Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

231results about How to "Small elastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

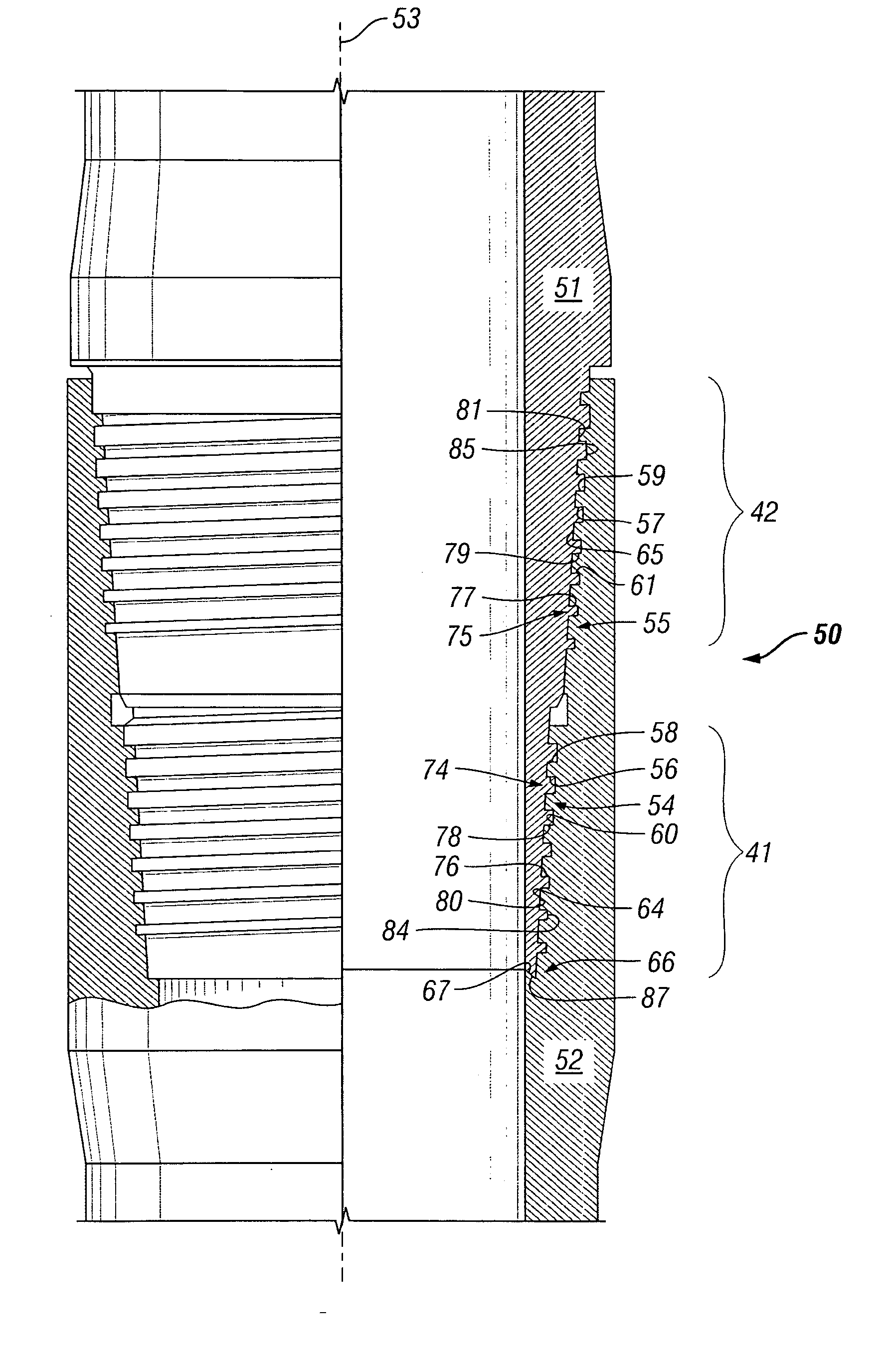

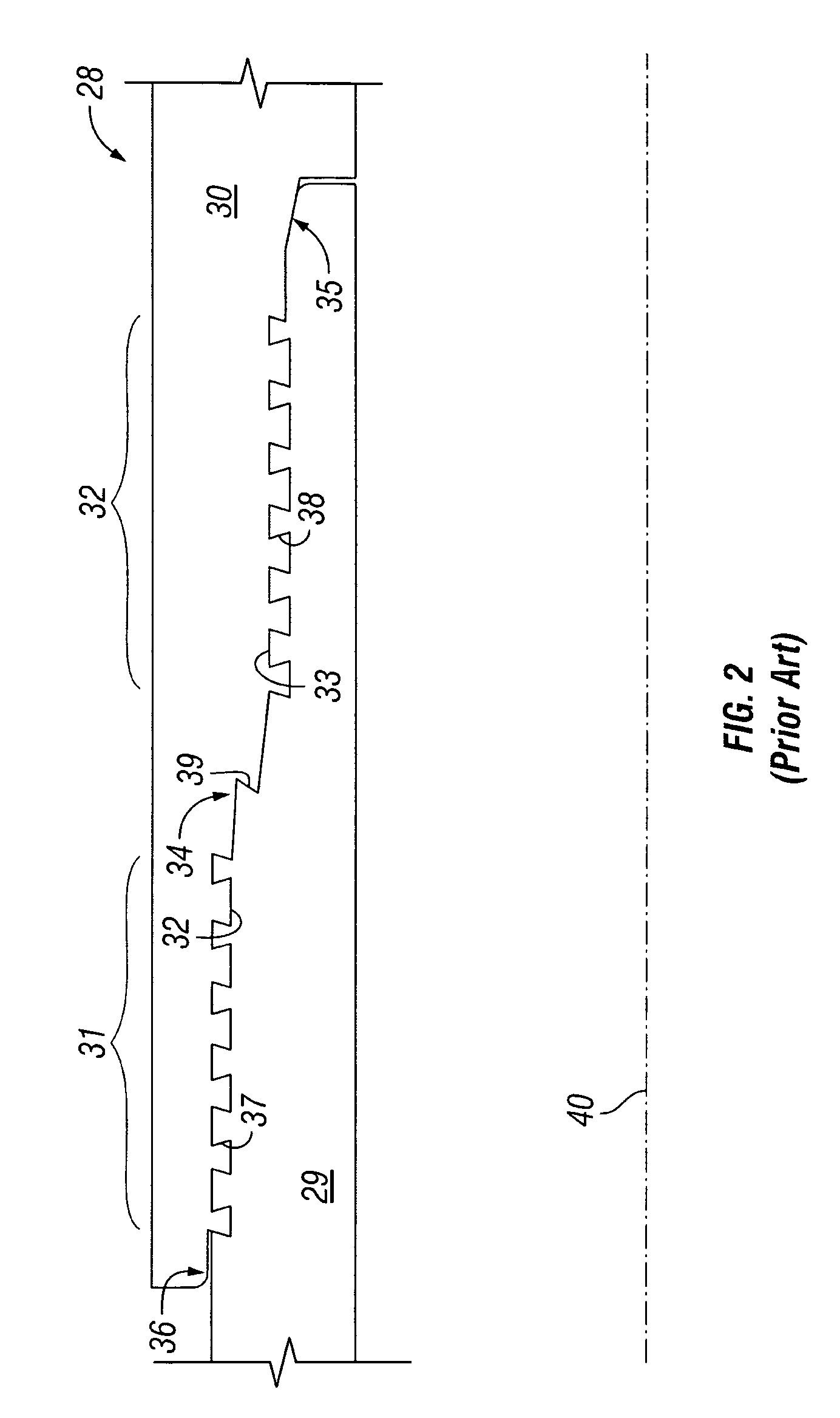

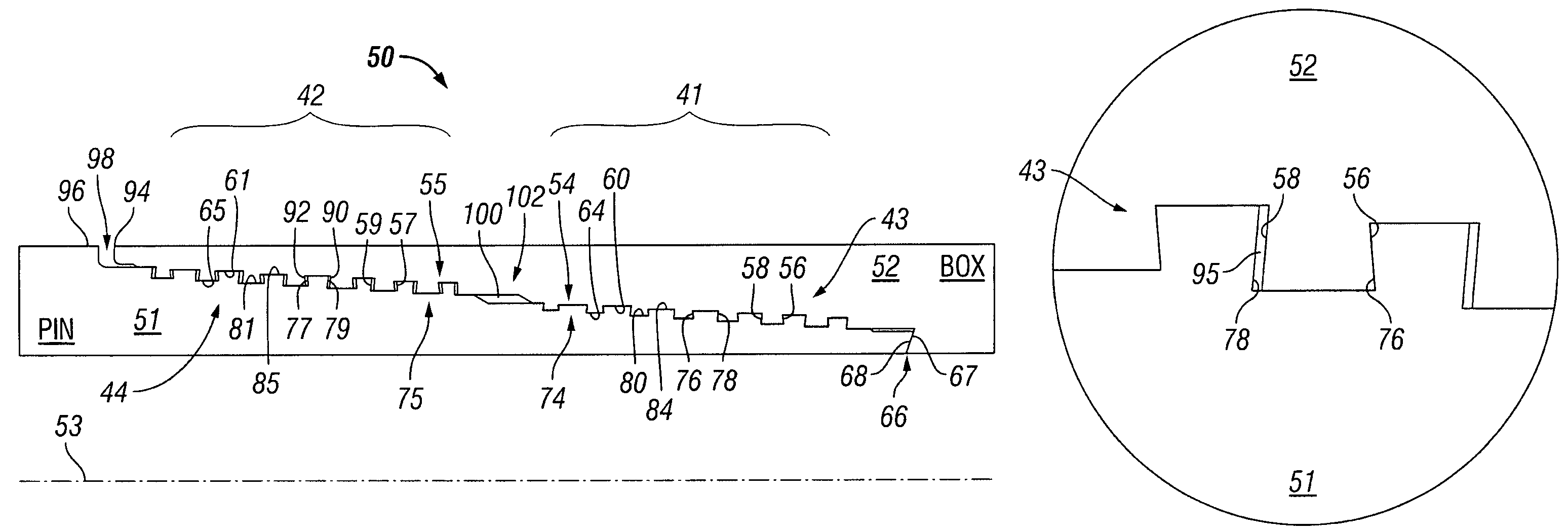

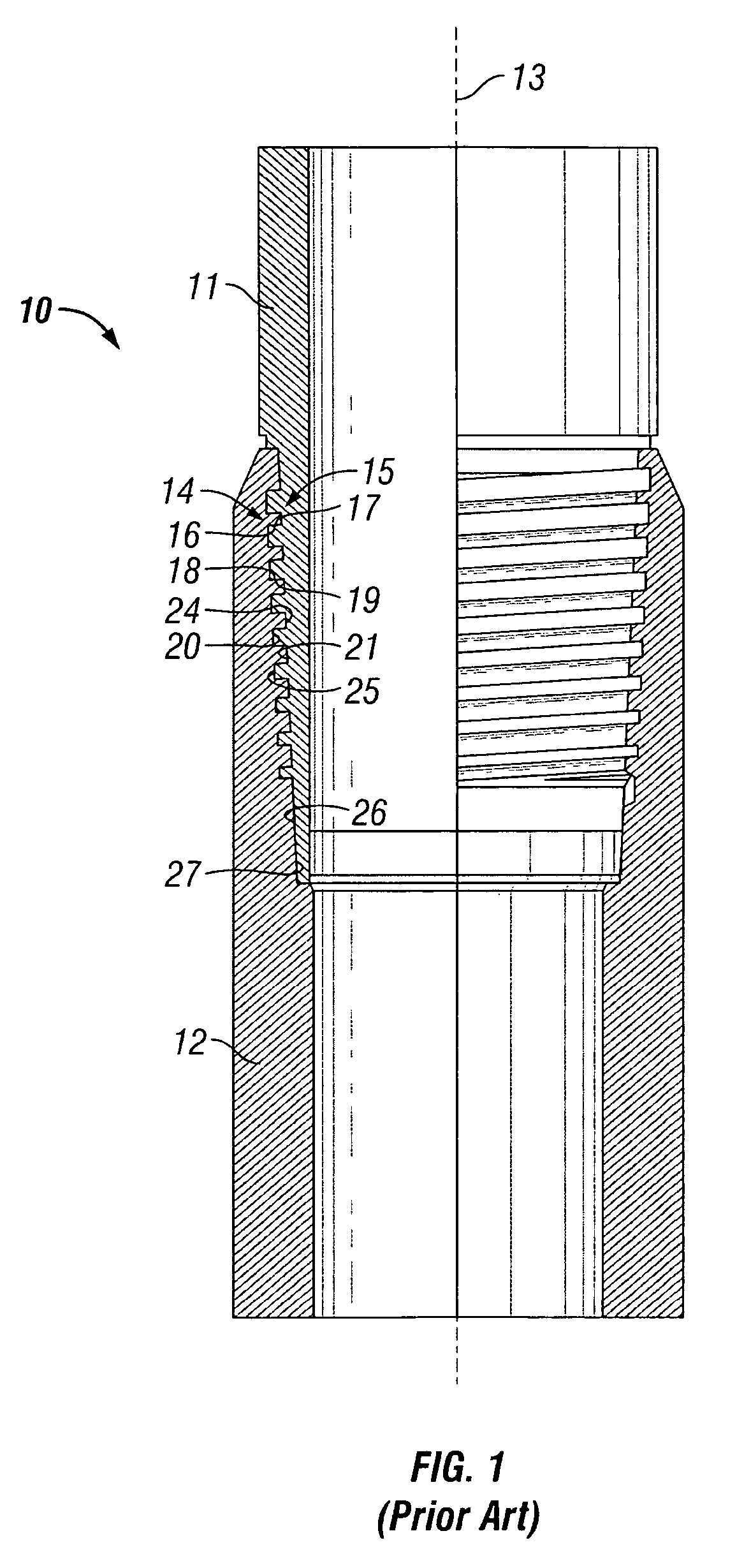

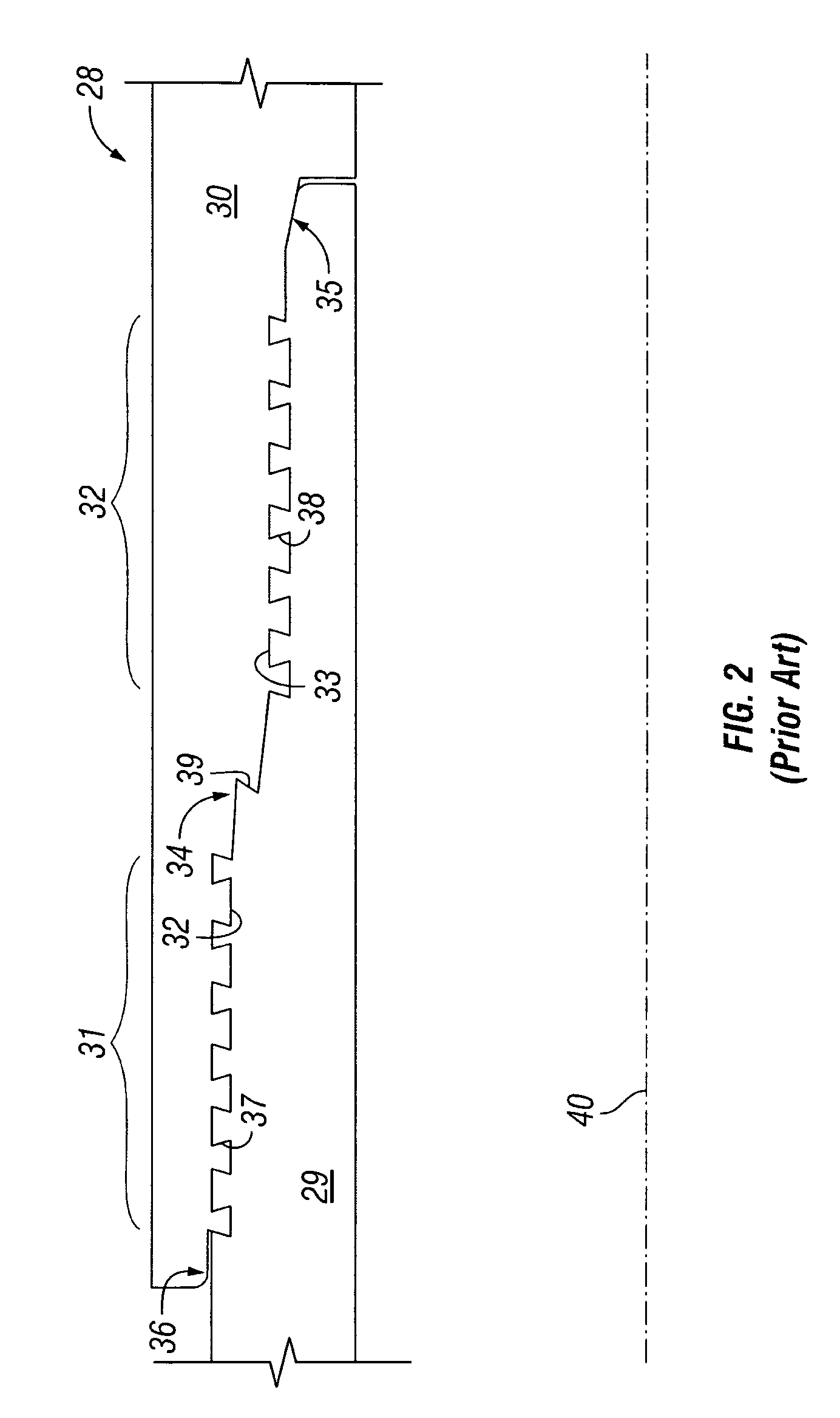

Floating wedge thread for tubular connection

ActiveUS20060145480A1Reduce the amount requiredLarge applied makeup torqueDrilling rodsHose connectionsEngineeringWedge shape

Owner:HYDRIL CO

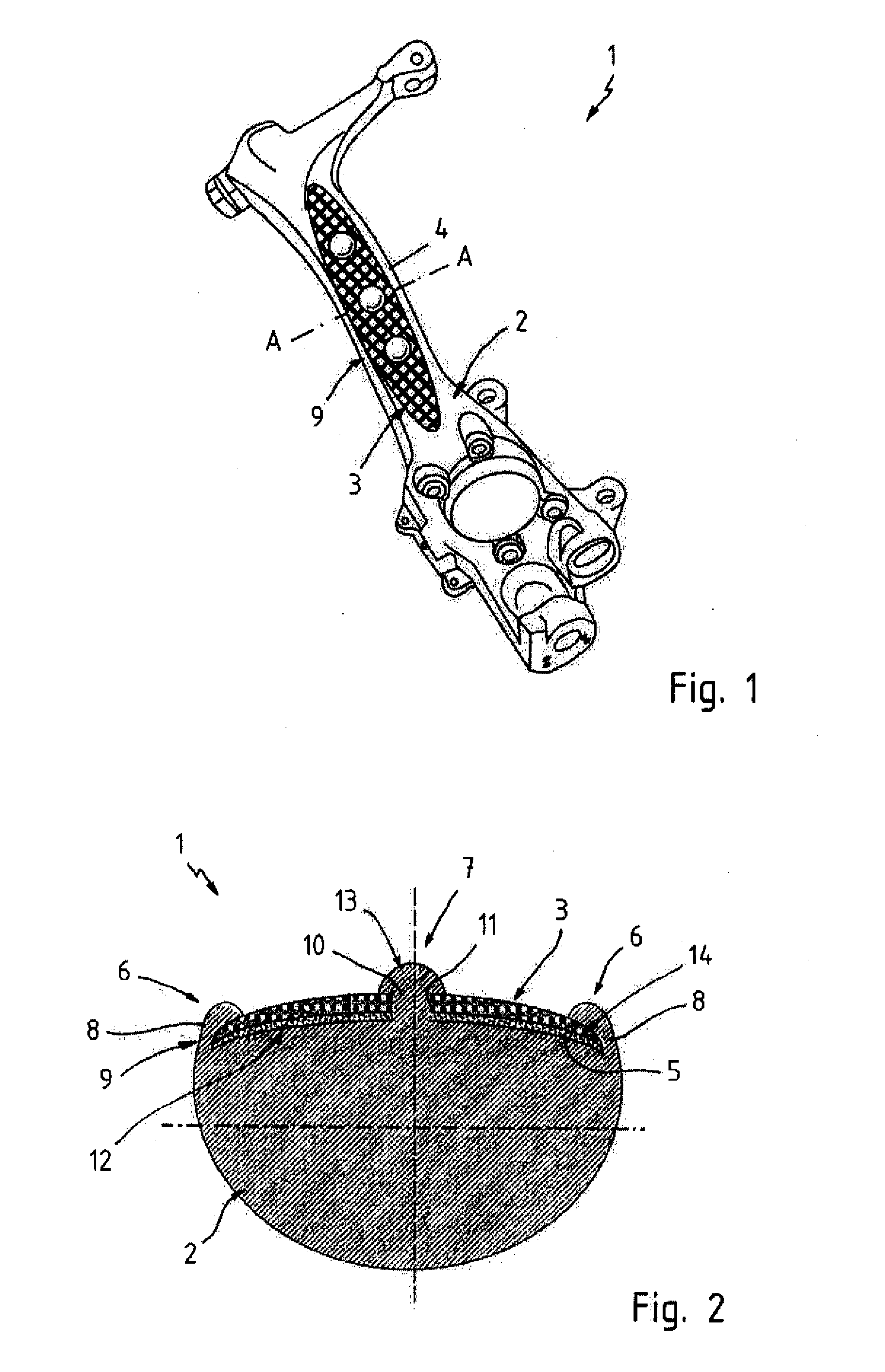

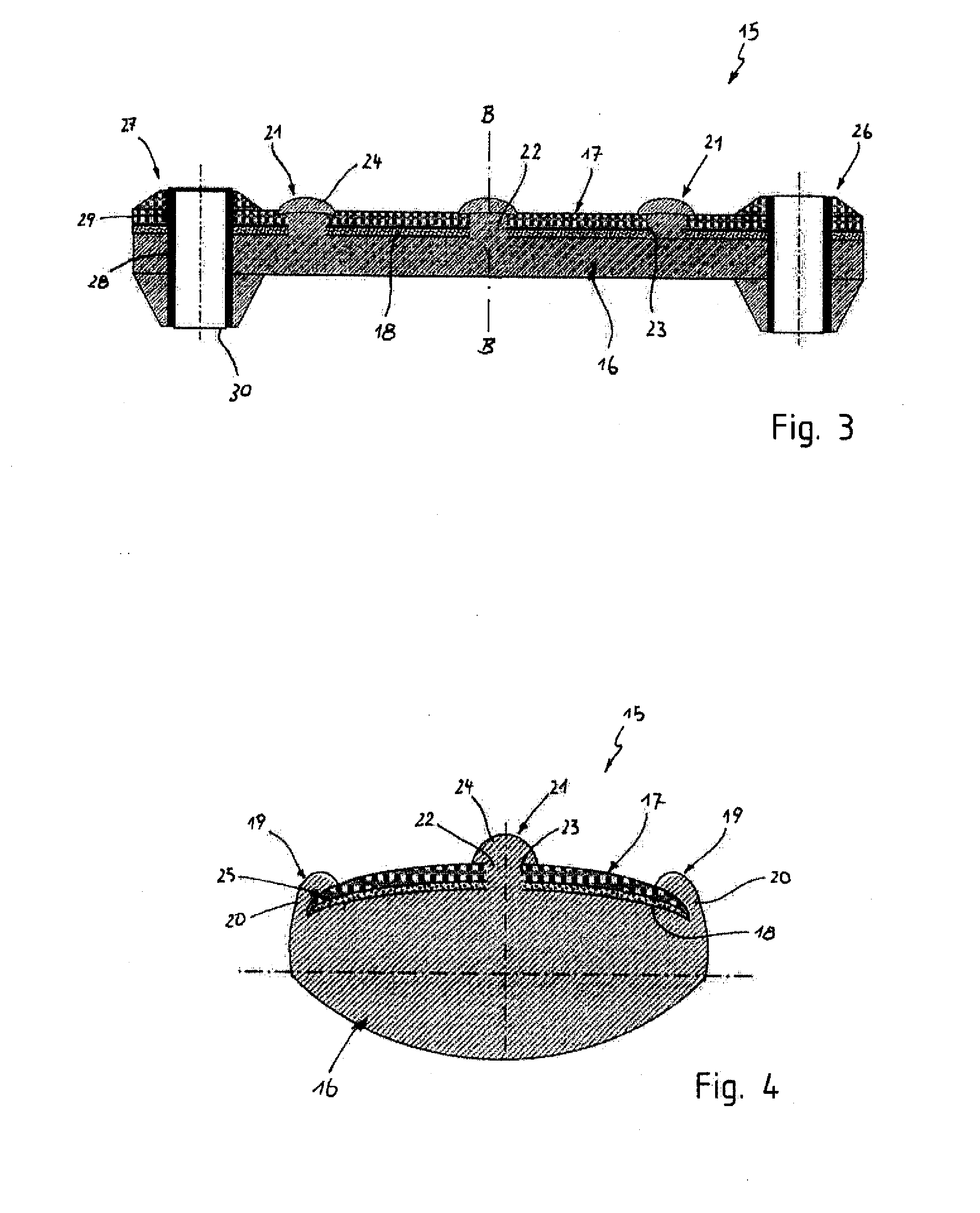

Pipe Coupling

InactiveUS20130207388A1Improve wear resistanceSufficient sealing capacitySleeve/socket jointsFlanged jointsCouplingEngineering

A pipe coupling includes a first and second connected tubular element forming an elongated tube and being connected by a connection arrangement that biases the first tubular element against the second tubular. An annular sealing element is provided between and overlapping opposed end portions of the elements. The annular sealing element has a generally T-shaped cross-section and includes a first portion that forms a stem of the T-shaped cross section and extends in a radial direction and defines the outer periphery thereof, and a second portion formed by two opposing flanges that form the cross-bar of the T-shaped cross section and define the inner periphery thereof. At least one of the flanges presents a rounded bulge forming an outer peripheral surface of one flange. The bulge is sealed with an inner periphery of one of the tubular elements and extends continuously around the circumference of the annular sealing element.

Owner:IKM GRUPPEN AS

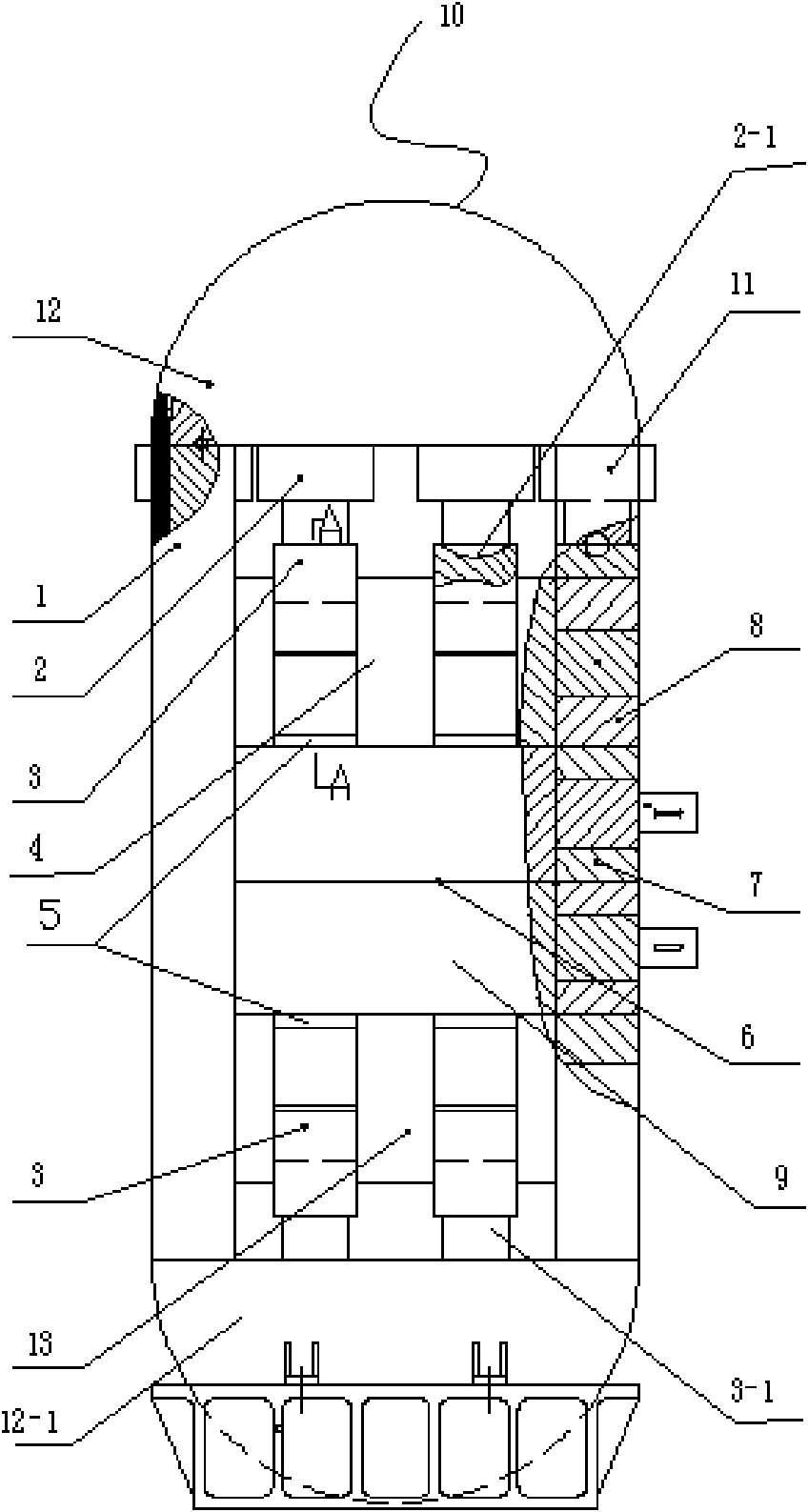

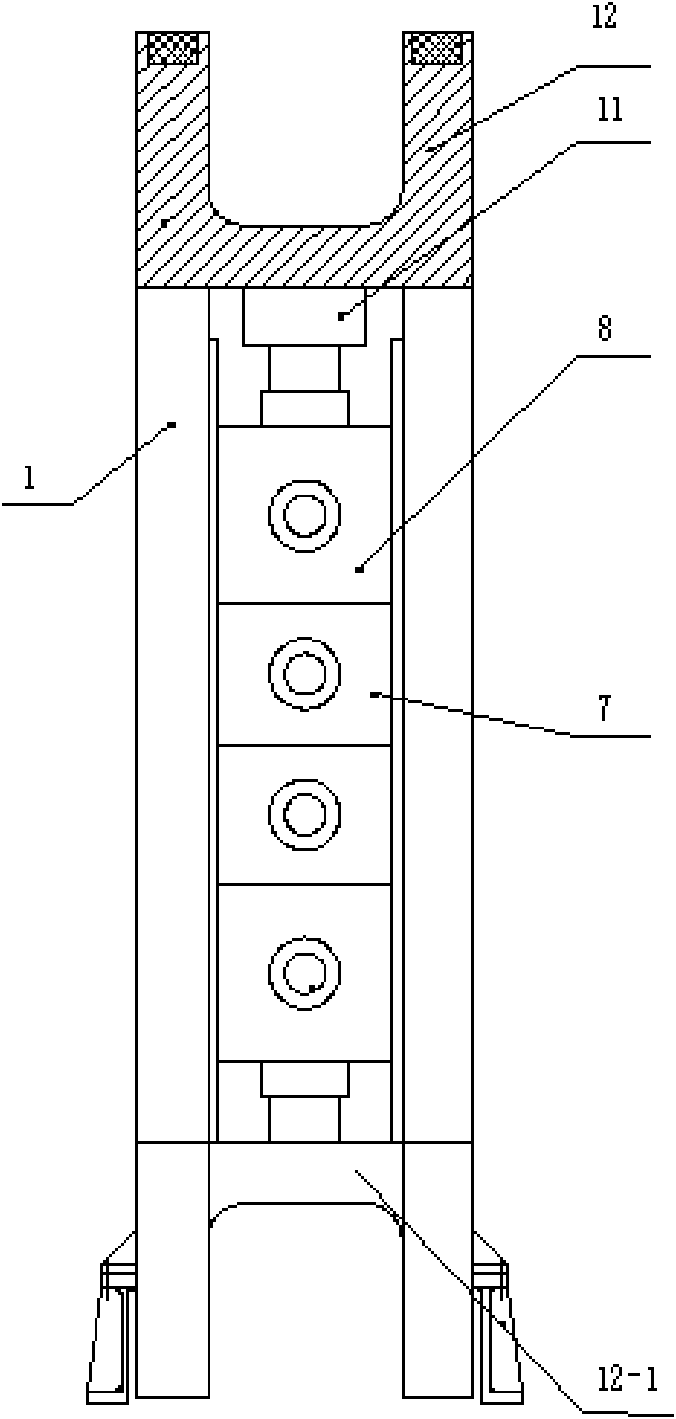

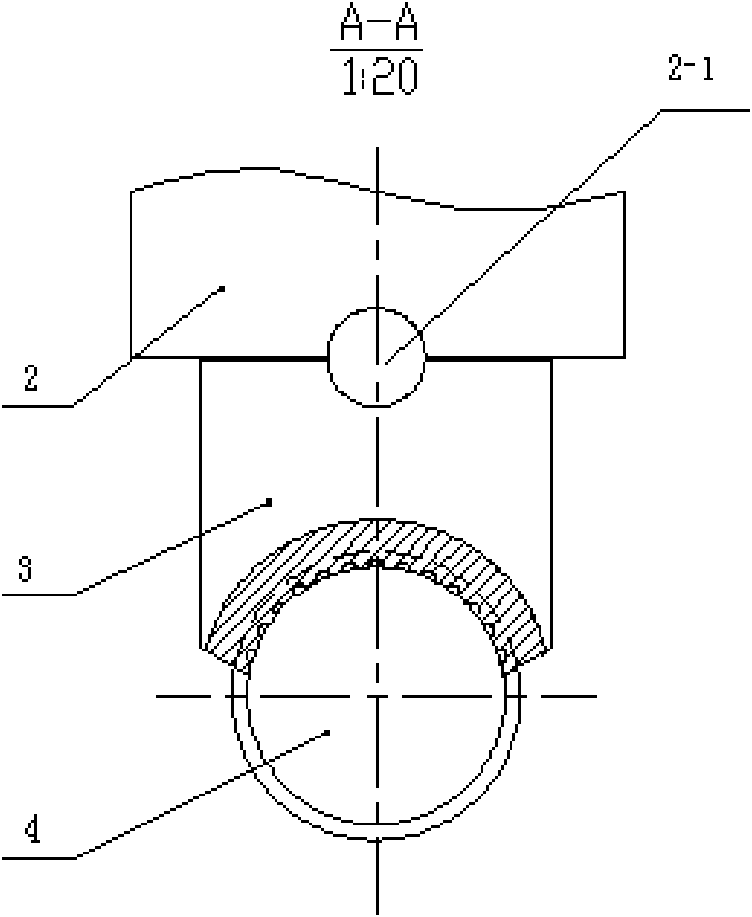

Sheet rolling mill with hydraulic screwdown on support roll

ActiveCN101658862AIncrease the amount of each pressLow costMetal rolling stand detailsCounter-pressure devicesSteel platesWork roll

The invention relates to a sheet rolling mill with a hydraulic screwdown on a support roll. The mill is characterized in that a frame is a horizontal rectangular columnar frame, both sides of an upperbeam of the frame is provided with a journal hydraulic screwdown of an upper support roll, a bearing pedestal and two rectangular columns of a working roll and the support roll form two horizontal frames of the mill, hydraulic screwdown of one or two support rolls which are fixed in the middle of the upper beam of the horizontal frame press a cylindrical surface of the support roll body by a hydrostatic semicircular block, a hydrostatic semicircular block with a bearing is supported in the position of a lower support roll which is the same as that of the upper support roll, the bearing is fixed on a lower beam of the frame. The mill has the following advantages: the position and pressure of the hydraulic screwdown of the journal and the roll body are regulated by a sensor to greatly reduce elastic deformation of the support roll during working, and can realzie rolling of the accurate-sized steel plate and increase percent reduction under the condiiton of reducing number and diameter of the supprt rolls and diameter, thus reducing cost and enhancing efficiency.

