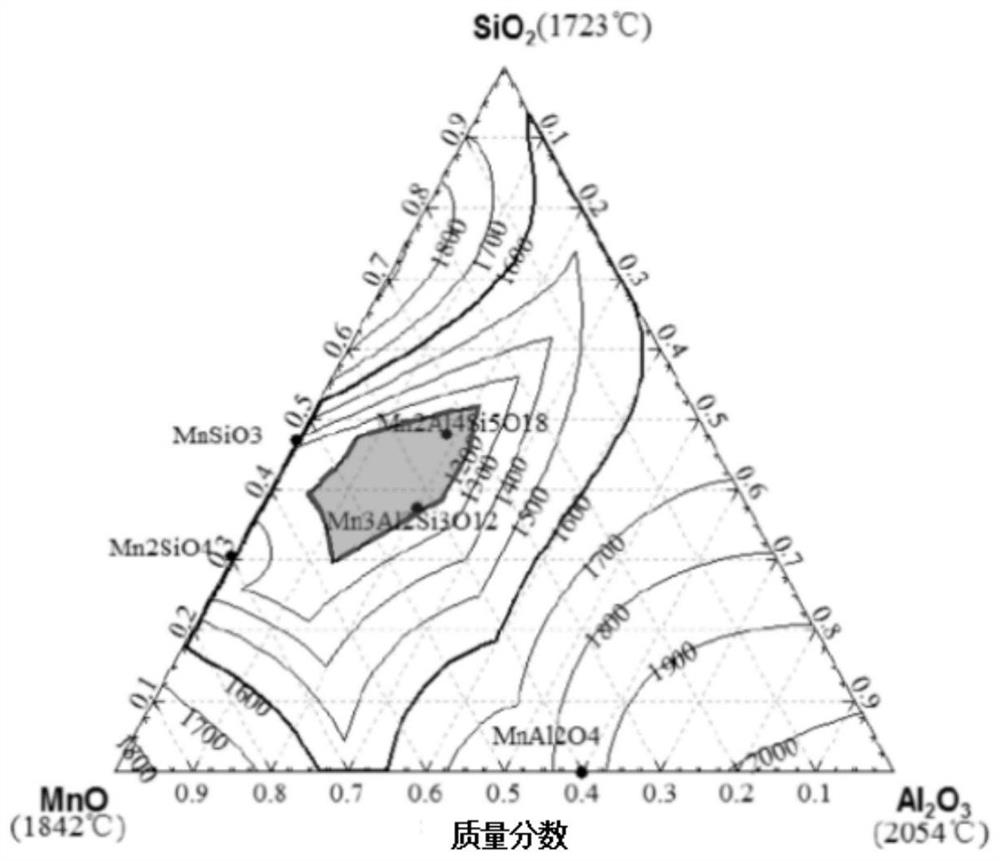

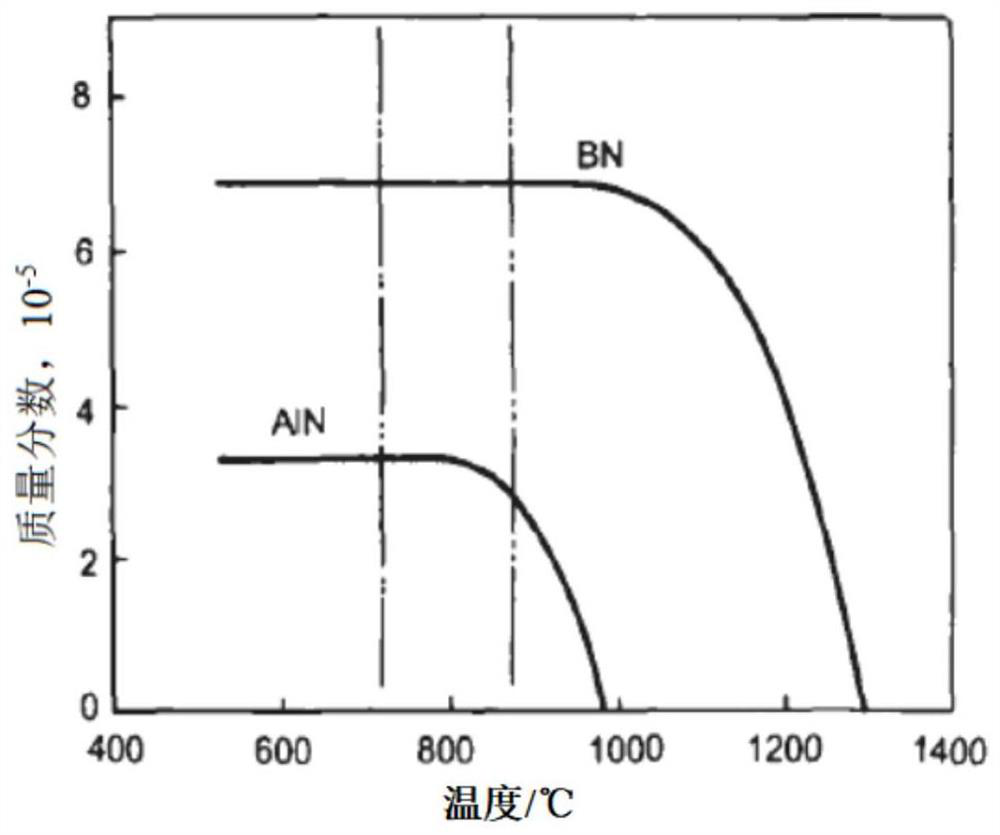

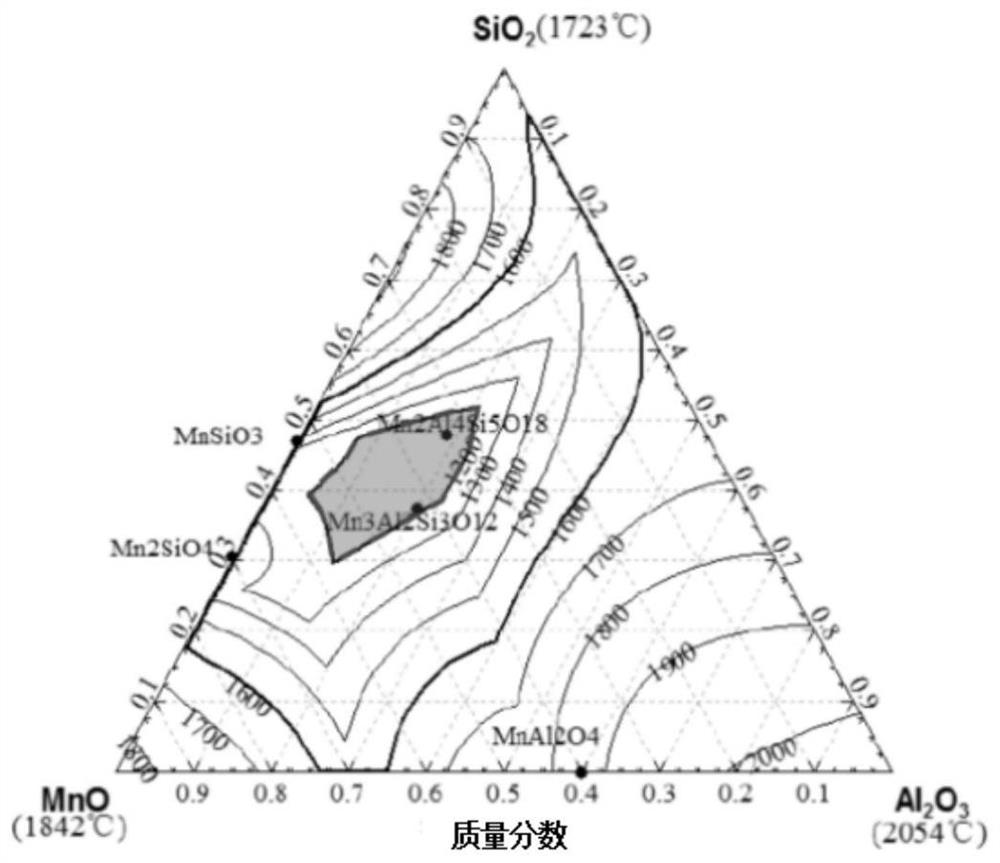

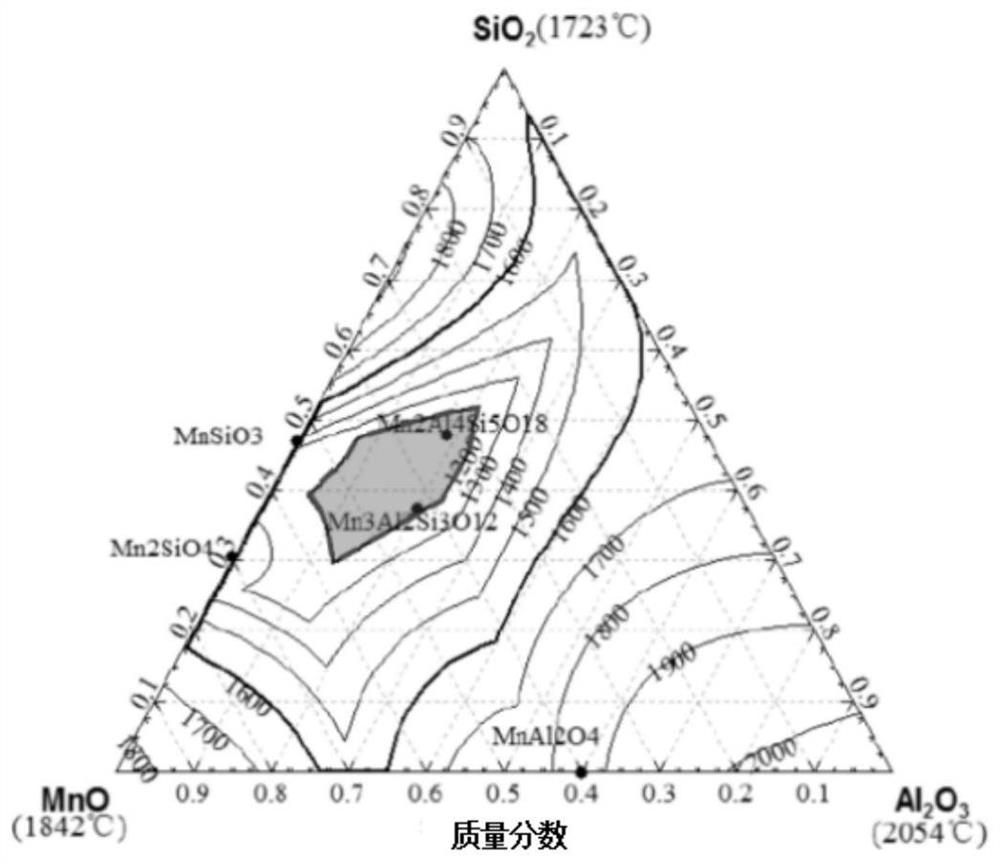

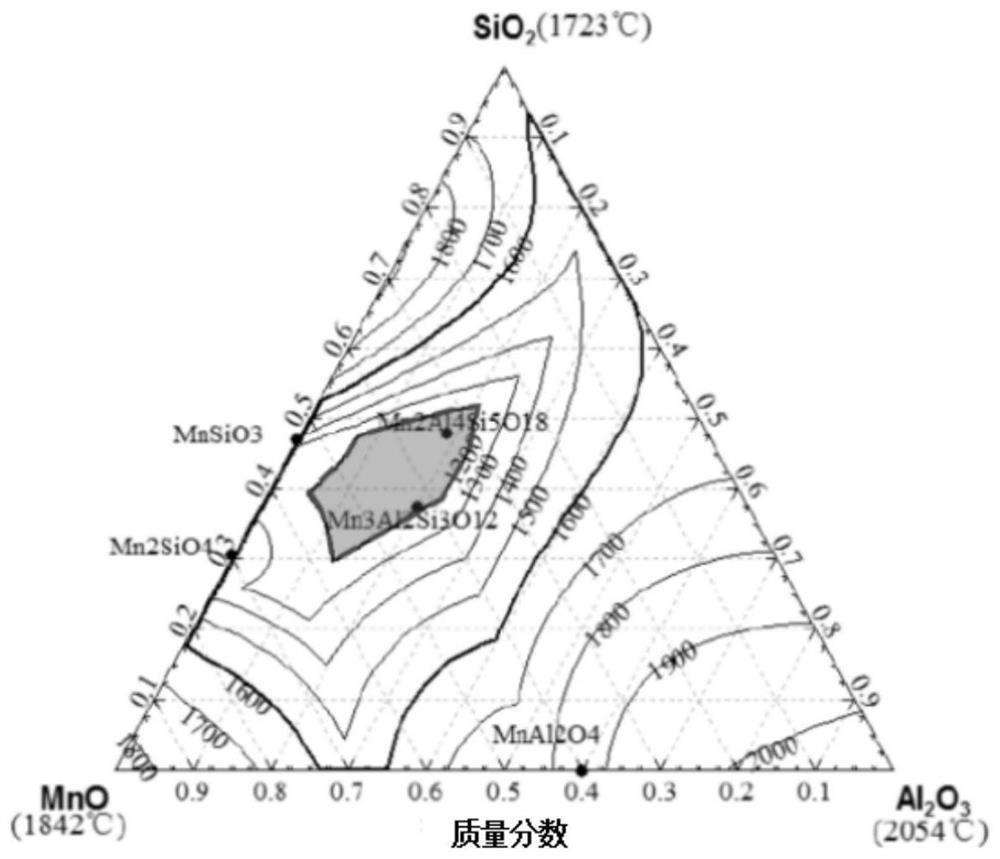

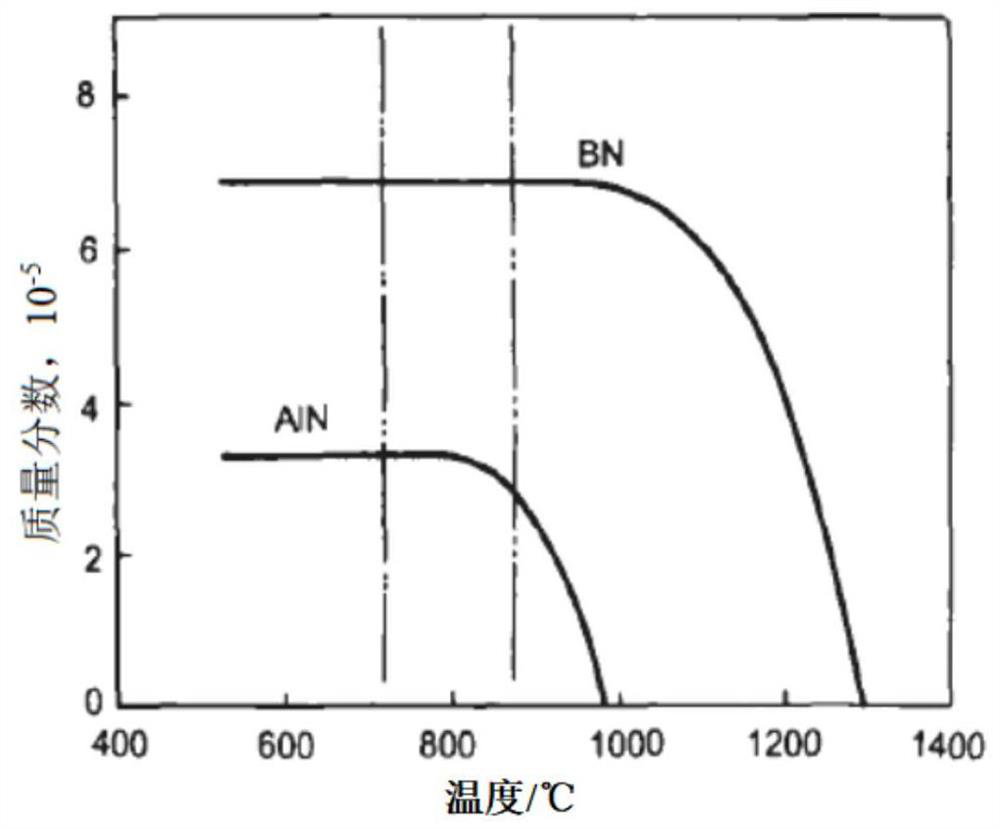

The invention discloses a martensitic steel strip and a manufacturing method thereof. The martensitic steel strip is prepared from the components in percentage by weight: 0.16-0.26% of C, 0.1-0.5% ofSi, 0.4-1.7% of Mn, less than or equal to 0.02% of P, less than or equal to 0.007% of S, 0.004-0.010% of N, less than 0.001% of Als, 0.001-0.006% of B, 0.007-0.020% of total oxygen [O]< T>, and the balance of Fe and inevitable impurities; the conditions that Mn / S is greater than 250, and one or two of 0.01-0.08% of Nb or 0.1-0.4% of Mo are included need to be met at the same time. Nb, Mo and B elements are selectively added; the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in the smelting process. According to the martensitic steel strip and the manufacturing method thereof, the yield strength of the martensitic steel strip is 700-1200 MPa, tensile strength is 1000-1800 MPa, elongation is 3-12%, the martensitic steel strip can be widely applied to the field of high-strength automobile steel, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

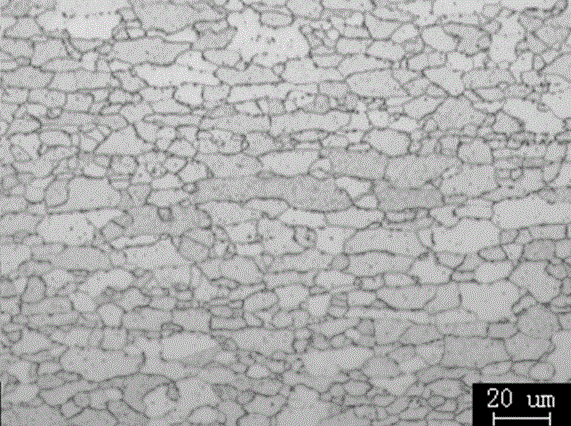

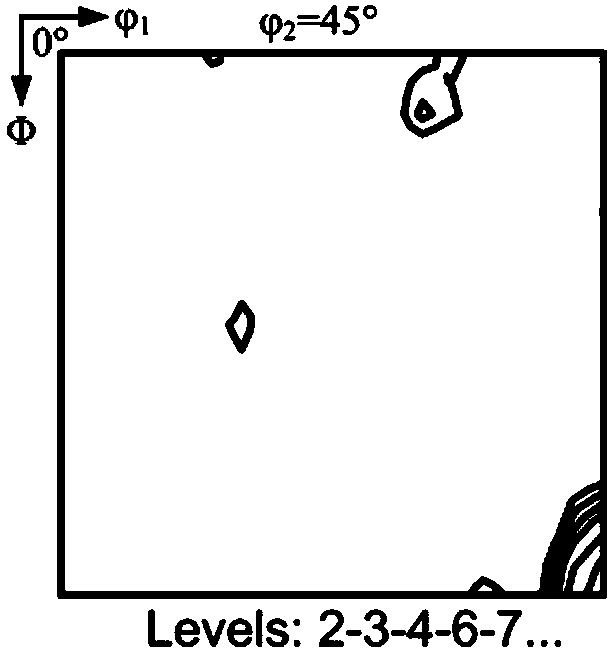

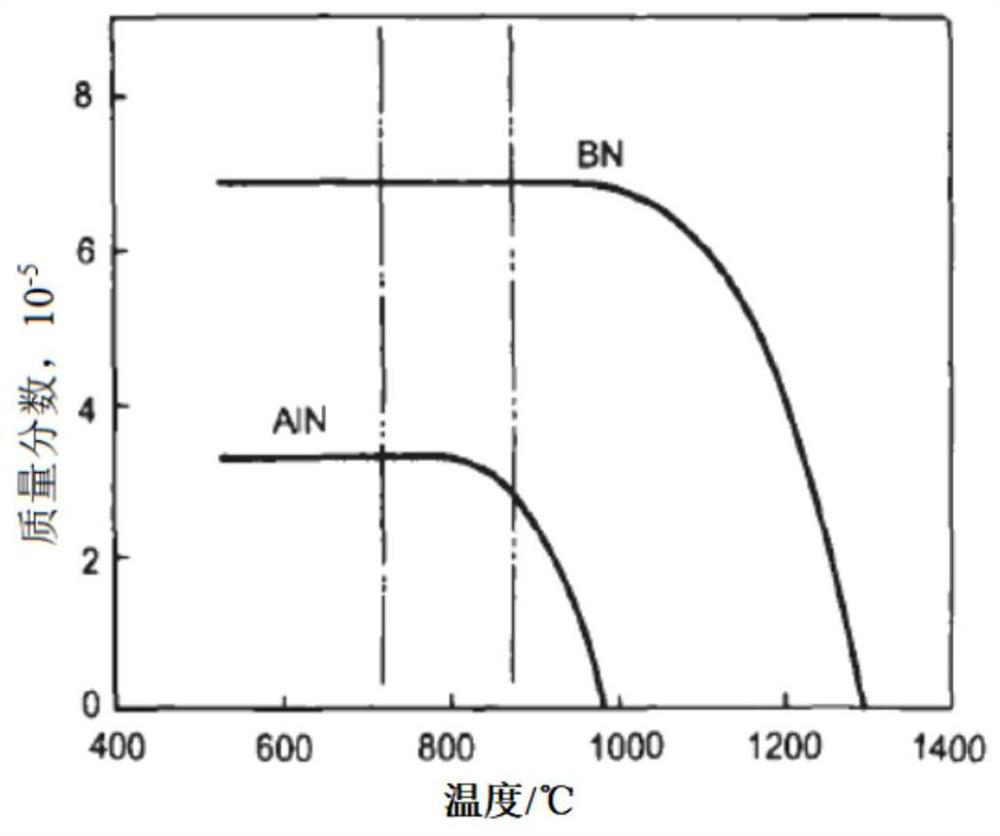

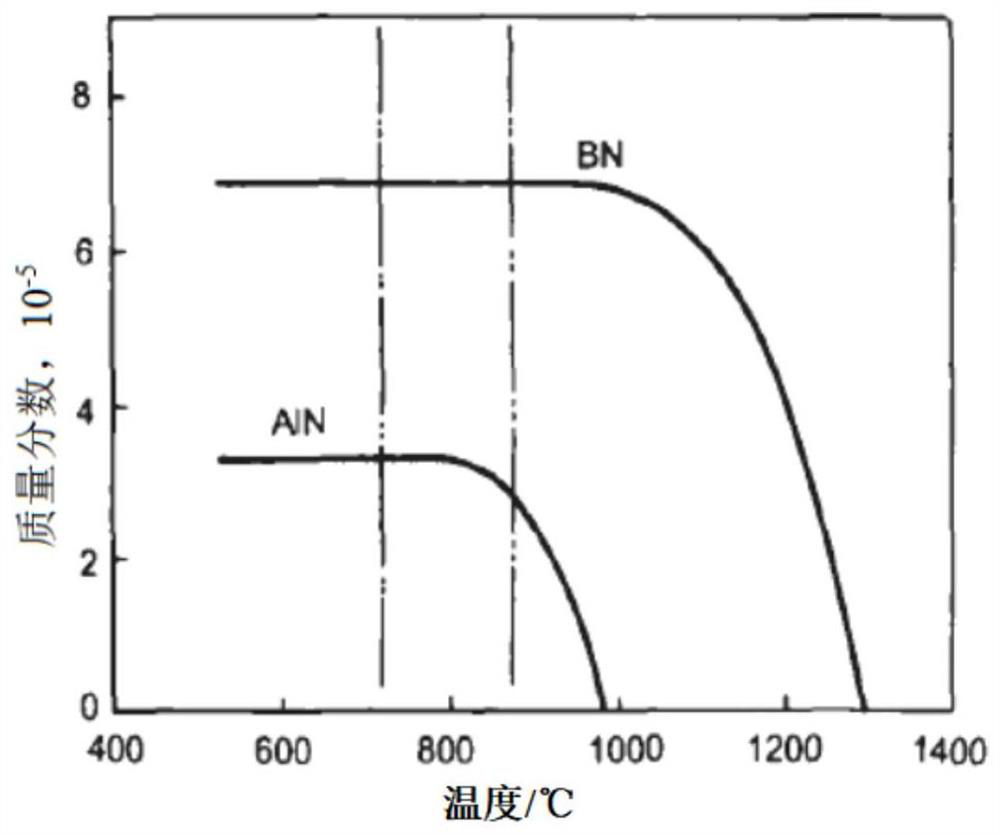

