Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193results about How to "Improved deformation coordination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquefied soil foundation quake-proof road-bridge transition section structure of ballastless track of high-speed railway

InactiveCN101691724ALower fill longitudinalReduce lateral deformationRailway tracksBridge structural detailsReinforced concreteCrushed stone

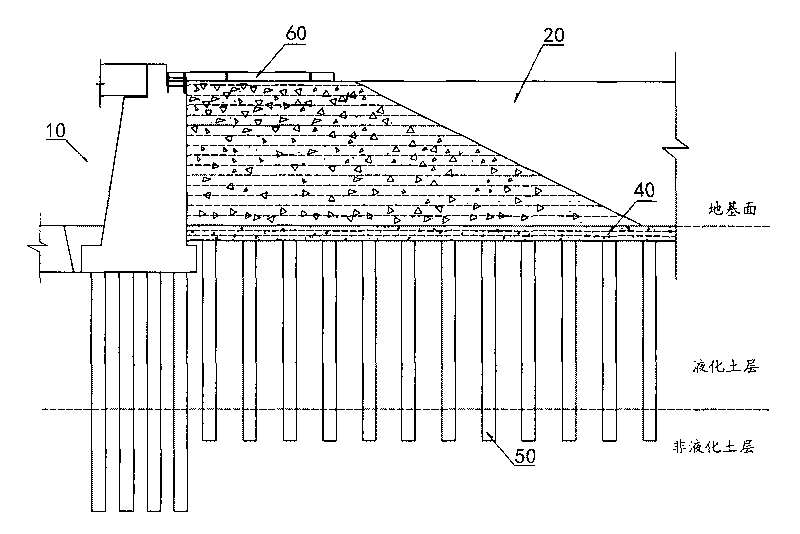

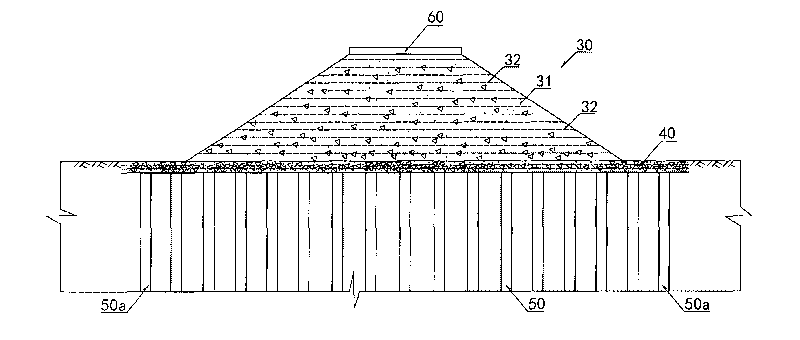

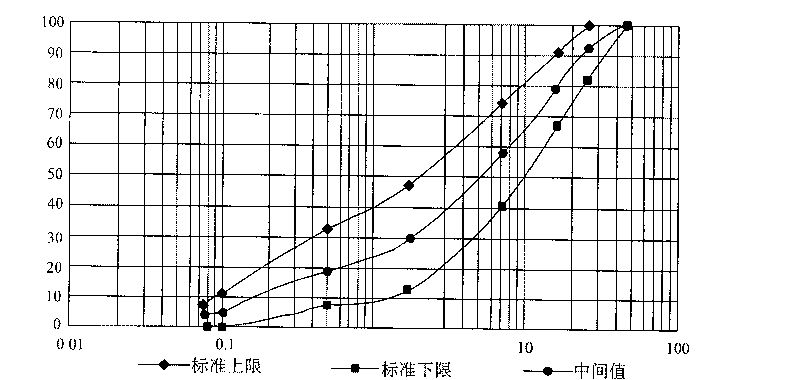

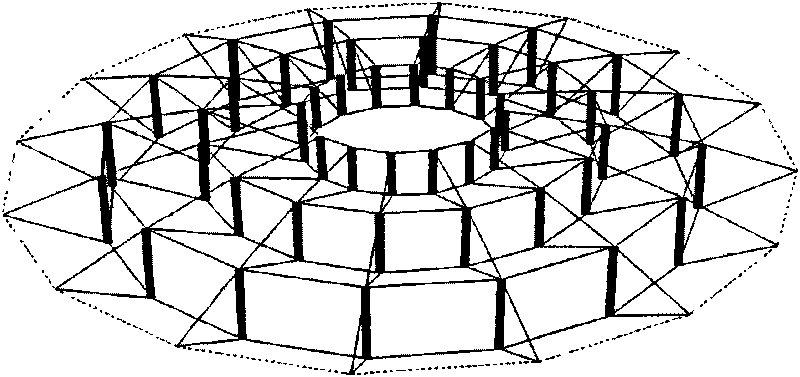

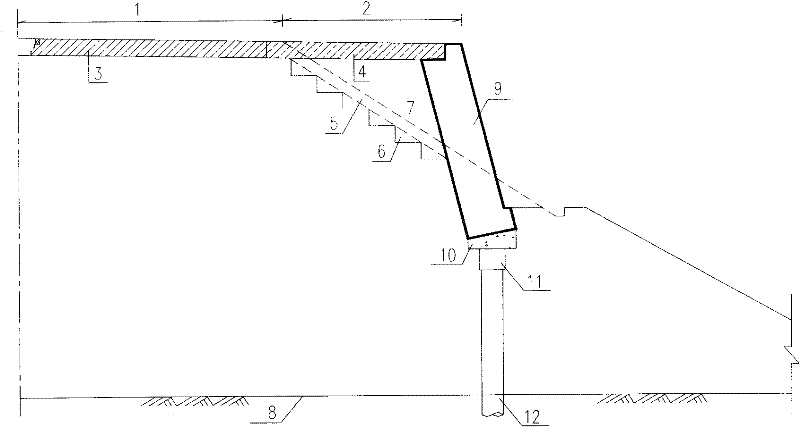

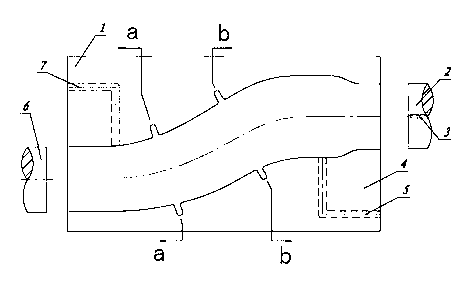

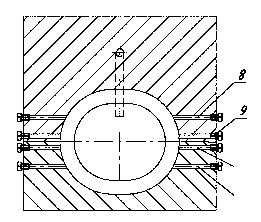

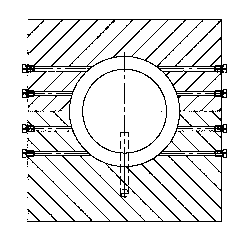

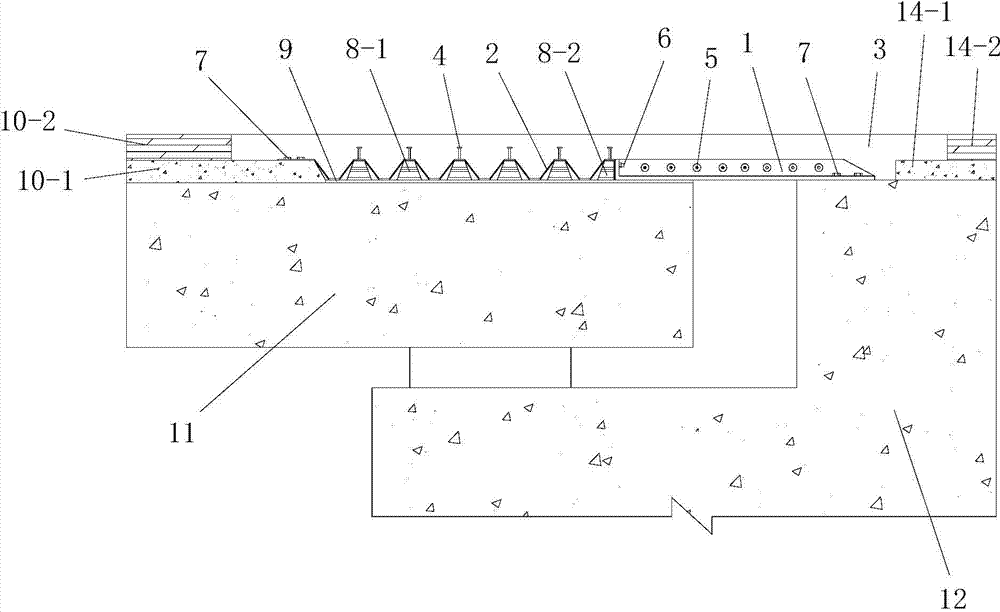

The invention discloses a liquefied soil foundation quake-proof road-bridge transition section structure of a ballastless track of a high-speed railway, and aims to improve the stability and the integrity of the roadbed at the transition section and meet the quake-proof design requirements of lines. The structure comprises a concrete bridge abutment (10) and a soil roadbed (20). A reinforced grading gravel transition section (30) is arranged between the concrete bridge abutment (10) and the soil roadbed (20), wherein the longitudinal section of the transition section is wedge-shaped and the transverse section of the transition section is right trapezoidal. Rows of reinforcing piles (50) are arranged in the liquefied soil foundation at intervals along the longitudinal and transverse directions under the transition section (30). The pile ends of the reinforcing piles (50) pass through the liquefied soil layer of the foundation and enter a non-liquefied soil layer. A cement grading gravel reinforced cushion layer (40) is paved between the foundation surface and the pile top of the reinforcing pile (50). A reinforced concrete lap plate (60) is arranged on the top surface of the reinforced grading gravel transition section (30). One end of the reinforced concrete lap plate (60) is simply supported or fixedly supported on the concrete bridge abutment (10), while the other end is placed on the soil roadbed (20).

Owner:SOUTHWEST JIAOTONG UNIV +1

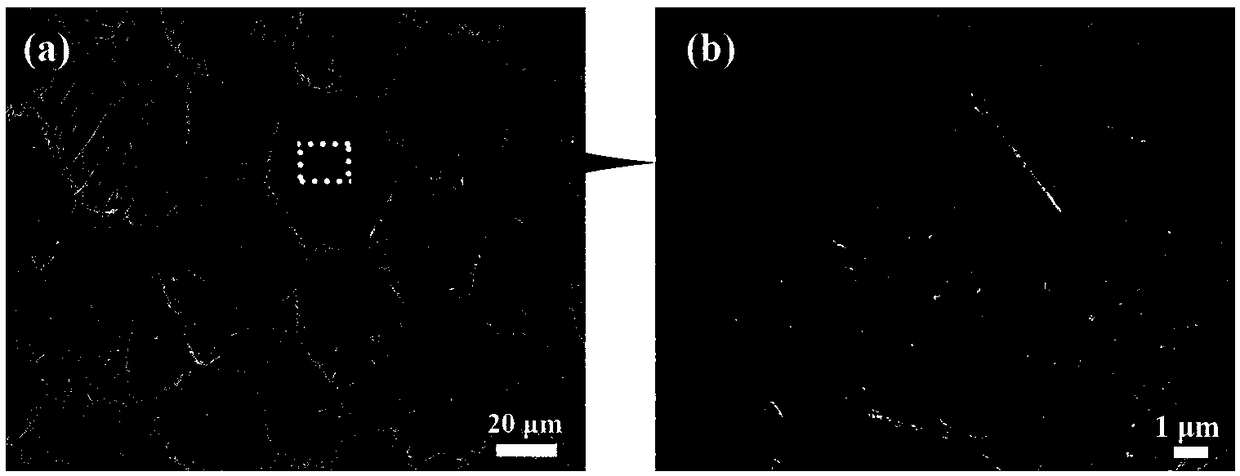

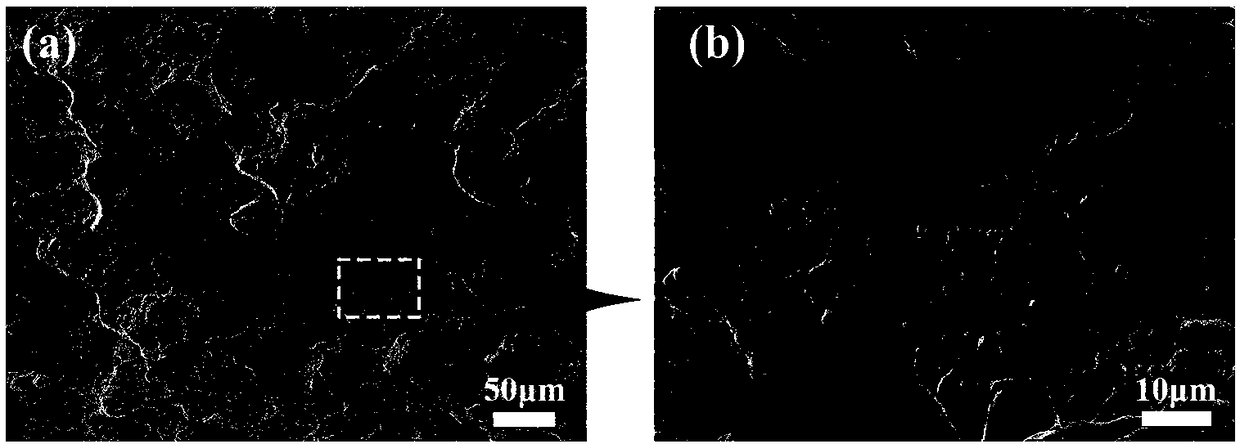

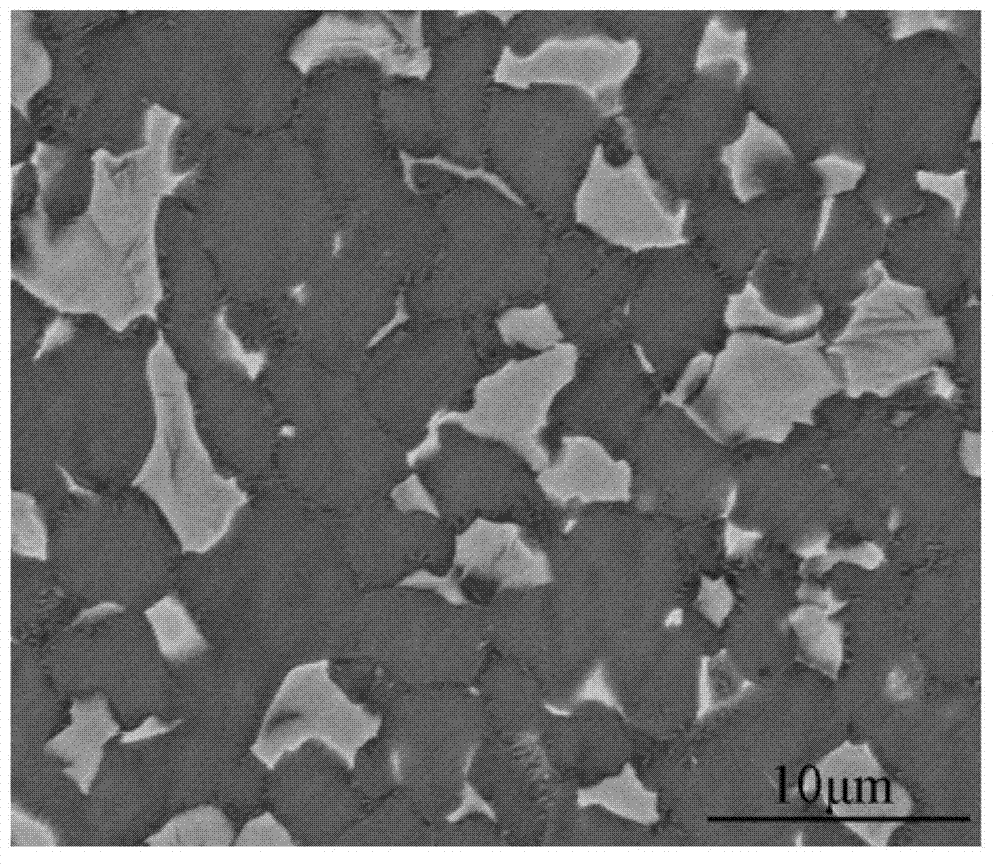

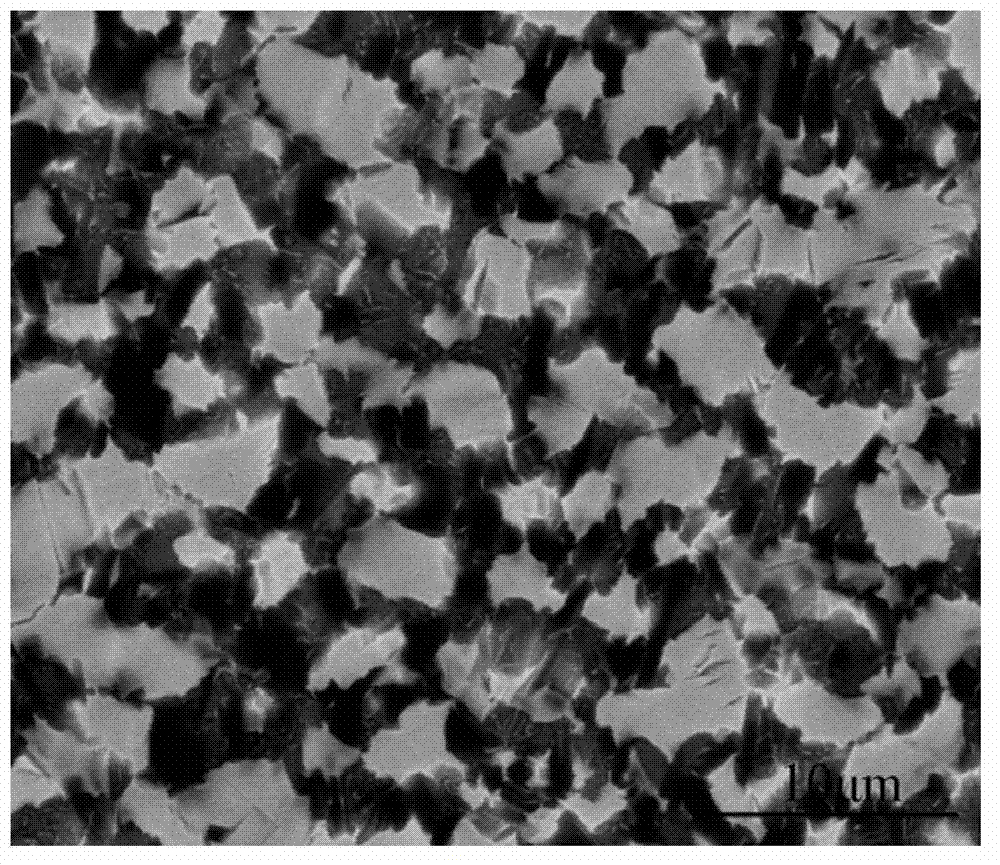

Powder metallurgy preparation method for high-strengthening-toughening metal-based composite material

ActiveCN108080644AImproved deformation coordinationAchieve toughnessMetal matrix compositeMetal powder

The invention discloses a powder metallurgy preparation method for a high-strengthening-toughening metal-based composite material and belongs to the field of metal-based composite materials. The method comprises the steps that (1), mixed powder of metal powder and part reinforcing phase is subjected to ball-milling treatment, and ball-milling is stopped before all crystal particles in the metal powder reach ultrafine crystal; (2), the rest reinforcing phase is added to the powder after ball-milling in the step (1), the ball-milling is continued, and the ball-milling is stopped until the reinforcing phase is completely dispersed; (3), after the powder after the ball-milling in the step (2) is treated by powder metallurgy sintering process, then the high-strengthening-toughening metal-basedcomposite material is obtained. According to the powder metallurgy preparation method for the high-strengthening-toughening metal-based composite material, the reinforcing phase is made to be orderlydistributed in a base body by adding the reinforcing phase step by step; crystal particle distribution is adjusted and controlled utilizing the crystal particle refining effect of the reinforcing phase on the base body, a coarse and fine crystal gradient grading structure is formed, thus the strengthening-toughening of materials is realized; and by means of the powder metallurgy preparation methodfor the high-strengthening-toughening metal-based composite material, the process procedure can be simplified, and the strong plasticity of the materials can be improved at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cut-off wall slurry material and wall building technique

InactiveCN101130993AGuaranteed flexibilityGood anti-seepageArtificial islandsSolid waste managementCross-linkSodium Bentonite

The present invention discloses one kind of water tight wall grout material and the wall building process therewith. The wall grout material includes wall protecting slurry comprising bentonite or clay, sodium carbonate, selective flocculant, water loss lowering assistant and water; and curing original mortar comprising Portland cement, sand, fly ash, water glass, water reducing agent, cross-linking agent and water. The water tight wall building process includes the following steps: pouring wall protecting slurry into dug water tight wall slot, adding curing original mortar gradually into the slurry for mixing with wall protecting slurry during digging operation, and adding more water glass in the last stage for curing to form water tight wall. The water tight wall has excellent water tight performance, controllable solidification time, low cost and no pollution.