Owner:朱勉学

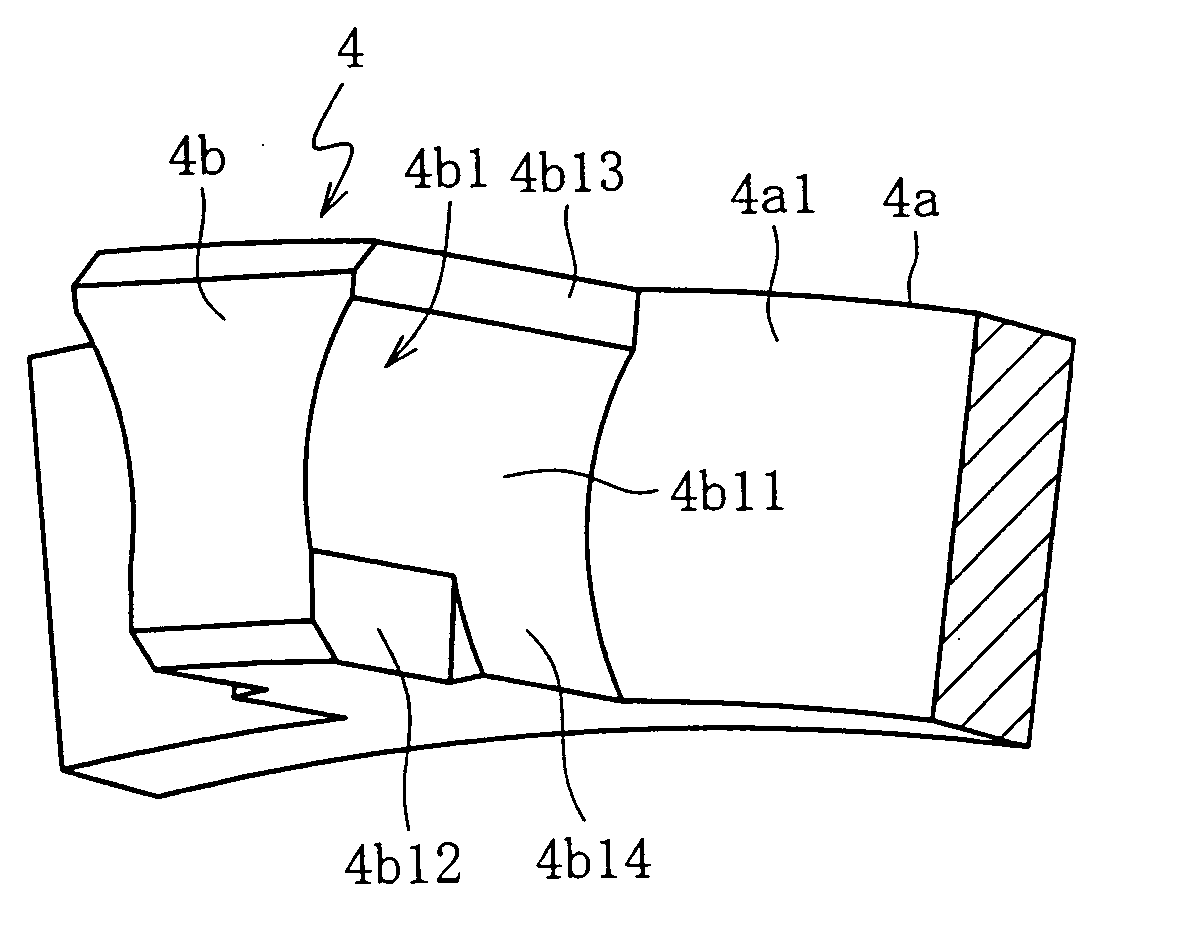

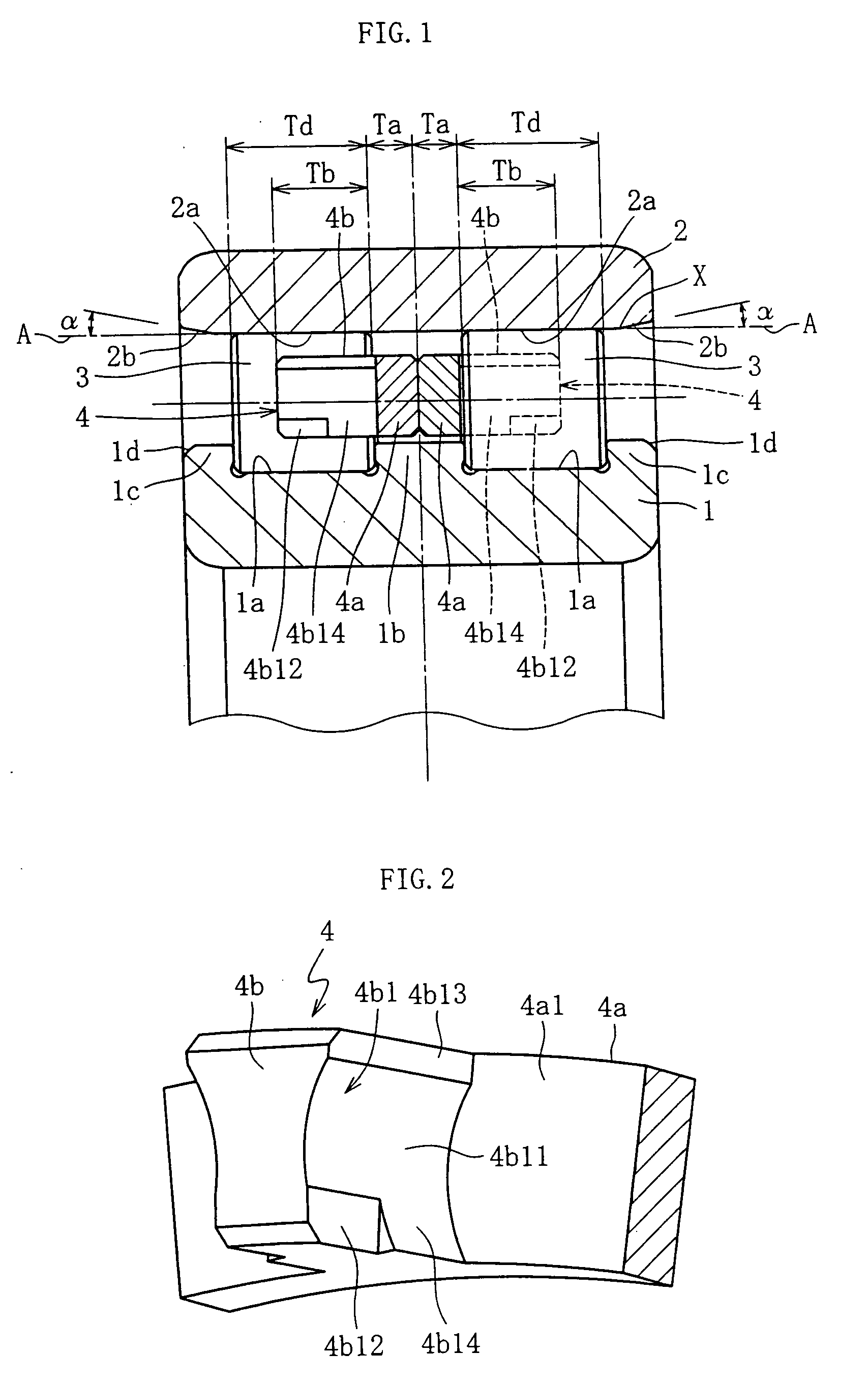

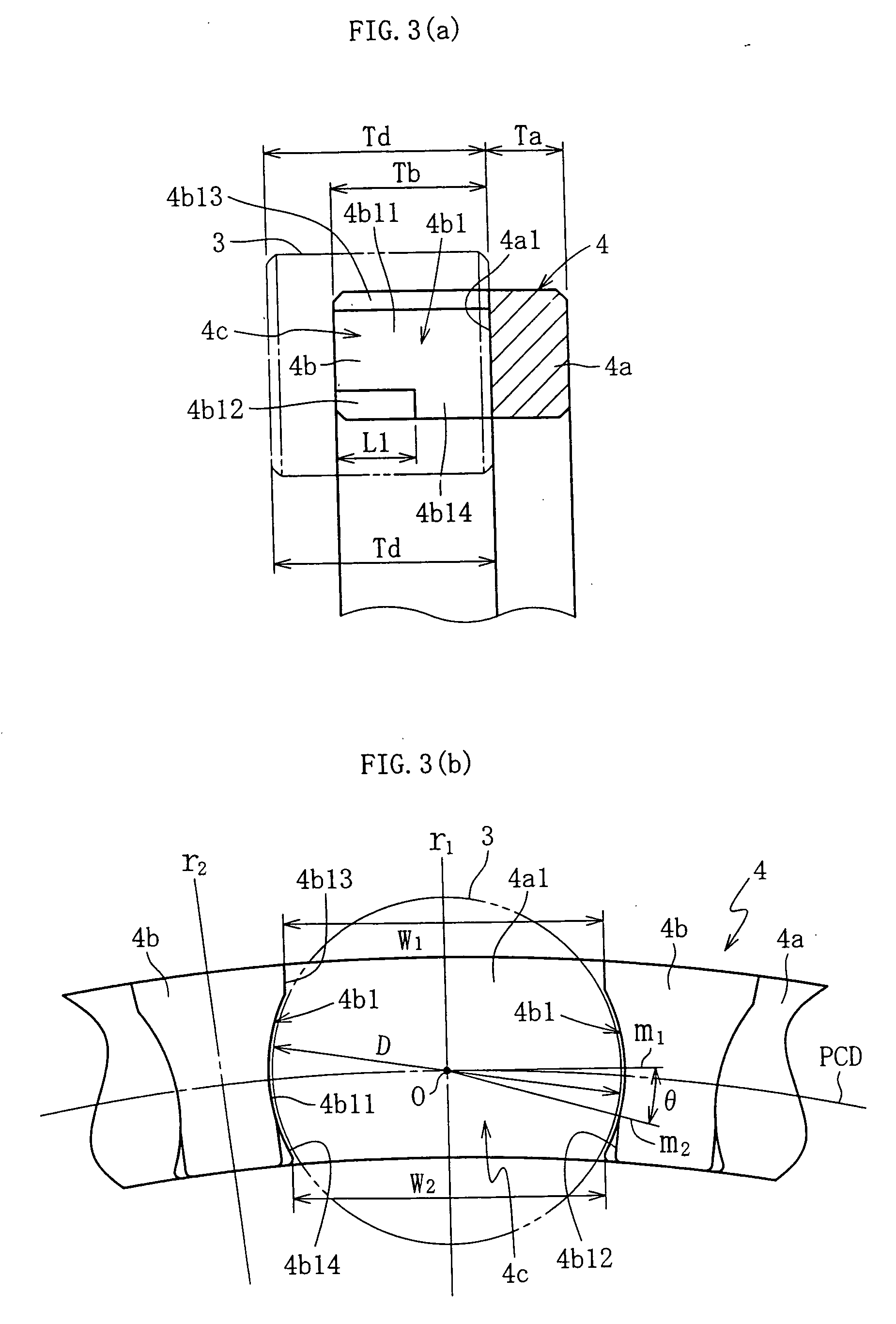

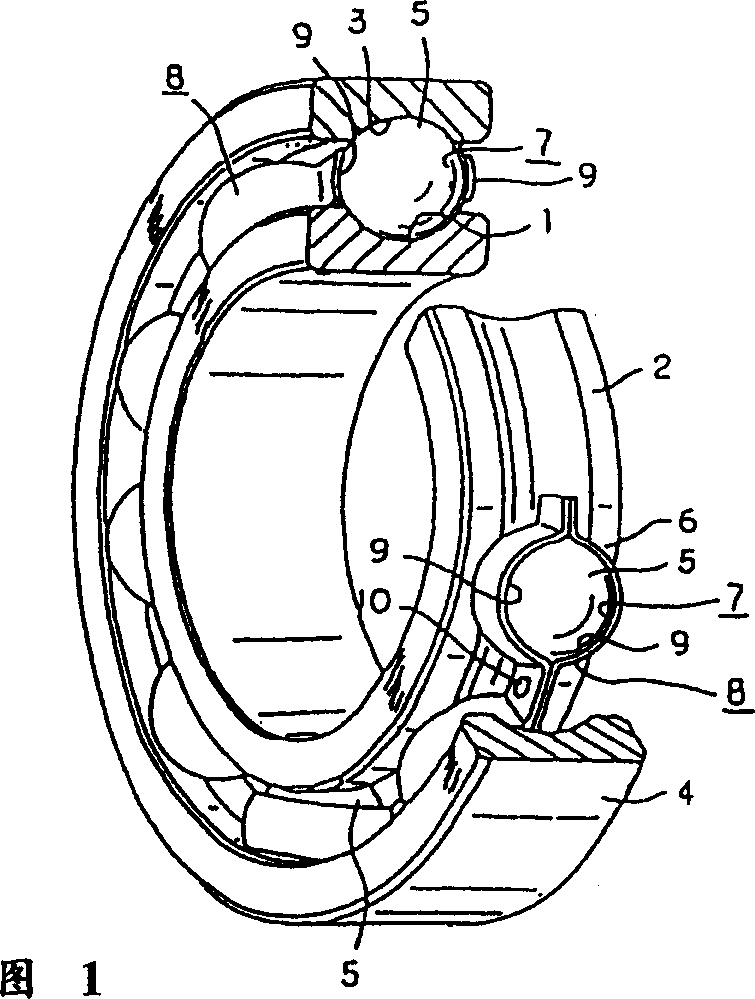

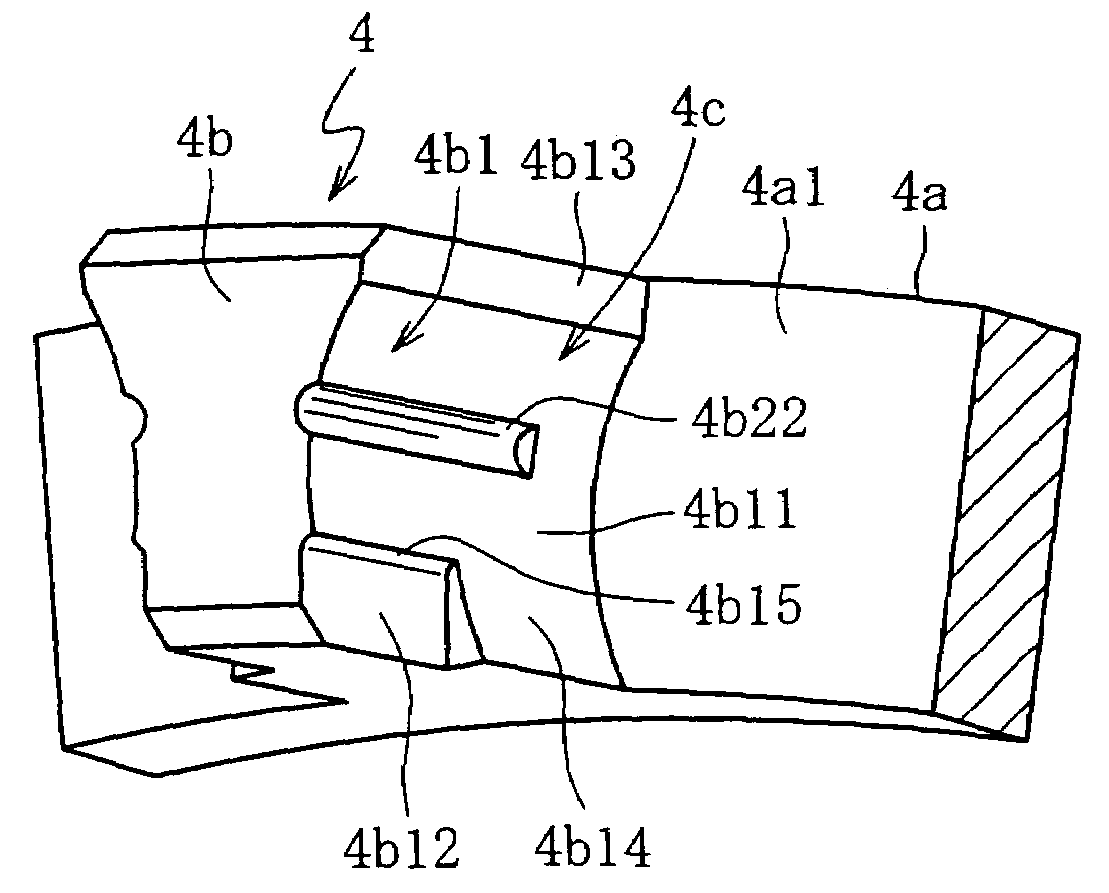

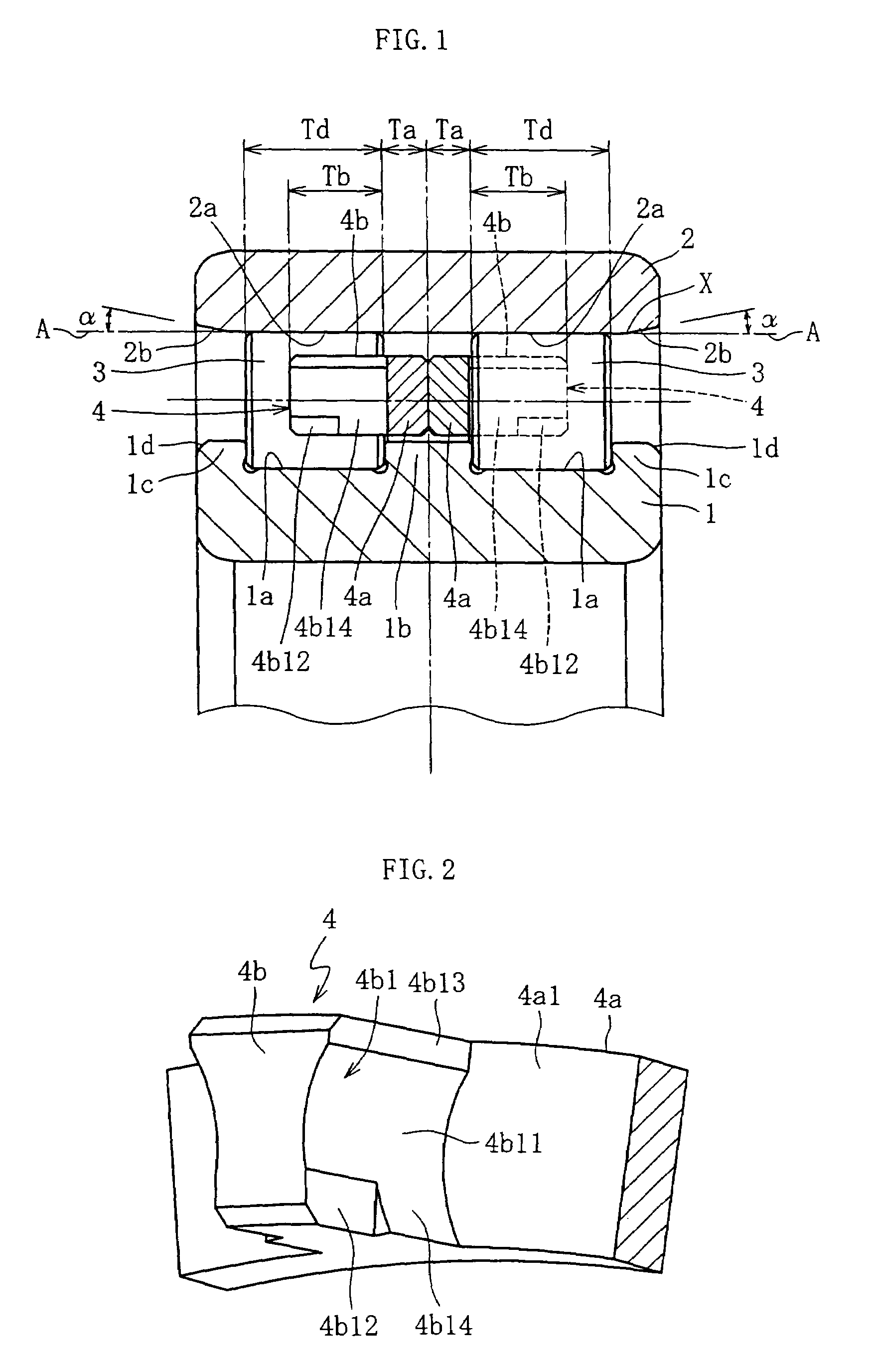

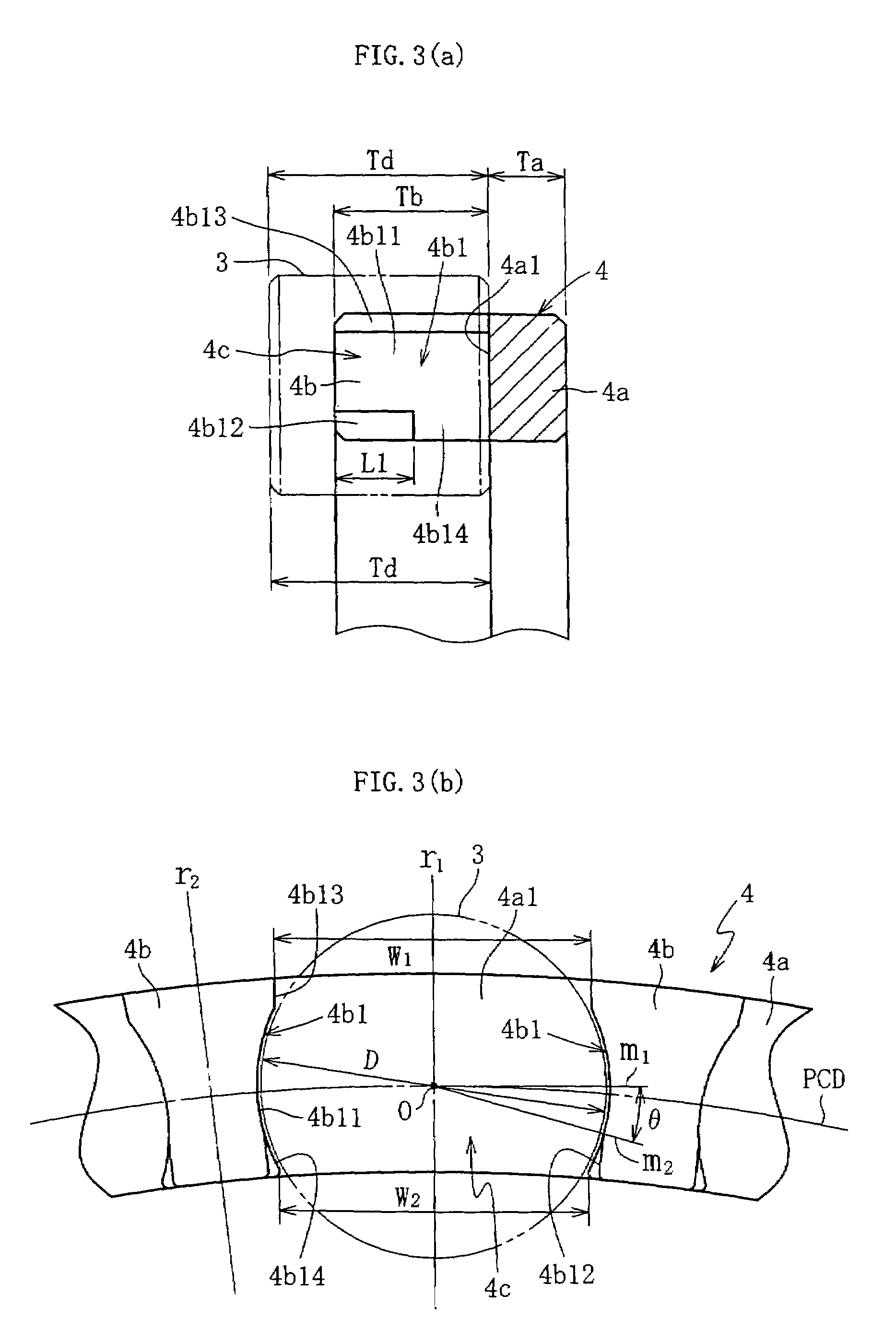

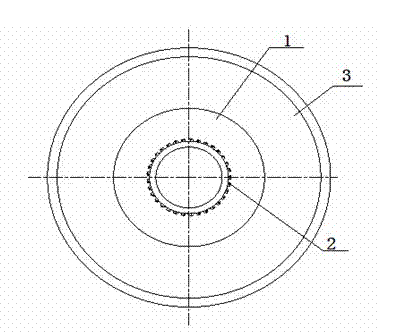

Cylindrical roller bearing

ActiveUS20050069239A1Reduce bearing temperatureAvoid abnormal wearRoller bearingsBearing componentsFree rotationEngineering

A cage of a cylindrical roller bearing includes an annular section, a plurality of pillars that extend axially in an integrated, continuous manner from the inside surface of the annular section, and a plurality of pockets, which are formed between the inner circumferential direction side faces of adjacent pillars, and hold the cylindrical rollers in a freely rotatable manner. The circumferential direction side faces of the pillars incorporate a circular arc surface formed in both the inside and outside diameter directions from the pocket PCD which passes through the pocket center of the pocket, and a roll-off section (lubricant reservoir) provided at the tip end inner circumferential section.

