A kind of steel plate with a tensile strength of 750mpa grade thick gauge automobile frame and its preparation method

A technology for automobile girders and tensile strength, which is applied in the field of metallurgy, and can solve problems such as scale shedding, slow rolling rhythm, and large deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

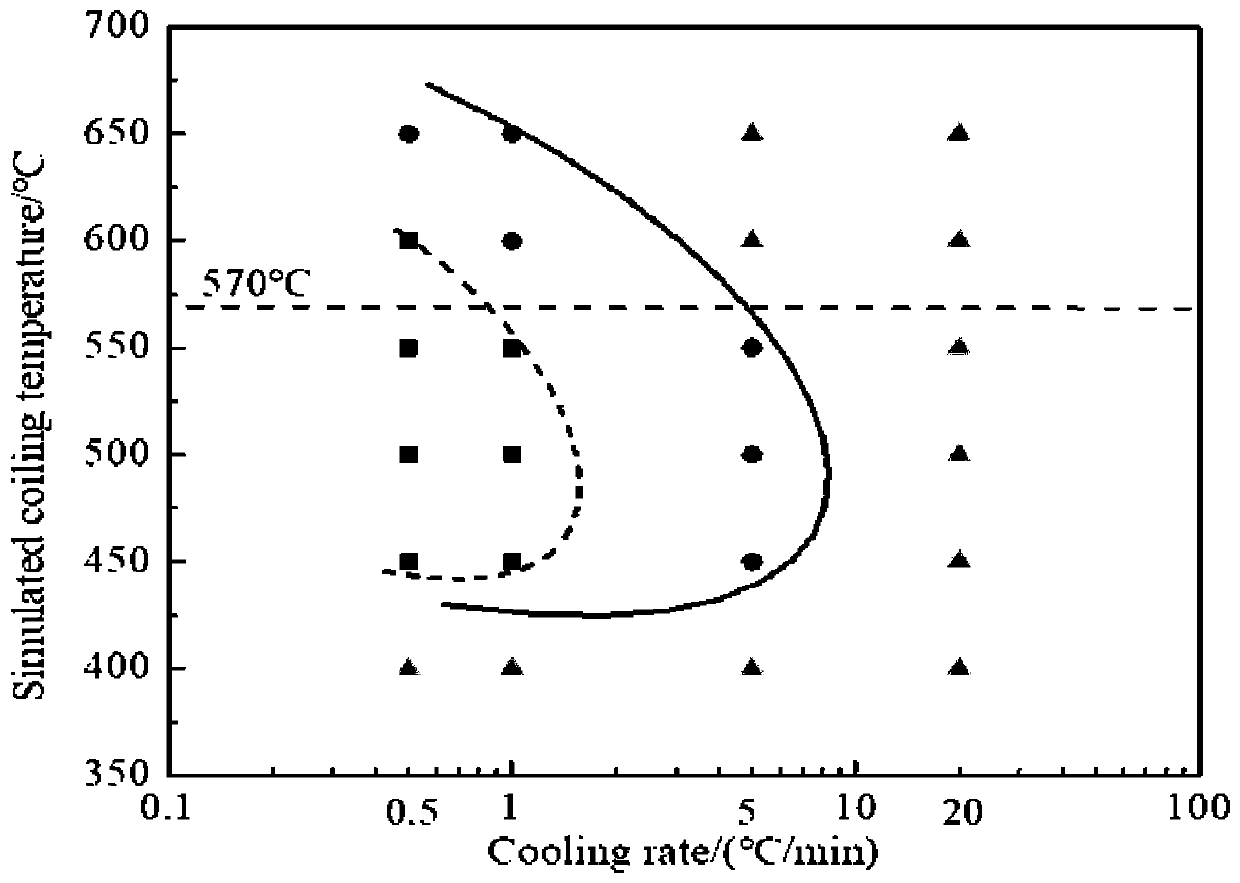

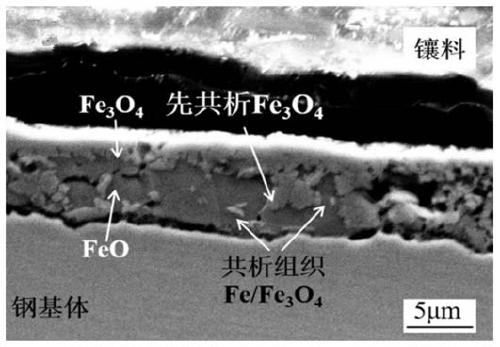

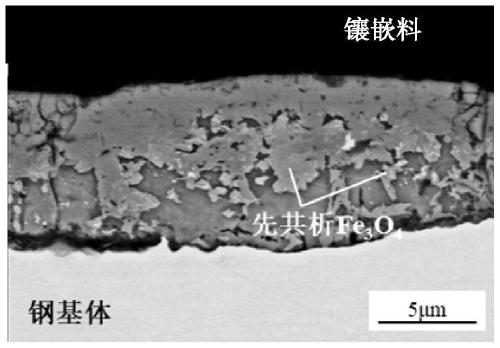

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of thick gauge automobile frame steel with a tensile strength of 750MPa and a thickness specification of 6mm:

[0034] Heat the slab with a thickness of 230mm to 1200°C and hold it for 240min. The chemical composition of the slab is: C: 0.03, Si: 0.05%, Mn: 1.0%, S: 0.015%, P: 0.025%, Als : 0.015%, Cr: 0.2%, Ti: 0.07%, Nb: 0.02%, and the rest are Fe and unavoidable impurities during smelting. The steel slab after being released from the furnace is subjected to rough rolling at a starting temperature of 1130°C for 5 passes to obtain an intermediate slab with a thickness of 34mm; the rough rolled intermediate slab is subjected to finish rolling with 7 passes. The finish rolling entrance temperature is 1050°C, the finish rolling temperature is 890°C, and the rolling speed of the F7 stand is 8m / s to obtain a 6mm thick strip. The descaling water pressure for heating furnace descaling, rough rolling descaling and finishing rolling descaling is 20MPa. The cooling...

Embodiment 2

[0036] Preparation of thick gauge automobile frame steel with a tensile strength of 750MPa and a thickness specification of 6mm:

