Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Cerebellum granule cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerebellar granule cells form the thick granular layer of the cerebellar cortex and are among the smallest neurons in the brain. (The term granule cell is used for several unrelated types of small neurons in various parts of the brain.) Cerebellar granule cells are also the most numerous neurons in the brain: in humans, estimates of their total number average around 50 billion, which means that they constitute about 3/4 of the brain's neurons.

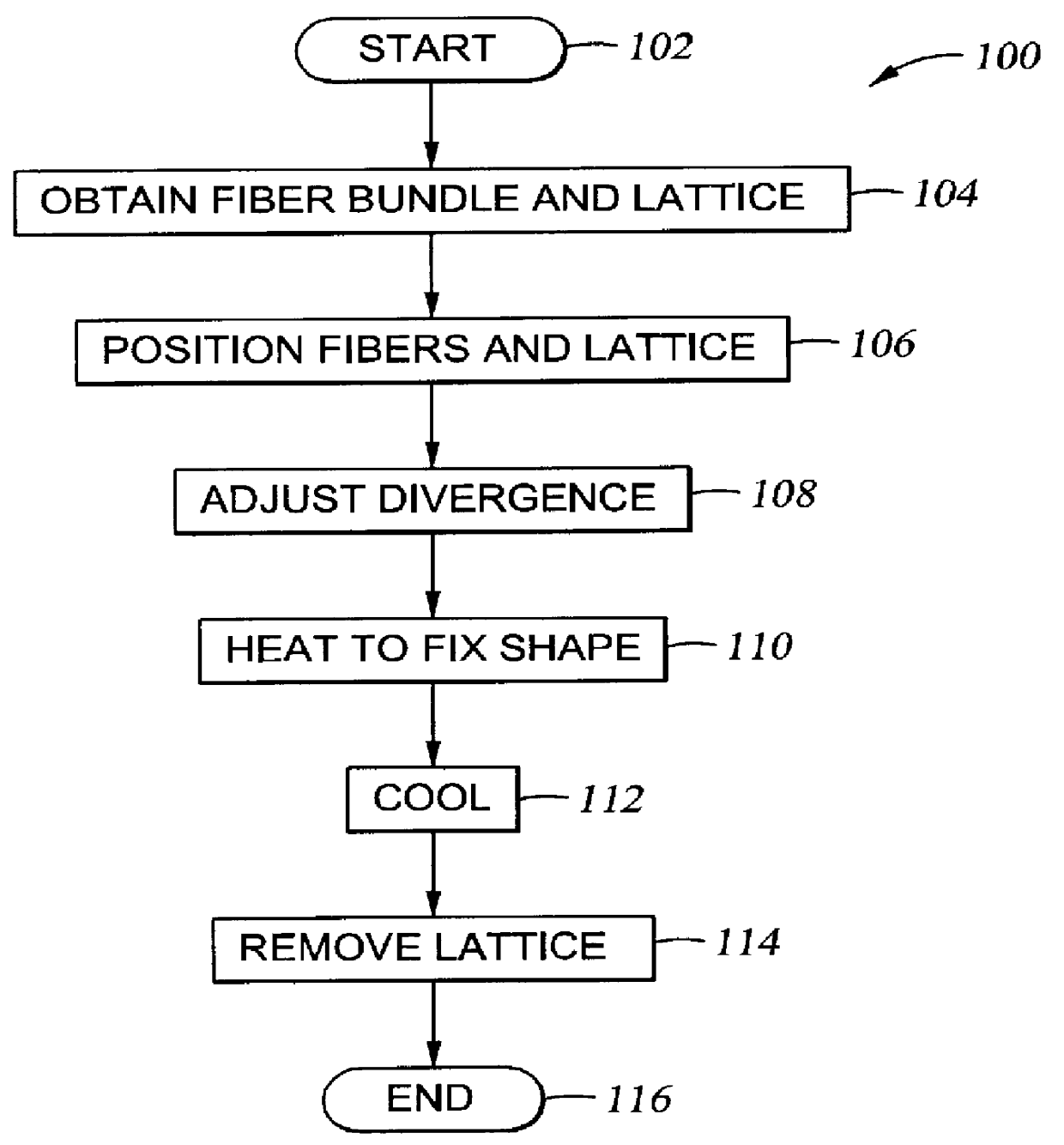

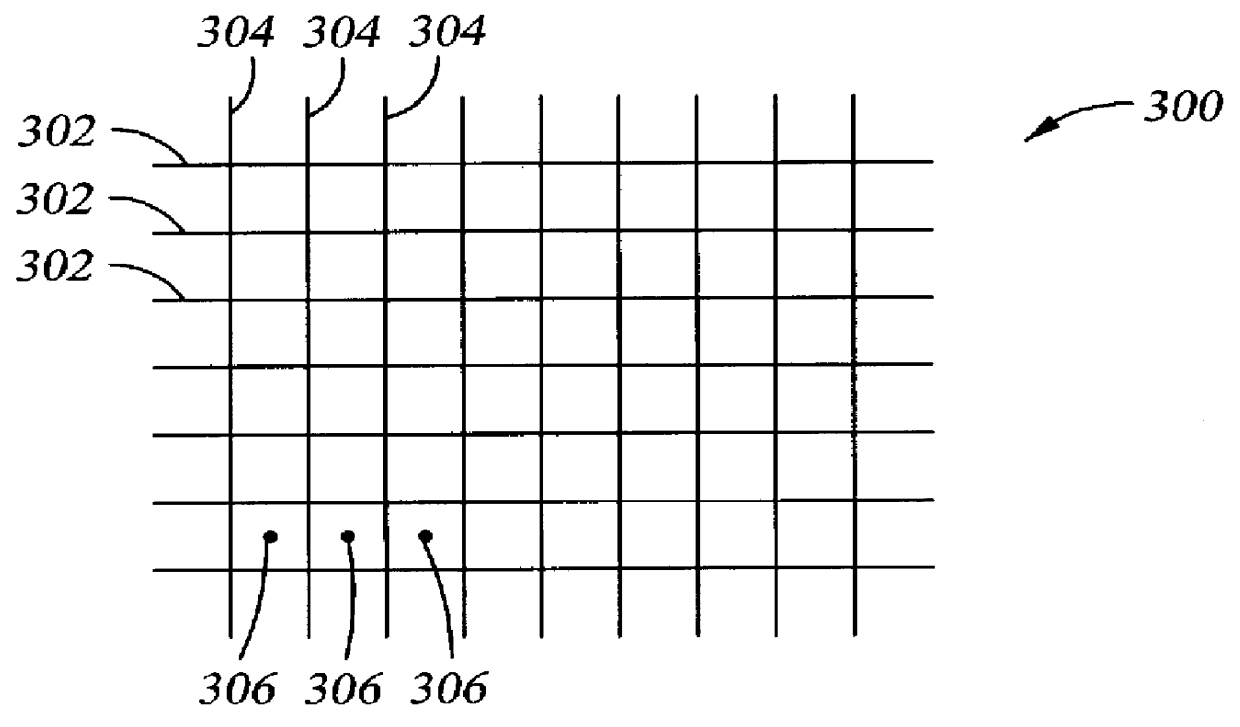

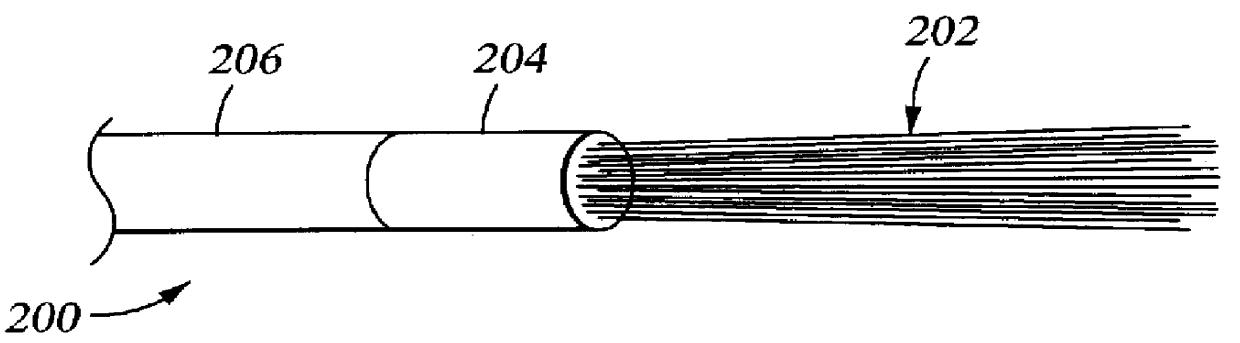

