Vacuum temperature adjustment type extrusion molding method of copper part

A technology of extrusion forming and vacuum, which is applied in the direction of metal extrusion dies, etc., can solve the problems of long process flow, achieve the effects of improving forming precision, improving dislocation density and plastic deformation ability, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

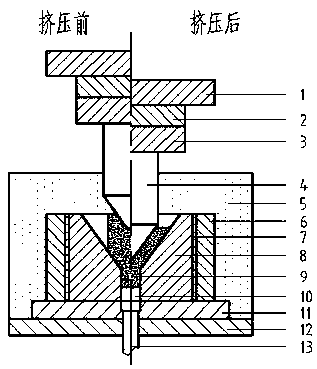

[0016] figure 1 It is a schematic diagram of extrusion molding die device of copper cone with vacuum temperature. Among them, the upper mold is mainly composed of the upper mold plate 1, the upper backing plate with heat insulation 2, the upper mold fixing plate 3, and the punch 4; the lower mold is mainly composed of the lower mold fixing ring 6 with heat insulation, the heating element 7, and the concave mold 8 , Block 10, lower backing plate 11 with heat insulation, lower formwork 12, ejector rod 13 to form.

[0017] The maximum outer diameter of the copper cone extrusion is Φ86.1mm, and the wall thickness is 13mm (such as figure 1 The billet after extrusion), the designed copper billet has a diameter of Φ47.8mm and a height of 77.2mm (such as figure 1 blank before extrusion). The copper billet is cooled to -100°C by liquid nitrogen; then the billet is placed in the cavity of the concave mold, and the temperature of the die is 20°C; then the upper die moves downward to e...

Embodiment 2

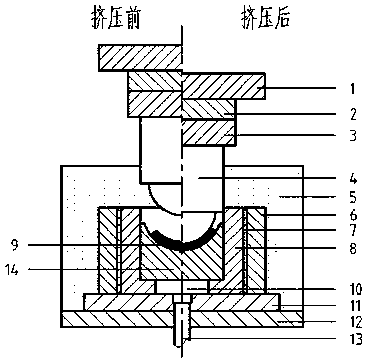

[0020] figure 2 It is a schematic diagram of extrusion molding die device for copper arc parts vacuum temperature. Among them, the upper mold is mainly composed of the upper mold plate 1, the upper backing plate with heat insulation 2, the upper mold fixing plate 3, and the punch 4; the lower mold is mainly composed of the lower mold fixing ring 6 with heat insulation, the heating element 7, and the concave mold 8 , Block 10, lower backing plate 11 with heat insulation, lower formwork 12, push rod 13, lower mandrel 14 composition.

[0021] The wall thickness of the copper arc extrusion is 7mm (such as figure 2 The billet after middle extrusion), the maximum wall thickness of the designed copper billet is 11.6mm (such as figure 2 blank before extrusion). The initial temperature of the copper billet is 20°C, and then the billet is placed in the positioning cavity of the lower mandrel. When the upper mold moves downward for 3mm, the upper mold maintains the pressure; then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com