[0037]Heat the slab with a thickness of 210mm to 1300°C and hold it for 180min. The chemical composition of the slab is: C: 0.12%, Si: 0.60%, Mn: 2.5%, S: 0.010%, P: 0.020%, Als: 0.045%, Cr: 1.0%, Ti: 0.15%, Nb: 0.08%, and the rest are Fe and unavoidable impurities during smelting. Rough rolling is carried out on the steel slab after being released from the furnace, the rolling temperature is 1180°C, and rolling is carried out for 5 passes to obtain an intermediate slab with a thickness of 48 mm; the rough rolled intermediate slab is subjected to finish rolling, and the finishing rolling passes are 7 passes. The finish rolling entrance temperature is 1050°C, the finish rolling temperature is 850°C, and the rolling speed of the F7 stand is 7m / s to obtain a 6mm thick strip. The descaling water pressure for heating furnace descaling, rough rolling de...

Embodiment 3

[0039] Preparation of thick gauge automobile frame steel with a tensile strength of 750MPa and a thickness specification of 8mm:

[0040] Heat the slab with a thickness of 230mm to 1250°C and hold it for 200min. The chemical composition of the slab is: C: 0.05%, Si: 0.05%, Mn: 1.5%, S: ≤0.015%, P: ≤0.025 %, Als: 0.025%, Cr: 0.2%, Ti: 0.09%, Nb: 0.03%, and the rest are Fe and unavoidable impurities during smelting. The steel slab after being released from the furnace is subjected to rough rolling at a starting temperature of 1130°C for 5 passes to obtain an intermediate slab with a thickness of 52mm; the rough rolled intermediate slab is subjected to finish rolling with 7 passes. The finish rolling entrance temperature is 1040°C, the finish rolling temperature is 880°C, and the rolling speed of the F7 stand is 6m / s to obtain a strip with a thickness of 8mm. The descaling water pressure for heating furnace descaling, rough rolling descaling and finishing rolling descaling is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com