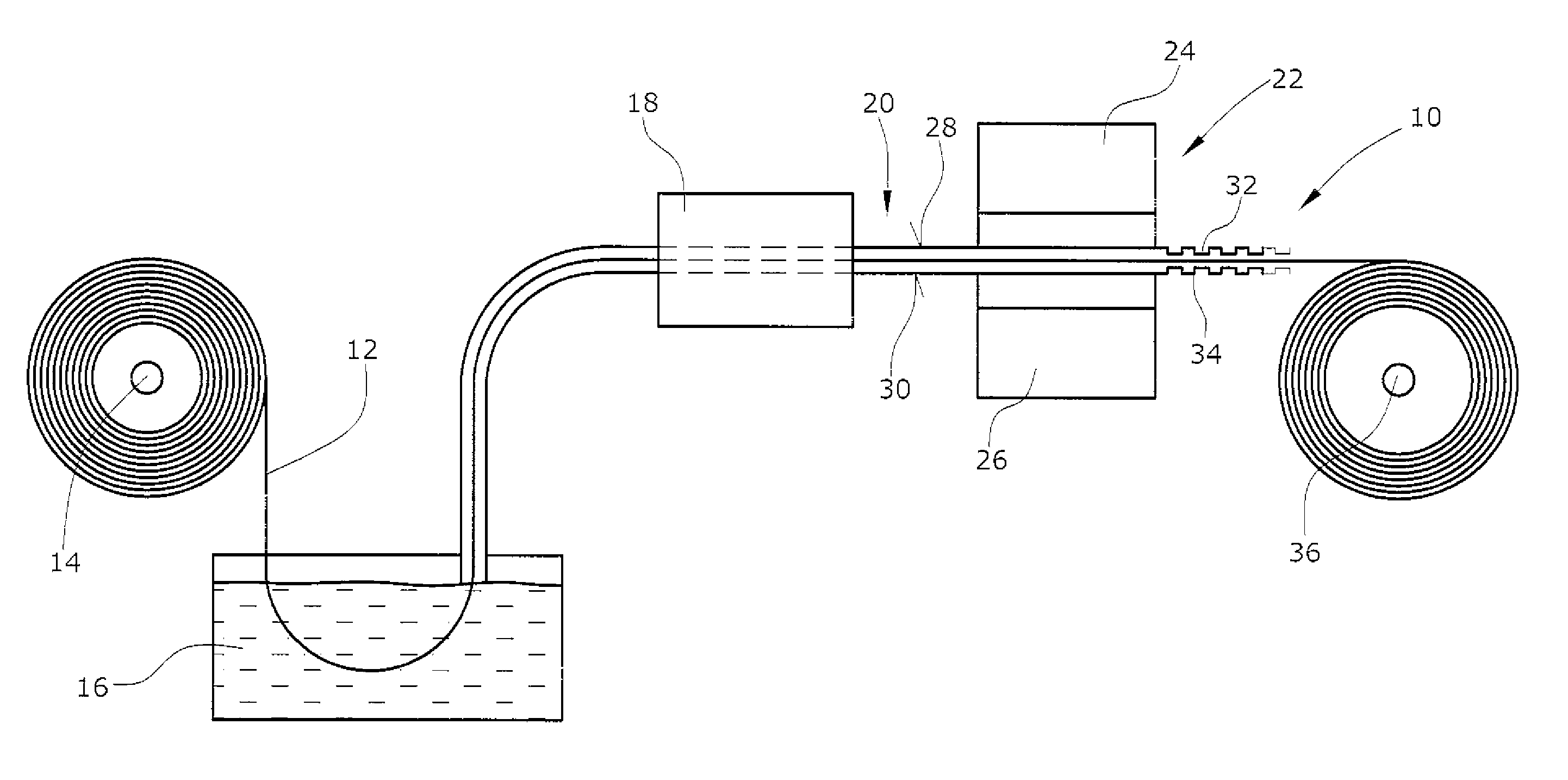

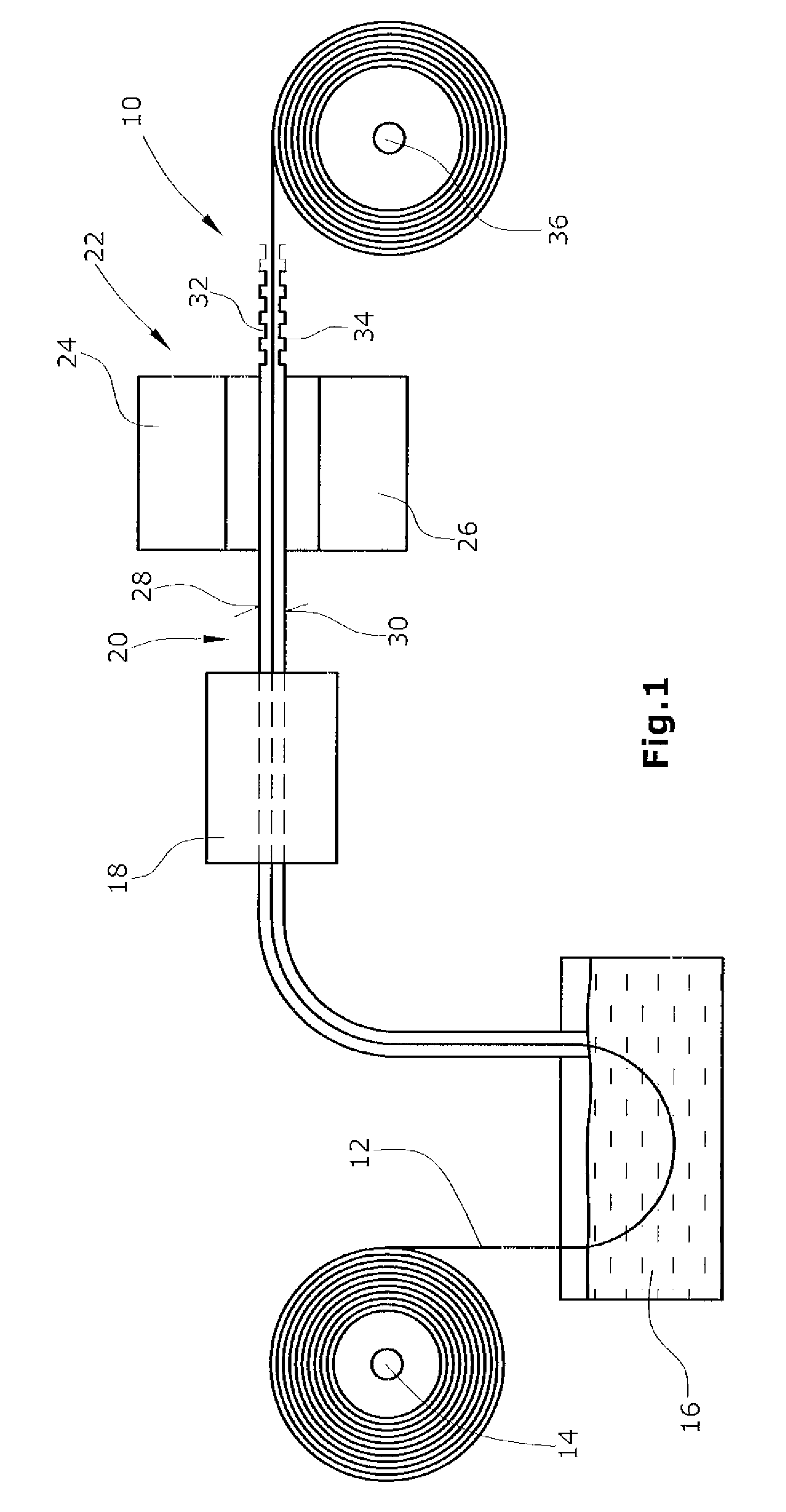

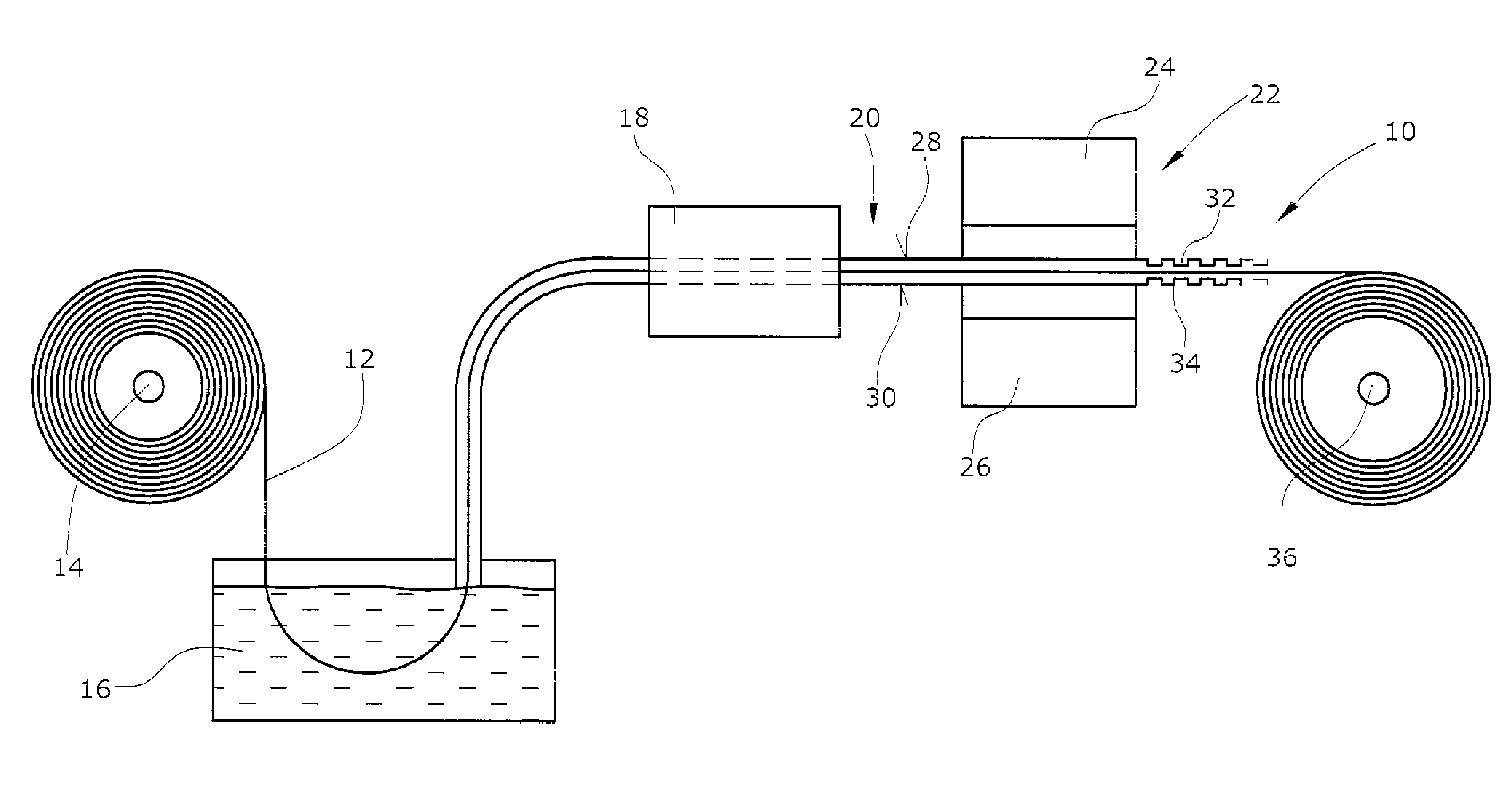

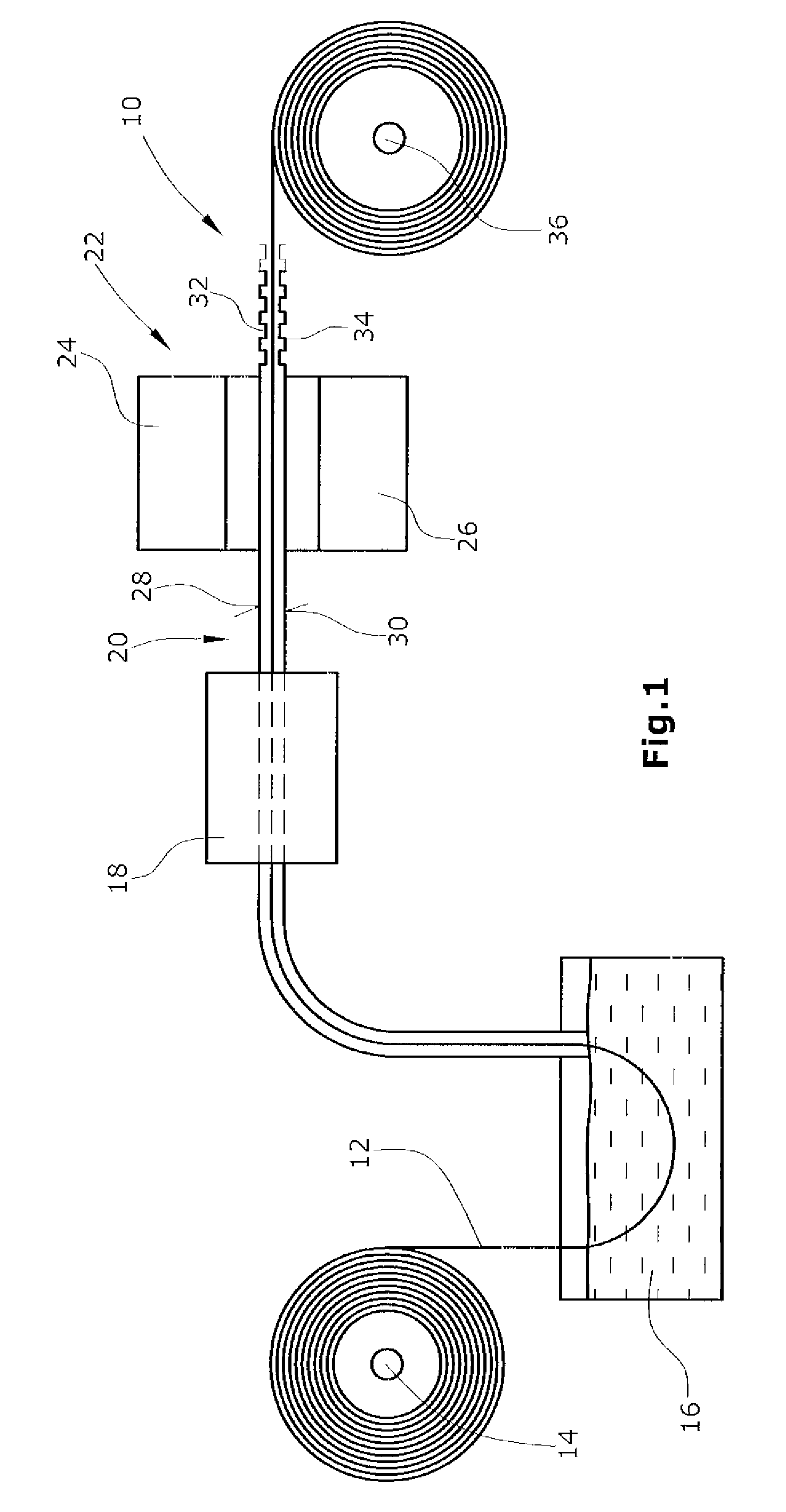

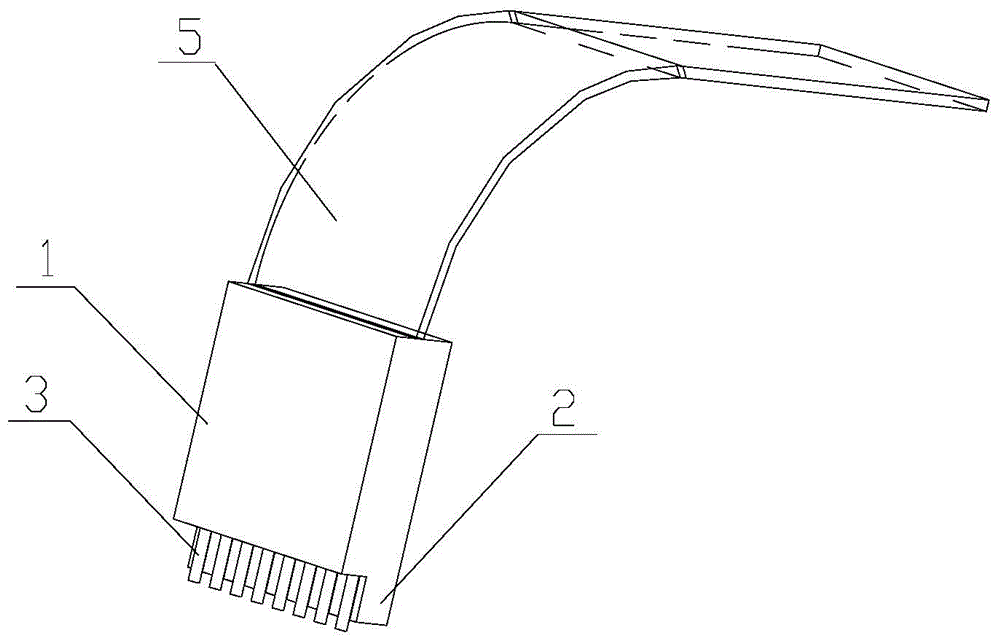

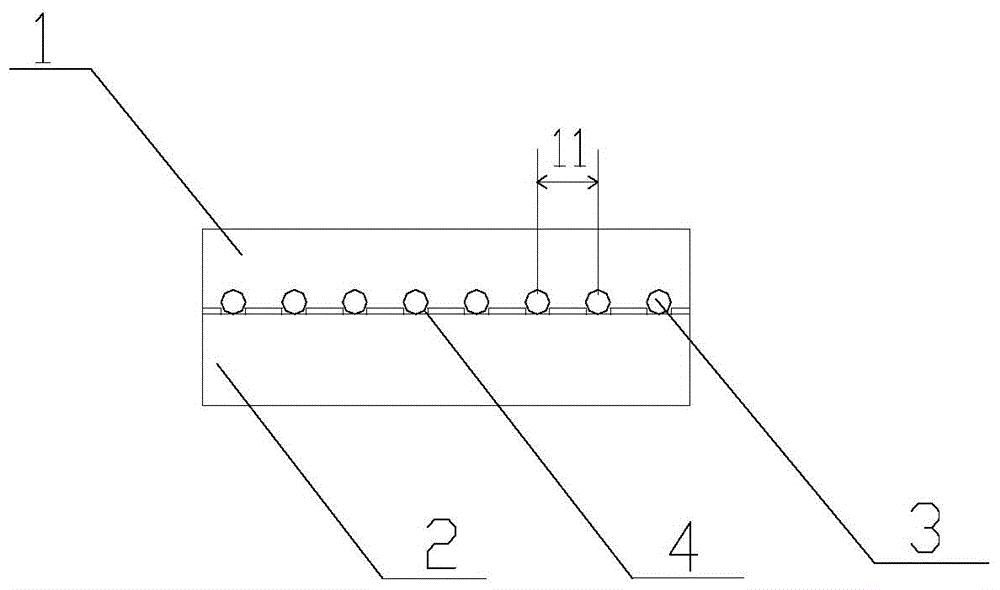

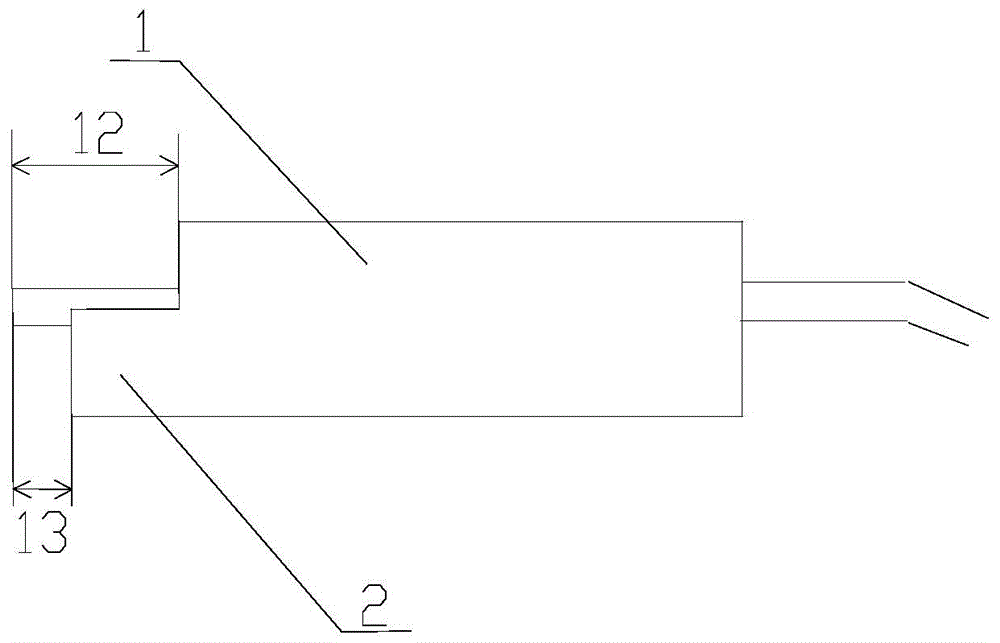

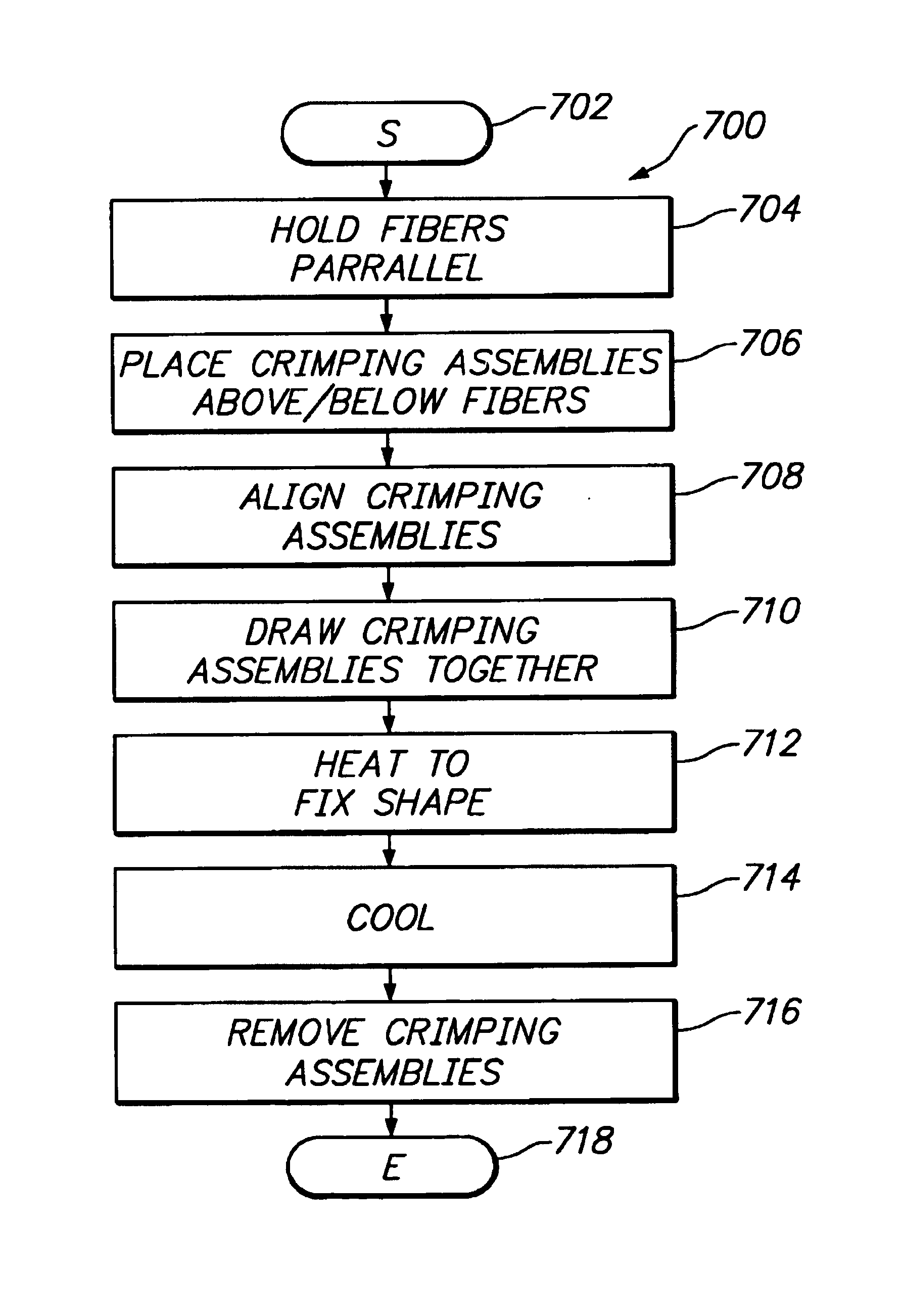

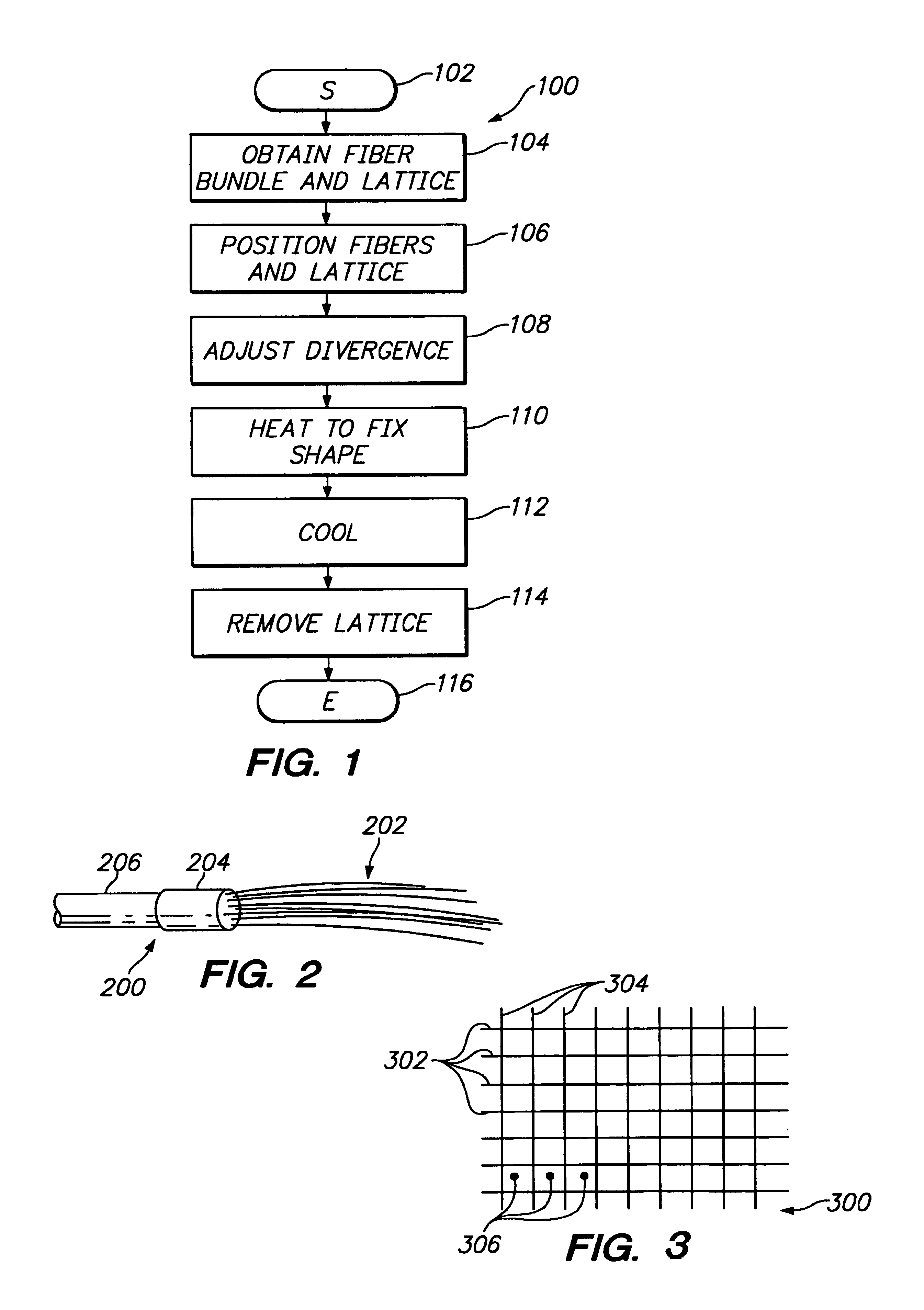

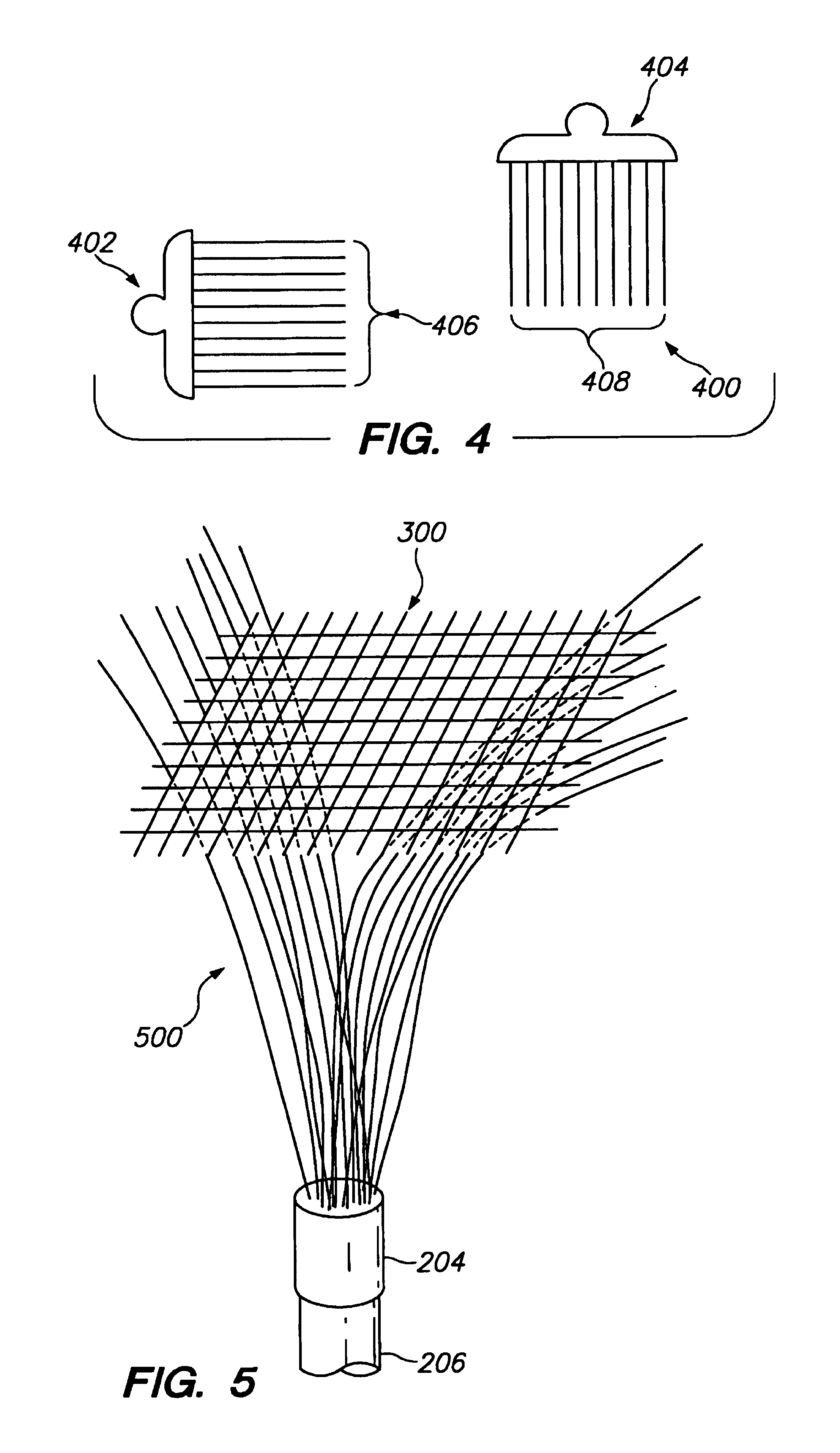

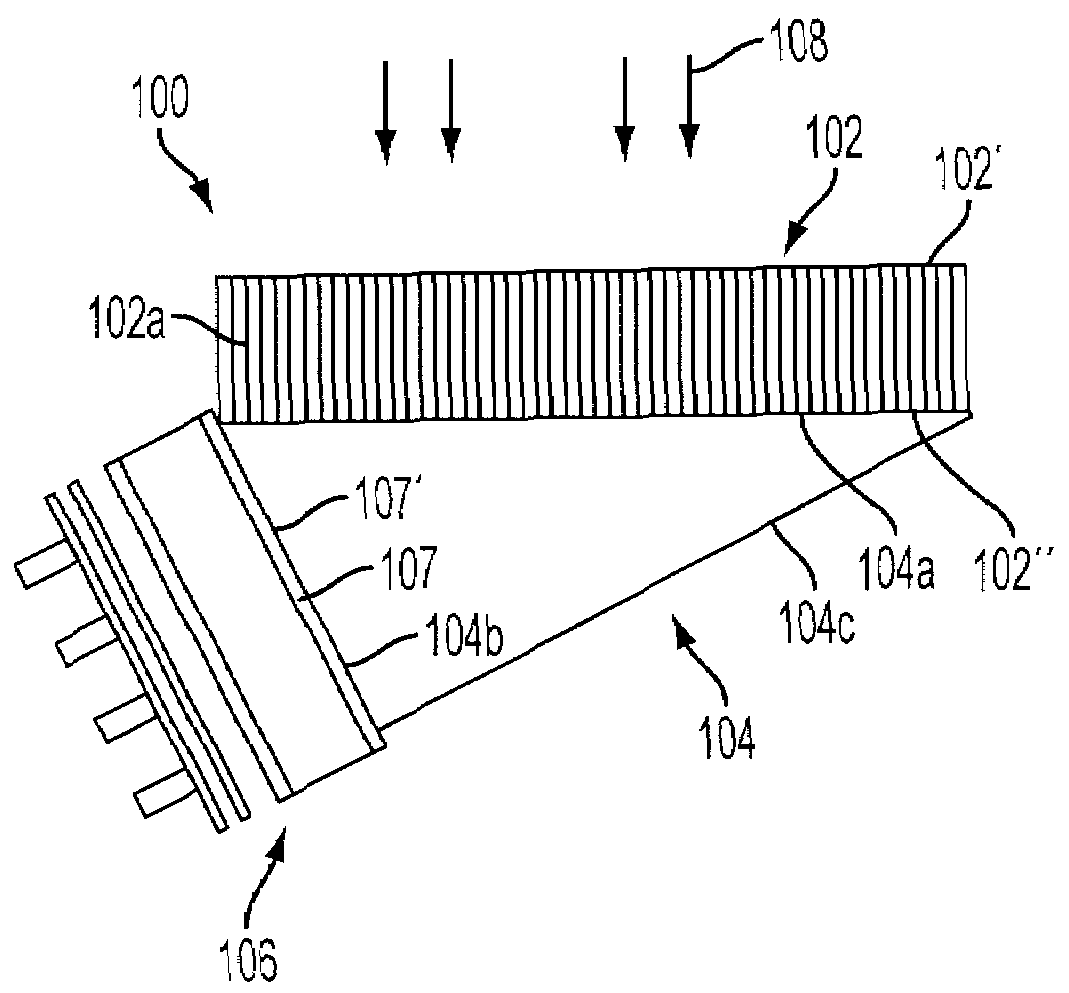

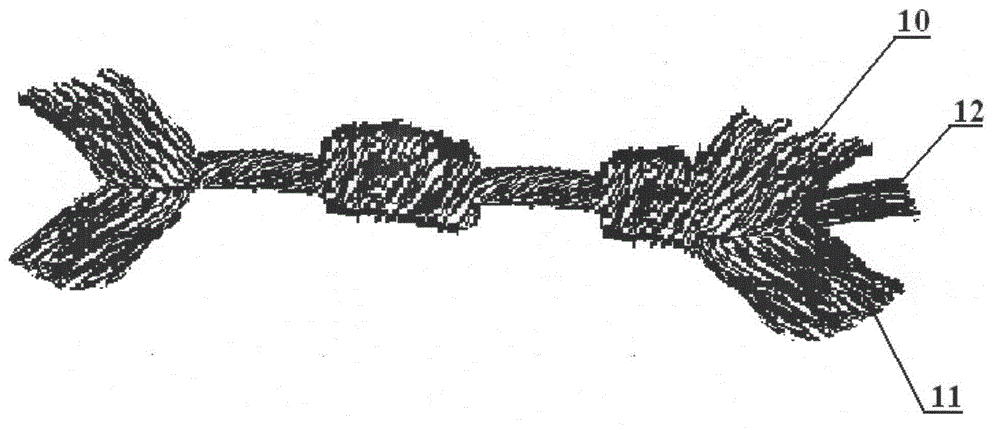

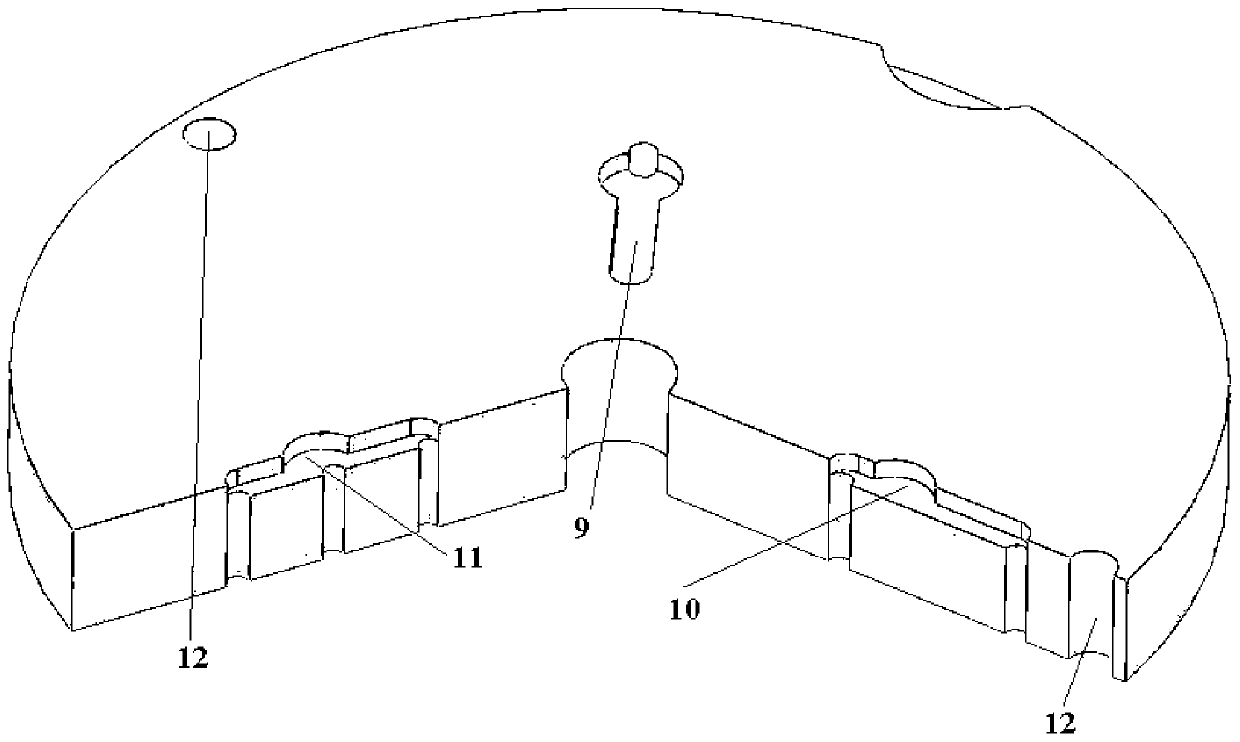

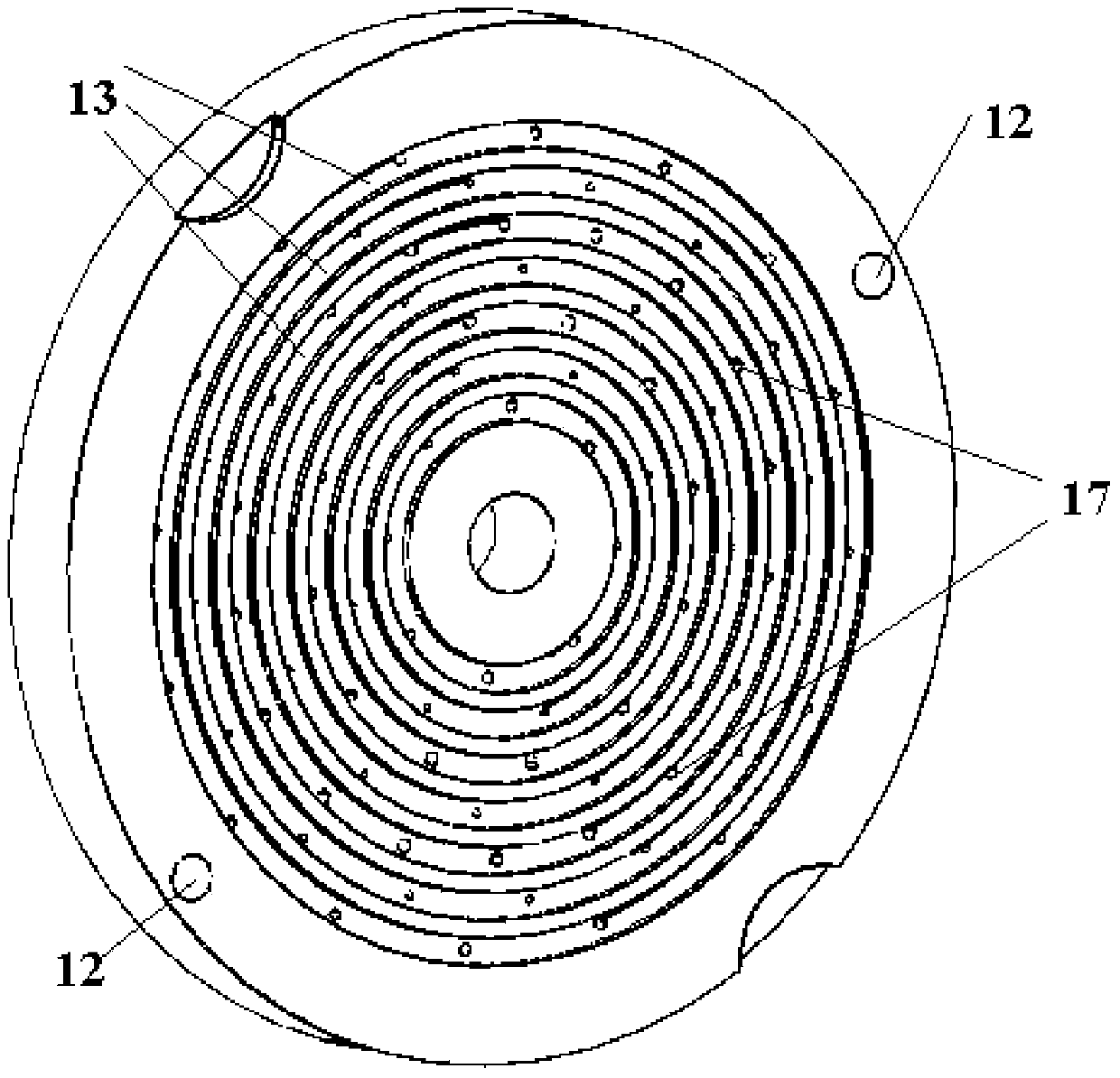

Method of selectively shaping hollow fibers of heat exchange catheter

