Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Reduce forming process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

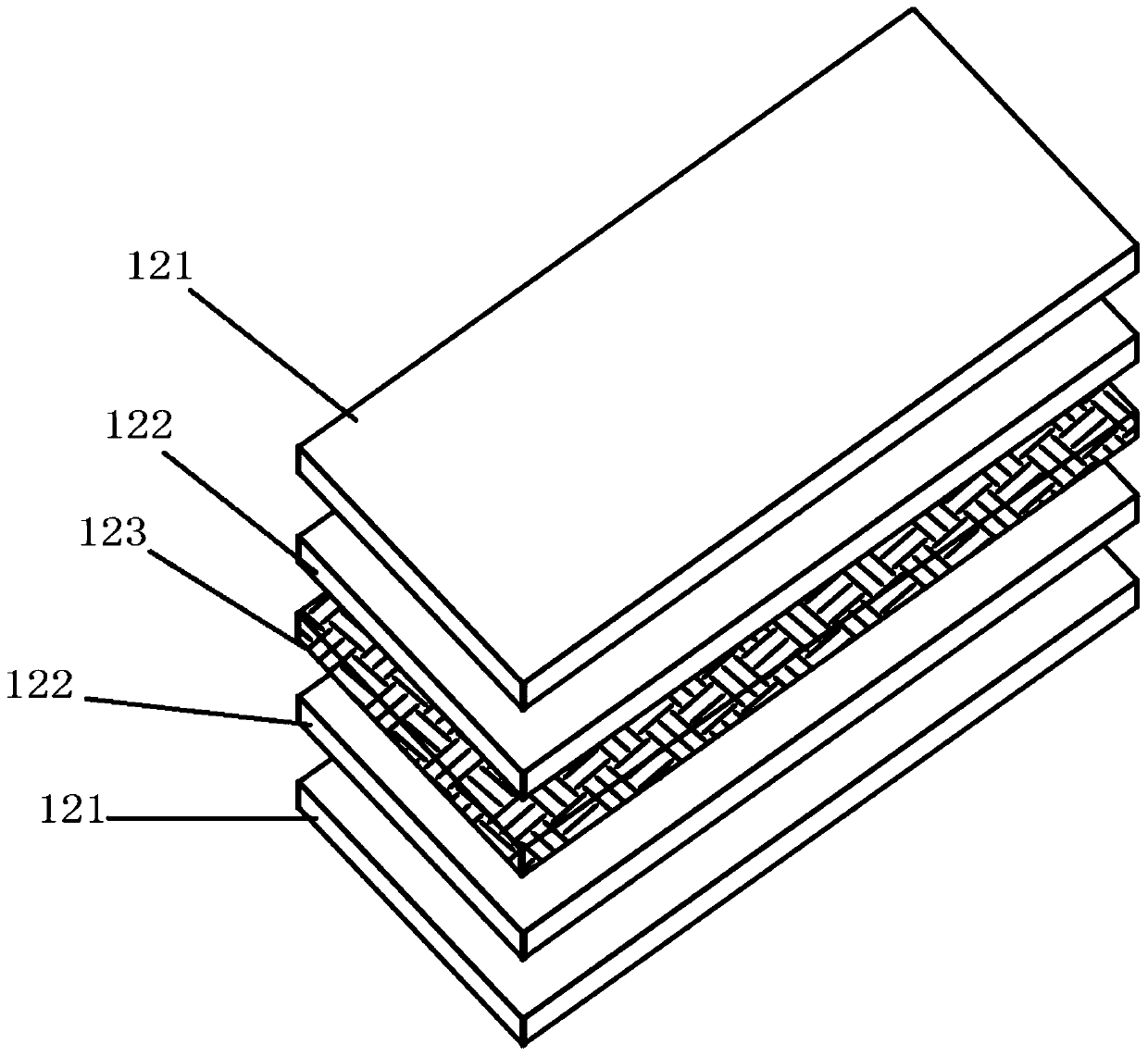

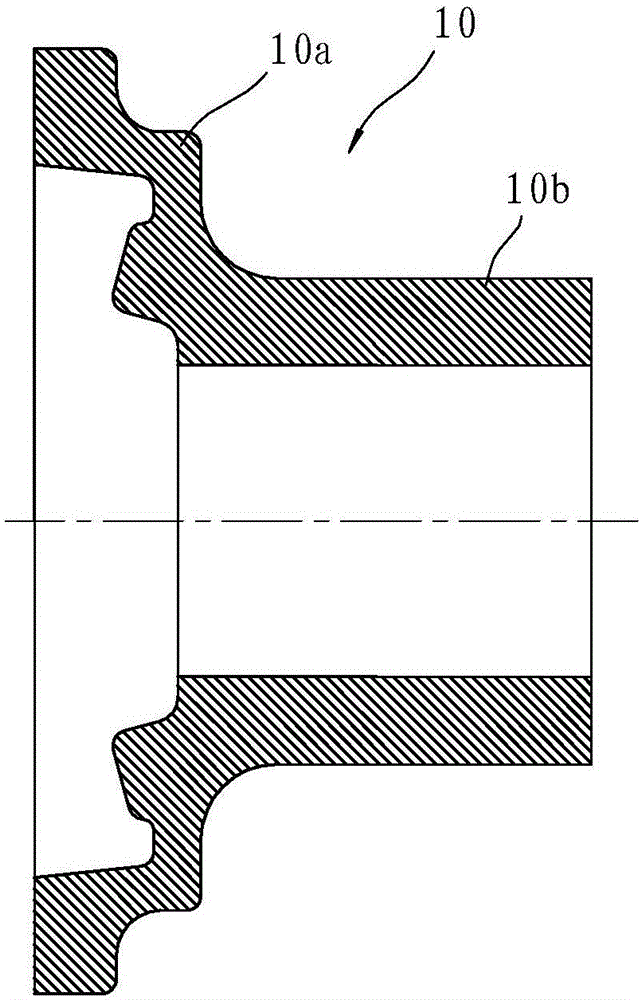

Fiber-metal composite laminate, forming die therefor and forming method

ActiveCN109986860AHigh strengthGood formabilitySynthetic resin layered productsFlat articlesFiberCarbon fibers

The invention discloses a fiber-metal composite laminate, a forming die therefor and a forming method. The fiber-metal composite laminate comprises two aluminum-alloy layers, wherein at least two PEEKresin layers are arranged between the two aluminum-alloy layers, and a carbon fiber prepreg layer is arranged between every two adjacent PEEK resin layers. The forming die for the fiber-metal composite laminate comprises a male die and a combined female die which are arranged correspondingly. The forming method for the fiber-metal composite laminate comprises the step of carrying out hot stampingforming on the fiber-metal composite laminate by using the forming die. According to the fiber-metal composite laminate, the forming die therefor and the forming method, disclosed by the invention, the efficiency and quality of production of the fiber-metal composite laminate are improved.

Owner:CENT SOUTH UNIV

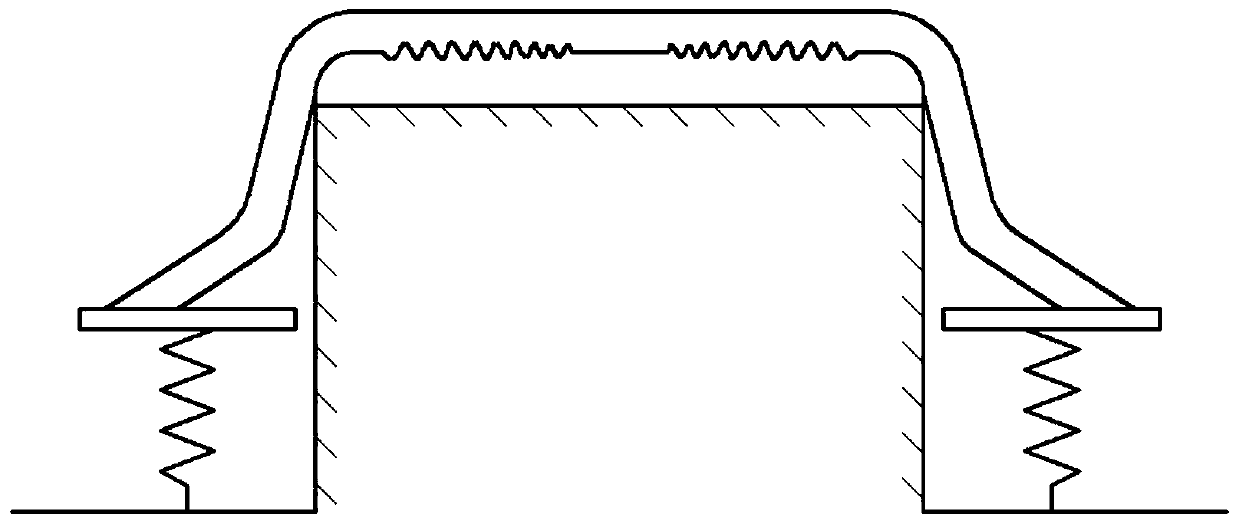

Integral forming process method of thin-wall hooped tube workpieces

The invention discloses an integral forming process method of thin-wall hooped tube workpieces. The technical scheme comprises the flowing steps of: 1, preparing a mould: firstly forming overflow holes in corresponding parts on the mould, welding reinforcing ribs in a thin-wall tubing without welded lines in advance and placing into a mould cavity, performing spotting on the mould, sealing ends of a tube blank, filling a strain rate sensitive medium between the mould and the tube blank, then filling liquid forming medium in the tube blank and applying certain pressure; 2, forming: increasing the pressure of the inside liquid, meanwhile adjusting the flow state of the strain rate sensitive medium to cause a tube body and a reinforcing plate to be deformed in a coordinated way to form qualified parts; and 3, picking up the parts: reducing the pressure to 0MPa, opening the mould and then taking out the parts from the mould. The integral forming process method of the thin-wall hooped tube workpieces has the advantages of few forming processes, low manufacturing cost, high mechanical property of formed members, high dimension precision and the like, and is particularly suitable for forming thin-wall hooped tube workpieces with a sealed complex section shape.

Owner:HARBIN INST OF TECH AT WEIHAI +1

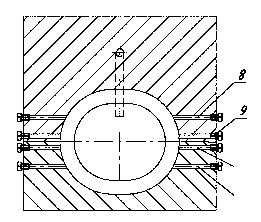

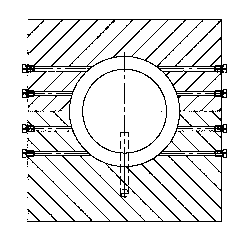

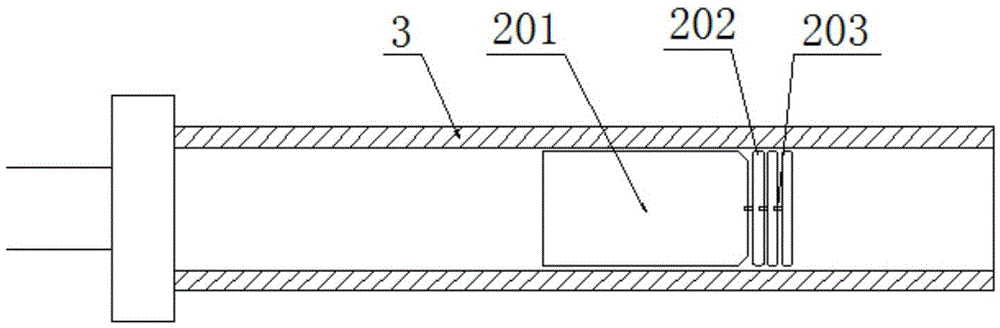

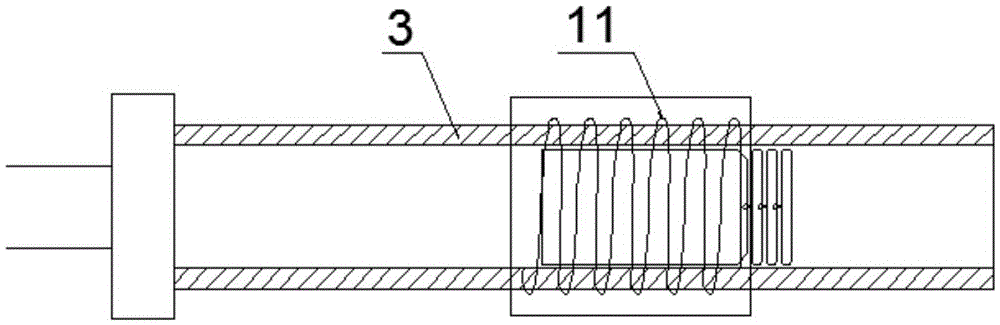

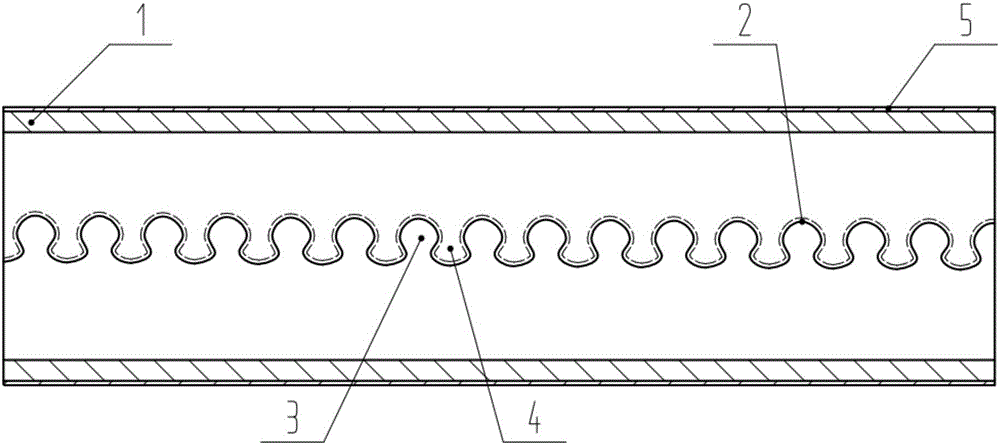

Solid solution-bending-aging forming device and method for vehicle body aluminum alloy pipe

The invention discloses a solid solution-bending-aging forming device and method for a vehicle body aluminum alloy pipe. The device comprises a heating mechanism and a bending mechanism. The heating mechanism comprises an induction coil and a high-frequency power source. The induction coil is arranged on the periphery of a bent part of the pipe in a sleeving mode and connected with the high-frequency power source. The bending mechanism comprises a bending die, a fixed clamp block, a crease-resistant block, movable clamp blocks and a rigid / flexible core die. The bent part of the pipe is placed on the bending die. One end of the pipe is clamped on the bending die through the fixed clamp block and the crease-resistant block, and the other end of the pipe is clamped by the movable clamp blocks. The rigid / flexible core die is arranged in the pipe. The fixed clamp block, the crease-resistant block and the movable clamp block are designed in a split mode, and the bending die is designed in an insert mode, so that water channels are processed conveniently and replacement after abrasion is convenient. The bending die, the fixed clamp block, the crease-resistant block and the movable clamp blocks are all internally provided with serpentine channels used for introducing cooling water. The solid solution-bending-aging forming device and method for the vehicle body aluminum alloy pipe can significantly improve the strength, the hardness and the forming precision of aluminum alloy pipes, and the springback problem of the pipes after bending and quenching is effectively solved.

Owner:WUHAN UNIV OF TECH

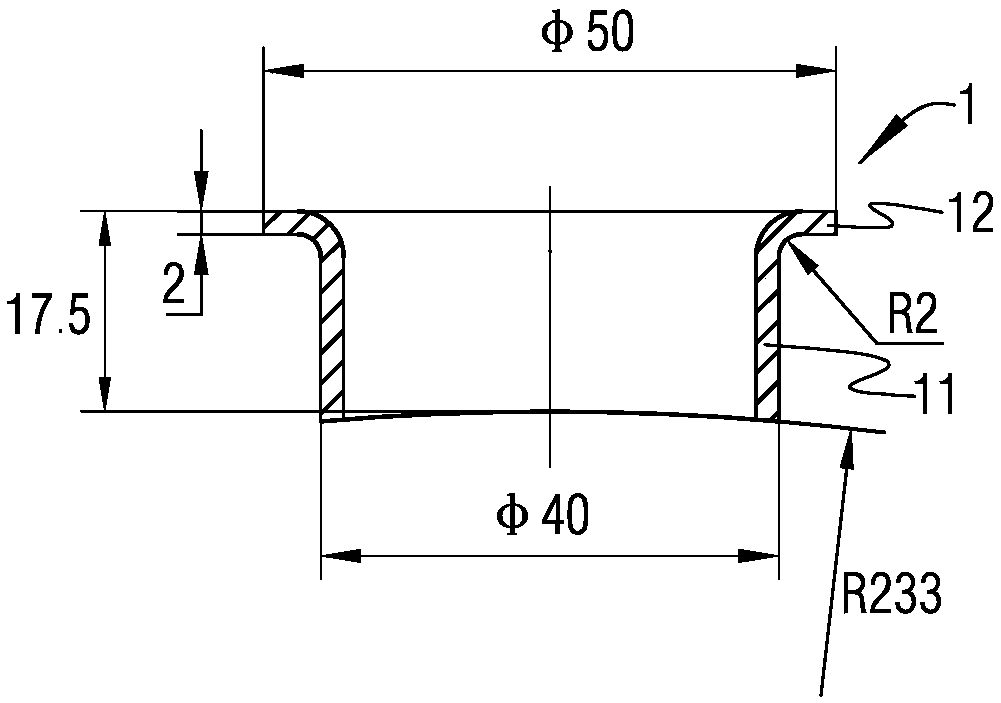

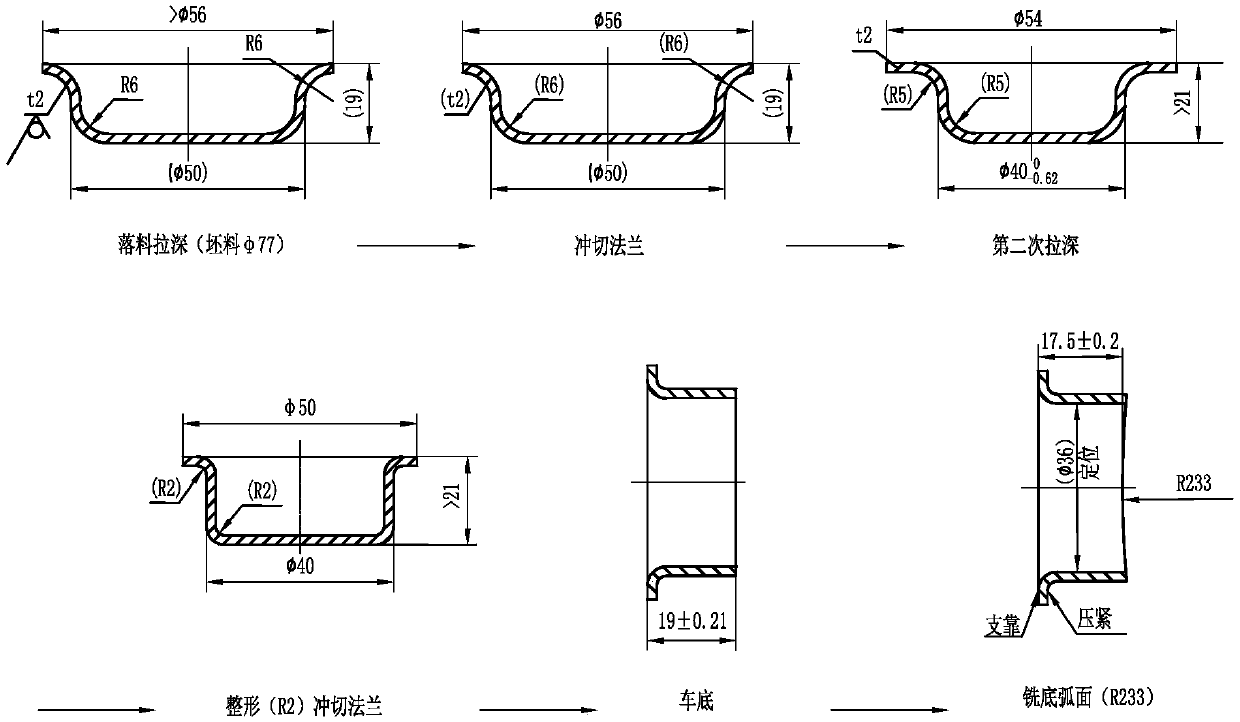

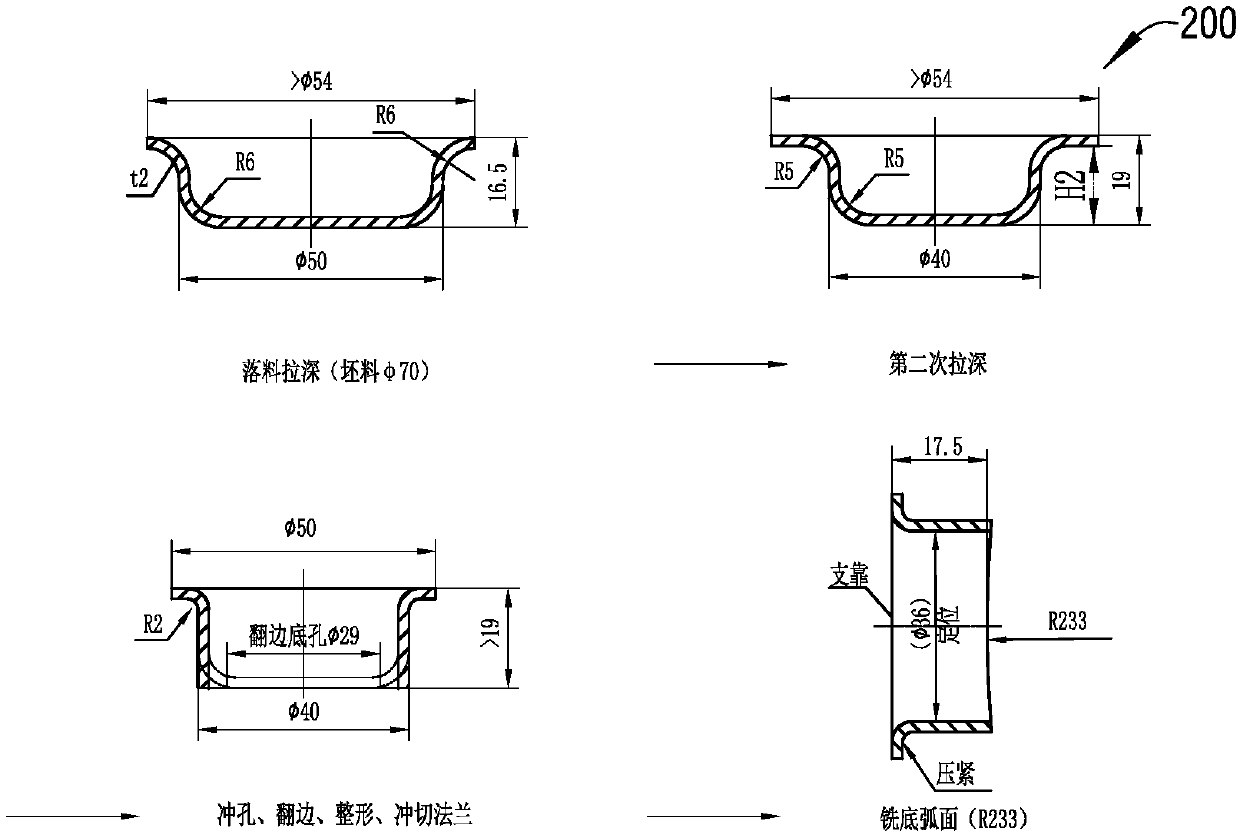

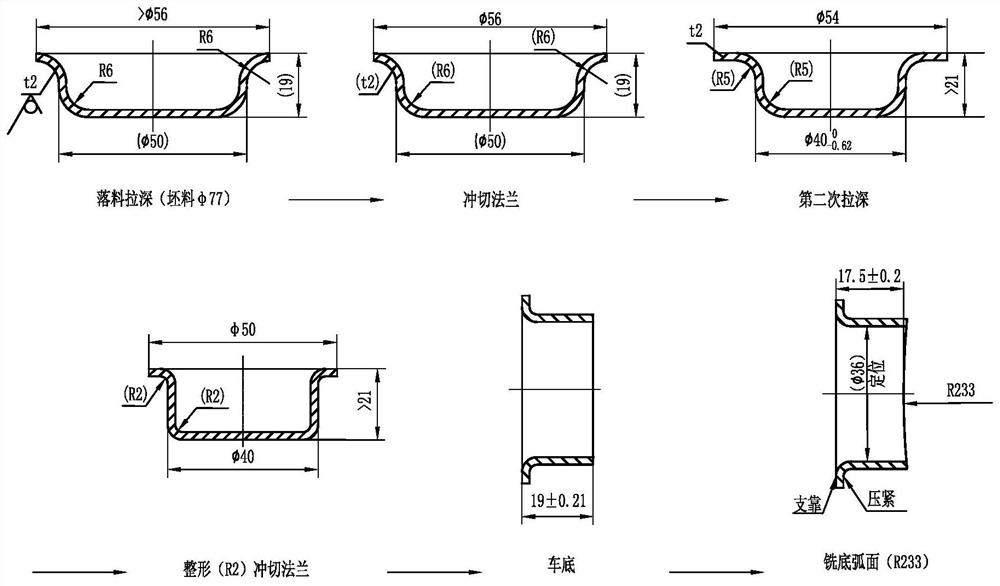

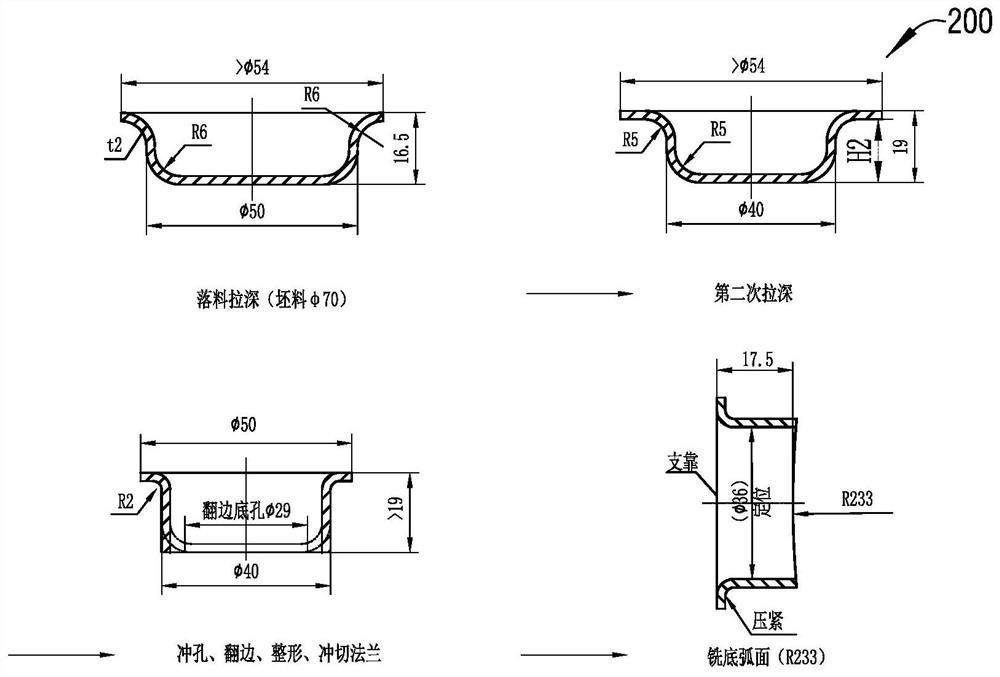

Sleeve forming method

ActiveCN109604472AReduce the impact of surface qualityReduce the impactShaping toolsRisk strokeMachining