Owner:NTN CORP

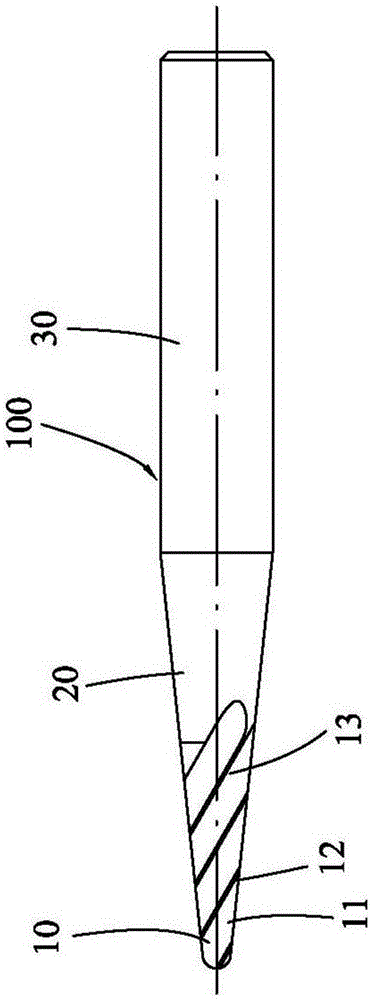

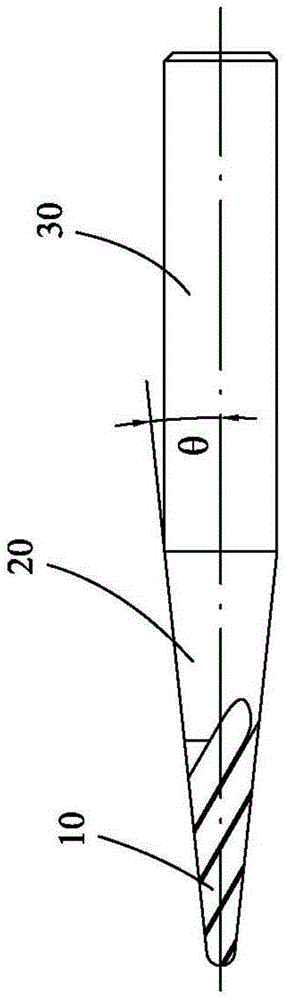

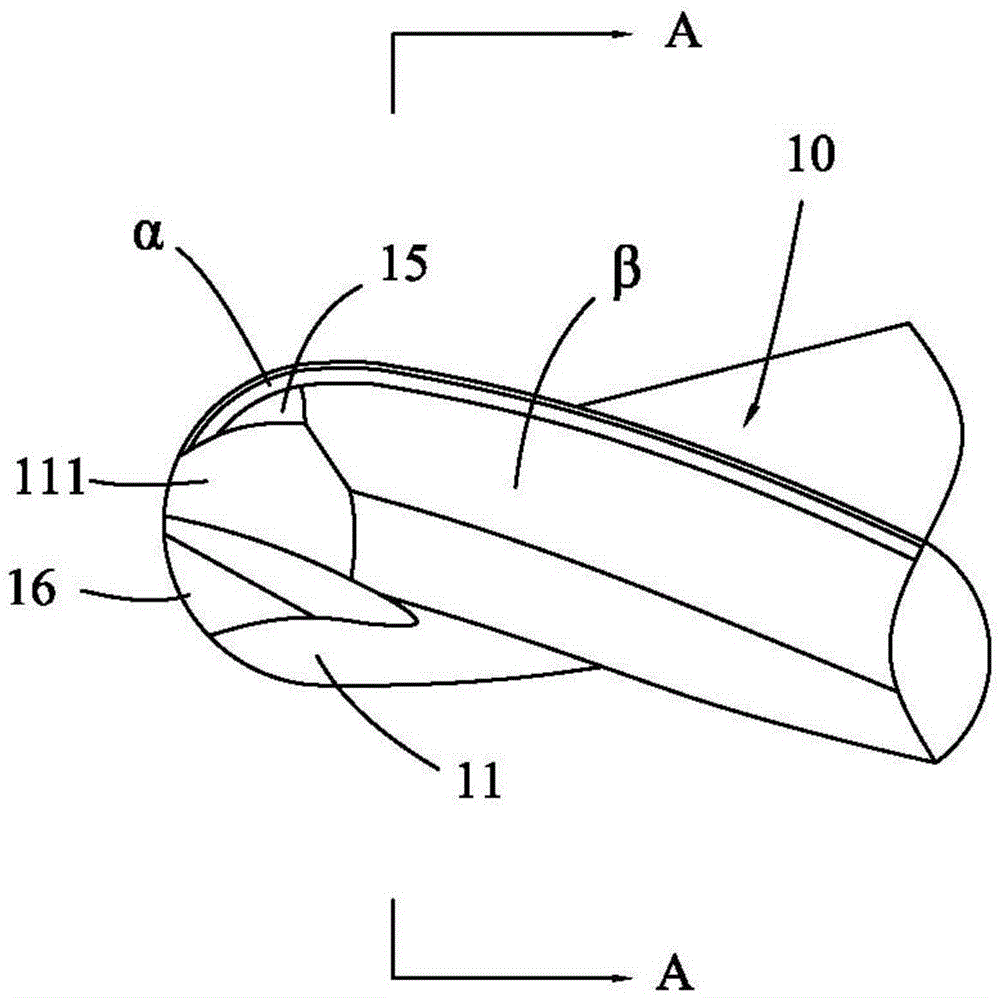

Taper and ball-end milling cutter

InactiveCN105642986AIncrease sharpnessGuaranteed StrengthMilling cuttersMilling cutting insertsMilling cutterNeck parts

The invention provides a taper and ball-end milling cutter. The milling cutter comprises a head part, a neck part connected with the head part, and a handle part connected with the neck part, wherein the head part is provided with a chip removal slot, an entity part used for forming the chip removal slot, and a cutting edge formed at an intersection line between the chip removal slot and the entity part, wherein the cutting edge is provided with a front cutter face and a rear cutter face, the front cutter surface and the rear cutter surface are contacted and form a front angle, and the rear cutter face of the cutting edge and a machining piece are contacted and form two rear angles, including the first rear angle and the second rear angle respectively. According to the taper and ball-end cutter provided by the invention, the front angle and the rear angles are reasonably designed, so that the rigidity of the milling cutter is guaranteed, the sharp degree of the milling cutter is guaranteed at the same time, and the probability of burr generation in a milling process is effectively reduced; the taper and ball-end milling cutter has a long service life and can keep good surface roughness when machining an aluminum alloy pressure wheel.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

Floating wedge thread for tubular connection

ActiveUS7527304B2Reduce the amount requiredLarge applied makeup torqueDrilling rodsHose connectionsEngineeringWedge shape

Owner:HYDRIL CO

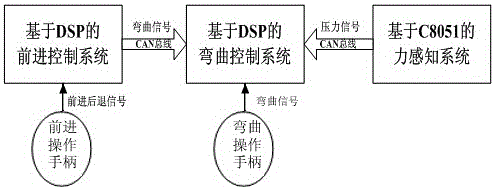

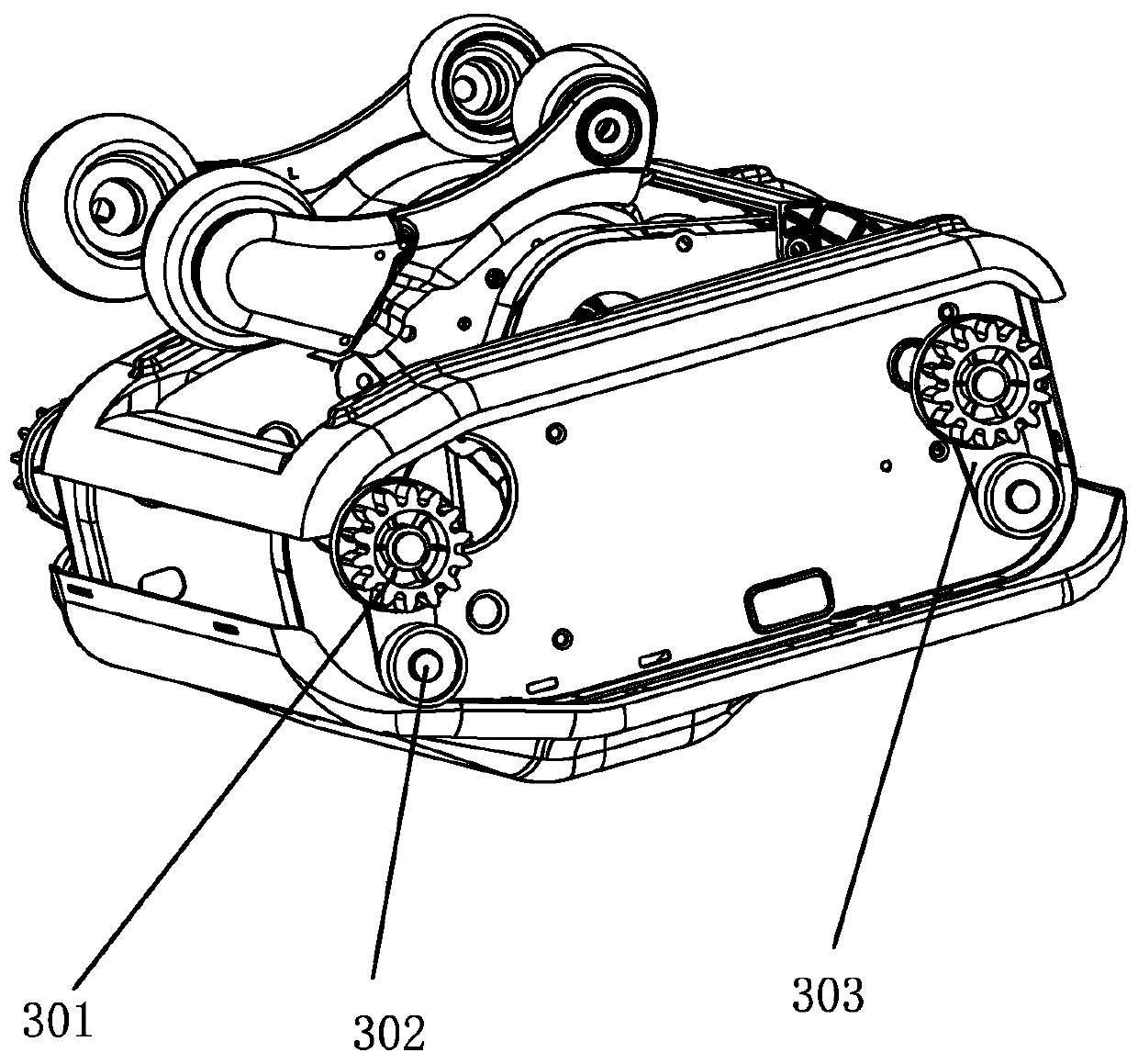

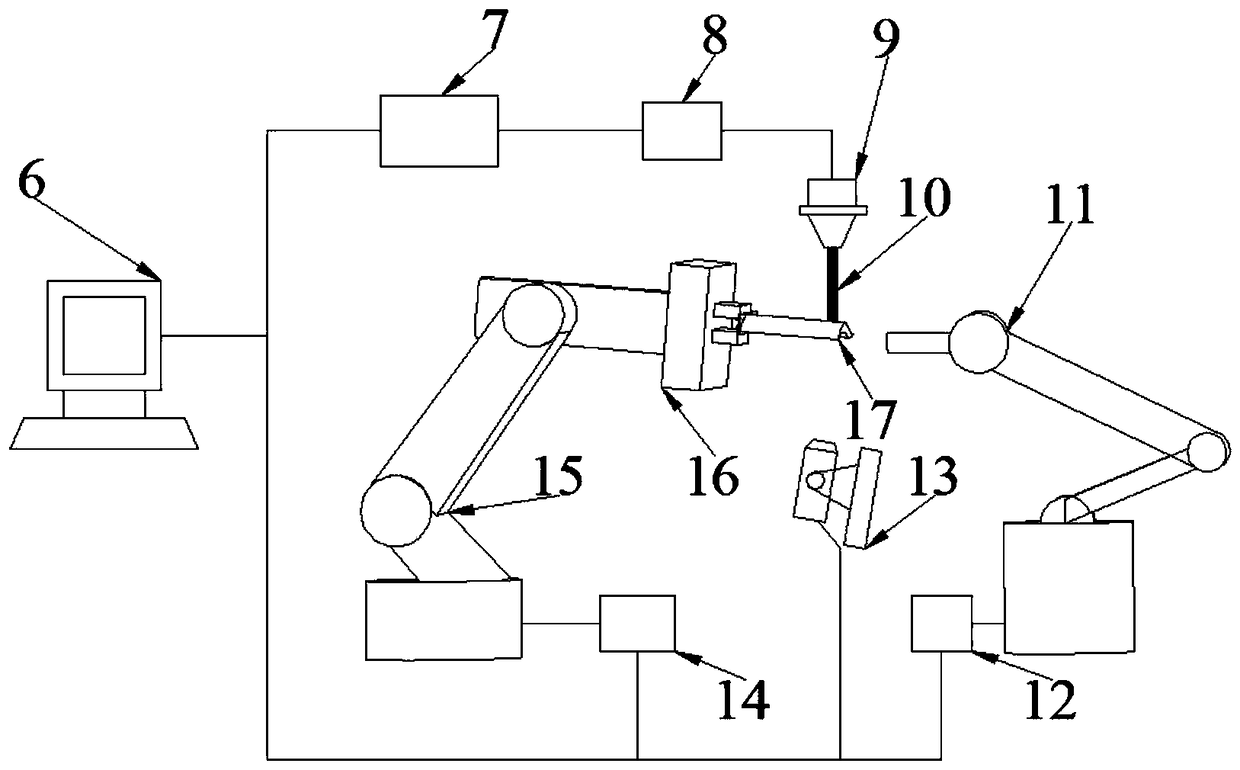

Endoscope robot control method and device based on pressure sensor information

ActiveCN105796043AControl contact forceSmall elastic deformationSurgeryEndoscopesControl systemSimulation

The invention discloses an endoscope robot control method and device based on pressure sensor information. An operator actively controls a robot to bend in the intestine according to intestinal interior information fed back by a camera at the front end of an S-shaped body of the colonoscope robot; a robot control system collects contact force information of the robot and the intestine in real time by means of a pressure sensor of the bent body part, and the relation between the robot motion distance r and contact force F is obtained by analyzing the colon tissue biomechanical characteristics, so that the joint posture of the robot is adjusted to ensure that the contact force is within the safety threshold value range; the control system corrects the whole posture of all joints of the robot by means of the motion coupling relation of all the joints, the contact force coming from all the joints of the robot can be effectively detected, and when the robot touches the intestine, the colonoscope robot control system can control the robot gently to enable the contact force between the robot and the intestine to be within the safety threshold value range, so that safety of the intestine of the human body during examination is ensured.

Owner:SUZHOU UNIV

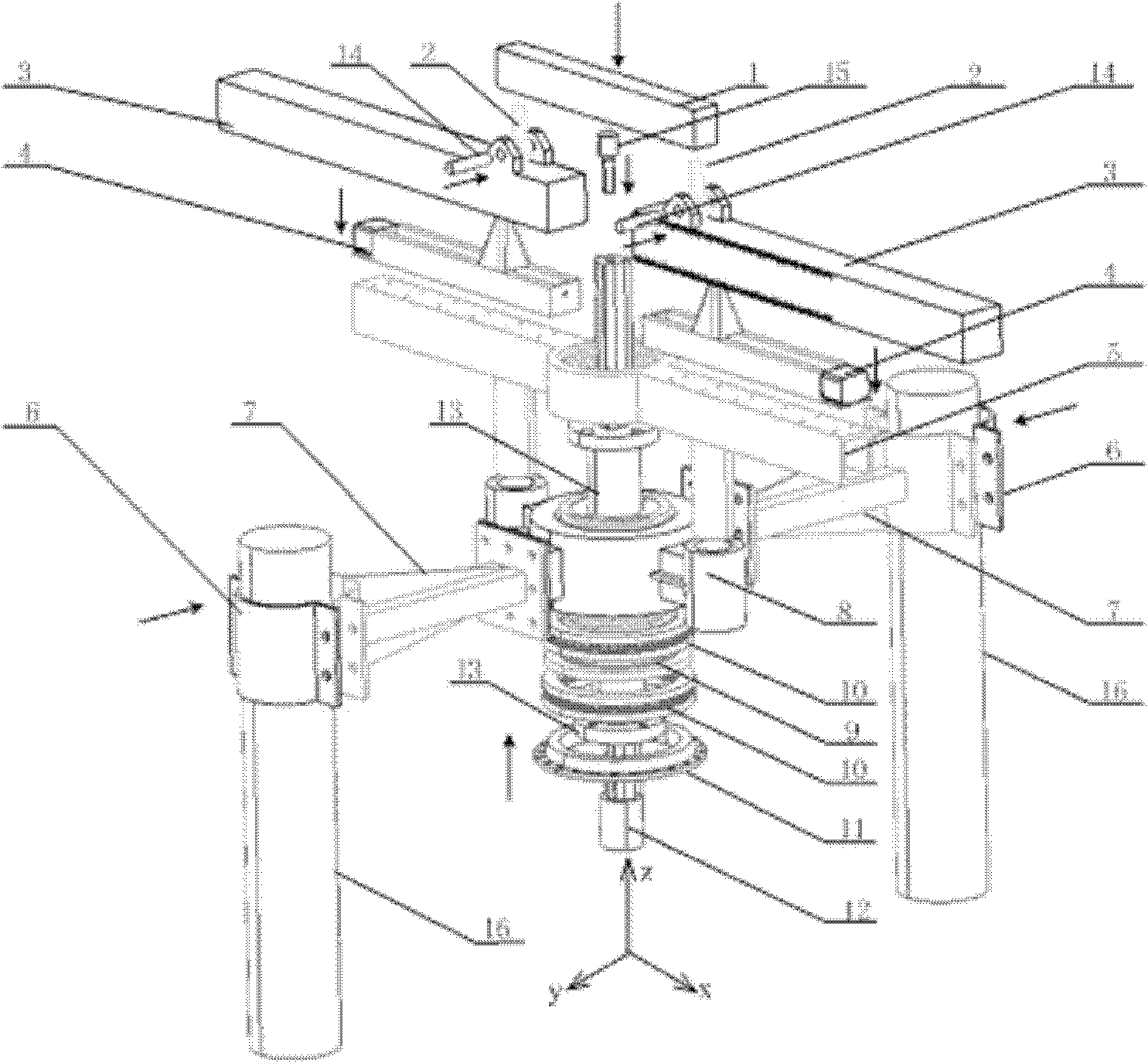

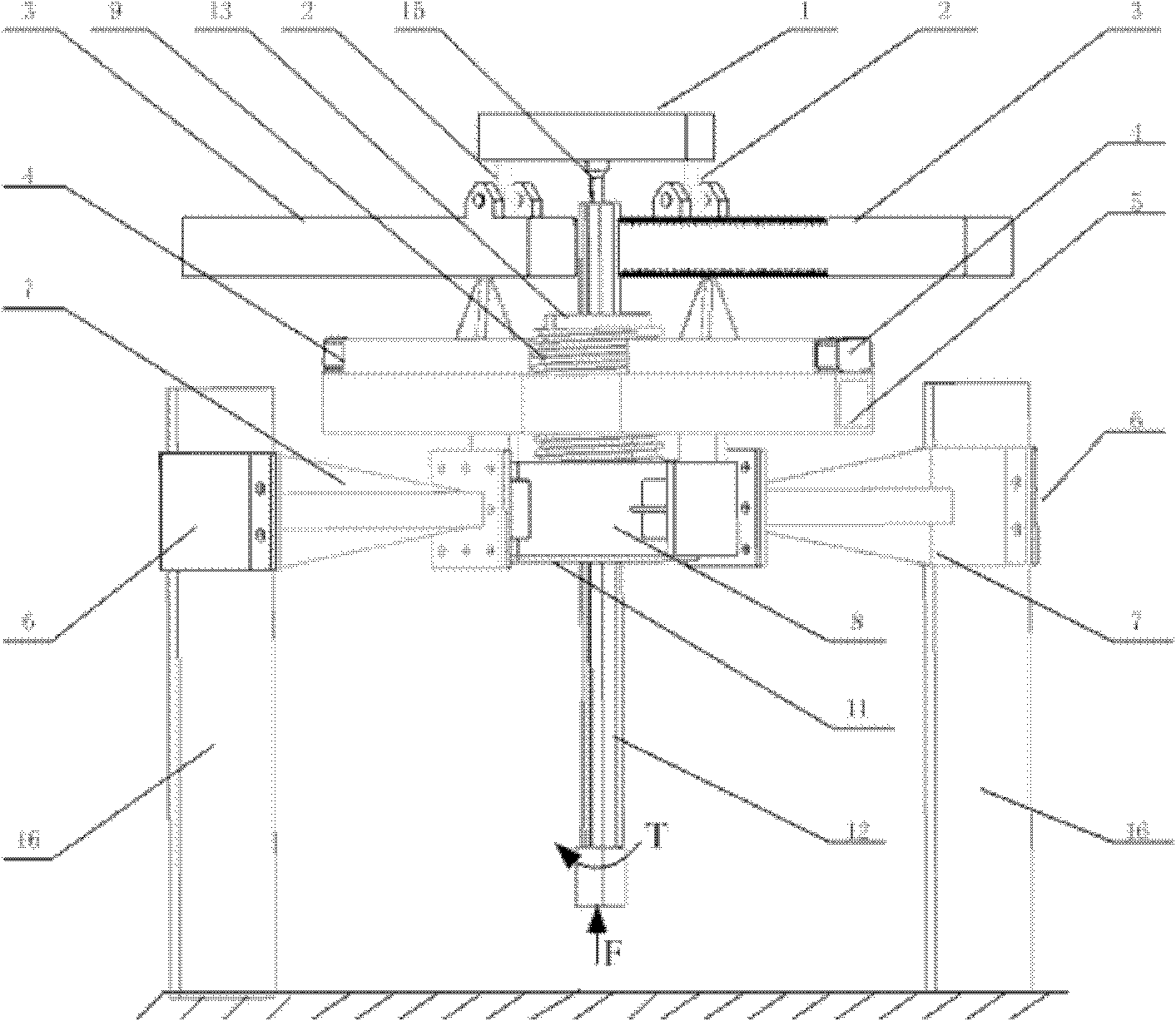

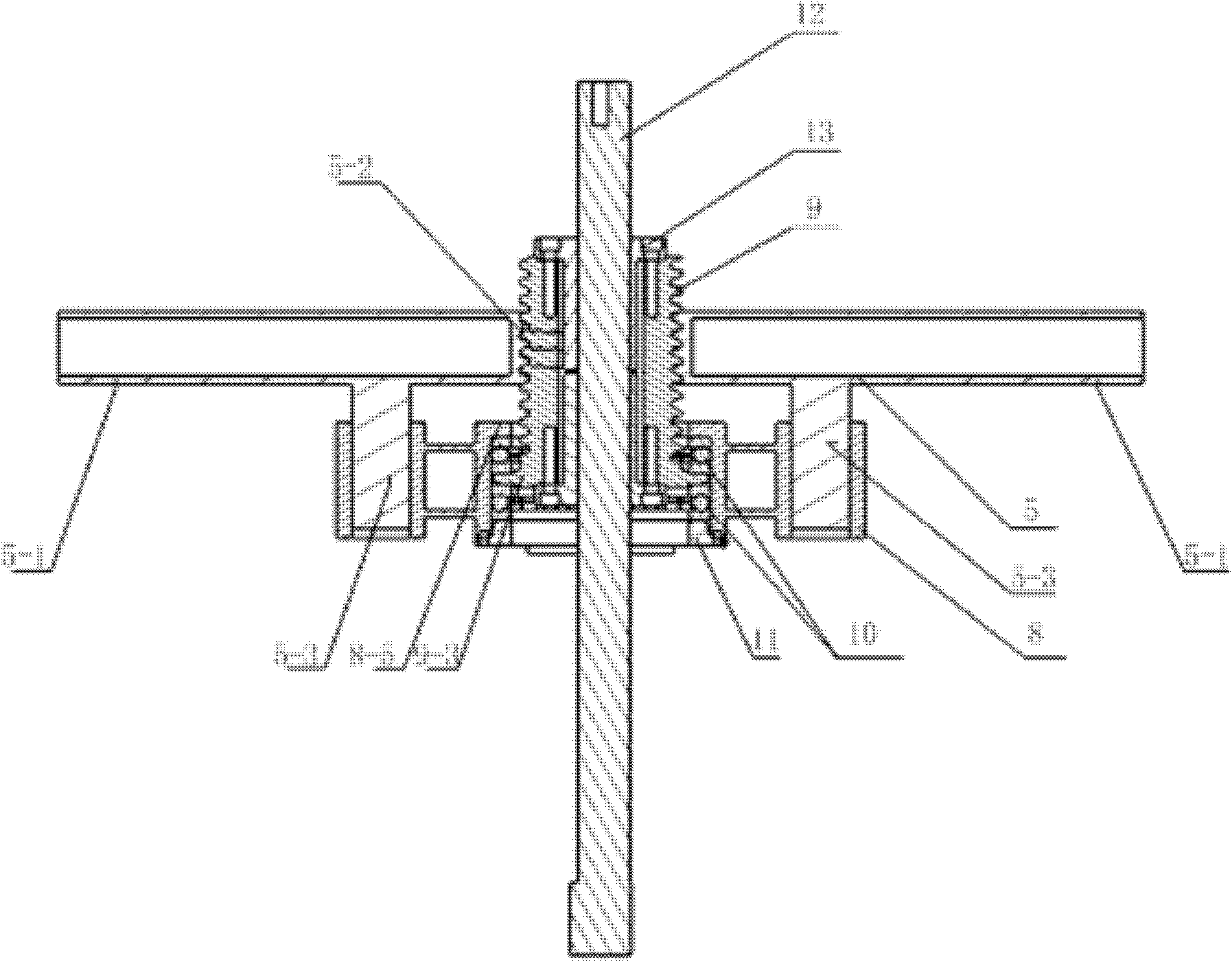

Impact loading mechanism

InactiveCN102156081AImprove applicabilityGuaranteed continuous gradientMaterial strength using repeated/pulsating forcesBall bearingThrust bearing

The invention relates to an impact loading mechanism comprising two sets of bracket arms, two bracket arm splints, an installation barrel, a seal cover, two sets of thrust force bearings, two sets of movable loading cones, a threaded sleeve, a spline shaft, two flange splines, two loading arms, two rod end joint ball bearings, two support columns, two impact loading rods and a joint ball bearing.The impact loading mechanism can convert the torque of the load input end of the spline shaft into the thrust force of the movable loading cones and apply the thrust force of the movable loading cones to the impact loading rods, and the impact loading mechanism can directly apply the thrust force or pull force of the load input end of the spline shaft to the impact loading rods through the first loading arm. Because mobile blocks on the movable loading cones can be movable or static, the distance between two loading points on a single impact loading rod can change along with time or keep unchanged. Thus, the dynamic synchronous multi-point movement simulation impact loading of the impact loading rods can be realized, and random dynamic or static shearing force and torque can be obtained at the roots of the impact loading rods.

Owner:BEIHANG UNIV

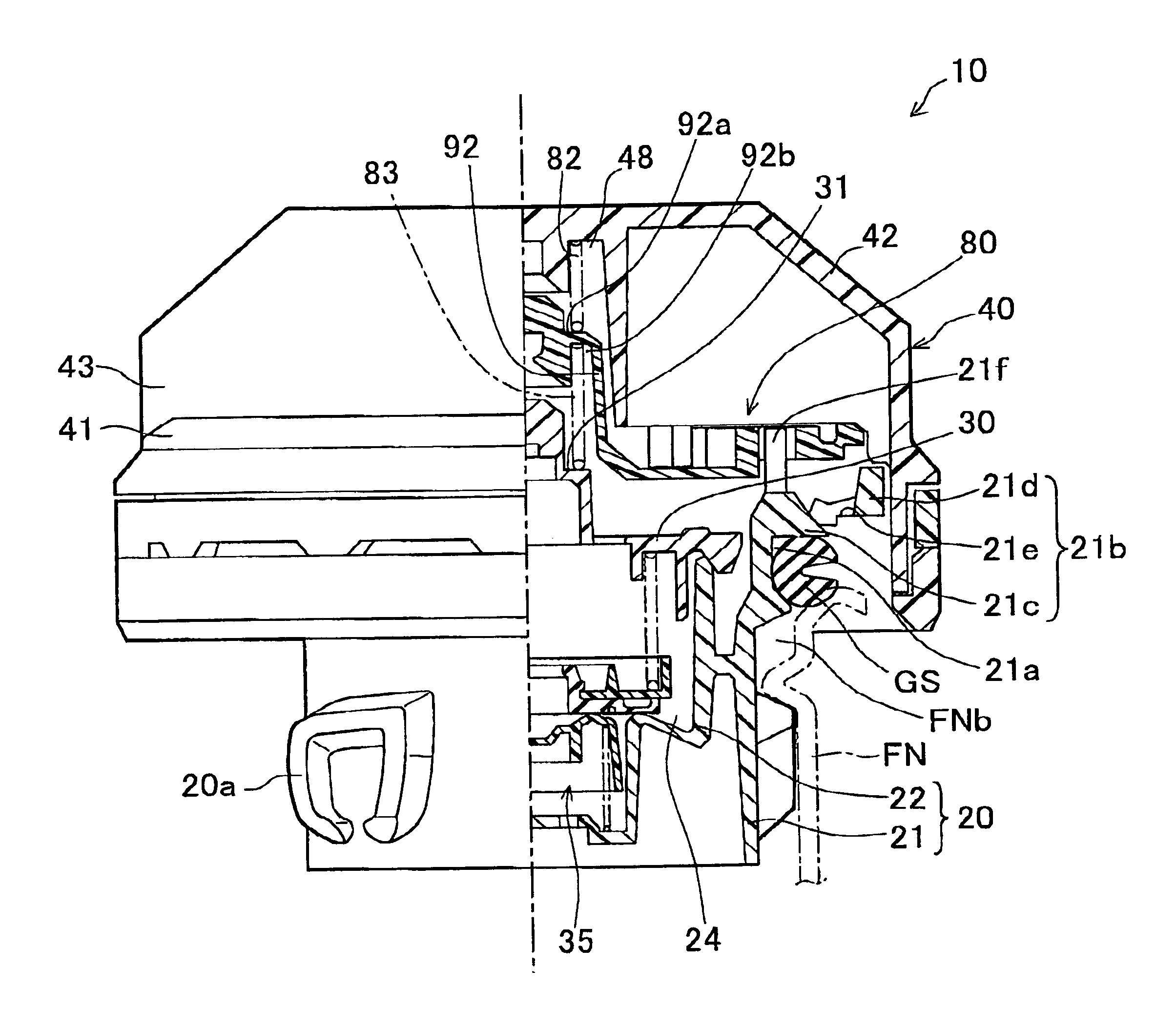

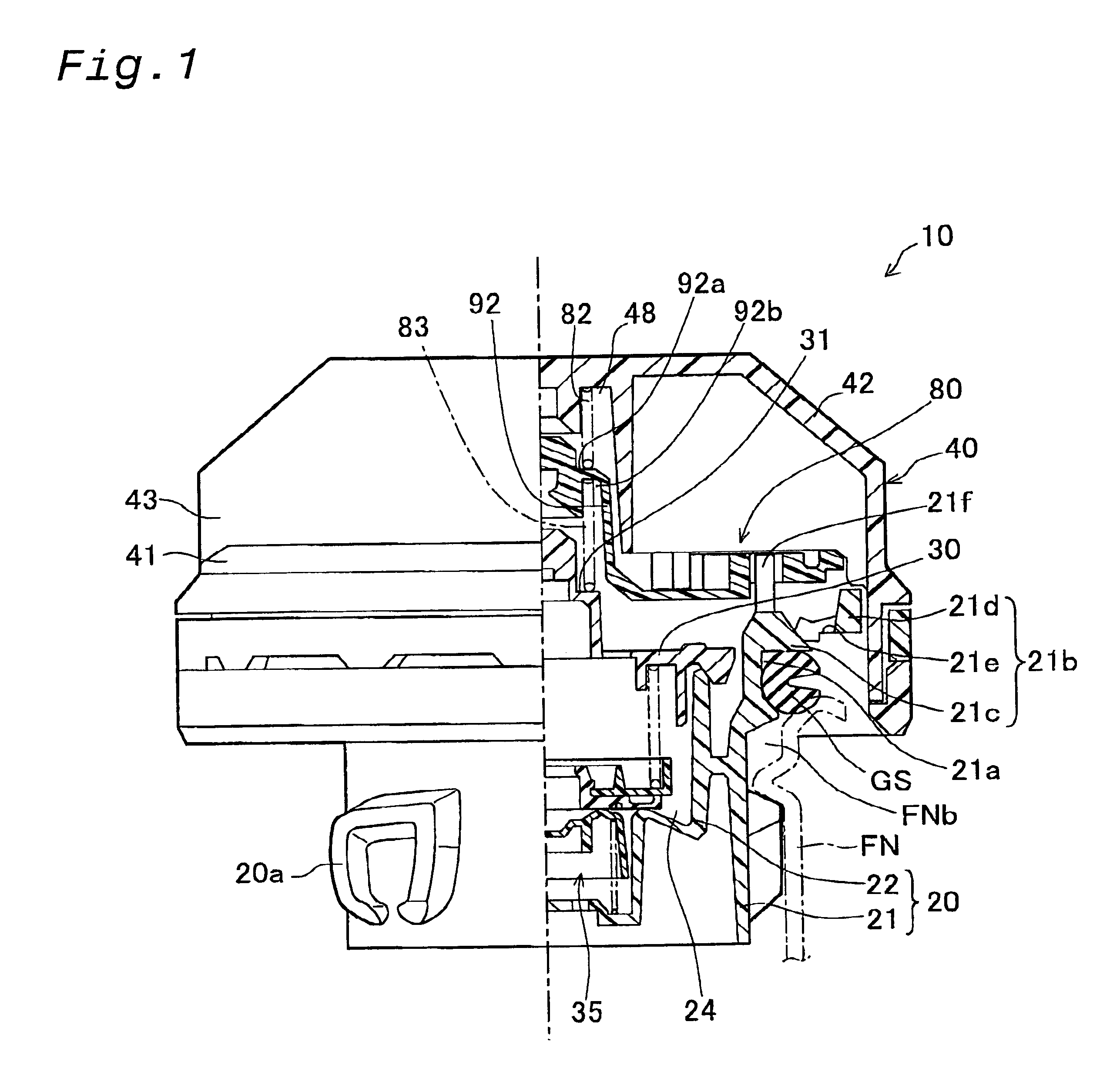

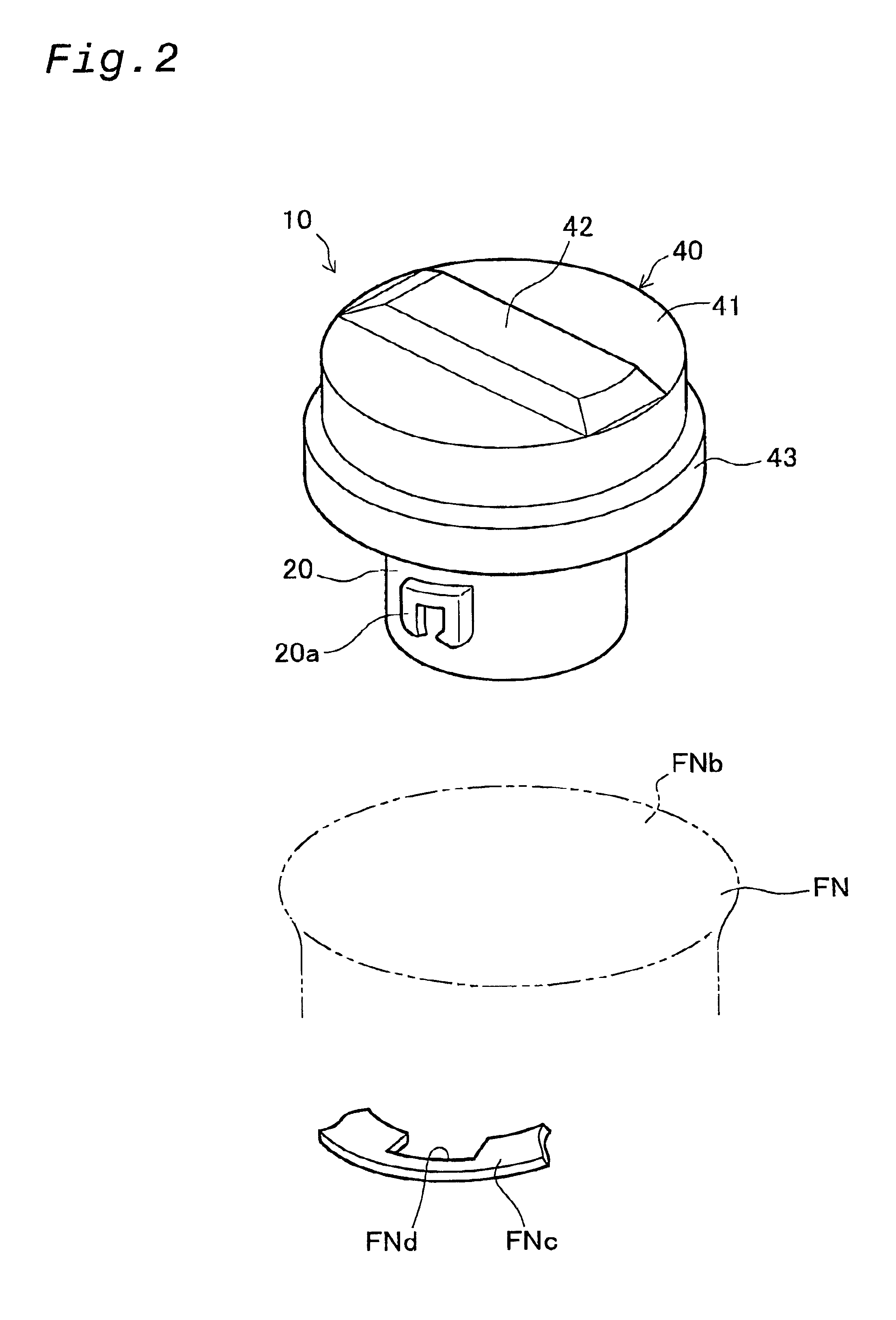

Tank cap

A fuel cap is equipped with the torque mechanism 80. The torque mechanism 80 comprises the handle engagement element 46a formed on the cover 40; the torque plate 90, having the torque piece engagement element 94b; and a spring. When the cover 40 is rotated in the closing direction, the handle engagement element 46a disengages from torque piece engagement element 94b and the engagement gives the user a feeling of attachment by an audible click. At that time, elastic torque piece 94 elastically deforms so that the handle engagement vertical surface 46b is pushed in the radial direction by the engaging vertical surface 94d, a slot 94c. Conversely, when the cap is rotated in the opening direction, the engaging inclined surface 46c pushes the engaging inclined surface 94e and elastic torque piece 94 inclines with the support end 94a, and thus the cap transitions to a non-engaged state, and the cover 40 is returned to an initial position relative to the casing main body 20. The fuel cap closes the fuel tank fueling inlet with a small value of rotating torque, the disengaging force used for tightening or untightening the cap is small, and operating noise is reduced.