Owner:CHANGZHOU INST OF TECH

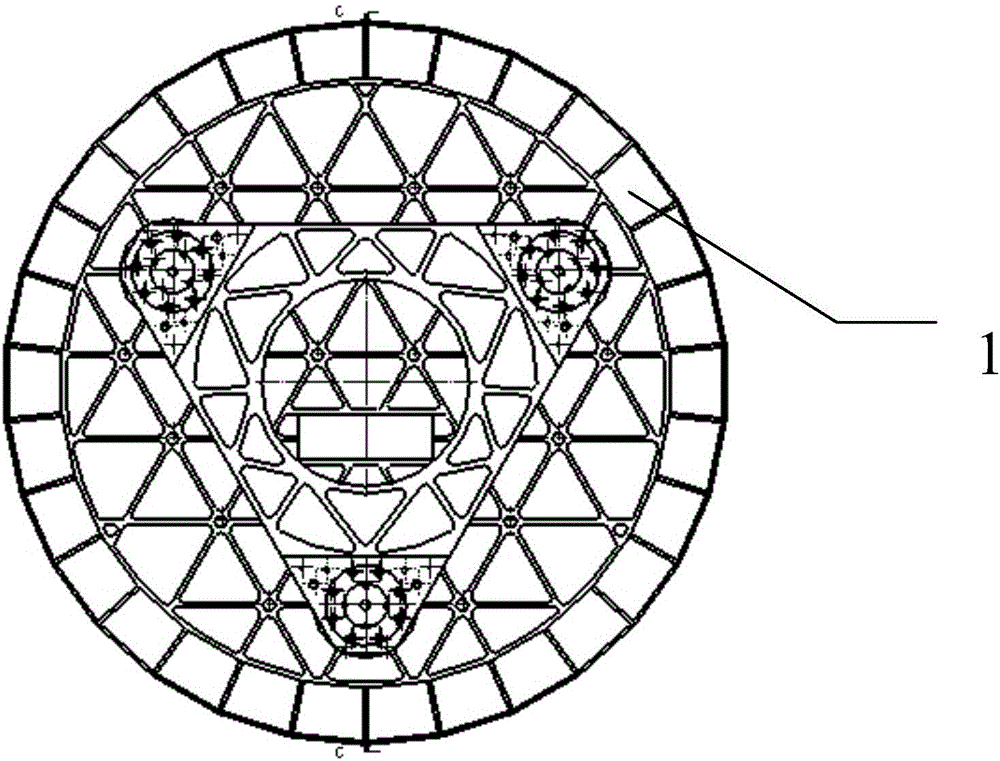

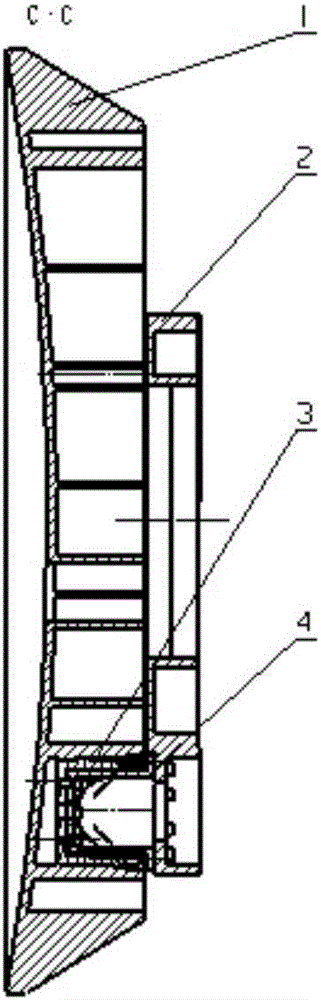

Layer-by-layer double-ring rib-ring type cable dome structure and construction forming method

InactiveCN101691791AImprove construction accuracyImprove shape coordinationBuilding roofsArched structuresRing typePre stress

The invention discloses a layer-by-layer double-ring rib-ring type cable dome structure and a construction forming method. A circle of brace struts in a vertical surface is taken as one layer, each layer other than a top layer comprises a plurality of elements which are the same in geometrical characteristic and quantity, and every two adjacent layer are arranged at equal intervals. The upper end and the lower end of one brace strut of each element are respectively provided with an upper cable strut joint and a lower cable strut joint; one side of the upper cable strut joint is connected with an upper stayed cable of the same layer, and the other side of the upper cable strut joint is respectively connected with an upper stayed cable of an upper layer, a lower stayed cable of the upper layer and an upper hoop cable through the middle of the upper cable strut joint; the lower cable strut joint at the same side of upper stayed cable of the same layer is connected with a lower stayed cable of the same layer and a lower hoop cable through the middle of the lower cable strut joint; and the top layer comprises the upper cable strut joint, the lower cable strut joint and a retractable brace strut, the upper cable strut joint is connected with all the upper stayed cables at the top layer, and the lower cable strut joint is connected with all the lower stayed cables at the top layer. The invention has the advantages of high construction accuracy, convenient construction method, low construction cost and safe structure use.

Owner:ZHEJIANG UNIV +2

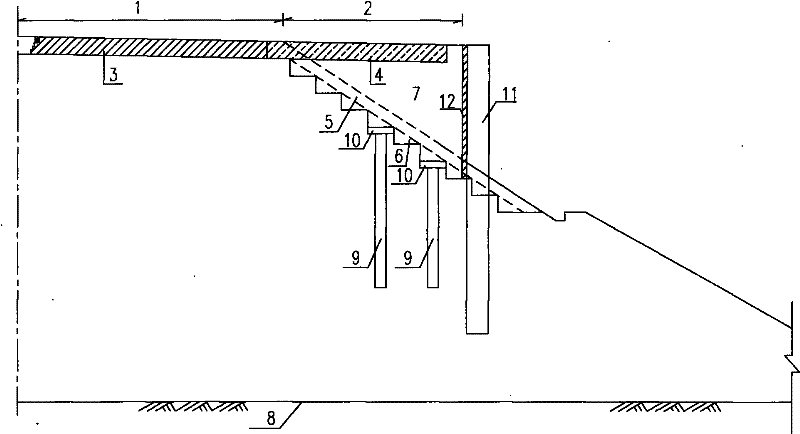

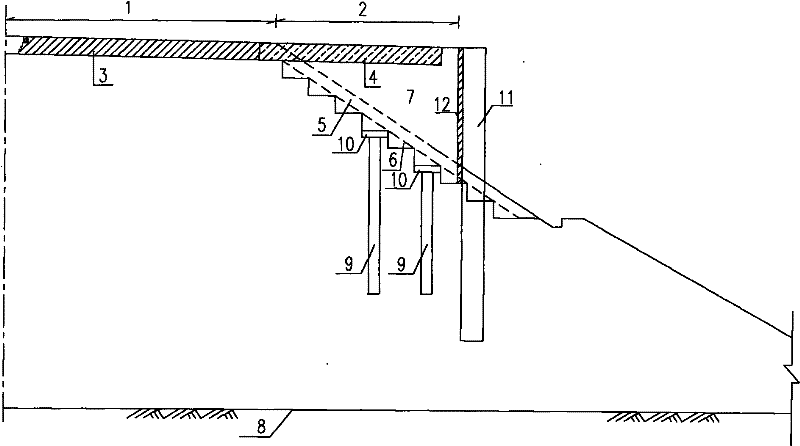

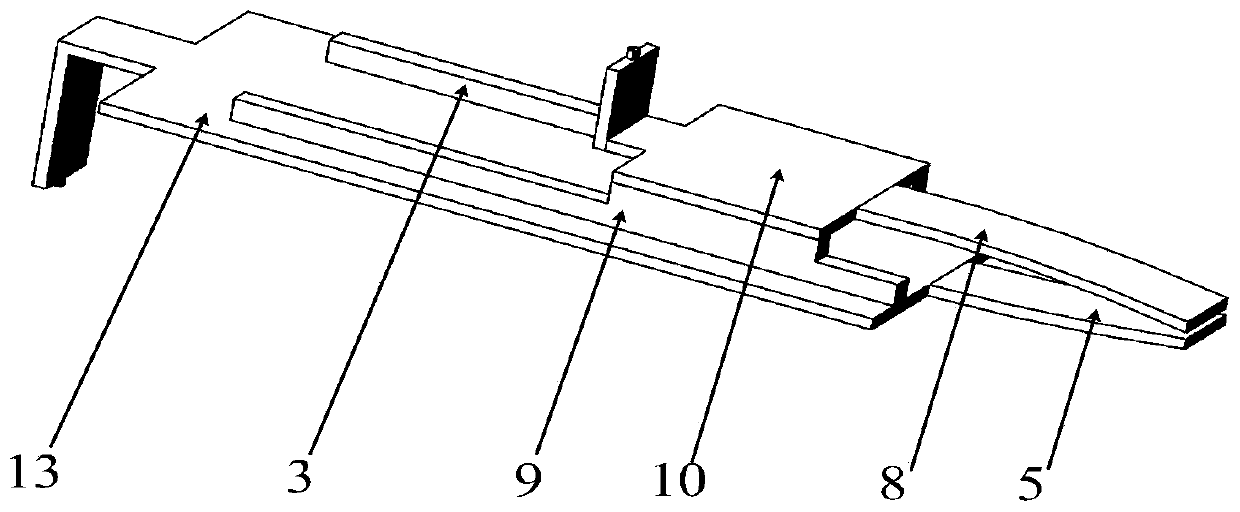

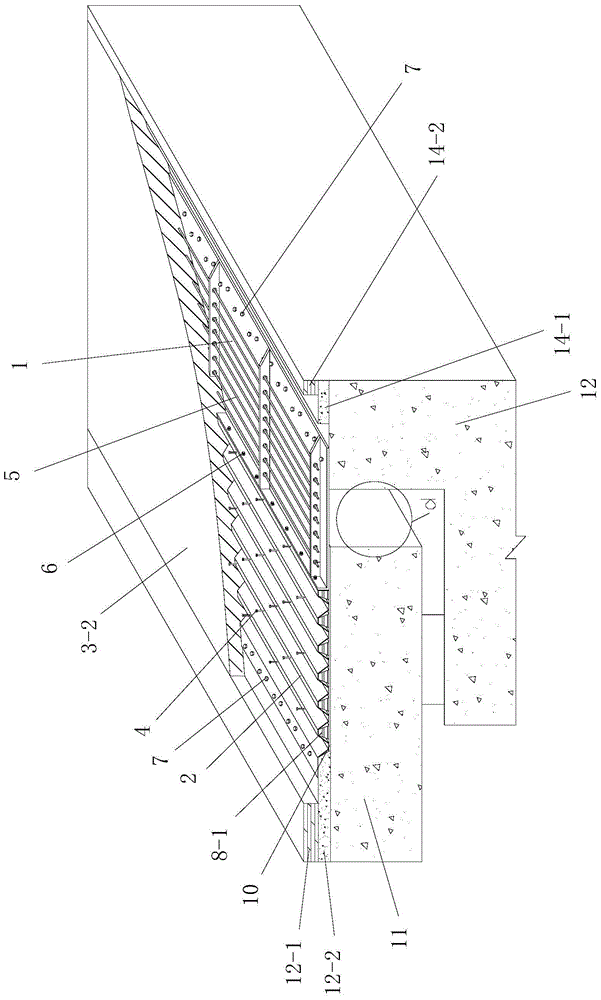

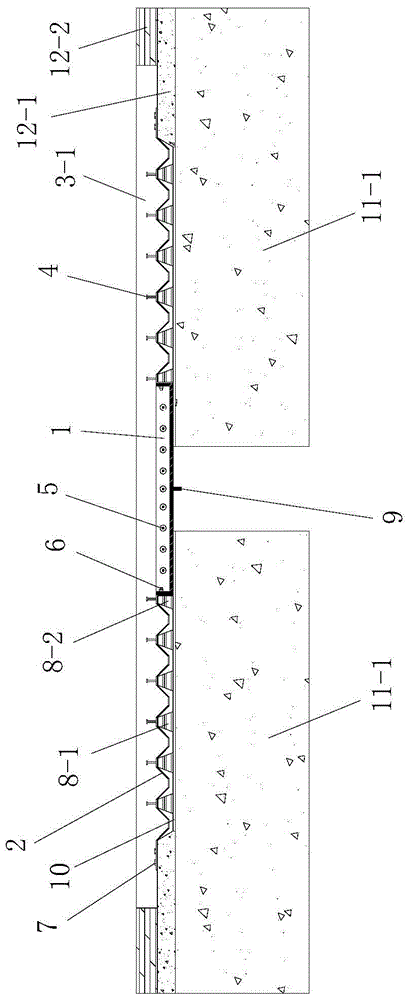

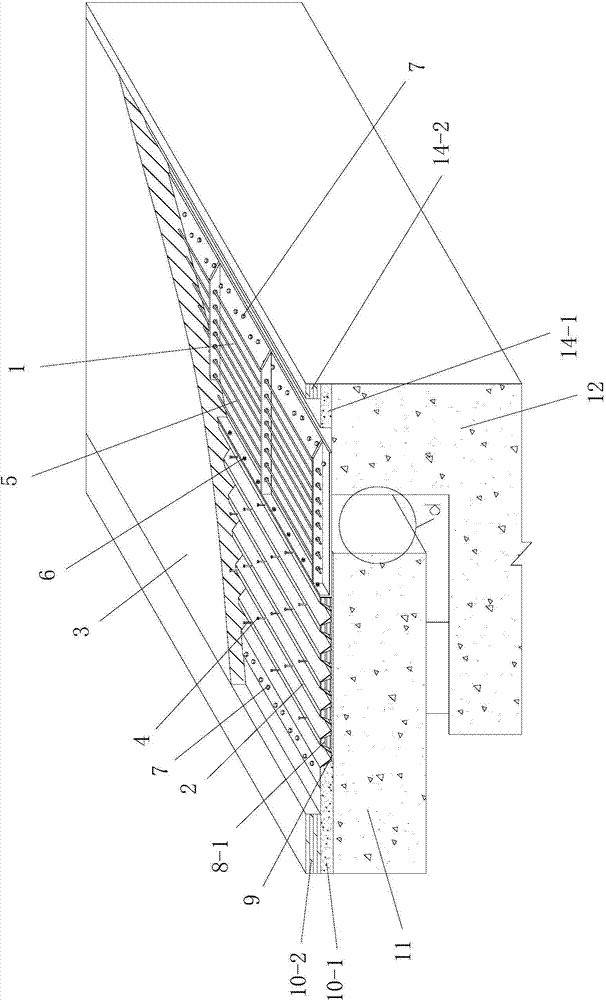

Method for splicing highfill roadbed by adopting pile-sheet retaining wall

ActiveCN102352590AReduce disturbanceReduce land occupationArtificial islandsRoadwaysReinforced concreteEngineering

The invention discloses a method for splicing a highfill roadbed by adopting a pile-sheet retaining wall, comprising the following steps of: forming an operation platform by using an old roadbed (1), a cutting slope (5) and an excavation step (6); longitudinally constructing an excavation filling pile (11); hoisting the cutting slope (5) and the excavation step (6) layer by layer from bottom to top during construction; installing a reinforced concrete soil retaining plate (12) so that the reinforced concrete soil blocking plate (12) is in overlap joint with the excavation filling pile (11); constructing an excavation C10-C12 element concrete pile (9) and a C20 reinforced concrete pile follower (10) step by step; and filling and compacting filler (7) layer by layer to realize seamless overlap joint of an old road surface (3) and a new road surface (4). The method has the advantages of no increase of occupied land, simple and convenient construction machines, short construction period, low cost and simplicity in maintaining traffic moving, thereby being extremely suitable for road sections widened by using highfill.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