The invention discloses a sleeve forming method. The sleeve forming method comprises the following steps that step A, blank drawing is conducted, a blank material is preformed after the first time stamping forming; step B, drawing is conducted for the second time, the blank material subjected to stamping forming in the step A is subjected to stamping forming for the second time; step C, a die is provided, forming of the flange part of the blank material formed in the step B is completed by one time of stamping stroke, the bottom surface is cut off, and the straight cylinder part is formed; andstep D, the blank material formed in the step C is milled, an arc of the opening part of the straight wall is formed, and final machining of the sleeve is completed. Compared with the prior art, thesleeve forming method reduces forming procedures and bottom turning procedures, so that influence on the quality of the accessory surface by multi-procedure forming is reduced, and the utilization rate of accessory materials is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

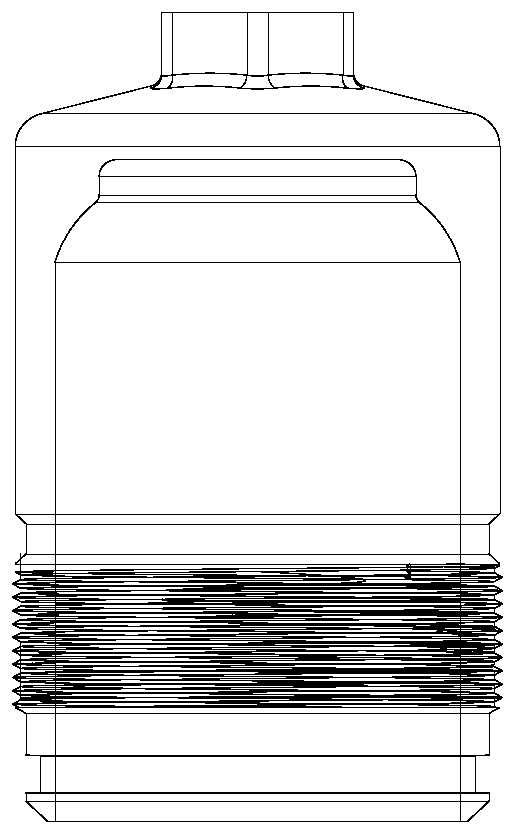

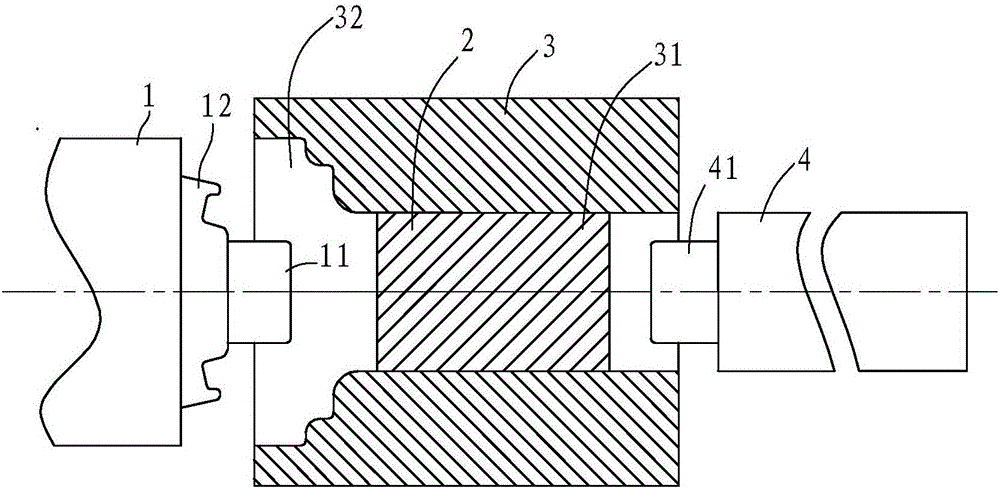

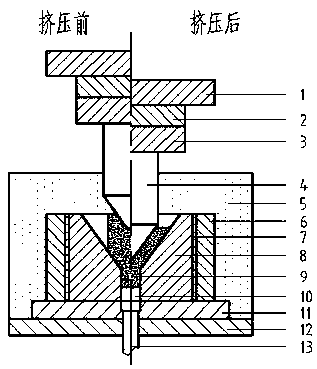

Near-net forming method of high-strength internal hexagon bored bolt

ActiveCN103240359APrevent deviationReduce forming processShaping toolsNutsHigh volume manufacturingHeat treated

The invention discloses a near-net forming method of a high-strength internal hexagon bored bolt. The method includes: firstly, feeding a pipe; secondly, cold-extruding, machining, thermally annealing, surface-treating, and lubricating; thirdly, placing a treated hollow blank into a cavity of a forming die of a forming tool for a high-strength internal hexagon bored bolt, forming an internal hexagon bore and a boss on the bolt, smoothly ejecting an extruded part out of the die; and fourthly, cutting ends and threads on the near-net-shaped extruded part to obtain a standard internal hexagon bored bolt. The method is convenient and simple to operate and high in production efficiency, has fewer machining procedures compared with those of the traditional method, has effectively lowered production cost, and is suitable for batch production.

Owner:ZHONGBEI UNIV

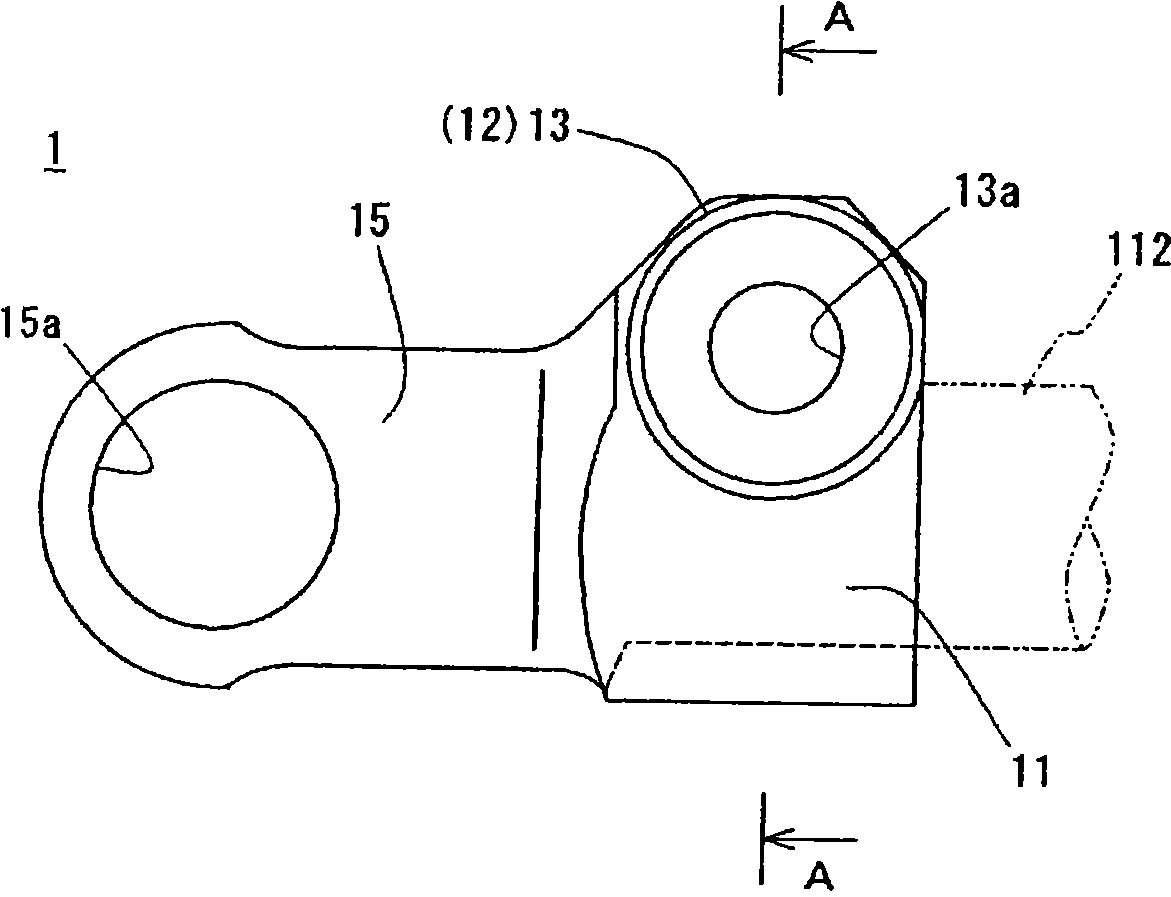

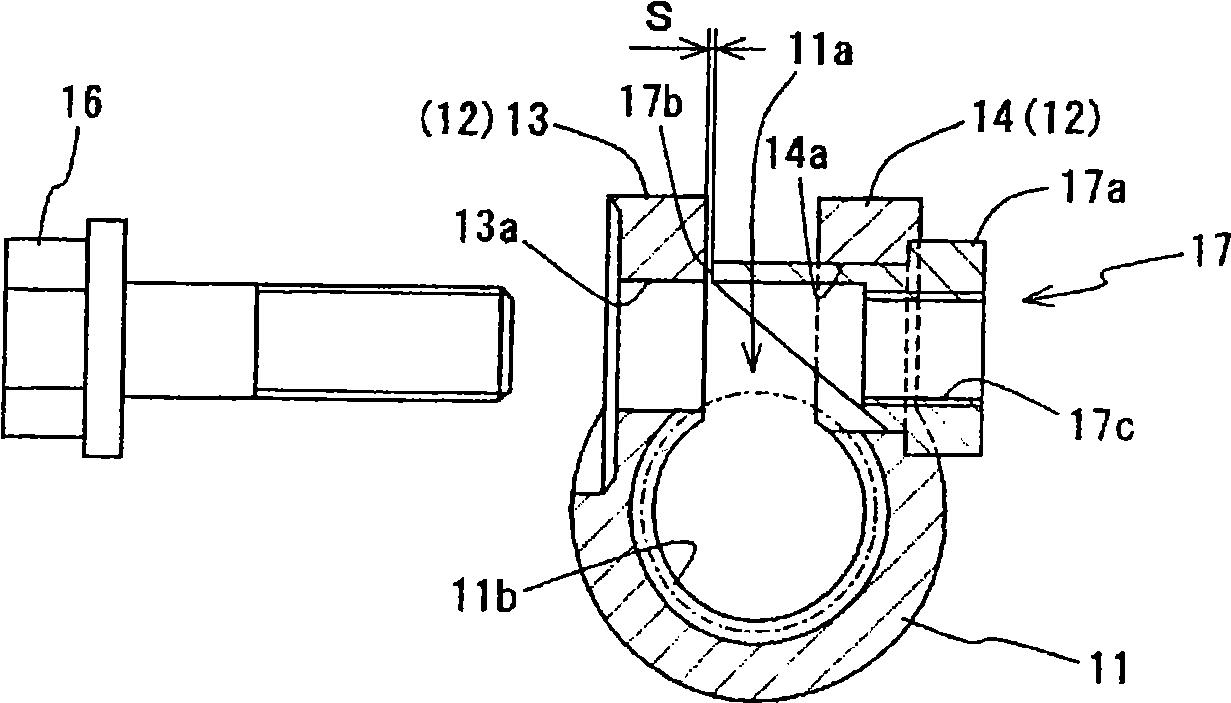

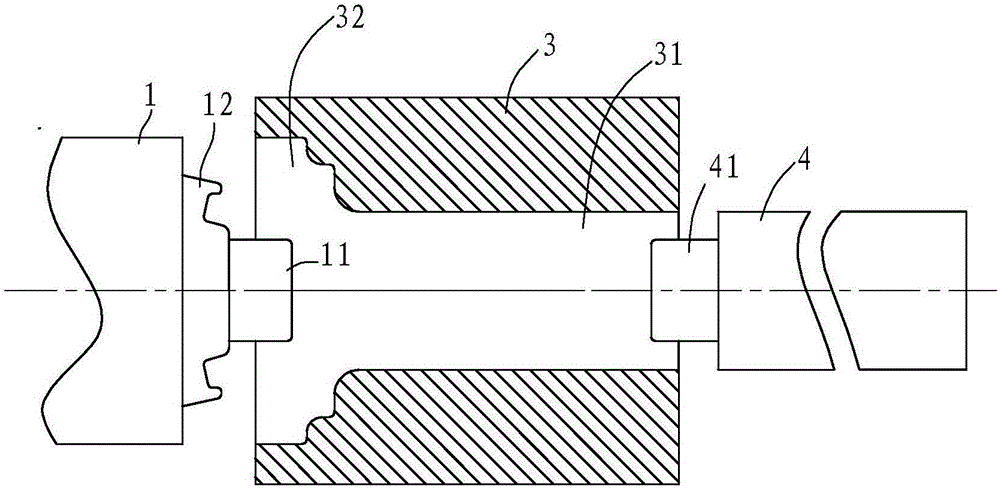

Yoke for universal joint

InactiveCN101501357AAvoid deformationEasy to shapeYielding couplingCouplings for rigid shaftsUniversal joint

A yoke for a universal joint, where deformation of a set of a fastening section and a bolt is prevented, increasing durability of the bolt. The yoke (1) for a universal joint has an insertion section (11) formed in a tubular shape with an opening in the direction of axis of a rotating shaft and into which one end of the rotating shaft is inserted, a first fastening section (13) and a second fastening section (14) as a pair of fastening sections (12) extended from the insertion section (11) so as to face each other with an opening of the insertion section (11) held in between, and a set of a bolt (16) and a nut (17) for tightening the pair of fastening sections (12) from both sides. When the pair of fastening sections (12) is fastened together, the rotation shaft inserted in the insertion section (11) is held and fixed. The bolt (16) is inserted in a through-hole (13a) of the first fastening section (13). The nut (17) is fitted in an engageable manner in a through-hole (14a) of the second fastening section (14), and that portion of the end face of the nut (17) which faces the first fastening section (13) is formed extended toward the first fastening section (13) such that a gap (S) between the extended portion and the first fastening section (13) has a predetermined width.

Owner:KOYO MASCH IND CO LTD

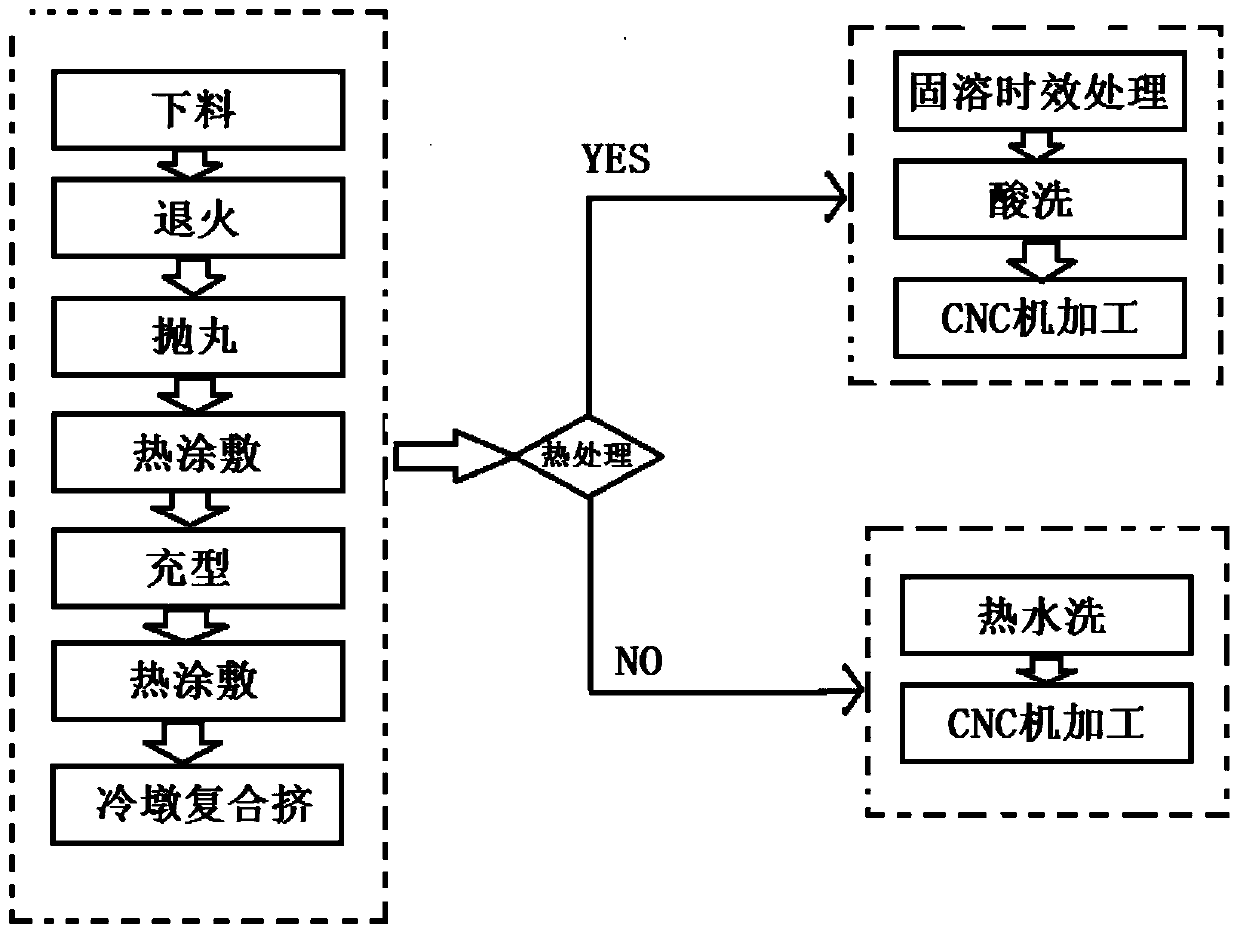

Cold upsetting extrusion composite forming method of automotive non-ferrous metal shell part

The invention discloses a cold upsetting extrusion composite forming method of an automotive non-ferrous metal shell part. According to the method, the surface of a blank is subjected to hot coating treatment by adopting a water-based high-molecular lubricant before the blank is subjected to cold upsetting extrusion composite forming, and the hot coating treatment is characterized by infiltratingfor 3-6 s by using the water-based high-molecular lubricant after the blank is heated to 180-220 DEG c. According to the cold upsetting extrusion composite forming method of the automotive non-ferrousmetal shell part, the surface of the blank is subjected to hot coating treatment by adopting the water-based high-molecular lubricant, so that green lubrication is realized, and the non-environment-friendly phosphating treatment is replaced; the mold filling process provides a guarantee for reverse-extrusion finishing of the blank, the mold can be positioned in reverse-extrusion at the same time,so that the precision of the part is improved; after mold filling, the mold is reversely extruded at one time, so that the production period is greatly shortened, the mold opening cost is greatly reduced, and the production cost is low; and the material utilization rate is high, the mechanical property of parts is good, the required equipment tonnage is low, the requirements of modern green manufacturing are met, and the method is wide in application prospect.