Owner:TOYODA GOSEI CO LTD

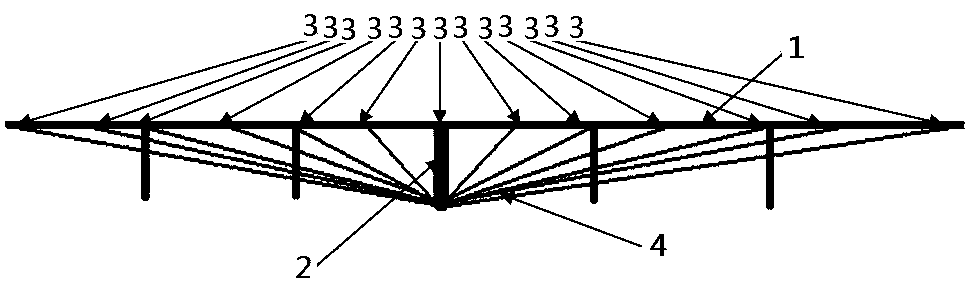

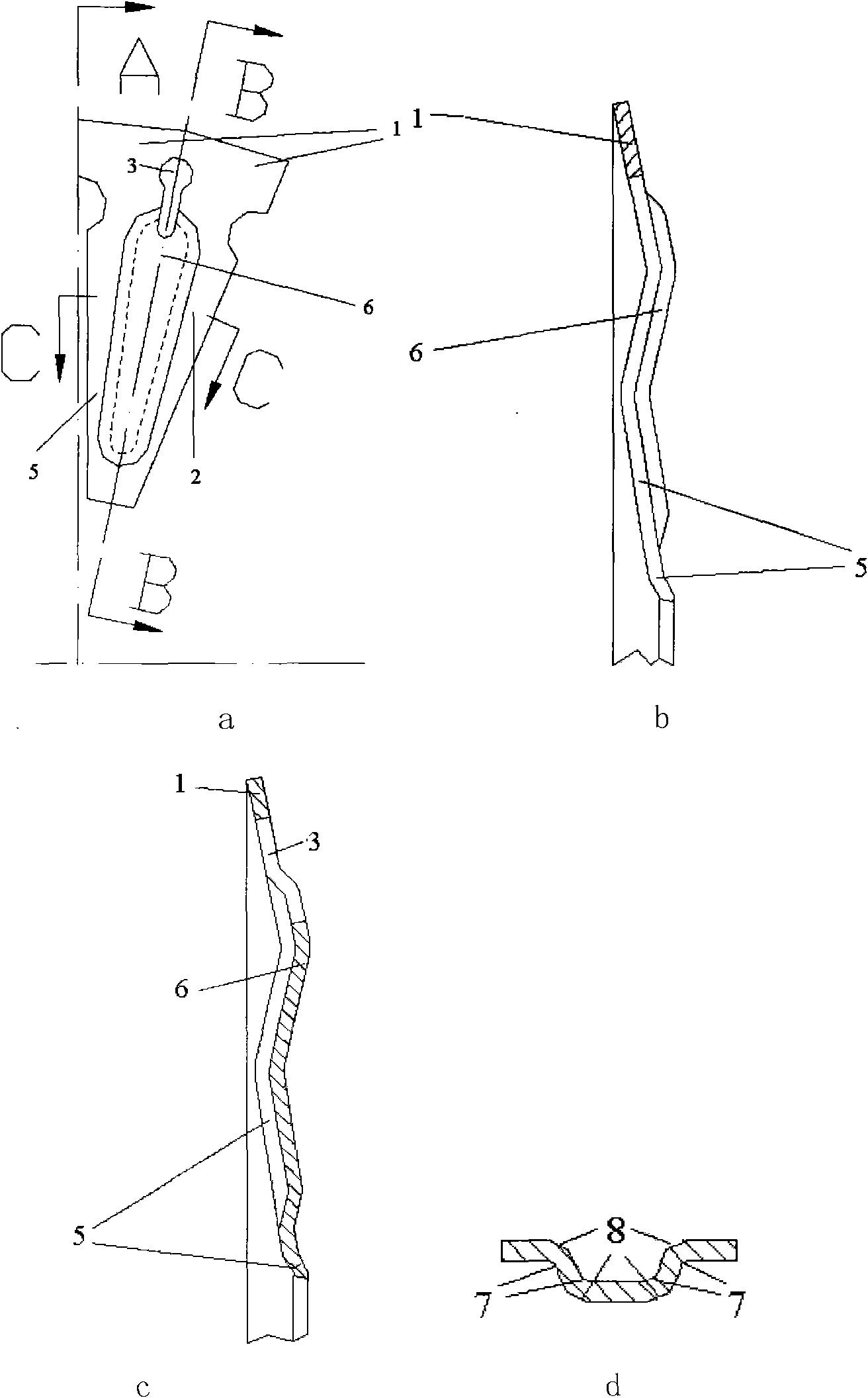

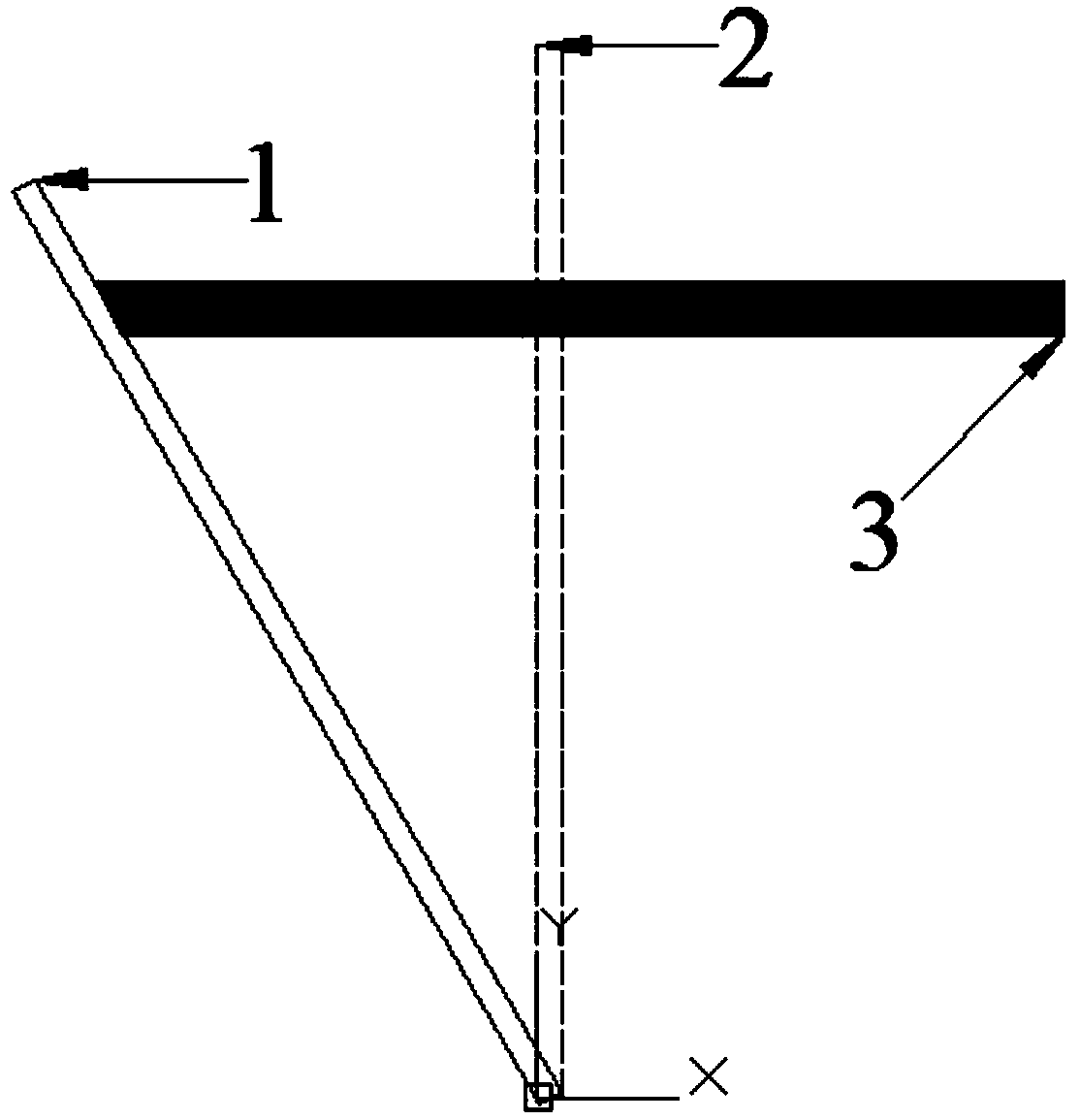

Manufacturing method of light aerofoil with super-high aspect ratio and high lift-drag ratio and aerofoil manufactured thereby

The invention discloses a manufacturing method of a light aerofoil with super-high aspect ratio and high lift-drag ratio and an aerofoil manufactured thereby. At present, some used optimized design methods for improving the strength and the rigidity of the aerofoil with the high aspect ratio have the limited improvement space; and if a method for increasing geometrical characteristic parameters of the sections of the plasmodium is adopted, the structure weight of the aerofoil needs to be increased and the effect is poor. By the manufacturing method adopted by the invention, these problems are solved. According to the overall configuration of an aircraft, the aerofoil is divided into a plurality of sections; tensile wires are arranged according to a certain mode section by section. The research result shows that the original bending function of the aerofoil is replaced by the tension of the tensile wires and the impaction of the aerofoil, and under the premise that the structure weight is basically not increased, the rigidity and the strength of the aerofoil with the high aspect ratio are greatly improved, and the pneumatic elastic deformation is reduced to be within 10 percent of the traditional aerofoil. The manufacturing method is very important for the practical application of the aerofoil with super-high aspect ratio, the cruising efficiency of the aircraft can be greatly improved, and the fuel consumption and the cost are reduced.

Owner:AERODYNAMICS NAT KEY LAB

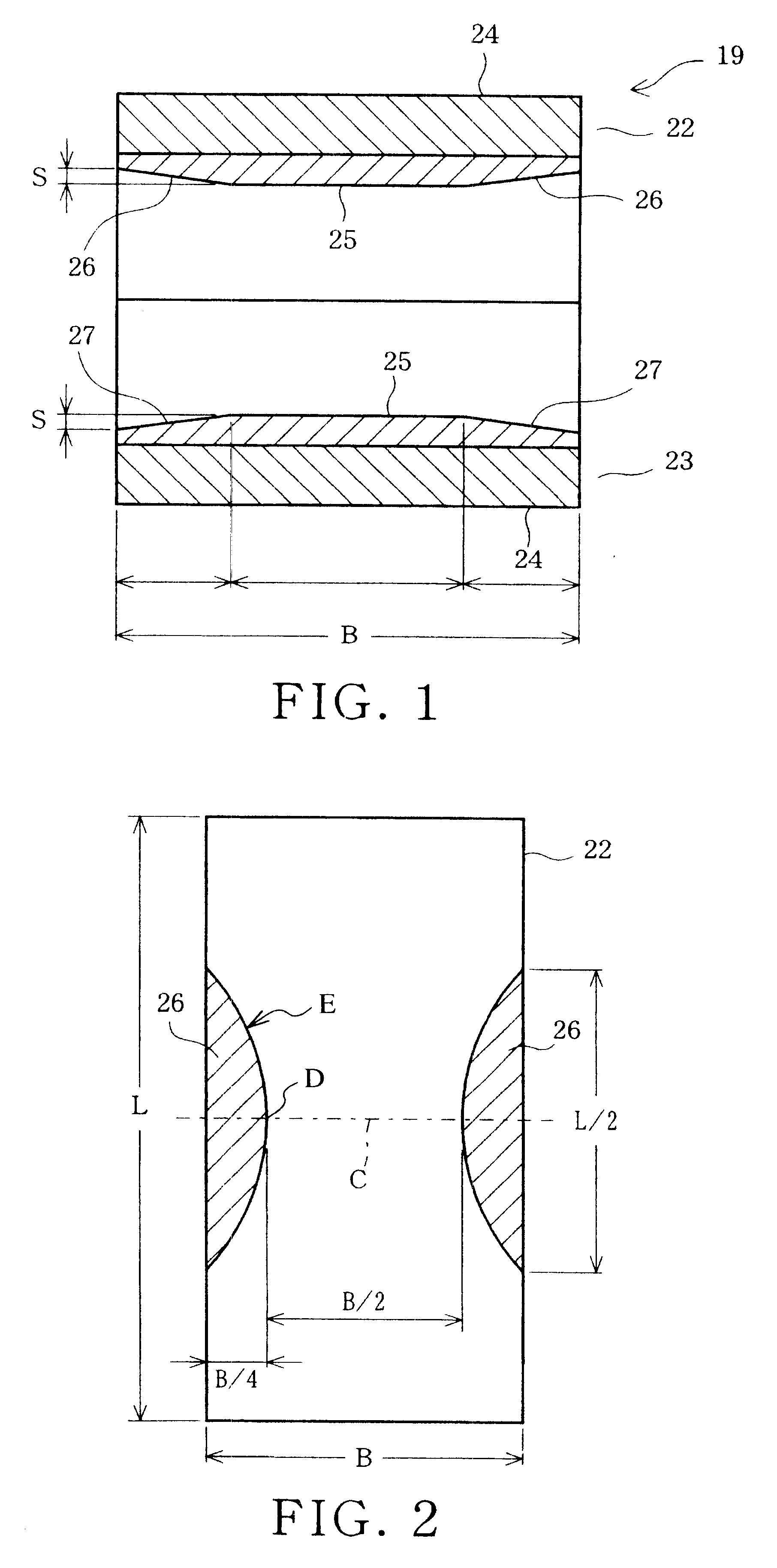

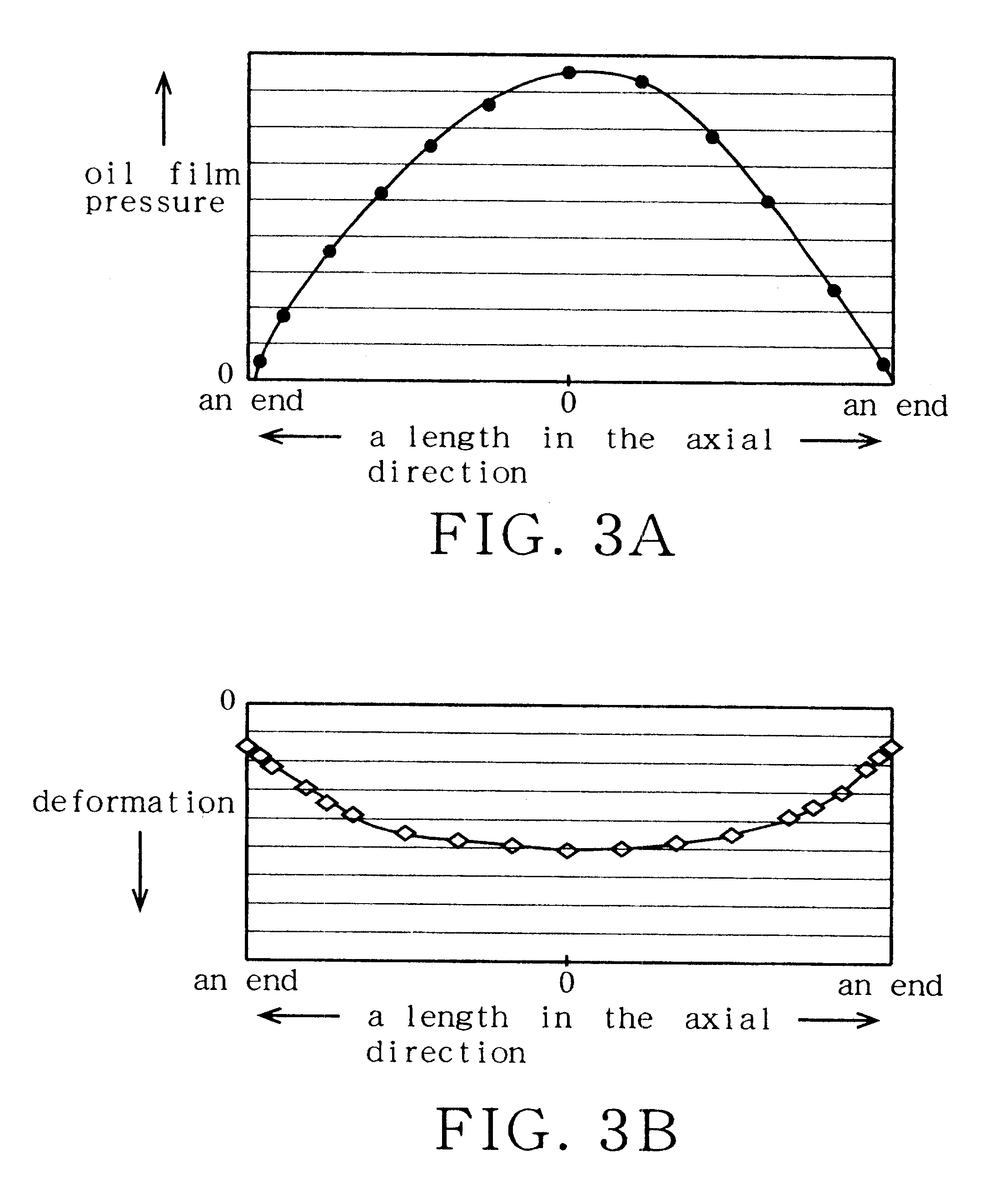

Plain bearing

InactiveUS6648513B2Reduce stiffnessLight weightConnecting rod bearingsRolling contact bearingsAlloyMechanical engineering

There is disclosed a plain bearing comprising: a back metal; and a bearing alloy layer bonded onto the back metal which bearing alloy layer is provided at a surface side thereof with a cylindrical bearing face extended in the direction of the axis of the plain bearing, the bearing alloy face being provided at each of axial terminal portions thereof with an inclination face inclined radially outwardly from a location defined between both of axially terminal ends of said bearing face toward said axially terminal ends thereof, the inclination face having an axial length varying along the circumference of the inclination face.

Owner:DAIDO METAL CO LTD

Rolling bearing

InactiveCN1357693AImprove sound durabilityReduce frictionShaftsBall bearingsFiberRolling-element bearing

A rolling bearing to exhibit outstanding initial (cage) acoustic characteristics at the start of operation under a low temperature atmosphere, suppress fretting damages (abrasions) and reduce bearing torque by making the radius of curvature of the cross-sectional shape of the inner raceway and the radius of curvature of the cross-sectional shape of the outer raceway equal to 51.0% to smaller than 60.0% of the diameter of the rolling element, and packing a grease composition comprising a base oil that is a mixture of a lubricant containing a polar group in its molecular structure and a non-polar lubricant and a metallic soap-based thickener containing a long-fiber material with a major axis part length of at least 3 mum.

Owner:NSK LTD

Cylindrical roller bearing

ActiveUS7101088B2Increase temperatureAvoid elastic deformationRoller bearingsBearing componentsFree rotationEngineering

A cage of a cylindrical roller bearing includes an annular section, a plurality of pillars that extend axially in an integrated, continuous manner from the inside surface of the annular section, and a plurality of pockets, which are formed between the inner circumferential direction side faces of adjacent pillars, and hold the cylindrical rollers in a freely rotatable manner. The circumferential direction side faces of the pillars incorporate a circular arc surface formed in both the inside and outside diameter directions from the pocket PCD which passes through the pocket center of the pocket, and a roll-off section (lubricant reservoir) provided at the tip end inner circumferential section.

Owner:NTN CORP

Diaphragm spring for normally open type clutch

The invention relates to a diaphragm spring for a normally open type clutch, belonging to the technical field of the automatic clutch of the automobile. The diaphragm spring is of disc-shaped structure and comprises a disc-spring part, a plurality of jointing finger parts and a plurality of stress releasing holes, wherein the plurality of jointing finger parts with the same structure are centrally symmetrical by the center of a circle of the diaphragm spring; and the outer ends of the jointing finger parts are fixedly connected with the disc-spring part which is provided with the plurality of stress releasing holes along the peripheral direction. The diaphragm spring not only reserves the advantages of being capable of reducing resilience force and having zero rigidity in a wearing route of a frictional plate, but also overcomes the problem of overlarge pressure, thus leading the elastic deformation of a thrust plate and a housing to decrease, leading the starting operation of an executive device to become easy and leading the load borne in the process of the executive device to obviously decrease.

Owner:SHANGHAI JIAO TONG UNIV

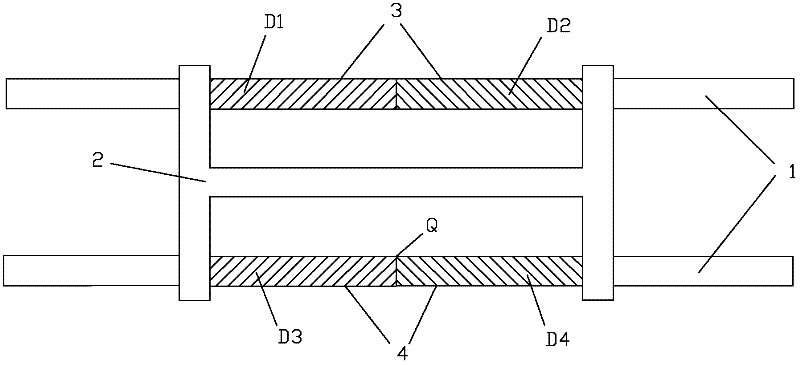

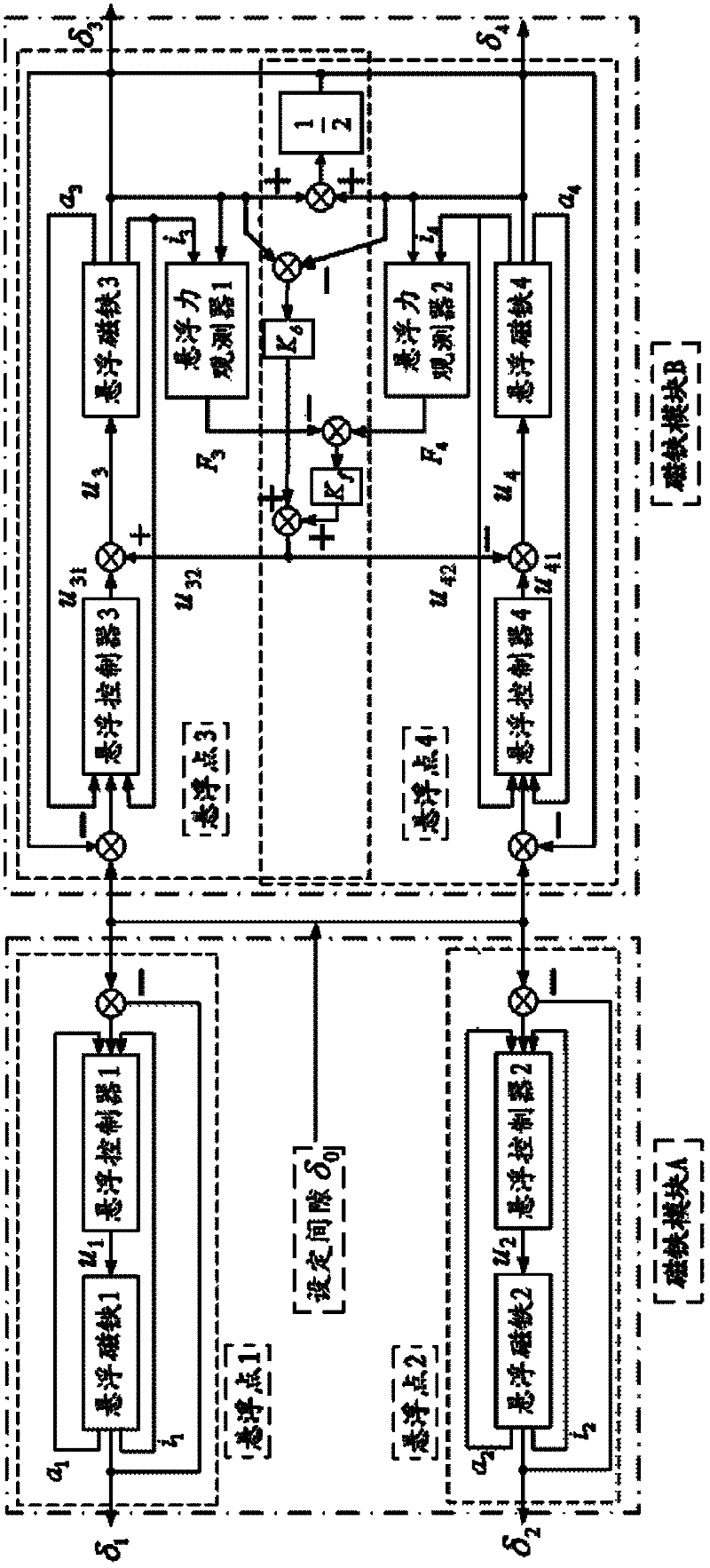

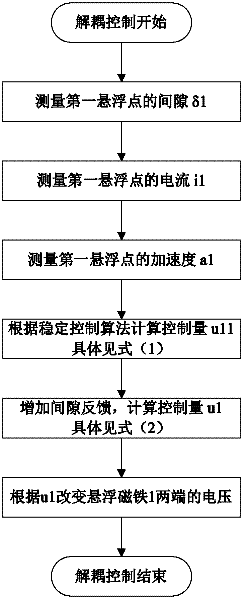

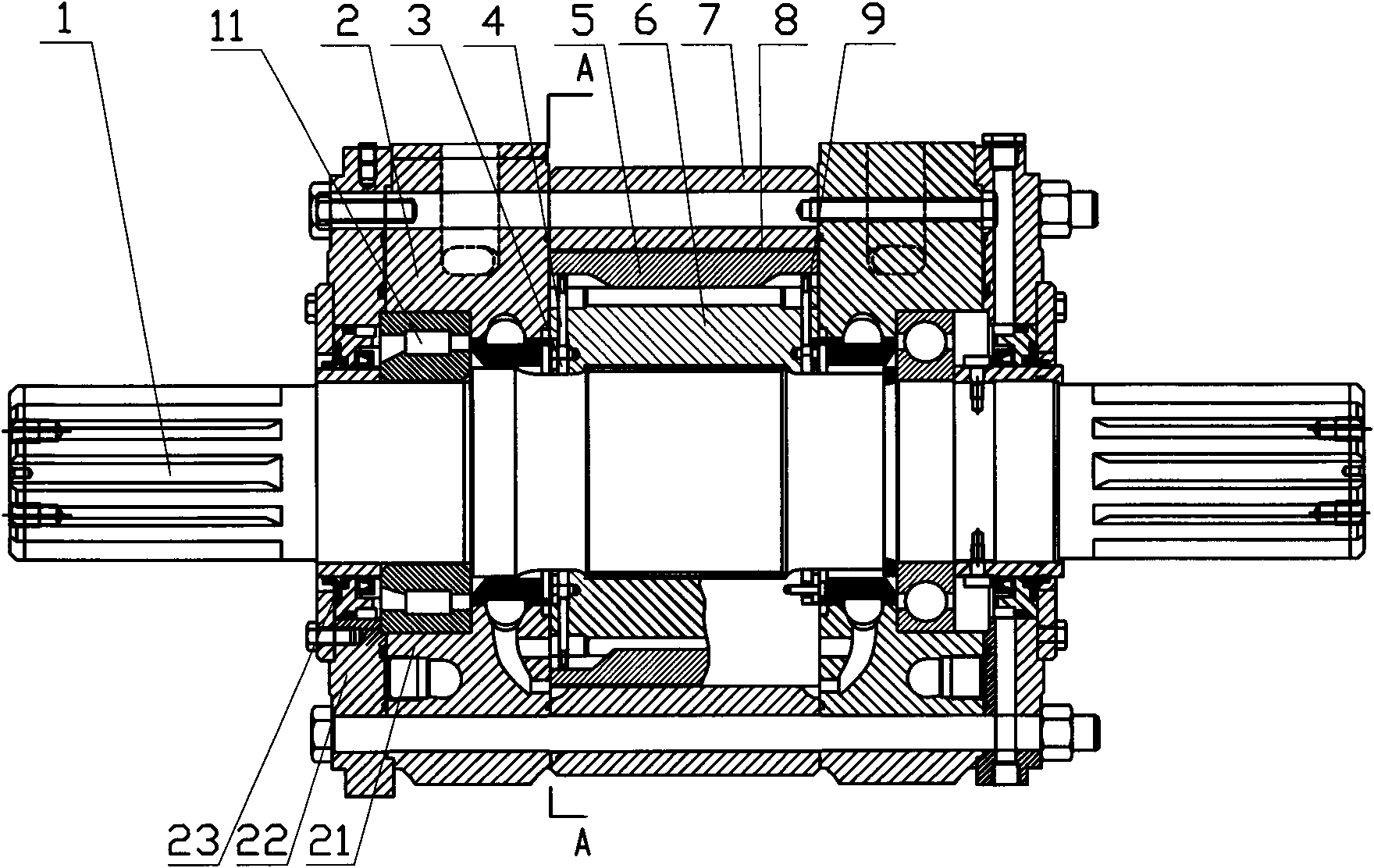

Decoupling control method for bogie suspension system of electromagnetic maglev train

InactiveCN102529744AGood Tracking CapabilityLittle elastic deformationElectric propulsionAutomotive engineeringMagnet

Disclosed is a decoupling control method for a bogie suspension system of an electromagnetic maglev train. The decoupling control method includes steps of (1), setting suspension points: respectively defining magnet modules on two sides of a bogie as a magnet module A and a magnet module B, controlling the magnet module A via two suspension points including a first suspension point and a second suspension point, and controlling the magnet module B via two suspension points including a third suspension point and a fourth suspension point; (2), controlling the magnet module A: controlling the first suspension point and the second suspension point of the magnet module A in an equal gap manner, and accordingly keeping a stable gap between the first suspension point and the second suspension point as a set value; and (3), controlling the magnet module B: coordinately controlling the third suspension point and the fourth suspension point of the magnet module B comprehensively according to states of the third suspension point and the fourth suspension point, accordingly, keeping an average gap value as a set value, and controlling the difference of gaps and the difference of suspension force within certain ranges. By the aid of the decoupling control method, requirements of the bogie on decoupling functions can be lowered, and safety and comfort of the suspension system of the maglevtrain can be improved.