A group of multiple hollow fibers may be shaped to introduce angular divergence among the fibers, or to introduce a selected longitudinal oscillation into the fibers. In one shaping technique, the fibers are held in parallel while upper and lower crimping assemblies of parallel crimping bars are drawn together on opposite sides of the parallel fibers. When bars of the opposing assemblies draw sufficiently close, they sandwich the fibers in between them, causing each fiber to assume a shape that oscillates as the fiber repeatedly goes over and then under successive bars. Since the crimping bars are aligned at oblique angles to the fibers, the peaks and troughs of successive fibers are offset. While in this position, the fibers are heated and then cooled to permanently retain their shapes. A different shaping technique utilizes a lattice of crisscrossing tines defining multiple apertures. In this technique, the lattice and fibers are positioned so that each fiber passes through one of the apertures. Then, the lattice and / or the fibers are slid apart or together until the lattice holds the fibers in a desired configuration, where the fibers have a prescribed outward divergence relative to each other. While in this position, the fibers are heated and then cooled to permanently retain this angular divergence.

Owner:ZOLL CIRCULATION

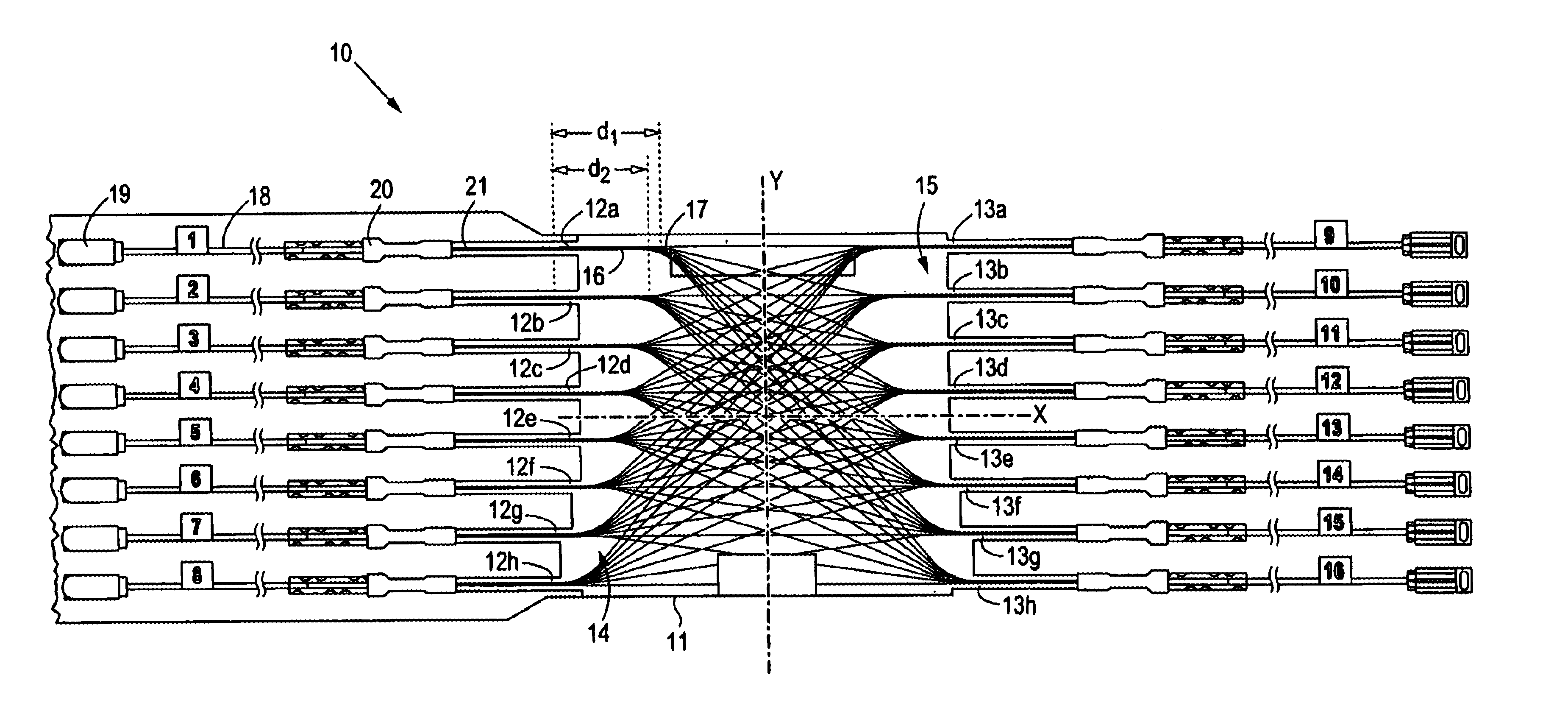

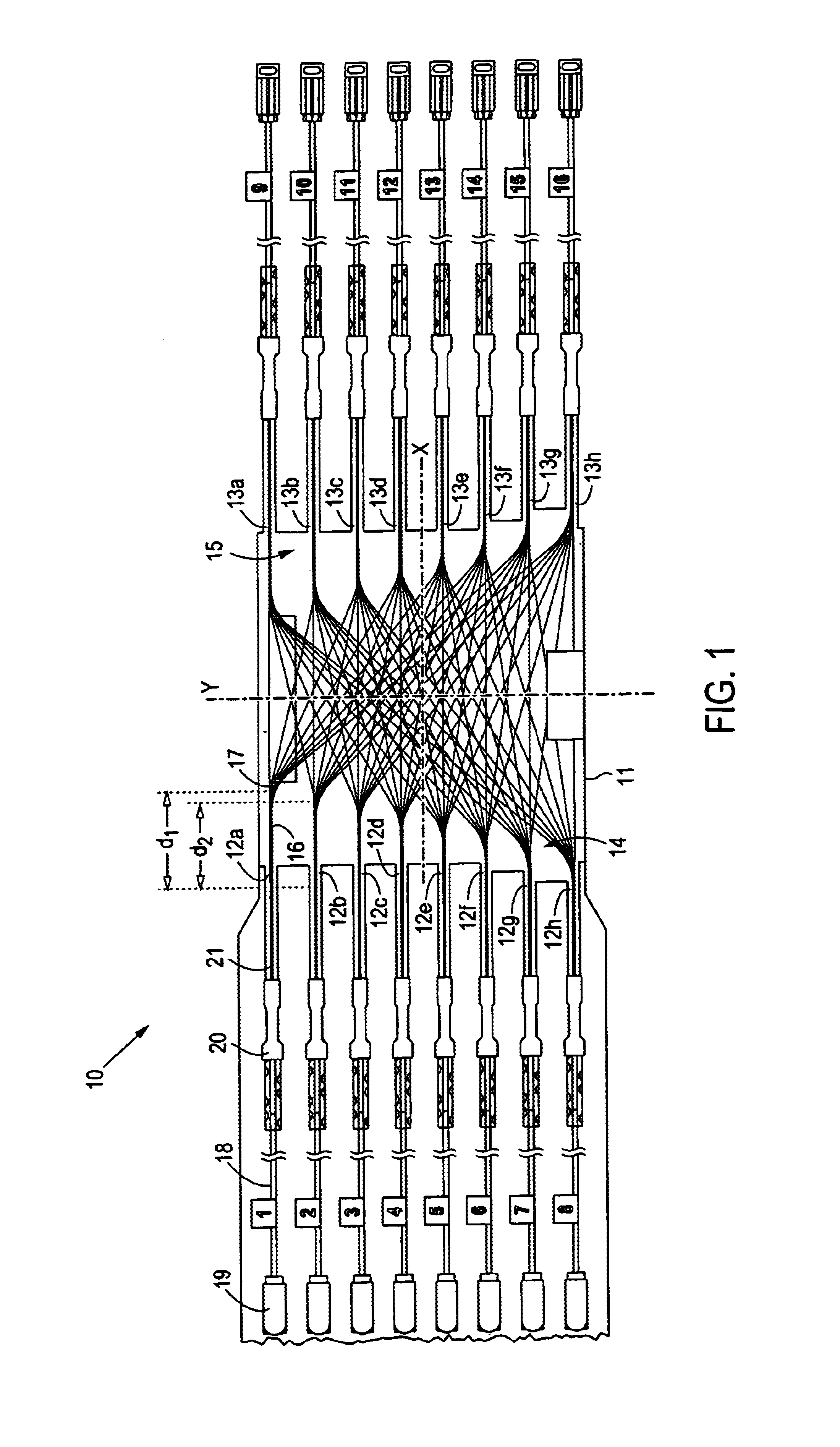

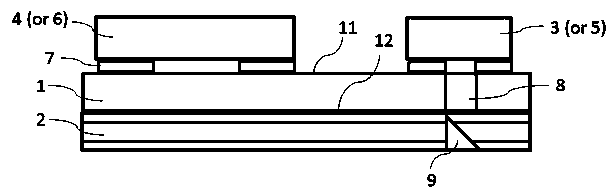

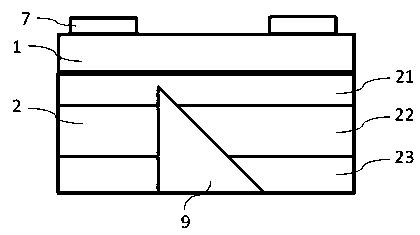

Optical fiber circuit

An optical circuit comprises: (a) a body having an x and y axis and two sides substantially parallel to the y-axis and separated along the x-axis; (b) a plurality of first ports along one of the two sides, each first port comprising a number of substantially paralleled fibers; and (c) a plurality of second ports along the other of the two sides, each second port comprising a number of substantially parallel fibers. The ports are interconnected with the fibers such that (i) the fibers of a given second port comprise a fiber from each of the first ports, and (ii) the fibers interconnecting the first and second ports are arranged asymmetrically about at least one of the x or y axes.