Owner:SHANGHAI UNIV OF ENG SCI +1

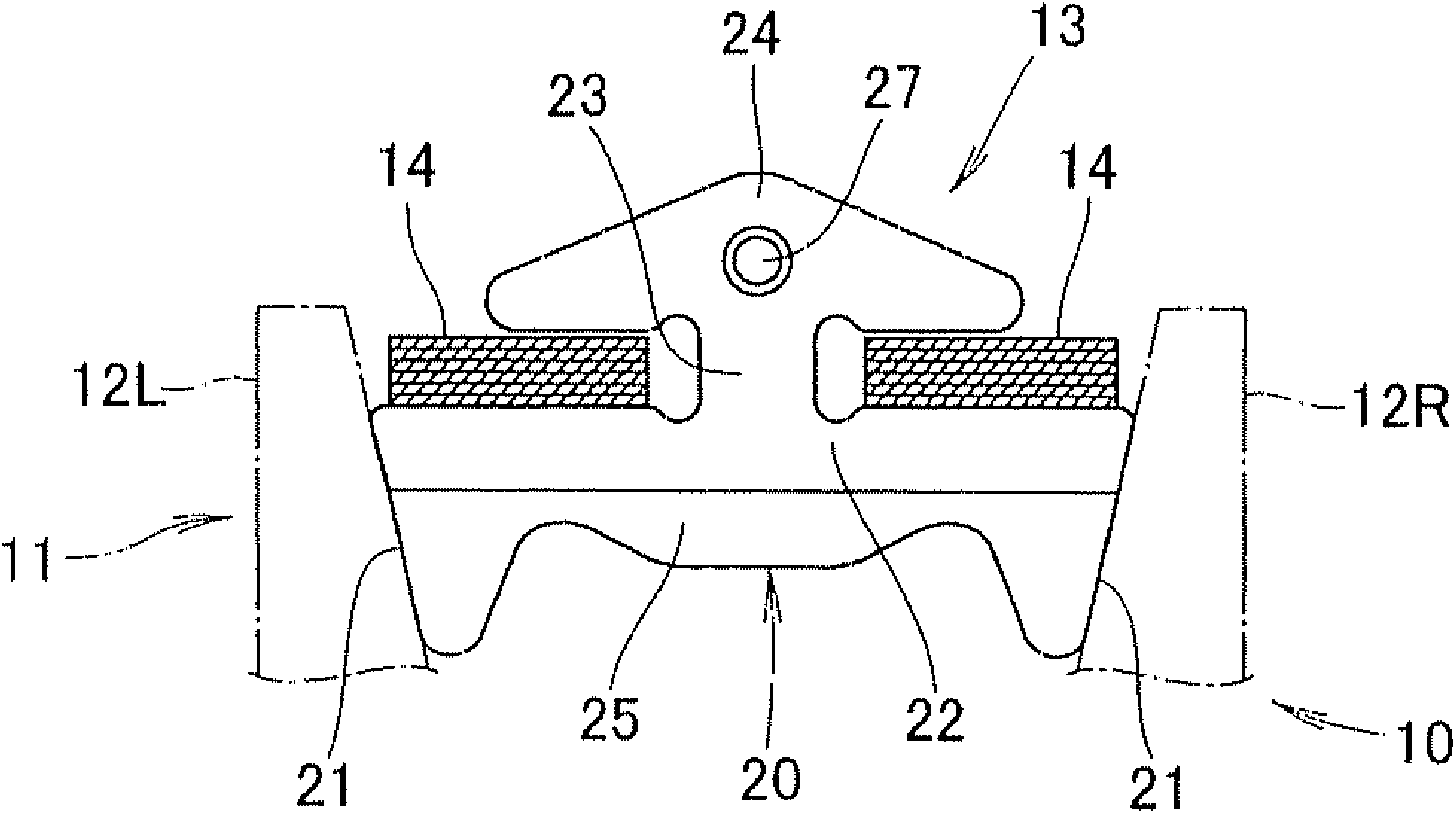

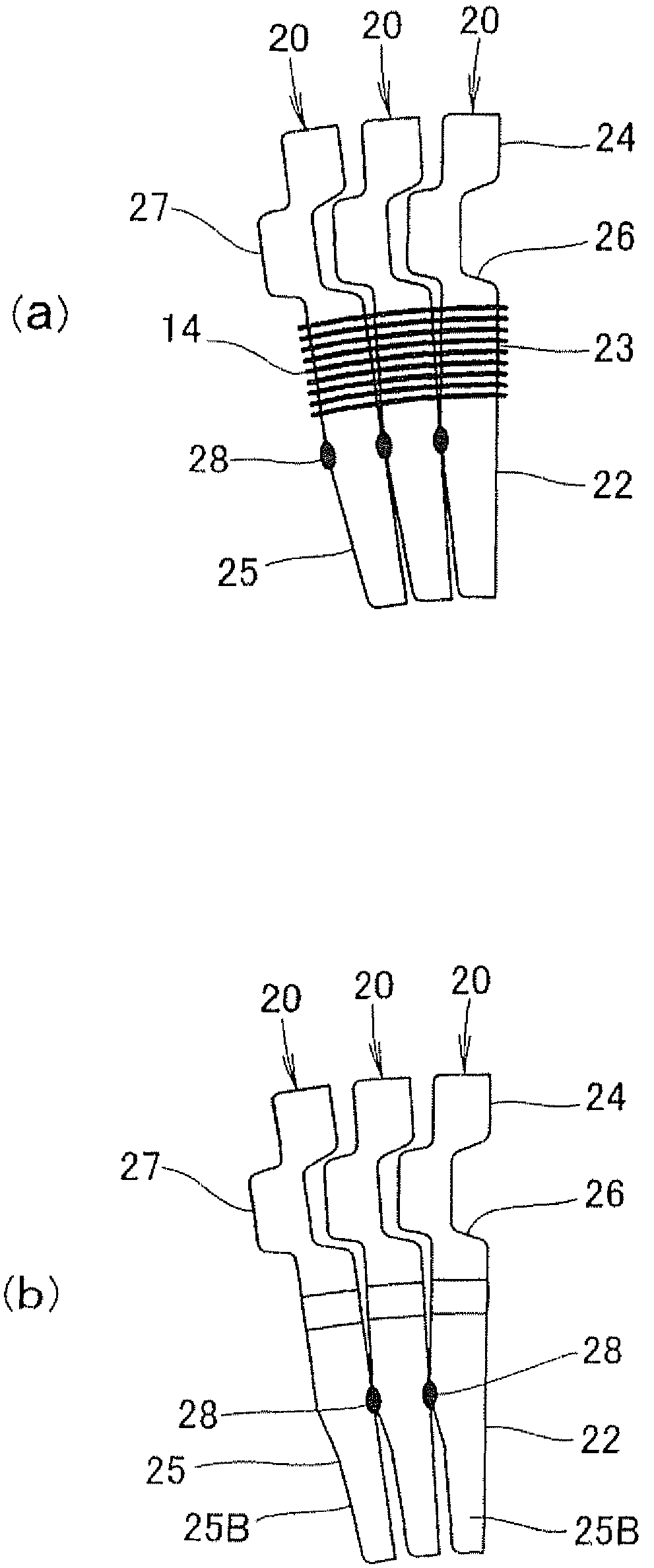

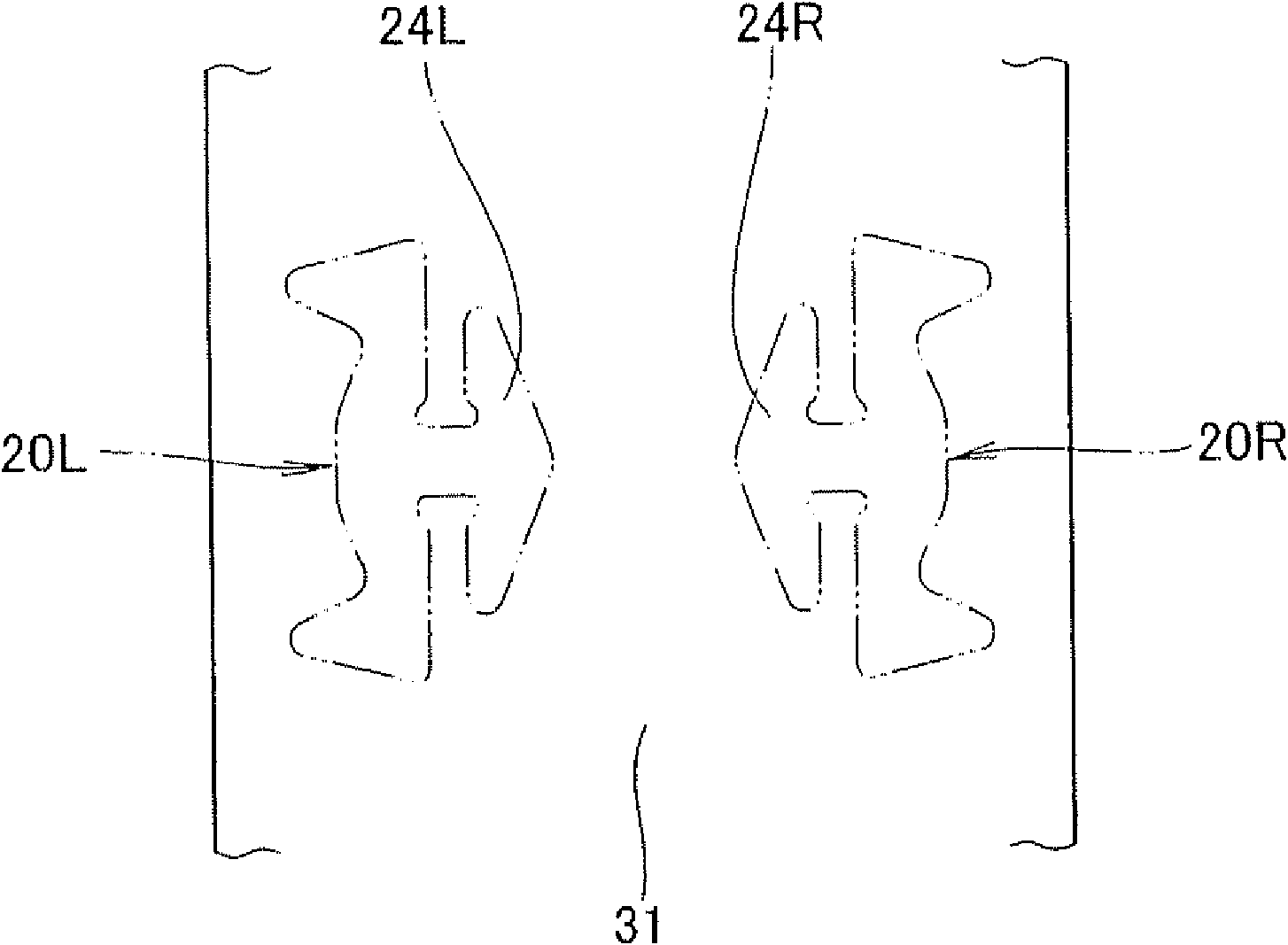

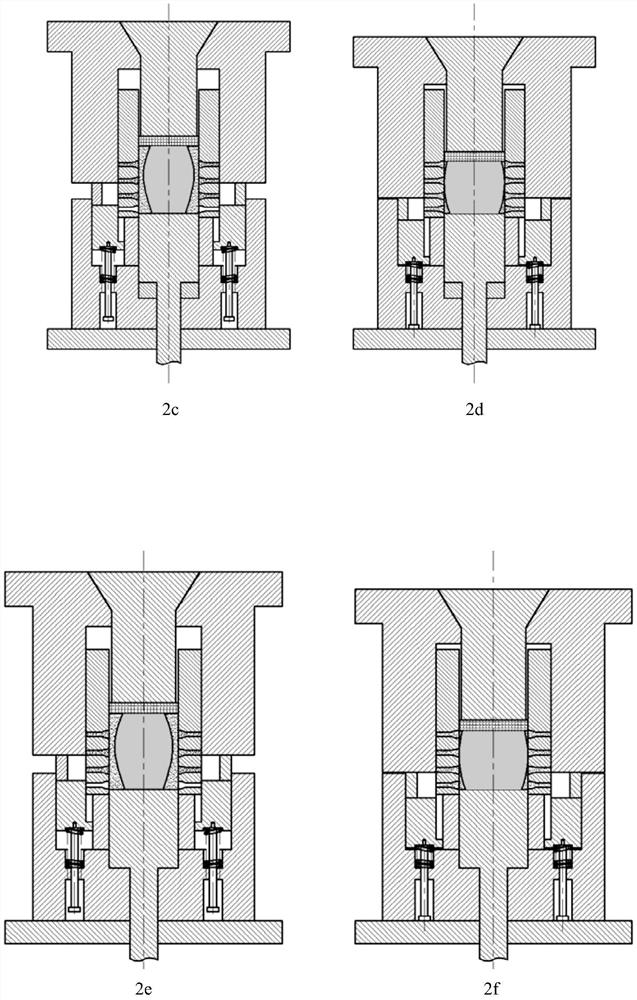

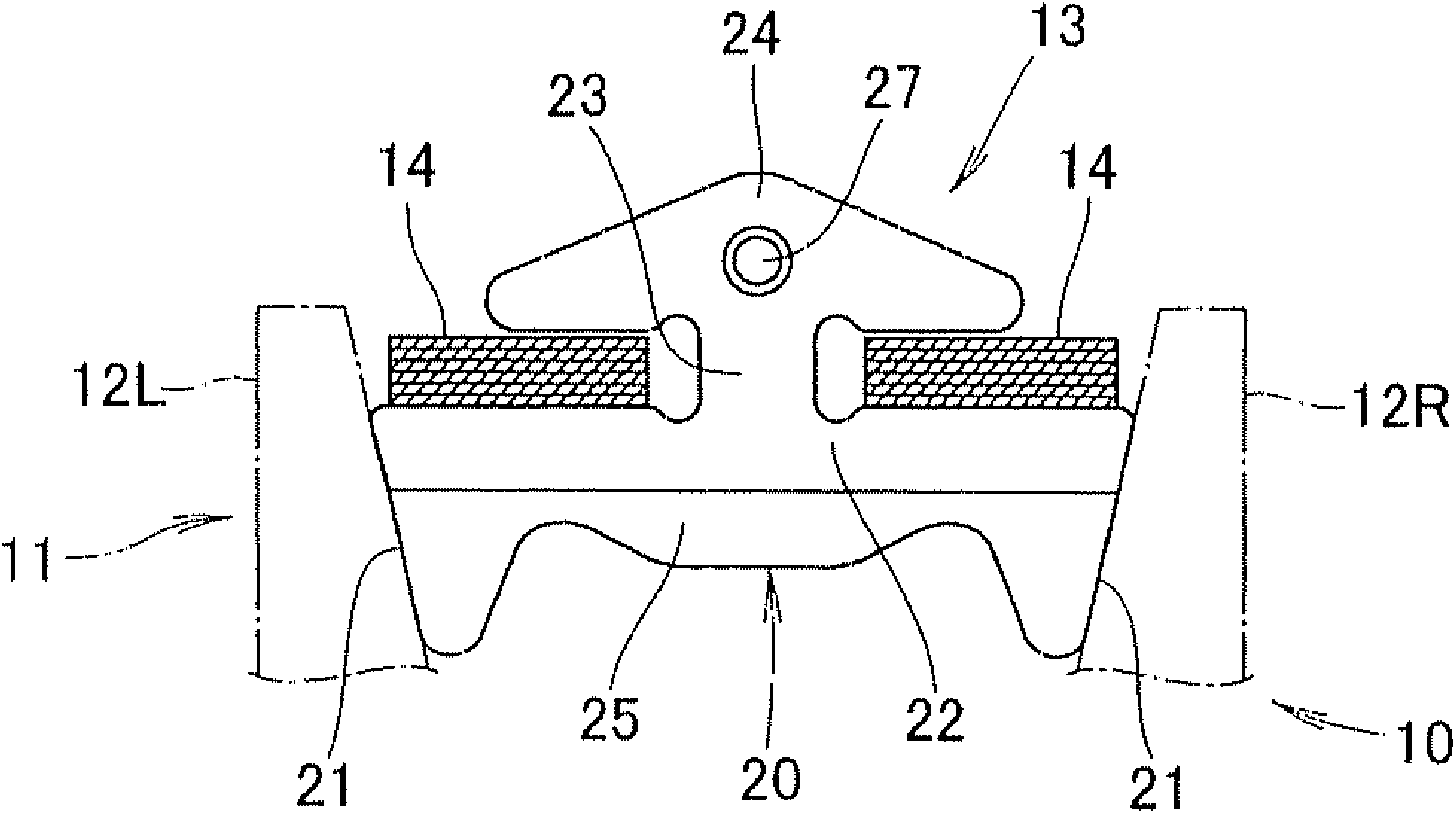

Method for manufacturing element for belt of continuously variable transmission

InactiveCN102438766AElimination of taper forming processSmooth flowV-beltsDomestic articlesEngineeringMechanical engineering

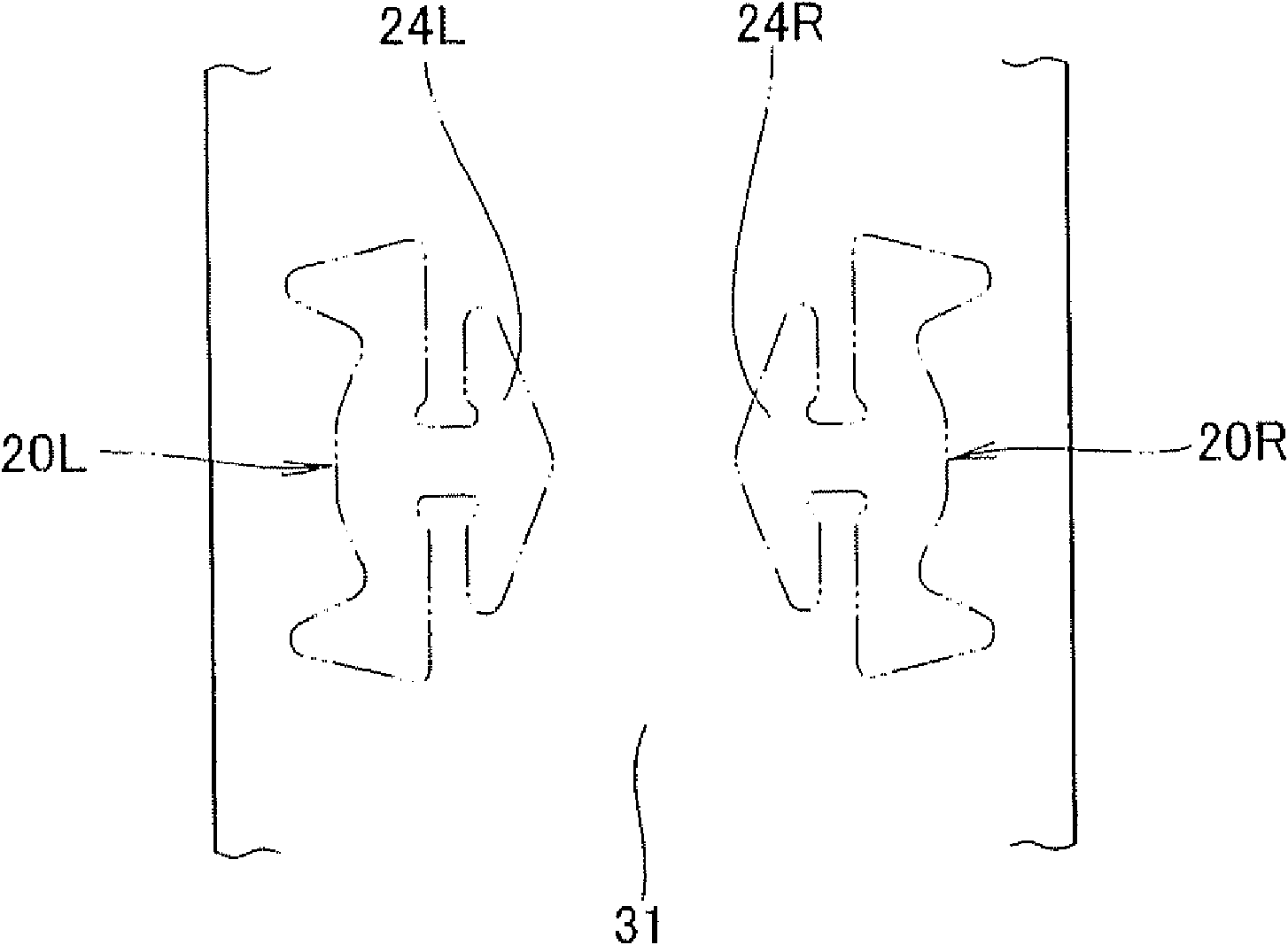

Provided is a method for manufacturing an element for a CVT belt, comprising a body portion (22L, 22R) having right and left sides and a tapered portion with a downwardly reducing width, a neck portion extending upward from the body portion, and a head portion extending upward from the neck portion. The manufacturing method comprises a first punching step in which a metal strip blank (31) which has a uniform thickness and a width which makes it possible to obtain elements arrayed on an even number of lines in an arrangement in which the head portions are opposed to each other or an arrangement in which the body portions are opposed to each other, is punched along an outline (33L, 33R) of an excess material (21b) added to profiles of the left and right sides (21L, 21R) of the body portion, and along an outline (58L, 58R) of an excess material (32b) added to a profile of a lower side (32L, 32R) of the body portion a plastic deformation step in which the blank is compressed in the thickness direction to form a predetermined projection and depression, and form the tapered portion while displacing the material in the outline directions and a second punching step in which the element is obtained as a product by punching the blank.

Owner:HONDA MOTOR CO LTD

Extruding-expanding molding method for rim provided with flange

An extruding-expanding molding method for a rim provided with a flange is characterized by comprising the following steps: (1) blanking; (2) heating: rods subjected to blanking and an extrusion mold are heated to an extrusion start temperature respectively; and (3) two-way extruding-expanding molding. Compared with the prior art, the extruding-expanding molding method has the advantages that fewer procedures are included, the whole set of molding tool and equipment investment is small, and the method is suitable for industrial batch production; the molding cycle is shortened, and the molding efficiency is increased; and the manufacture cost is reduced.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

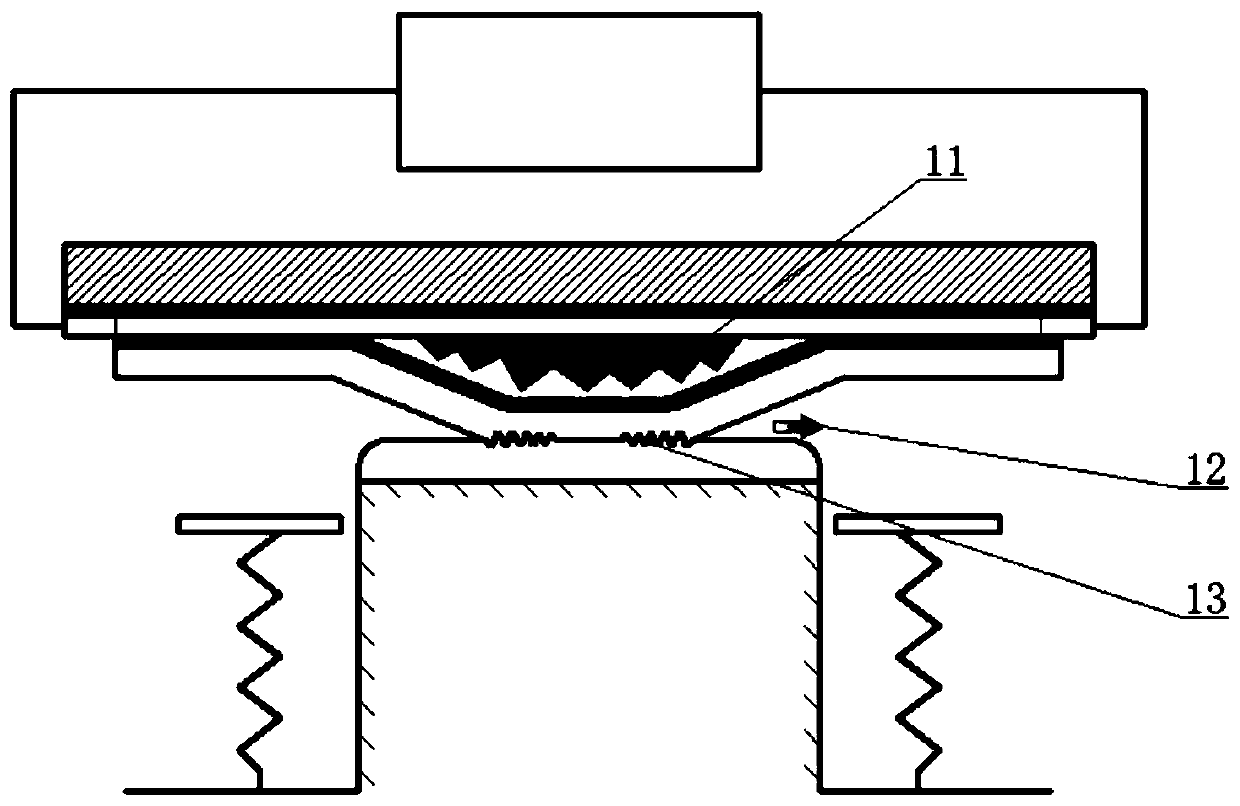

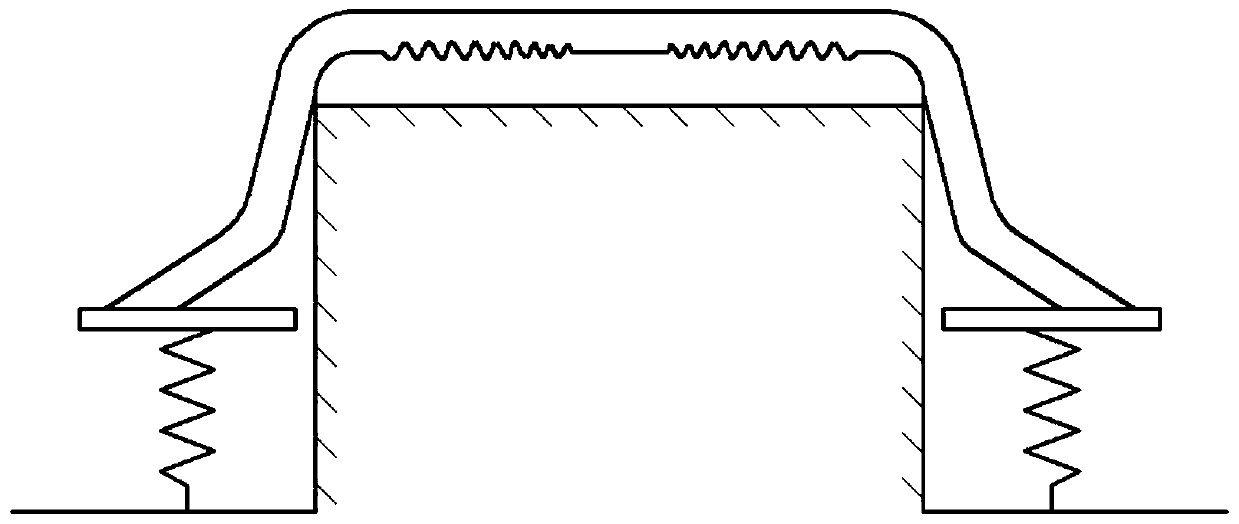

Metal plate component connection and forming composite manufacturing method based on high-speed impact