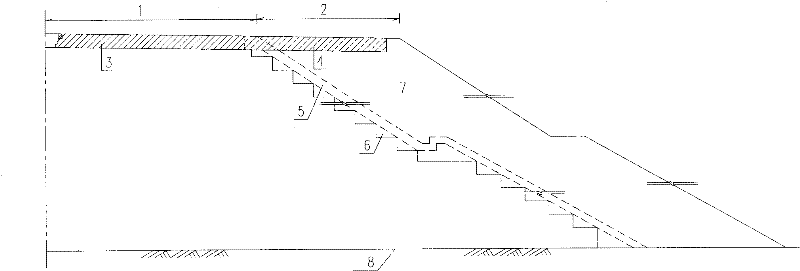

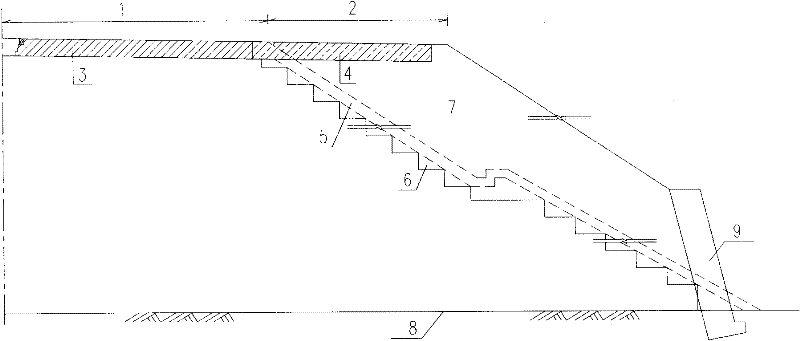

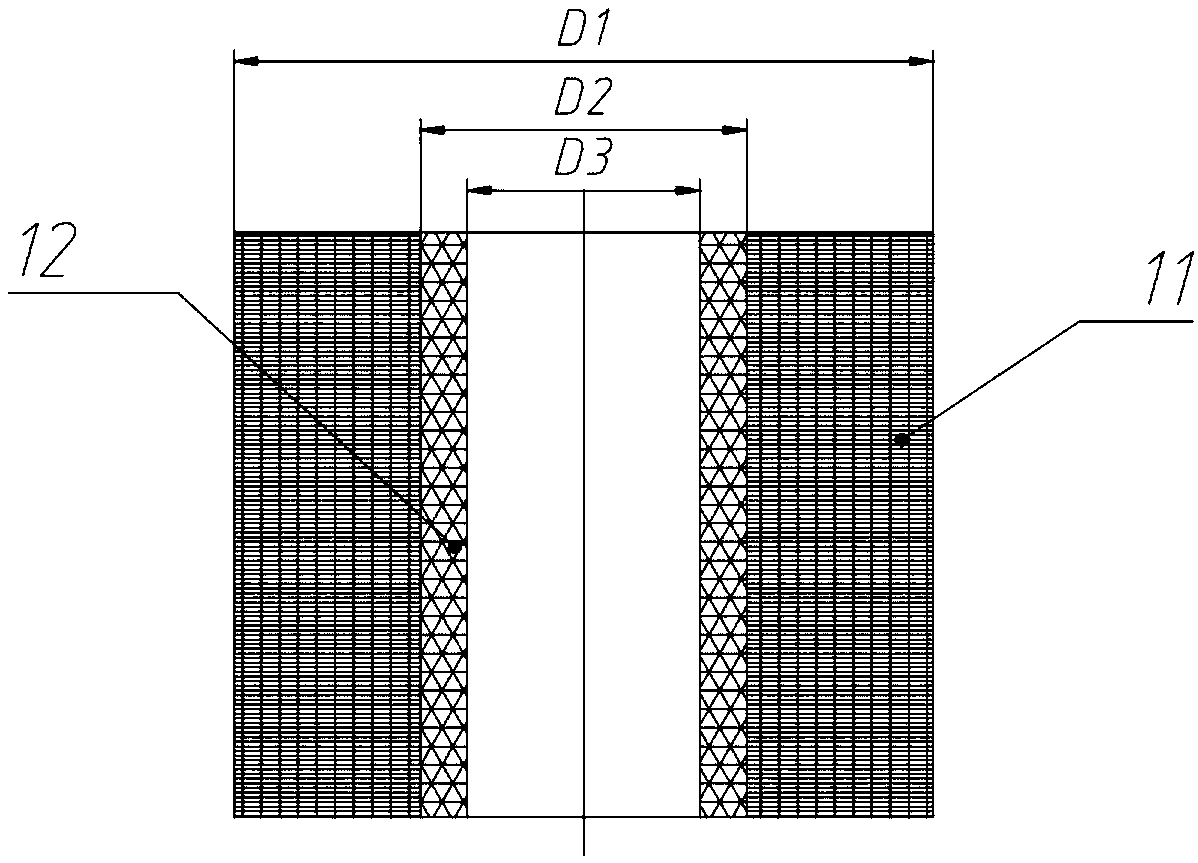

High fill subgrade connection method

The invention discloses a high fill road section connection method, comprising the steps of: conducting bored pile (12) construction vertically at a side slope of an old subgrade (1), connecting multiple bored piles (12) into a vertically continuous bearing platform by means of a reinforced concrete supporting beam (11), the top surface of which is paved with a hardcore bed (10), and carrying out retaining wall (9) construction on the hardcore bed, when the retaining wall strength reaches over 75% of a designed strength level, performing cut slope (5) and step (6) excavation construction to the old subgrade slope, implementing filler (7) filling layer by layer and layering compaction, and finally paving newly connected wide pavement (4). The method of the invention restrains lateral deformations of a new subgrade (2) by means of various supporting and retaining structures, and opposes vertical deformations caused by various loads through a foundation reinforcing structure formed by the bored piles (12) and the reinforced concrete supporting beam (11), thus reaching the purposes of a stable overall structure and usage requirement satisfiable deformations.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

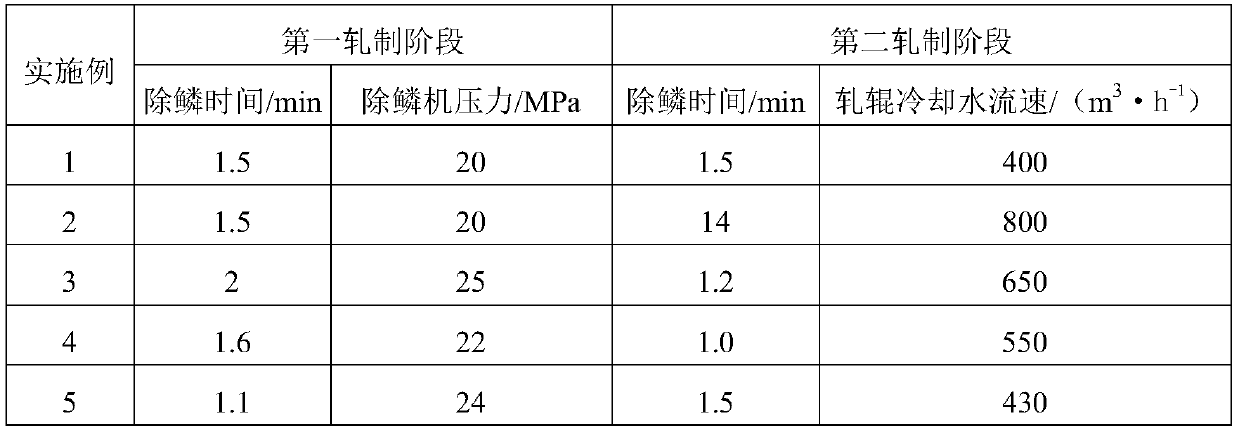

Method for eliminating cracks of hot processed surface of 2205 dual-phase stainless steel middle plate

InactiveCN106391704AQuality improvementNo crackWork treatment devicesMetal rolling arrangementsReduction rateMetallurgy

The invention belongs to the technical field of stainless steel rolling, and particularly discloses a method for eliminating cracks of a hot processed surface of a 2205 dual-phase stainless steel middle plate. The method is characterized by comprising the steps that blank selection and grinding are carried out; a cast blank is heated, specifically, the temperature of a preheating section is 1100-1150 DEG C, the temperature of a heating section is 1150-1240 DEG C, the temperature of a soaking section is 1220-1240 DEG C, and for every 10 mm of the cast blank thickness, the furnace standing time is 9-10 min; scale removal is carried out with water of high pressure of 20-25 MPa; the initial rough rolling temperature is higher than 1150 DEG C, the reduction rate is smaller than 25%, rolling is carried out for 8-11 passes, and the thickness of an intermediate blank is 35-45 mm; and the initial finish rolling temperature is larger than 1050 DEG C, the final rolling temperature is larger than 950 DEG C, the reduction rate is smaller than 18%, and rolling is carried out for 8-12 passes. The method has the advantages that the blank specifications are selected reasonably, parameters such as rolling temperature and reduction rate are matched reasonably after grinding and optimal heating, and the surface crack defect of the 2205 dual-phase stainless steel middle plate is effectively avoided.

Owner:NORTHEASTERN UNIV

Method for eliminating surface cracks of ultra-wide ferrite stainless steel middle-thick plate

