Riveting type joint seam steel pipe

A technology of riveting and steel pipes, which is applied in the field of seamed steel pipes, can solve the problems of complicated processing technology and low efficiency of welded pipes, and achieve the effects of low cost, high strength and few forming processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

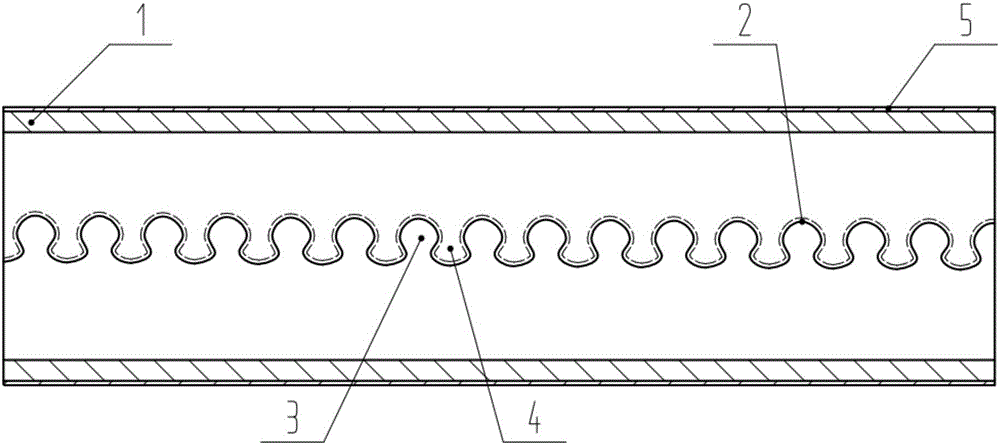

[0014] as attached figure 1 with attached figure 2 The shown riveted seam steel pipe is a steel plate bent into a closed cylinder 1 as a whole, and the edges on both sides of the seam 2 forming the closed cylinder 1 are respectively provided with a notch array composed of a plurality of notches 3, And the shape of the protruding part 4 between the adjacent notches 3 is the same as that of the notches 3; the notch arrays at the two side edges of the seam 2 are arranged in a staggered manner and are embedded and riveted together.

[0015] Preferably, the shape of the notch 3 is Ω-shaped, and the Ω-shaped notch 3 has a better overlap, is not easy to disengage, and has a larger occlusal area.

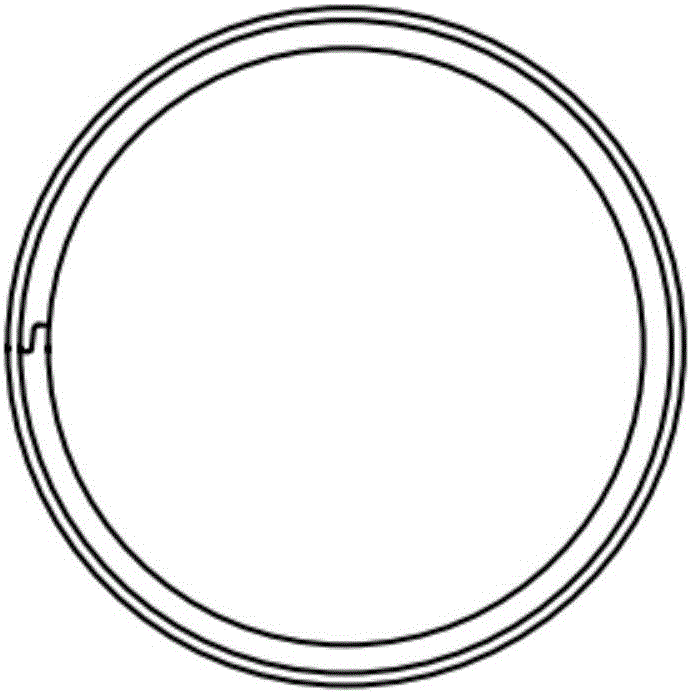

[0016] In order to ensure airtightness, such as figure 2 As shown, the two side edges of the seam 2 forming the closed cylinder 1 have overlapping parts after being riveted tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com