Owner:TE CONNECTIVITY CORP

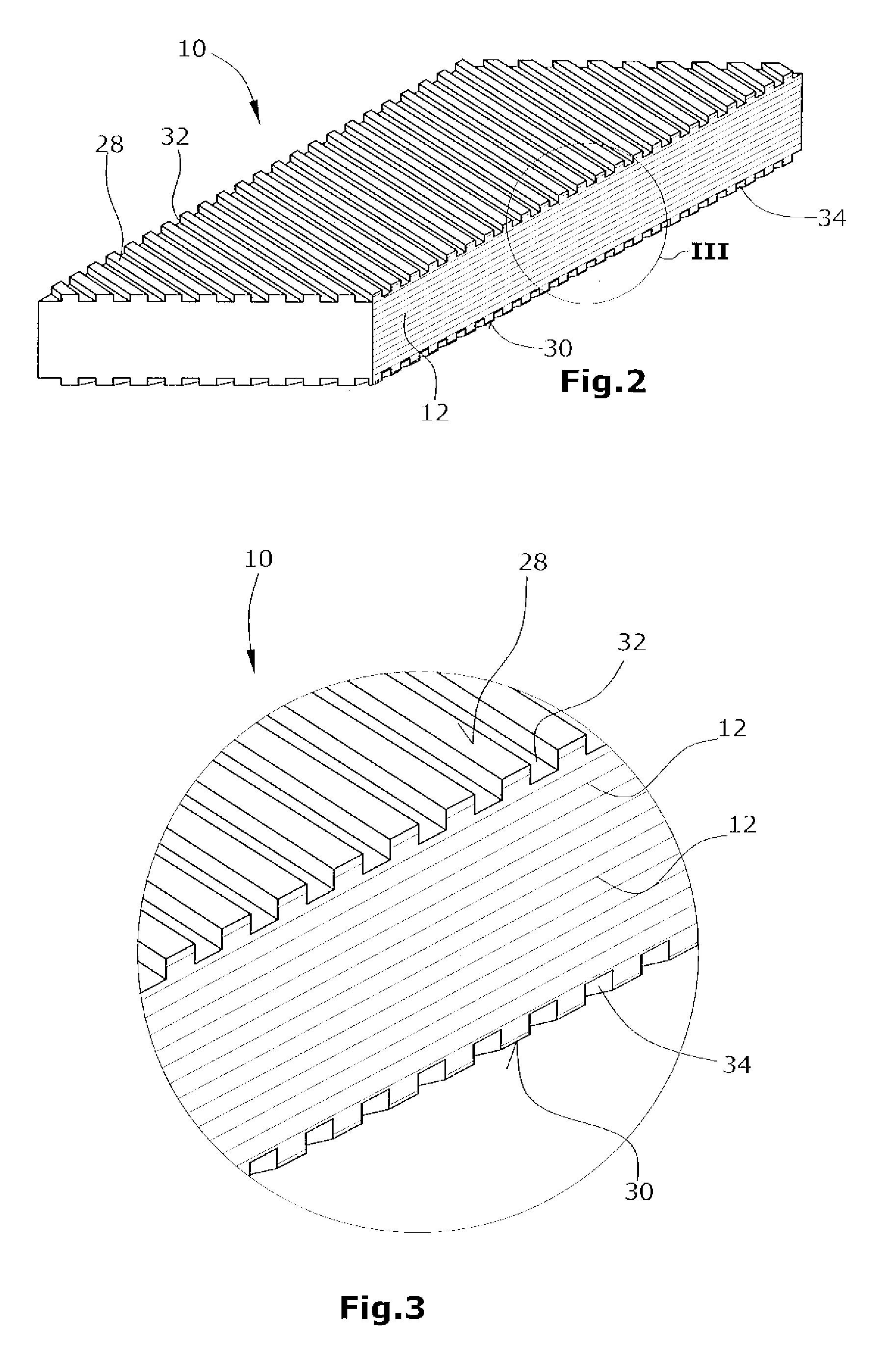

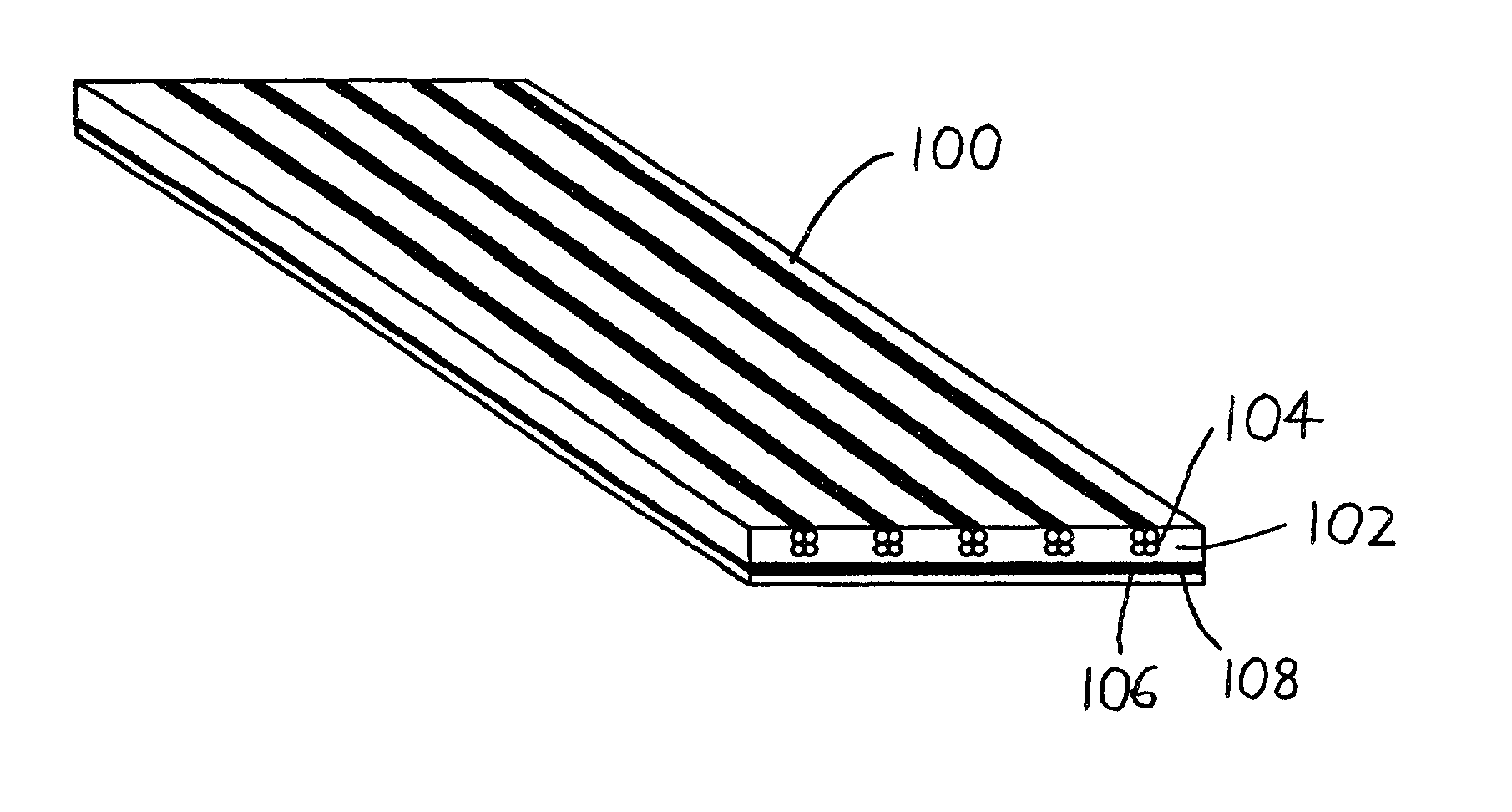

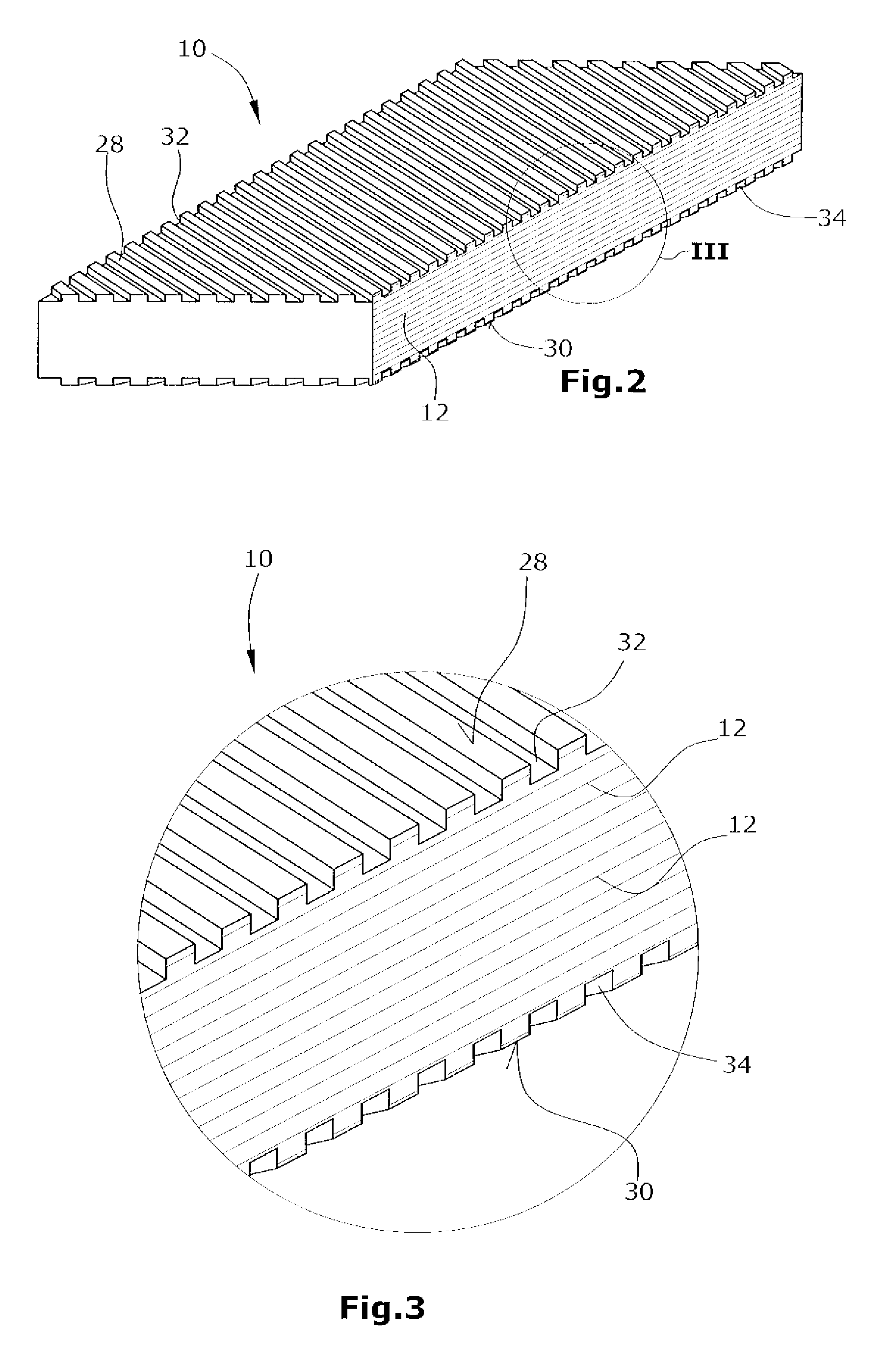

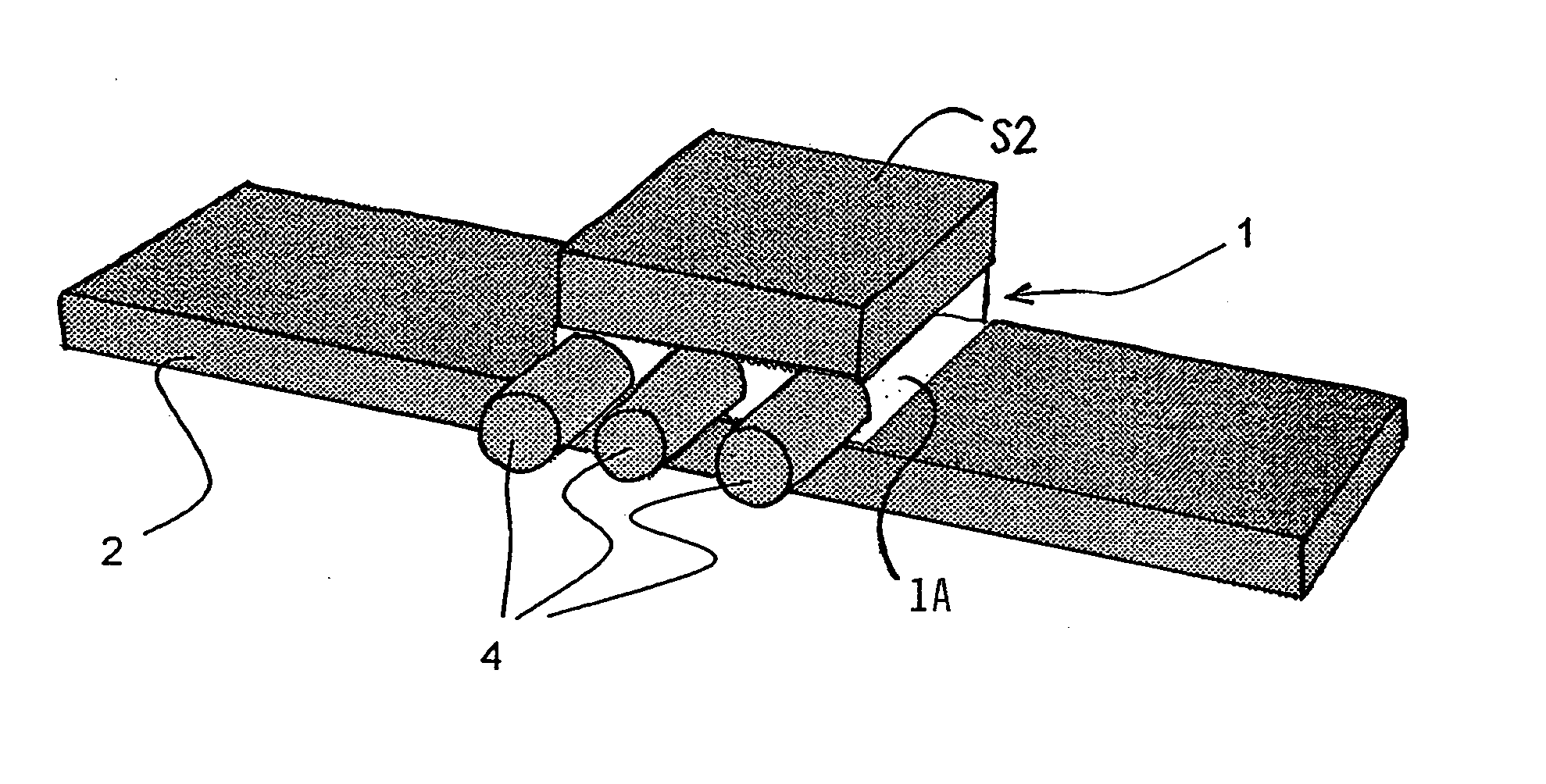

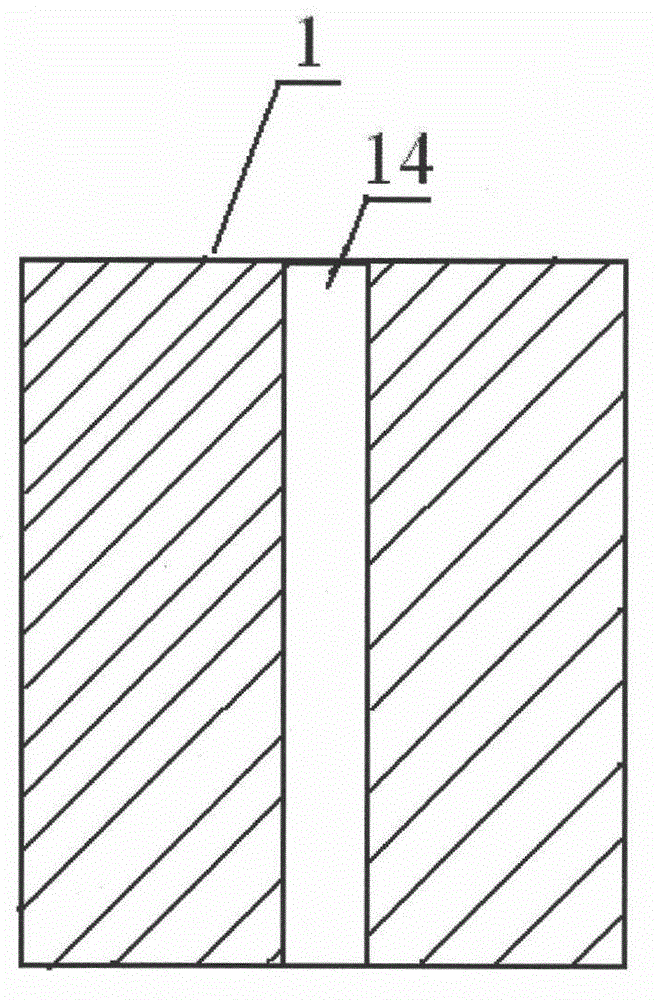

Method For Making A Continuous Laminate, In Particular Suitable As A Spar Cap Or Another Part Of A Wind Energy Turbine Rotor Blade

The method for making a continuous laminate, in particular suitable as a spar cap or another part of a wind energy turbine rotor blade comprises the steps of providing a plurality of parallel fibers, embedding the fibers in a curable matrix material, curing the matrix material so as to obtain a fiber reinforced laminate having upper and lower major surfaces, and forming channels into at least one of the upper and lower major surfaces of the laminate wherein the channels on the upper and / or lower major surfaces are angled with respect to the direction of the fibers.

