Woven fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

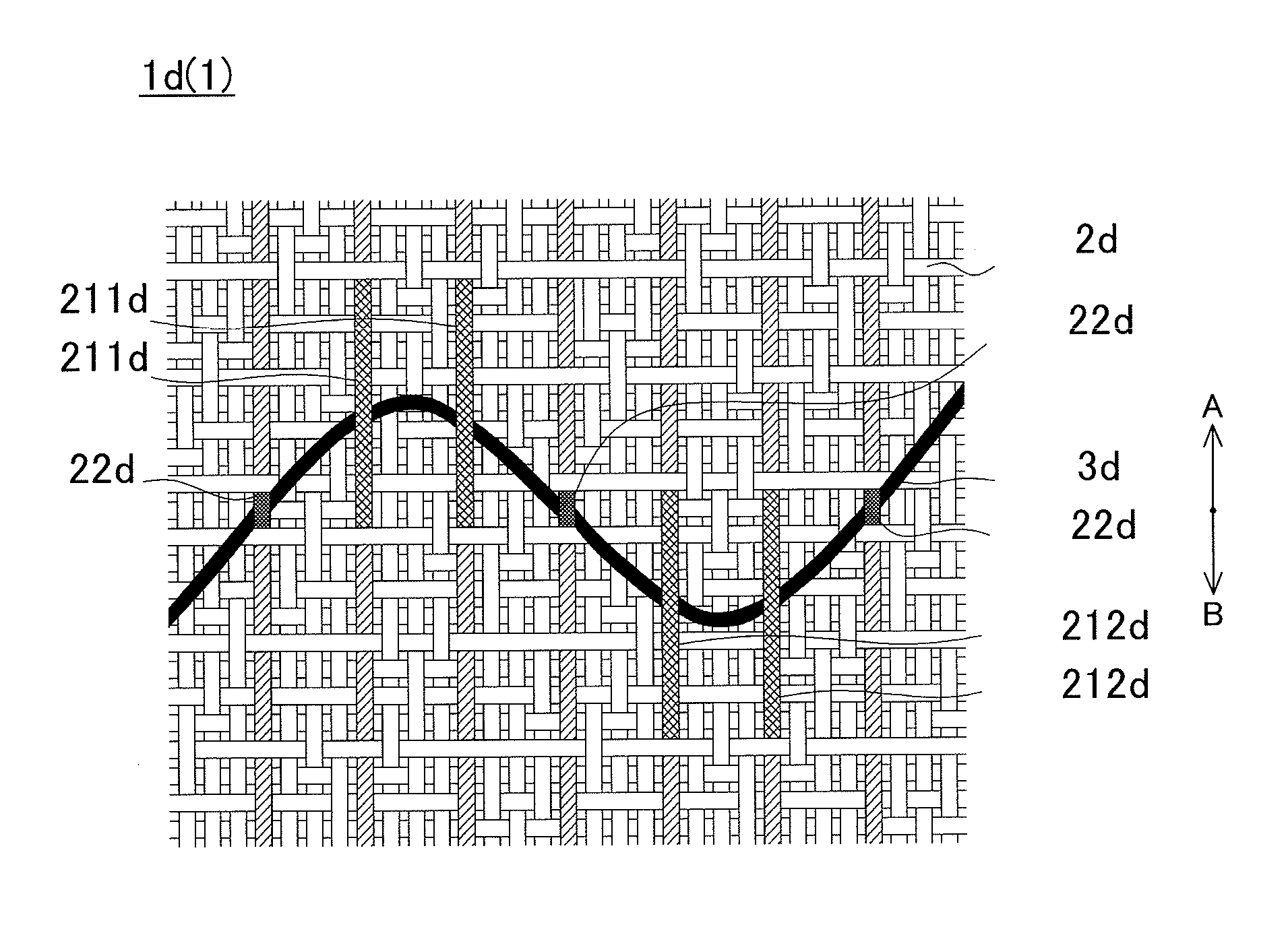

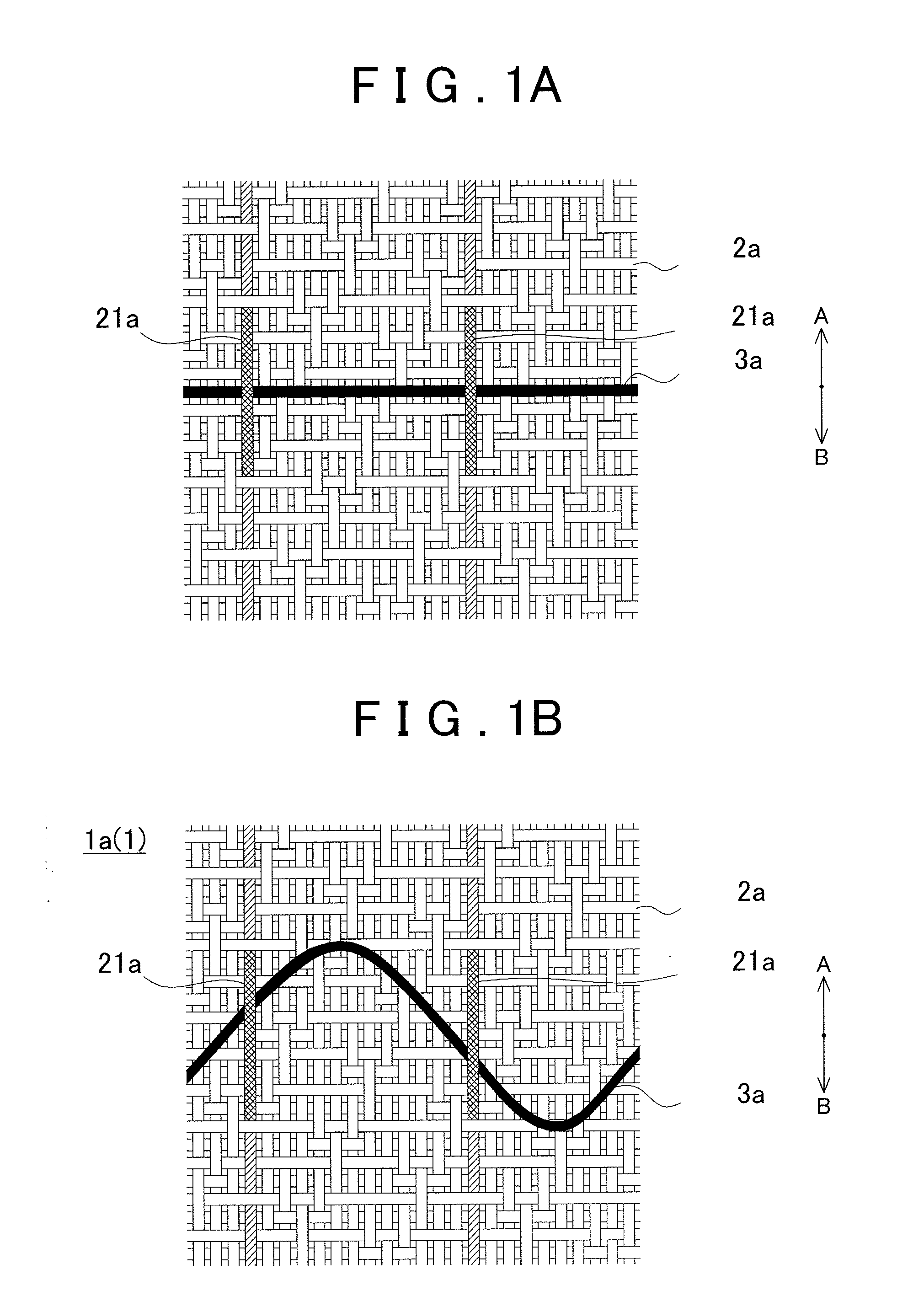

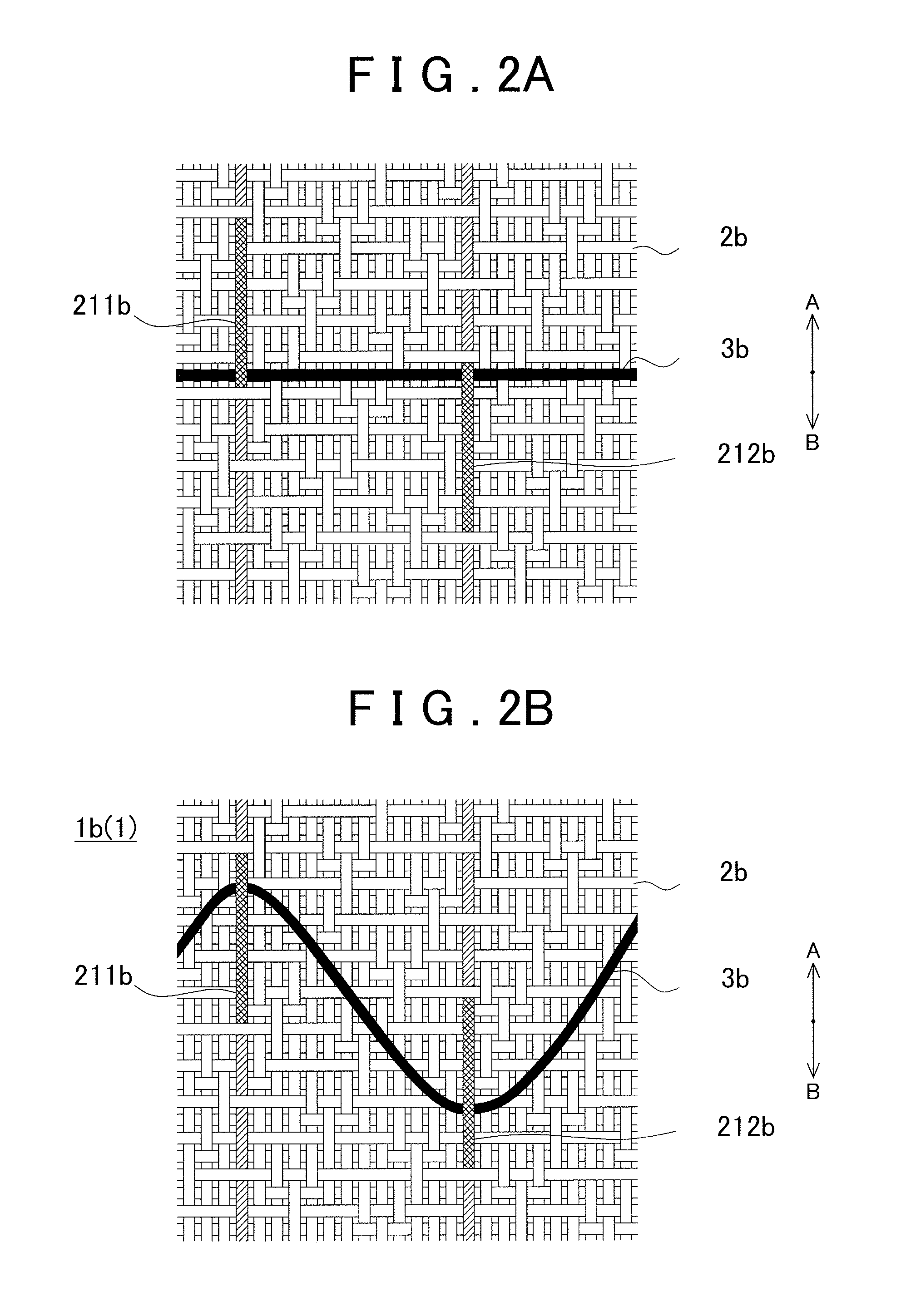

[0028]Example embodiments of the invention will now be described with reference to the accompanying drawings. A seat cover of a vehicle seat will be given as an example of that to which a woven fabric 1 according to the example embodiments of the invention is applied. Hereinafter, various structures will be described in detail, with a woven fabric used as a seat cover of a vehicle seat as an example.

[0029]The woven fabric 1 according to the example embodiments includes a high shrinkage yarn 2 and a low shrinkage yarn 3. The high shrinkage yarn 2 is a yarn made of material with a relatively high shrinkage ratio (i.e., it shrinks easily) (compared to the low shrinkage yarn 3). The low shrinkage yarn 3 is a yarn made of material with a relatively low shrinkage ratio (i.e., it does not shrink easily) (compared to the high shrinkage yarn 2). The woven fabric 1 according to the example embodiments is such that a portion that will be the base of the woven fabric is formed by the high shrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shrinkage | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com