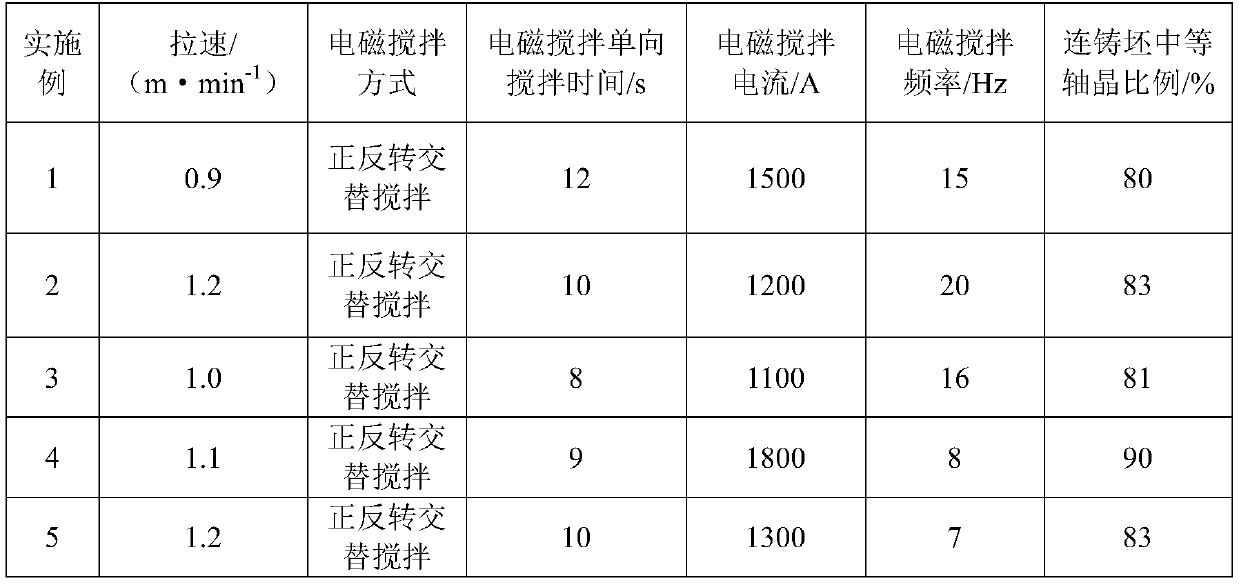

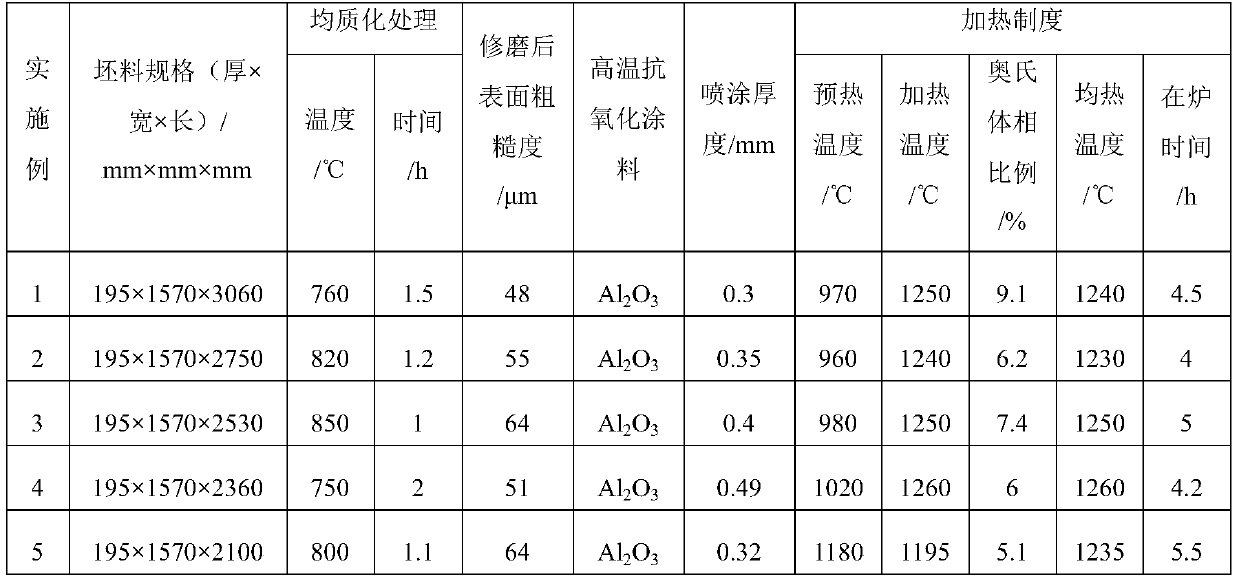

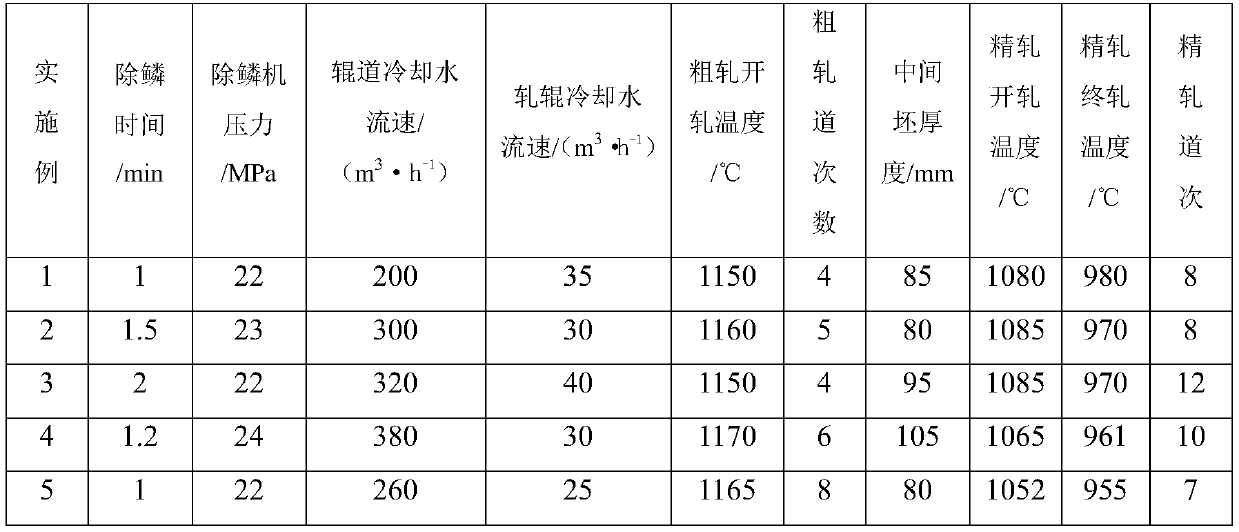

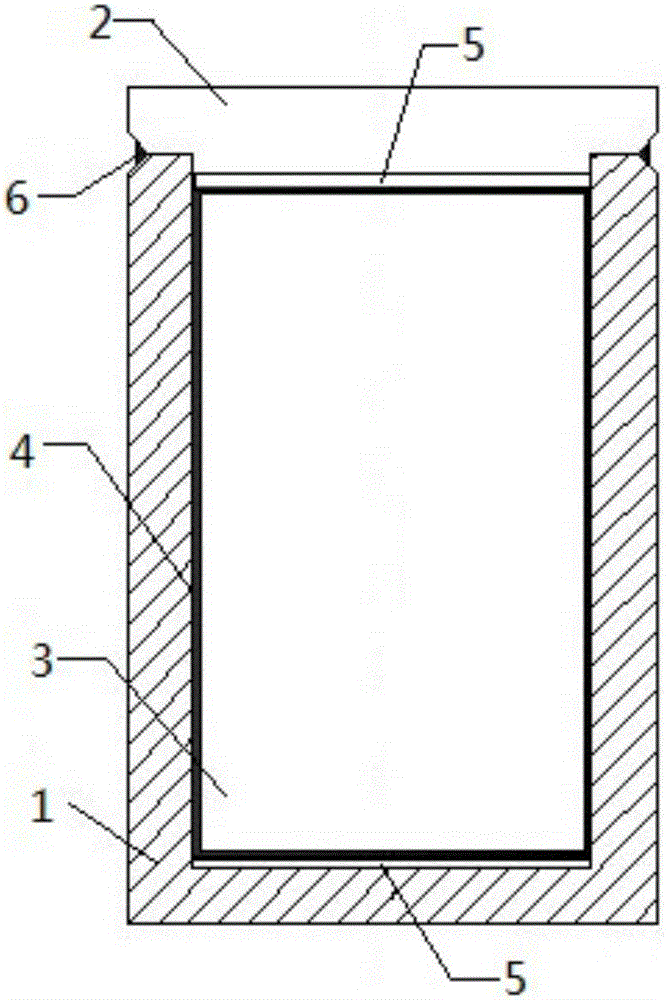

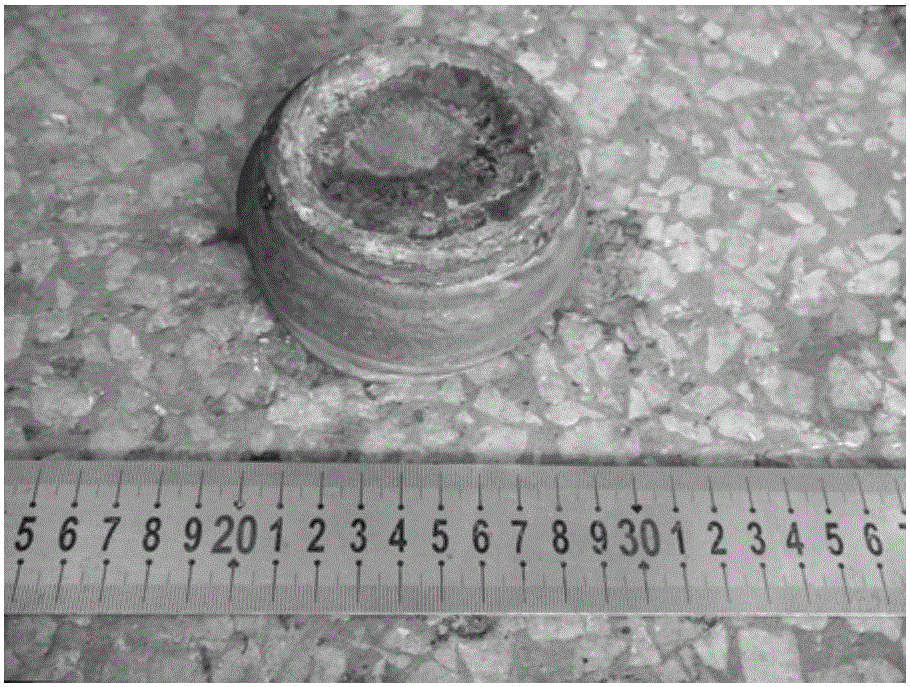

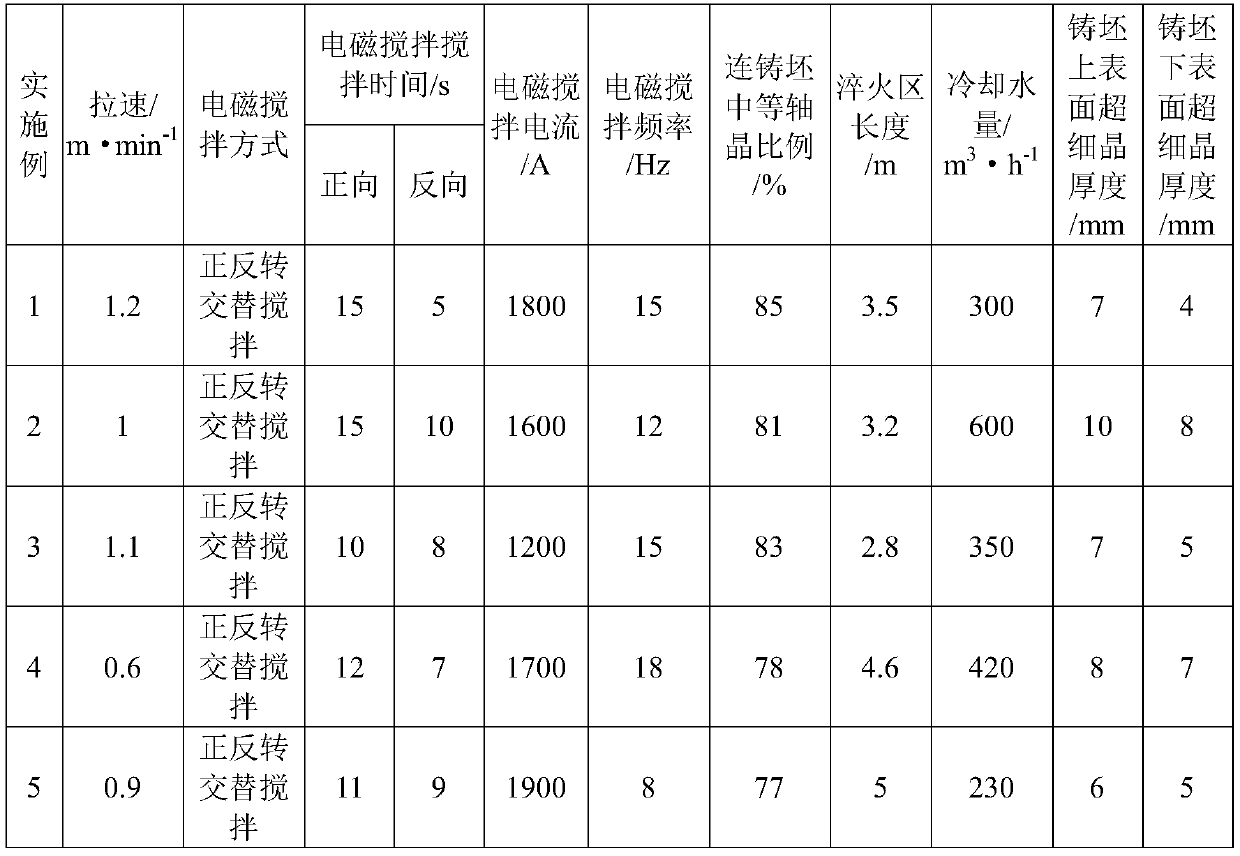

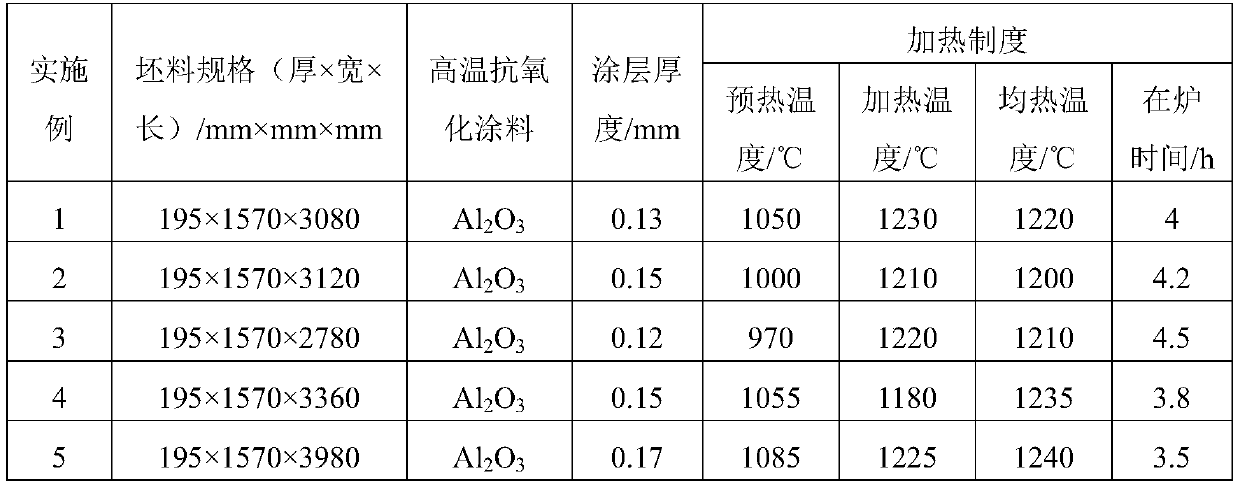

ActiveCN110438414AIncrease equiaxed crystal ratioShorten the forming intervalProcess efficiency improvementWork heating devicesSingle passThick plate

The invention discloses a method for eliminating surface cracks of an ultra-wide ferrite stainless steel middle-thick plate. The proportion of the medium axis crystal of a continuous cast blank is notlower than 75%; the homogenization temperature of the cast blank is 750-850 DEG C, the duration in the furnace is 1-2 hours, and water cooling is carried out to the room temperature; the surface roughness Ra of the cast blank after grinding is less than or equal to 70 microns, and high-temperature antioxidant coating is sprayed; the cast blank is processed by a preheating section, a heating section and a soaking section in sequence, and then is discharged from the furnace; the temperature of the preheating section is 950-1180 DEG C, the temperature of the heating section is 1180-1260 DEG C, the temperature of the soaking section is 1220-1250 DEG C, and the furnace time is 4-5.5 hours; the rough rolling temperature is larger than or equal to 1150 DEG C; the finish rolling temperature is larger than or equal to 1150 DEG C, the final rolling temperature is larger than or equal to 950 DEG C, the rolling single-pass pressing rate is less than or equal to 20%, the annealing temperature is 750-880 DEG C, the furnace time is 2-5 min / mm, and air cooling is carried out. The product width is 2500-4000 mm and the thickness is 8-30 mm. The rejection rate of the surface cracks is reduced from 6% or above to 0.5% or below.

Owner:ANGANG STEEL CO LTD

Integral forming process method of thin-wall hooped tube workpieces

The invention discloses an integral forming process method of thin-wall hooped tube workpieces. The technical scheme comprises the flowing steps of: 1, preparing a mould: firstly forming overflow holes in corresponding parts on the mould, welding reinforcing ribs in a thin-wall tubing without welded lines in advance and placing into a mould cavity, performing spotting on the mould, sealing ends of a tube blank, filling a strain rate sensitive medium between the mould and the tube blank, then filling liquid forming medium in the tube blank and applying certain pressure; 2, forming: increasing the pressure of the inside liquid, meanwhile adjusting the flow state of the strain rate sensitive medium to cause a tube body and a reinforcing plate to be deformed in a coordinated way to form qualified parts; and 3, picking up the parts: reducing the pressure to 0MPa, opening the mould and then taking out the parts from the mould. The integral forming process method of the thin-wall hooped tube workpieces has the advantages of few forming processes, low manufacturing cost, high mechanical property of formed members, high dimension precision and the like, and is particularly suitable for forming thin-wall hooped tube workpieces with a sealed complex section shape.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Diamond-like carbon film of gradient structure and preparation method thereof

ActiveCN106521493AImprove performanceImproved deformation coordinationSuperimposed coating processCarbon filmDiamond-like carbon

The invention relates to metal surface treatment, in particular to surface treatment of low-temperature iron-base alloy molds of sliding components, bearings and the like and provides a diamond-like carbon film of a gradient structure and a preparation method of the diamond-like carbon film of the gradient structure. The diamond-like carbon film of the gradient structure is provided with a coating structure comprising a pure metal layer, a first gradient transition layer, a metal nitride layer, a second gradient transition layer, a tungsten carbide, a third gradient transition layer and a surface layer. The surface layer is a diamond-like layer or a silicon-containing type diamond layer. According to the diamond-like carbon film of the gradient structure, gradient control over elasticity modulus and hardness is achieved through ingredient gradient control between all the layers, and therefore the film-substrate cohesion force and the delaminating resistance of the coating are greatly improved.

Owner:广州今泰科技股份有限公司 +1

Excellent-performance high-N austenitic stainless steel medium-thick plate and manufacturing method thereof

ActiveCN110499448AIncrease the axial grain rateQuality improvementProcess efficiency improvementReduction rateThick plate

The invention discloses an excellent-performance high-N austenitic stainless steel medium-thick plate and a manufacturing method thereof. The continuous casting slab medium axialite ratio is higher than or equal to 80%; the casting blank surface roughness is smaller than or equal to 100 microns; the casting blank preheating section temperature is 980 DEG C to 1100 DEG C, the heating section temperature is 1160 DEG C to 1230 DEG C, the soaking section temperature is 1200 DEG C to 1230 DEG C, and the in-furnace time is 3 h-4 h; the rough rolling starting temperature is higher than or equal to 1150 DEG C, the first-two gate rolling reduction rate is higher than or equal to 20%, the rough rolling follow-up gate reduction rate is smaller than or equal to 15%, and the intermediate blank thickness is 80 mm to 120 mm; the finish rolling start temperature is higher than or equal to 1050 DEG C, the final rolling temperature is higher than or equal to 950 DEG C, and the rolling reduction rate issmaller than or equal to 20%; and the solution temperature is 980 DEG C to 1050 DEG C, and the in-furnace time is 2 min / mm to 5 min / mm. The product width is 2200 mm to 4000 mm, and the product thickness is 30 mm to 60 mm. The -196 DEG C yield strength is larger than or equal to 350 MPa, the tensile strength is larger than or equal to 1250 MPa, the elongation is larger than or equal to 40%, and thesurface crack rejection rate drops from more than 15% to less than 5%.

Owner:ANGANG STEEL CO LTD

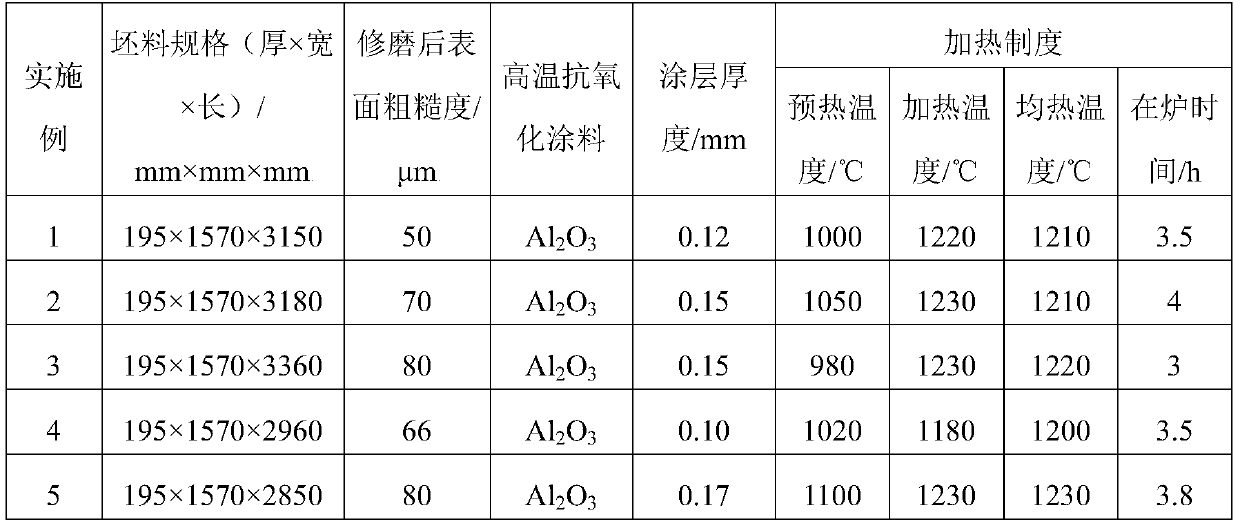

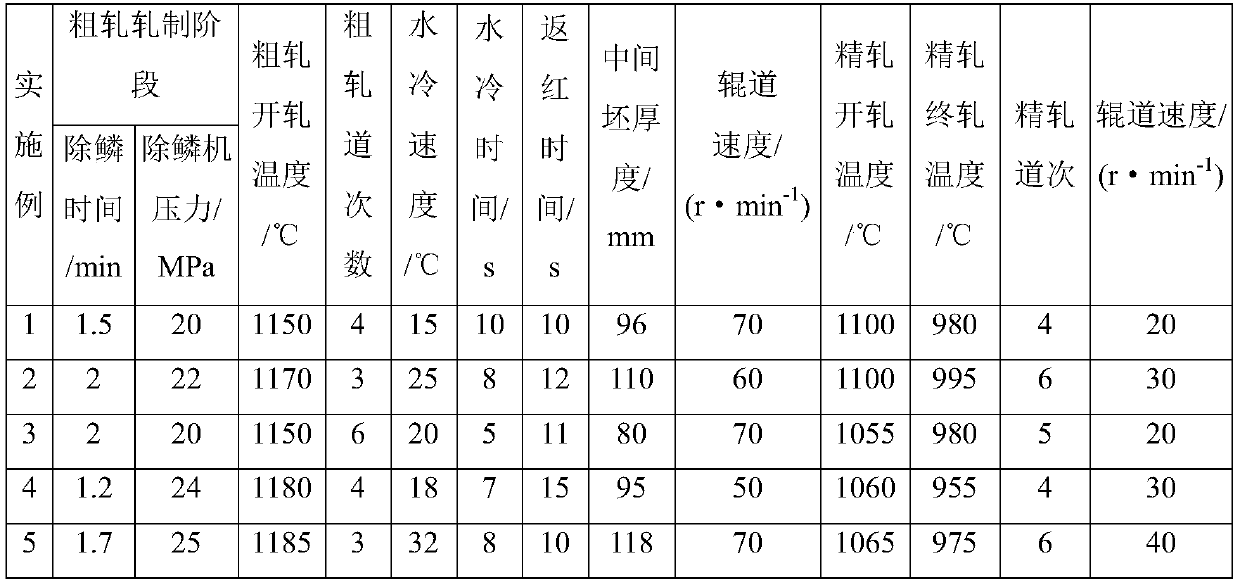

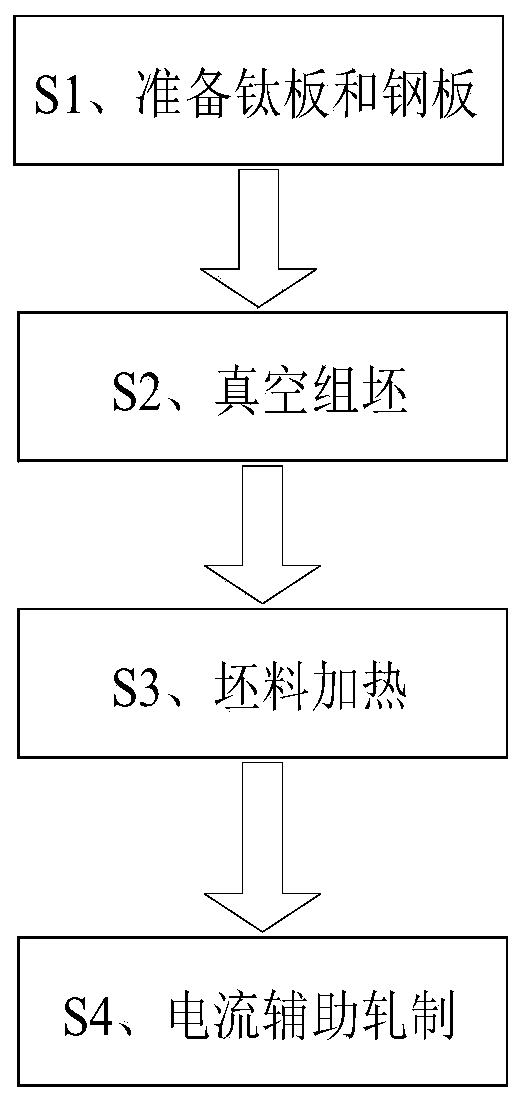

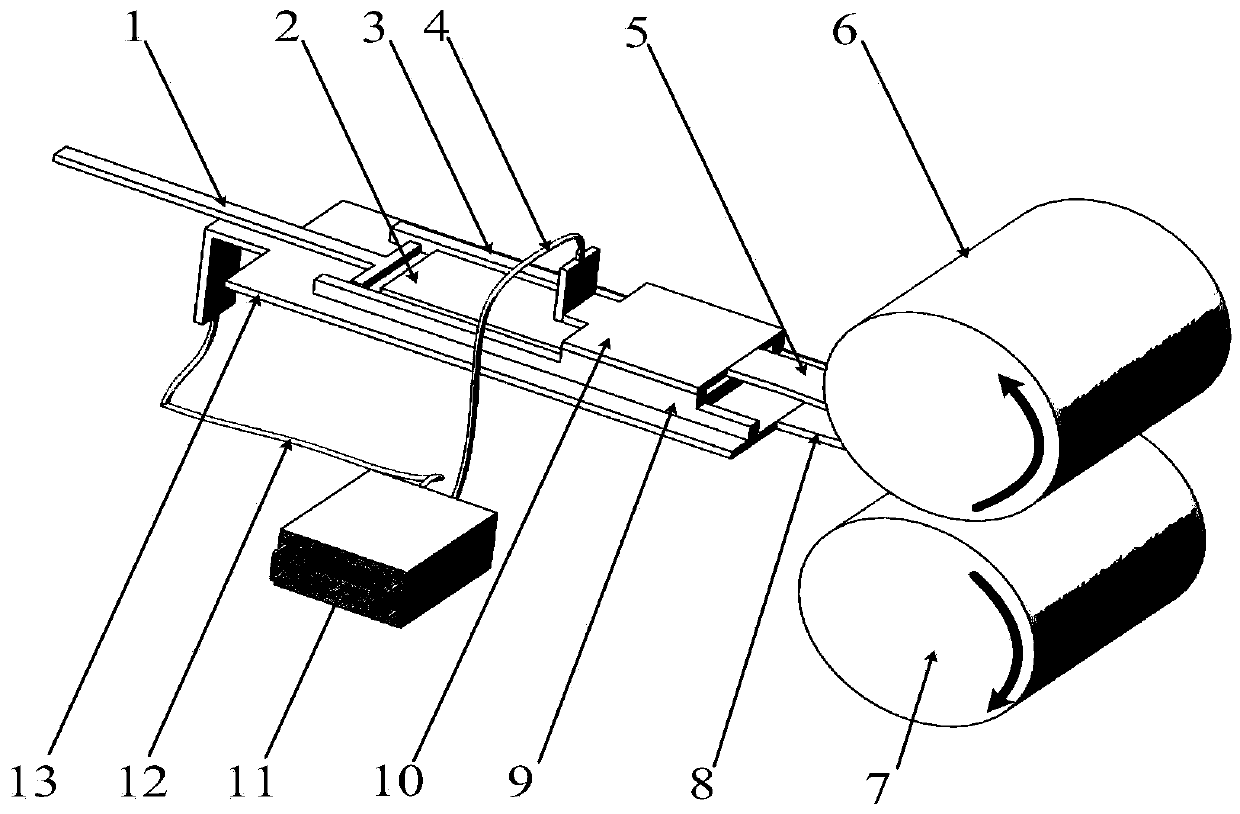

Method for preparing titanium steel composite plate through auxiliary hot rolling of pulse current

InactiveCN110788136AImprove plastic deformationFacilitated DiffusionRoll force/gap control deviceWork cleaning devicesTitaniumComposite plate

The invention provides a method for preparing a titanium steel composite plate through auxiliary hot rolling of pulse current. The method comprises the following steps that S1, a titanium plate, a steel plate and a middle layer material are prepared, and to-be-composited surfaces of the titanium plate, the steel plate and the middle layer material are subjected to treatment and cleaning thoroughly; S2, the titanium plate and the steel plate are subjected to vacuum assembling; S3, a heating device is heated to the designated temperature, a blank is put in the device, and vacuum heat preservation treatment is carried out for a certain time; S4, a roller gap and a rolling speed of a rolling mill are set in advance, the blank obtained after heat treatment is taken out to be put into a rollingmill inlet connected with a pulse power source device, an insulation push plate is used for pushing the blank into the rolling mill, and according to the certain rolling reduction and the rolling speed, rolling is carried out to obtain the titanium steel composite plate. According to the method for preparing the titanium steel composite plate through auxiliary hot rolling of the pulse current, theelectroplastic effect and the tip end effect of the pulse current are used, the two kinds of materials of titanium and steel achieve metallurgical bonding under the small reduction amount, and the titanium steel composite plate good in plate shape and high in combination strength can be obtained.