The invention belongs to the relevant field of machining and forming of plate components, and discloses a metal plate component connection and forming composite manufacturing method based on high-speed impact. The method comprises the following steps that a reinforcing plate is placed on a mould, and a substrate is arranged above the reinforcing plate; a circuit loop is provided for the substrate, and an aluminum foil is used as a material source for generating gasification drive at the same time; current flows through the aluminum foil and gasification occurs, and generated local high-pressure air mass drives the substrate to move downwards at a high speed and hit the reinforcing plate; and the reinforcing plate is connected with the substrate at an impact position, and with the continuous impact and final stop of the impact, the reinforcing plate and the substrate are gradually connected and formed into a whole in the mould until the whole composite manufacturing process is completed. The invention also discloses a corresponding metal plate product. Through the method, the forming limit of plate component can be improved, the machining defects such as excessive strain at corners and connection with the mould can be reduced advantageously, and the method has the advantages of less required processes, high forming precision and efficiency, convenience in operation and control, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Vacuum temperature adjustment type extrusion molding method of copper part

InactiveCN108311549AImprove performanceIncrease the dislocation densityExtrusion diesAtmospheric pressureCopper

The invention discloses a vacuum temperature adjustment type extrusion molding method of a copper part. The vacuum temperature adjustment type extrusion molding method is characterized by comprising the following steps: putting a copper blank with the initial temperature of -150 DEG C to 20 DEG C into an extrusion lower die cavity; then extruding the blank under the action of an upper die; when the upper die moves to designed displacement, keeping pressure of the blank; the carrying out vacuumizing treatment on a device space where the upper die and a lower die are arranged, wherein the vacuumdegree is -0.095MPa to -0.09MPa; meanwhile, heating the lower die and controlling temperature, wherein the temperature of a concave die is 20 DEG C to 300 DEG C; when the concave die reaches designedtemperature, continually downward moving the upper die and carrying out extrusion deformation on the blank; after the extrusion is finished, pressurizing the device space to atmospheric pressure; then returning back the upper die and taking materials. By adopting the method disclosed by the invention, the deformation capability of metal can be increased and elastic deformation is reduced; the comprehensive performance of the copper part is improved and molding procedures are reduced.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

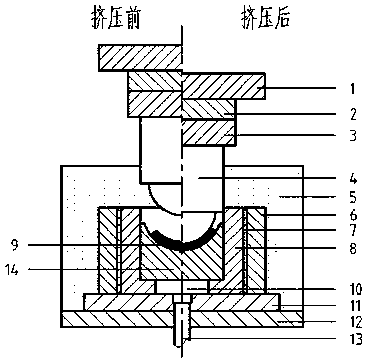

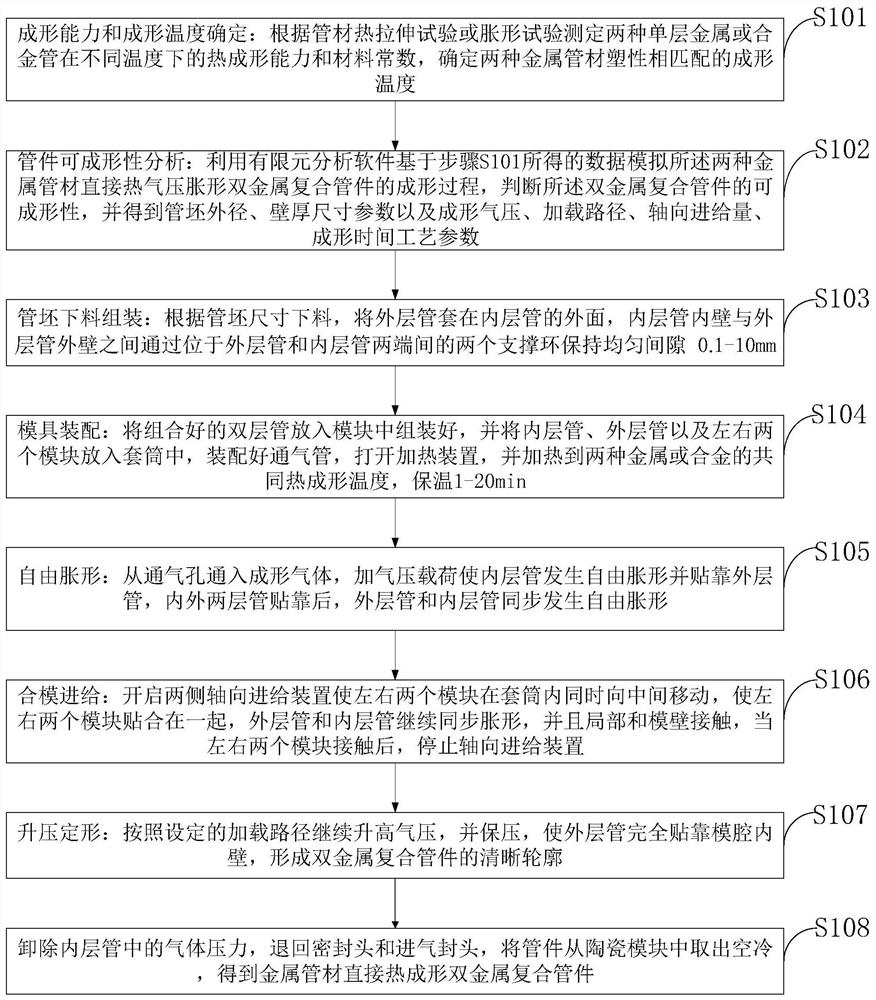

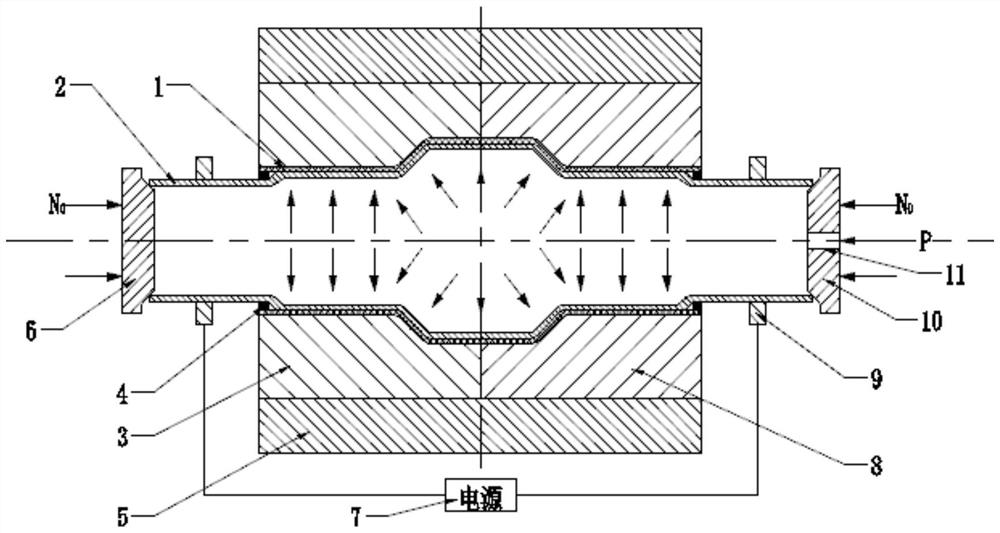

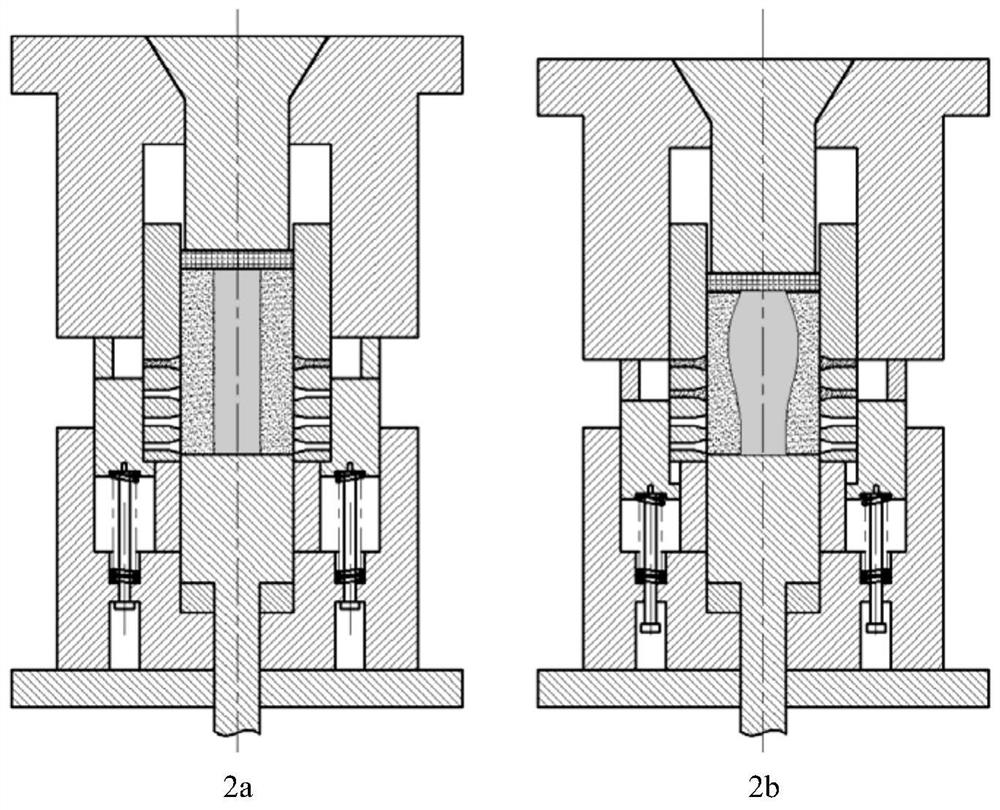

Method and device for directly hot-forming bimetal composite pipe fitting from metal pipe

The invention belongs to the technical field of bimetal composite pipe fittings and discloses a method and a device for directly hot-forming a bimetal composite pipe fitting from a metal pipe. The forming capacity and the forming temperature are determined, the formability of the pipe fitting is analyzed, and a pipe blank is subjected to blanking and assembly. Blanking is conducted according to the available pipe blank size, an inner-layer pipe sleeves an outer-layer pipe, and a uniform gap of 0.1-10 mm is kept between the inner wall of the inner-layer pipe and the outer wall of the outer-layer pipe through two supporting rings located between the two ends of the outer-layer pipe and the two ends of the inner-layer pipe; a die is assembled, free bulging is conducted, die assembly and feeding are performed, boosting pressure and shaping are performed, unloading is performed, and a part is picked up. The bimetal composite pipe fitting is obtained. An air pressure bulging method is adopted, the process is simple, and compounding and forming of the bimetal composite pipe fitting difficult to deform at the room temperature can be achieved at the same time through a single process. The deformation resistance of the pipe at high temperature is small, the plastic forming performance is high, and large plastic forming of materials difficult to deform can be achieved. The bimetal composite pipe fitting is combined through cold shrinkage, and the combination is reliable.

Owner:HARBIN INST OF TECH AT WEIHAI

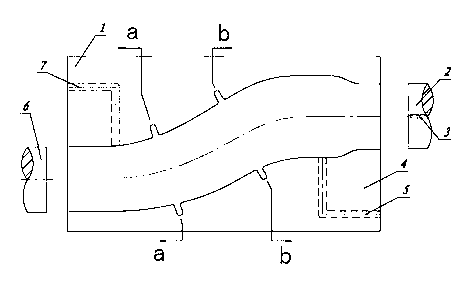

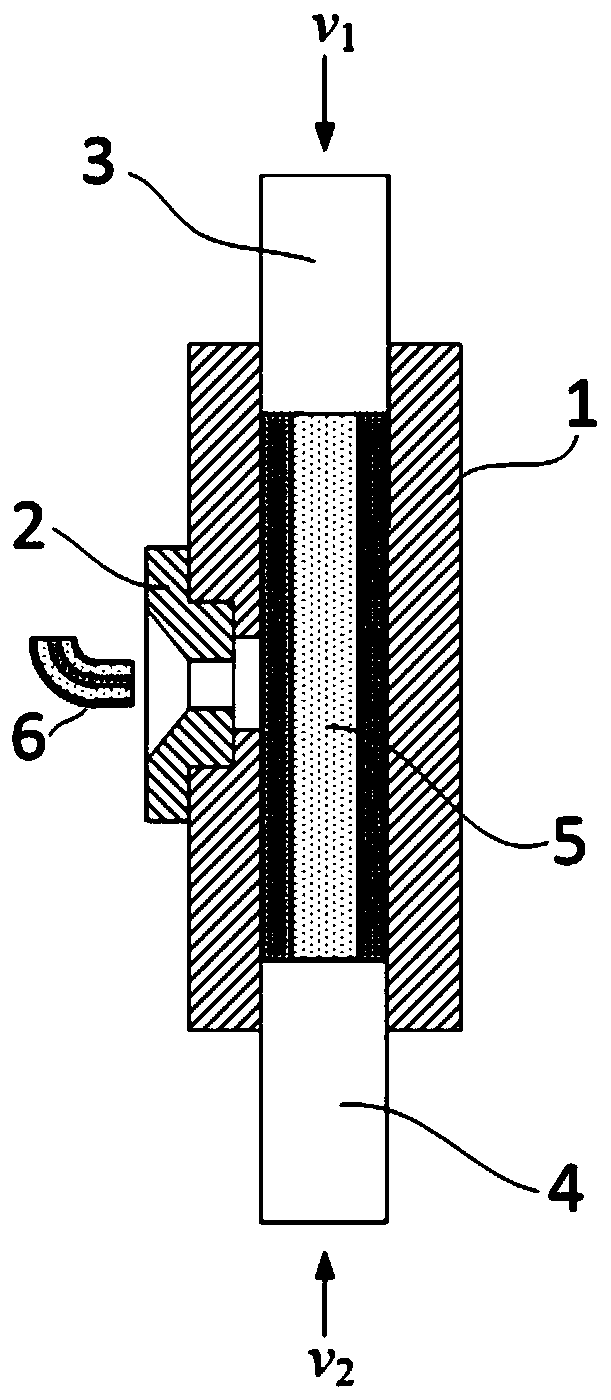

Manufacturing method of multi-layer bending structure

ActiveCN111283008AImprove performanceUniform layer thicknessExtrusion diesExtrusion containersComposite effectEngineering

The invention discloses a manufacturing method of a multi-layer bending structure. The problems that in the prior art, bending forming of a multi-layer material composite structure is difficult to realize, the production efficiency is low, and the application range is narrow are solved. The method has the advantages of being uniform in composite layer thickness, good in interface composite effect,high in composite efficiency, and capable of manufacturing various forms of composite structures. According to the manufacturing method of the multi-layer bending structure, the method comprises thefollowing steps that a composite original blank is prepared; the composite original blank is put into an extrusion barrel, and the composite original blank, the extrusion barrel and a forming die areheated; and a first extrusion push rod and a second extrusion push rod are moved to make contact with the composite original blank; and by varying the propulsion speed v1 of the first extrusion push rod and the propulsion speed v2 of the second extrusion push rod, the composite original blank is made to obtain a varying velocity gradient when passing through a forming channel of the forming die, thereby obtaining the variable curvature multi-layer bending structure.

Owner:CURVEX LIGHTWEIGHT INTELLIGENT MFG RES INST HEZE CO LTD

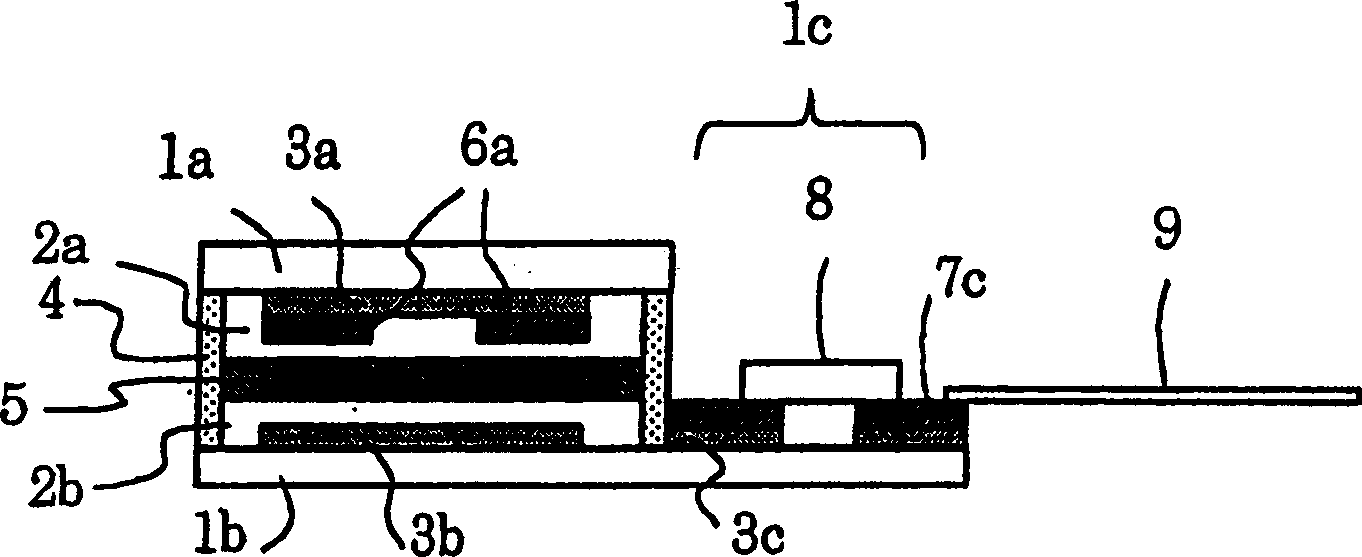

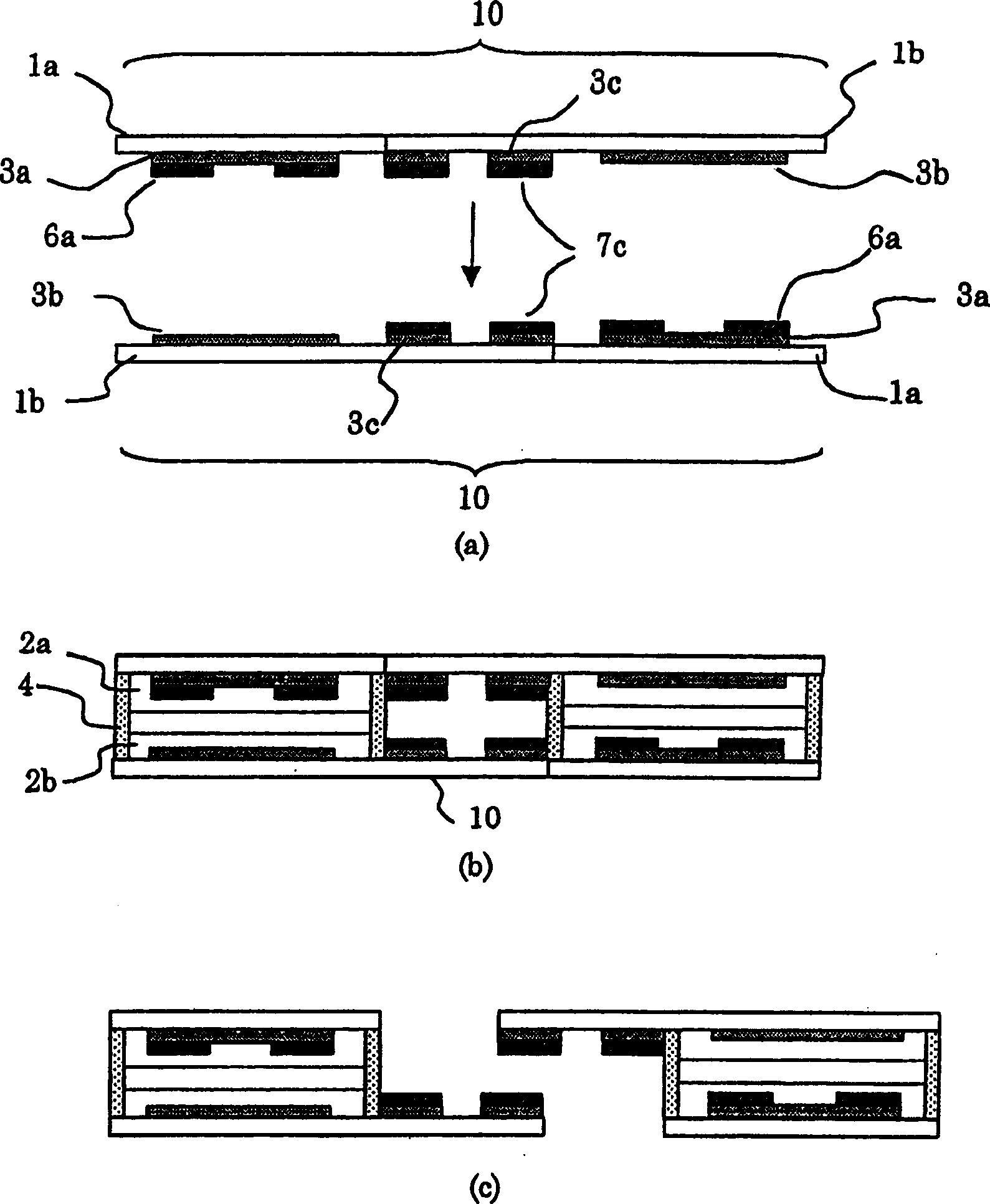

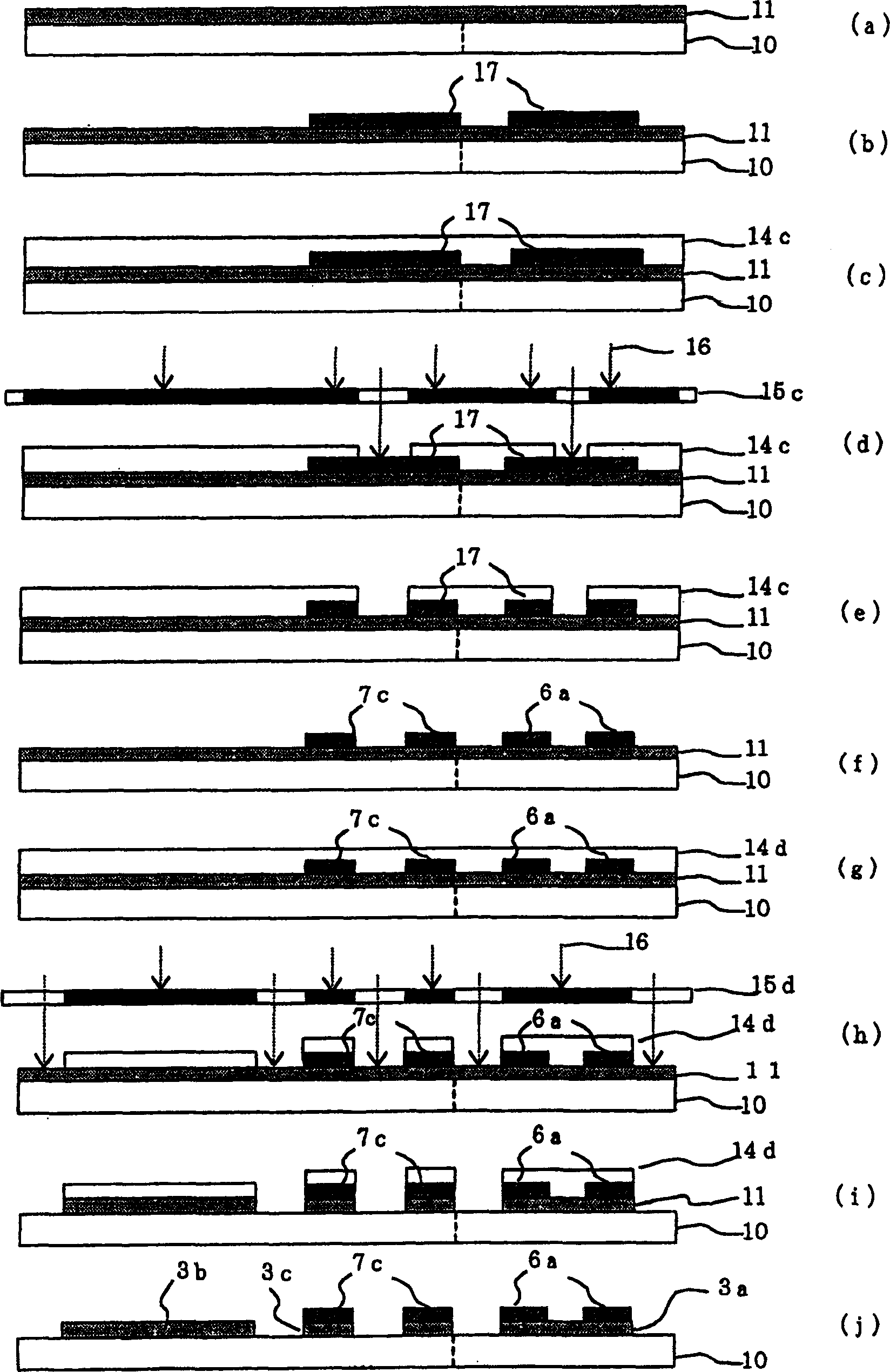

Liquid crystal light shutter, optical printing head and method for producing lquid crystal light shutter

InactiveCN1437057AReduce forming processSave metal materialSemiconductor/solid-state device manufacturingVisual representatino by photographic printingPlatinumPt element

In the forming method of blocking mask and electrode pattern of the prior art, precious metals such as gold and platinum are consumed too much to form metal film on the whole glass substrate, and the manufacturing cost of masks which need to have three manufacturing steps. A blocking mask (6a) and an electrode coating (7c) are formed using a gold film. The blocking mask (6a) and the electrode coating (7c) are formed together by printing an organic gold paste only in a necessary part and baking the printed organic gold paste.