Owner:NAT UNIV OF DEFENSE TECH

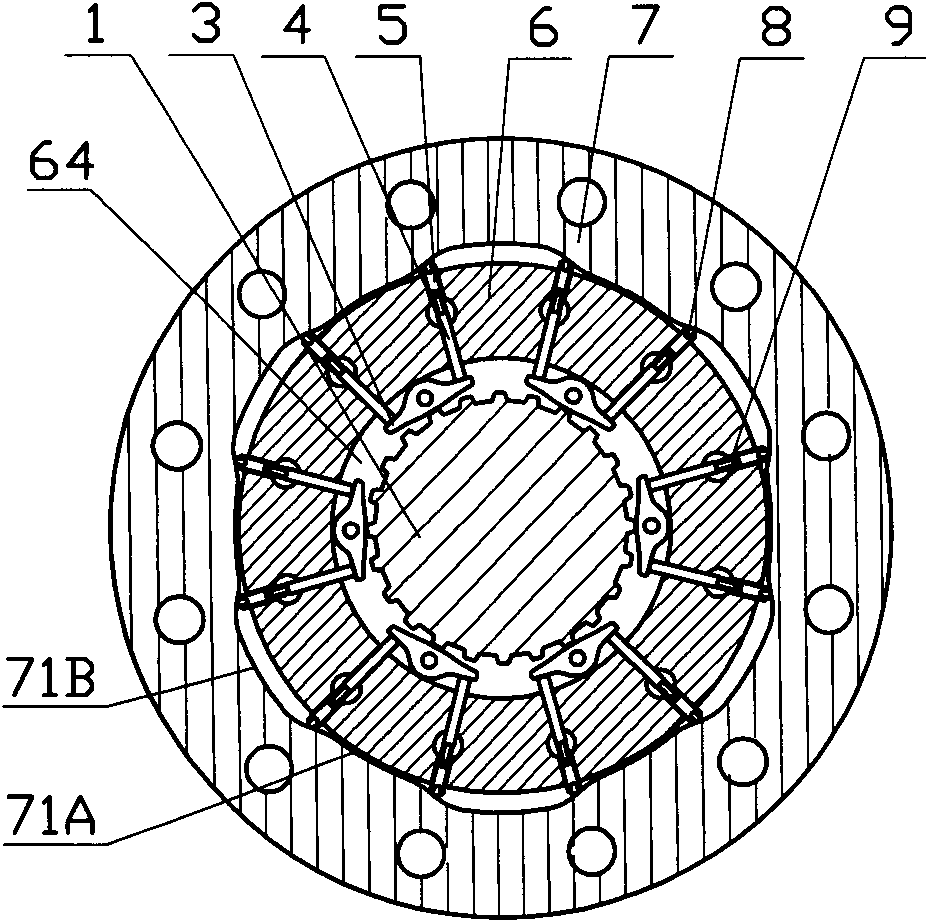

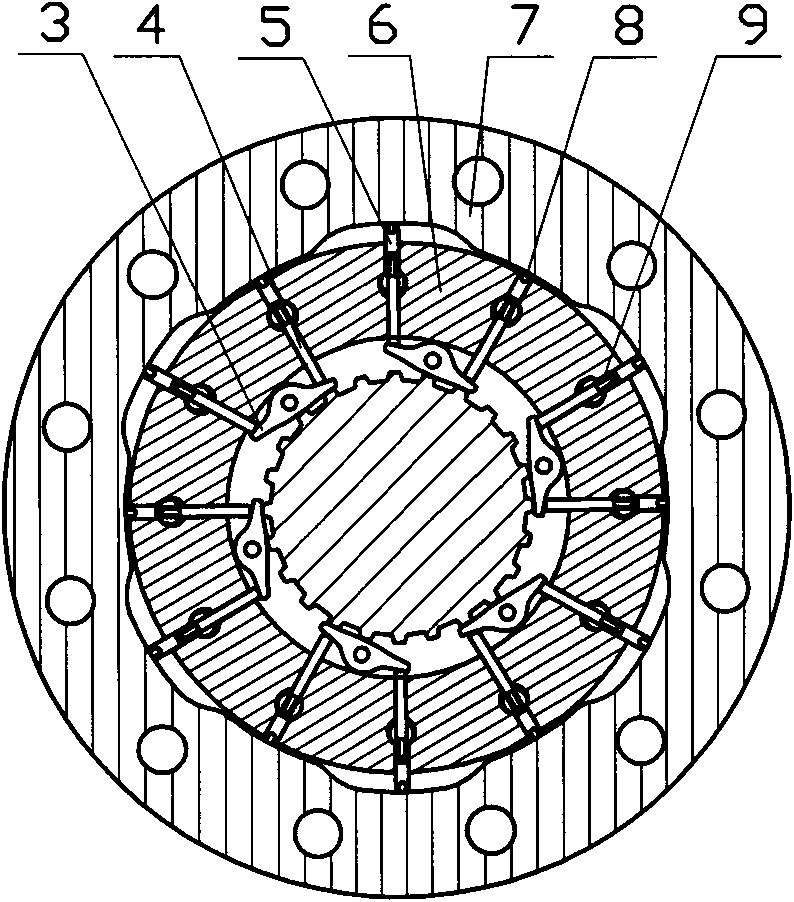

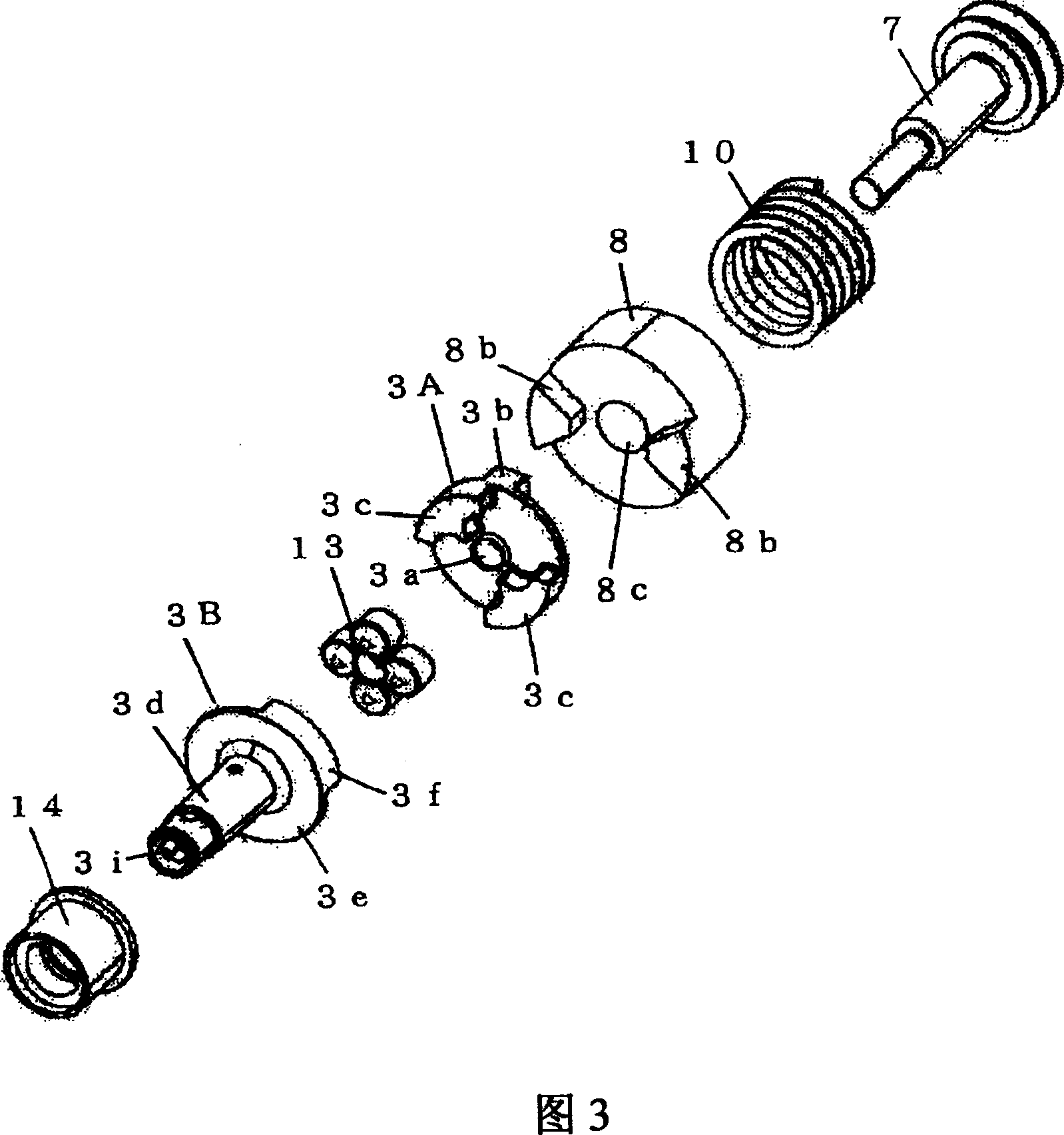

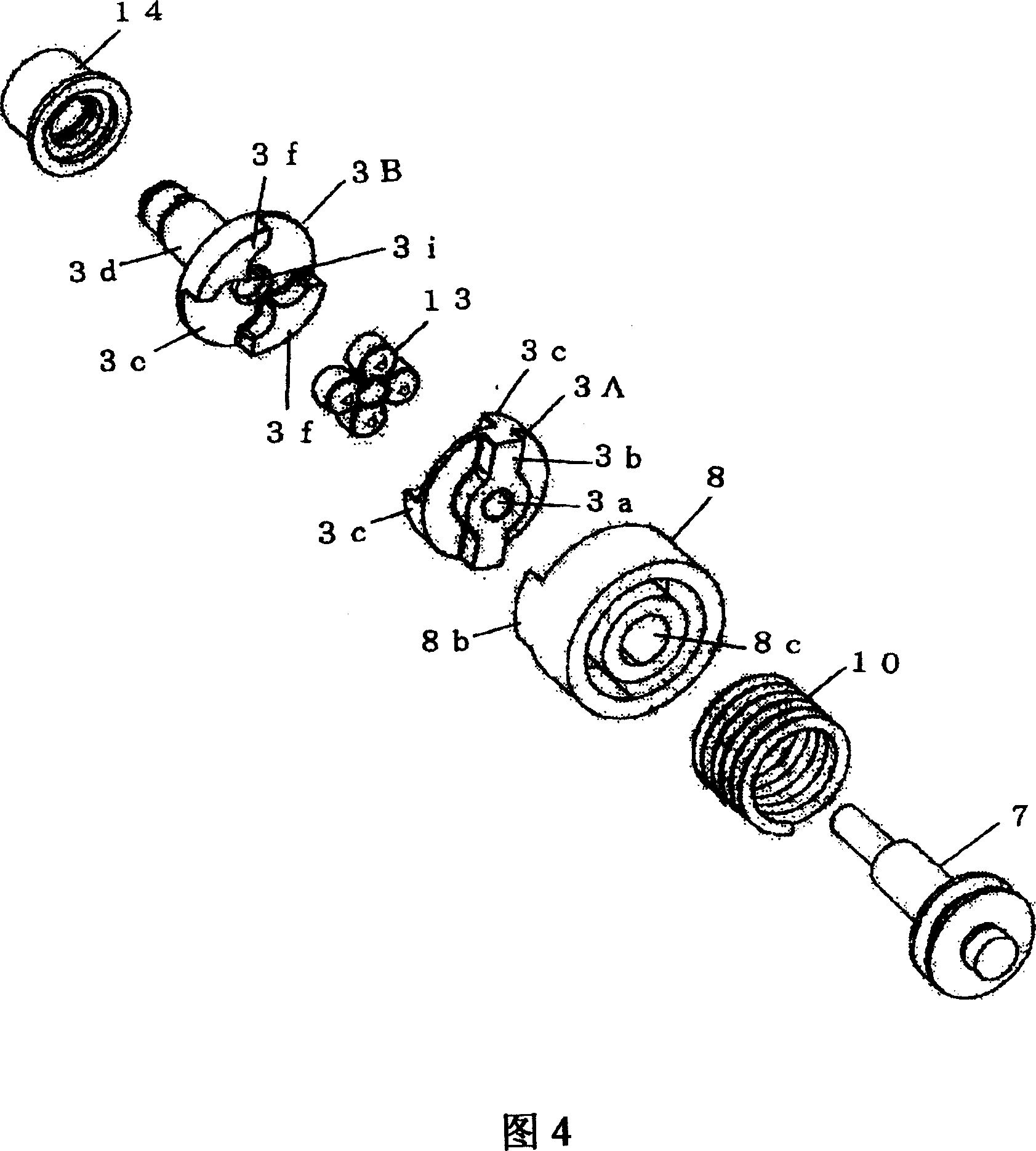

Blade type hydraulic motor with rocker arm structure

ActiveCN102174901AImprove performanceCooperate wellEngine componentsRotary piston enginesHydraulic motorEngineering

The invention discloses a blade type hydraulic motor with a rocker arm structure. The hydraulic motor comprises an end cover, an oil distribution disc, a stator, a rotor and a rotating shaft, wherein the rotor is connected with the rotating shaft by a spline; a plurality of blade grooves are uniformly formed on the rotor; two layers of rocker arm beams are arranged in circular grooves at the two ends of the rotor, each layer comprises a plurality of rocker arm beams, holes are formed in the centers of the rocker arm beams; pin shafts pass through the holes to rotationally connect the rocker arm beams with the rotor; circular cavities are formed at the two ends of each blade groove; through holes which are intersected with the circular cavities along the radial direction are formed below the circular cavities; pull rods and springs are arranged in the through holes sequentially; the bottom surfaces of the pull rods are contacted with the arms of the rocker arm beams; blades are arranged in the blade grooves; the bottom ends of the blades are contacted with the springs; the springs are positioned in the circular cavities; an oil circuit is communicated with the circular cavities; grooves are formed on the tops of the blades; and blade heads are inserted into the grooves, are tightly matched with the blades, are higher than the tops of the blades and are contacted with the inner curve surface of the stator. The hydraulic motor has high sealing performance between the blades and the stator, small abrasion during rotation, higher efficiency and longer service life.

Owner:宁波恒通诺达液压股份有限公司

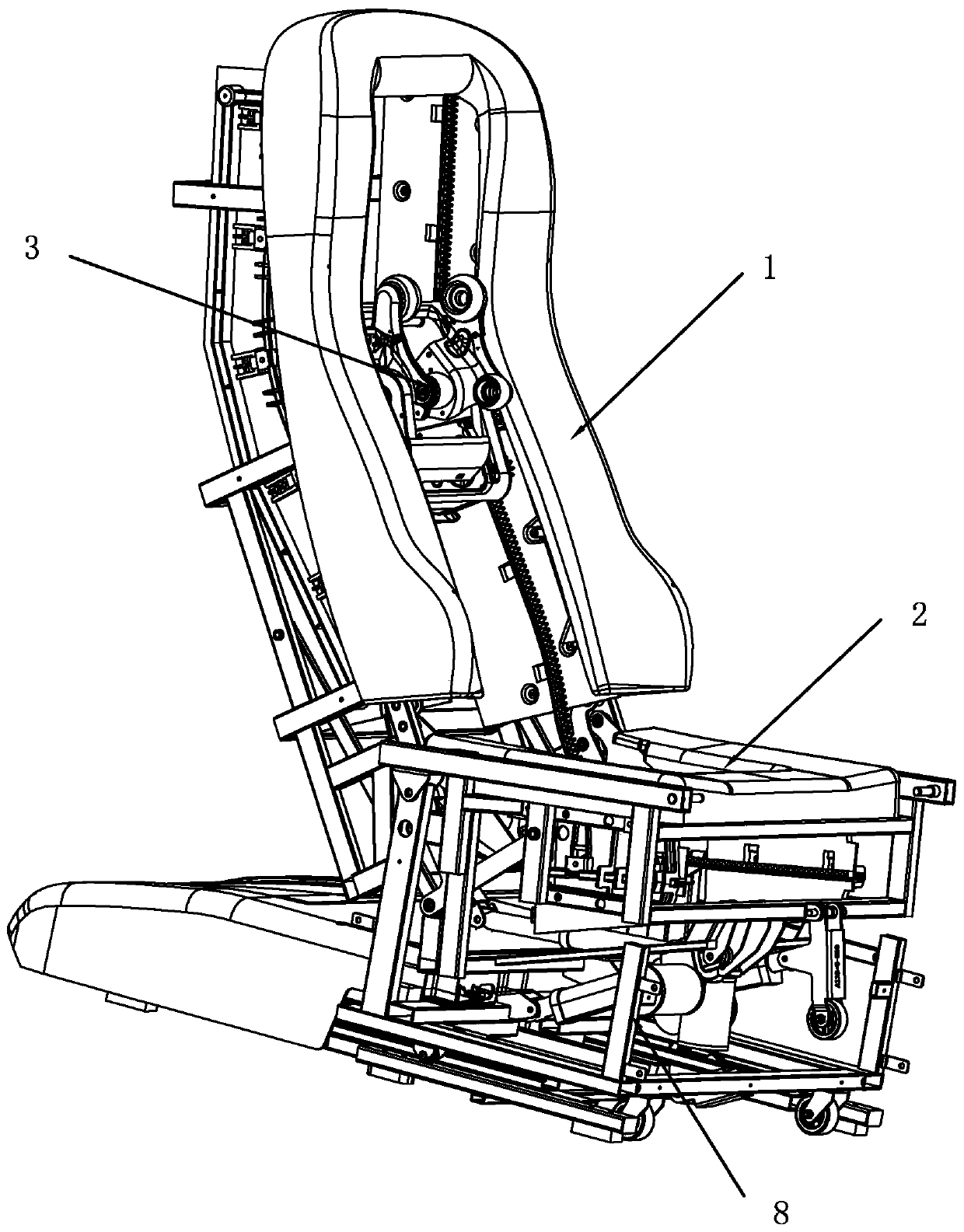

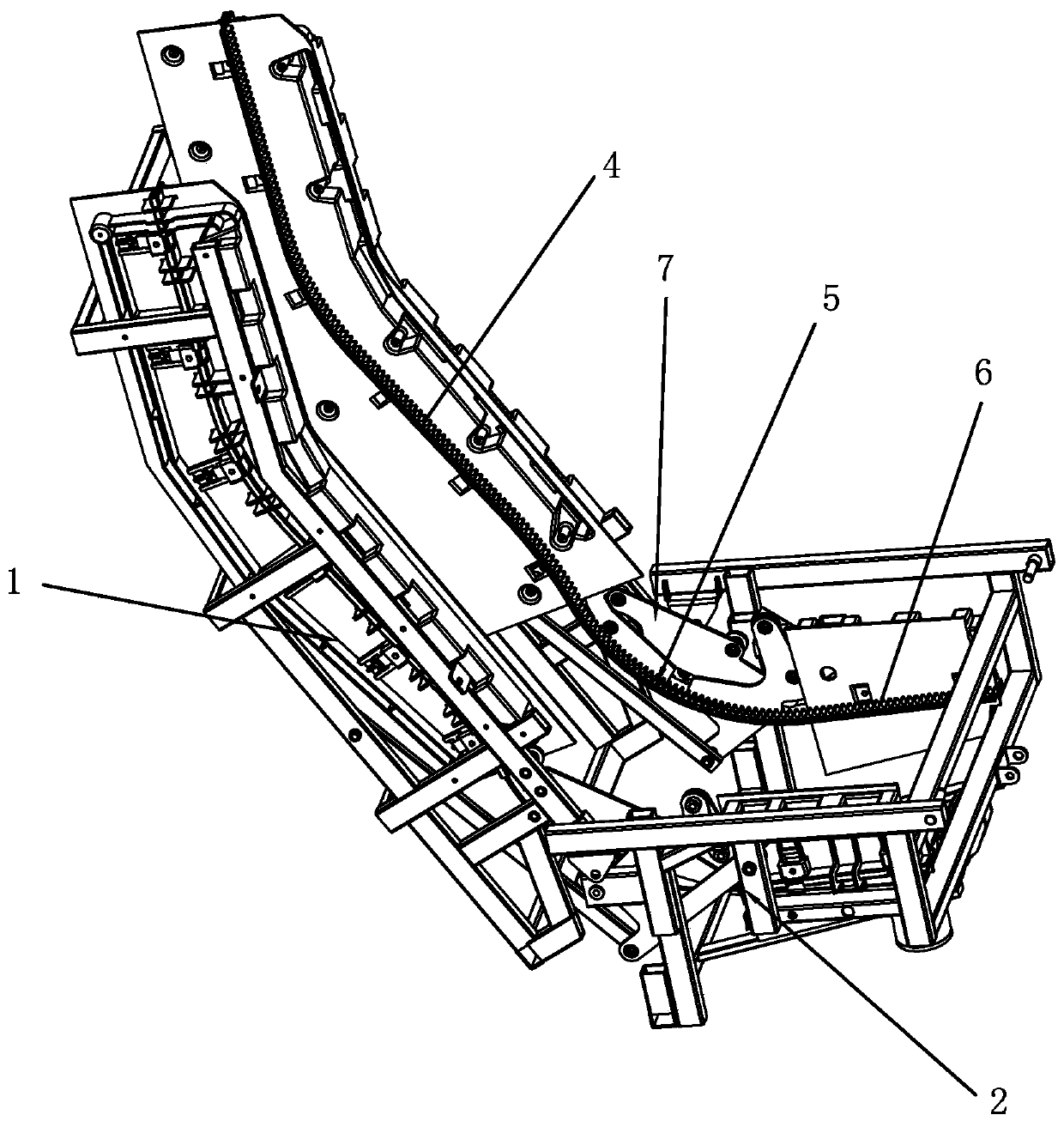

Full-body massage chair and chair frame structure thereof

ActiveCN110960391AMassage achievedAchieve conversionChiropractic devicesRoller massageWhole bodyClassical mechanics

The invention relates to the field of massage appliances, and specifically discloses a whole-body massage chair and a chair frame structure thereof. The chair frame comprises a back frame, which is fixedly provided with a back guide rail; a seat frame is fixedly equipped with a seat guide rail; the back frame adjusts the treatment angle between the back frame and the seat frame by rotating about aset axis, and the place where the back guide rail and the seat guide rail are adjoined has a spacing gap; a linkage mechanism for connecting the back guide rail and the seat guide rail is arranged atthe spacing gap so as to enable a massage movement to smoothly walk from the back frame to the seat frame to massage legs, and the linkage mechanism comprises a transition guide rail and an elastic plate, wherein the elastic plate is driven by the rotational motion of the back frame and / or the seat frame to generate elastic deformation, the transition guide rail and the elastic plate are fixedlyconnected, and both the elastic plate and the transition guide rail are arc-shaped; and the back frame and / or the seat frame are / is provided with a deformation holding mechanism followed by the back frame and / or the seat frame, and the deformation holding mechanism is pressed against the elastic plate and / or the transition guide rail. According to the invention, full-body massage can be realized,and the massage comfort is improved.

Owner:NINGBO BINGHANG ELECTRONICS SCI & TECH CO LTD

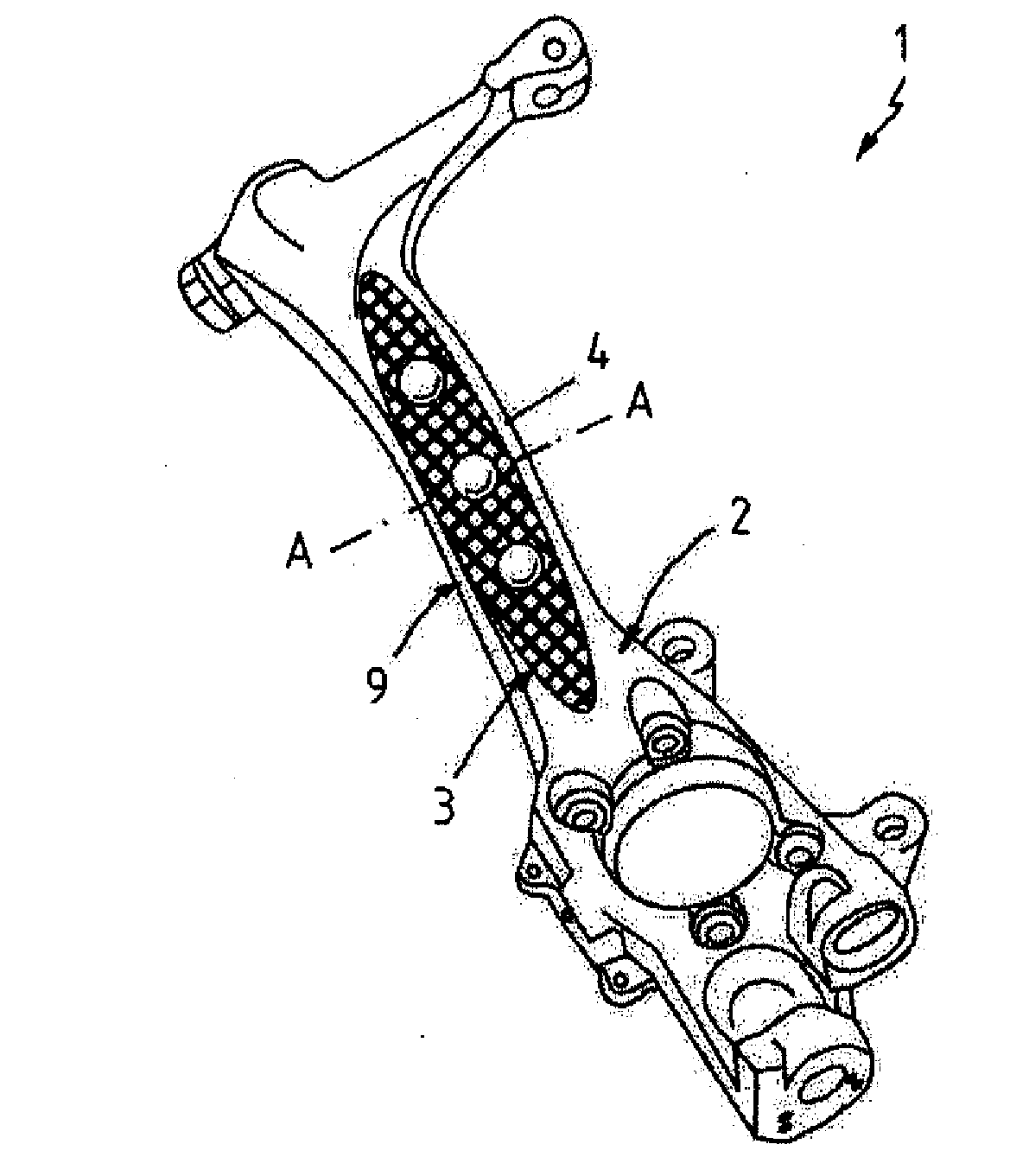

Chassis structure for a motor vehicle

InactiveUS20130154310A1High malleabilityHigh stiffnessVehicle seatsUnderstructuresFiberMotorized vehicle

A chassis structure for a motor vehicle includes a forged base body of light metal and a reinforcement body made of fiber material. The base body and the reinforcement body are bought into forced engagement by an adhesive layer, wherein the base body has at least one first region which is plastically deformed and partially encompasses the reinforcement body by a form fit.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

