Low carbon cold-rolled steel sheet for LED lead frame and production method thereof

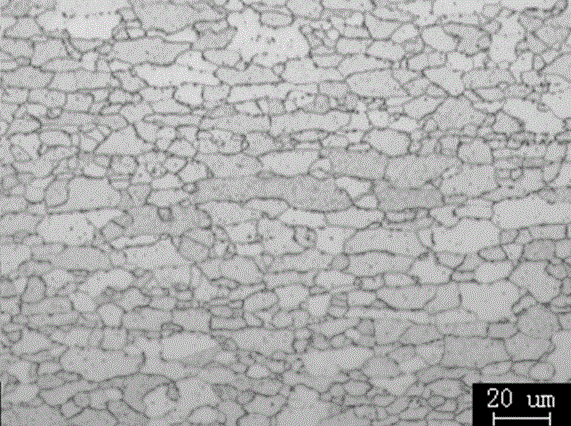

A lead frame and cold-rolled steel sheet technology, which is applied to low-carbon cold-rolled steel sheets for LED lead frames and their production fields, can solve the problems of uneven hardness, poor aging resistance, and high surface roughness, and achieve a "pie shape" of crystal grains. The effect of increased degree, good processing and aging resistance, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] This implementation selects product specification to be 0.5mm*836mm, below in conjunction with embodiment 1 ~ 3 and comparative example---Chinese patent application number is disclosed in the patent application of CN200580032921.5, the present invention is further described, as table 1 ~ table 4 shown.

[0040] Table 1 Chemical composition of the present invention (% by weight), the balance is Fe and unavoidable impurities.

[0041] element C% Si% Mn% P% S% Alt% B% N% this invention 0.025-0.05 ≤0.03 0.15-0.25 ≤0.020 ≤0.010 0.025-0.048 0.001-0.0014 ≤0.0035 Example 1 0.0268 0.0119 0.2215 0.0135 0.0086 0.0426 0.0013 0.002 Example 2 0.0392 0.0117 0.1857 0.0134 0.0085 0.0308 0.0010 0.00198 Example 3 0.0485 0.0116 0.1951 0.0130 0.0088 0.0375 0.0011 0.0028 comparative example 0.02-0.055 ≤0.04 0.2-0.3 ≤0.015 ≤0.015 0.05-0.25 0.0009-0.0015 ≤0.0060

[0042] According to the requirements of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com