Owner:MITSUBISHI ELECTRIC CORP

Riveting type joint seam steel pipe

InactiveCN106287010AReduce forming processLow costElongated constructional elementsRigid pipesSheet steelButt joint

The invention discloses a riveting type joint seam steel pipe, which is integrally a steel plate bent into a closed tube body; notch arrays formed by a plurality of notches are respectively formed in the edges of the two sides of a joint seam forming the closed tube body; the shape of a projected part between the adjacent notches is identical to the shape of the notches; the notch arrays at the edge parts of the two sides of the joint seam position are in staggered arrangement and are mutually embedded and riveted. The riveting type joint seam steel pipe has the advantages that the forming work procedures are few; the cost is low; the embedding riveting is performed through the notch arrays in staggered arrangement in a curled steel plate butt joint edge position; the intensity is high; a lamination part is arranged in the joint seam position; the air tightness is good; the riveting type joint seam steel pipe is applicable to occasions such as automobiles with high requirements on the steel pipe intensity and air tightness.

Owner:SUZHOU SANTI INTELLIGENT TECH

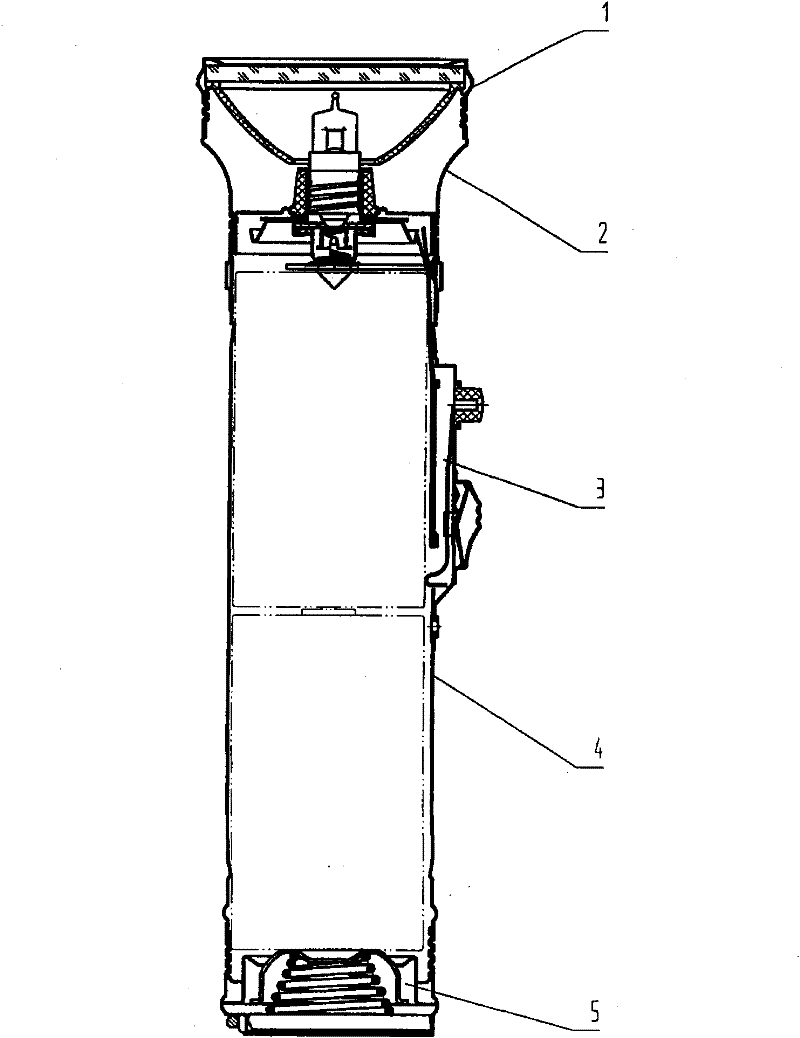

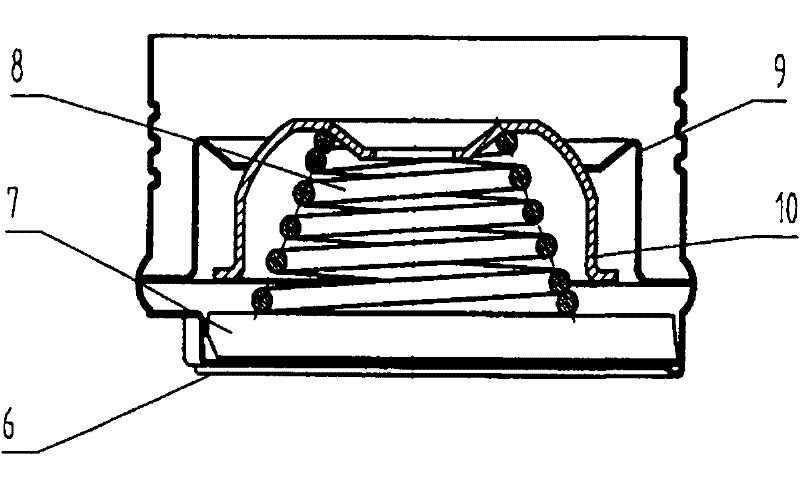

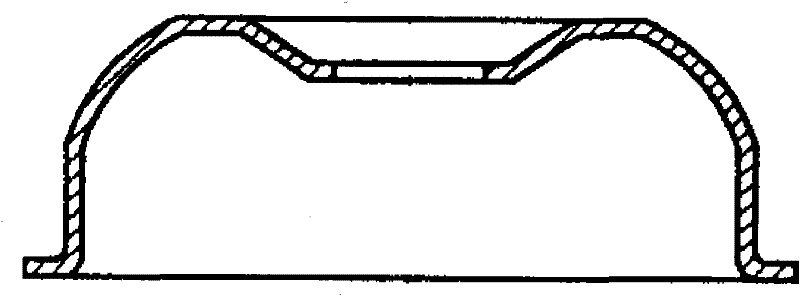

New tail cap flashlight

InactiveCN102269336ASimple structureReduce forming processElectric circuit arrangementsWith electric batteriesFixed frameEngineering

The invention relates to a new flashlight with a tail cover, which includes a head cover, a barrel neck, a switch part, a barrel body and a tail cover. The top electric frame is movably sleeved in the fixed top electric frame, and its disc-shaped bottom surface is in contact with the tail spring, and is pressed against the ring opening at the top of the fixed top electric frame, and can expand and contract in the fixed top electric frame with the top spring. The invention has the beneficial effects of simple structure, beautiful appearance, practicality, less forming process and low production cost.

Owner:顾兰如

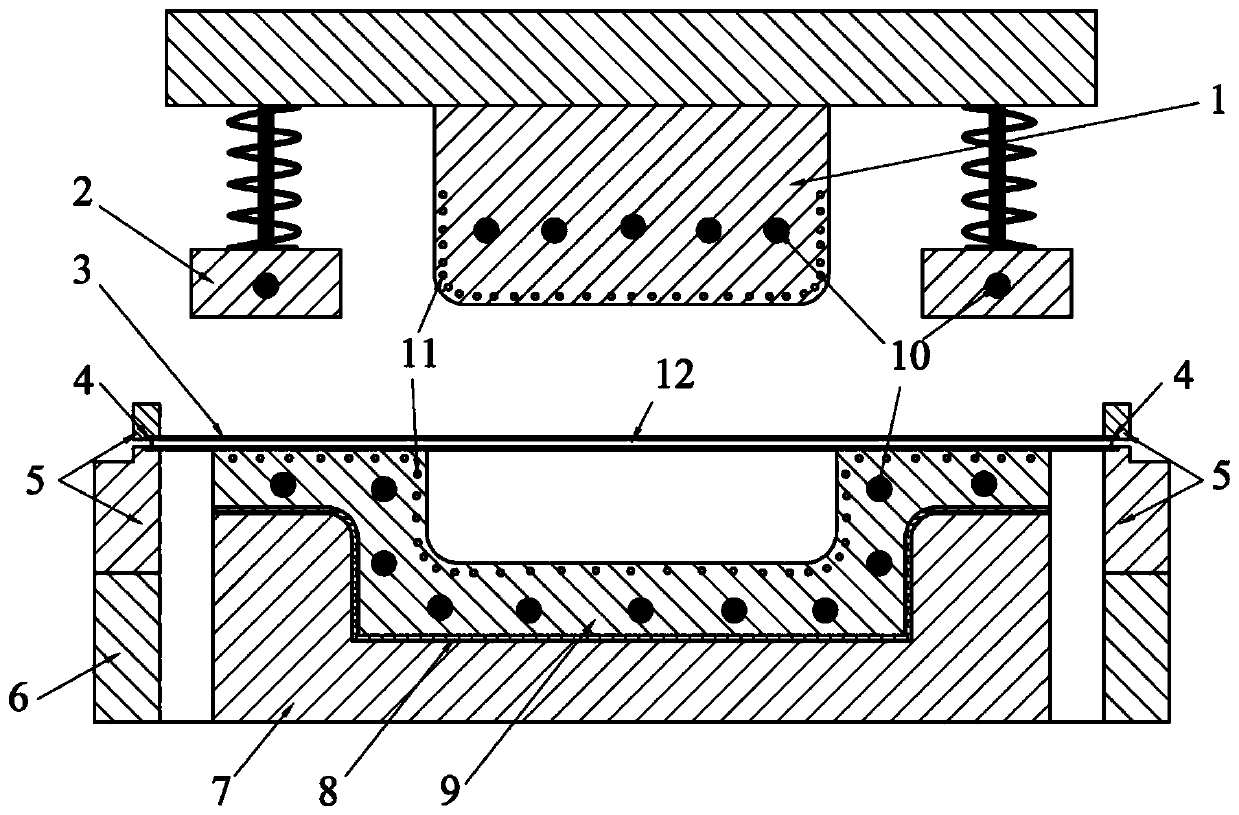

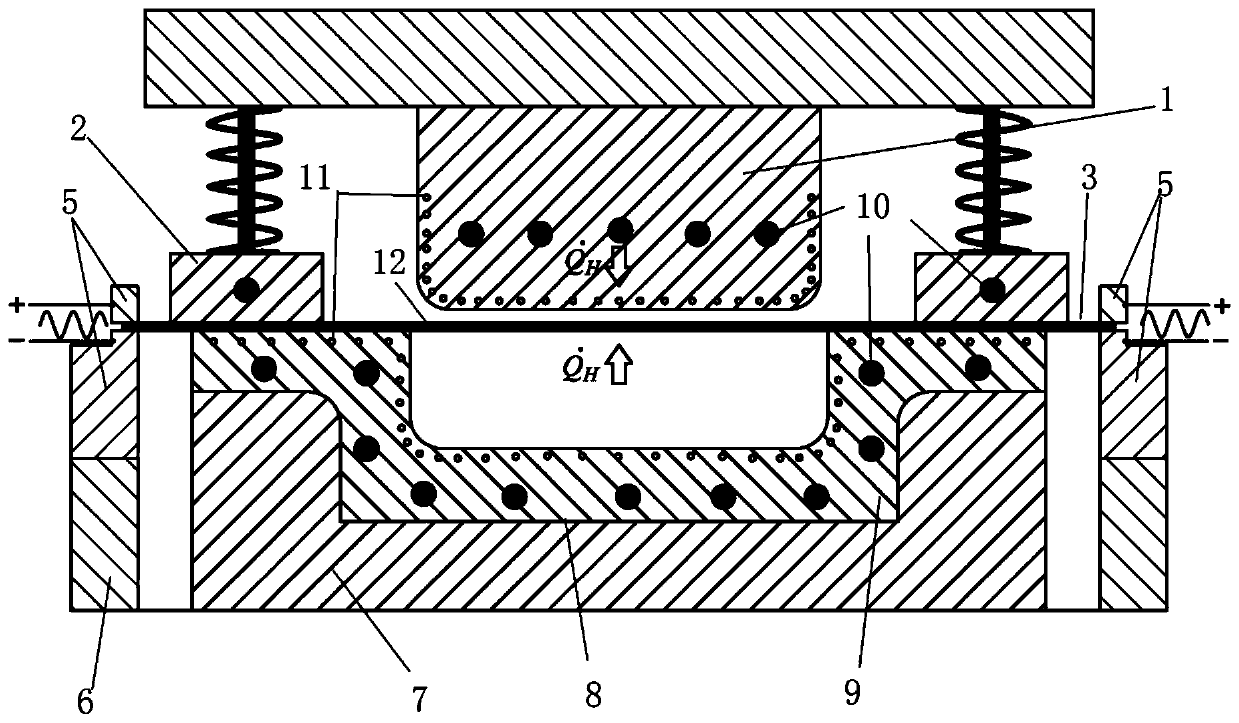

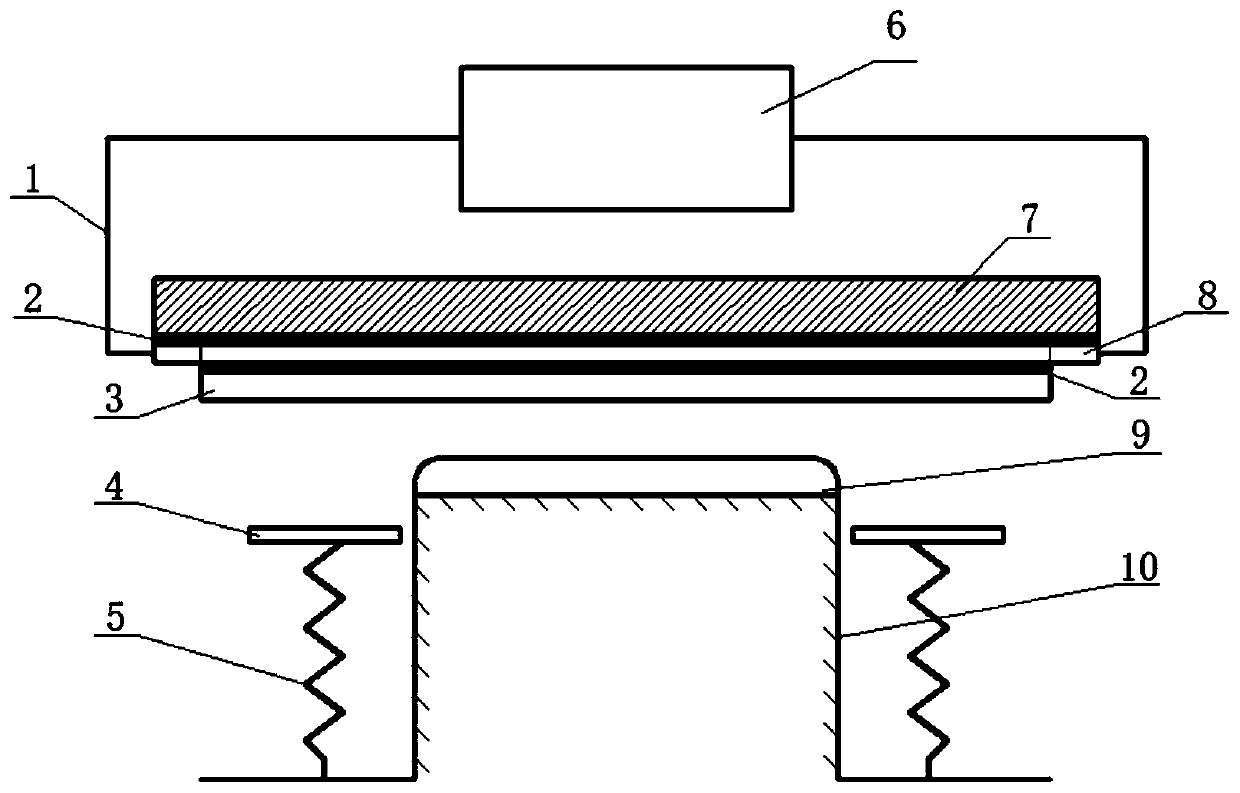

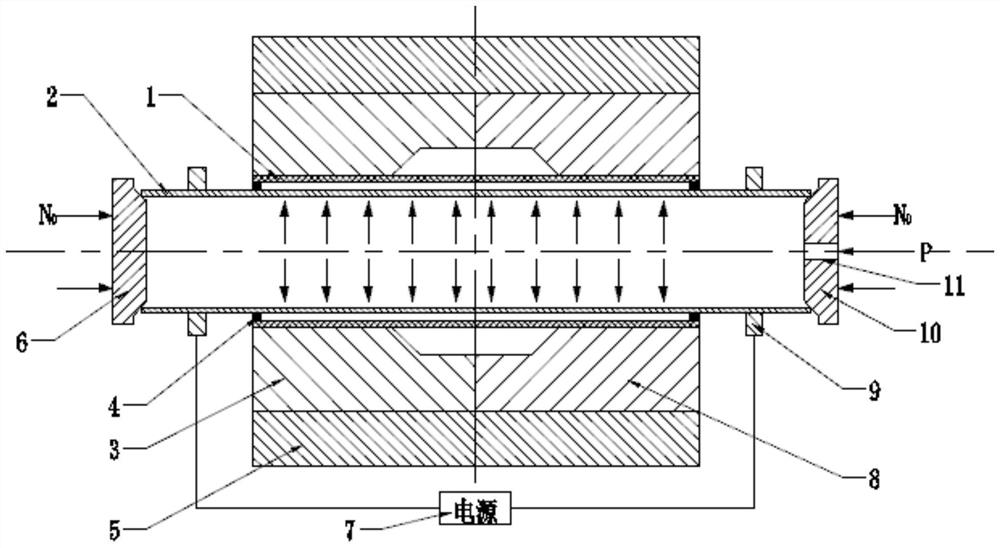

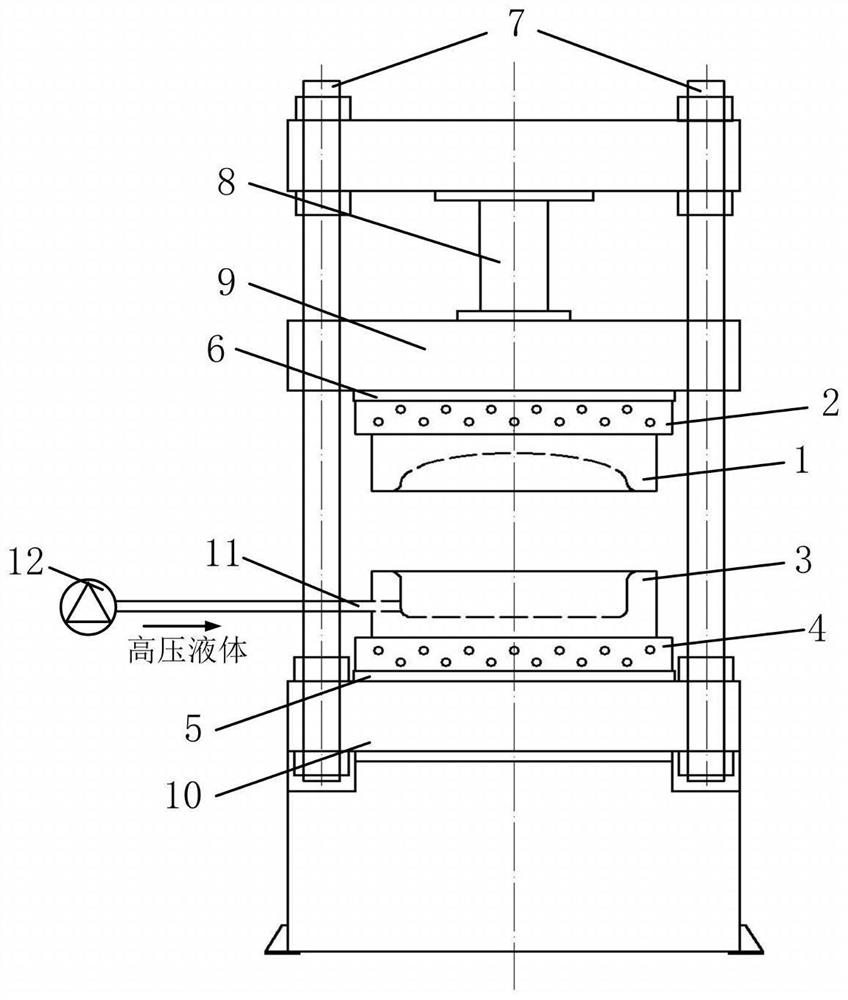

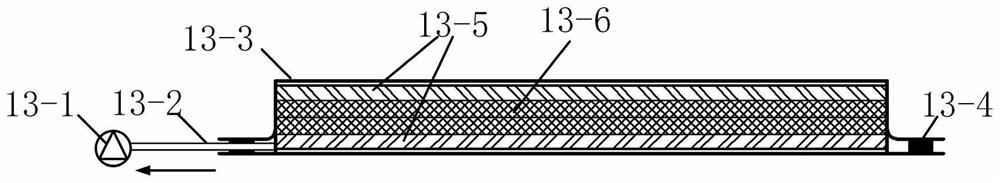

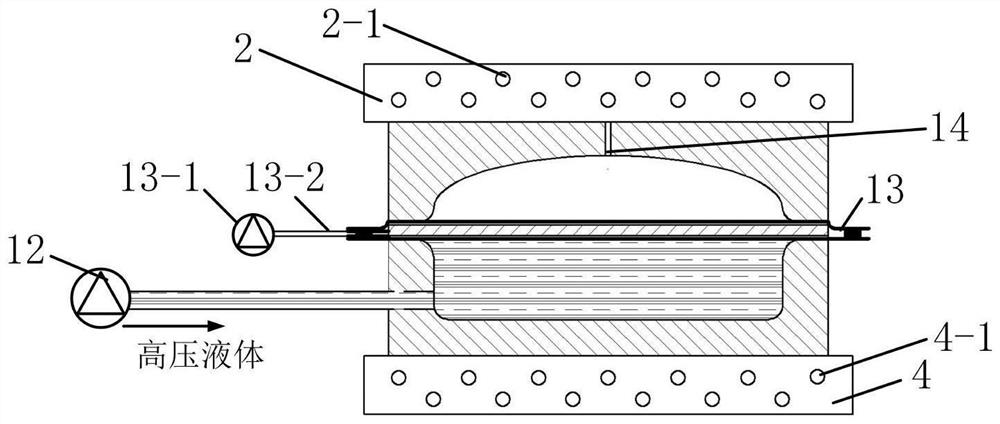

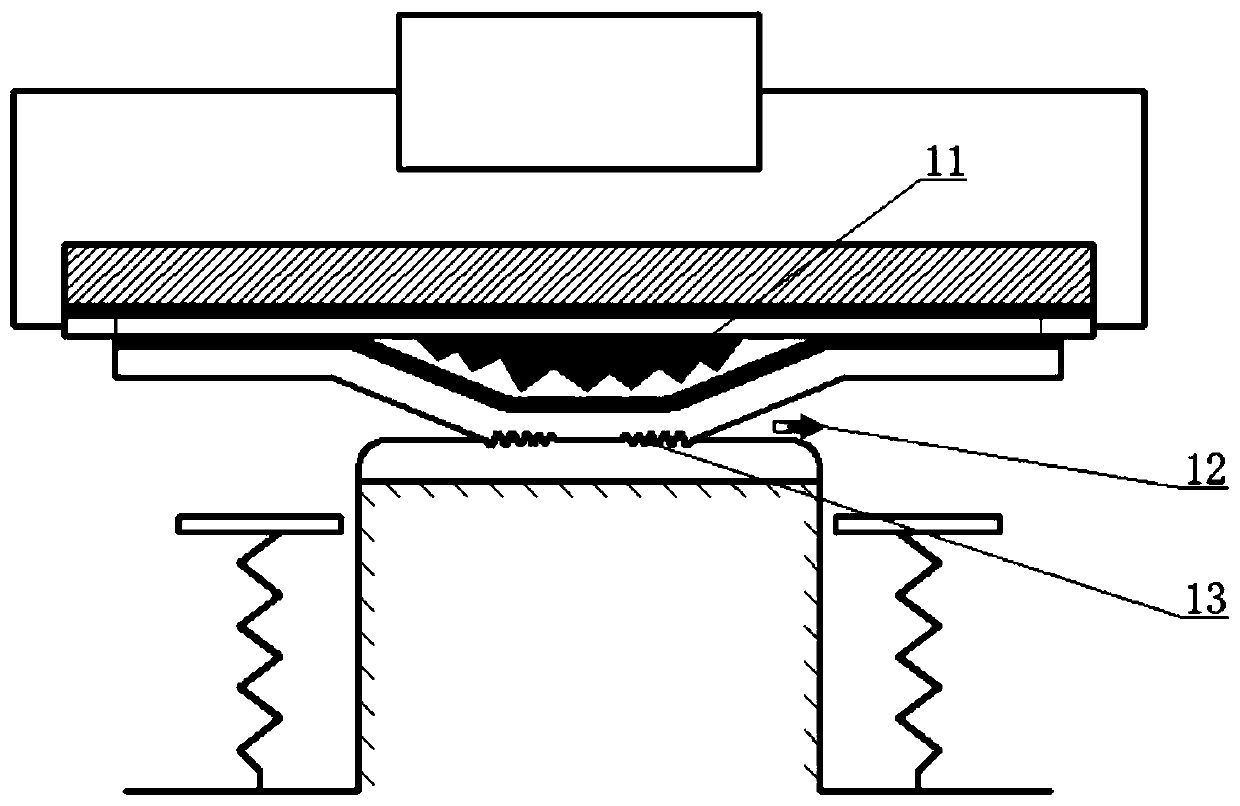

Vacuum-assisted fiber-reinforced metal laminate flexible medium hydroforming method and device

The invention discloses a vacuum-assisted fiber-reinforced metal laminate flexible medium hydroforming method, and relates to the technical field of composite material forming. The method mainly comprises the five process steps of fiber reinforced metal laminate blank preparation, vacuum treatment, vacuum bag assisted flexible medium hydroforming, fiber reinforced metal laminate composite material component curing treatment and process supplementary surface removal. The invention further discloses a vacuum-assisted fiber-reinforced metal laminate flexible medium hydroforming device. The prepared fiber-reinforced metal laminate component is high in dimensional precision and few in internal defect, layering, stripping and other defects are not prone to being generated, the mode that vacuum bag forming and flexible medium liquid filling forming and curing integrated technology is combined is adopted, the forming quality and forming efficiency of the fiber-reinforced metal complex component are improved, and the manufacturing cost is reduced. And the application field of the fiber-reinforced metal laminate composite material is greatly widened.