Owner:TAIYUAN UNIV OF TECH

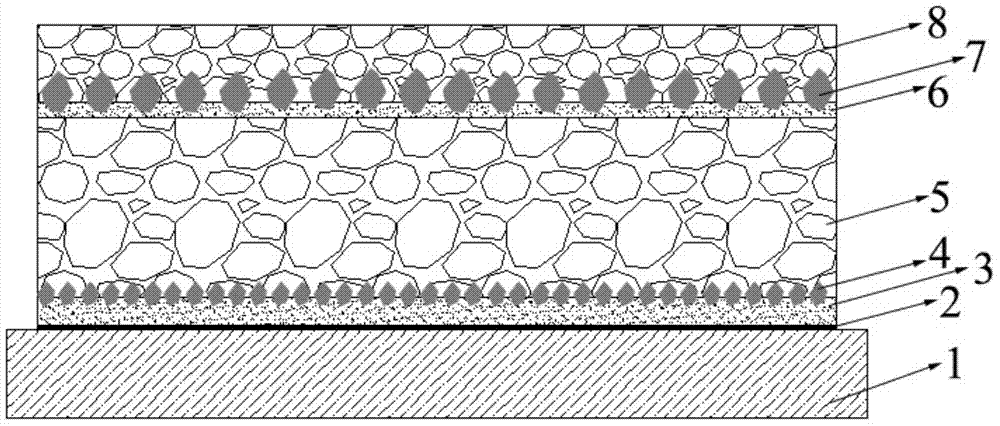

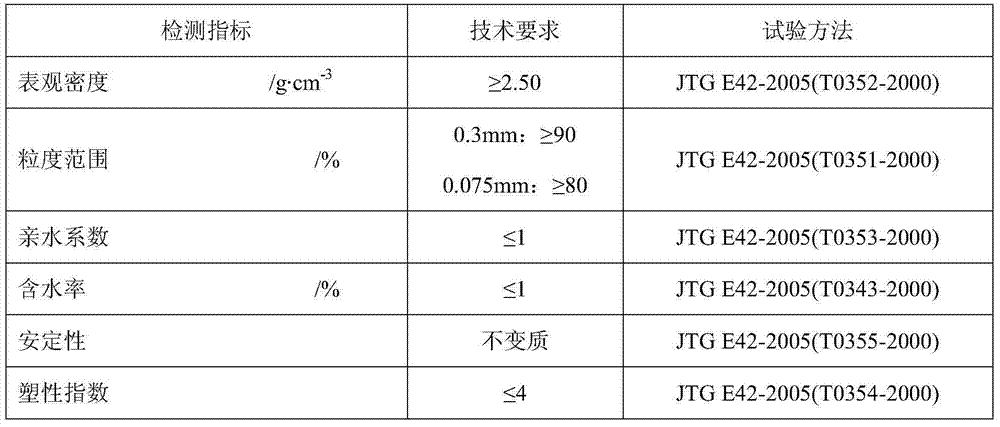

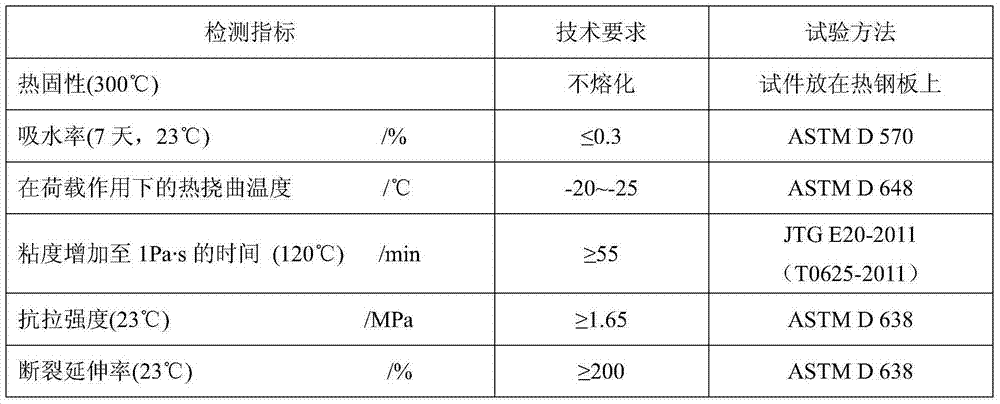

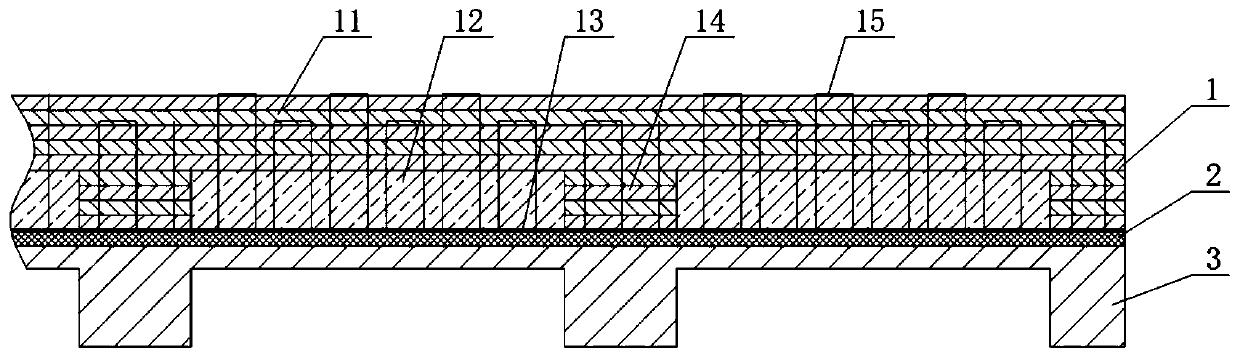

Long-life pavement structure for steel bridge deck and pavement method of pavement structure

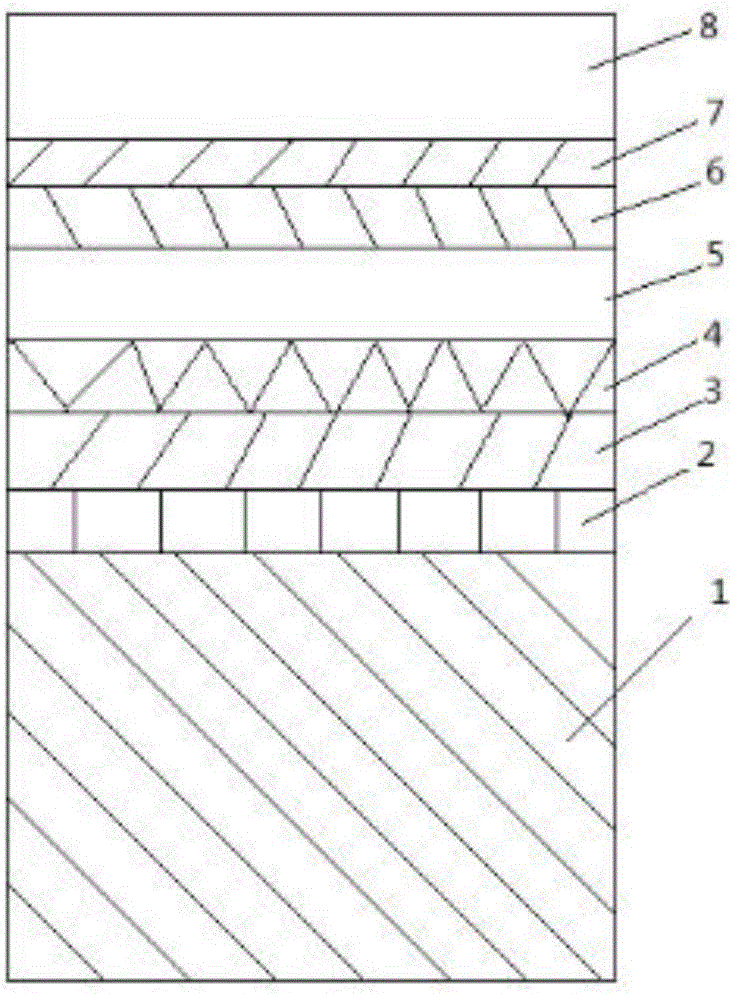

ActiveCN104499431AAvoid performance requirementsAdd depthIn situ pavingsBridge structural detailsSteel platesWear resistant

The invention discloses a long-life pavement structure for a steel bridge deck and a pavement method of the pavement structure. The long-life pavement structure comprises an anti-corrosion layer, a lower adhesive layer, a lower gravel layer, a structural layer, an upper adhesive layer, an upper gravel layer and a wearing layer which are sequentially arranged on the steel bridge deck from bottom to top. The pavement structure has excellent antiskid and waterproof performances, low-temperature cracking resistance, high-temperature rutting resistance, fatigue resistance and water stability, is fine in deformation compatibility with a steel plate and wear-resistant, surface aggregates do not easily fall off, the pavement method of the pavement structure is high in mechanization degree and strong in feasibility, the paved steel bridge deck can be put into operation in a short time, only the wearing layer of the pavement structure is damaged, only regular surface milling and top facing repair are needed, the pavement structure does not need to be structurally reconstructed in a long service life period, maintenance is facilitated, maintenance cost is saved, and the pavement method conforms to the design concept of a long-life pavement and also conforms to the energy conservation and environmental protection concept of modern society.

Owner:SOUTHEAST UNIV

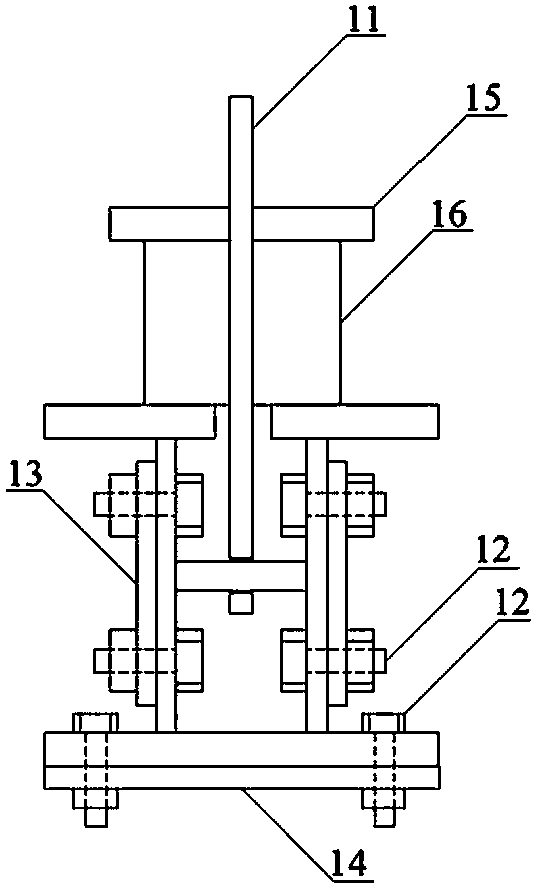

Split type bi-material flexible mechanism of space-based large-calibre high-facial-contour-precision reflector assembly

InactiveCN106443959AImproved deformation coordinationSurface shape error changes littleMountingsFlexible MechanismsStructure of the Earth

The invention, which belongs to the technical field of spatial remote sensing, relates to a split type bi-material flexible mechanism of a space-based large-calibre high-facial-contour-precision reflector assembly. The provided flexible mechanism is formed by an invar flange plate and a titanium-alloy flexible link. Flatness of a twenty-first flange surface and a twentieth flange surface of the invar flange plate is higher than 0.005mm and depths of parallelism of the twenty-first flange surface and the twentieth flange surface of the invar flange plate are not lower than 0.008mm. The titanium-alloy flexible link has a structure with three claws distributed around the periphery uniformly at 120 degrees; three radial flexible grooves and two axial flexible grooves are formed in each claw; flatness of a thirteenth flange plane and a nineteenth flange plane of the titanium-alloy flexible link is higher than -.005mm and depths of parallelism of the thirteenth plane and the nineteenth plane of the titanium-alloy flexible link are not lower than 0.008mm; and the thirteenth flange plane is formed by three small planes. The invar flange plate and the titanium-alloy flexible link are connected by connection of the thirteenth flange plane and the twenty-first flange surface with twelve bolts six cylindrical pins, thereby forming the flexible mechanism. According to the flexible mechanism provided by the invention, the influence on the facial contour precision by a thermal load and an assembling error is reduced substantially; and the anti-facial-contour-changing performance under a gravitational load is optimized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