Preparation method of high grade non-oriented silicon steel based on thin-strip casting

The invention belongs to the technical field of metallurgy, and particularly relates to a preparation method of high grade non-oriented silicon steel based on thin-strip casting. The high grade non-oriented silicon steel is prepared from the following chemical components in percentage by weight: less than or equal to 0.004 percent of C, 2.6 to 3.4 percent of Si, 0.1 to 0.4 percent of Mn, 0.4 to 0.8 percent of Al, less than or equal to 0.003 percent of S, less than or equal to 0.003 percent of N and the balance of Fe. The preparation method comprises the following steps: preparing smelted molten steel into a casting strip of 2 to 3 mm through a thin-strip casting machine, and directly rolling at 1000 to 1150 DEG C after 8 to 15 percent of hot rolling; then keeping warm for 10 to 20 minutesat 1000 to 1100 DEG C; carrying out acid pickling and warm rolling, wherein the warm rolling temperature is 200 to 500 DEG C, and the rolling reduction is 70 to 85 percent; carrying out annealing andcoating treatment on a plate coil which is subjected to the warm rolling, thus preparing a non-oriented silicon steel sheet. According to the preparation method disclosed by the invention, the technology is simple, energy consumption and equipment investment are reduced, and meanwhile, an induction value of the high grade non-oriented silicon steel can be remarkably increased.