Owner:BEIHANG UNIV

High-temperature alloy bar blank upsetting forming device and method based on high-temperature-resistant medium

ActiveCN114012012AAvoid instabilityAvoid crack defectsForging/hammering/pressing machinesSuperalloyLarge deformation

The invention relates to a high-temperature alloy bar blank upsetting forming device and method based on a high-temperature-resistant medium. A bar blank and the high-temperature-resistant medium are placed in an extrusion cylinder to be subjected to primary upsetting forming; and the high-temperature-resistant medium flows out from a discharge hole formed in the wall of the extrusion cylinder. According to the method, the steady-state upsetting deformation of the high-temperature alloy which is large in height-diameter ratio and difficult to deform is achieved, and meanwhile the cracking defect caused by rapid temperature reduction in the deformation process of the alloy bar blank is effectively avoided. Besides, according to the forming method, in the large-deformation upsetting deformation process, a die does not need to be replaced, one-time forging forming is adopted, and the heating times and forming procedures in the hard-to-deform high-temperature alloy upsetting process are reduced; and under the condition that a traditional isothermal forging technology is not adopted, the defect of instability or cracking of the bar billet with the large height-diameter ratio in the upsetting deformation process can be avoided, the cost is saved, and the production efficiency is improved. And a new selection way is provided for upsetting deformation of small-batch high-temperature alloy bar billets which are large in height-diameter ratio and difficult to deform.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for manufacturing element for belt of continuously variable transmission

Owner:HONDA MOTOR CO LTD

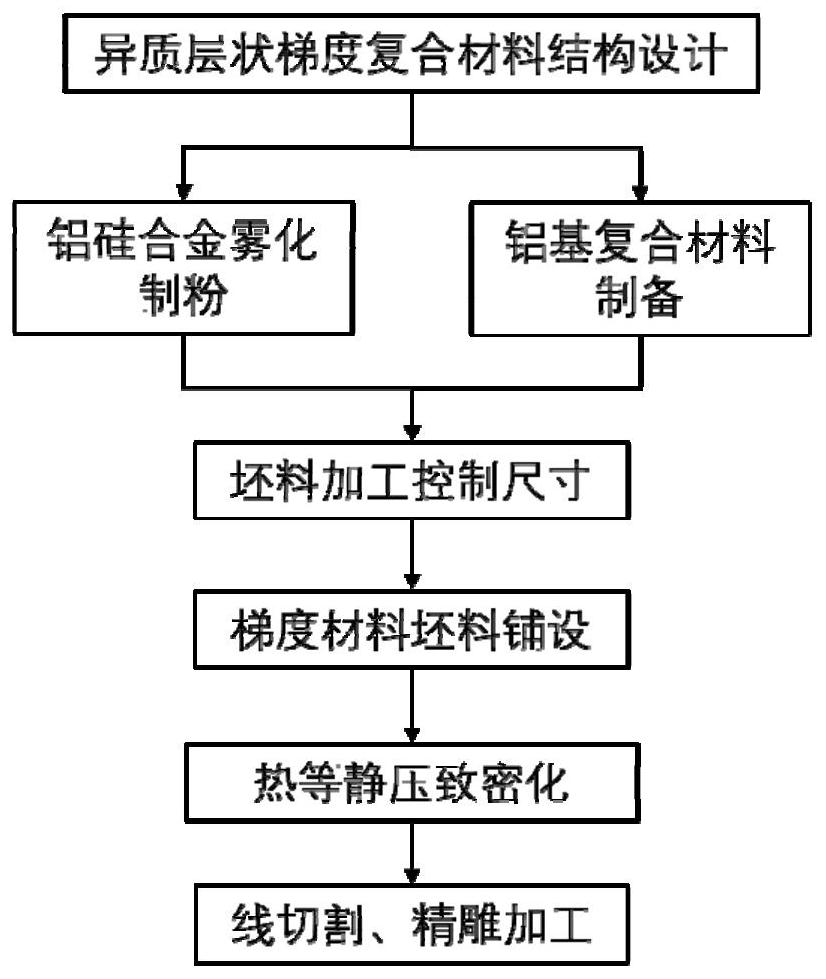

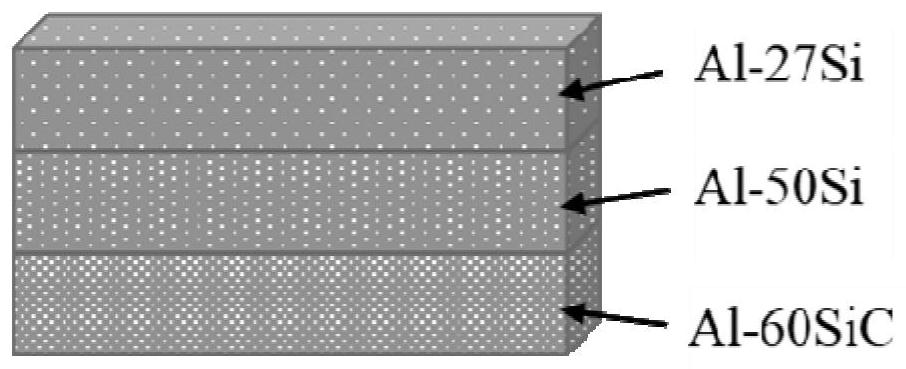

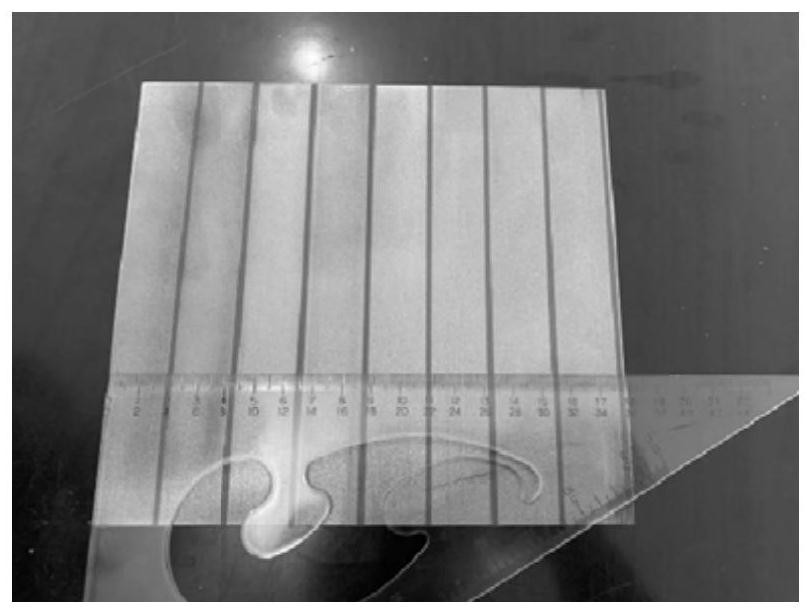

A kind of heterogeneous gradient composite material and its preparation method

The invention provides a heterogeneous gradient composite material and a preparation method thereof. The preparation method comprises the steps that an aluminum base composite material is manufacturedinto a slab, then the aluminum base composite material slab and aluminum-silicon alloy powder are laid in sequence, and finally, the aluminum base alloy composite material and aluminum-silicon alloyare tightly combined to obtain the heterogeneous gradient composite material by pressure sintering. By preparing the aluminum base composite slab in advance without cold pressing and molding, high volume fraction can be obtained, thermal expansion coefficient can be reduced, the thickness and shape of an aluminum base composite layer are controlled easily, and the repeatability of the process is ensured; and the sintering performance of the aluminium-silicon alloy is good, pressure sintering with powder direct laying can reduce the forming process and reduce the cost, the using requirements can be better met, and the stability of the process is ensured.