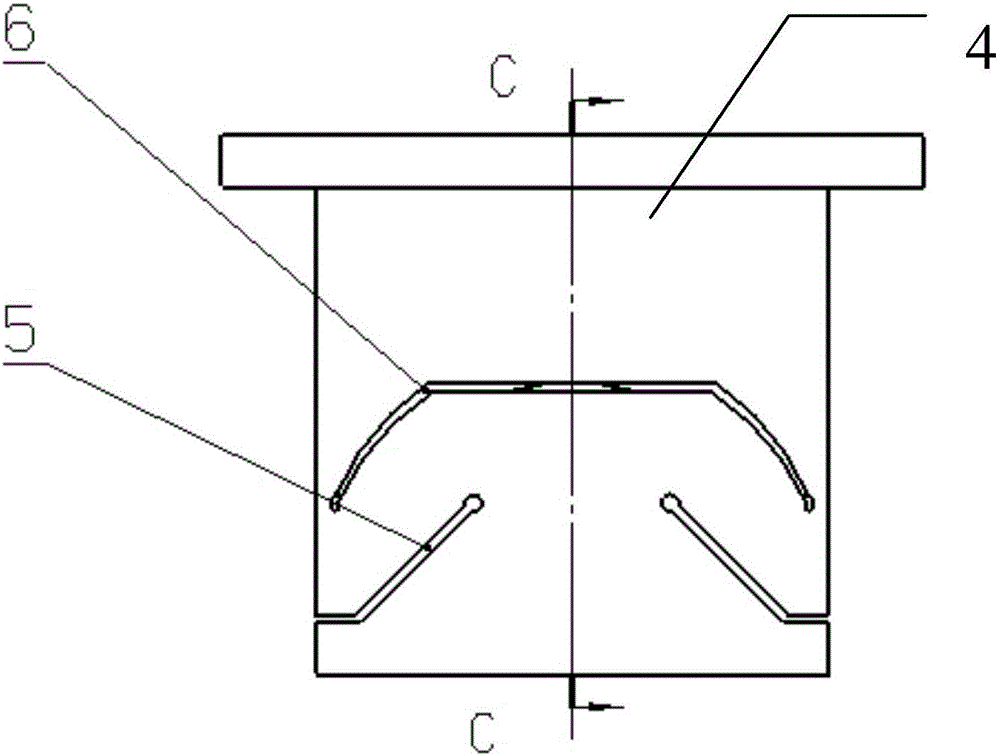

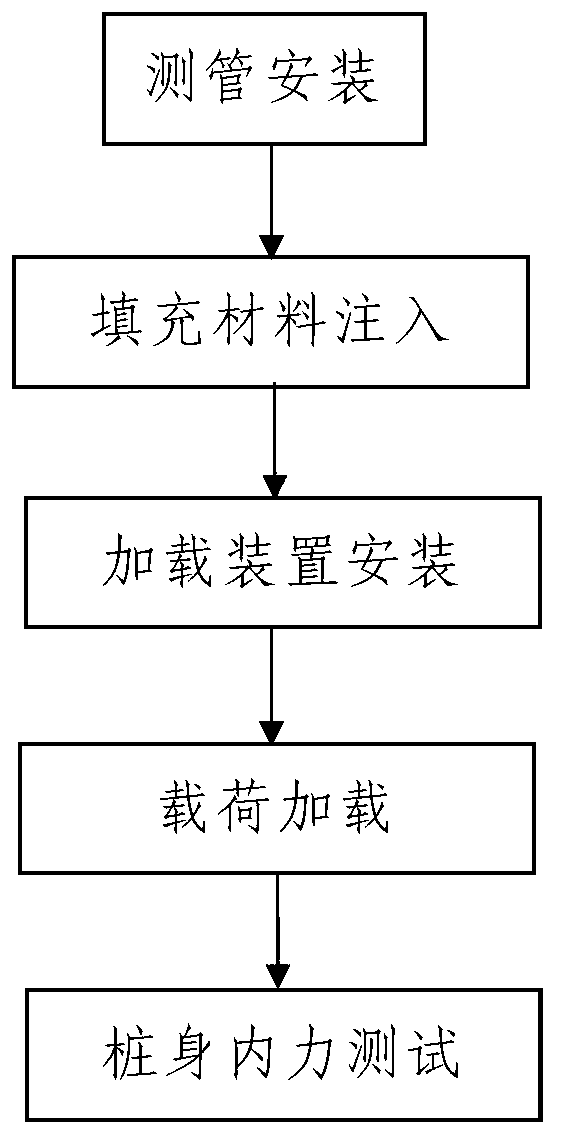

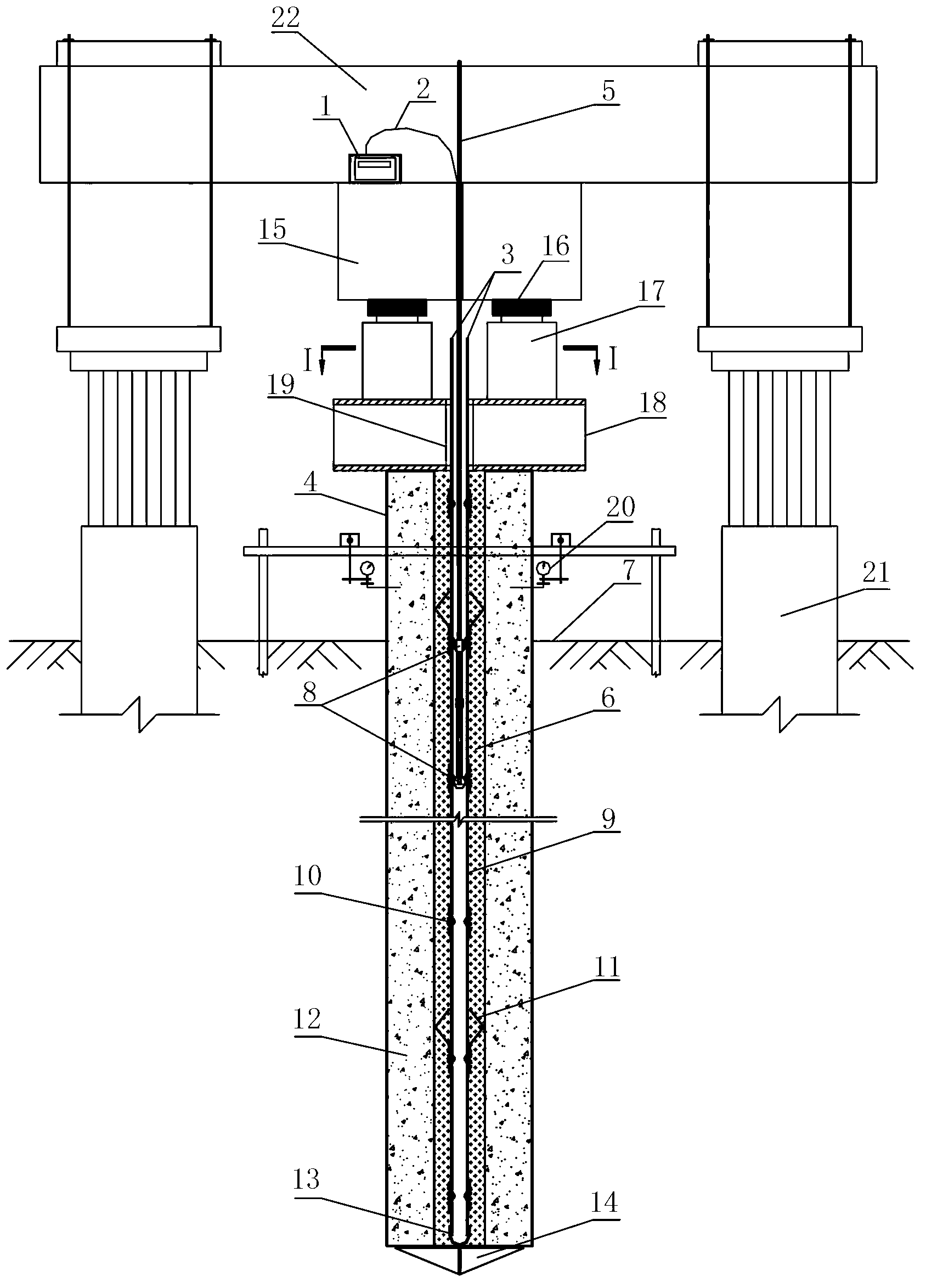

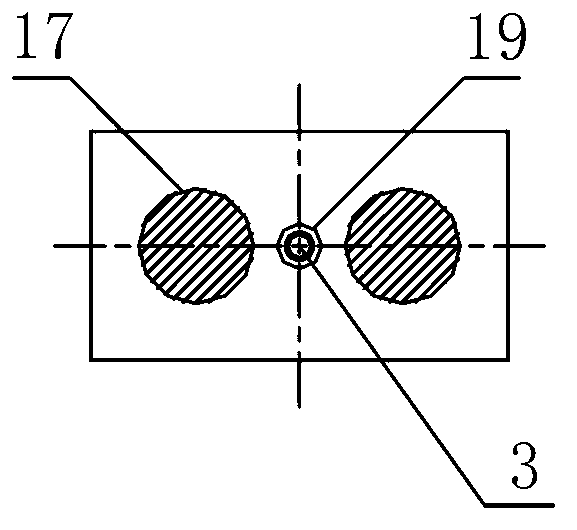

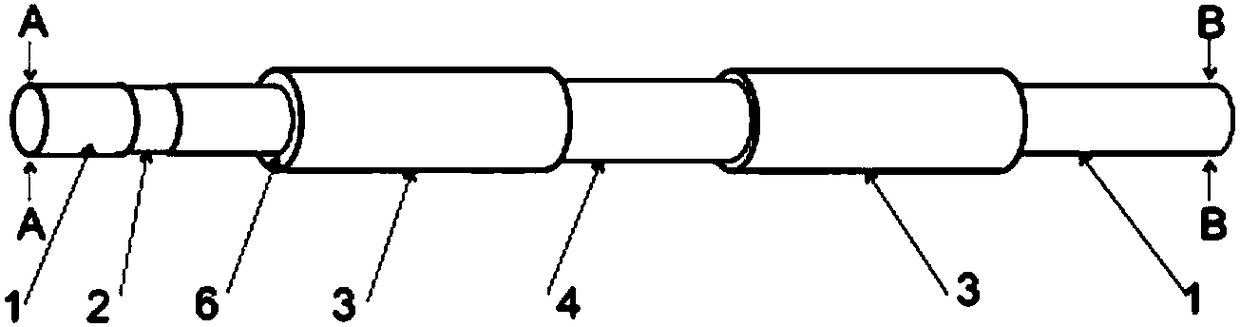

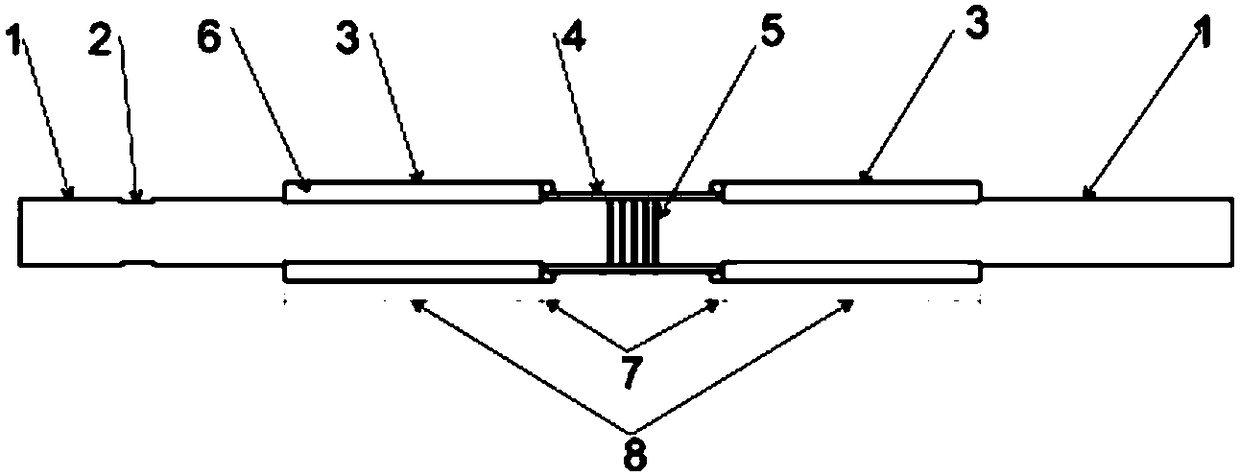

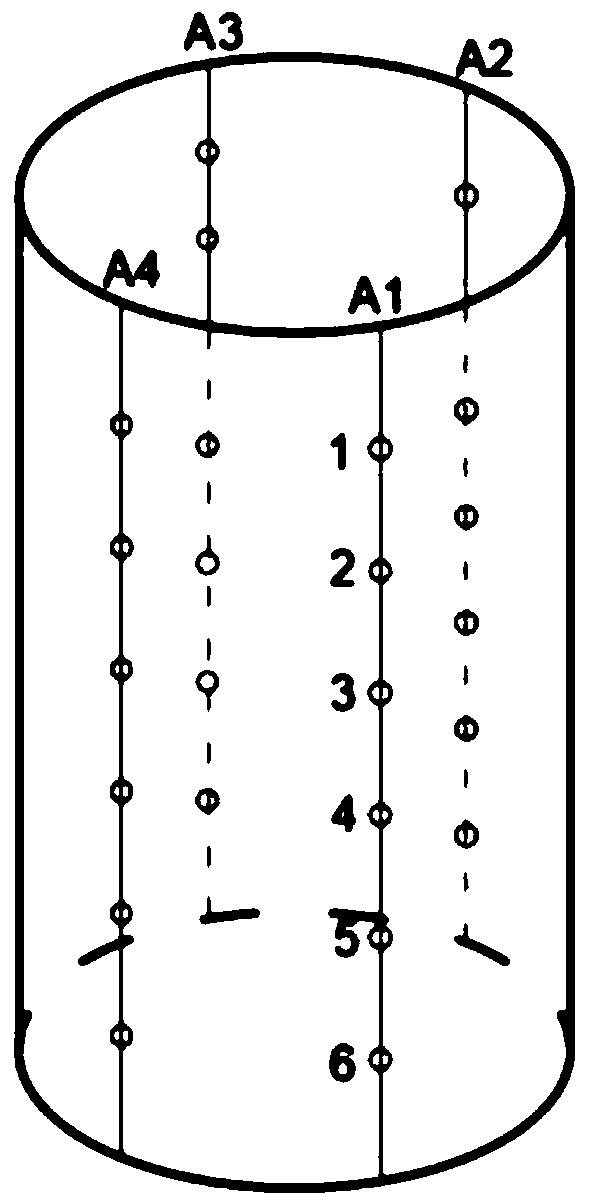

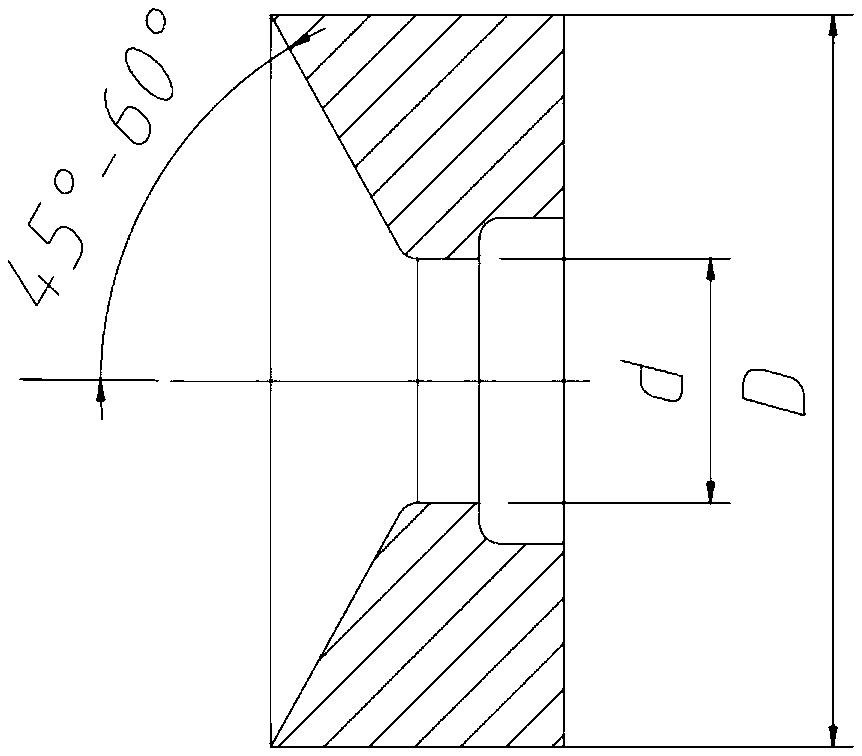

Internal force testing method for load test of pre-stress tubular pile

ActiveCN102797269AReasonable designSimple and fast operationFoundation testingMicrometerFilling materials

The invention discloses an internal force testing method for a load test of a pre-stress tubular pile. The method comprises the following steps: 1, installing a testing tube: the testing tube of a slide micrometer is installed in a constructed pre-stress tubular pile, and the testing tube is arranged in the middle of the pile core of the pre-stress tubular pile in the vertical direction; the bottom of the testing tube is sealed through a sealing cap and the testing tube is full of water; 2, injecting a filling material: the filling material is injected into the cavity between the tubular pile core of the pre-stress tubular pile and the testing tube from bottom to top by adopting grout injecting equipment, and comprises water, cement and bentonite; 3, loading an installation device; 4, loading a load; and 5, testing the internal force of a pile body: after the load is loaded and the pre-stress pile is settled and stabilized, the internal force of the pile body of the pre-stress tubular pile is tested by adopting the slide micrometer. According to the invention, the measuring method has simple steps and is convenient to implement while having high test precision and low investment, so as to obtain the internal force test result of the pre-stress tubular pile simply, conveniently, rapidly and accurately.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

Titanium boride nanowhisker reinforced titanium-based composite material and preparation method thereof

The invention discloses a titanium boride nanowhisker reinforced titanium-based composite material and a preparation method of the composite material. The composite material comprises a base body anda reinforcement phase. The base body is pure titanium or titanium alloy. The reinforcement phase is TiB nanowhiskers, the content is 0.5-12vol.%, and the distribution of the TiB nanowhiskers is of a net woven structure. The titanium alloy comprises alpha, alpha and beta and beta titanium alloy. Nanometer boron or nanometer boride is used as a raw material for generating TiB nanowhiskers to be mixed with pure titanium powder or titanium and alloying element mixed powder or titanium alloy prefabricated alloy powder to form a blank, selective discharge plasma low-temperature pressurization sintering is carried out for compactness, and the net woven distributed TiB nanowhiskers are obtained. The tensile strength of the titanium-based composite material is obviously improved, the tensile plasticity is excellently kept, and the elongation can reach 20% or above. The long-standing key problem that a titanium-based composite material prepared in the prior art is poor in plasticity when bearingtensile loads even being high in strength is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Beta-gamma TiAl alloy and preparation method thereof

InactiveCN102828067AGood deformabilitySmall high temperature deformation resistanceVacuum induction meltingAerospace

The invention provides a beta-gamma TiAl alloy and a preparation method thereof, relating to a TiAl alloy and a preparation method thereof. The invention mainly solves the problem that the existing TiAl alloy has poor high temperature deformability. The beta-gamma TiAl alloy is prepared from Al, X, A and balance of Ti, wherein X is element Mo or Mn, and A is element B or Y. The preparation method comprises the following steps of: firstly, weighing raw materials in percent by atom; secondly, pouring the raw materials into a vacuum induction melting furnace to be subjected to vacuum melting; and thirdly, pouring an alloy melt into a preheated metal casting mould, thus the beta-gamma TiAl alloy is obtained. The beta-gamma TiAl alloy prepared by adopting the invention improves high temperature deformability of a titanium-aluminium alloy, deformation adopting nearly isothermal sheath forging can reach up to 80%, surface of a prepared forging stock is smooth, internal tissue is thin and uniform, and the prepared forging stock is mainly applied to aviation and automobile industrial materials.

Owner:HARBIN INST OF TECH +1

FBG packaging structure capable of monitoring soil-body small deformation and packaging method

The invention provides an FBG packaging structure capable of monitoring soil-body small deformation and a packaging method. The method is characterized by using a thermoplastic tube and a quartz tubecapable of increasing a surface friction coefficient to carry out packaging protection on an FBG, and according to an actual monitoring demand, selecting the thermoplastic tube and the quartz tube with appropriate sizes; using abrasive paper to polish a thermoplastic tube surface and then installing and fixing to one side of an FBG raster; installing a quartz casing pipe in a grid area so as to protect the grid area and preventing a shear strain from damaging the grid area; and installing the thermoplastic tube after same processing on the other side of an FBG grid area, which is a soil-body small deformation FBG sensor. In the invention, a friction effect between the FBG sensor and a soil body is increased, coordination deformation between the FBG sensor and the soil body is improved, andthe small deformation of the soil body can be sensed; and shearing effect generated by the direct extrusion of the soil body is effectively avoided, the survival rate of the FBG buried in the soil body and the service life in the soil body are increased and prolonged, and soil body changes can be reliably and durably monitored.