Owner:NORTHEASTERN UNIV

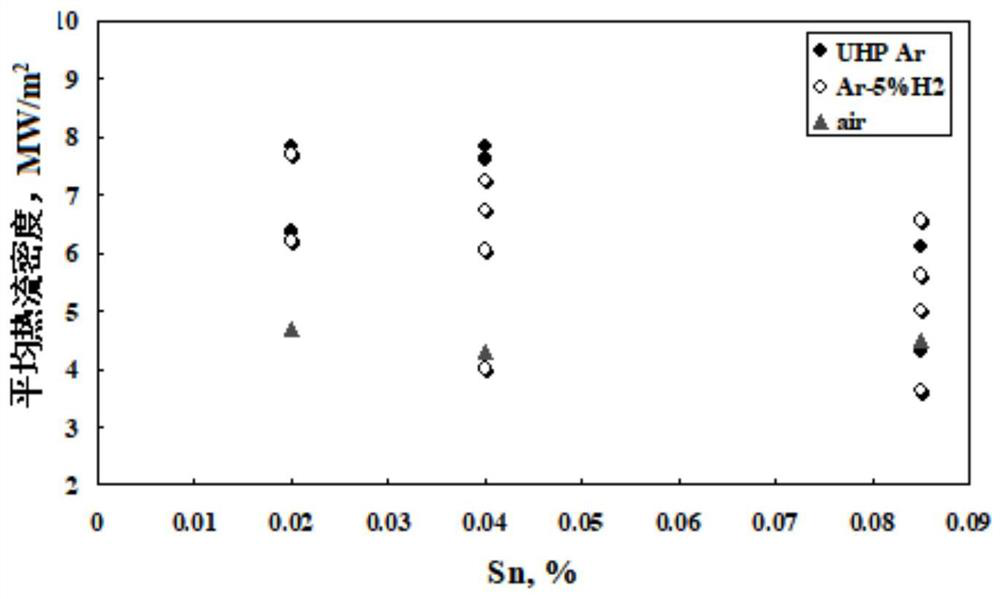

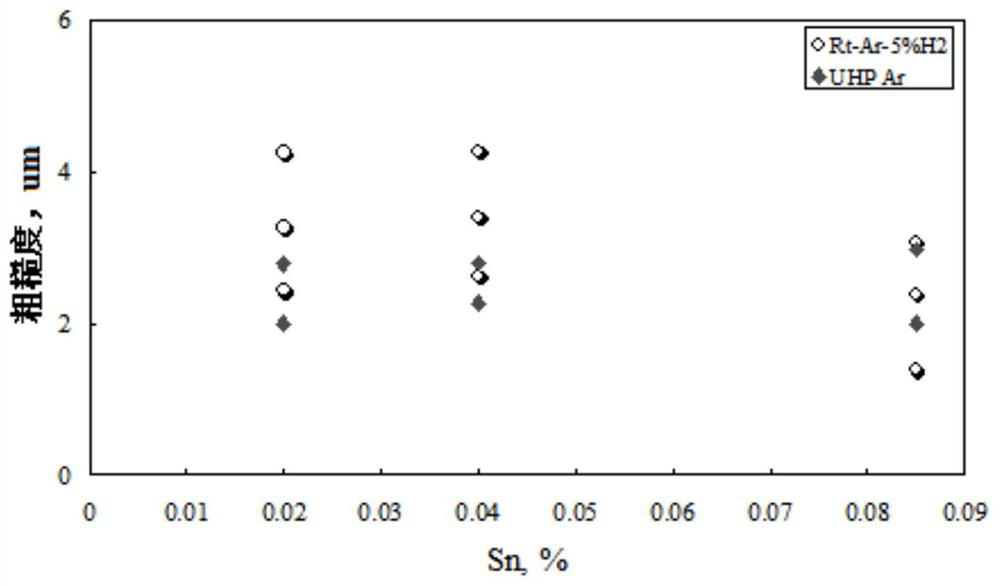

B-containing martensitic steel strip and manufacturing method thereof

The invention relates to a B-containing martensitic steel strip and a manufacturing method thereof. The B-containing martensitic steel strip comprises the following components in percentage by weight:0.16-0.26% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.007% of S, 0.004-0.010% of N, smaller than 0.001% of Als, 0.001-0.006% of B, 0.007-0.020% of total oxygen [O]T, the balance of Fe and inevitable impurities, one or two of 0.1-0.6% of Cu or 0.005-0.04% of Sn, one or two of 0.01-0.08% of Nb and 0.1-0.4% of Mo, and greater than 250 of Mn / S. According to the B-containing martensitic steel strip, residual Sn, Cu and other elements in scrap steel are used for smelting, and Nb / Mo and other microalloy elements and an element B are selectively added. According to the B-containing martensitic steel strip, the yield strength is 800-1200 MPa, the tensile strength is 1100-1900 MPa, the elongation is 3-12%, the martensitic steel strip can bewidely applied to the field of high-strength automotive steel, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-gauge riffled plate/strip and manufacturing method thereof