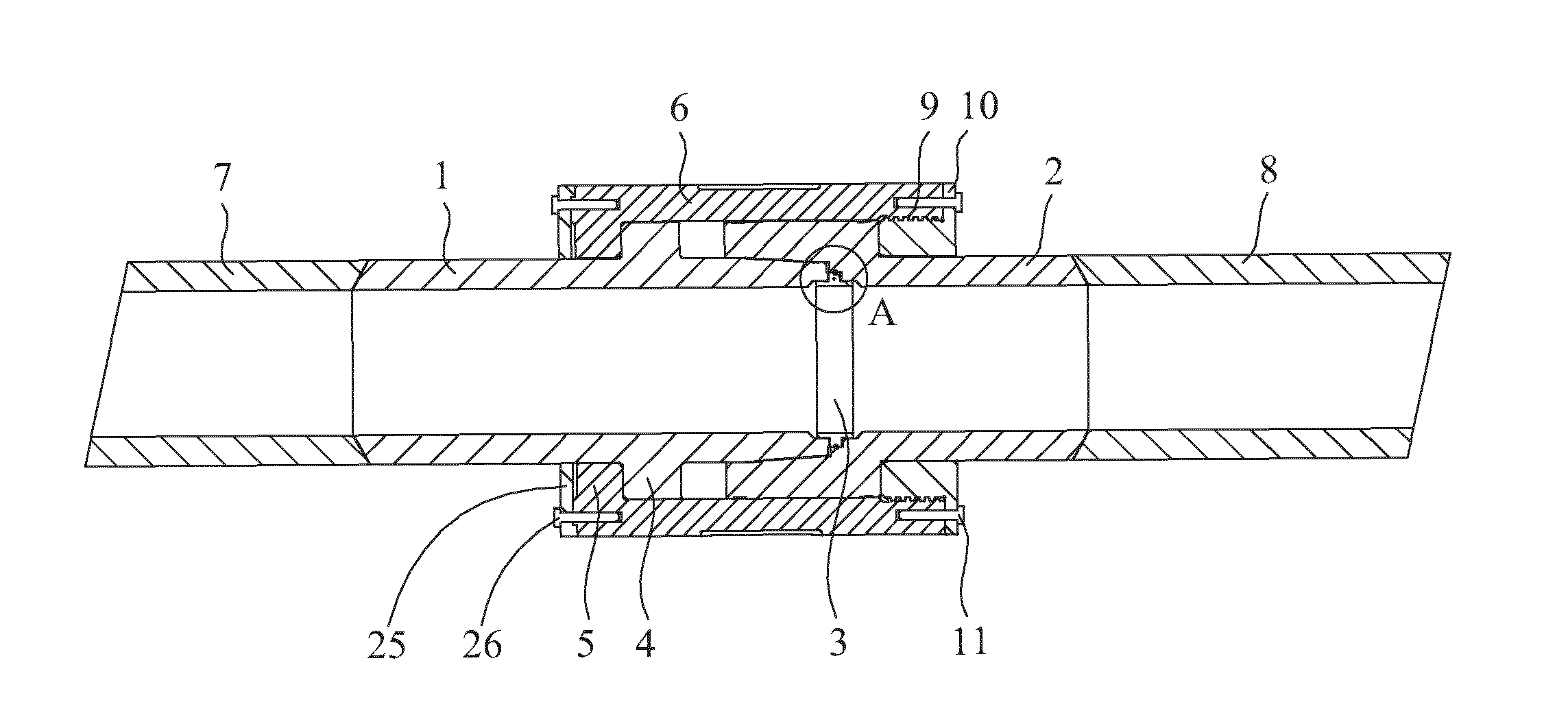

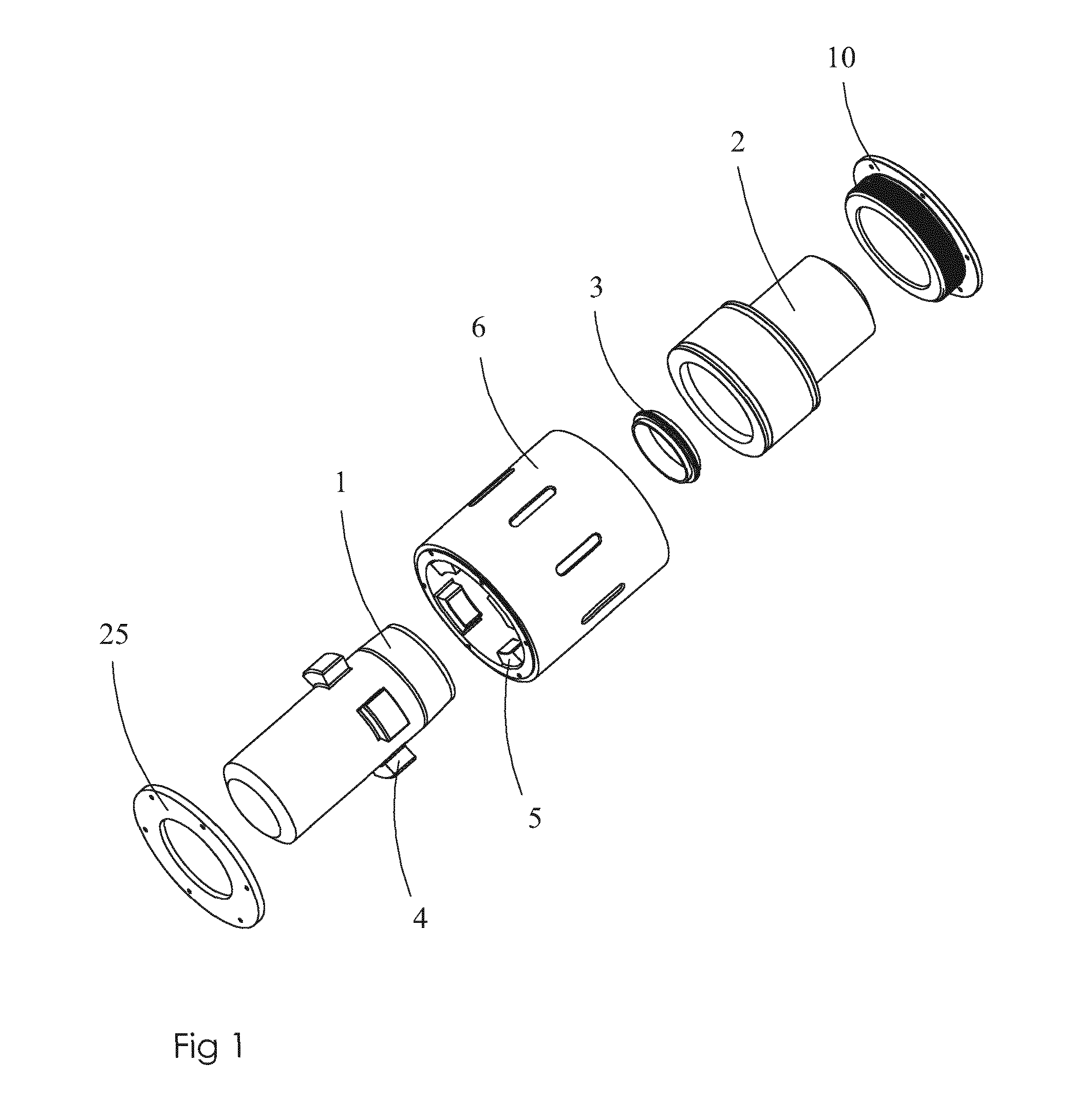

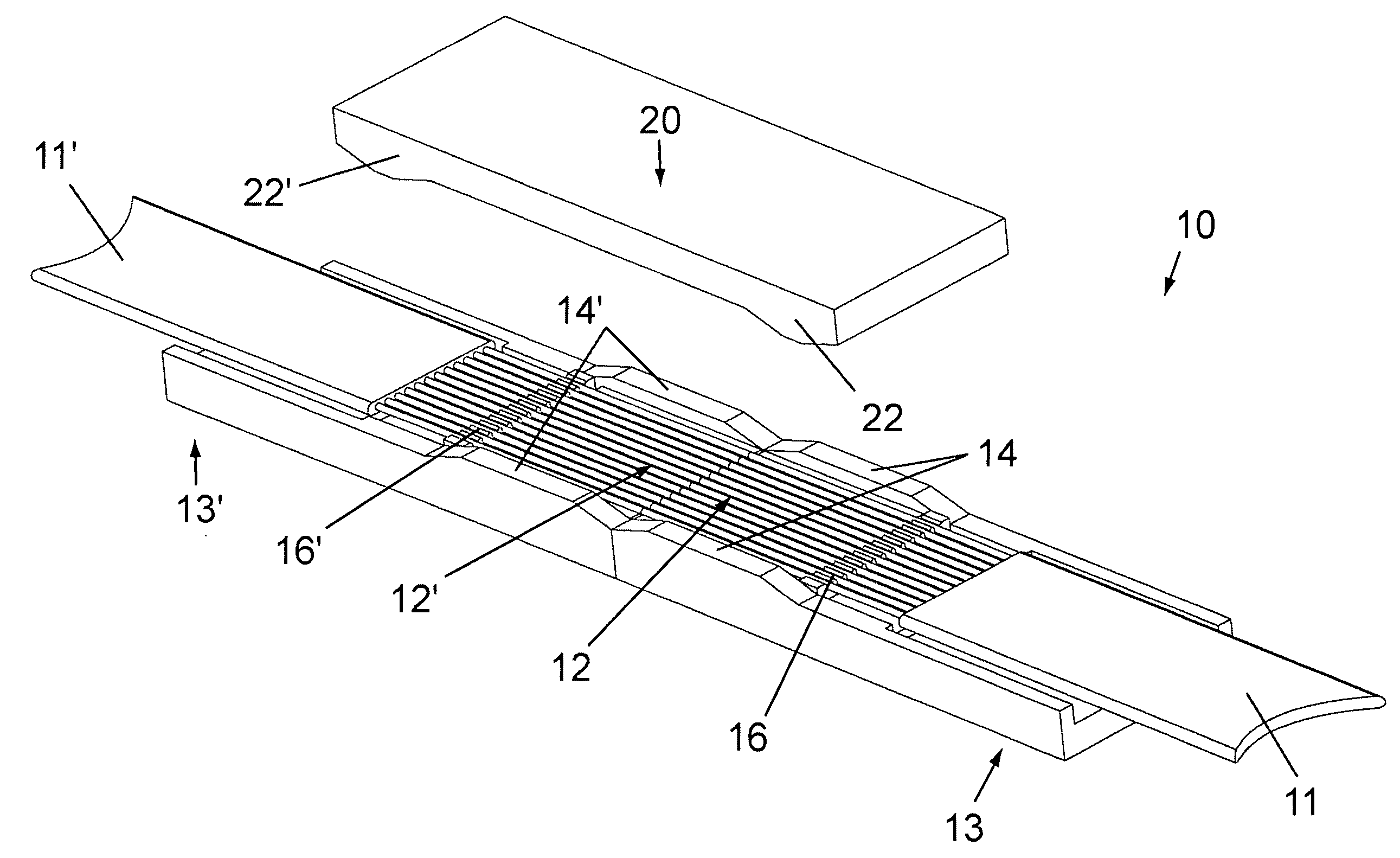

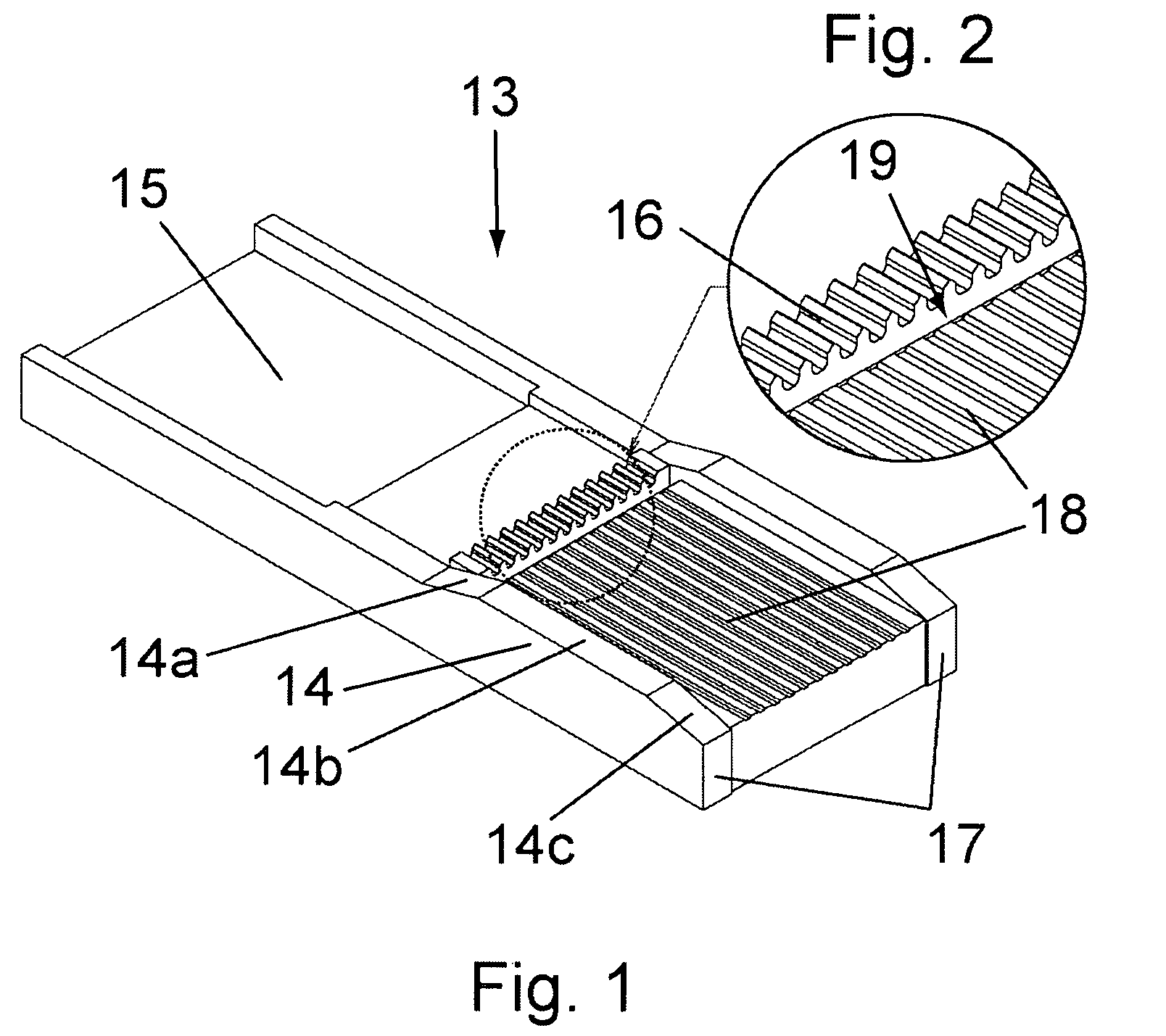

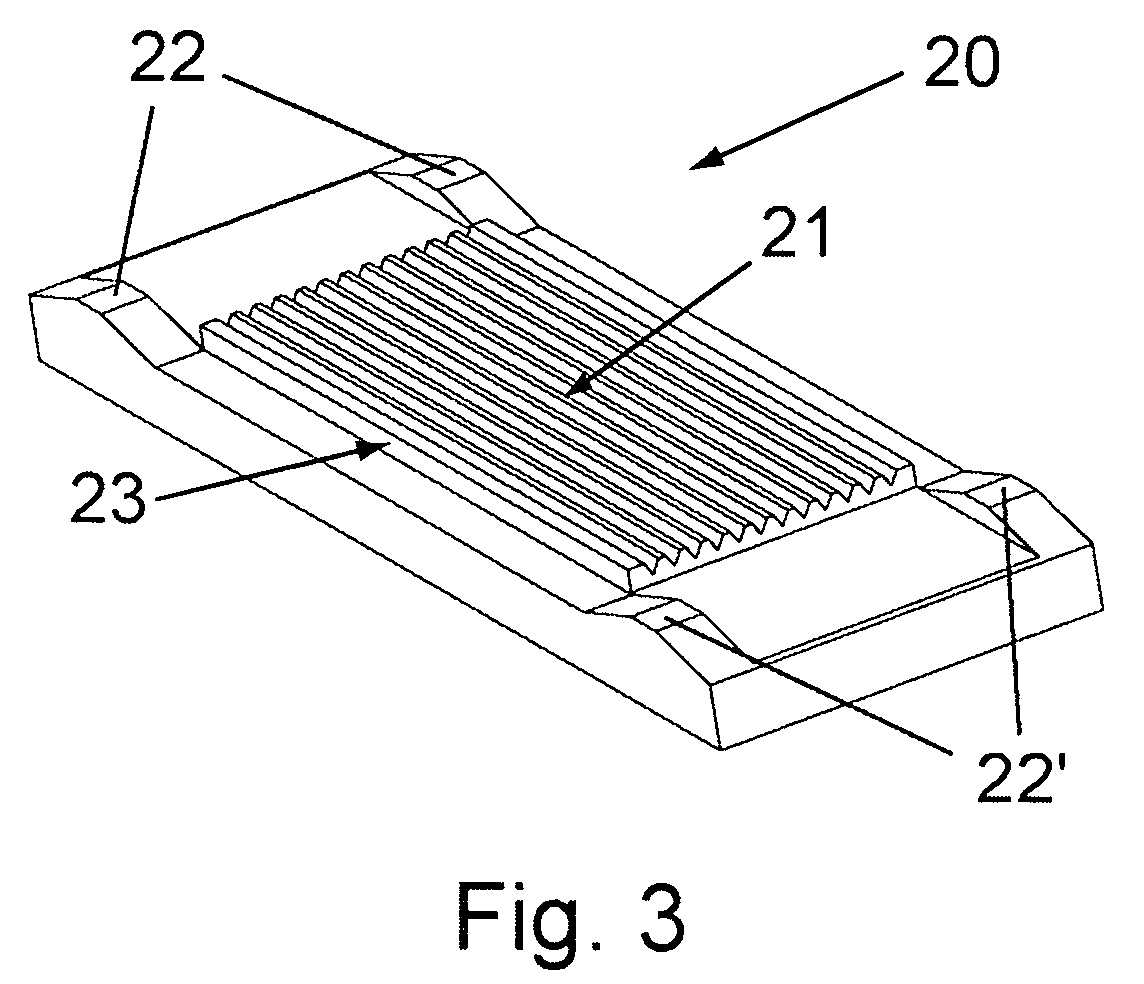

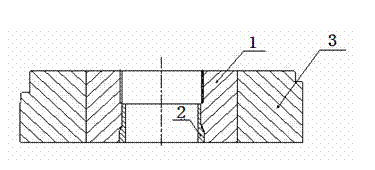

Method for releasably connecting two groups of optical fibers, and plug-in connector for carrying out said method

InactiveUS20060159402A1Improve surface hardnessReduce sliding frictionCoupling light guidesFiberCerebellum granule cell

Disclosed is a method for removably connecting two groups of individual, parallel fibers that are delimited by end faces that are perpendicular to the fiber axis. The two groups of fibers are moved towards each other in an axial direction until each of the fibers abuts against the end face of the assigned fiber from the other group. The fibers of the two groups are aligned in pairs relative to each other before being moved into contact with each other, and any differences in fiber lengths is compensated for by elastically deforming the fiber along the fiber main axis. This method eliminates the disadvantages associated with bending the fibers because length variations are essentially compensated for by axially compressing the fibers.

Owner:HUBERSUHNER AG

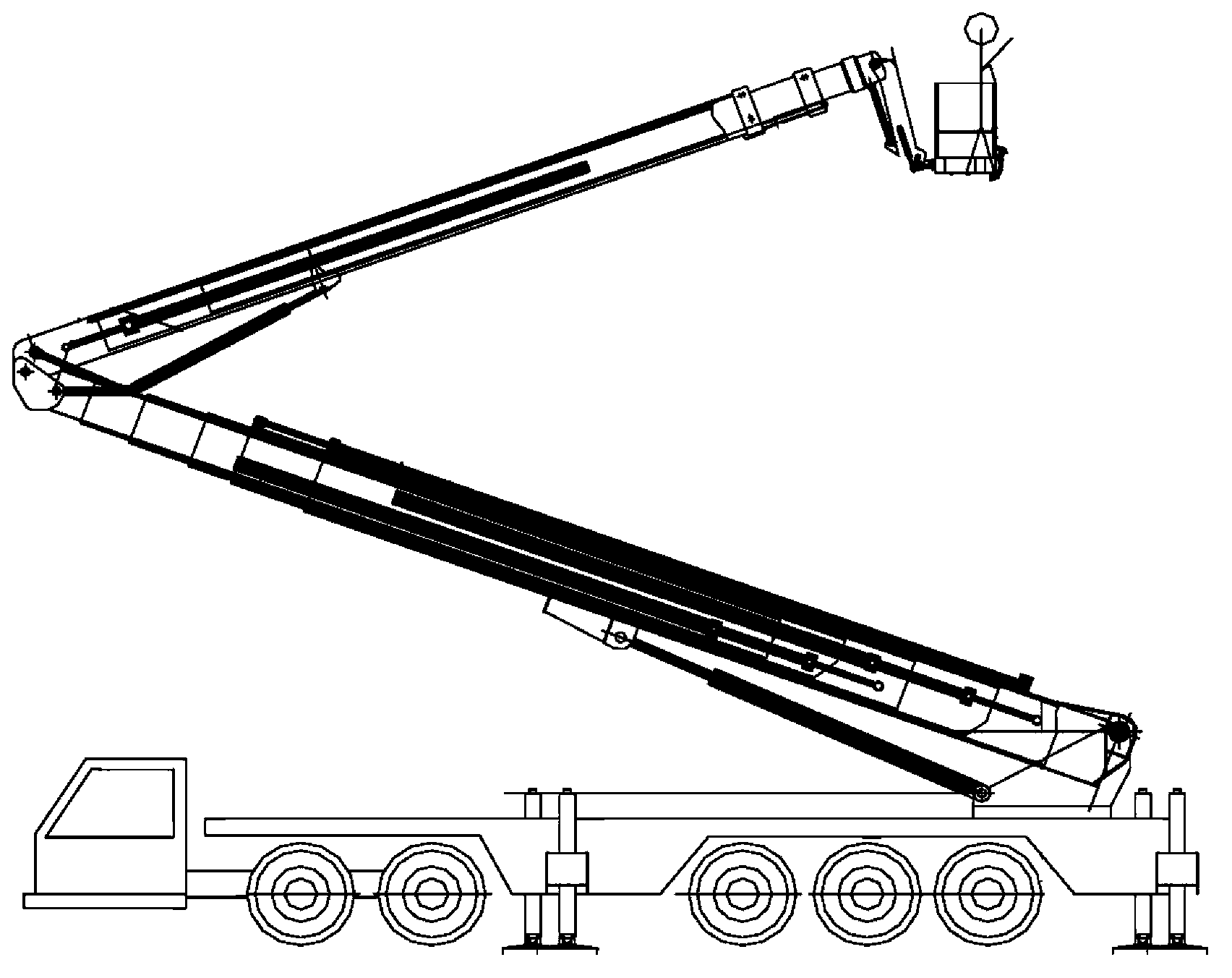

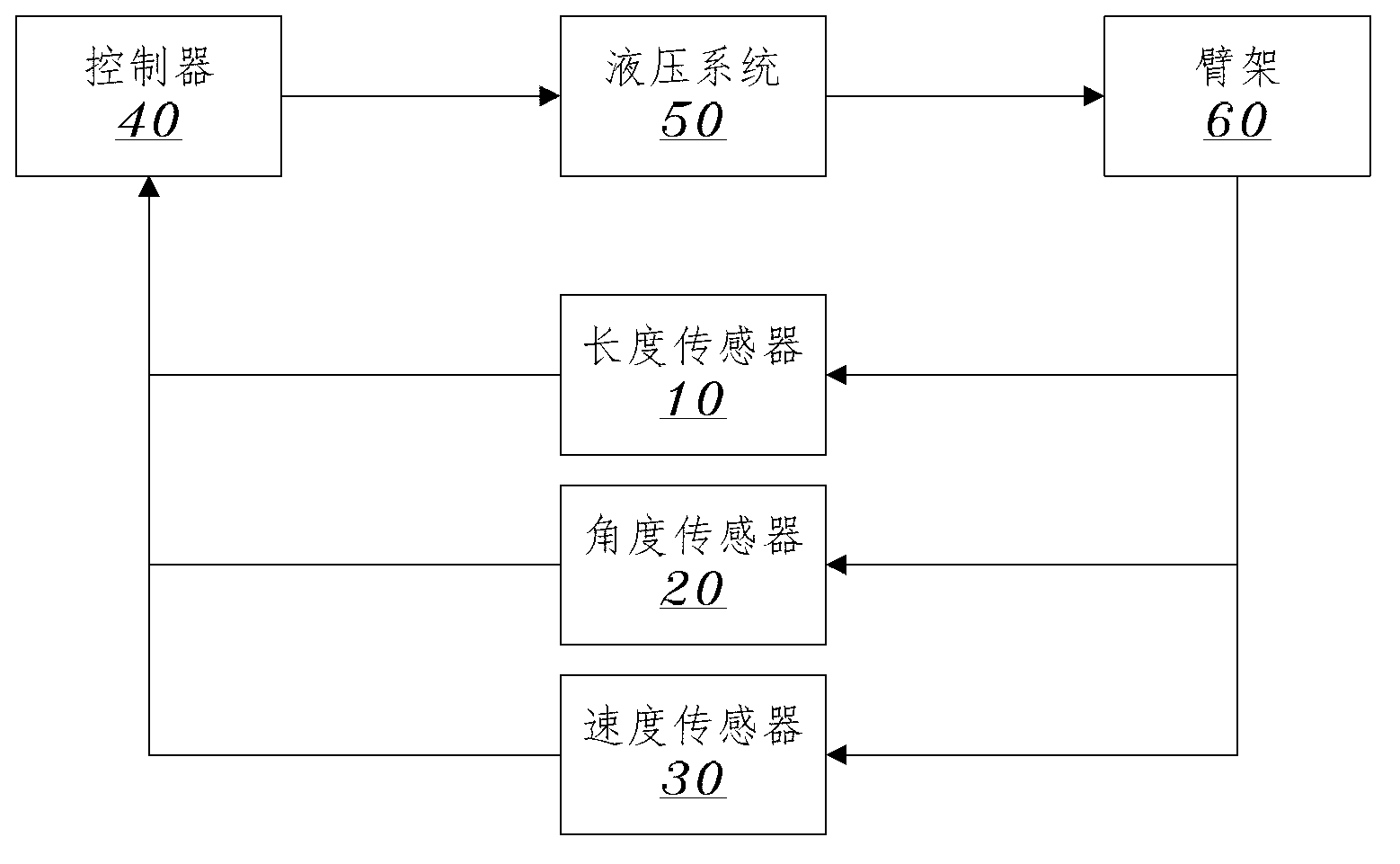

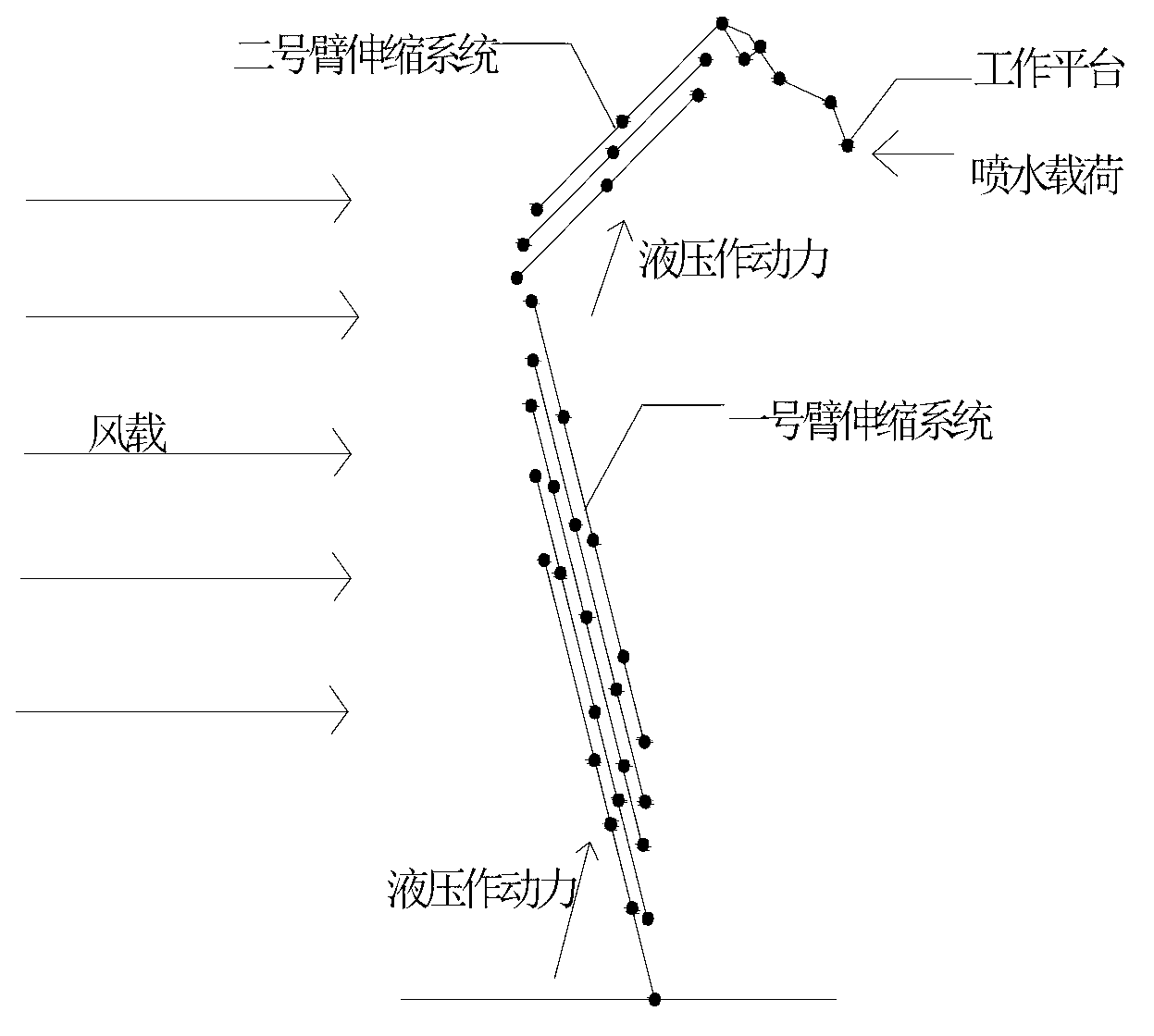

Method, system and engineering machinery for improving arm frame movement stability

The invention discloses a method, a system and engineering machinery for improving arm frame movement stability. The method for improving the arm frame movement stability comprises a step of receiving elastic deformation of an arm frame, and a step of reducing the speed of movement of the arm frame when the elastic deformation exceeds a preset range, in the process of controlling the arm frame to move along a track. The faster the arm frame moves, the larger dynamic load the arm frame bears. Therefore, according to the technical scheme, reducing the speed of movement of the arm frame is beneficial for reducing the elastic deformation of the arm frame and improving the stability of the arm frame.