Owner:GENERAL ELECTRIC CO

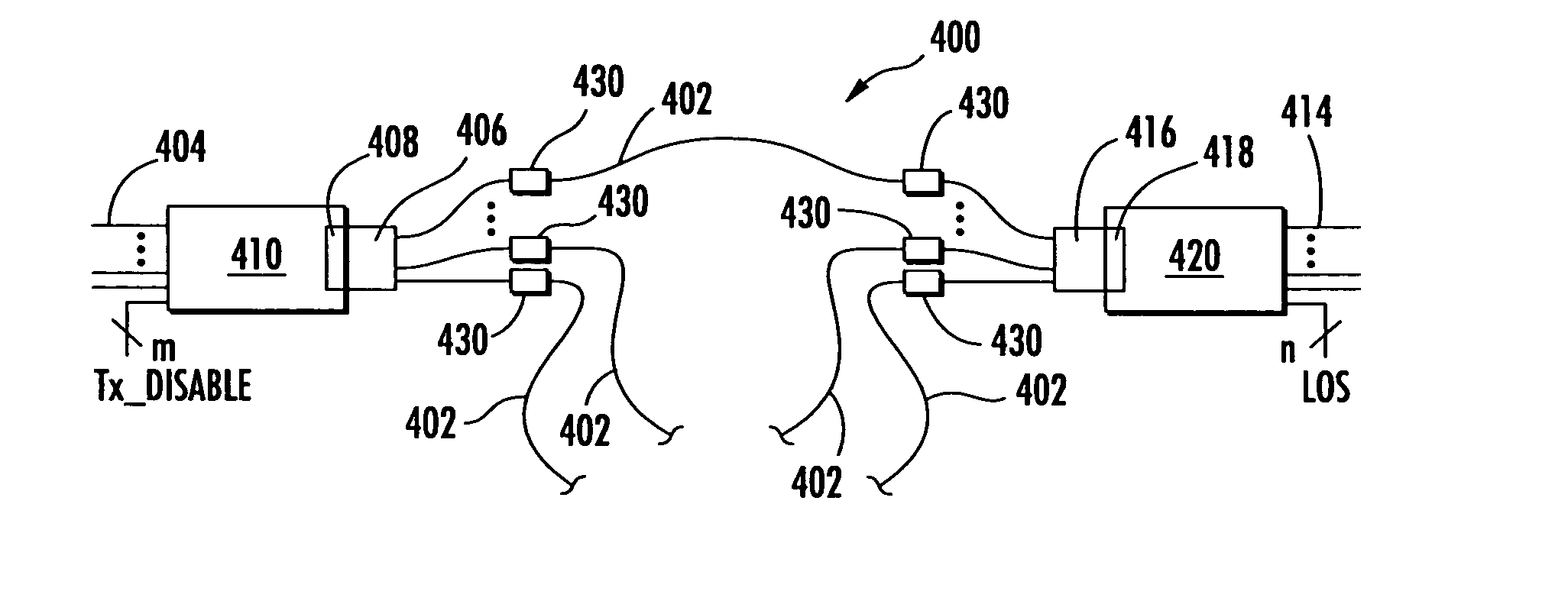

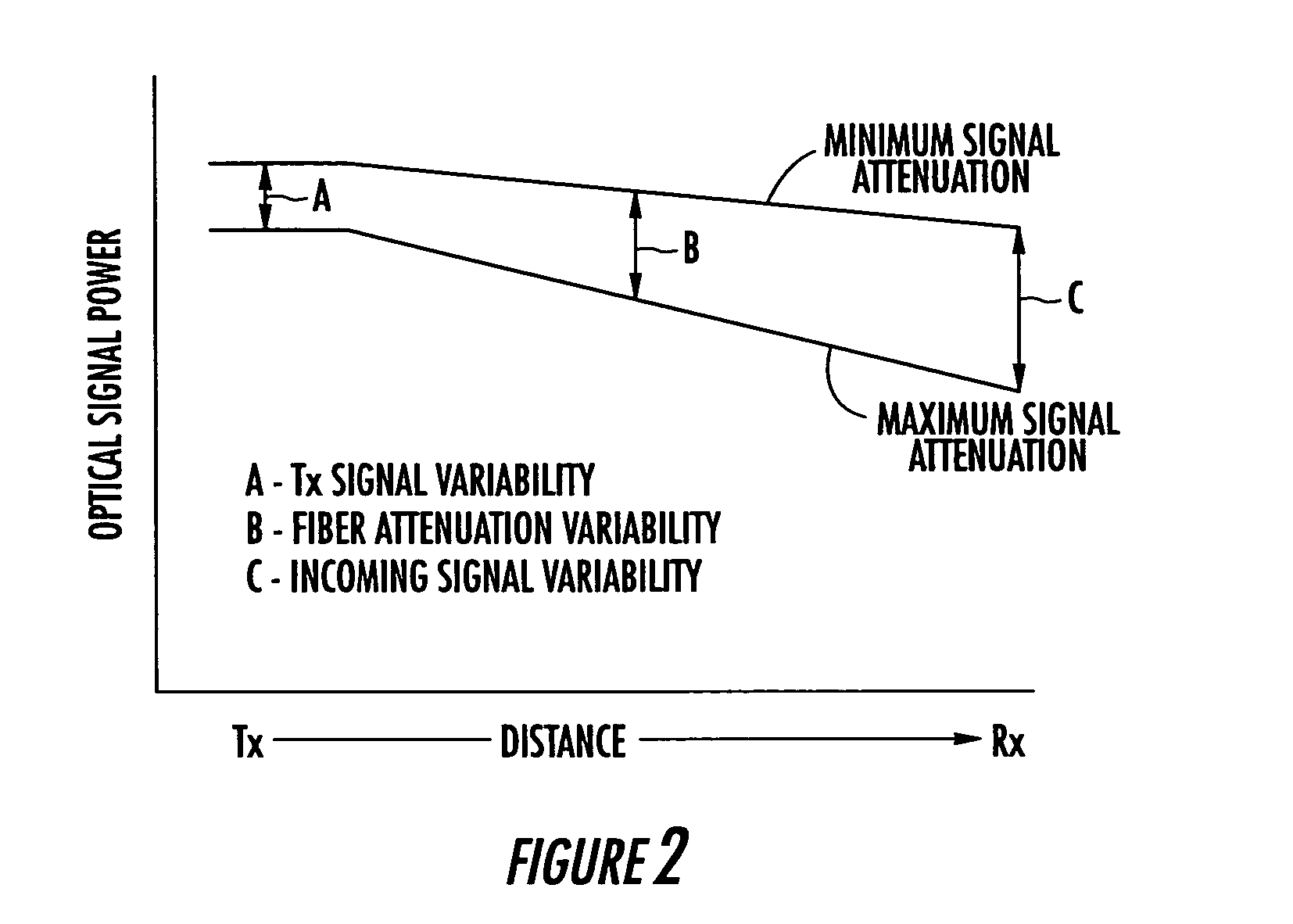

Apparatus and methods for using fiber optic arrays in optical communication systems

InactiveUS7020359B2Increased battery back up timeHigh densityCoupling light guidesFibre mechanical structuresCommunications systemFiber array

Systems and methods for optical communication that may be employed to couple together fiber optic arrays of two or more optical communication modules using parallel fiber optic connectors and physically distinct and signal-independent optical communication paths. The disclosed systems and methods may be employed to provide separate signal-independent communication paths having signal transport characteristics that meet standards required for single fiber single point-to-single point applications.