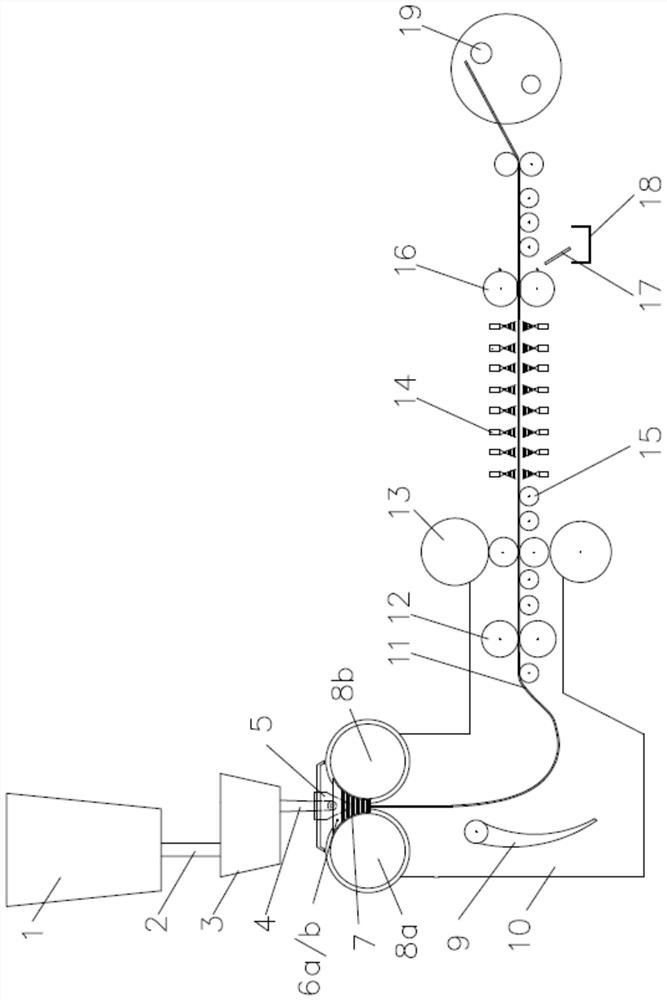

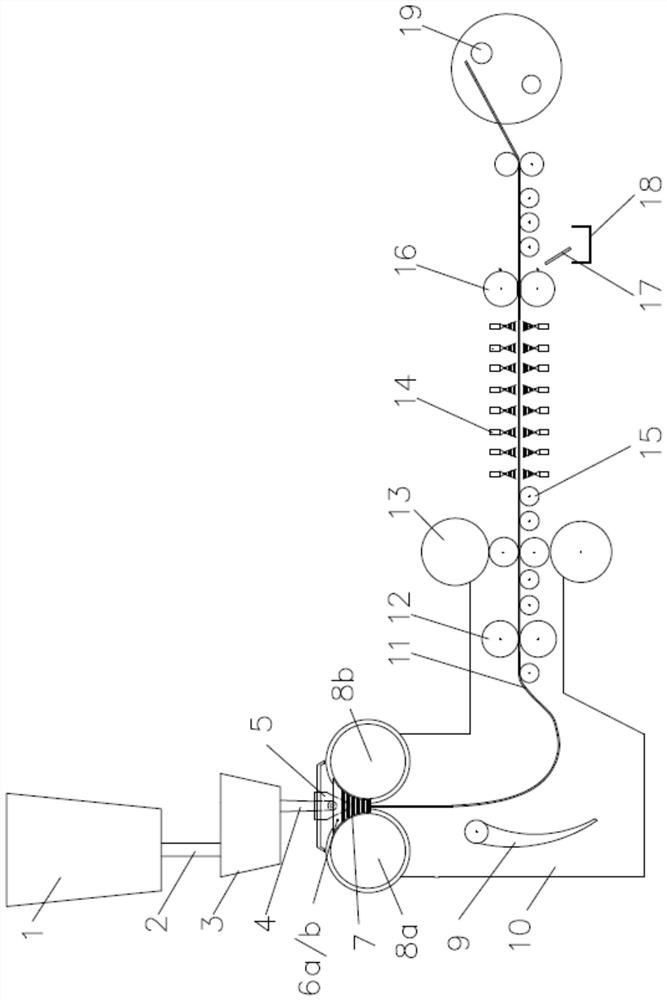

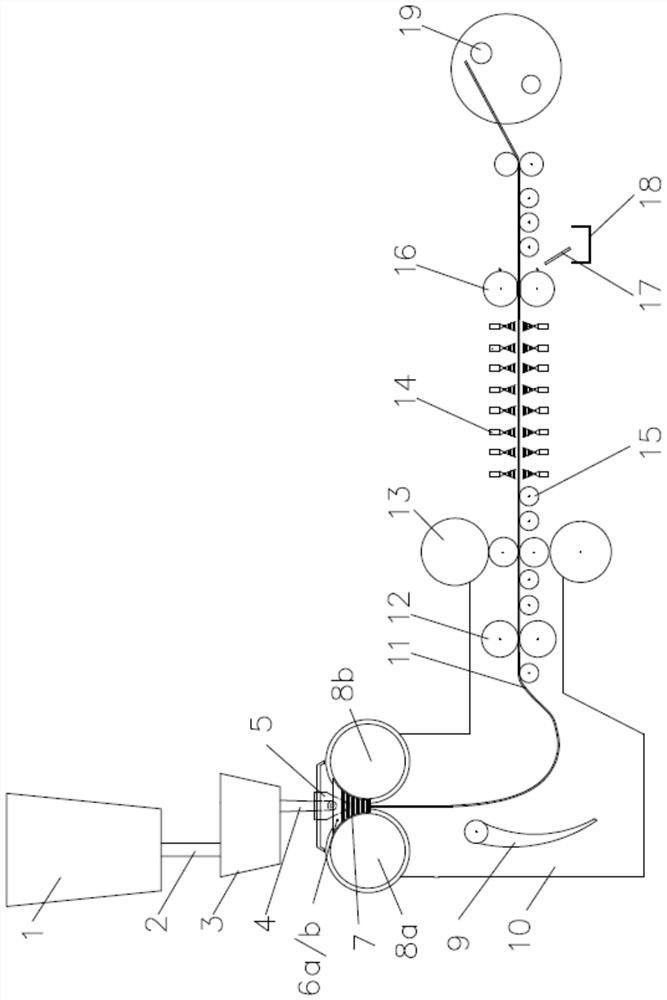

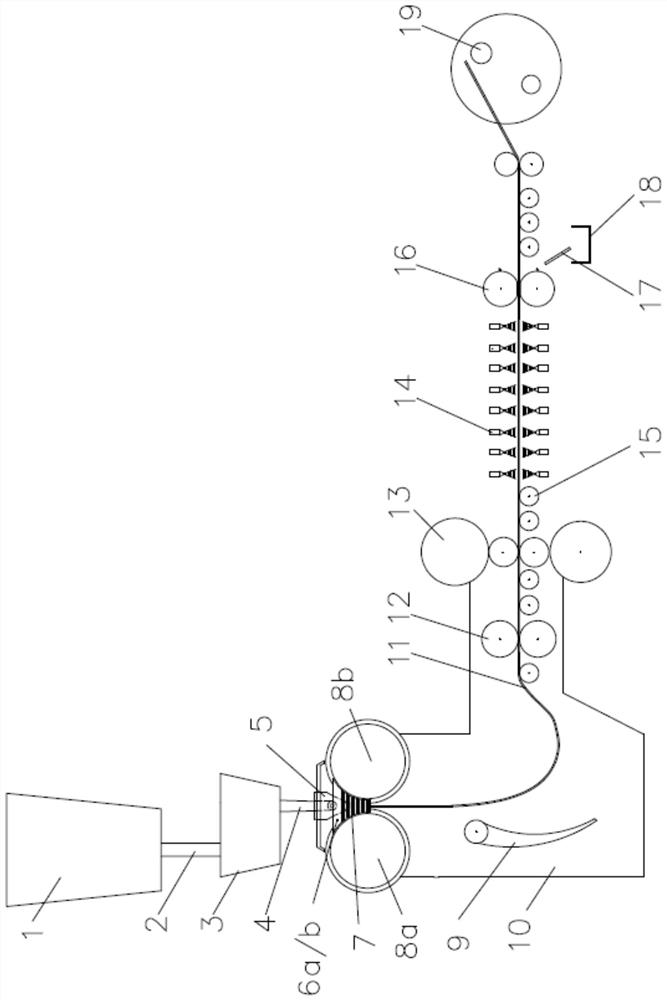

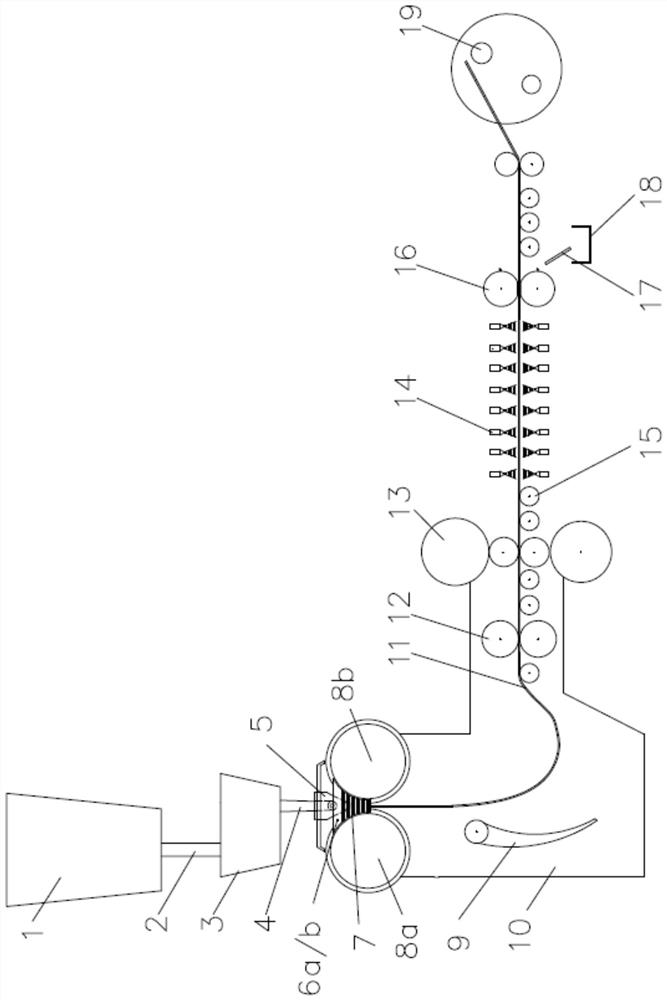

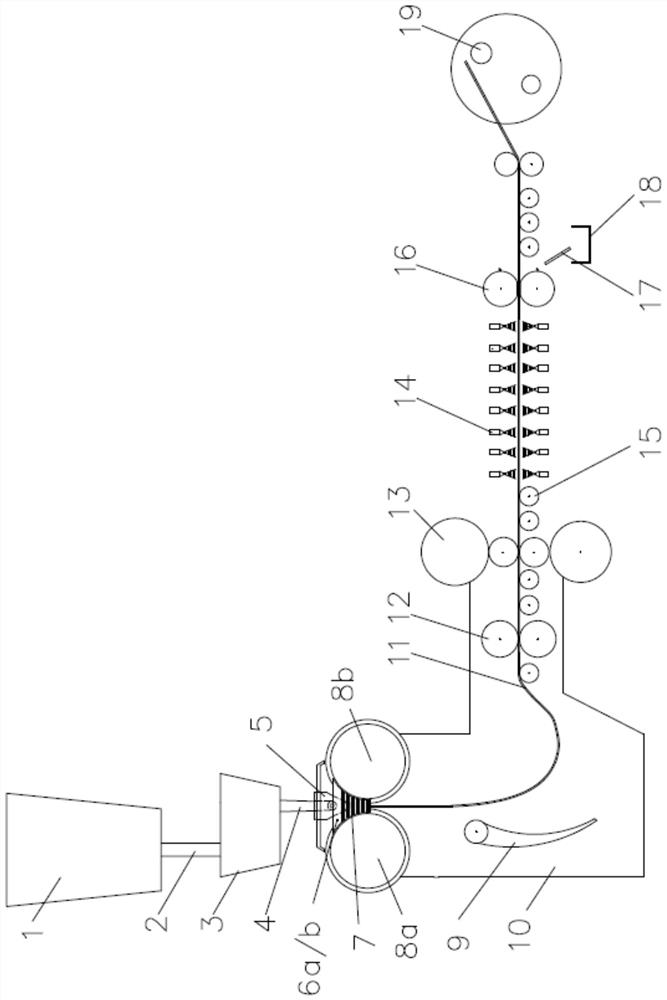

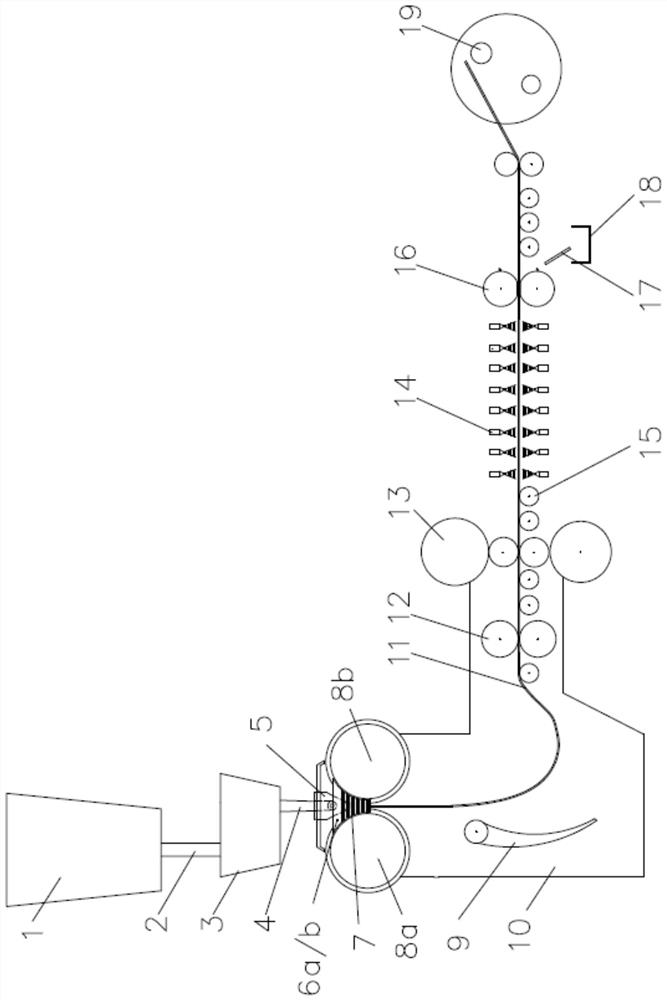

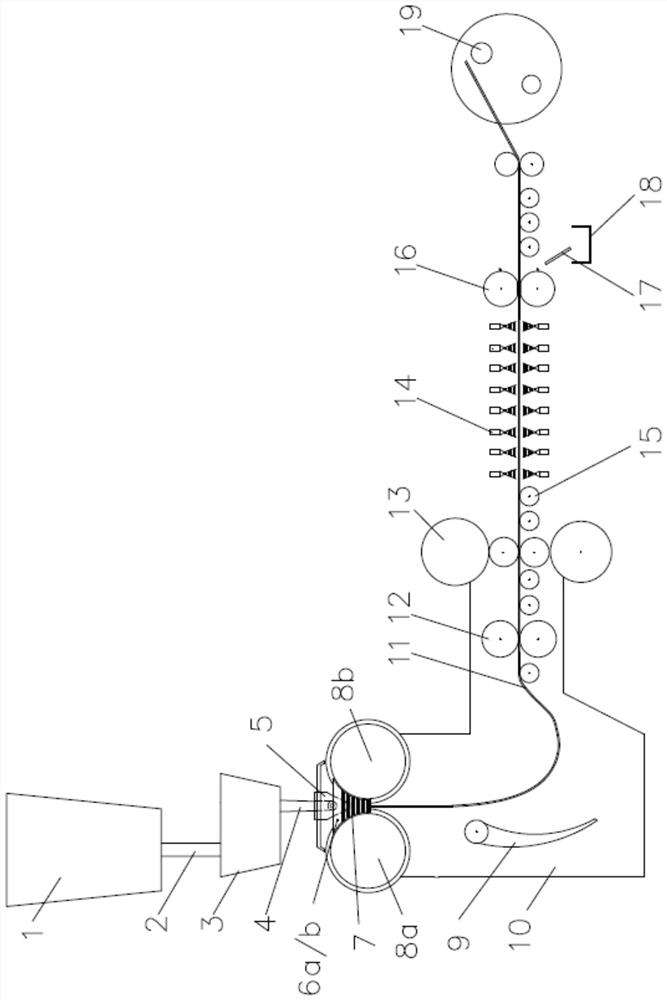

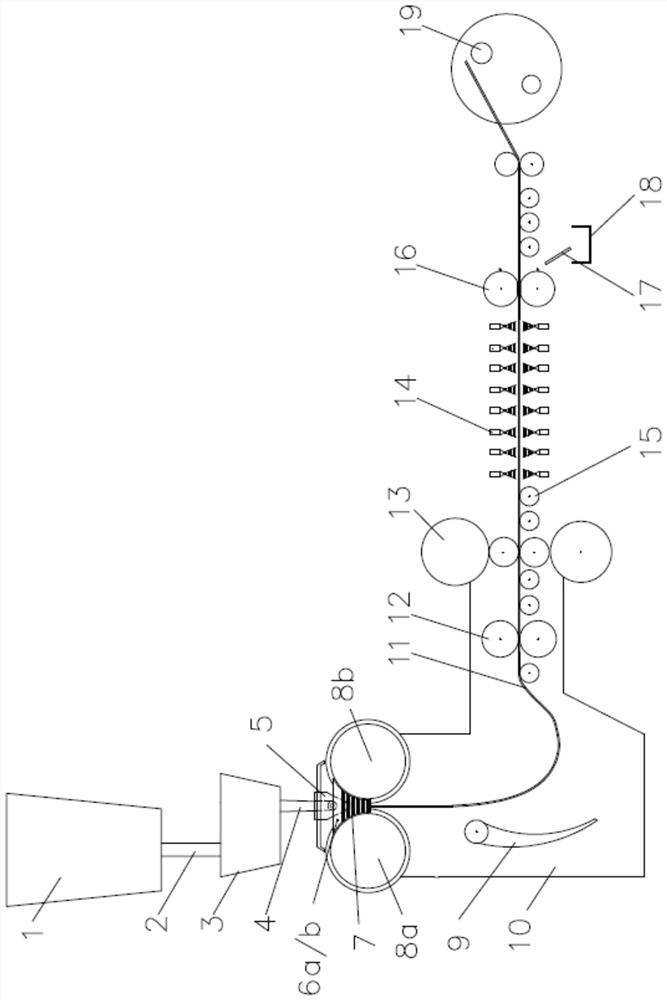

ActiveCN112522566AShort production processImprove efficiencyFurnace typesWork cooling devicesSmelting processMachine building

The invention discloses a thin-gauge riffled plate / strip and a manufacturing method thereof. Microalloy elements such as B are selectively added into steel; the alkalinity of slag, the type and melting point of inclusions in the steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in the smelting process; then, double-roller thin-strip continuous casting is carried out to cast strip steel with the thickness of 1.5-3 mm, and the strip steel directly enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of crystallization rollers and enters an online rolling mill under the closed condition to be subjected to hot rolling; and the rolled strip steel is cooled by adopting a gas atomization cooling mode,and the gas atomization cooling mode can effectively reduce the thickness of surface scale of the strip steel, improve the temperature uniformity of the strip steel and improve the surface quality ofthe strip steel. A finally produced steel coil can be directly used as a hot-rolled riffled plate / strip, can also be used as a finished riffled plate / strip after being trimmed and leveled, and can bewidely applied to the fields of buildings, machine manufacturing, automobiles, bridges, traffic, shipbuilding and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Boron-containing high-reaming steel and production method thereof