Owner:SHANXI PROVINCIAL RES INST OF COMM

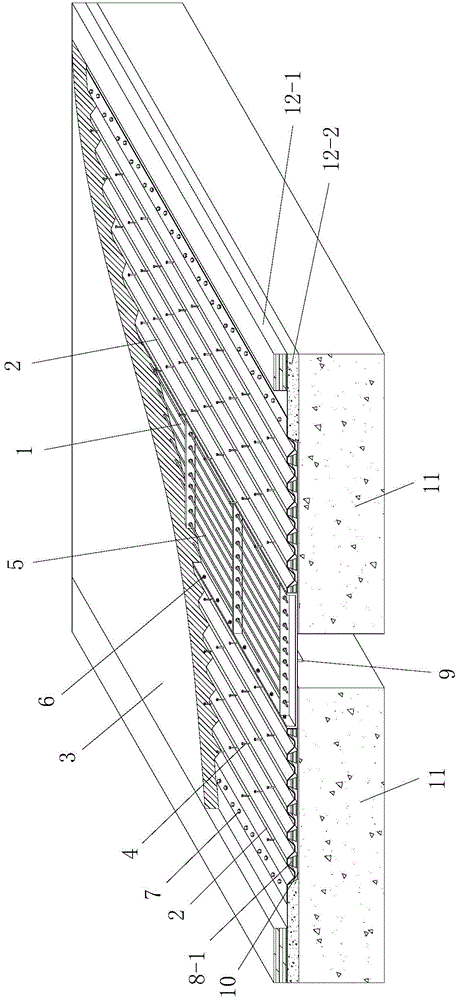

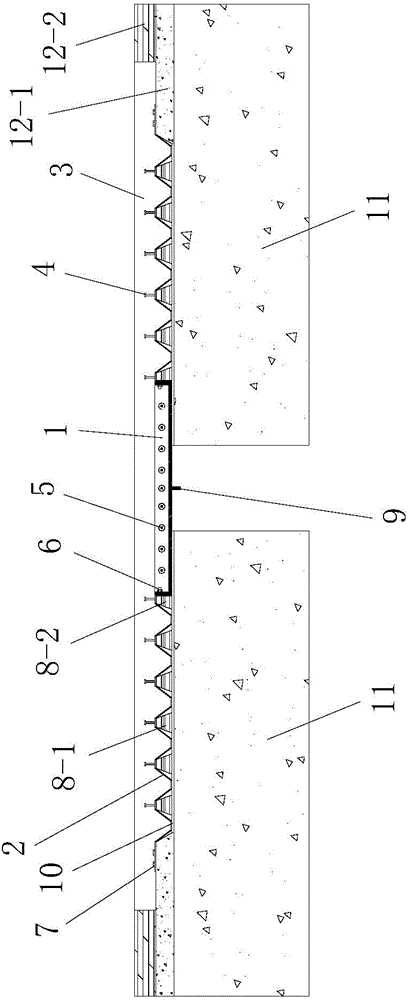

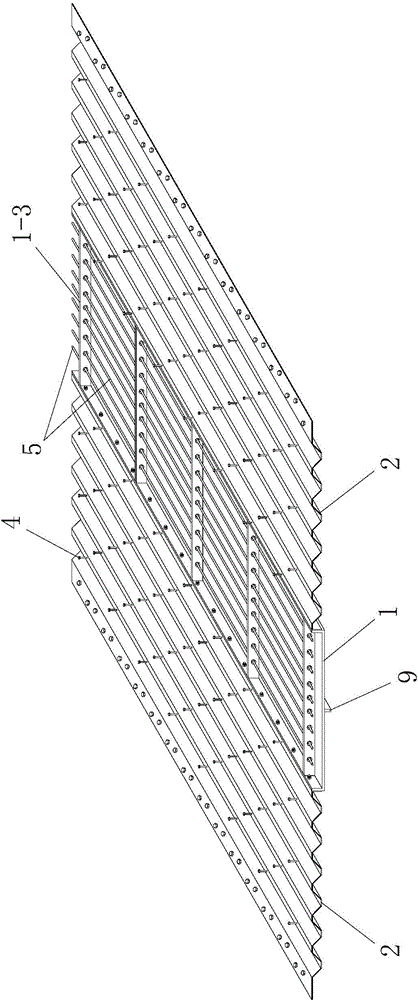

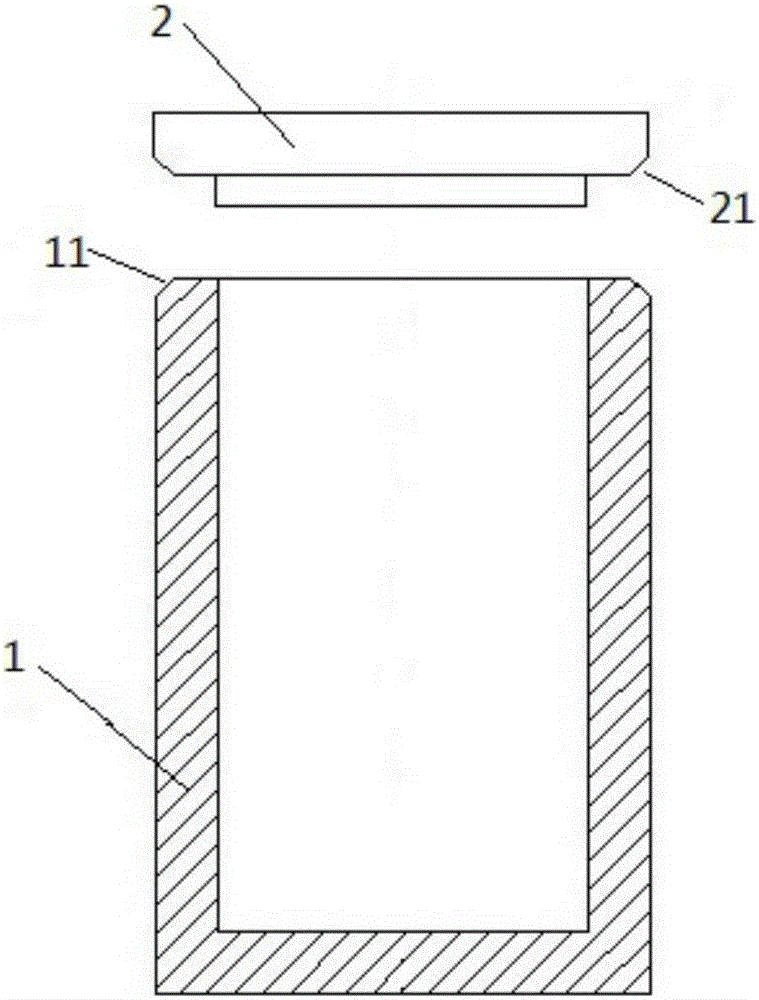

Stiffened joint-crossing plate based bridge deck jointless expansion device and construction method thereof

InactiveCN104674650ASimple structureReasonable designBridge structural detailsBridge erection/assemblyWave shapeExpansion joint

The invention discloses a stiffened joint-crossing plate based bridge deck jointless expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion assembly and an expansion joint filler filled layer filled above the prefabricated expansion assembly, wherein the prefabricated expansion assembly is arranged on an expansion joint reserved between every two adjacent girder segments, and a sliding layer is laid on a girder exposed segment of each girder segment; the prefabricated expansion assembly comprises a stiffened joint-crossing plate and two wave-shaped expansion plates. A construction method for an expansion device to be repaired comprises the steps of cleaning an original bridge expansion device, constructing reserved mounting grooves, constructing the sliding layers, carrying out field assembly and mounting on the prefabricated expansion assembly and constructing the expansion joint filler filled layer. A construction method for an expansion device to be constructed comprises the steps of prefabricating the prefabricated expansion assembly, carrying out field assembly on the prefabricated expansion assembly, constructing the sliding layers, mounting the prefabricated expansion assembly and constructing bridge deck pavement structures and the expansion joint filler filled layer. The stiffened joint-crossing plate based bridge deck jointless expansion device and the construction method thereof have the advantages that the design is reasonable, the construction is convenient, the use effect is good, and multiple problems of the existing expansion devices can be solved.

Owner:XIAN HIGHWAY INST

Wrapping cover method suitable for isothermal forging of Ti-Al-series intermetallic compound

The invention relates to a wrapping cover method suitable for isothermal forging of a Ti-Al-series intermetallic compound. The method comprises the following steps that firstly, wrapping cover pretreatment is conducted; secondly, the surface of a blank of the Ti-Al-series intermetallic compound is coated with a high-temperature anti-oxidization coating; thirdly, in the state that the high-temperature anti-oxidization coating is kept wet, the blank of the Ti-Al-series intermetallic compound is arranged in a wrapping cover, and a transition layer is arranged between the wrapping cover and the blank of the Ti-Al-series intermetallic compound; and fourthly, the wrapping cover is welded and sealed. Compared with the prior art, the wrapping cover method has the beneficial effects that the wrapping cover is simple and easy to use, the production efficiency is high, labor intensity is low, cracking and oxidizing in the Ti-Al-series intermetallic compound deforming process can be effectively prevented, and heat losses of the blank in the transferring process are reduced.

Owner:TONGJI UNIV

Method for eliminating surface cracks of ultra-wide-amplitude saving type double-phase stainless steel medium-thick plate

ActiveCN110484817AIncrease the axial grain rateGuaranteed finishing temperatureProcess efficiency improvementSurface layerThick plate

The invention discloses a method for eliminating surface cracks of an ultra-wide-amplitude saving type double-phase stainless steel medium-thick plate. A high-hardness ultrafine grain region with thethickness of 5-10 mm is formed on the upper surface and the lower surface of a continuous casting blank and the medium axis crystal proportion of the continuous casting blank is not lower than 75%, and the surface layer superfine crystal region is free of brittle phase separation; the casting blank is subjected to a preheating section, a heating section and a soaking section, and the casting blankis in the furnace 3.5-4.5 hours; the rolling temperature in the first stage is larger than or equal to 1150 DEG C; and the rolling temperature in the second stage is larger than or equal to 1100 DEGC, the final rolling temperature is larger than or equal to 980 DEG C, the solution temperature is 1020-1080 DEG C, and the furnace time is 2-5 min / mm. The product has the width of 2800-4000 mm and the thickness of 15-60 mm. The yield strength of the steel plate is larger than or equal to 450 MPa, the tensile strength is more than or equal to 650 MPa, the elongation percentage is larger than or equal to 30%, and the impact power is larger than or equal to 27J at at 40 DEG C below zero. The rejection rate of the surface cracks is reduced to be 1% or below from 10% or above. The product is applied to the fields of nuclear power, oil gas, shipbuilding, sea water desalination and the like.

Owner:ANGANG STEEL CO LTD

Anchor rod-steel frame integrated yielding primary support structure and construction method thereof

ActiveCN108386211AReasonable structural stressPracticalUnderground chambersTunnel liningStructural stressEngineering

The invention discloses an anchor rod-steel frame integrated yielding primary support structure and a construction method thereof, and belongs to the field of tunneling. The anchor rod-steel frame integrated yielding primary support structure comprises a steel arch frame, a buckling energy-dissipating structure, a yielding anchor rod and a force conversion rod, wherein the steel arch frame consists of two arc-shaped arch sections or more; every two adjacent arc-shaped arch sections are connected through a web connecting plate and a lower wing edge connecting plate; the buckling energy-dissipating structure is welded on the outer edge of the steel arch frame; the yielding anchor rod is arranged on a joint of every two adjacent two steel arch frames; one end of a force transmitting rod is connected with a tray on the yielding anchor rod, and the other end of the force transmitting rod is connected with the force conversion rod; and the other end of the force conversion rod is hinged in acavity formed by two webs of the steel arch frame through high-strength bolts. In a yielding process, radial force, on the support structure, of surrounding rocks is converted into circumference force, so that structural stress is more reasonable, and cooperative deformation of the surrounding rocks and the support structure is realized; and the problems that a current tunnel primary support system is twisted and deformed, and even damaged under action of high crustal stress, and the like are solved, and the deformation and damages of the surrounding rocks are effectively controlled.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Heat preventing and insulating integrated thermal protection structure suitable for negative curvature shape

ActiveCN110524974AImprove resistance to damageSolve problems prone to separationSynthetic resin layered productsFuselage insulationAdhesiveNear space vehicle

The invention discloses a heat preventing and insulating integrated thermal protection structure suitable for a negative curvature shape, and belongs to the technical field of thermal protection of hypersonic-speed near space aircrafts. The thermal protection structure includes a force bearing shell and a thermal protection layer; the thermal protection layer includes a heat insulating layer and aheat preventing layer, the inner wall of the heat preventing layer is provided with grid-like heat-preventing layer reinforcement ribs, the heat insulating layer is arranged in the grids of the heat-preventing layer reinforcement ribs, and the surface of the heat insulating layer is provided with a heat insulating layer covering skin; the heat preventing layer, the heat insulating layer coveringskin, and the heat-preventing layer reinforcing ribs are sewed together with the heat insulating layer through a sewing line in a prepreg state, and the whole is subjected to high-temperature curing to form the heat preventing and insulating integrated structure; and an adhesive layer is located between the force bearing shell and the thermal protection layer, and the adhesive layer is an adhesivewith high-temperature resistance and heat matching performance. The thermal protection structure provided by the invention adopts the heat preventing and insulating integrated thermal protection layer, and the thermal protection layer is bonded to the force bearing shell by using the high-temperature-resistant adhesive, so that interface separation at the negative curvature part of the thermal protection structure of an aircraft can be avoided.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

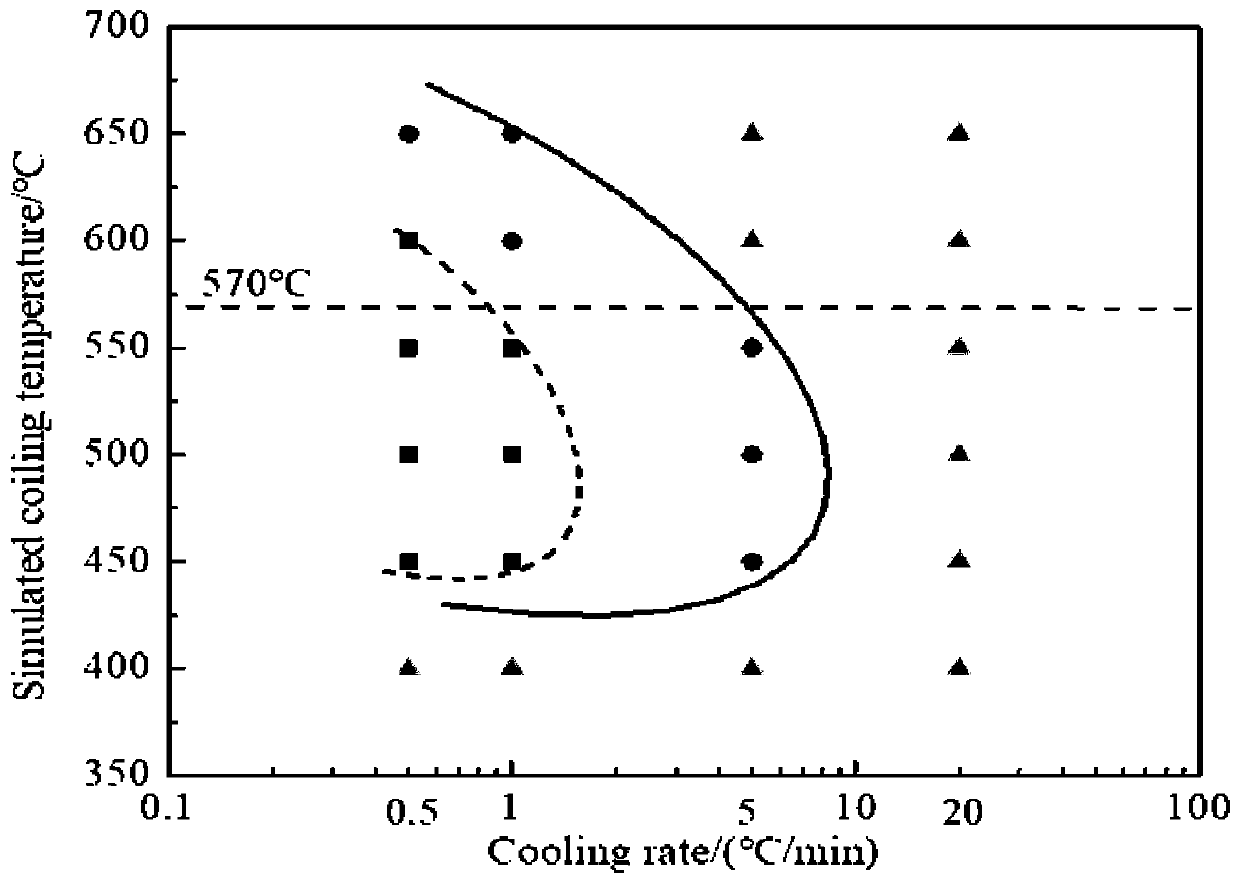

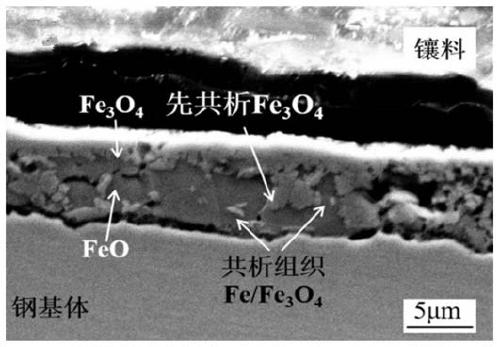

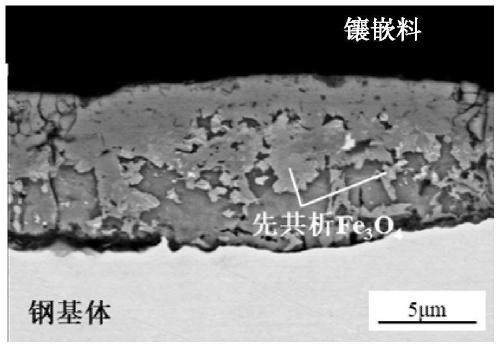

Automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and preparation method of automobile beam steel plate

The invention relates to an automobile beam steel plate with tensile strength of 750MPa grade and heavy gauge, and a preparation method of the automobile beam steel plate. The steel plate comprises, by mass, 0.03 to 0.12% of C, 0.05 to 0.60% of Si, 0.2 to 1.0% of Cr, 1.0 to 2.5% of Mn, not greater than 0.015% of S, not greater than 0.025% of P, 0.015 to 0.045% of Als, 0.07 to 0.15% of Ti, 0.02 to0.08% of Nb, and the balance being Fe and impurities that are unavoidable during smelting. During preparation, a steel billet adopting the above chemical composition proportion is subjected to reasonable process design, so as to prevent the pickling preparation process from replacing the original process, reduce the thickness of the scale, and obtain the scale complex structure of Fe3O4, FeO and eutectoid Fe3O4 coexisting with alpha-Fe, so that the surface quality of the steel plate is significantly improved, and the requirements of the use of pickling-free direct stamping or roll forming andeliminate the pickling process can be met, production efficiency is improved, environmental pollution is reduced and production cost is reduced.

Owner:NORTHEASTERN UNIV

Bridge seamless telescopic device and construction method of device

InactiveCN104594190ASimple structureWell formedBridge structural detailsBridge erection/assemblyWave shapeArchitectural engineering

The invention discloses a bridge seamless telescopic device and a construction method of the device. The bridge seamless telescopic device comprises a main beam span telescopic device and a bridge abutment telescopic device, wherein the main beam span telescopic device comprises a first prefabricated telescopic component and a first telescopic joint filler filling layer; the bridge abutment telescopic device comprises a second prefabricated telescopic component and a second telescopic joint filler filling layer; the first prefabricated telescopic component and the second prefabricated telescopic component are formed by reinforced joint-crossing plates and wave-shaped telescopic plates. A construction method of a telescopic device to be repaired comprises the following steps: cleaning an original bridge telescopic device, constructing a preserved mounting slot, constructing a sliding layer, assembling and mounting prefabricated telescopic components, and constructing telescopic joint filler filling layers. A construction method of a telescopic device to be constructed comprises the following steps: prefabricating and processing prefabricated telescopic components, assembling the prefabricated telescopic components on site, constructing a sliding layer, mounting prefabricated telescopic components, paving a structure and constructing telescopic joint filler filling layers. The bridge seamless telescopic device is reasonable in design, convenient to construct and high in using effect, and can be used for solving various problems of the existing telescopic device.

