Integral forming process method of thin-wall hooped tube workpieces

A technology of overall forming and process method, which is applied in the field of forming and manufacturing of sheet metal parts, can solve the problems such as the inability to realize local deformation self-adjustment, achieve the effects of improving integrity and reliability, avoiding longitudinal welds, and eliminating rollover moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

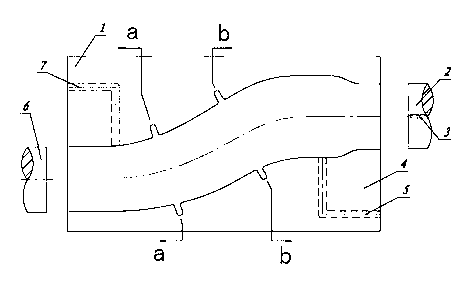

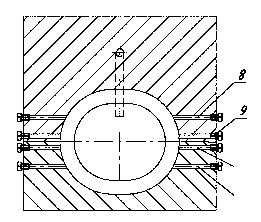

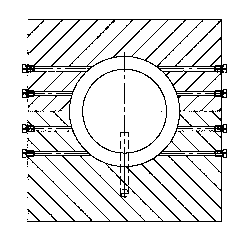

[0048] combined with Figure 1-10 , to further describe the present invention:

[0049] 1. Mold operation preparation,

[0050] a, make mold, mold is made up of upper mold 1, lower mold 4 and sealing punch, mold cavity is divided into feeding zone, bulging zone, and sealing punch comprises left punch and right punch, and above-mentioned is the same as prior art , which will not be described here, an overflow hole 8 is set at the part corresponding to the bulging area of the mold and the reinforcing rib, such as figure 1 , Figure 1.1 , Figure 1.2As shown, the number and diameter of the overflow holes depend on the bulging amount of the component and the height-thickness ratio of the reinforcement. The design principles are as follows: the bulging amount is greater than 15%, the number of overflow holes should be no less than 20, and the cross-sectional area It is not easy to exceed 5% of the initial ribbed tube blank cross-sectional area; the height-thickness ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com