The invention discloses boron-containing high-reaming steel and a production method thereof. The steel comprises the following chemical components of, in percentage by weight, 0.01%-0.05% of C, 0.2%-0.6% of Si, 0.8%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, less than 0.001% of Als, less than or equal to 0.0050% of Ca, 0.001%-0.006% of B, 0.007%-0.020% of total oxygen [O]T, Mn / S is large than 250 and the balance Fe and inevitable impurities. According to the steel, microalloy elements such as B are selectively added intothe steel; in a smelting process, the alkalinity of slag, a type and a melting point of an inclusion in steel, a content of free oxygen in molten steel and a content of acid-soluble aluminum Als are controlled; then, double-roller thin strip continuous casting is carried out to cast a cast strip with a thickness of 1.5-3 mm, and the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere and enters an online rolling mill for hot rolling under the closed condition; and after rolling, strip steel is cooled in a gas atomization cooling mode, and a produced steel coil canbe directly used as a hot rolled plate and can also be used after being subjected to acid pickling and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

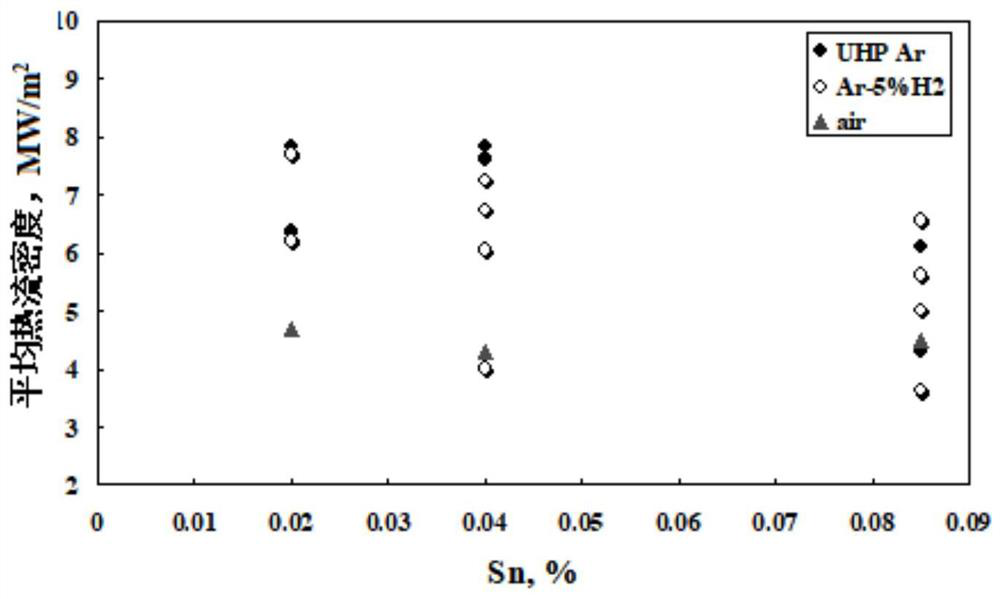

Production method of thin hot-rolled steel plate/strip for sulfuric acid dew point corrosion resistance

ActiveCN112522585AShort production processImprove efficiencyProcess efficiency improvementAir preheaterPetrochemical

The invention relates to a thin hot-rolled steel plate / strip for sulfuric acid dew point corrosion resistance and a production method thereof. Residual Sn, Cu and other elements in scrap steel are used fully to smelt molten steel, and Cr, Ti, Sb and other microalloy elements and B element are selectively added into the steel. The production method comprises the steps of: in a smelting process, controlling the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als; and then casting a cast strip through double-roller thin strip continuous casting, feeding the cast strip into an on-line rolling mill for hot rolling under a closed condition, cooling strip steel in a gas atomization cooling mode after rolling, and finally conducting coiling. The steel disclosed by the invention can be widely applied to the field of products with sulfuric acid dew point corrosion resistance requirements inuse environments such as tobacco baking equipment, air preheater heat exchange elements, conveying pipelines, flues, chimney manufacturing structural parts, boiler preheaters and economizer equipmentin industries of petroleum, chemical engineering, electric power, metallurgy and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

High-corrosion-resistance steel and manufacturing method thereof

The invention discloses high-corrosion-resistance steel and a manufacturing method thereof. The high-corrosion-resistance steel is prepared from the chemical components in percentage by weight: 0.02-0.06% of C, 0.1-0.5% of Si, 0.4-1.7% of Mn, less than or equal to 0.02 % of P, 4.0-6.0% of Cr, 1.0-3.0% of Ni, less than or equal to 0.007% of S, 0.004-0.010 % of N, less than 0.001% of Als, 0.001-0.006% of B, greater than 250 of Mn / S, 0.007-0.020% of total oxygen [O]<T>, and the balance of Fe and inevitable impurities. Alloying elements such as Cr and Ni and an element B are selectively added intoplain carbon steel; the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled in the smelting process; double-roller thin strip continuous casting is adopted for casting a cast strip, the cast strip directly enters a lower closed chamber with a non-oxidizing atmosphere and enters an online rolling mill for hot rolling under a closed condition, and strip steel is cooled in a gas atomization cooling mode after rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

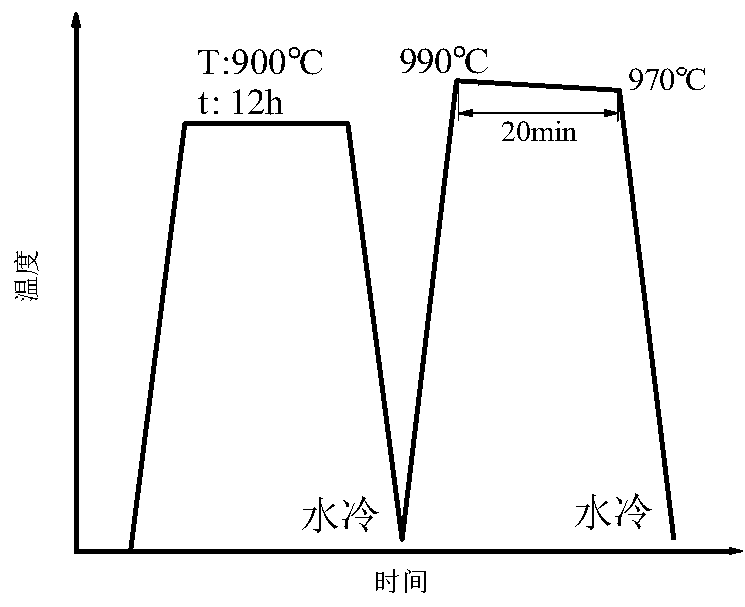

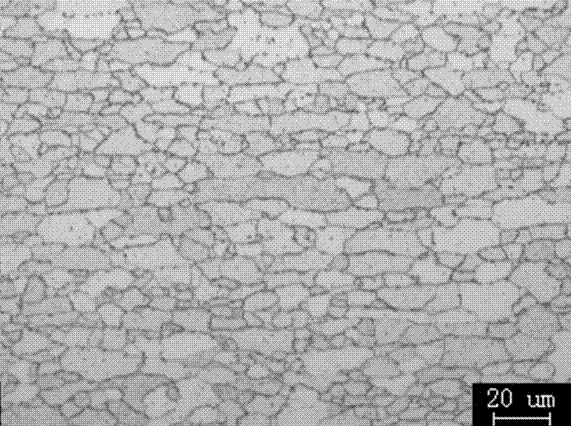

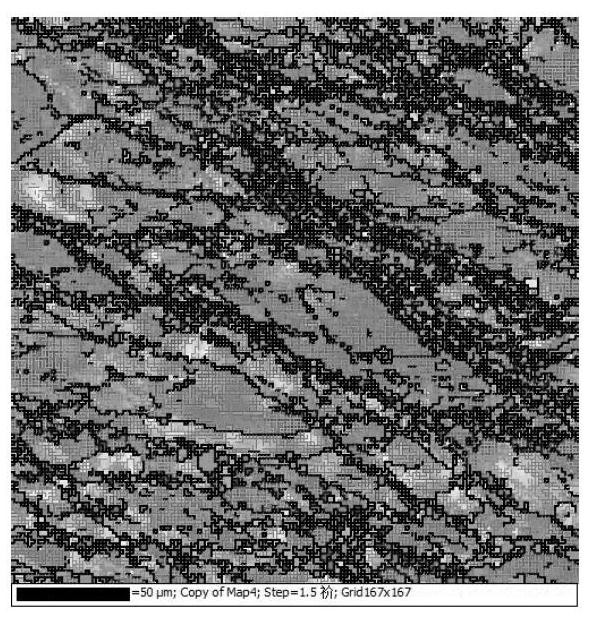

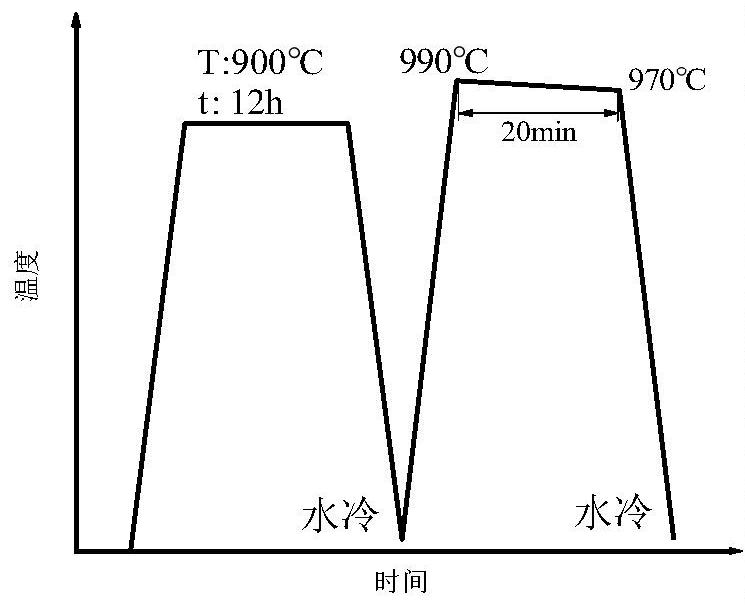

Method for obtaining GH4169 alloy ultra-fine grain forging

The invention discloses a method for obtaining a GH4169 alloy ultra-fine grain forging. The method includes the following steps that (1), a GH4169 forging stock is subjected to solution treatment andaging treatment in sequence, and a uniform structure with a certain quantity of delta phases is obtained; (2), the forging stock obtained after solution treatment and aging treatment is subjected to forging deformation, the deformation temperature is controlled with 950 DEG C-1,010 DEG C, the strain rate is not smaller than 0.05s<-1>, and the equivalent strain is not smaller than 0.35; (3), the obtained forging is subjected to aging treatment again, the aging temperature is controlled within 880 DEG C-920 DEG C, and the aging time is 9 h-24 h; and (4), the forging is subjected to recrystallization heat treatment in a continuous cooling manner, the cooling initial temperature is controlled within 990 DEG C-1,030 DEG C, the cooling rate is 1 DEG C / min-3 DEG C / min, and the cooling final temperature is controlled within 950 DEG C-990 DEG C. By means of the method, the GH4169 alloy ultra-fine grain forging can be obtained, and an effective way is provided for manufacturing high-quality forgings.

Owner:CENT SOUTH UNIV

Ultrasonic-enhanced magnetic powder core compression molding method and compressed powder magnetic core

PendingCN113871179APromote sportsFacilitate rearrangementInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingInitial permeability

The invention discloses an ultrasonic-enhanced magnetic powder core compression molding method and a compressed powder magnetic core. The invention discloses an ultrasonic enhanced magnetic powder core compression molding method which comprises the following steps: placing soft magnetic powder (coated) in ultrasonic compression molding equipment, setting the ultrasonic frequency to be 15-60kHz and the vibration amplitude to be 70-90%, and simultaneously starting a pneumatic system to pressurize, wherein the pressure is 0.3-0.9 MPa, the compression time is 0.1-10s and the dwell time is 3-5s, and completing the compression molding of a magnetic powder core. The method / process has the advantages of being small in required pressure, short in completion time, high in powder forming density, simple and efficient. The invention further discloses the magnetic powder core prepared by the ultrasonic enhanced magnetic powder core compression molding method, the magnetic powder core has high saturation flux density, low iron loss and high initial magnetic conductivity, and the magnetic conductivity of the magnetic powder core shows good high-frequency stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Boron-containing high-strength high-reaming steel and manufacturing method thereof

The invention relates to boron-containing high-strength high-reaming steel and a manufacturing method thereof. The boron-containing high-strength high-reaming steel is prepared from the chemical components in percentage by weight: 0.01-0.05% of C, 0.2-0.6% of Si, 0.8-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, less than 0.001%of Als, less than or equal to 0.0050% of Ca, 0.001-0.006% of B, 0.01-0.08% of Nb, 0.007%-0.020% of total oxygen [O]<T>, and the balance of Fe and other inevitable impurities. Nb, B and other microalloy elements are selectively added into the steel; the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-solublealuminum Als are controlled in the smelting process; then a cast strip is casted through double-roller thin strip continuous casting, directly enters a lower closed chamber with a non-oxidizing atmosphere, and enters an online rolling mill for hot rolling under a closed condition; rolled strip steel is cooled in a gas atomization cooling mode, and a produced steel coil can be directly used as a hot rolled plate and can also be used after being subjected to acid pickling and leveling.

