Near-net forming die for high-strength internal hexagonal through-hole bolt

A near-net shape, high-strength technology, applied in the direction of forming tools, nuts, manufacturing tools, etc., to reduce the forming process, reduce production costs, and prevent deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention specifically illustrates the near-net-shaping method of hexagonal inner through-hole bolts and the mold used therefor through specific examples.

[0027] A near-net-shaping method for high-strength hexagonal through-hole bolts, the sequence comprising:

[0028] (1), pipe blanking (such as figure 1 shown);

[0029] (2), cold extrusion, machining, heat treatment annealing, surface treatment and lubrication;

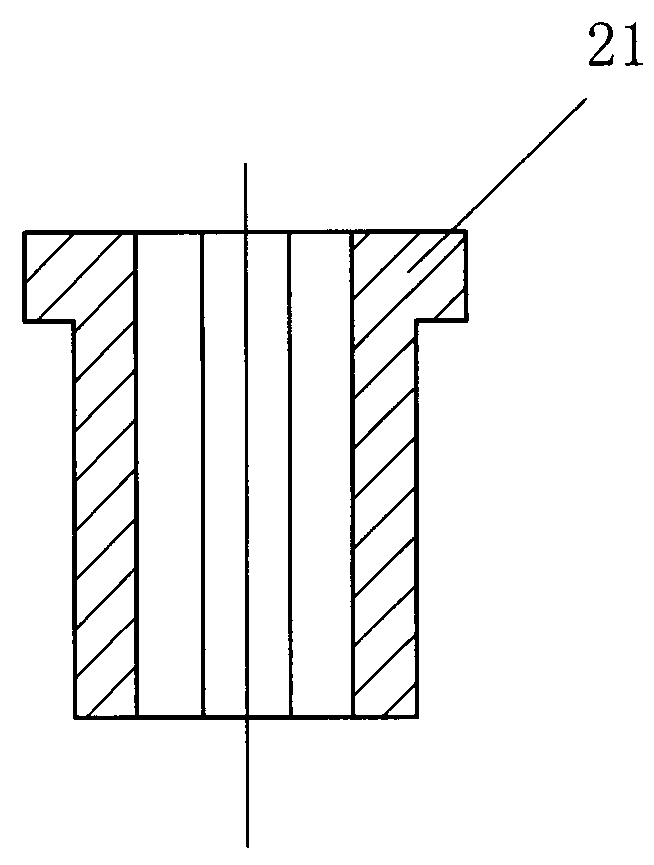

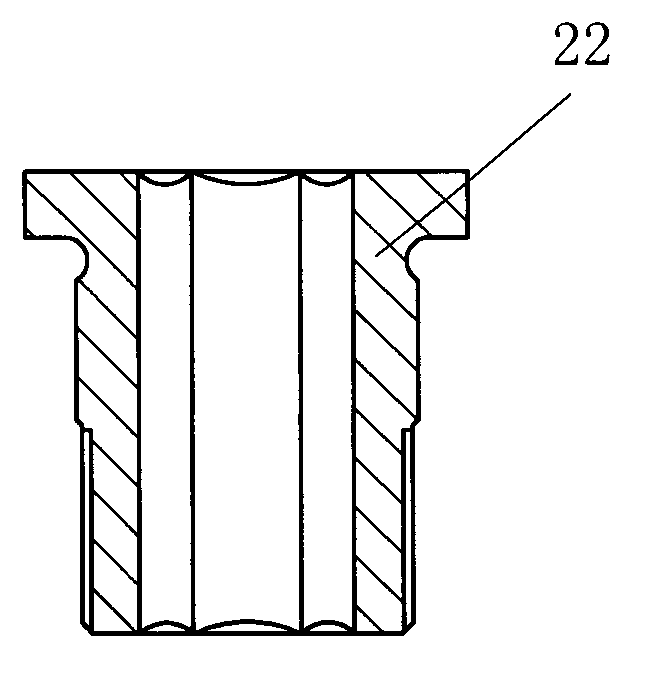

[0030] (3), put the processed hollow blank 2 into the die cavity 101 of the forming die 10 of a high-strength inner hexagonal through-hole bolt near the net forming die (such as Figure 11 shown), such as image 3 As shown, the mold mainly includes an upper template 3, a movable briquetting block 4, a fixed plate 5 on the punch, a forming inner hexagonal through-hole punch 6, a forming head boss briquetting block 8, a material punching seat 7, and a material punching plate 15 (as Figure 8 shown), die prestressing ring 9, forming die 10, ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com