Method for improving laser shock precision and efficiency of weak rigidity parts

A laser shock and weak stiffness technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems affecting laser shock strengthening, changing the position of laser processing, reducing processing efficiency, etc., to achieve precise processing and reduce recovery Time, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

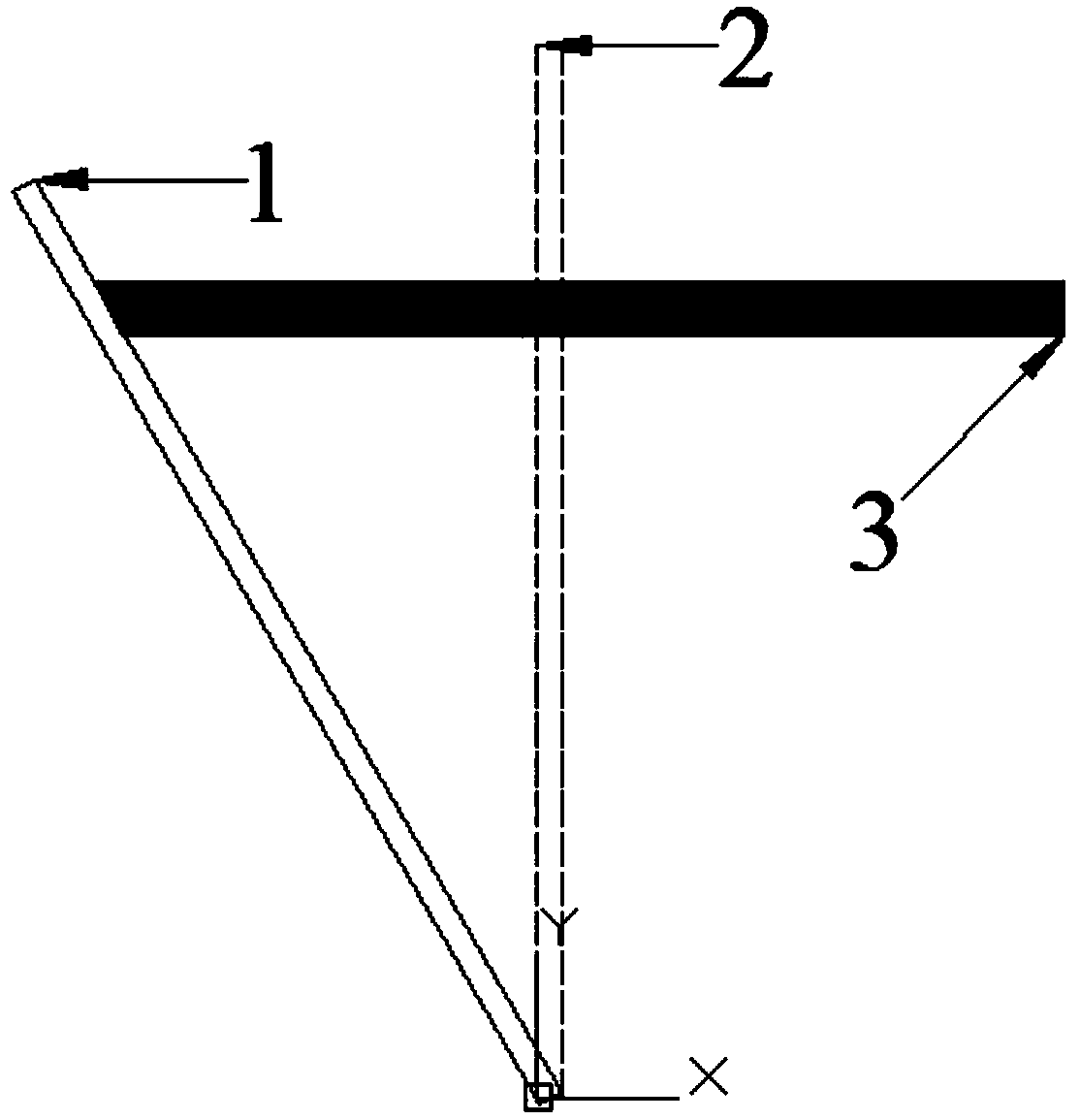

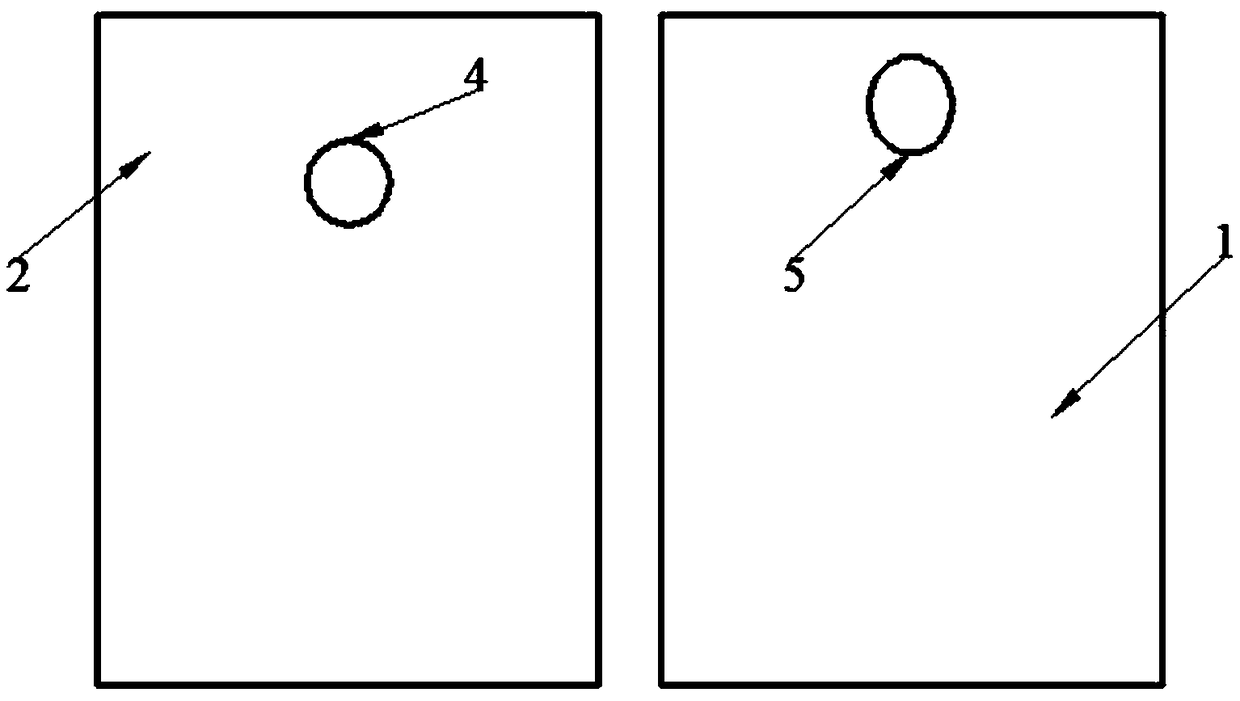

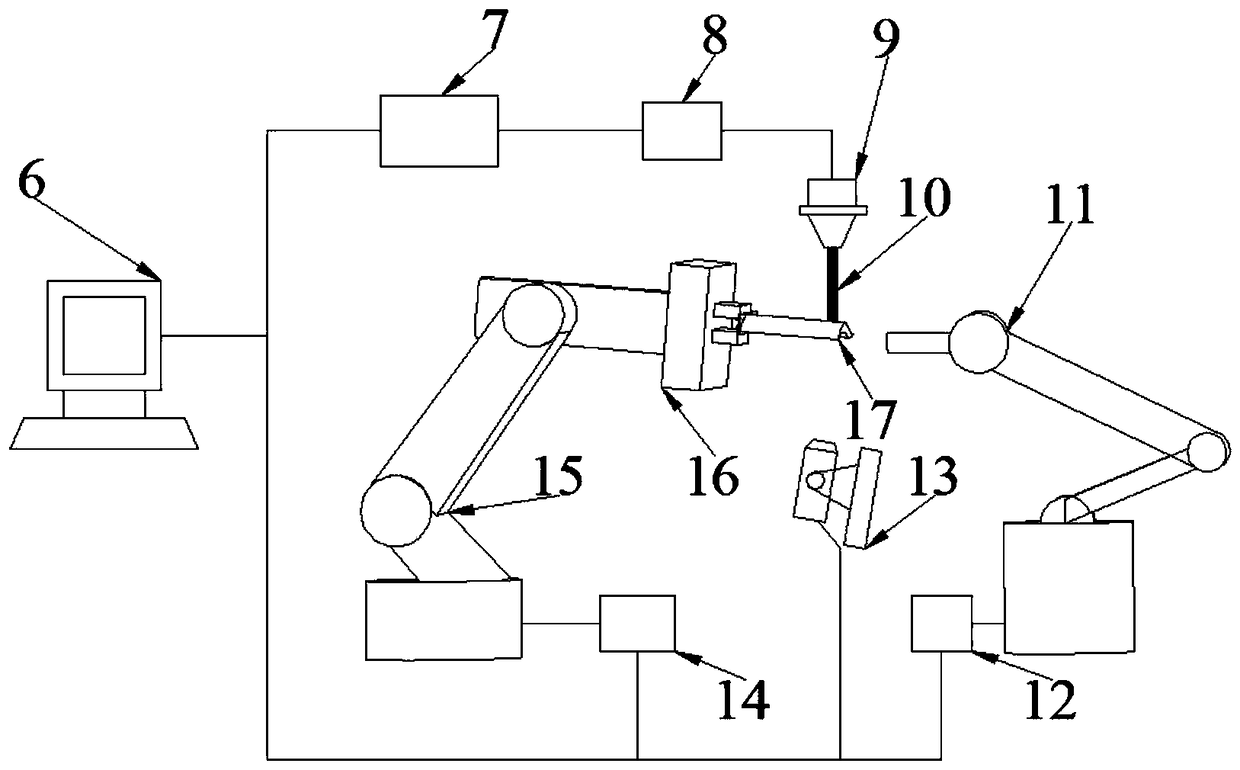

[0026] figure 1 Schematic diagram of the elastic deformation of a weakly rigid part subjected to laser shock. figure 2 It is a schematic diagram of the comparison of the spot shape of the laser beam hitting the thin plate and the deformed thin plate. Among them, 1 is the elastically deformed thin plate, 2 is the thin plate, 3 is the pulsed laser beam, 4 is the light spot on the thin plate, and 5 is the light spot on the deformed thin plate. Such as figure 1 As shown, under the action of the laser shock wave force, the weak stiffness area of the part will undergo elastic deformation. When the deformation hits the target, the laser beam cannot act on the part perpendicularly, which will cause the spot shape to change when the laser beam hits the thin plate. , at the same time the position of the laser action has shifted, such as figure 2 shown. This makes the laser energy distribution, overlapping rate, etc. inconsistent with the set parameters, and the area where the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com