Owner:BAOSHAN IRON & STEEL CO LTD

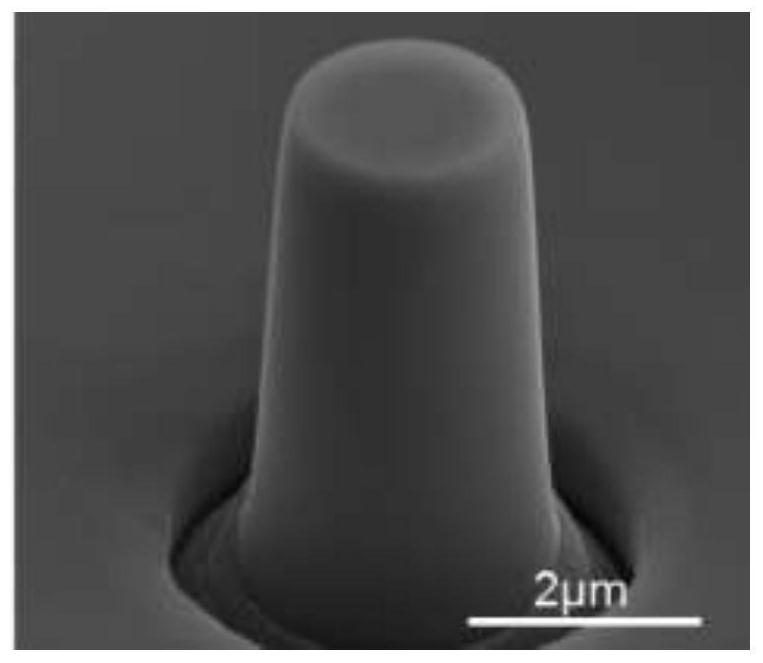

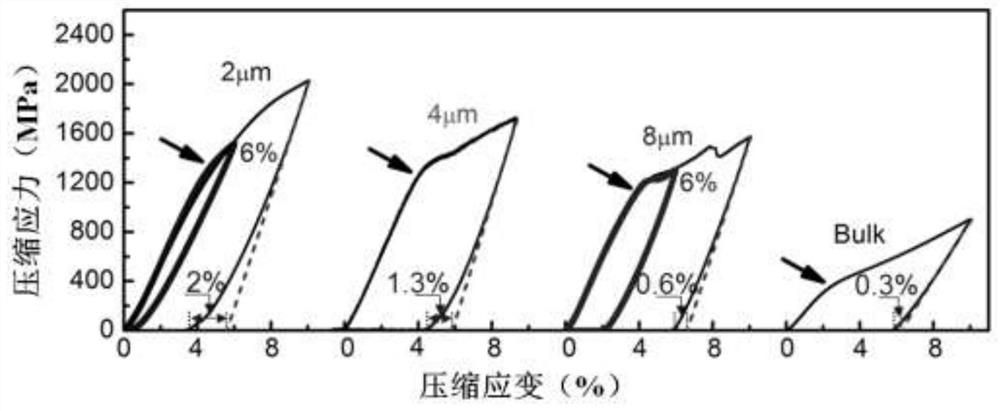

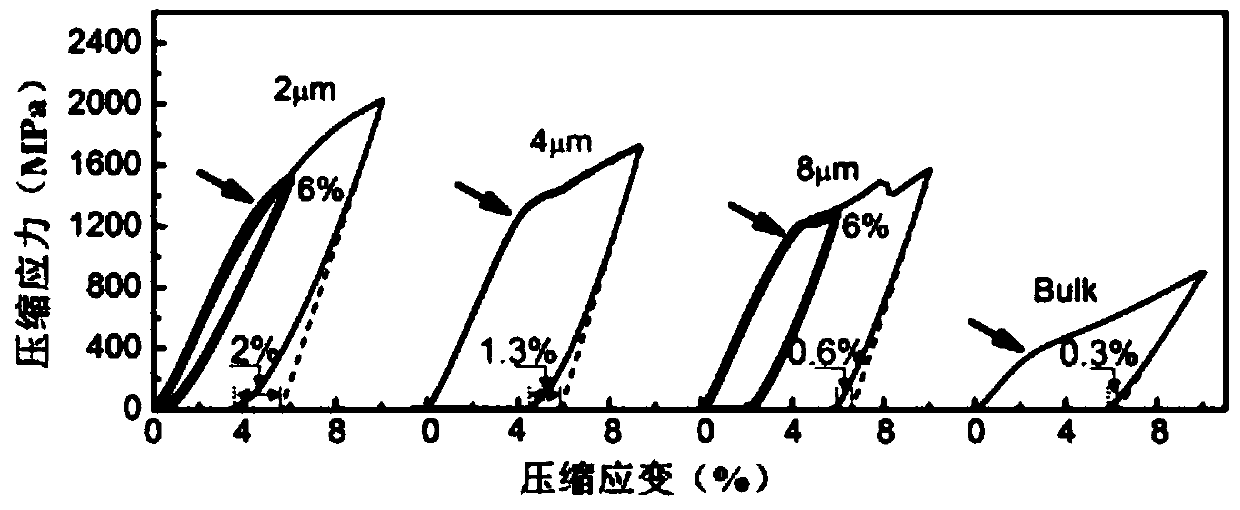

A method to improve the superelasticity of β titanium alloy

ActiveCN110541133BGood superelasticityConducive to inverse phase transitionMartensite transformationUltimate tensile strength

The invention discloses a method for improving the superelasticity of β-titanium alloy, which includes: selecting a bulk β-titanium alloy with shape memory effect as a sample, and determining the martensitic phase transformation favorable amount according to the martensitic phase transformation strain amount of the sample. Orientation; electropolishing the sample; marking the surface of the treated sample; testing and analyzing the treated sample to obtain the grain orientation distribution map of the sample; The trace mark and the grain orientation distribution map of the sample can be used to determine the position of the grain that is conducive to the martensitic transformation; the inside of the grain that is conducive to the martensitic transformation is processed to obtain a micron-sized cylindrical sample. The size of the sample decreases, the size of the martensite decreases, and the martensite is difficult to form and easy to reverse phase transformation, resulting in superelasticity. At the same time, the size of the sample is reduced, the strength of the material is improved, the opening time of the dislocation is delayed, and the pinning effect of the dislocation on the reverse martensitic transformation is reduced, thereby improving the superelasticity of the β-titanium alloy.

Owner:XIAN UNIV OF TECH

High-wear-resistance aluminum alloy material treatment process

The invention discloses a high-wear-resistance aluminum alloy material treatment process which comprises the following operation steps that a pure aluminum block is added into a boiler for melting, and subjected to impurity removing and deoxidizing; an aluminum alloy material is put into a refining furnace for refining; alloy is added for modulation treatment, and an aluminum alloy melt X is obtained; the aluminum alloy melt X is subjected to argon shield die casting at the temperature of 600 DEG C, and finally subjected to air cooling to the room temperature; and the aluminum alloy melt X iscast through a semi-continuous casting method, water cooling is conducted after casting, and an aluminum alloy casting body Y is obtained. Through the heat treatment process, the cracking risk of thecasting can be greatly reduced on the premise that the mechanical property of the aluminum alloy casting is improved, and the quenching quality of parts is improved, so that the structural hardness ofthe aluminum alloy material can be greatly improved, and the wear resistance of the material is further improved. According to the high-wear-resistance aluminum alloy material treatment process, an aluminum alloy cylinder body is subjected to surface treatment through electrochemistry, and the surface hardness of the aluminum alloy after surface treatment is high.