Owner:XIAN HIGHWAY INST

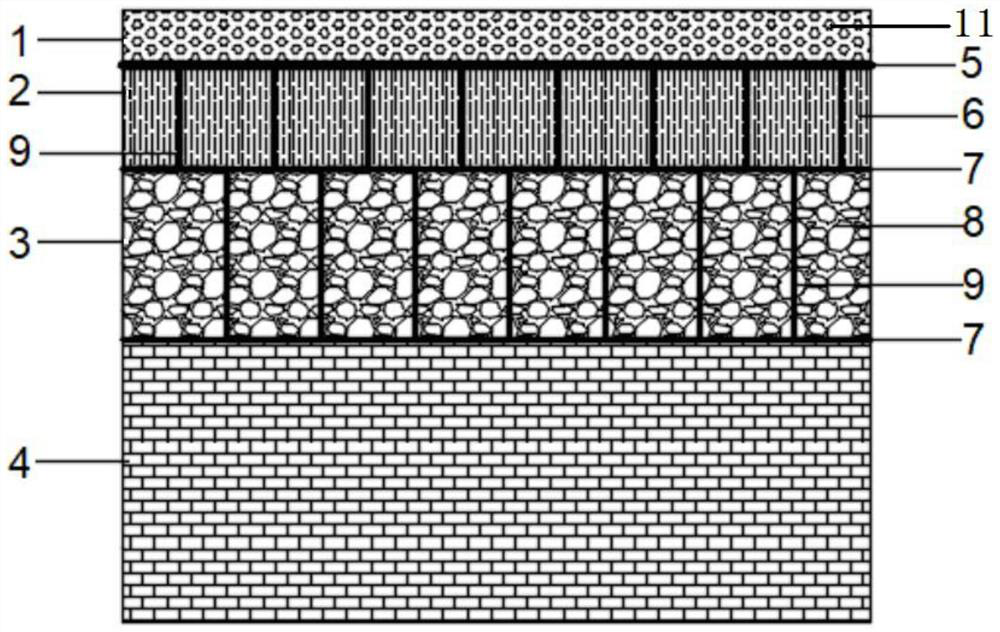

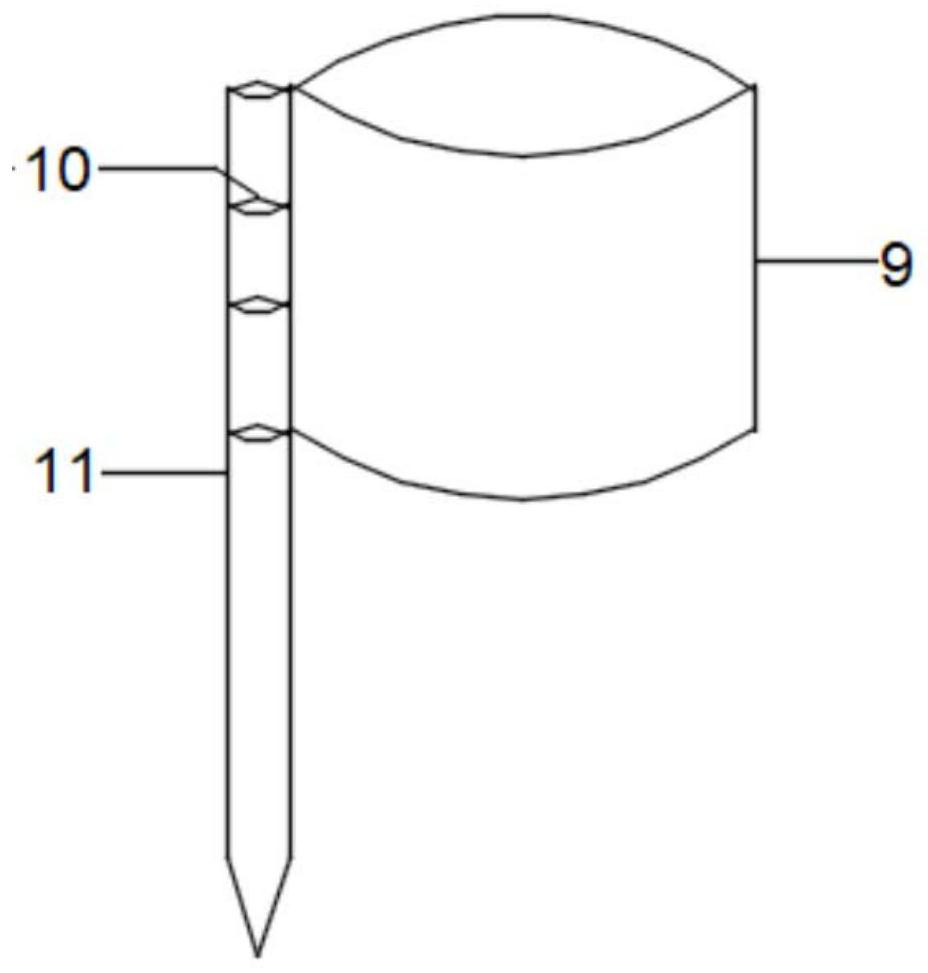

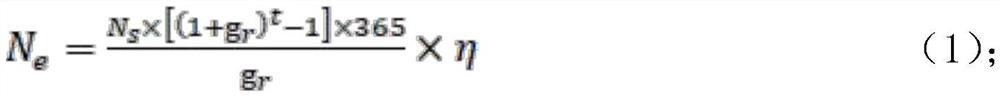

Geocell reinforced cement concrete pavement structure and surface layer plate thickness calculation method

PendingCN111962350AReduce crackingReduce thicknessIn situ pavingsRoads maintainenceCrushed stoneGeocells

The invention discloses a geocell reinforced cement concrete pavement structure and a surface layer plate thickness calculation method. The pavement structure mainly comprises a base layer, a surfacelayer and a wearing layer which are sequentially laid from bottom to top. The base layer is composed of an upper geotextile layer, a lower geotextile layer and a middle geocell reinforced graded broken stone layer; the surface layer is a cement concrete layer reinforced by a geocell; the wearing layer comprises a cement mixture wearing layer and a geogrid; pull rings are reserved on the two sidesof each geocell in a road direction, the geocells are stretched to be in a tensioned state, and wooden wedges penetrate through the pull rings to fix the geocell at the outermost end. The surface layer plate thickness calculation method mainly comprises the steps of traffic analysis, initial simulation of a pavement structure, determination of pavement material parameters, and checking of load stress, temperature stress and a structure limit state. The problems that an existing pavement structure is low in strength, and a cement concrete pavement is subjected to fatigue fracture, mud pumping,slab staggering and the like under heavy-load traffic are solved, so that the pavement structure has high bearing capacity and deformation resistance, and damage to the pavement structure is reduced.

Owner:HUNAN UNIV OF SCI & TECH

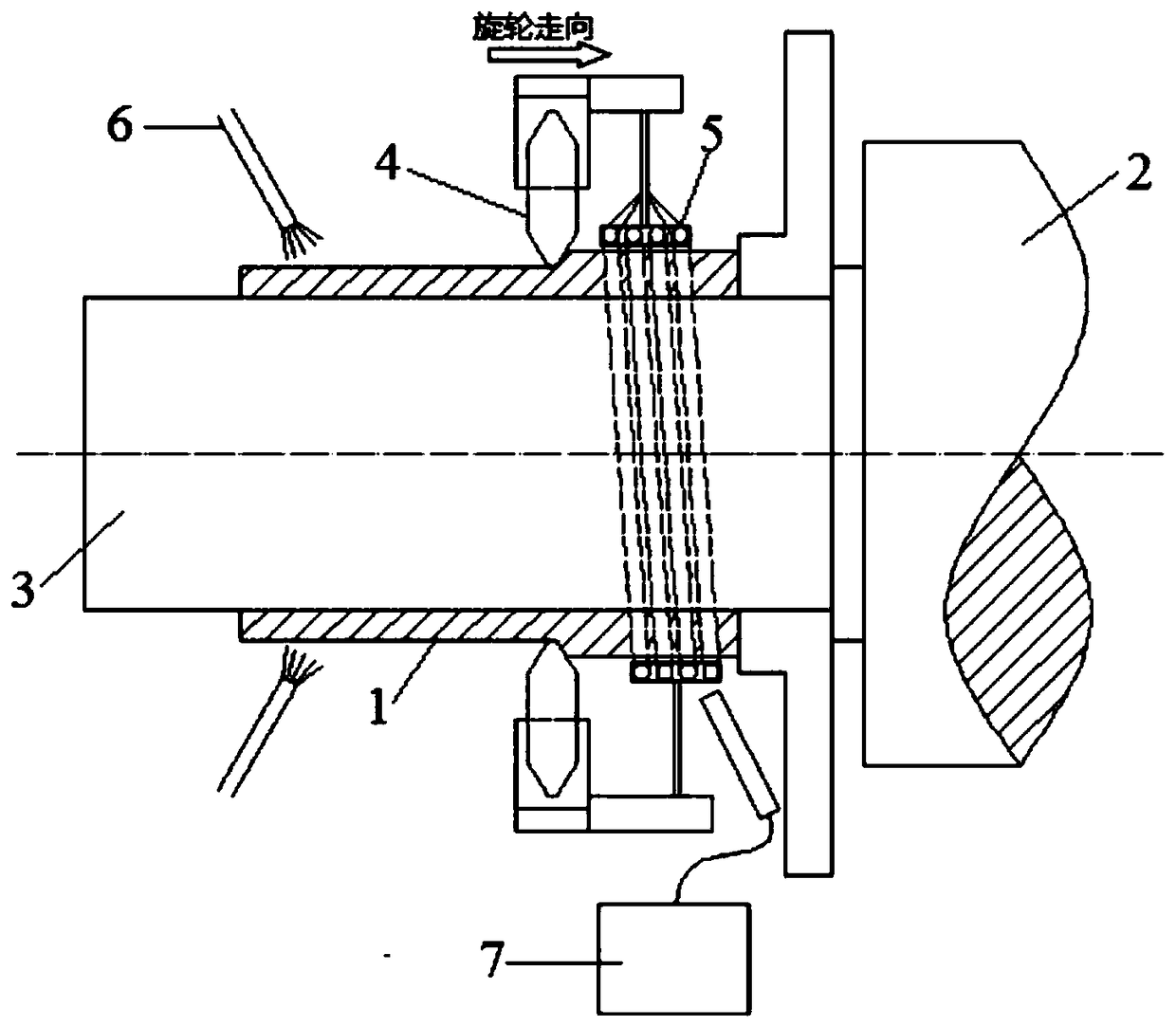

Titanium-based alloy material spinning forming method based on composite heating

ActiveCN109108139AEvenly heatedImproved deformation coordinationShaping toolsTemperature controlInstability

The invention provides a titanium-based alloy material spinning forming method based on composite heating. The titanium-based alloy material spinning forming method comprises the steps that firstly, ablank, a central spindle and a spinning roller are preheated with a flame gun; and secondly, the blank is heated to the spinning temperature with a follow-up induction heating coil, the temperature is monitored with an infrared thermal imager in the spinning process, and heating and heat preserving are conducted on the blank in a spun area behind the spinning roller with the flame gun. Accordingto the titanium-based alloy material spinning forming method based on composite heating, two heating modes including front-end electromagnetic induction heat source heating and back-end flame source heat compensating are combined, the temperature is monitored with the infrared thermal imager, and then online heating and precise temperature controlling in the spinning forming process are achieved.Embodiment results show that when spinning forming is conducted on a titanium-based alloy through the method, an obtained spun part is uniform in wall thickness, has no cracking phenomenon, is high inquality and can not generate defects such as instability wrinkling in the spinning process.

Owner:HARBIN INST OF TECH

Forming die and method for magnesium/aluminum alloy bimetal composite pipe

ActiveCN109570253AAchieving strain softeningUniform deformationExtrusion diesMagnesiumThrough transmission

The invention provides a forming die and method for a magnesium / aluminum alloy bimetal composite pipe, and belongs to the technical field of metal plastic working. The forming die for the magnesium / aluminum alloy bimetal composite pipe comprises a main shaft, an extrusion gasket, an extrusion core pin, an extrusion cylinder lining, an extrusion cylinder, an extrusion die, a die-filling extrusion shaft, a cylindrical roller bearing, a thrust bearing, a gear A, a gear B, a sleeve, a gearbox, an end cap A, an end cap B and a shearing device. The extrusion cylinder, the extrusion cylinder lining,the main shaft and the extrusion core pin simultaneously move to the right to realize the extrusion forming process, furthermore, repeated rotation of the die-filling extrusion shaft in the extrusionprocess is realized through transmission of the gear A and the gear B, and after the extrusion is completed, extrusion remnant materials are cut off by the shearing device. Advantages of high pressuretorsion and extrusion forming are combined, blank is simultaneously subjected to extrusion and torsion actions, so that the metal flow resistance, the preheating temperature of the blank and the diecan be reduced, and the interface quality and dimensional accuracy of the composite pipe is improved.

Owner:UNIV OF SCI & TECH BEIJING

Abutment hidden expansion device and construction method thereof

InactiveCN104762873AWell formedSimple structureIn situ pavingsBridge structural detailsExpansion jointAbutment

The invention discloses an abutment hidden expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion component arranged on an abutment expansion joint, and an expansion joint filler filling layer filled in the upper side of the prefabricated expansion component, wherein a bridge deck pavement structure is paved on a main beam; a slide layer is paved on an exposed section of the main beam; a road surface pavement layer is arranged at the outer side of the upper part of an abutment; the prefabricated expansion component comprises a reinforced joint plate and a waveform expansion plate; a construction method of an expansion device to be repaired comprises the steps of cleaning of an original bridge expansion device, construction of a reversed mounting groove, construction of the slide layer, field assembly and installation of the prefabricated expansion component and construction of the expansion joint filler filling layer; and a construction method of an expansion device to be constructed comprises the steps of prefabrication of the prefabricated expansion component, field assembly of the prefabricated expansion component, construction of the slide layer, installation of the prefabricated expansion component and construction of the bridge deck pavement structure and the expansion joint filler filling layer. The abutment hidden expansion device and the construction method thereof have the advantages of reasonable design, convenience for construction and good use effect, and can solve multiple problems in traditional expansion devices.

Owner:XIAN HIGHWAY INST

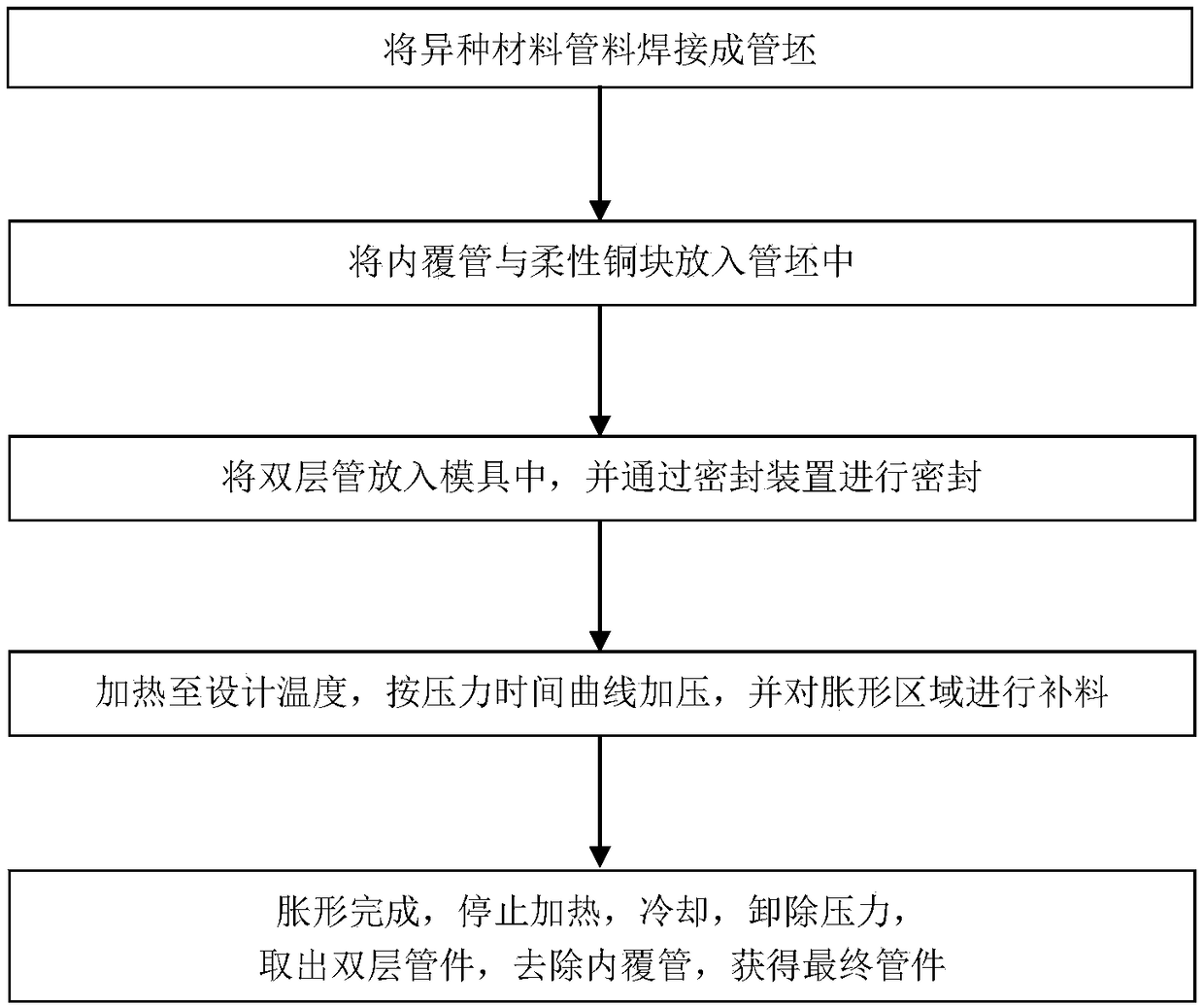

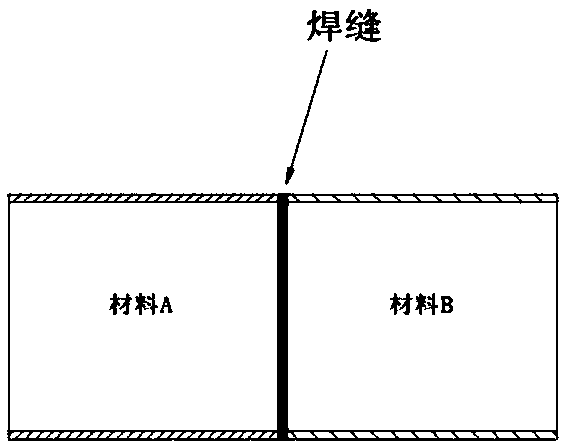

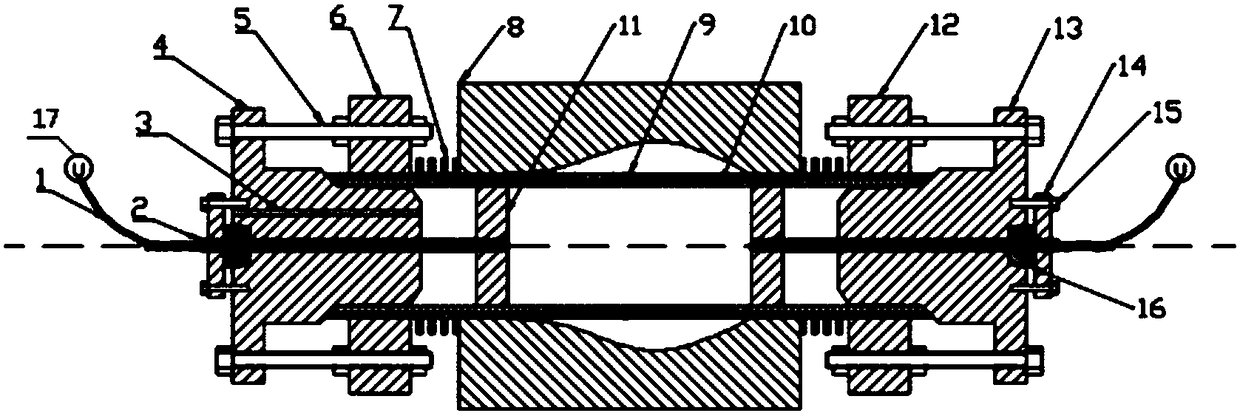

Electric assistant heating forming device and method for dissimilar material complicated section pipe fittings

The invention discloses an electric assistant heating forming device and method for dissimilar material complicated section pipe fittings. Pipe blanks welded by dissimilar material pipes and inner coating pipes positioned in the pipe blanks are positioned in an air expansion forming mold; two ends of the pipe blanks are sealed through sealing push heads and elastic sealing blocks; the positions offlexible copper blocks are adjusted by using advancement and retreating of push rods to realize local area heating; high-pressure gas is injected in the inner coating pipes to enable the pipe blanksto quickly bond on molds; meanwhile, the push heads are pushed for feeding; after formation, the heating is stopped; the high-pressure gas in the pipe blanks is relieved; formed double-layer pipe fittings are taken out; and the inner coating pipes are removed through acid washing to obtain final pipe fittings. The device and the method are suitable for expansion of the dissimilar material pipes, solve the problems of inharmonious deformation in expansion of traditional dissimilar material pipe blanks and rupture of welding lines through local heating and coating plate expansion, also can be used for gradual formation of pipe fittings in multiple expansion areas, meet urgent demands in such fields as aerospace, and achieve high practical value.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com