Owner:CENT SOUTH UNIV

Extrusion and expansion forming method of rim with flange flange

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

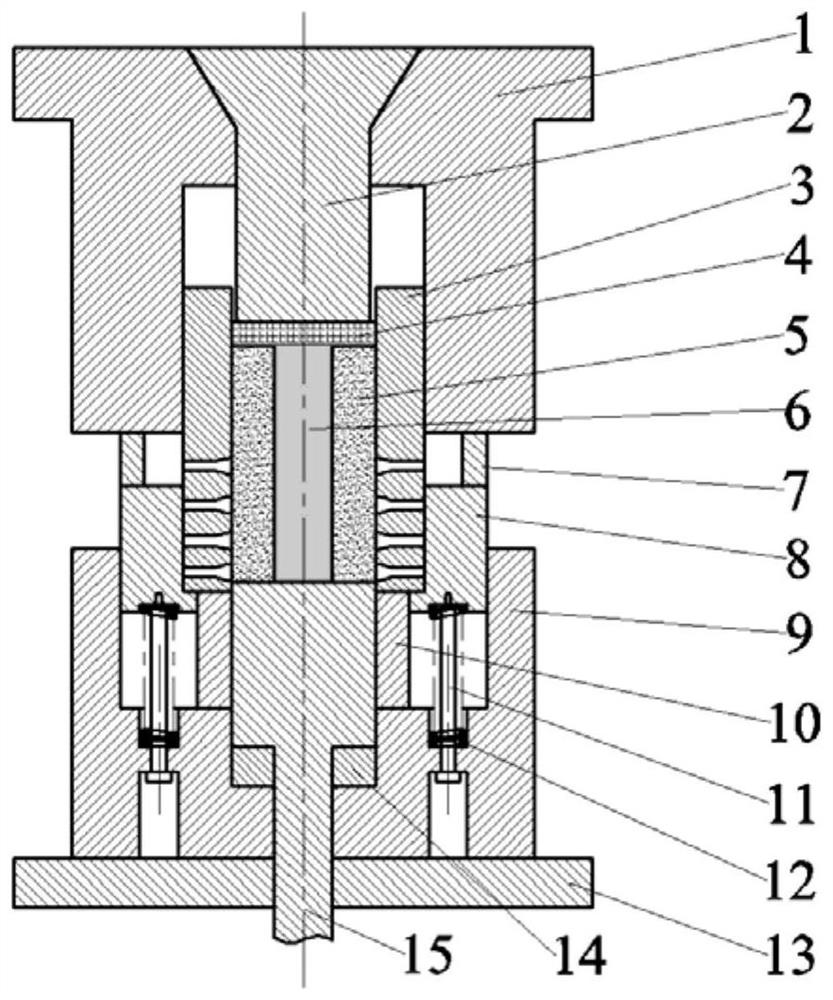

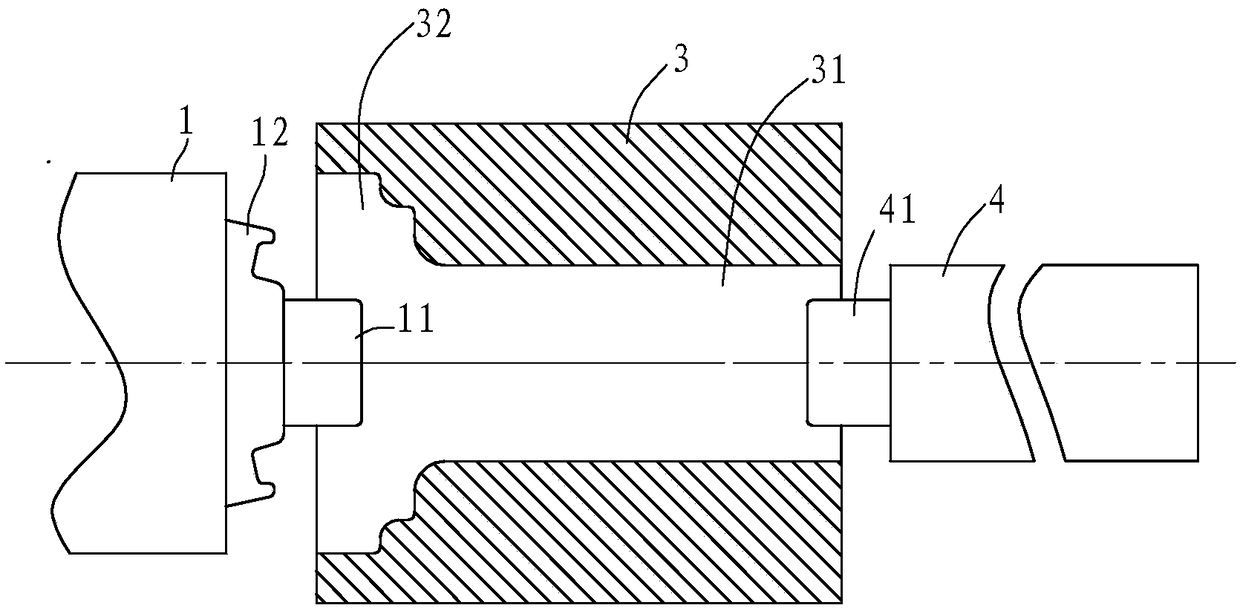

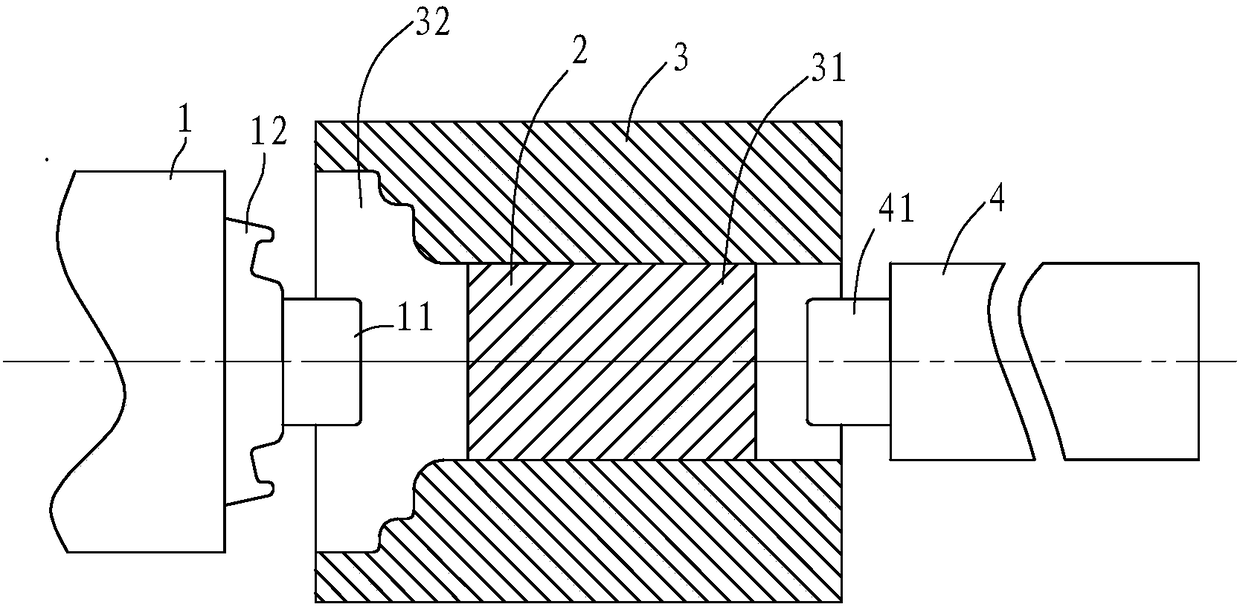

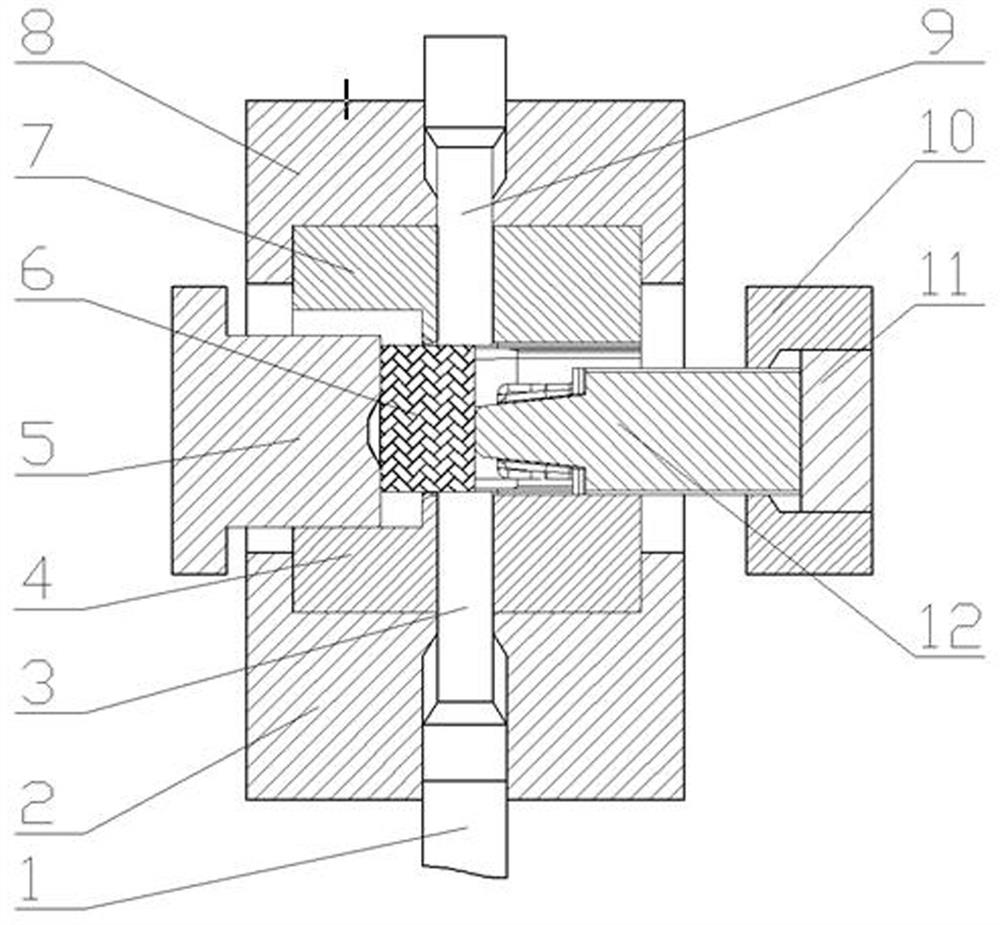

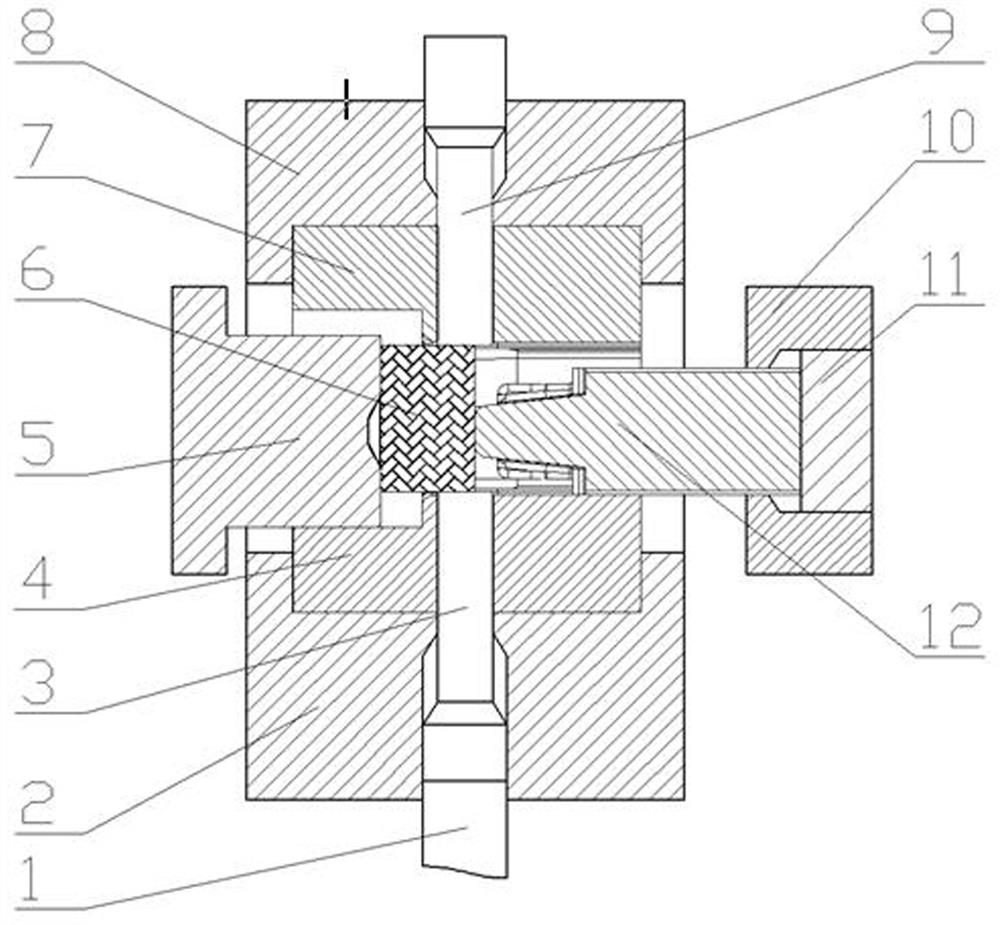

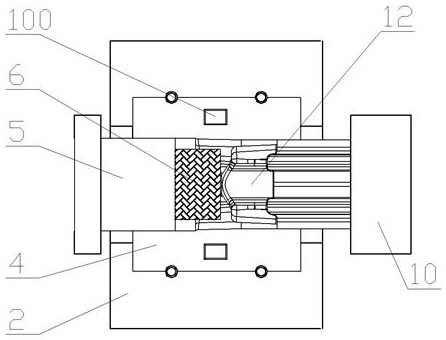

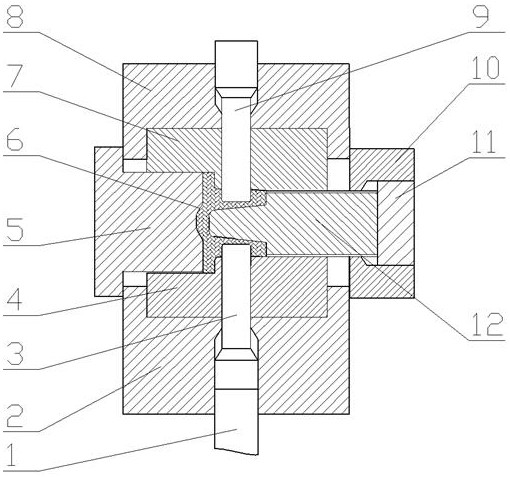

Near-net forming die for high-strength internal hexagonal through-hole bolt

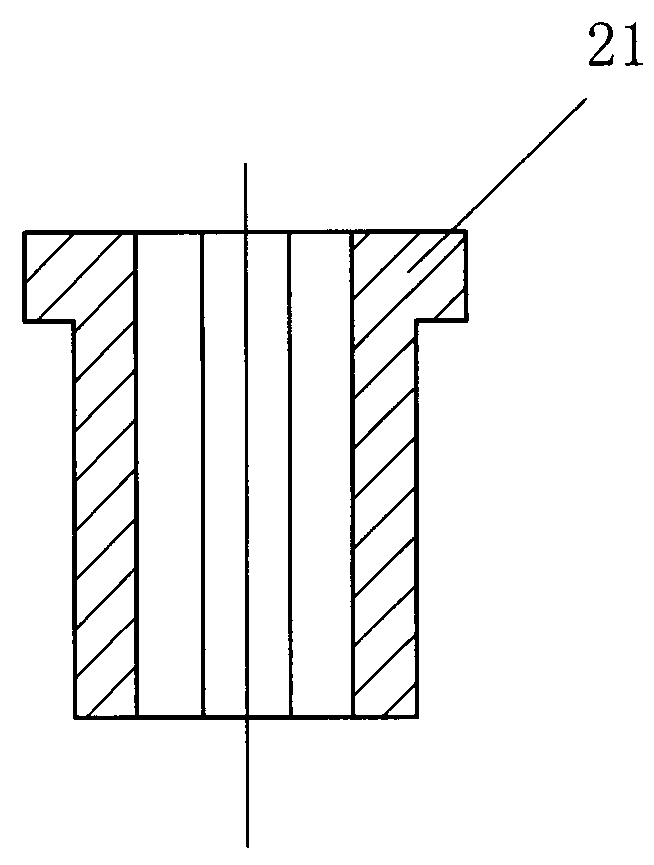

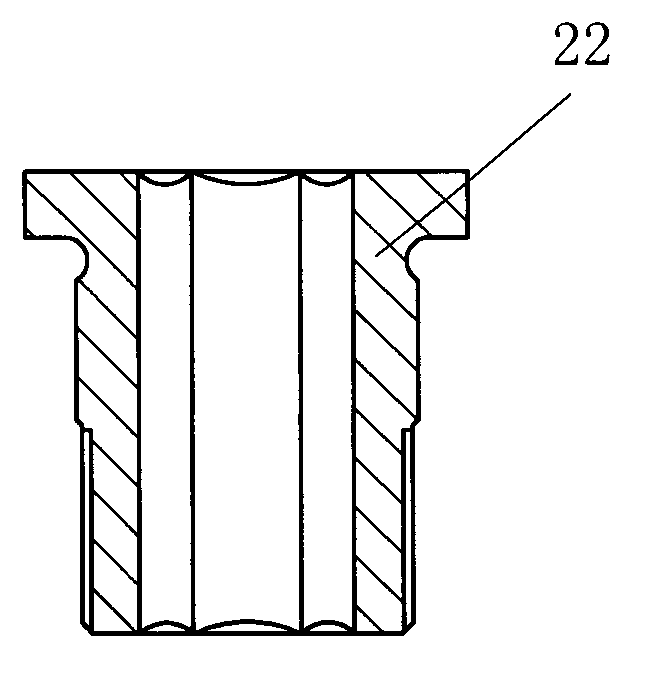

ActiveCN103252409BPrevent deviationReduce forming processShaping toolsNutsEngineeringMechanical engineering

The invention discloses a near-net forming die for a high-strength internal hexagonal through-hole bolt. The near-net forming die mainly comprises an upper die plate, movable press blocks, a male die upper fixing plate, an internal hexagonal through-hole forming punch, a head forming boss press block, a knockout seat, a knockout plate, a female die prestress ring, a forming female die, a base plate, a lower die plate and an ejector. An axial through hole is formed in the middle of the internal hexagonal through-hole forming punch. The head forming boss press block is penetratingly sleeved on a rod body of the internal hexagonal through-hole forming punch through the axial through hole. A plunger tip of the internal hexagonal through-hole forming punch extends out of the axial through hole. The near-net forming die has the main advantages that the internal hexagonal through-hole forming punch and the head forming boss press block are separated from each other and designed to be penetratingly sleeved with each other, so that an inner hexagonal through hole and a head boss can be formed sequentially, defects such as metal folding and turbulence generated during simultaneous forming of the inner hexagonal through hole and the head boss can be avoided, and a blank adhered on the plunger tip is facilitated to be knocked out by the knockout plate after completion of forming.

Owner:ZHONGBEI UNIV

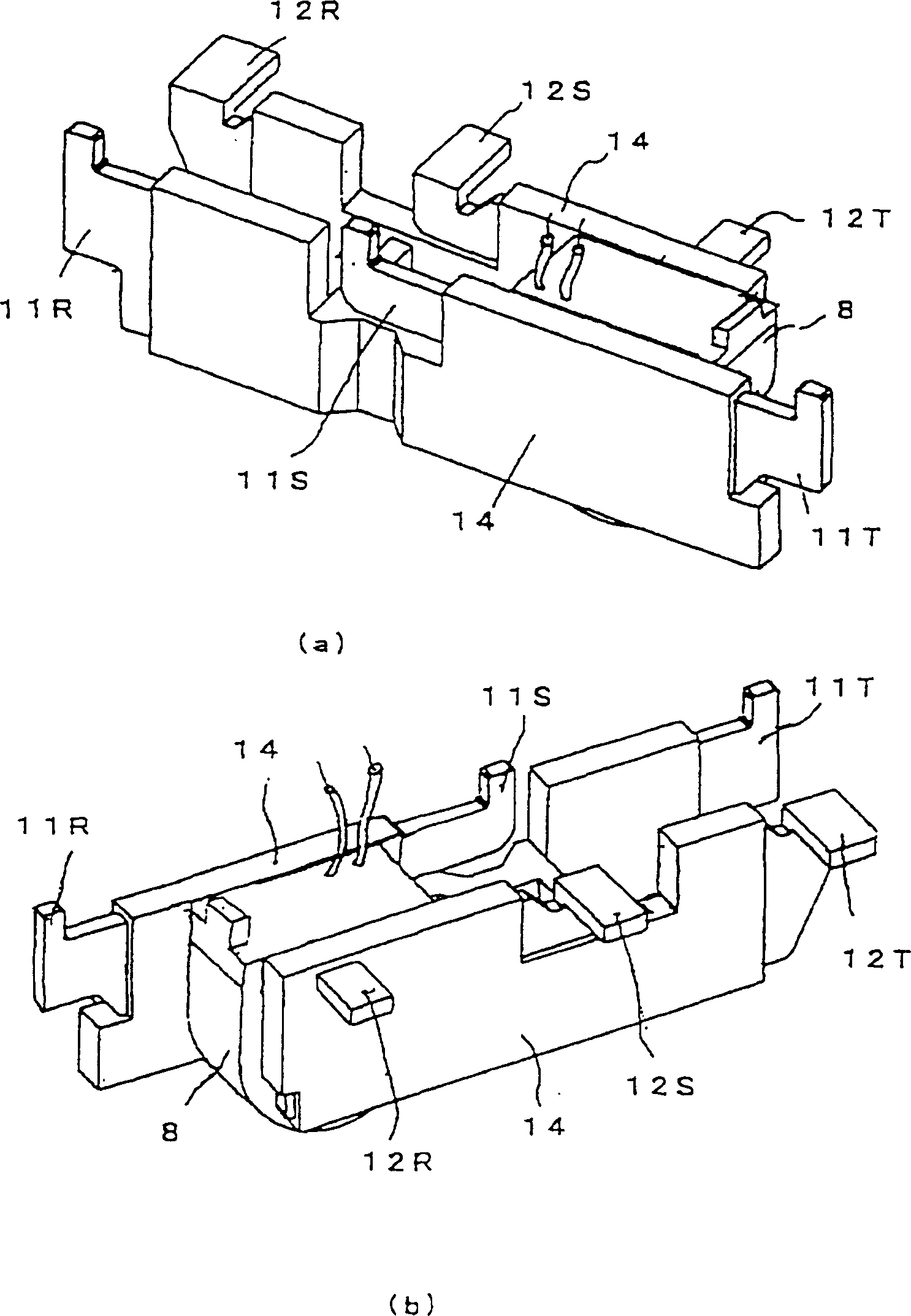

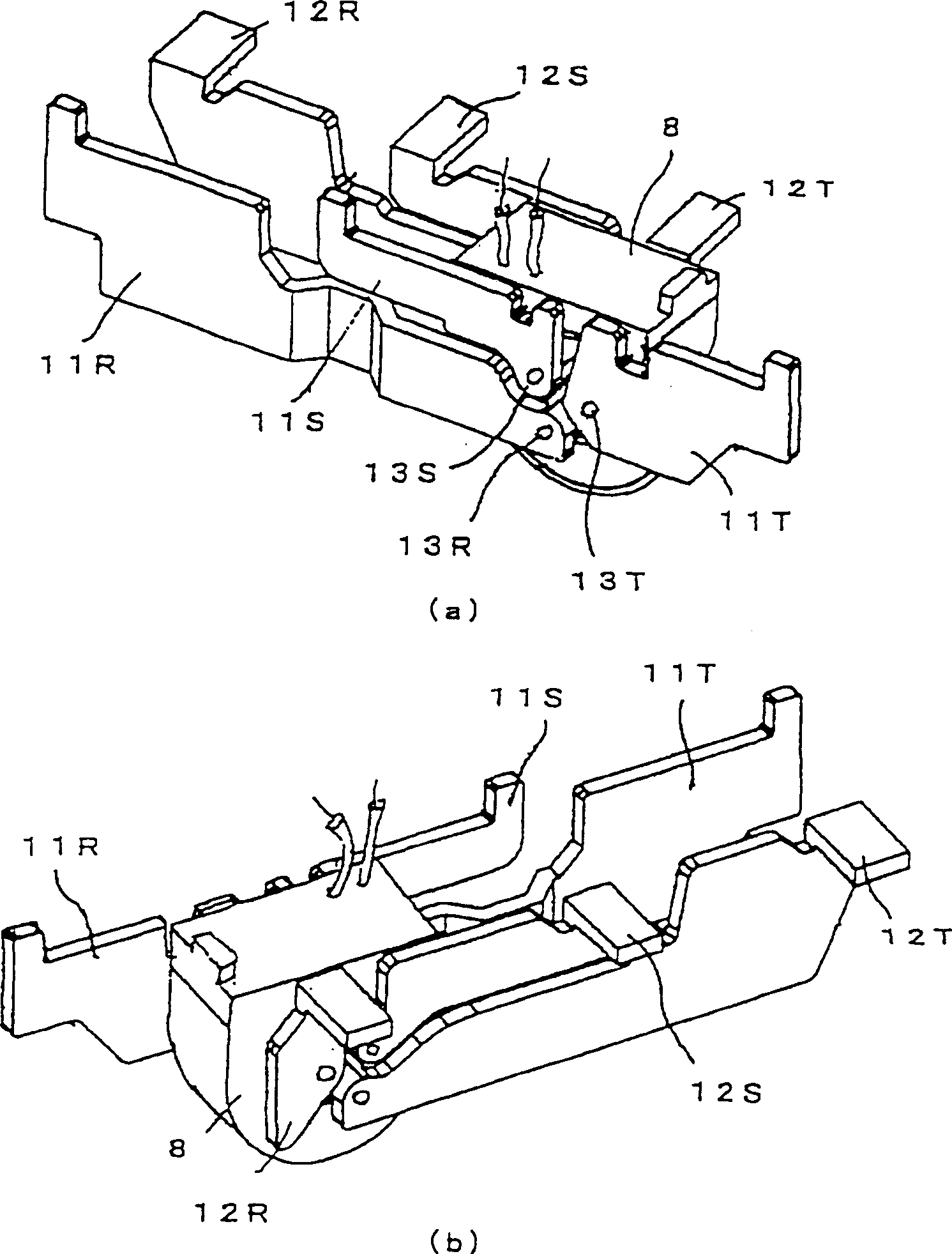

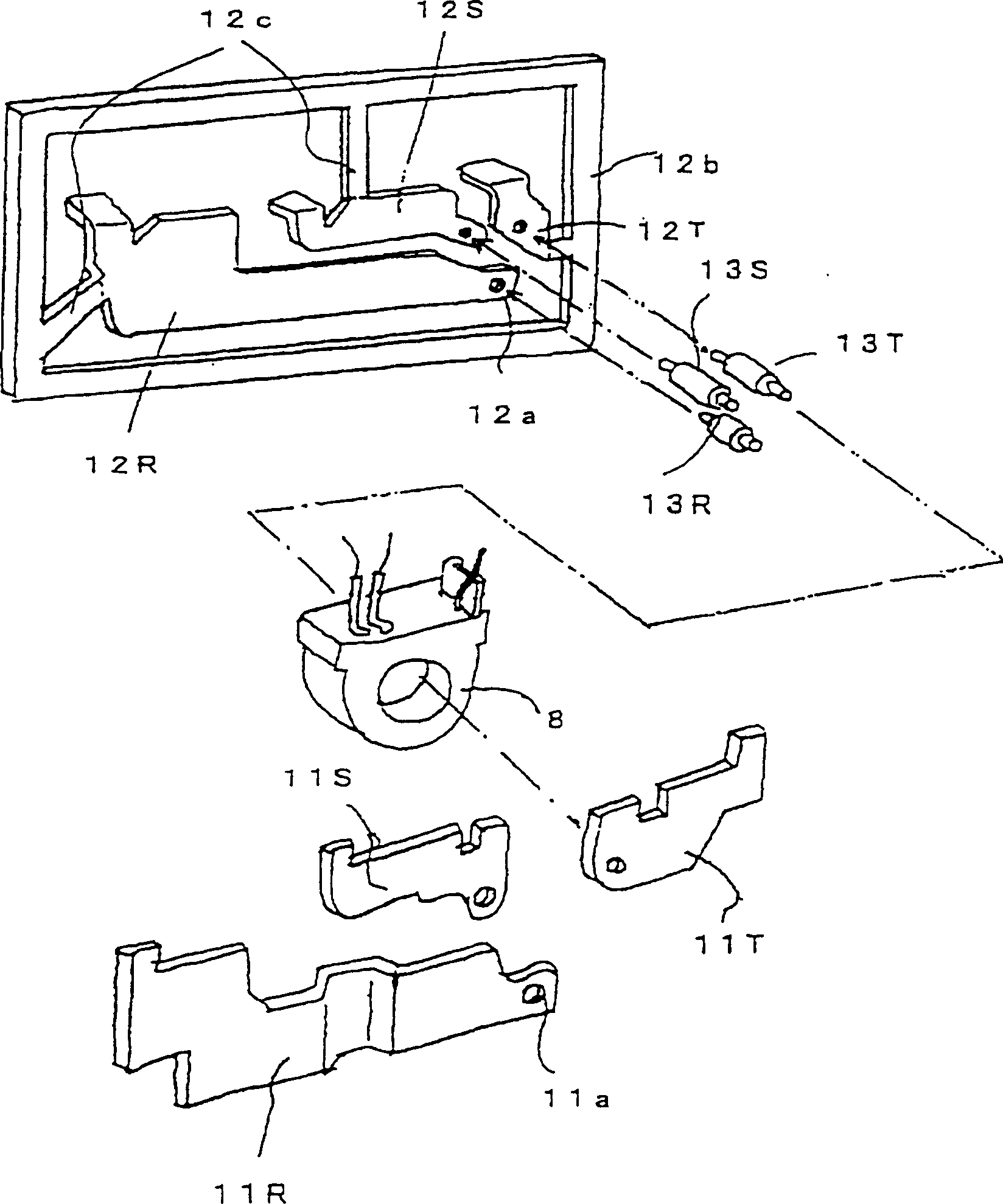

Method for fitting zero phase sequence converter in leakage circuit breaker

InactiveCN1150578CReduce forming processQuality improvementSwitch operated by current/voltage unbalanceTransformersElectrical conductorZero phase

Disclosed is an assembling method for a zero phase current transformer which is able to secure stable quality and yield in addition to cutting down a resin molding process. A primary conductor is composed of a three-phase flat conductors which are distributed on the same plane on both sides of the zero phase current transformer 8, and the rod conductors which are bonded between the flat conductors by penetrating through the primary conductor through holes of the zero phase current transformer. A unit is temporarily assembled by bonding both ends of the rod conductor that penetrates through the zero phase current transformers to the flat conductors placed side by side at fixed positions, with each conductor of the primary conductor left as a bare conductor. After that, the surrounding area of the temporarily assembled body of the unit, which includes the inside of the conductor through hole and the bonded part between the conductors, is collectively and integrally molded by a resin through the use of an injection molding method.

Owner:FUJI ELECTRIC FA COMPONENTS & SYST CO LTD

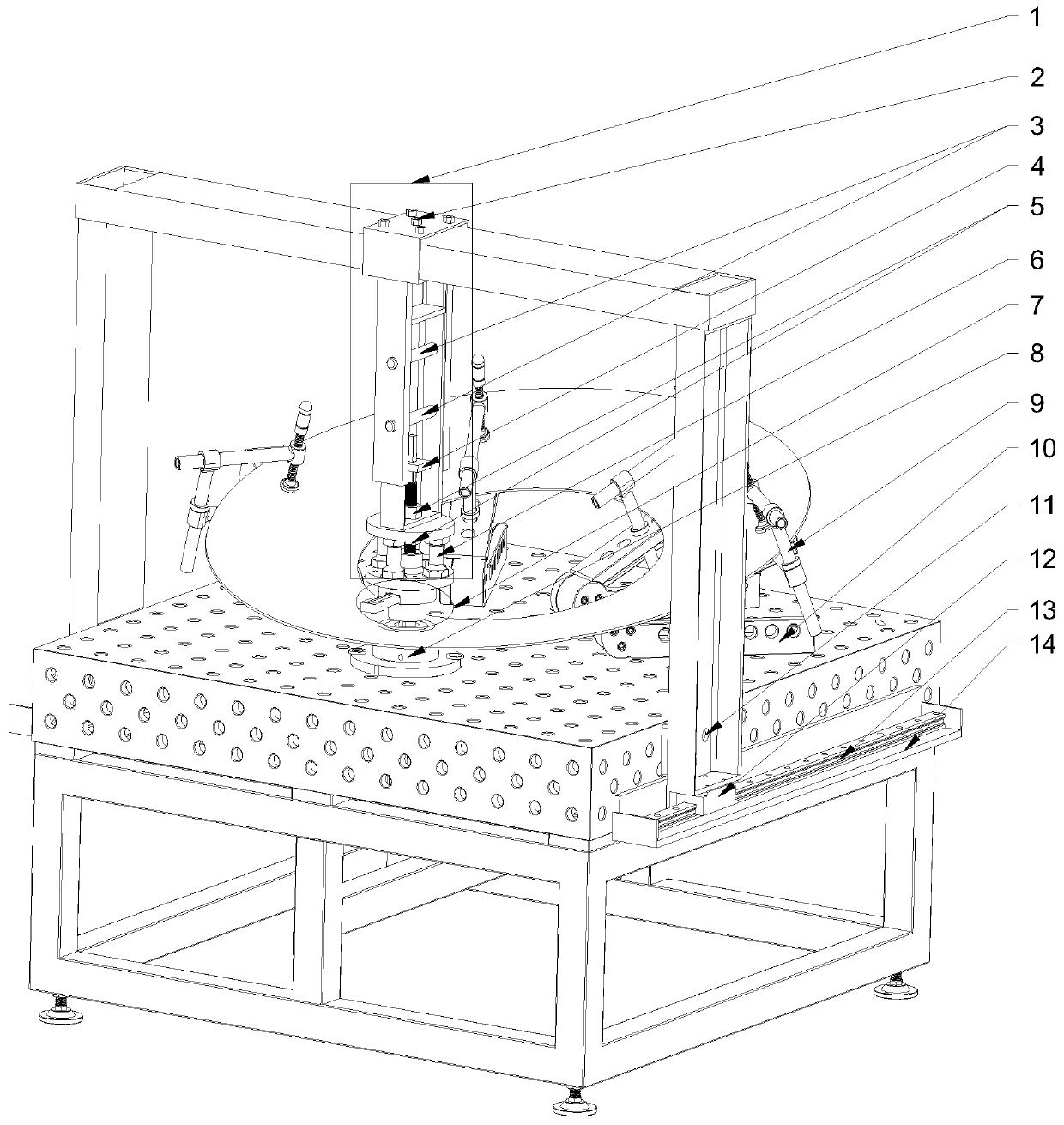

A device and process for hot extrusion forming of a steel diesel engine piston

ActiveCN112222342BAchieve flash-free forgingReduce draft anglePiercing pressesForging/hammering/pressing machinesDieselingProcess engineering

The invention provides a hot extrusion forming device and process for a steel diesel engine piston. The device includes a multi-directional forming extrusion device for extruding a metal blank to form a forging blank and a punching hole for punching the forging blank. The invention can realize the flashless forging forming of the steel diesel engine piston, and can form the piston pin hole, the process and the device can keep most of the metal streamlines of the forgings, and the metal streamlines are distributed along the contour of the forgings. It is beneficial to the stress state of the part during use, and at the same time, the required forming process of the process and the device is short, the energy consumption of the forming equipment is low, and the metal utilization rate is high.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Thermal extrusion forming device and process for steel diesel engine piston

ActiveCN112222342AAchieve flash-free forgingReduce draft anglePiercing pressesForging/hammering/pressing machinesPunchingDieseling

The invention provides a thermal extrusion forming device and process for a steel diesel engine piston. The device comprises a multi-direction forming extrusion device for extruding a metal blank to form a forge piece blank and a punching device for punching the forge piece blank. The device and process can achieve flash-free forge forming of the steel diesel engine piston and a piston pin hole can be formed. According to the process and device, most metal flow lines of the formed forge piece are reserved and are distributed along a contour of the forge piece, so that a stress state of a partin a using process is facilitated, and meanwhile, as the process and device need a short forming step, the forming equipment is relatively low in energy consumption and relatively high in utilizationratio of metals.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