Owner:ZOOMLION HEAVY IND CO LTD

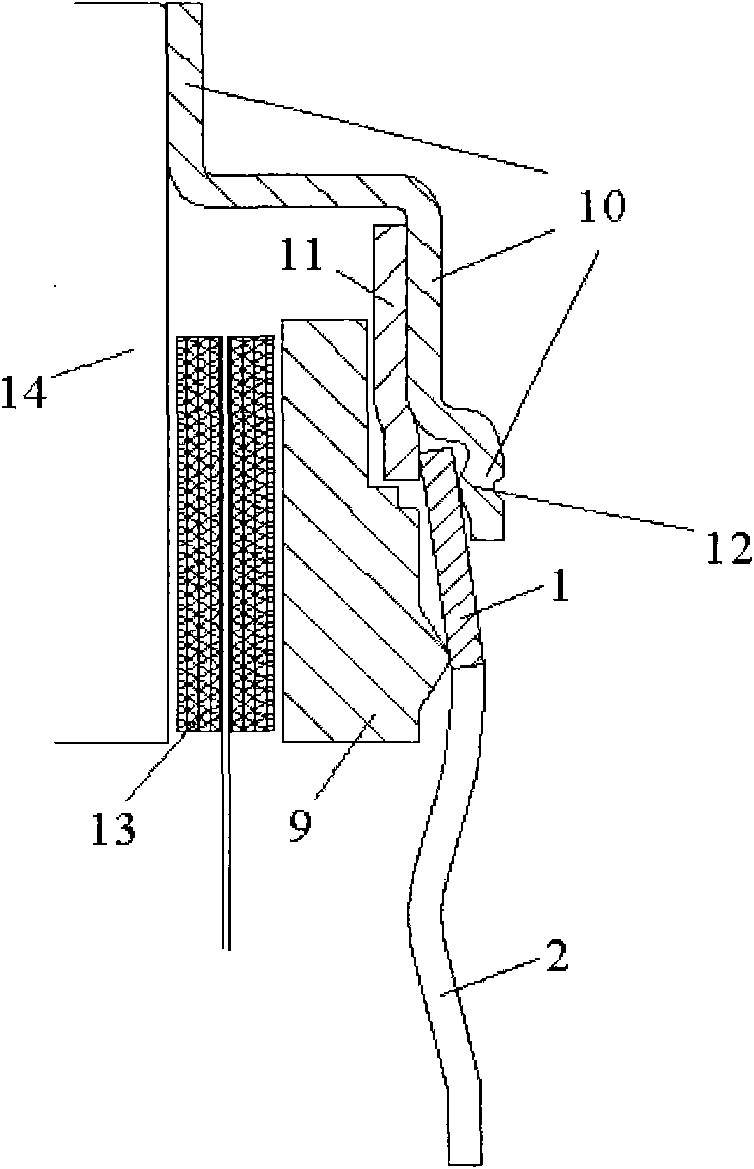

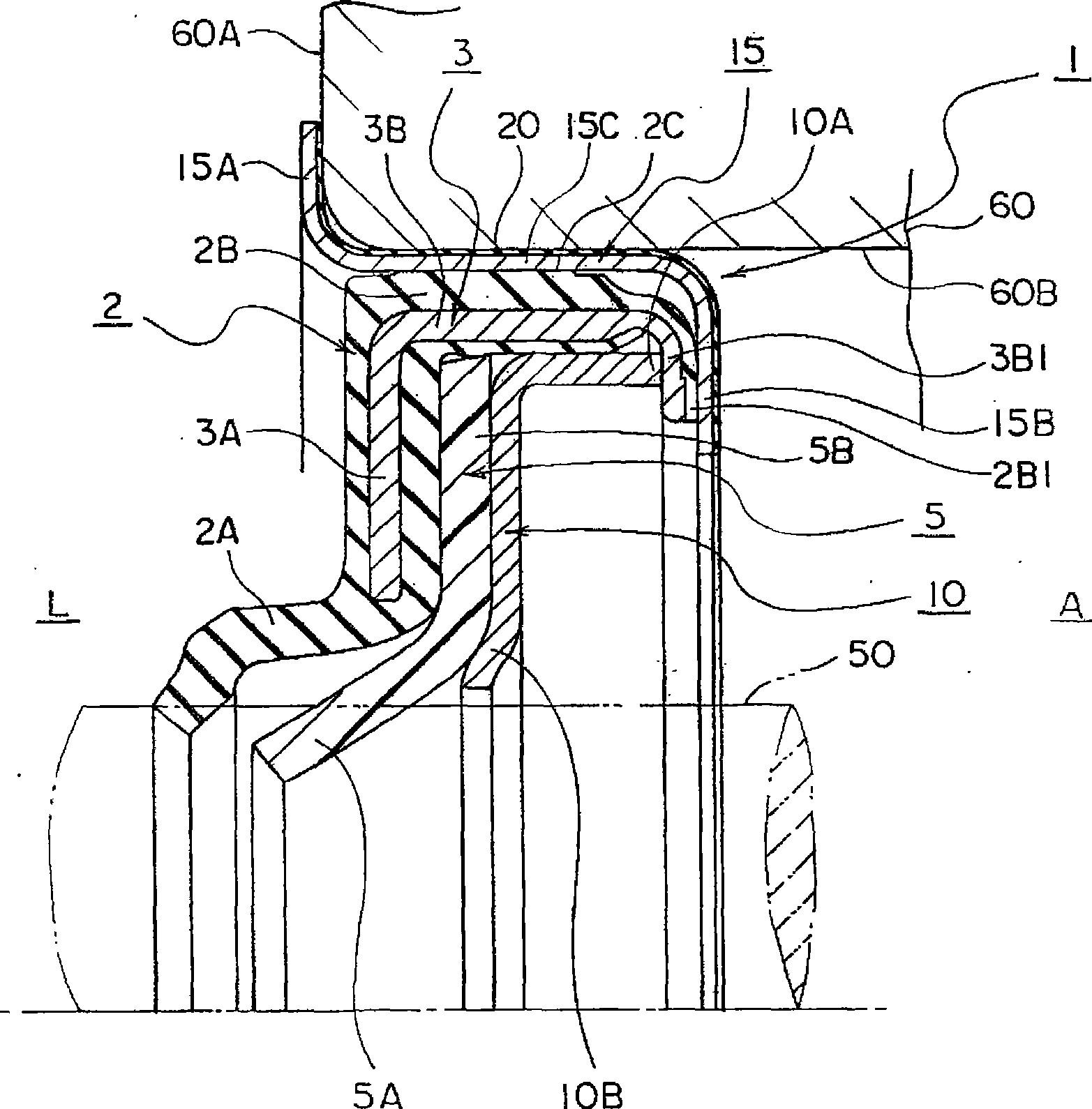

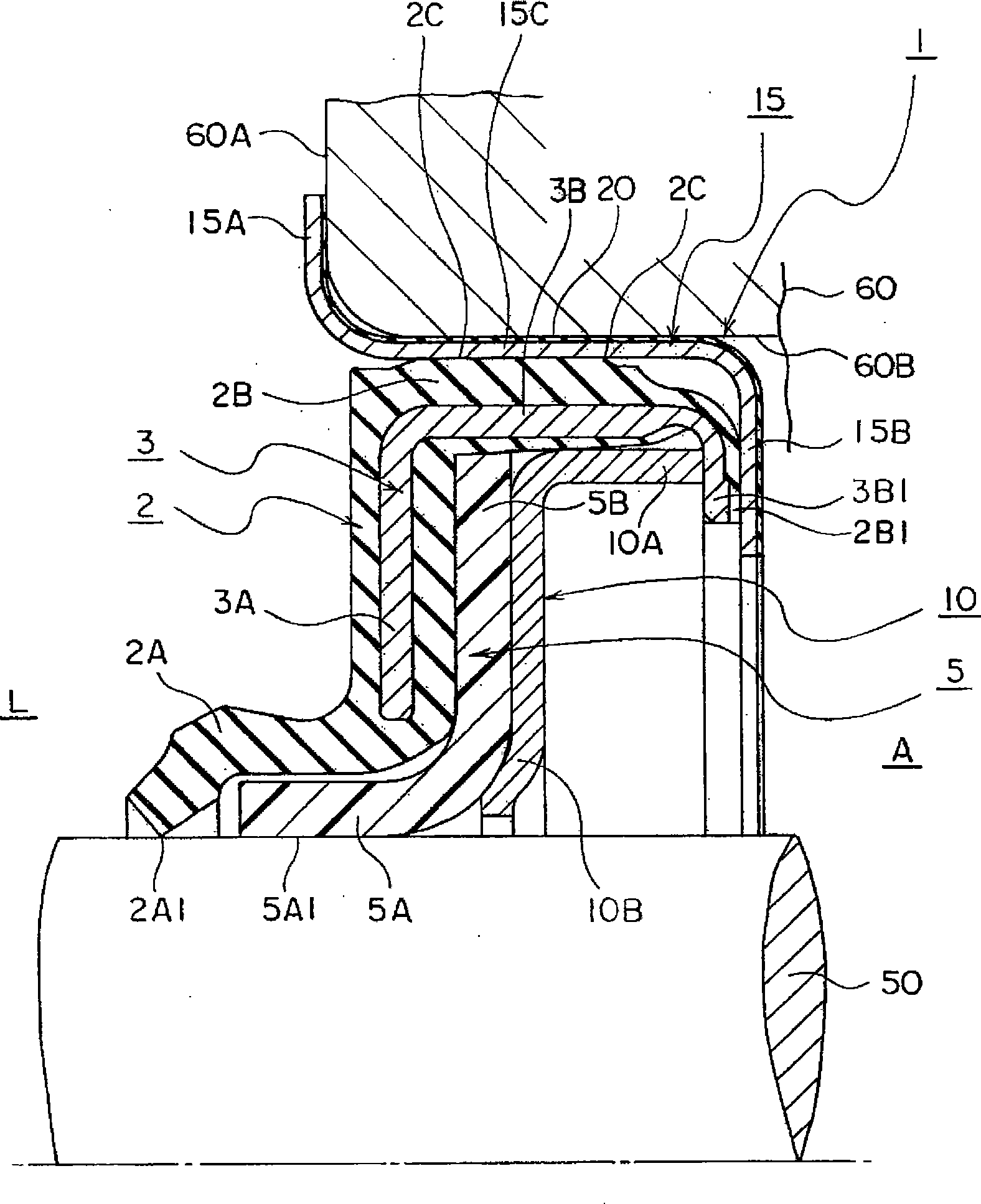

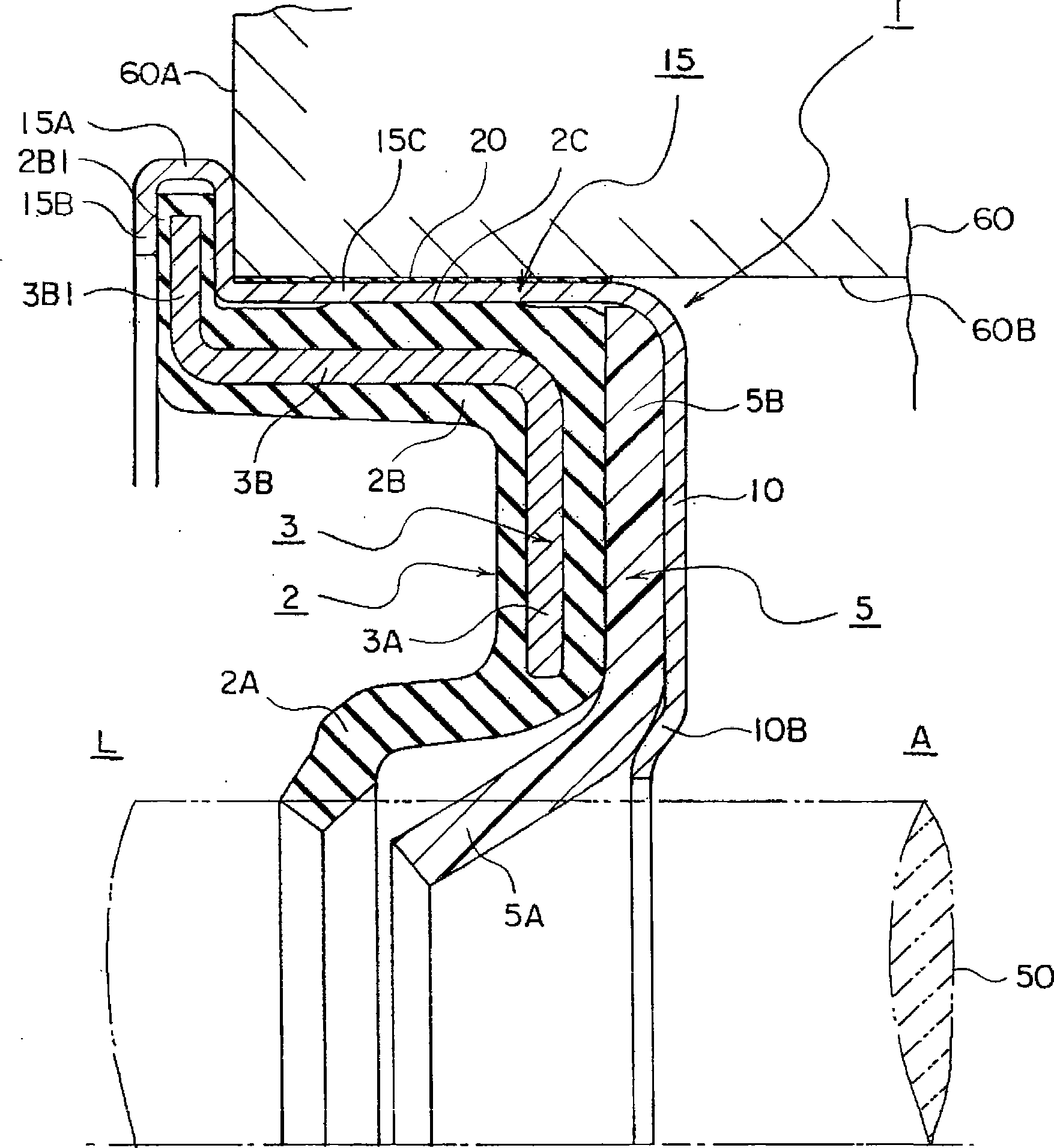

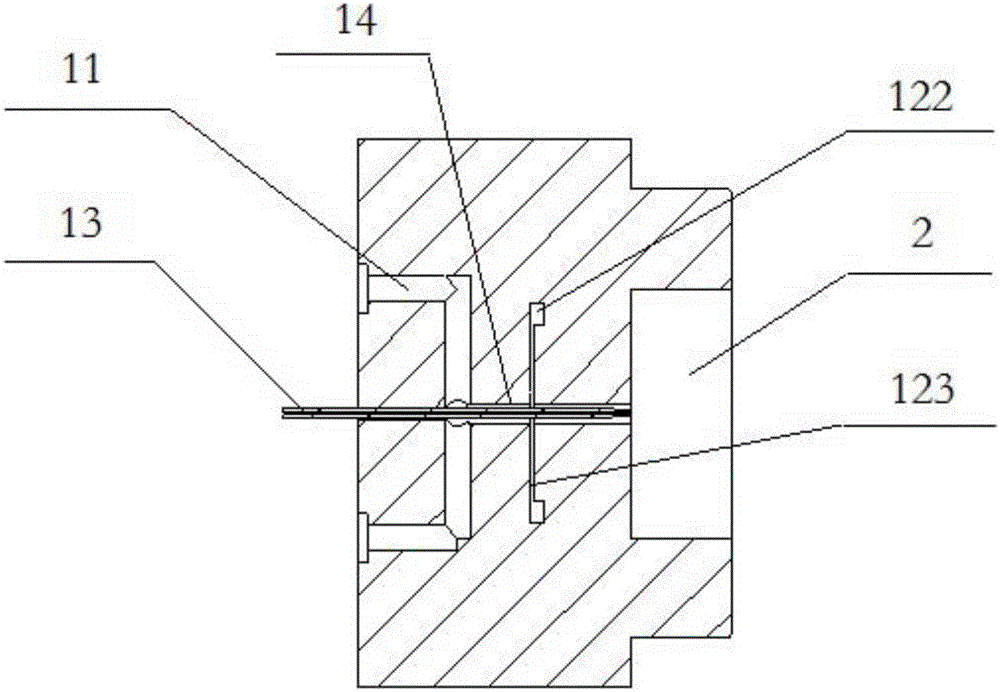

Shaft seal device

ActiveCN101501373ASimple assembly structureEasy to assembleEngine sealsEngineeringMechanical engineering

A shaft sealing device having a first seal section, a second seal section, a first back plate, and an engagement ring. The first sealing section has a fitting section fitted in a seal housing, a first seal lip whose inner peripheral surface is sealingly fitted on the outer peripheral surface of a shaft to seal fluid, and a reinforcement ring having reinforcement section for holding the first seal lip and also having a tube section and connection section that are integrally joined to the fitting section. The second seal section is made of resin, placed on the opposite side of the first seal section from the sealed fluid, and has the inner peripheral surface sealingly fitted on the shaft. The first back plate is supported by the reinforcement ring or engagement ring for holding a support section of the second seal section. The engagement ring has a fitting section fitted to a hole forming surface of the seal housing, has a first engagement section engaging with an end face of the seal housing, and has a second engagement section for causing the first engagement section to support the reinforcement ring. The device has a seal between the surface of the engagement ring and the hole forming surface, and the seal has a smaller radial thickness than the reinforcement ring or the engagement ring.

Owner:EAGLE INDS

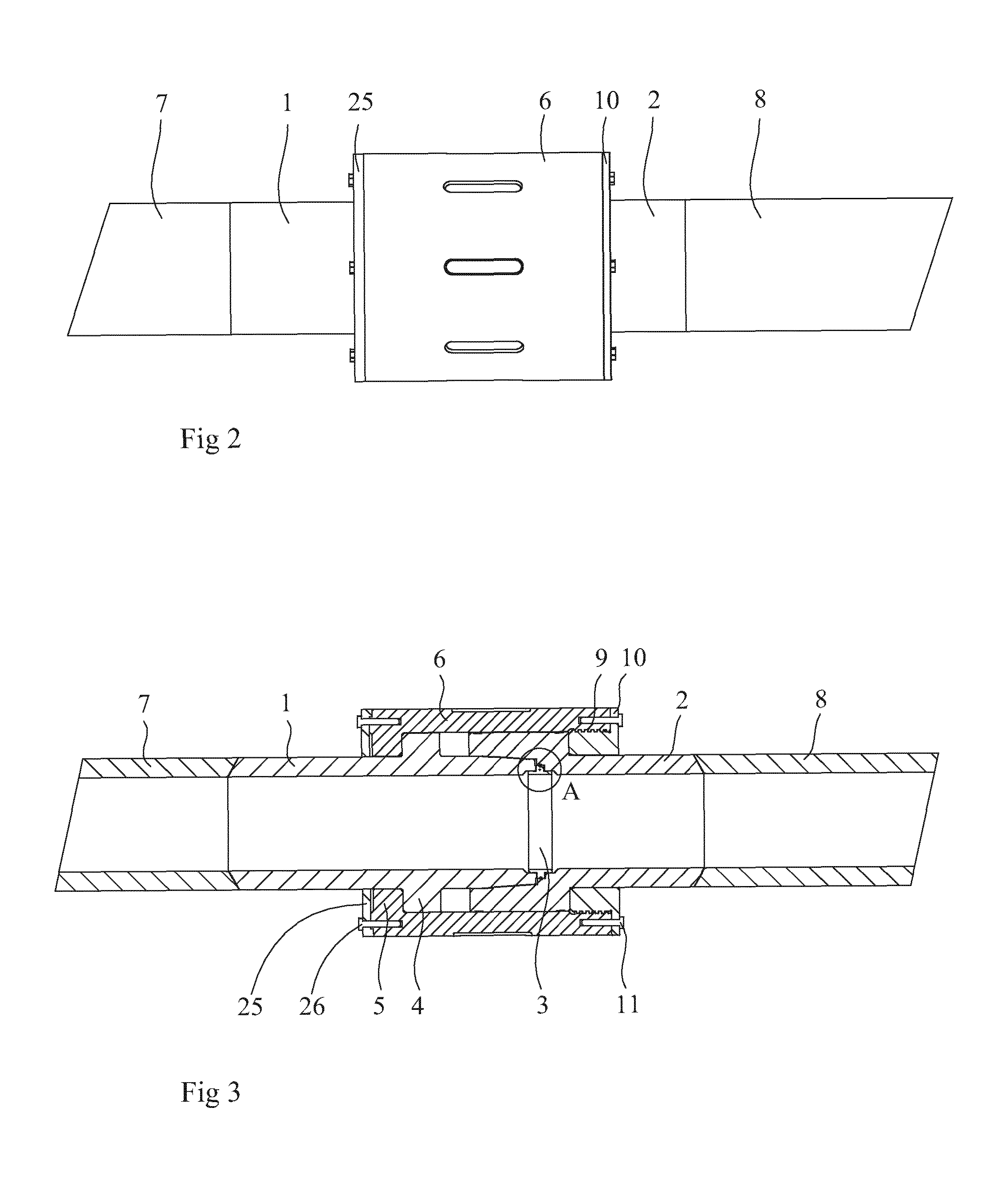

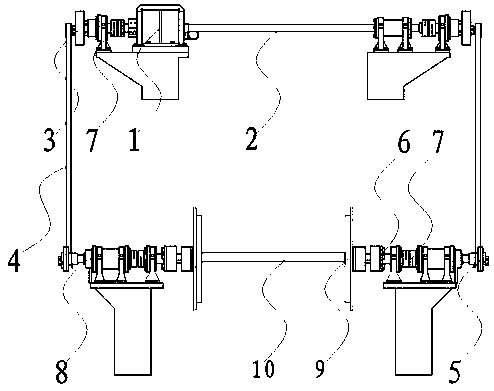

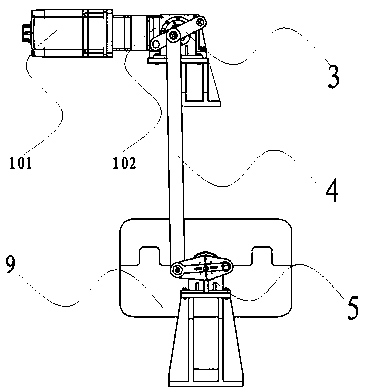

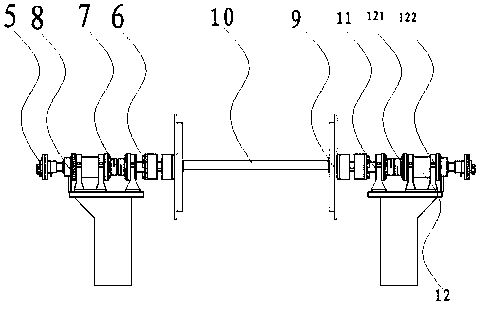

Airfoil high speed wind tunnel dynamic test device

InactiveCN109632249ASmall elastic deformationReduce control difficultyAerodynamic testingDrive shaftEngineering

The invention discloses an airfoil high speed wind tunnel dynamic test device which comprises a driving device. The driving device is connected with a driving shaft. A crank-link mechanism, a driven shaft, a balance and a rotating window bottom plate are symmetrically arranged on both ends of the driving shaft. The crank-link mechanism comprises an amplitude adjusting rod, a connecting rod and a balanced angle of attack converter. The amplitude adjusting rod is connected with both ends of the driving shaft. The amplitude adjusting rod is connected with the balanced angle of attack converter through the connecting rod. One end of the driven shaft is connected with the balanced angle of attack converter, and the other end is connected with the balance. After the driving device controls the rotation of the driving shaft, the crank-link mechanism drives the driven shaft to perform pitching oscillation. According to the invention, the airfoil high speed wind tunnel dynamic test device usessingle-motor double-end driving; double-end driving can reduce the elastic deformation of a loaded end compared with single-end driving; and compared with double-motor double-end driving, the scheme of single-motor double-end driving is simpler.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

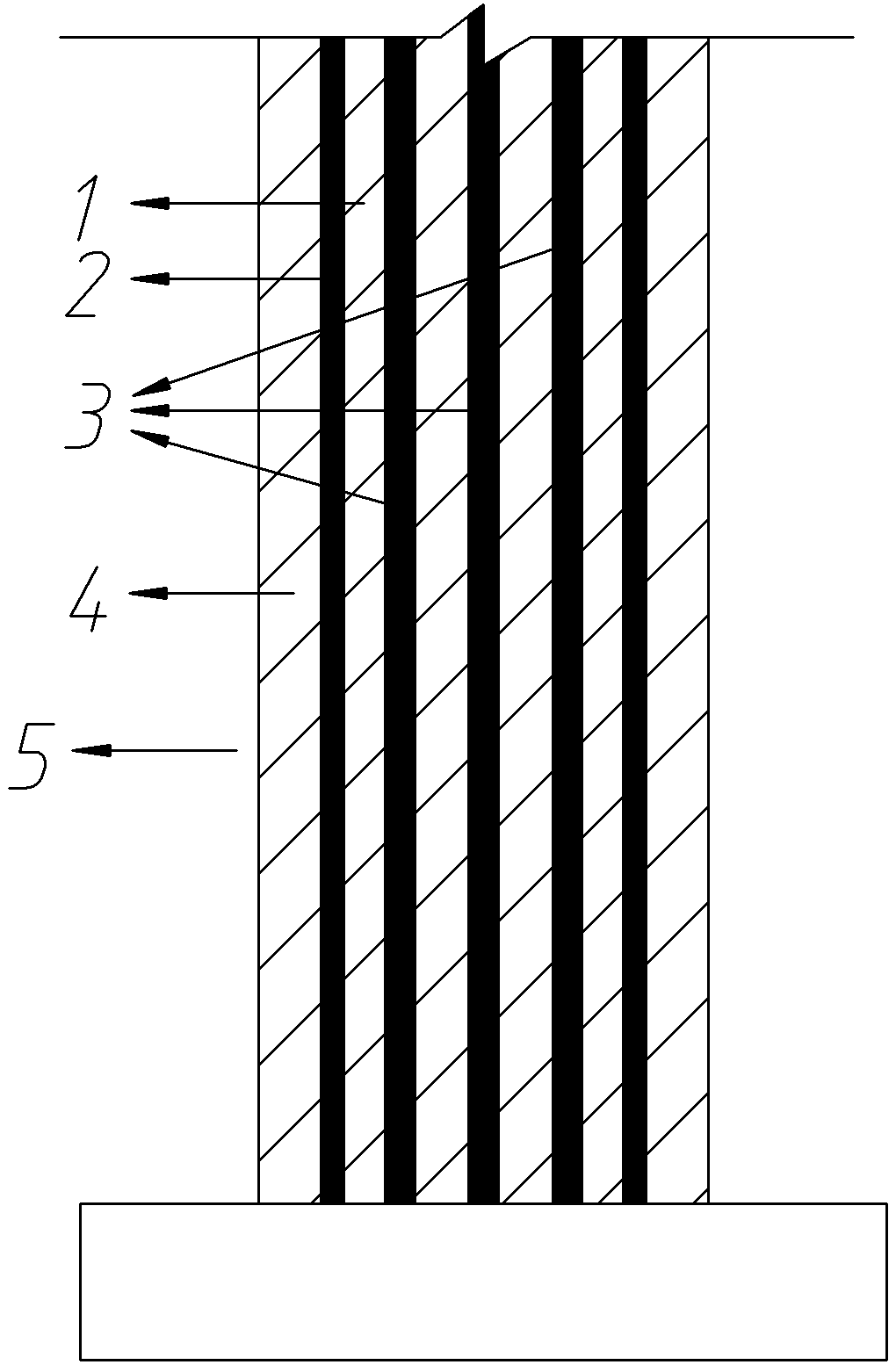

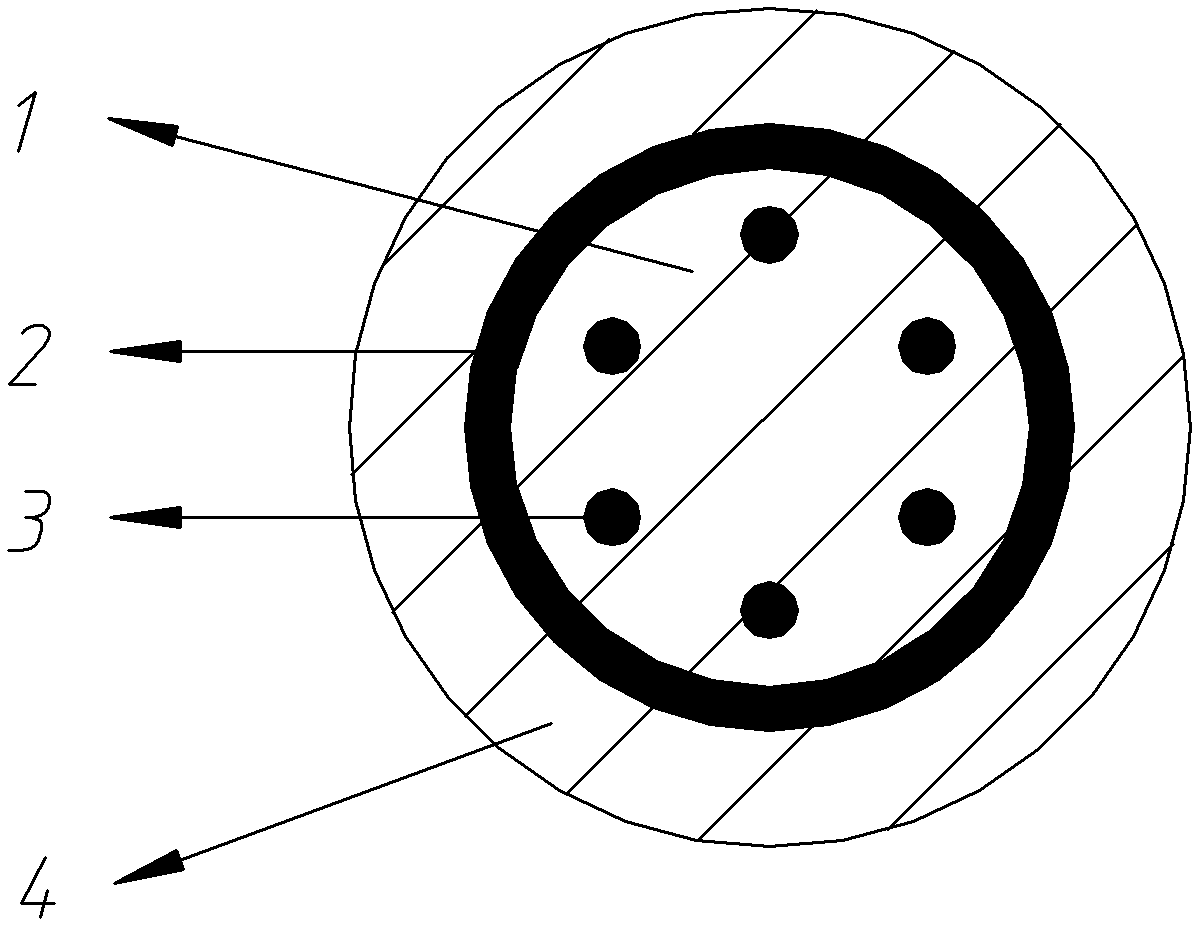

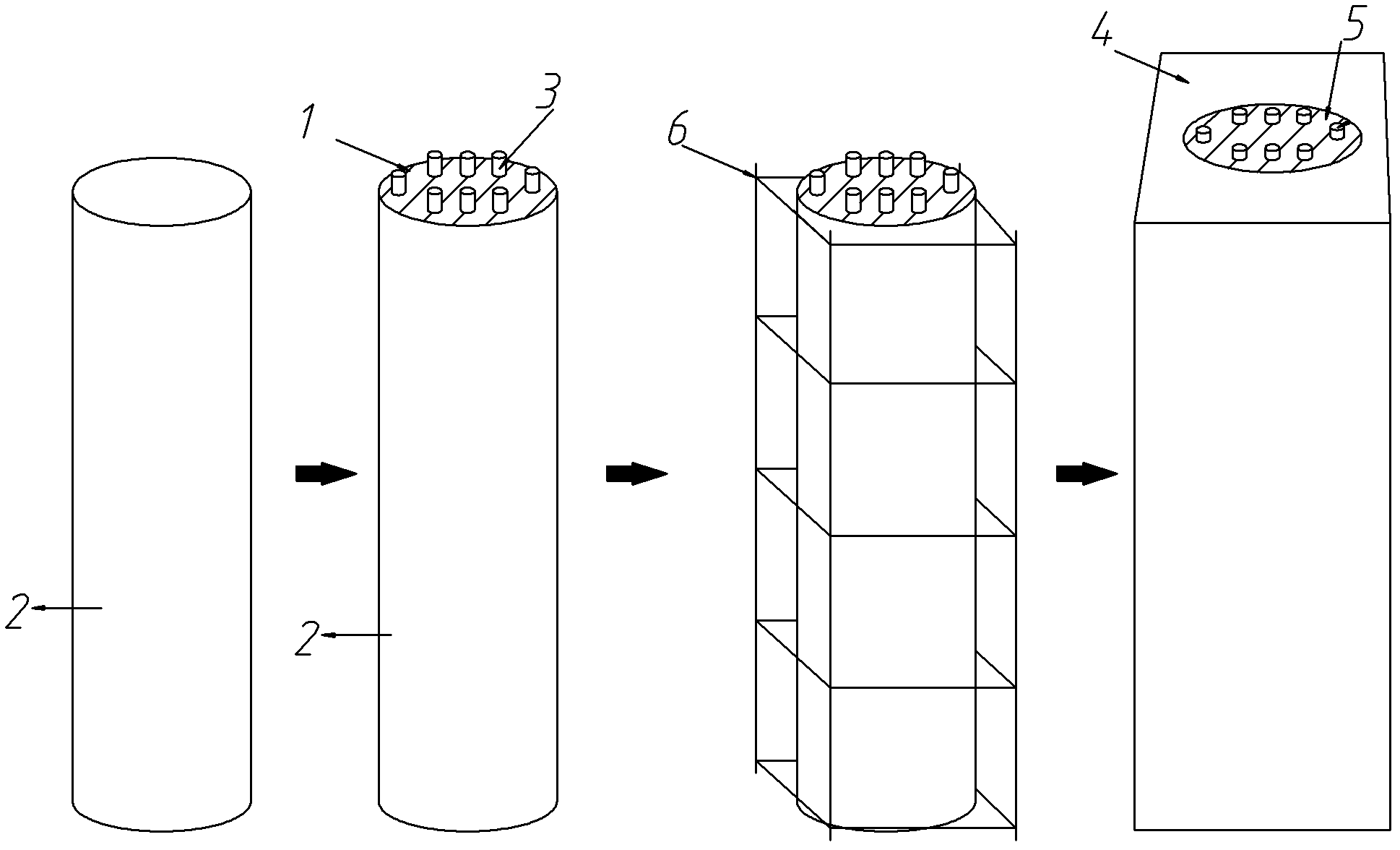

Post-tensioned prestressing steel pipe high-strength concrete superposition bridge pier and construction method thereof

InactiveCN102635063AEffective Small Bias DestructionReduce section sizeBridge structural detailsBridge erection/assemblyHigh strength concreteCarrying capacity

The invention relates to a post-tensioned prestressing steel pipe high-strength concrete superposition bridge pier and a construction method of the bridge pier. The bridge pier comprises steel pipes, wherein the steel pipes are provided with multiple unbonded tendons, pipe-in concrete is poured among the inner walls of the steel pipes and the unbonded tendons, and the steel pipes, the unbonded tendons and the pipe-in concrete form a core column; pipe-outside concrete is poured at the exterior of the core column so as to form the superposition bridge pier, the conventional reinforced concrete bridge pier is internally provided with a plurality of high-strength preforming steel pipe concrete core columns with vertical prestressing tendons; and the interior prestressing steel pipe high-strength concrete core column are installed and constructed, then a reinforced concrete framework arranged outside the bridge pier is banded and the exterior concrete is poured, namely the vertical prestressing steel pipe high-strength concrete superposition bridge pier poured by interior and exterior concrete of the steel pipe in different stages is formed, wherein the interior prestressing core column is manufactured by adopting a post-tensioning method. According to the bridge pier and the construction method, effectively improve the aseismic safety and the validity of the conventional bridge pier structure, and the bridge pier has the characteristics of high carrying capacity, good seismic performance, convenience in construction and self reset.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

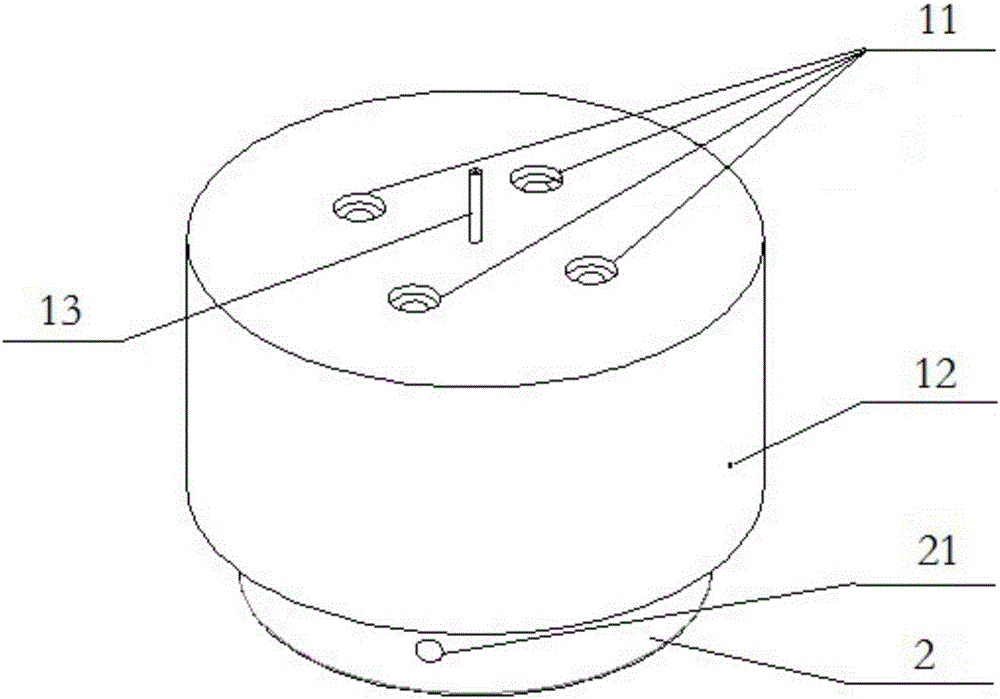

Hollow fiber membrane spinning nozzle and method for preparing hollow fiber membrane

ActiveCN106521654ANot easy to break awayGuarantee product qualityHollow filament manufactureFilament/thread formingEngineeringMembrane configuration

Disclosed are a hollow fiber membrane spinning nozzle and a method for preparing a hollow fiber membrane. The hollow fiber membrane spinning nozzle comprises a nozzle body with a solution channel, wherein a channel I, a channel II, a central liquid pipe, a liquid collection pipe and a spinning shaping area are arranged in the nozzle body, tail ends of the channel I and the channel II are both connected with the liquid collection pipe, the central liquid pipe is arranged at the center of the nozzle body, and the lower half portion of the central liquid pipe passes through the liquid collection pipe and extends to the spinning shaping area. A spinning solution for preparing the hollow fiber membrane is injected into the hollow fiber membrane spinning nozzle respectively through the channel I and the channel II, converges in the liquid collection pipe, and then is contacted with core liquid for solvent exchange, and finally forms the membrane through spinning. According to the hollow fiber membrane spinning nozzle and the method for preparing the hollow fiber membrane, the spinning solution converges well, and a stratification phenomenon of membrane filaments is avoided. A separating layer and a support layer of the hollow fiber membrane prepared by the hollow fiber membrane spinning nozzle are tightly combined, and can not be separated or layered, and the hollow fiber membrane has good selective permeability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

