Preparation method of quincuncial pile network distribution ceramic/metal composite material

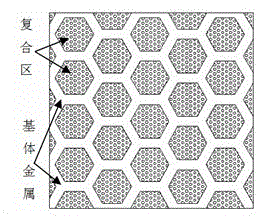

A technology of metal composite materials and plum blossom piles is applied in the field of metal matrix composite materials, which can solve the problems of falling off of surface layer composite materials, and achieve the effects of improving overall performance, improving service life and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

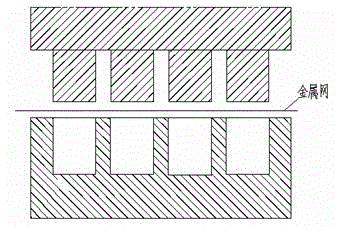

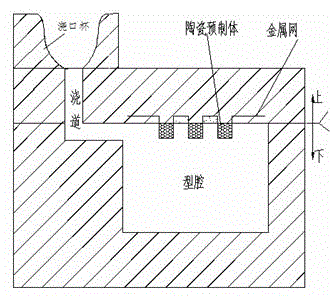

[0019] Embodiment 1: if Figures 1 to 4 As shown, the preparation method of the plum-blossom pile network distribution ceramic / metal composite material of the present embodiment is: pressing out several cylindrical grooves (the distance between adjacent grooves is The ratio of the cross-sectional radius of the groove is 1:3, the height of the groove is 3.5:3), and the ceramic particle alumina with a particle size of 0.55-1 mm is filled in the low The shape of the ceramic / metal composite material is distributed in the groove of the carbon steel wire mesh, and the shape of the ceramic / metal composite material is distributed according to the prepared plum blossom network to prepare a sand casting mold; the low carbon steel wire mesh filled with ceramic particles is installed on the cavity of the sand casting mold. Then pour the smelted base metal high manganese steel into the sand casting mold. After the base metal is cooled, the ceramic / metal composite material is peeled off fro...

Embodiment approach 2

[0020] Embodiment 2: as Figures 2 to 4 As shown, the preparation method of the plum-blossom pile network distribution ceramic / metal composite material of the present embodiment is: pressing out several triangular grooves (the distance between the adjacent grooves and the concave grooves) on a low-carbon iron wire metal mesh with a mesh screen aperture of 0.4 mm. The ratio of the distance from the midpoint of the groove to the farthest edge from the midpoint is 1.8:3, and the ratio of the height of the groove to the distance from the midpoint of the groove to the farthest edge from the midpoint is 1:1), then The ceramic particles alumina with a particle size of 0.8 to 1 mm are filled in the grooves of the low-carbon iron wire mesh, and the shape of the ceramic / metal composite material is distributed according to the prepared plum blossom network to prepare a sand casting mold; the ceramic particles are filled The low carbon iron wire mesh is installed on the upper surface of t...

Embodiment approach 3

[0021] Embodiment three: as Figures 2 to 4 As shown, the preparation method of the plum-blossom pile network distribution ceramic / metal composite material in this embodiment is as follows: several square grooves (the distance between adjacent grooves and the grooves) are pressed out of a stainless steel wire metal mesh with a mesh aperture of 0.38 mm. The ratio of the distance from the midpoint to the edge of the cross section is 1.8:3, and the ratio of the height of the groove to the distance from the midpoint to the edge of the cross section of the groove is 2:3), and then the ceramic particles with a particle size of 0.9 ~ 1.70mm Alumina is filled in the grooves of the stainless steel wire mesh, and the shape of the ceramic / metal composite material is distributed according to the prepared plum blossom network to prepare a sand casting mold; the stainless steel wire mesh filled with ceramic particles is installed in the sand casting mold. Then pour the smelted base metal or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com