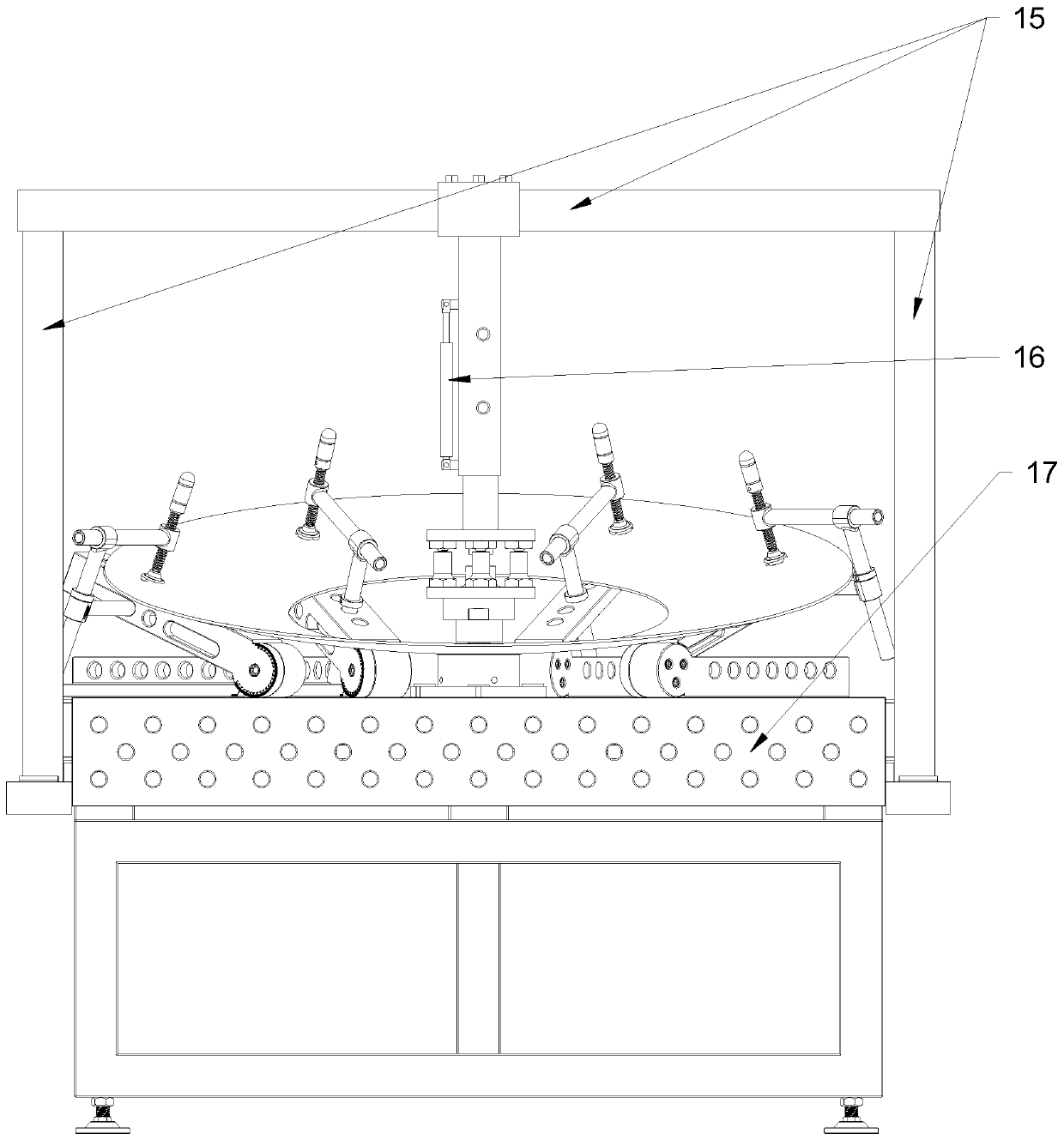

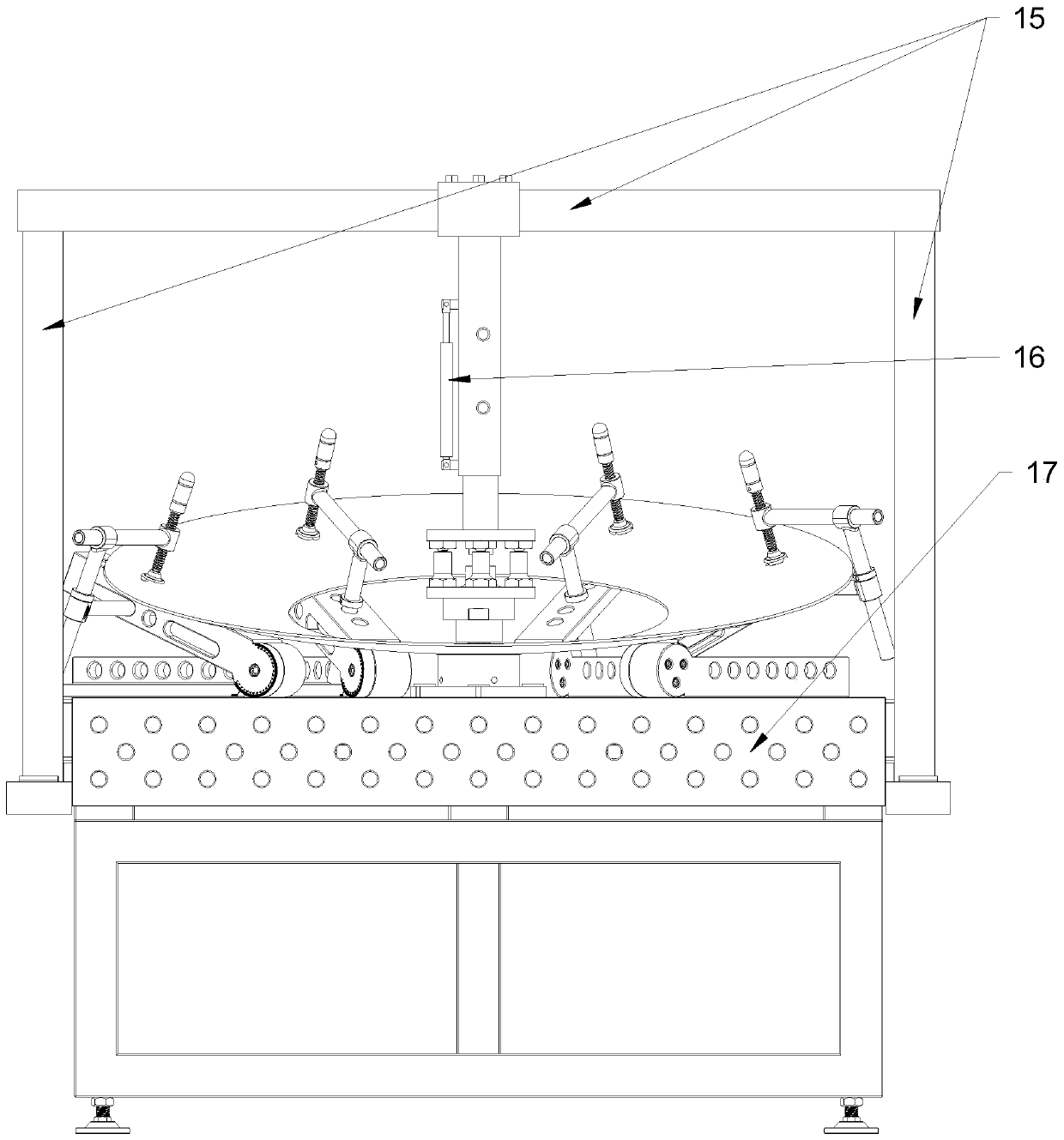

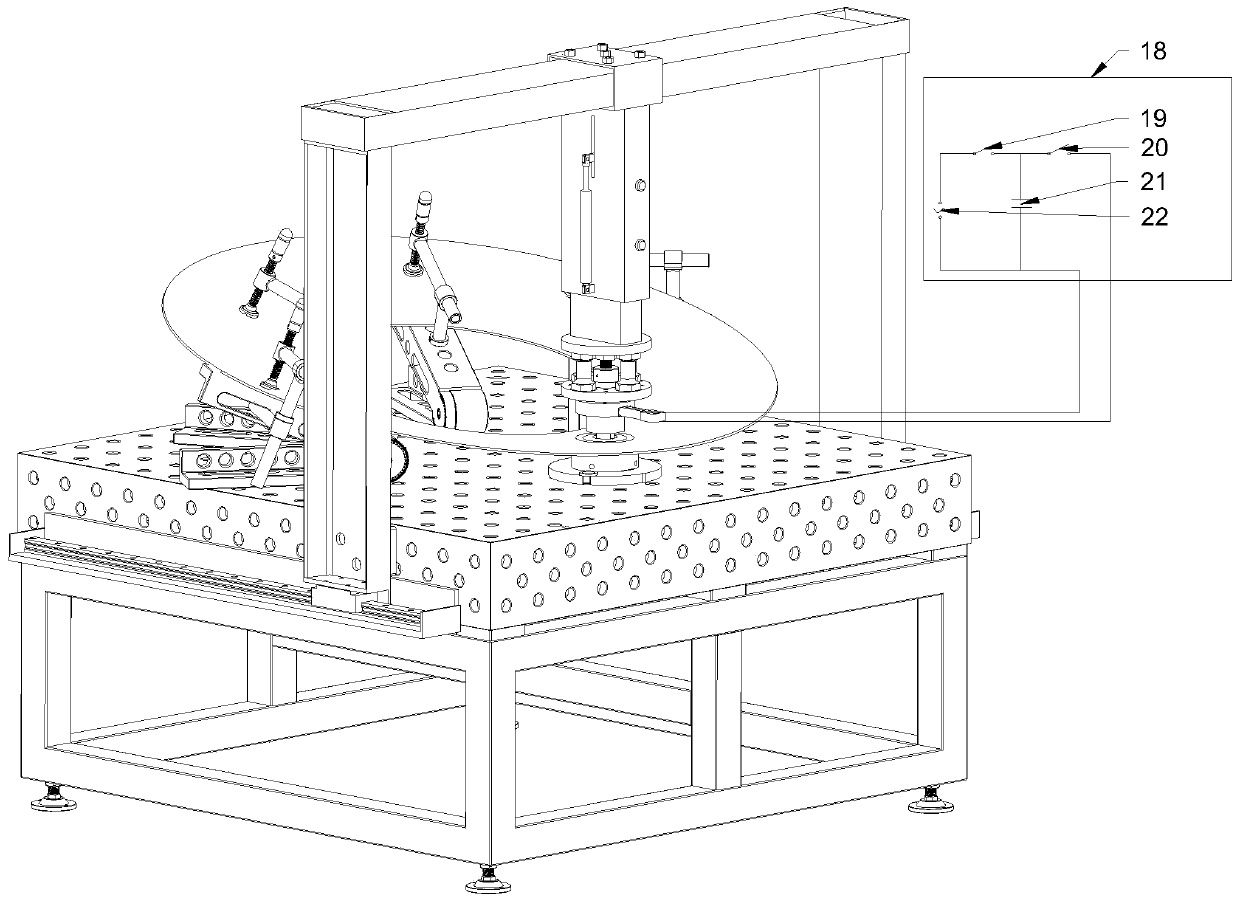

Large curved surface shell local feature forming device and forming method

ActiveCN110000270ASolving forming manufacturing challengesIncrease labor intensityEngineeringElectromagnetic forming

The invention discloses a large curved surface shell local feature forming device. The large curved surface shell local feature forming device comprises a flexible platform, guide rail fixing seats, asteel channel welding flexible frame, a lifting stand column, a die and an electromagnetic forming mechanism. The large curved surface shell local feature forming device implements large curved surface shell local feature forming through cooperation of electromagnetic forming and a flexible tool. The working procedures of traditional large curved surface shell local feature forming are substantially simplified. The time period cost is reduced, and the die machining cost is greatly reduced. Through the large curved surface shell local feature forming device and forming method, the forming limit of a material can be improved, the working procedures can be simplified, and the machining purpose can be achieved through one-time forming. The forming tool can be simplified. A large press machineis not needed. Only the single-face die corresponding to the local features is needed, and a male die is not needed. The surface quality of a formed part is good without scratches, and the rate of finished products is high.

Owner:HARBIN INST OF TECH

A sleeve forming method

ActiveCN109604472BReduce the impact of surface qualityEffective Portfolio IntegrationShaping toolsMachiningIndustrial engineering

The invention discloses a sleeve forming method. The sleeve forming method comprises the following steps that step A, blank drawing is conducted, a blank material is preformed after the first time stamping forming; step B, drawing is conducted for the second time, the blank material subjected to stamping forming in the step A is subjected to stamping forming for the second time; step C, a die is provided, forming of the flange part of the blank material formed in the step B is completed by one time of stamping stroke, the bottom surface is cut off, and the straight cylinder part is formed; andstep D, the blank material formed in the step C is milled, an arc of the opening part of the straight wall is formed, and final machining of the sleeve is completed. Compared with the prior art, thesleeve forming method reduces forming procedures and bottom turning procedures, so that influence on the quality of the accessory surface by multi-procedure forming is reduced, and the utilization rate of accessory materials is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

A composite manufacturing method for connecting and forming metal plate parts based on high-speed impact

The invention belongs to the relevant field of machining and forming of plate components, and discloses a metal plate component connection and forming composite manufacturing method based on high-speed impact. The method comprises the following steps that a reinforcing plate is placed on a mould, and a substrate is arranged above the reinforcing plate; a circuit loop is provided for the substrate, and an aluminum foil is used as a material source for generating gasification drive at the same time; current flows through the aluminum foil and gasification occurs, and generated local high-pressure air mass drives the substrate to move downwards at a high speed and hit the reinforcing plate; and the reinforcing plate is connected with the substrate at an impact position, and with the continuous impact and final stop of the impact, the reinforcing plate and the substrate are gradually connected and formed into a whole in the mould until the whole composite manufacturing process is completed. The invention also discloses a corresponding metal plate product. Through the method, the forming limit of plate component can be improved, the machining defects such as excessive strain at corners and connection with the mould can be reduced advantageously, and the method has the advantages of less required processes, high forming precision and efficiency, convenience in operation and control, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

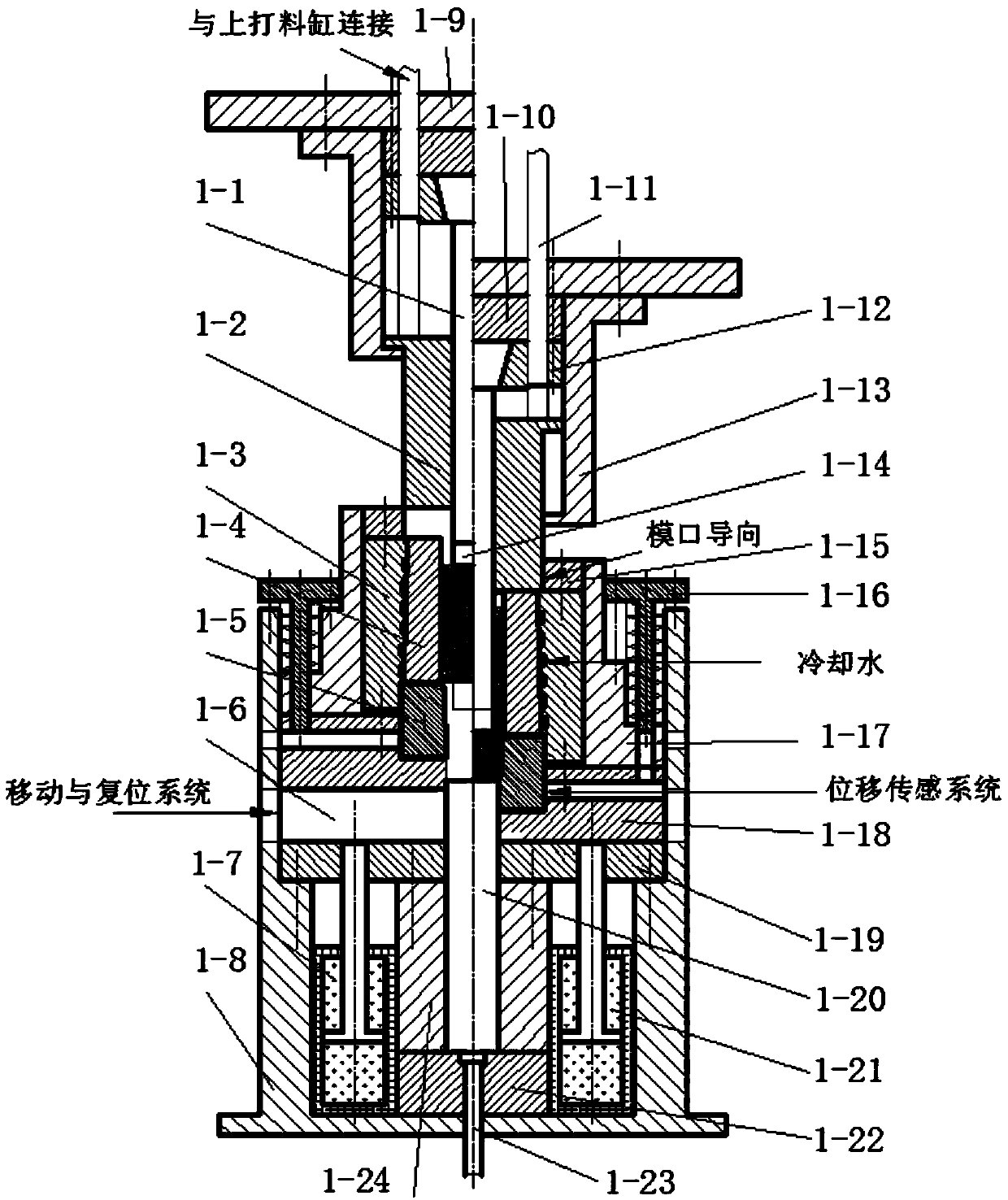

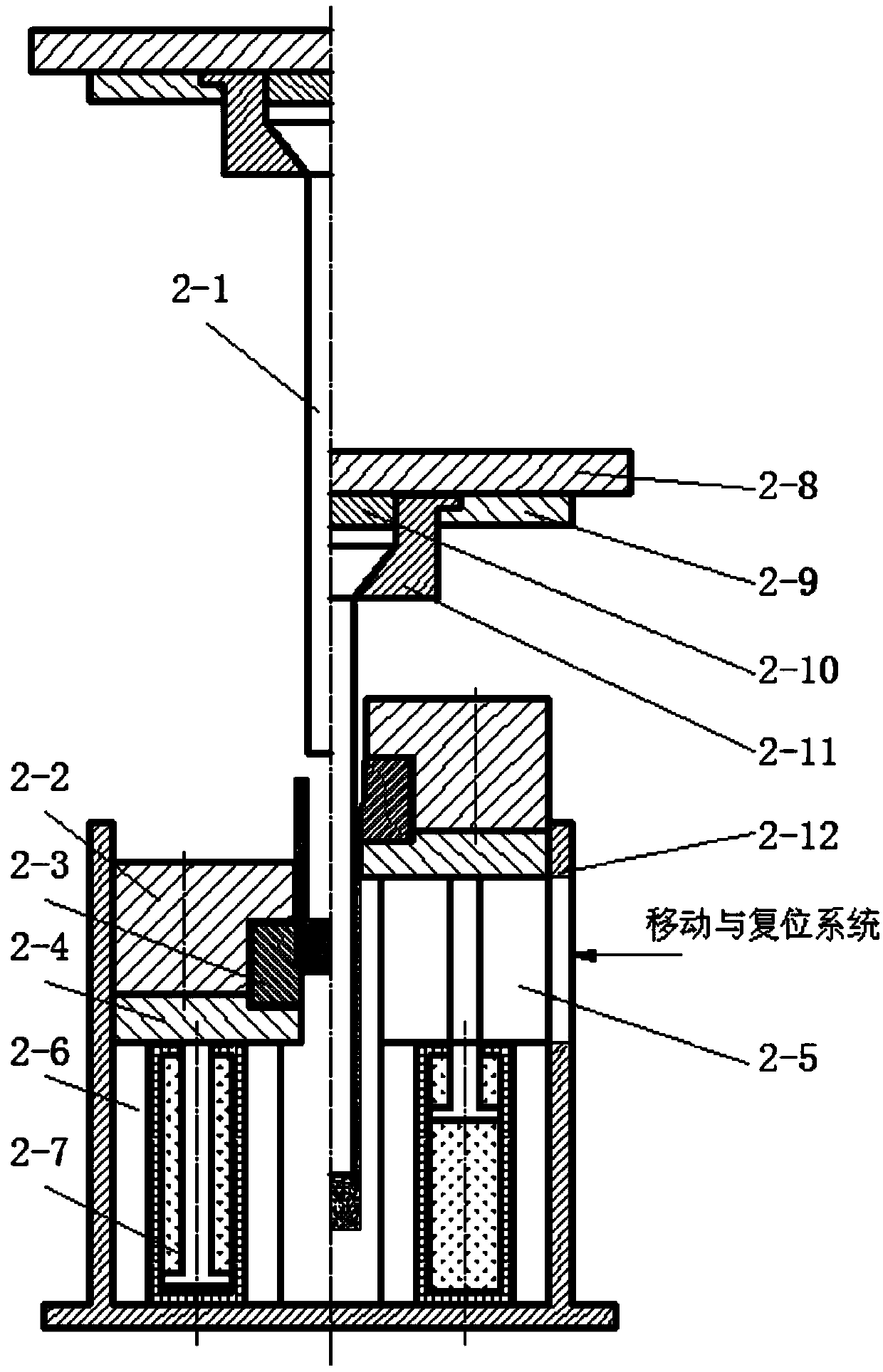

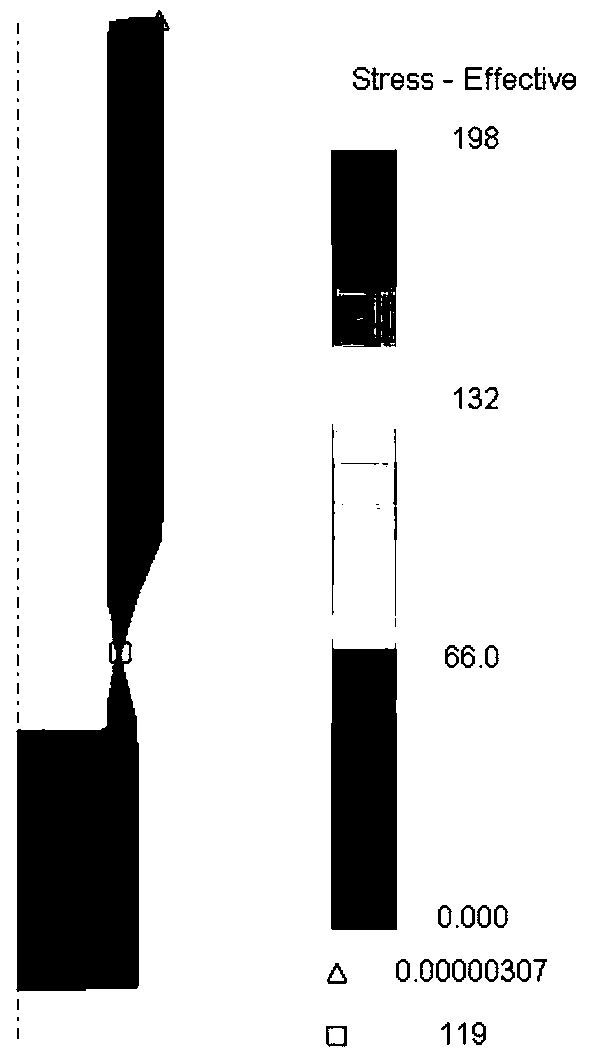

A kind of open cavity extrusion molding die

ActiveCN107433300BReduce forming loadIncrease the aspect ratio of the inner holeShaping toolsPunchingEngineering

The invention discloses an extrusion forming die for an open mold cavity. The extrusion forming die mainly comprises an extrusion punching die body and an extrusion pulling die body. In the extrusion punching stage, the open mold cavity is formed by a first female die and a second female die. The second female punching die is of a floating structure and moves downwards along an upper die, the forming load is reduced, and the bend resistance bearing capability of a male die is improved. After a blank makes contact with a first jacking rod, the upper die and an upper ramming cylinder are depressurized; piston rods of a left piston cylinder and a right piston cylinder move upwards to support a female die supporting ring; a left movable supporting block and a right movable supporting block are pulled out horizontally under the effect of a moving and resetting system; a lower die sleeve and the female die supporting ring overall move downwards under the effects of the resilience force of a spring and the pressing force of the upper ramming cylinder in the return stroke process of the left piston cylinder and the right piston cylinder; and when the blank makes complete contact with a lower fixed plate, the open mold cavity is formed again at the moment. The thinning pulling times can be effectively decreased, forming defects such as pull cracks and pull fractures are prevented, and the extrusion forming die for the open mold cavity can be applied to forming of various deep blind hole thin wall products.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

A device for forming local features of a large curved surface shell and a forming method thereof

ActiveCN110000270BSolving forming manufacturing challengesIncrease labor intensityEngineeringElectromagnetic forming

The invention discloses a large curved surface shell local feature forming device. The large curved surface shell local feature forming device comprises a flexible platform, guide rail fixing seats, asteel channel welding flexible frame, a lifting stand column, a die and an electromagnetic forming mechanism. The large curved surface shell local feature forming device implements large curved surface shell local feature forming through cooperation of electromagnetic forming and a flexible tool. The working procedures of traditional large curved surface shell local feature forming are substantially simplified. The time period cost is reduced, and the die machining cost is greatly reduced. Through the large curved surface shell local feature forming device and forming method, the forming limit of a material can be improved, the working procedures can be simplified, and the machining purpose can be achieved through one-time forming. The forming tool can be simplified. A large press machineis not needed. Only the single-face die corresponding to the local features is needed, and a male die is not needed. The surface quality of a formed part is good without scratches, and the rate of finished products is high.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com