Owner:江苏信轮美合金发展有限公司

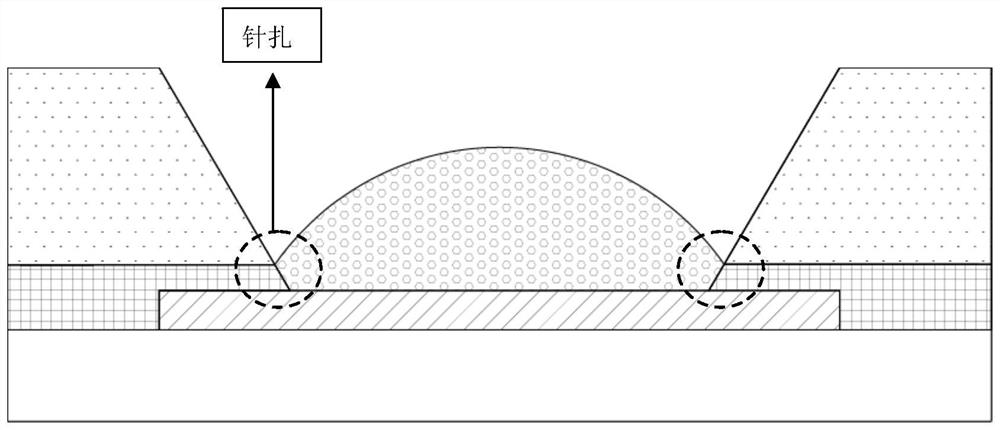

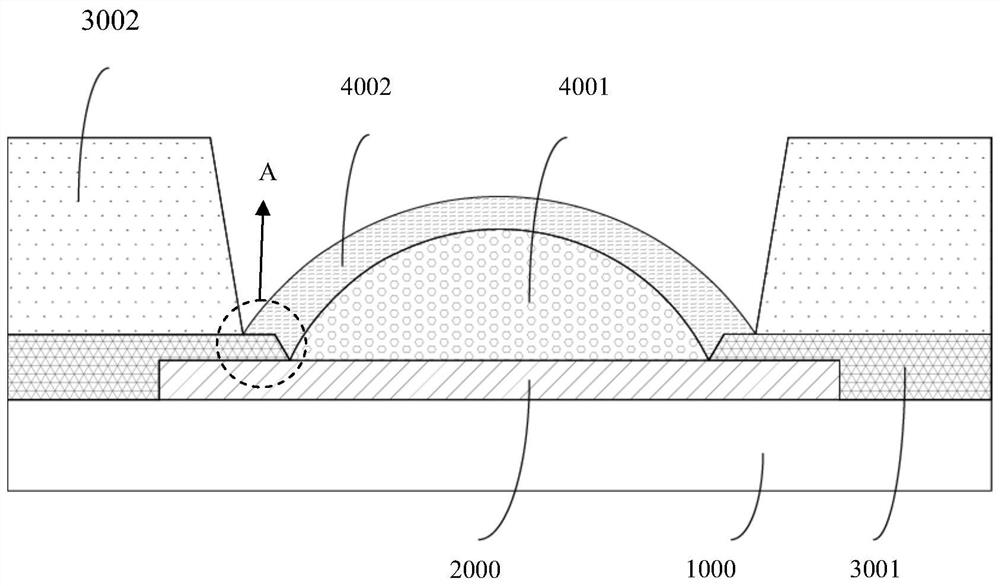

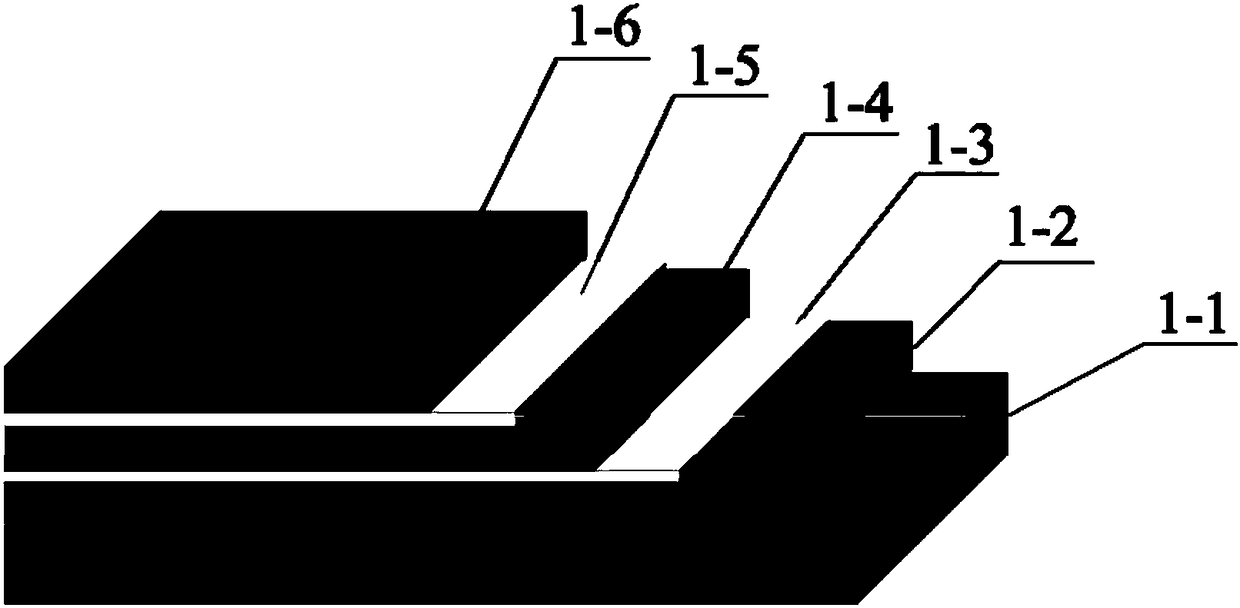

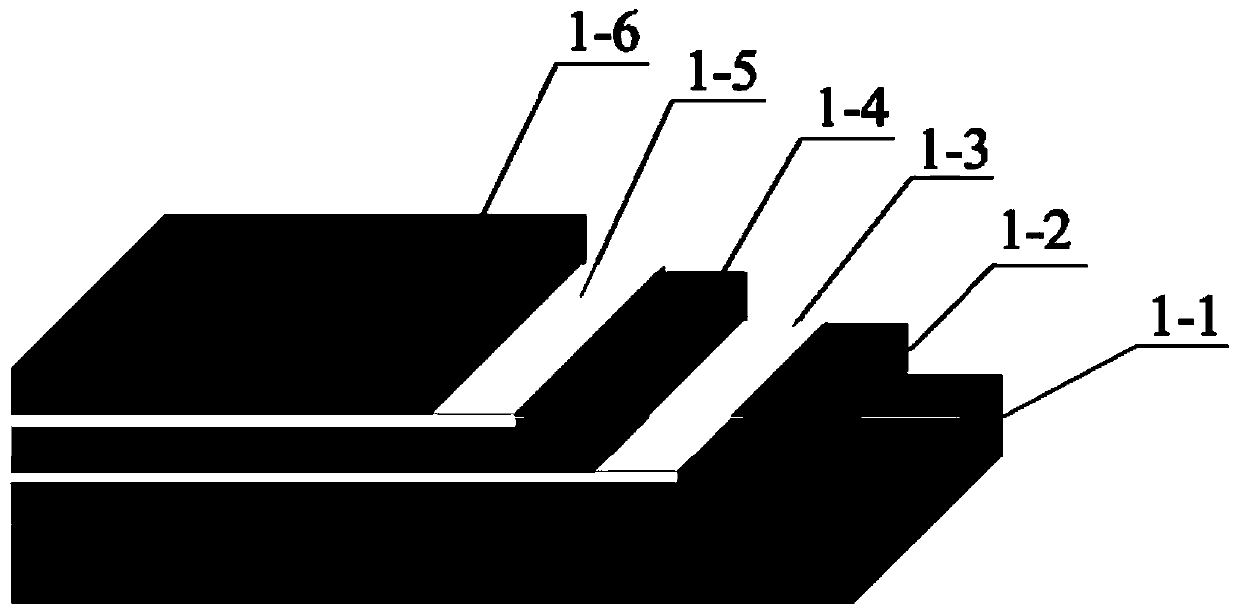

Pixel defining layer and its preparation method and application

ActiveCN107046048BImprove uniformityAvoid short circuitSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionWindow opening

The invention relates to a pixel defining layer and its preparation method and application. The pixel defining layer includes a first pixel defining layer and a second pixel defining layer stacked on the first pixel defining layer; the first pixel defining layer is provided with a plurality of pixels corresponding to the light emitting regions of each sub-pixel unit. a first window opening area, the second pixel defining layer is provided with a second window opening area corresponding to the first window opening area; the area of the second window opening area is larger than that of the first window opening area area, and there is a distance between the edge of the second window opening area and the edge of the first window opening area. The above-mentioned pixel defining layer can avoid the problem of "cathode disconnection", improve the printing resolution, improve the uniformity of the printing film and reduce the leakage current.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Preparation method of quincuncial pile network distribution ceramic/metal composite material

Owner:KUNMING UNIV OF SCI & TECH

High-strength wear-resistant type aluminum alloy material for doors and windows and heat treatment technology thereof

The invention discloses a high-strength wear-resistant type aluminum alloy material for doors and windows and a heat treatment technology thereof. The aluminum alloy material comprises the following raw materials, by weight percentage: 13.5-14.3% of Si, 0.7-0.8% of Fe, 2.6-3.2% of Cu, 0.3-1% of Mn, 0.11-0.29% of Cr, 0.7-1.3% of Zn, 0.31-0.37% of Mg, 0.18-0.22% of Sn, 0.12-0.16% of Ni, 0.14-0.16% of Ti, 0.002-0.004% of B, 0.015-0.025% of Sr and the balance Al. The high-strength wear-resistant type aluminum alloy material for the doors and windows has the advantages of being high in strength, good in oxidation resistance and good in wear resistance. The heat treatment technology has the advantages that the performance of an aluminum alloy can be enhanced, and relatively high use value and agood application prospect can be achieved.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