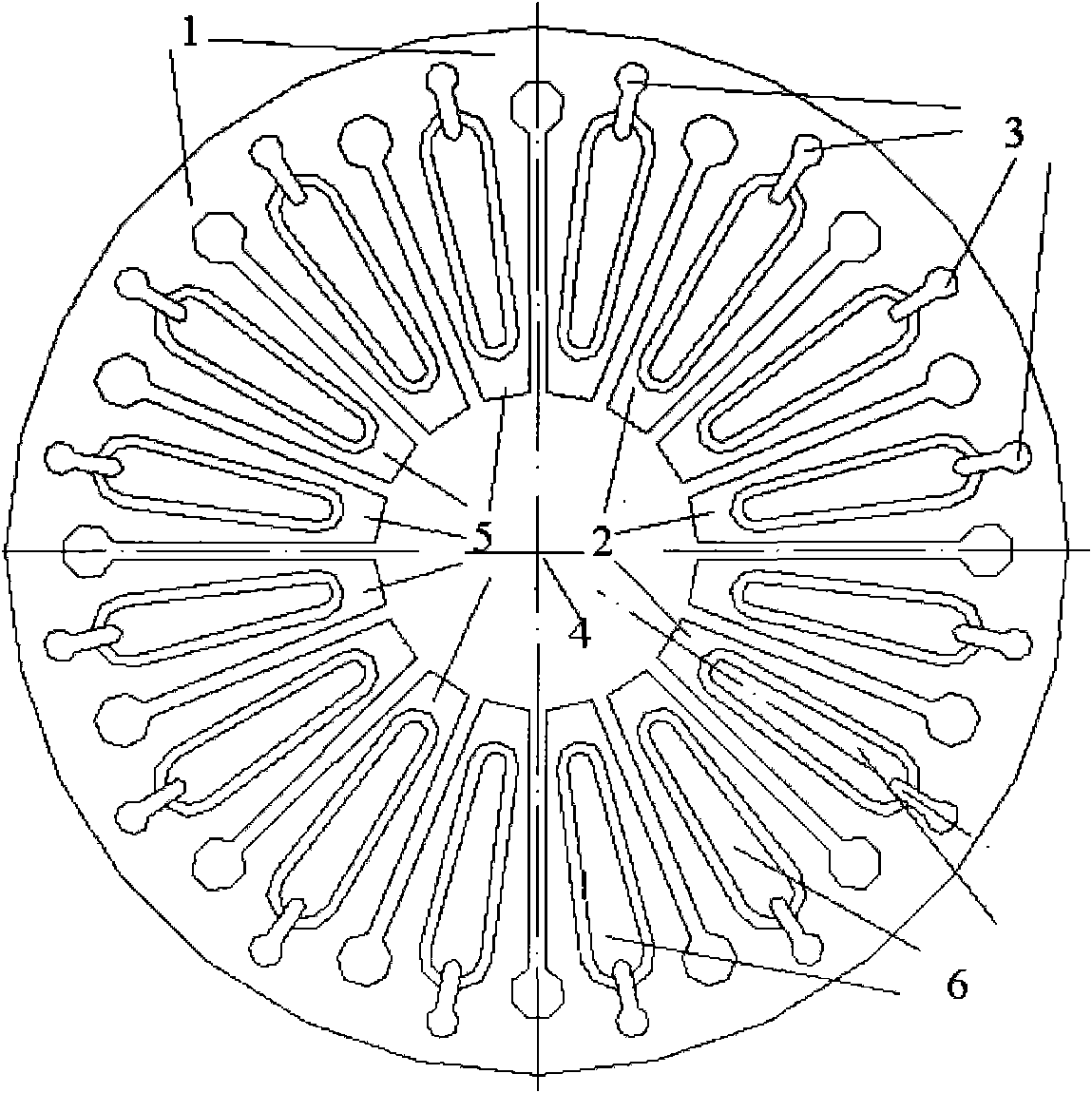

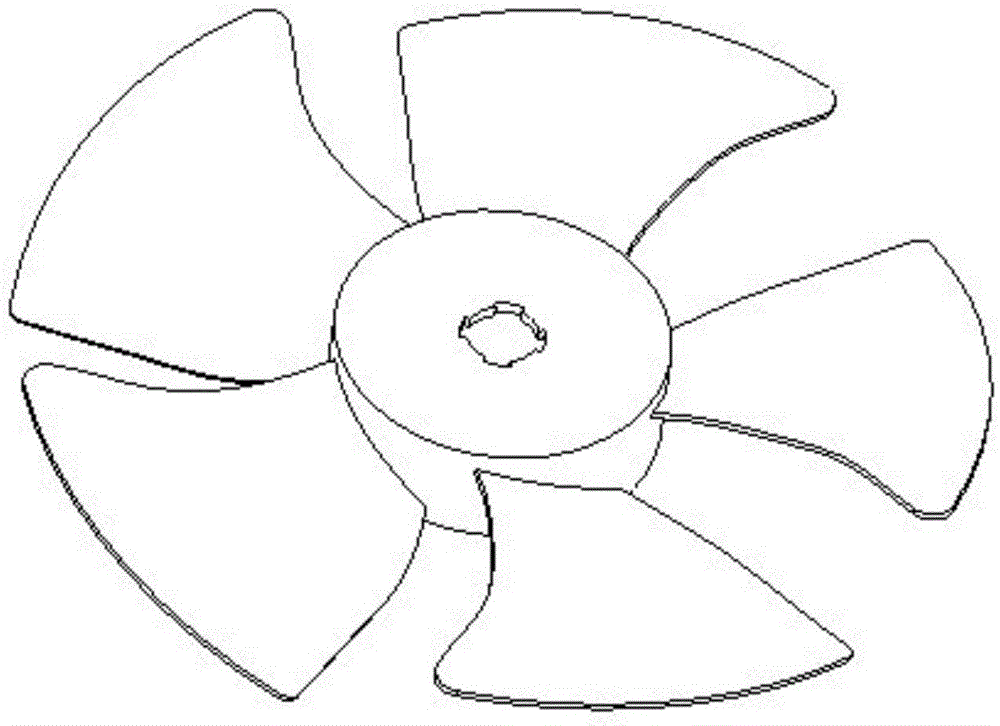

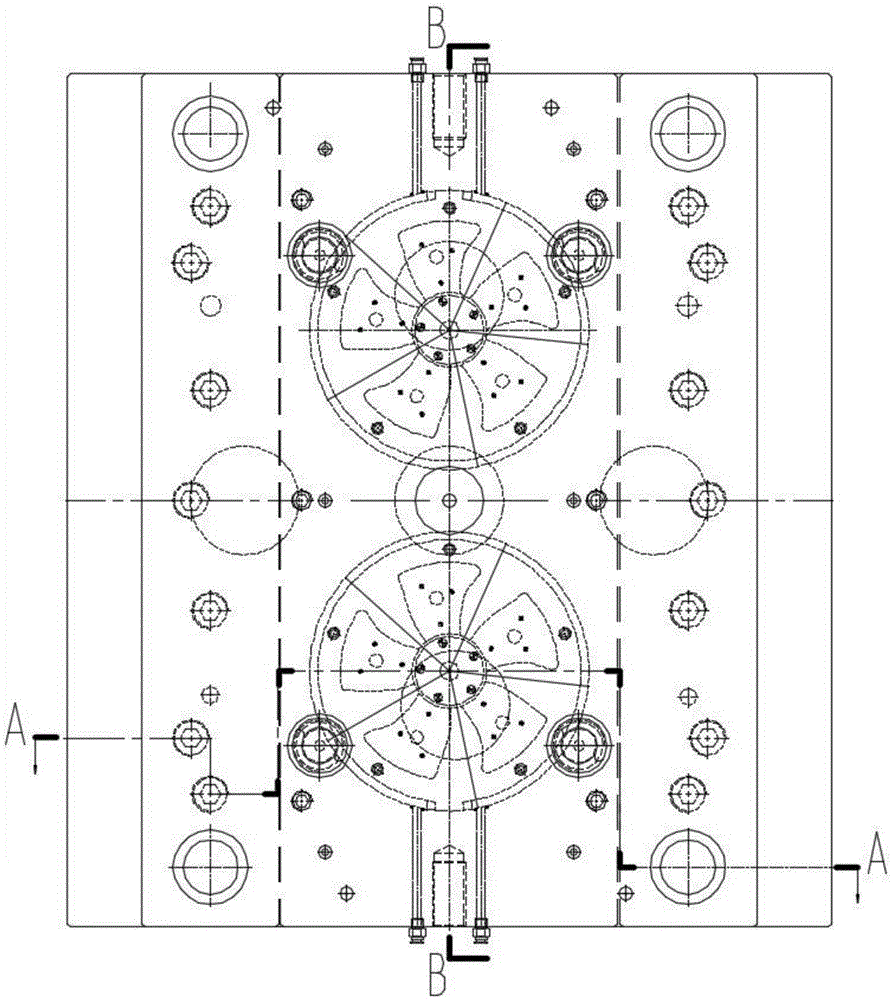

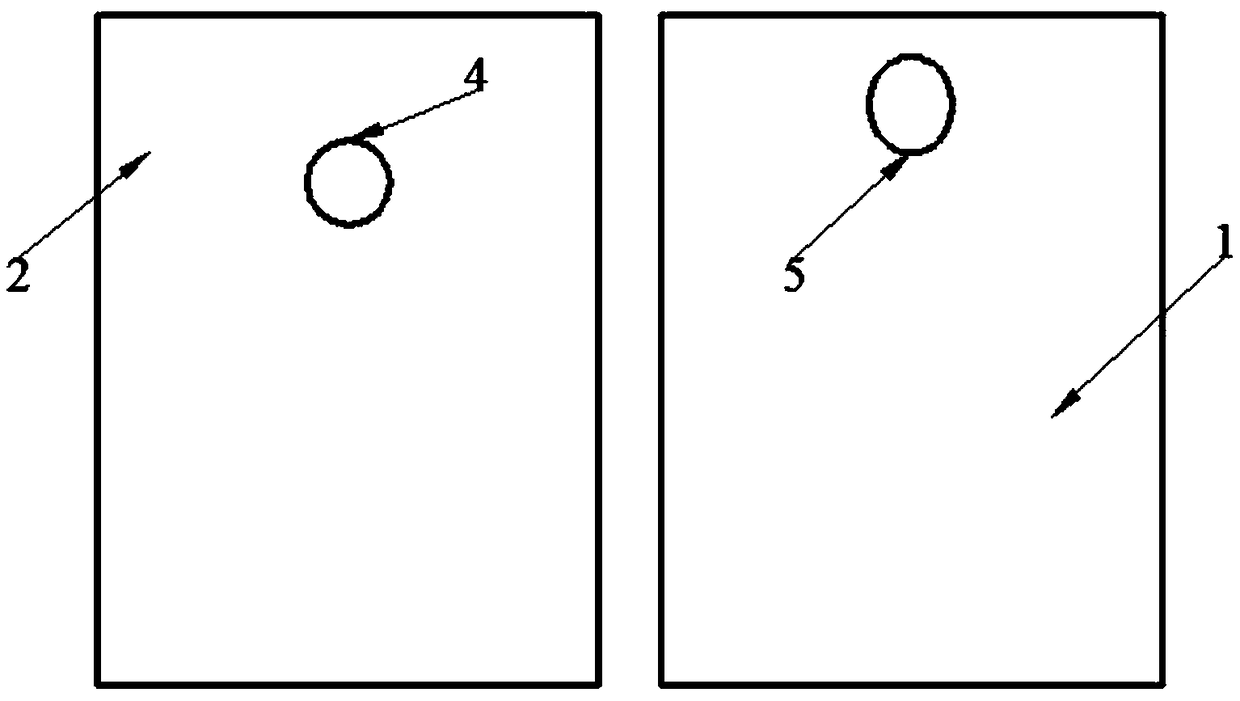

Fan blade injection mold for exhaust fan

The invention discloses a fan blade injection mold for an exhaust fan. The fan blade injection mold comprises a fixed mold assembly (1) and a movable mold assembly (2). A cavity (13) and a mold core (24) are both of a cylindrical split structure and comprise a plurality of structure-identical fan-shaped sub-cavities (131) and fan-shaped sub-mold cores (241) respectively, and the number of the fan-shaped sub-cavities and the fan-shaped sub-mold cores is equal to that of blades of a fan blade. The multiple sub-cavities are assembled in the circumferential direction to form an upper surface structure of the whole fan blade. The multiple sub-mold cores are assembled in the circumferential direction to form a lower surface structure of the whole fan blade. Circular-arc-shaped grooves are formed in circumferential direction of the cylindrical faces of the cavity and the mold core which are of the cylindrical split structure. The circular-arc-shaped grooves of the cavity are in sealed communication with a cooling water channel inside a fixed mold plate through the ends. The circular-arc-shaped grooves of the mold core are in sealed communication with a cooling water channel inside a movable mold plate through the ends. The cavity and the mold core of the fan blade injection mold for the exhaust fan are easy to process, and low mold manufacturing cost and mold maintaining cost can be achieved.

Owner:JIUZHOU VOCATION TECH COLLEGE

Novel hard alloy cold forging die for combined gear ring

InactiveCN102806297ASmall elastic deformationGuaranteed accuracyForging/hammering/pressing machinesStress concentrationAlloy

The invention discloses a novel hard alloy cold forging die for a combined gear ring. The hard alloy cold forging die comprises a tooth-shaped female die and a prestress outer ring arranged on an outer ring of the tooth-shaped female die, wherein the tooth-shaped female die has a split structure, and comprises a tooth-shaped die core and a lower die core; the tooth-shaped die core wraps the lower die core; and the prestress outer ring wraps the tooth-shaped die core. Compared with the prior art, the hard alloy cold forging die has the advantages that the tooth-shaped die core has a split structure, so that the defect that the die is cracked early due to stress concentration at a sharp corner of the die is overcome, and the service life of the die is prolonged; and the die is made of a hard alloy material, so that tooth-shaped elastic deformation is small, the tooth-shaped accuracy can be ensured, and the anti-wearing performance can also be improved greatly.

Owner:TAICANG JIUXIN PRECISION MOLD

Method for improving laser shock precision and efficiency of weak rigidity parts

ActiveCN109022756AHigh precisionImprove efficiencyHeat treatment process controlShape changeClassical mechanics

The invention belongs to the technical field of laser shock strengthening, and discloses a method for improving laser shock precision and efficiency of weak rigidity parts. The method comprises the steps that the rigidity of the weak rigidity parts is analyzed by UG three-dimensional software, and shock regions with different rigidity are obtained; laser shock parameters are set, laser with smaller power density is used in the area with weaker rigidity, and laser with larger power density is used in the area with larger rigidity; the depth and strength of residual compressive stress can meet the requirements by adjusting pulse width and increasing shock times; and a sensor is used to monitor the elastic deformation of the weak rigidity parts during processing, and parameters controlling and deformation monitoring are repeated so as to finally improve the laser shock precision and efficiency of the weak rigidity parts. According to the method for improving the laser shock precision andefficiency of the weak rigidity parts, the laser shock is carried out on different rigidity regions of parts by changing the laser parameters in real time, so that the elastic deformation degree is reduced, and the elastic deformation recovery time is shortened; and shocking parts under the condition of excessive elastic deformation which causes spot shape change and action position deviation to affect processing precision and strengthening effect is avoided.

Owner:GUANGDONG UNIV OF TECH

Impact tool

InactiveCN101011821AReduce noiseSuppresses propagating vibrationPortable percussive toolsPower driven toolsShock absorberTipped tool

An impact tool, which can realize the reduction of noise without inviting the reduction of a fastening ability and which can improve the durability of a damper while preventing its damage. The impact tool includes a rotary impact mechanism mounted on a spindle to be rotationally driven by a motor, so that rotary impact is applied to a tip tool by transmitting the rotary impact intermittently from a hammer through an anvil to the tip tool. A plurality of pawls are formed on two half members of the anvil in the axial direction. A rubber damper is disposed in a space between the pawls arranged alternately in the circumferential direction of the two half members. The minimum sectional area of the space formed between the pawls is set larger than the sectional area of the rubber damper.

Owner:KOKI HLDG CO LTD

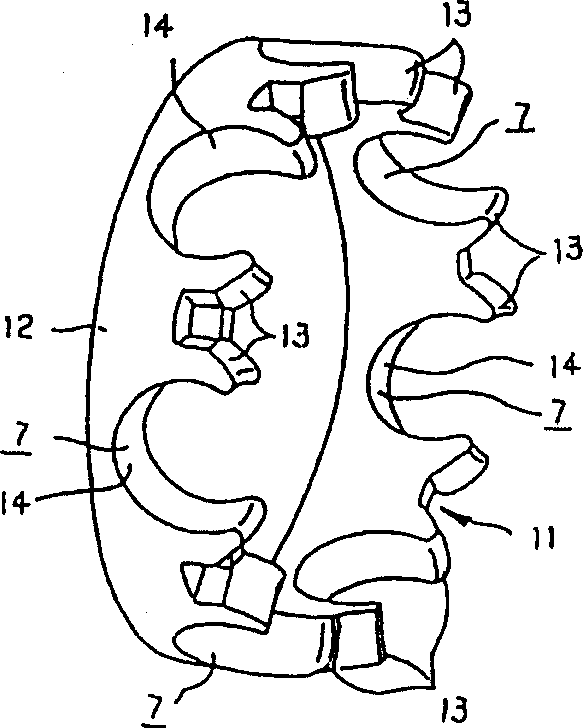

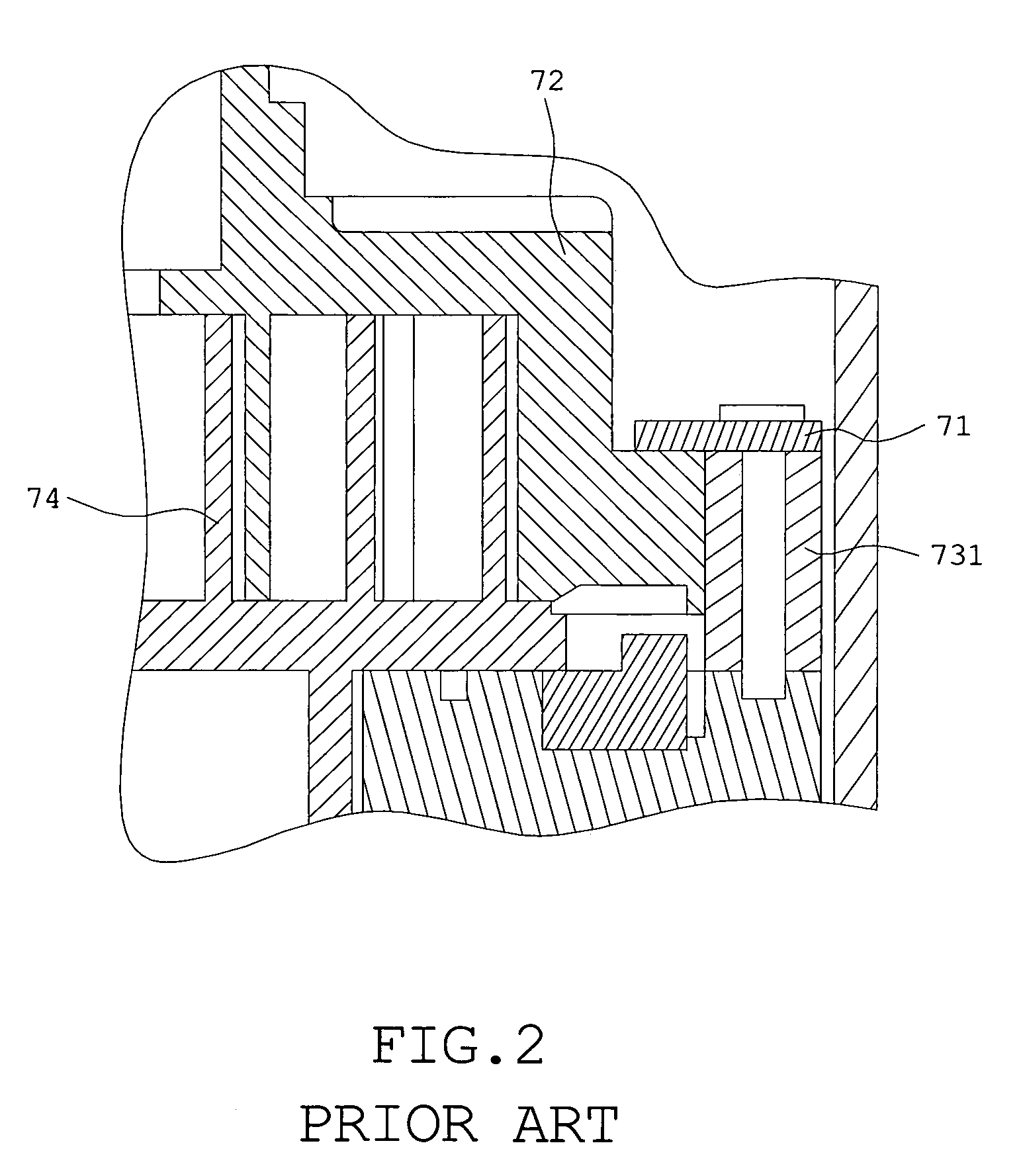

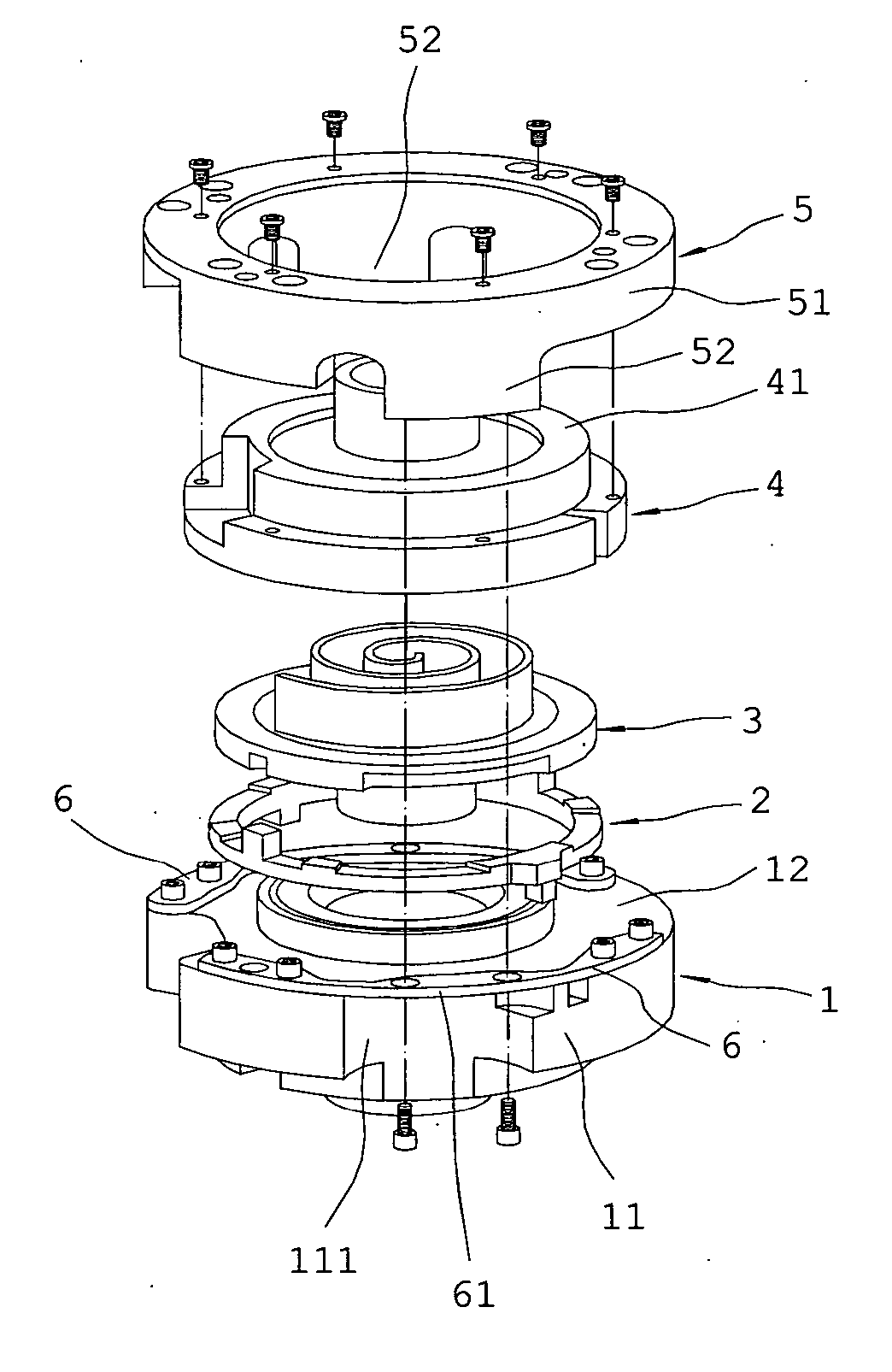

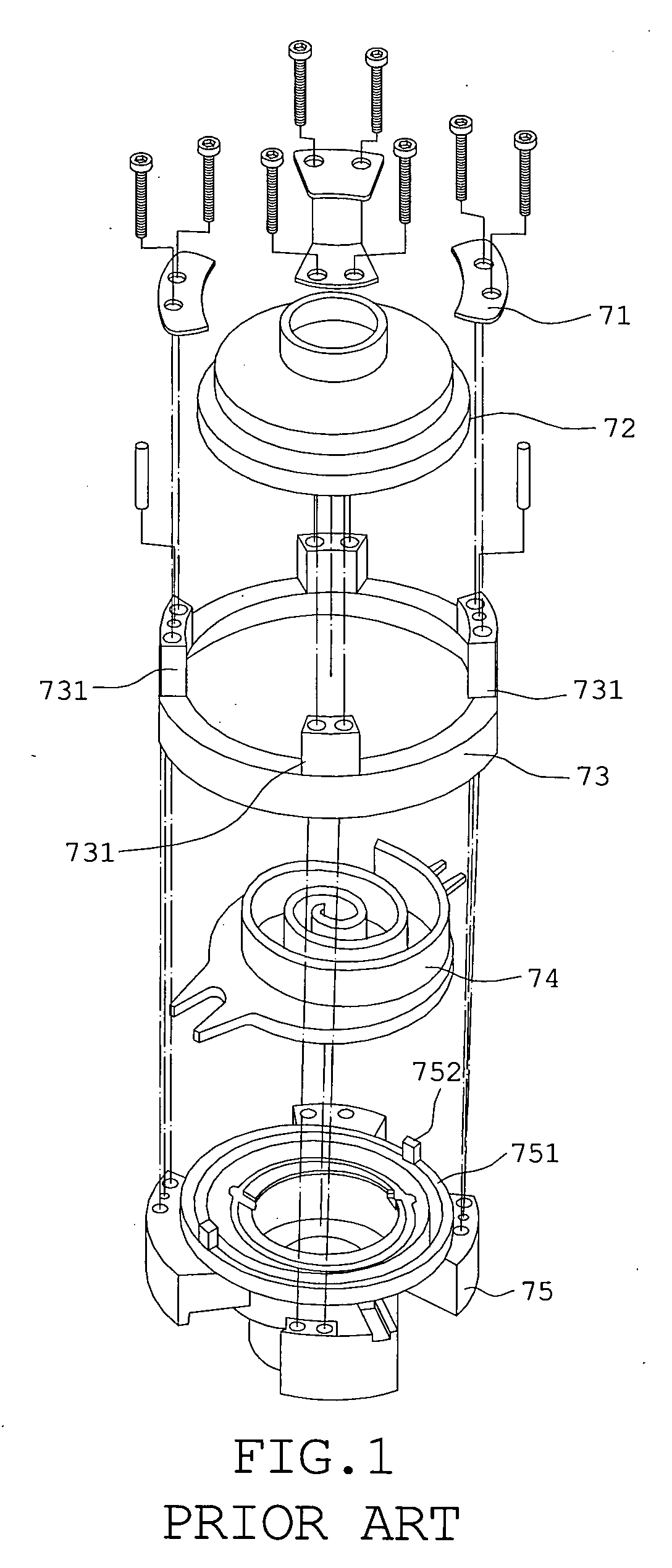

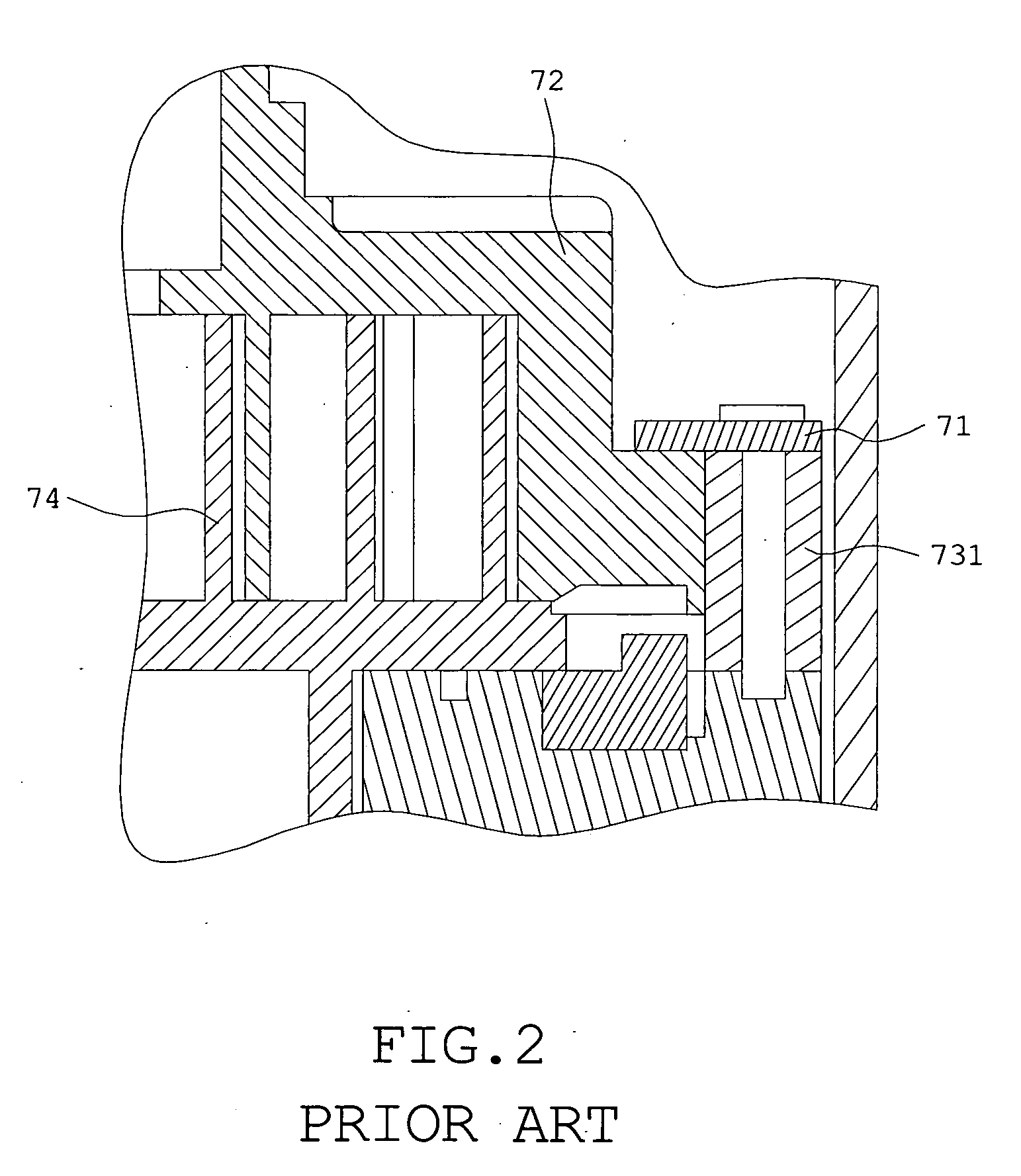

Scroll apparatus with an axial gap control function

ActiveUS7275918B2Reduce frictionPrevent leakageEngine of arcuate-engagement typeOscillating piston enginesEngineeringMechanical engineering

A scroll apparatus with an axial gap control function is described. The scroll apparatus is capable of controlling the axial gap between its fixed scroll and orbiting scroll. The scroll apparatus has a frame with a pair of indentations installed in the casing of the scroll apparatus, a pair of flexible elements installed at the lateral side top of the frame and spanning the pair of indentations for defining a suspended flexible segment at the span, a sidewall having a positioning ring with a downward protruding body corresponding to the indentation, in which the protruding body of the positioning ring is fixed to the flexible segment of the flexible element, a fixed scroll suspended at the positioning ring, and an orbiting scroll for orbiting into the fixed scroll.

Owner:IND TECH RES INST

Scroll apparatus with an axial gap control function

ActiveUS20060147331A1Reduce frictionPrevent leakageEngine of arcuate-engagement typeOscillating piston enginesEngineeringMechanical engineering

A scroll apparatus with an axial gap control function is described. The scroll apparatus is capable of controlling the axial gap between its fixed scroll and orbiting scroll. The scroll apparatus has a frame with a pair of indentations installed in the casing of the scroll apparatus, a pair of flexible elements installed at the lateral side top of the frame and spanning the pair of indentations for defining a suspended flexible segment at the span, a sidewall having a positioning ring with a downward protruding body corresponding to the indentation, in which the protruding body of the positioning ring is fixed to the flexible segment of the flexible element, a fixed scroll suspended at the positioning ring, and an orbiting scroll for orbiting into the fixed scroll.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com