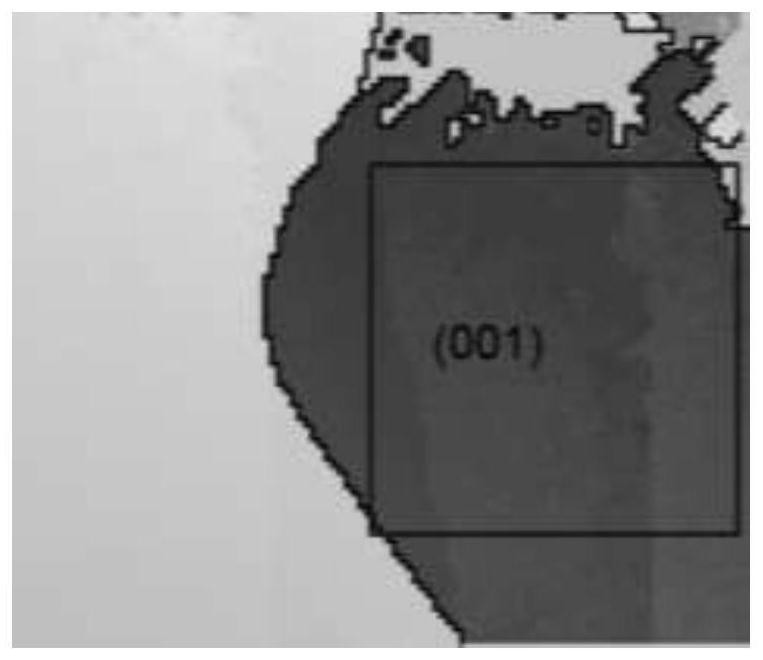

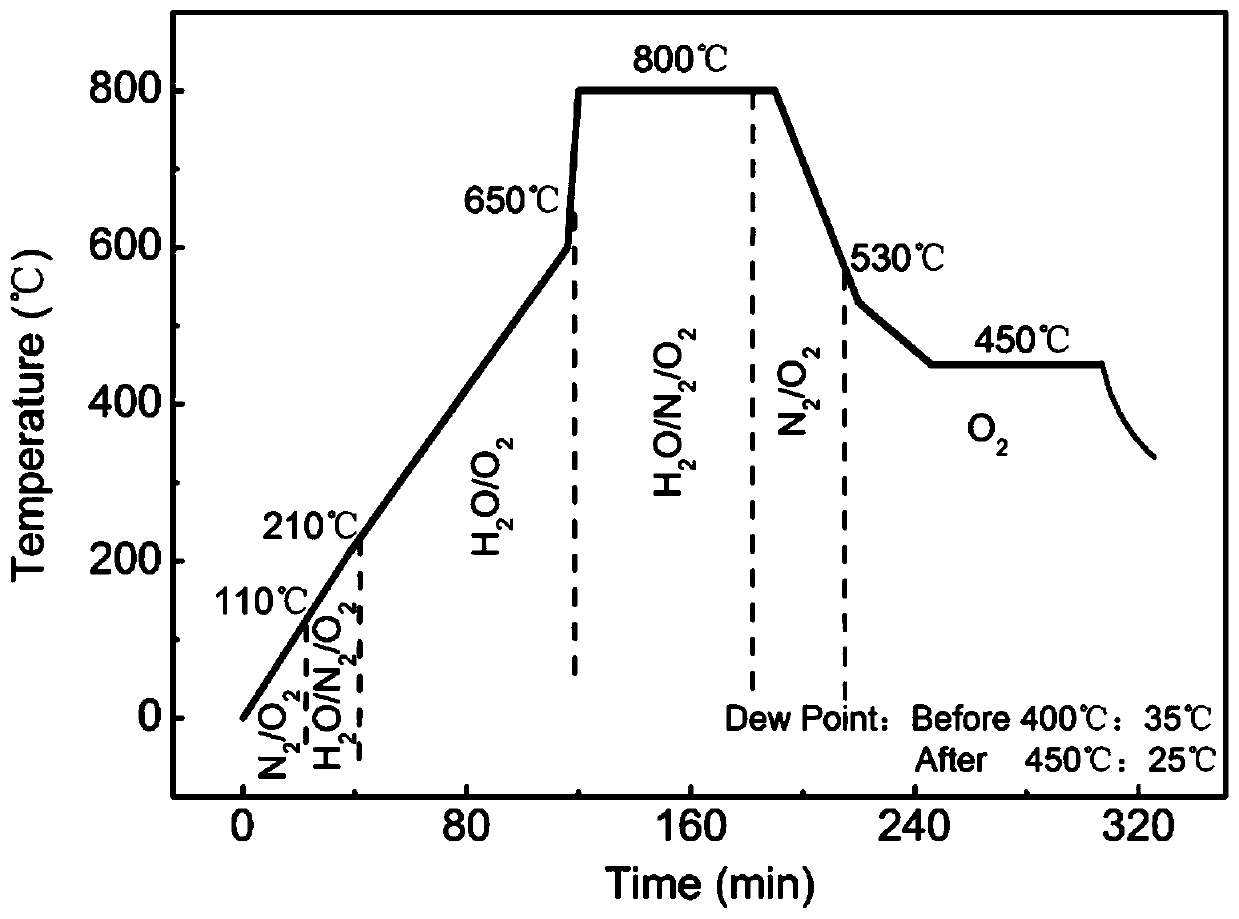

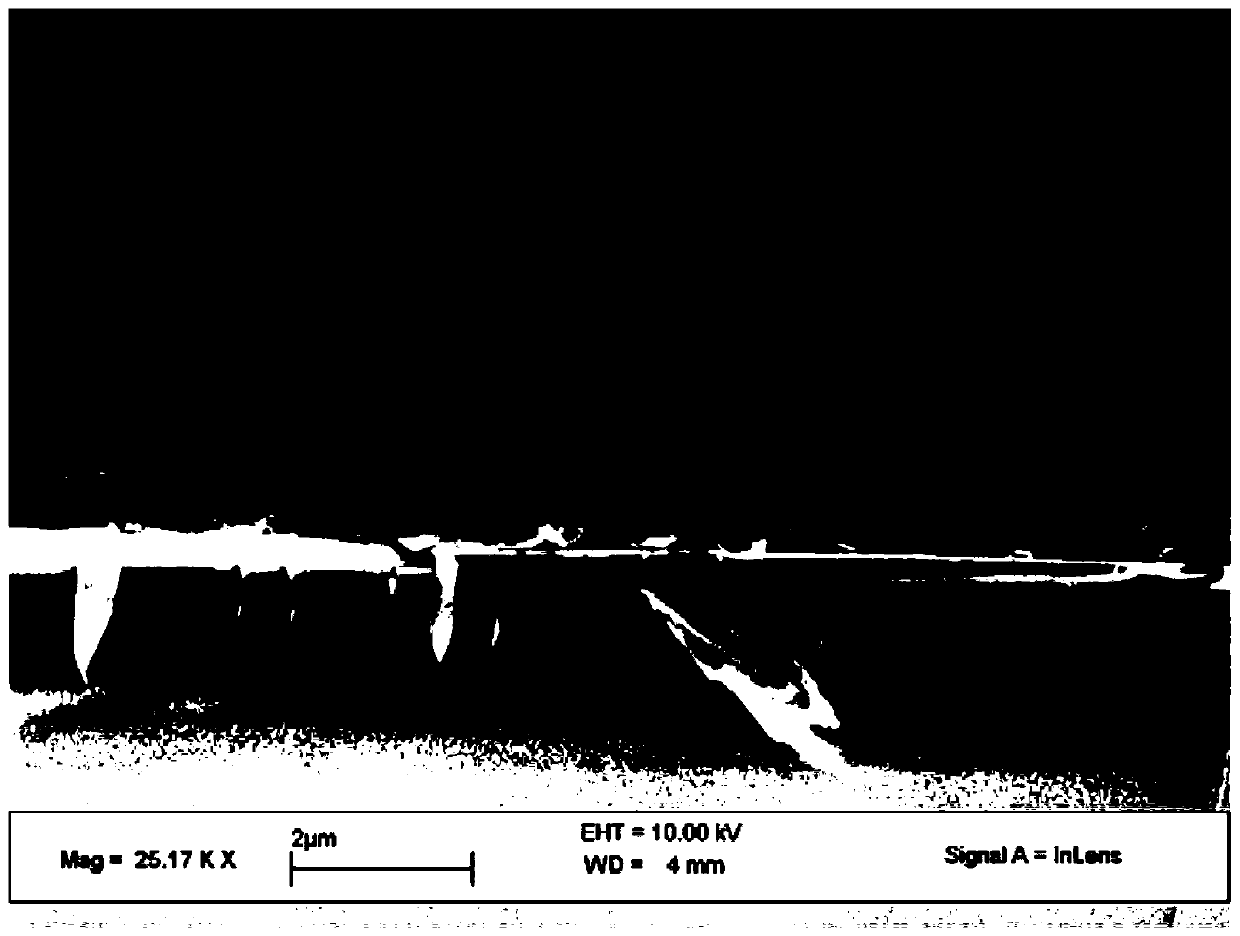

Multilayer composite structure rare earth barium copper oxygen superconducting film and preparation method thereof

ActiveCN108565067AImprove microstructureHigh densityApparatus for manufacturing conducting/semi-conducting layersRare-earth elementComposite structure

The invention discloses a multilayer composite structure rare earth barium copper oxygen superconducting film and a preparation method thereof. The preparation method comprises the steps that REBa1+xCuO7-y films and metal layers are alternately deposited on a substrate; a formed superconducting film is expressed as (REBa1+xCuO7-y / M)n, wherein RE is a rare earth element and M represents a metal layer; x is between 0.5 and 1, and y is greater than 0 and less than 0.5; REBa1+xCuO7-y is coated with a chemical solution; a precursor used by the coating of the chemical solution contains the salt of rare earth metal, barium and copper; each metal layer is subjected to physical vapor deposition; and heat treatment is carried out to acquire the multilayer composite structure rare earth barium copperoxygen superconducting film. The preparation method provided by the invention can be used to acquire the superconducting film of high quality and high critical current density.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

High-strength, thin-gauge and high-corrosion-resistance steel and manufacturing method thereof

ActiveCN112522567AShort production processImprove efficiencyHot-dipping/immersion processesFurnace typesSmelting processStrip steel

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of thin-gauge non-oriented silicon steel with high magnetic induction and low iron loss based on thin strip continuous casting

The invention belongs to the field of metallurgical technology, and particularly relates to a method for preparing thin-gauge non-oriented silicon steel with high magnetic induction and low iron loss based on thin strip continuous casting. In terms of mass percentage, the composition of the molten steel is: C≤0.005%, Si 2.6~3.2%, Mn 0.005~0.3%, Al 0.1~0.5%, P 0.005~0.05%, S≤0.003%, N≤0.003% , O≤0.003%, the balance is Fe and inevitable impurities. The thickness of non-oriented silicon steel is 0.10~0.20mm, and its preparation methods include: smelting, thin strip casting, pickling, warm rolling, two-stage cold rolling, finished product annealing and coating treatment. This invention is based on the twin-roller thin strip continuous casting technology, which eliminates the conventional slab reheating and hot rolling processes. By controlling the proportion of columnar crystals in the cast strip and the reduction amount of warm rolling and cold rolling, it enhances the advantageous { 100} and {110}<001> texture, improve plate shape and tissue uniformity, and improve magnetic properties. The invention has short process flow, low energy consumption, high magnetic induction and low iron loss of the product.

Owner:NORTHEASTERN UNIV LIAONING

B-containing hot-rolled steel plate/strip with sulfuric acid dew point corrosion resistance and manufacturing method thereof

The invention discloses a B-containing hot-rolled steel plate / strip with sulfuric acid dew point corrosion resistance and a manufacturing method thereof. In the method, microalloy elements such as Cr,Ti, Sb and Cu and an element B are selectively added; in the smelting process, the alkalinity of slag, the type and melting point of inclusions in steel, the content of free oxygen in molten steel and the content of acid-soluble aluminum Als are controlled; double-roller thin-strip continuous casting is adopted for casting a cast strip, and the cast strip enters a lower closed chamber with a non-oxidizing atmosphere after being discharged out of crystallization rollers and enters an online rolling mill under the closed condition to be subjected to hot rolling; and a gas atomization cooling mode is adopted for cooling strip steel after rolling, and finally the strip steel is coiled. The steel strip produced by the method can be widely applied to the field of products with use environmentsrequiring sulfuric acid dew point corrosion resistance, such as tobacco baking equipment and air preheater heat exchange elements, conveying pipes, flue and chimney manufacturing structural parts andboiler preheater and economizer equipment in the industries of petroleum, chemical engineering, electric power, metallurgy and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of super wear-resistant super amphiphobic coating and its preparation method and application

ActiveCN110240849BImprove wear resistanceExcellent ice-phobic performanceLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer scienceHigh wear resistance

A super-abrasion-resistant super-amphiphobic coating and its preparation method and application belong to the technical field of coating preparation. The preparation process is as follows: mix the resin powder, hydrophobic powder and additives, put them into a twin-screw mixer to melt, extrude, press and crush the flakes, grind and sieve the crushed flakes to obtain a powder coating, and disperse the water-based silica sol in In the aqueous solution, add ammonia water for alkali treatment, then add the above solution into the ethanol solution, mix well and then add the hydrophobic modifier, after stirring and standing still, the nano-super amphiphobic coating is obtained, and the powder coating is electrostatically sprayed to obtain the bottom paint coating, and then spray the nano-super amphiphobic coating on the surface of the primer coating to obtain a super wear-resistant super amphiphobic coating. The present invention prepares a surface structure with a large roughness through an electrostatic powder spraying process, and the introduction of a functional topcoat coating can obtain a super-amphiphobic coating with both ultra-high wear resistance and anti-icing performance, which can be applied to the preparation of kitchen equipment, The inner wall of refrigeration equipment or the outer wall of outdoor facilities in cold areas.

Owner:SOUTHEAST UNIV

A kind of steel plate with a tensile strength of 750mpa grade thick gauge automobile frame and its preparation method

The present invention is a thick automobile girder steel plate with a tensile strength of 750 MPa and a preparation method thereof. The chemical composition of the steel plate in mass percentage is: C: 0.03~0.12%, Si: 0.05~0.60%, Cr: 0.2~1.0%, Mn: 1.0~2.5%, S: ≤0.015%, P: ≤0.025%, Als: 0.015~0.045%, Ti: 0.07~0.15%, Nb: 0.02~0.08%, and the rest are Fe and inevitable impurities during smelting. During preparation, the steel billet with the above chemical composition ratio is used for reasonable process design, so as to avoid the pickling preparation process replacing the original process, reduce the thickness of the iron oxide scale, and obtain Fe at the same time. 3 O 4 , FeO and eutectoid Fe 3 O 4 / α-Fe coexist with the complex phase structure of iron oxide scale, thereby significantly improving the surface quality of the steel plate, which can meet the requirements of direct stamping or roll forming without pickling. Eliminating the pickling process improves production efficiency while reducing environmental pollution and production costs.

Owner:NORTHEASTERN UNIV LIAONING

A kind of low-carbon cold-rolled steel plate for LED lead frame and production method thereof

The invention relates to a low carbon cold-rolled steel sheet for a LED lead frame and a production method thereof, and mainly solves the technical problems that the low carbon cold-rolled steel sheet for the LED lead frame in prior art has nonuniform hardness, high surface roughness and bad aging-resistance. The production method comprises the following steps: smelting according to components, molten iron desulphurization, complex top-bottom blowing converter smelting, argon blowing from bottom of a ladle, protective casting with argon blowing in whole course, heating in a slab heating furnace, rough rolling, finish rolling, reeling for obtaining a hot-rolled steel coil, uncoiling, pickling, cold rolling, annealing in a vertical type continuous annealing furnace, flattening, and reeling for obtaining a finished product with a thickness of 0.4-0.5mm; the finishing temperature of the finish rolling is 860-900 DEG C, the reeling temperature of the hot rolling is 620-660 DEG C, the cold rolling reduction is 75-85%, the temperature scope of a soaking zone of the vertical type continuous annealing furnace for a band steel in hard rolled state after cold rolling is 710-730 DEG C, the soaking time for the band steel in the vertical type continuous annealing furnace is 105-120 s, and temper elongation is 1.0-1.4%. The low carbon cold-rolled steel sheet is mainly used for the LED lead frame.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A method for obtaining gh4169 alloy ultra-fine grain forging

The invention discloses a method for obtaining a GH4169 alloy ultrafine-grained forging. The steps of the method are as follows: (1) the GH4169 forging billet is subjected to solution treatment and aging treatment successively to obtain a uniform structure containing a certain amount of delta phase; (2) The forging billet after solid solution and aging treatment is forged and deformed, the deformation temperature is controlled between 950°C and 1010°C, and the strain rate is not less than 0.05s ‑1 , the equivalent strain is not less than 0.35; (3) The obtained forging is subjected to aging treatment again, the aging temperature is controlled between 880°C and 920°C, and the aging time is 9h to 24h; (4) The forging is subjected to continuous cooling. For recrystallization heat treatment, the starting temperature of cooling is controlled between 990°C and 1030°C, the cooling rate is between 1°C / min and 3°C / min, and the ending temperature of cooling is controlled between 950°C and 990°C. The method proposed by the invention can obtain GH4169 alloy ultra-fine grain forgings, and provides an effective way for manufacturing high-quality forgings.

Owner:CENT SOUTH UNIV

Multilayer composite structure rare earth barium copper oxide superconducting film and preparation method thereof

ActiveCN108565067BImprove microstructureHigh densityApparatus for manufacturing conducting/semi-conducting layersRare-earth elementChemical solution

The invention discloses a multilayer composite structure rare earth barium copper oxygen superconducting film and a preparation method thereof. The preparation method comprises the steps that REBa1+xCuO7-y films and metal layers are alternately deposited on a substrate; a formed superconducting film is expressed as (REBa1+xCuO7-y / M)n, wherein RE is a rare earth element and M represents a metal layer; x is between 0.5 and 1, and y is greater than 0 and less than 0.5; REBa1+xCuO7-y is coated with a chemical solution; a precursor used by the coating of the chemical solution contains the salt of rare earth metal, barium and copper; each metal layer is subjected to physical vapor deposition; and heat treatment is carried out to acquire the multilayer composite structure rare earth barium copperoxygen superconducting film. The preparation method provided by the invention can be used to acquire the superconducting film of high quality and high critical current density.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for improving super-elasticity of beta titanium alloy

ActiveCN110541133AGood superelasticityConducive to inverse phase transitionMartensite transformationElectrolysis

The invention discloses a method for improving the super-elasticity of a beta titanium alloy. The method comprises the steps that the block beta titanium alloy with the shape memory effect is selectedas a sample, and orientation beneficial for martensite phase transformation is determined according to the martensite phase transformation strain capacity of a sample; the sample is subjected to electrolysis polishing; the surface of the treated sample is marked; the treated sample is tested and analyzed, and a grain orientation distribution diagram of the sample is obtained; according to the orientation beneficial for martensite phase transformation, by means of combination with the indentation mark and the grain orientation distribution diagram of the sample, the grain position beneficial for the martensite phase transformation is determined; and the interior of grain beneficial for the martensite phase transformation is machined, and a micrometer size cylinder sample is obtained. The size of the sample is reduced, the size of martensite is reduced, the martensite does not generate inverse phase transformation easily, and the super-elasticity is generated. Meanwhile, the size of thesample is reduced, the material strength is improved, dislocation starting time is postponed, the pinning effect of dislocation to inverse phase transformation of the martensite is reduced, and thenthe super-elasticity of the beta titanium alloy is improved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com