Owner:OPTICAL COMM PRODS

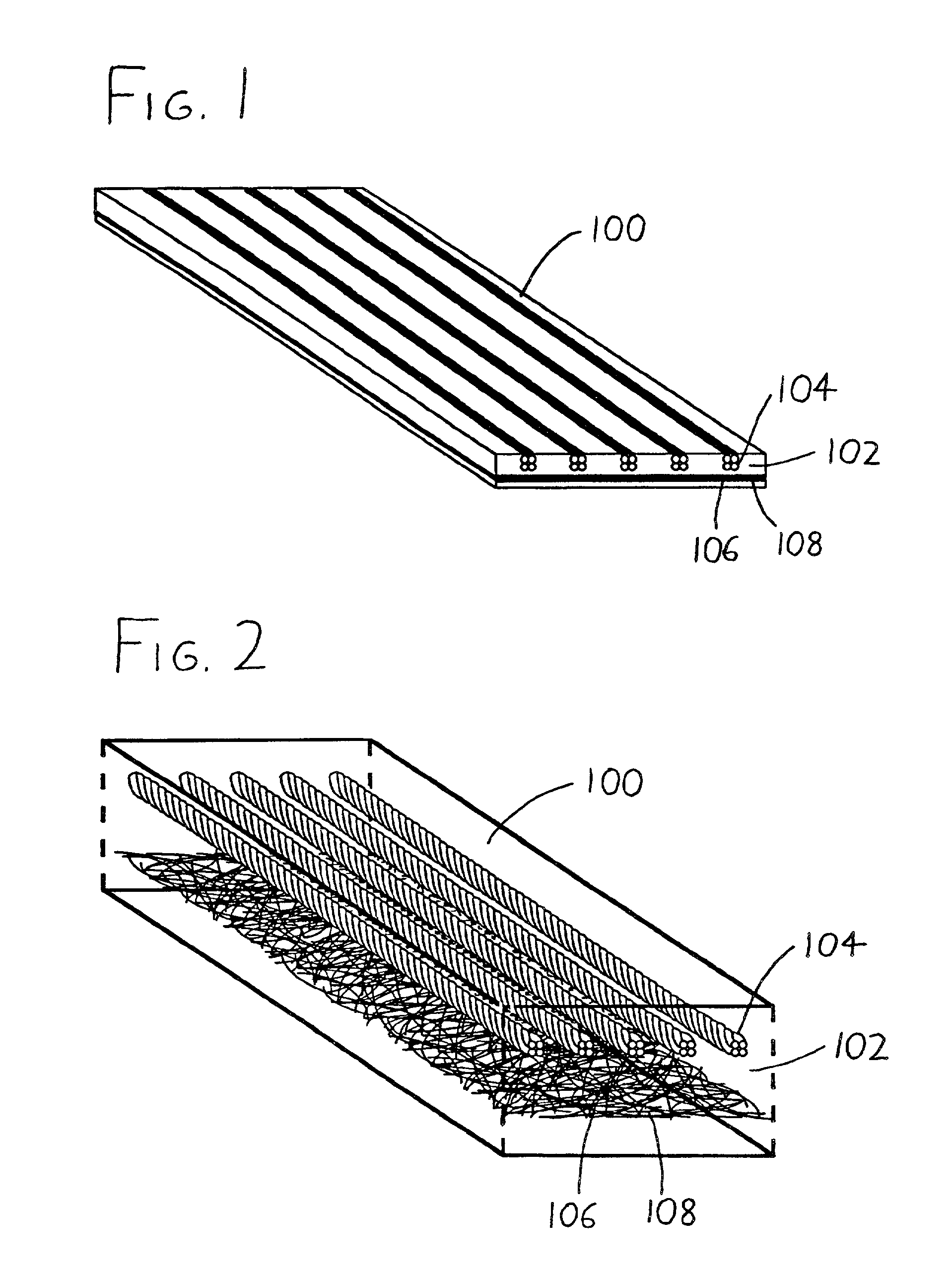

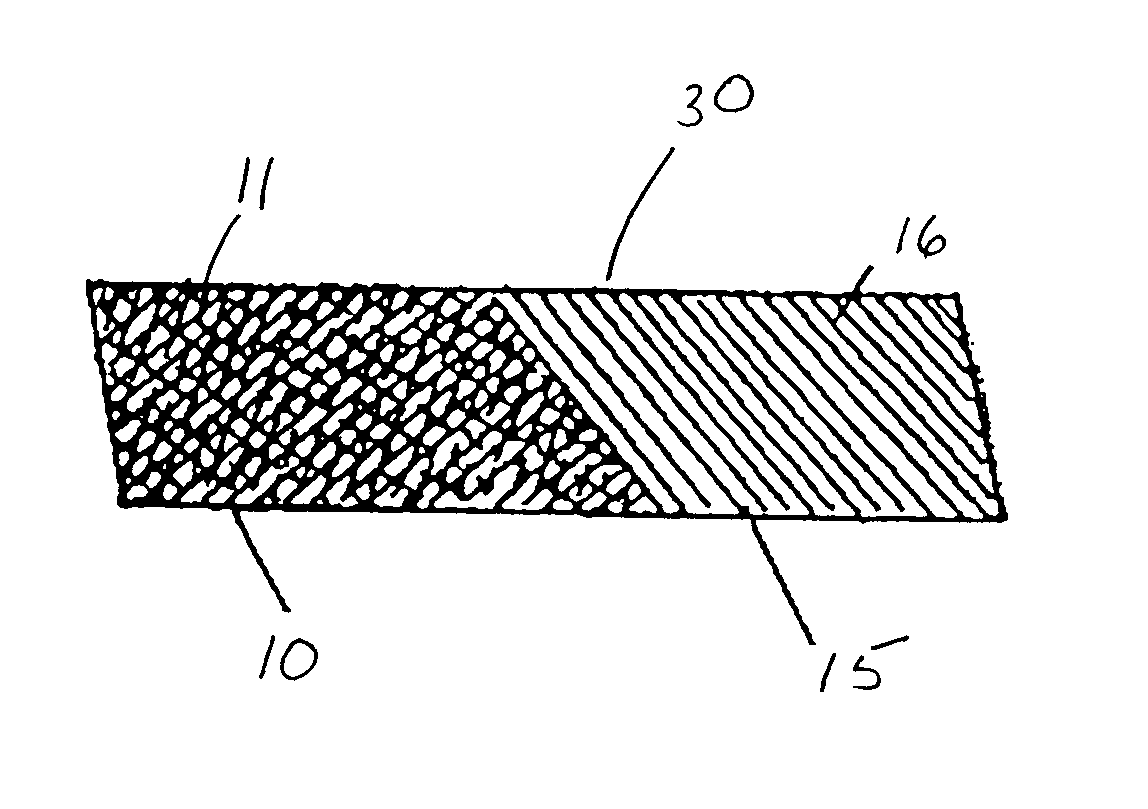

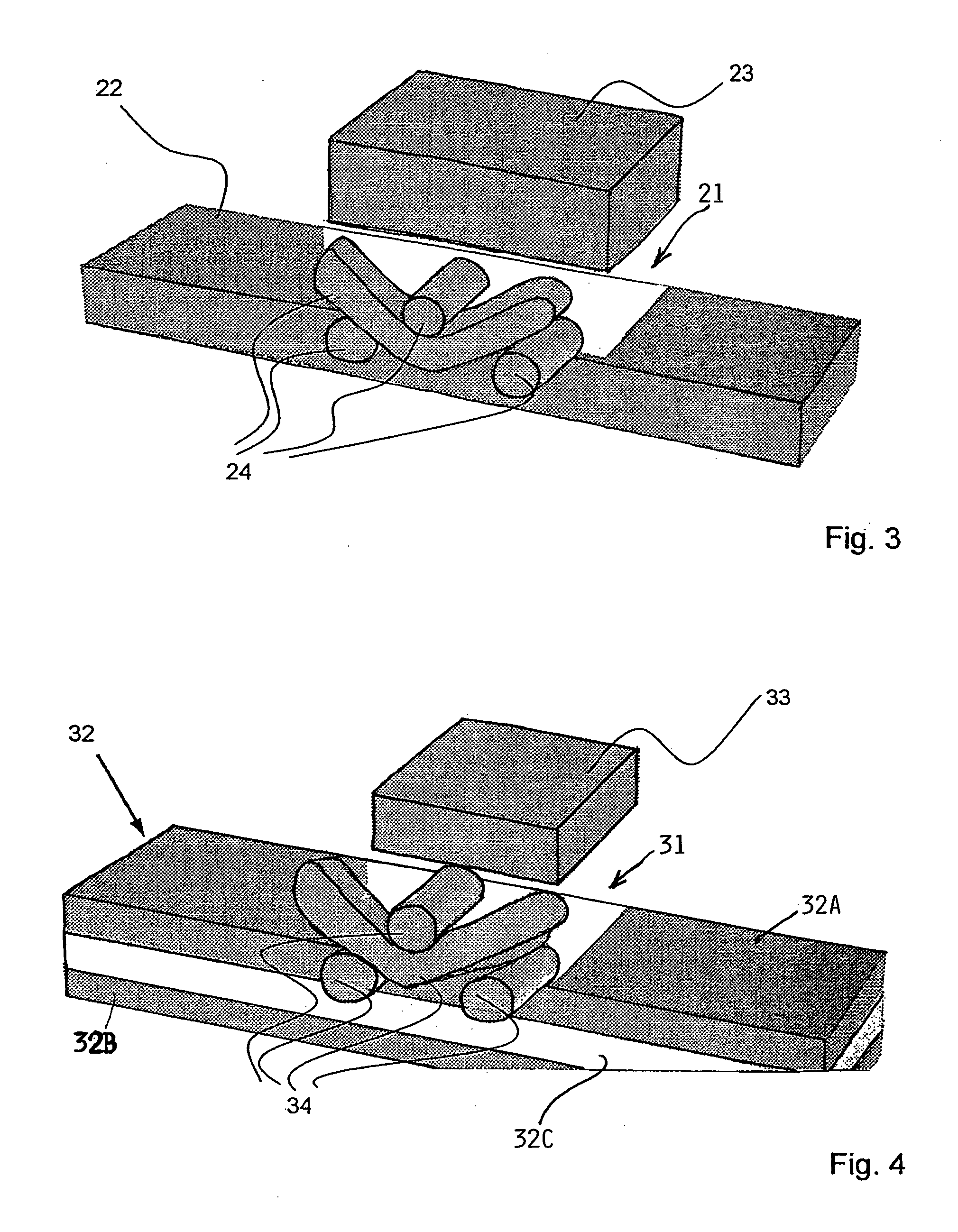

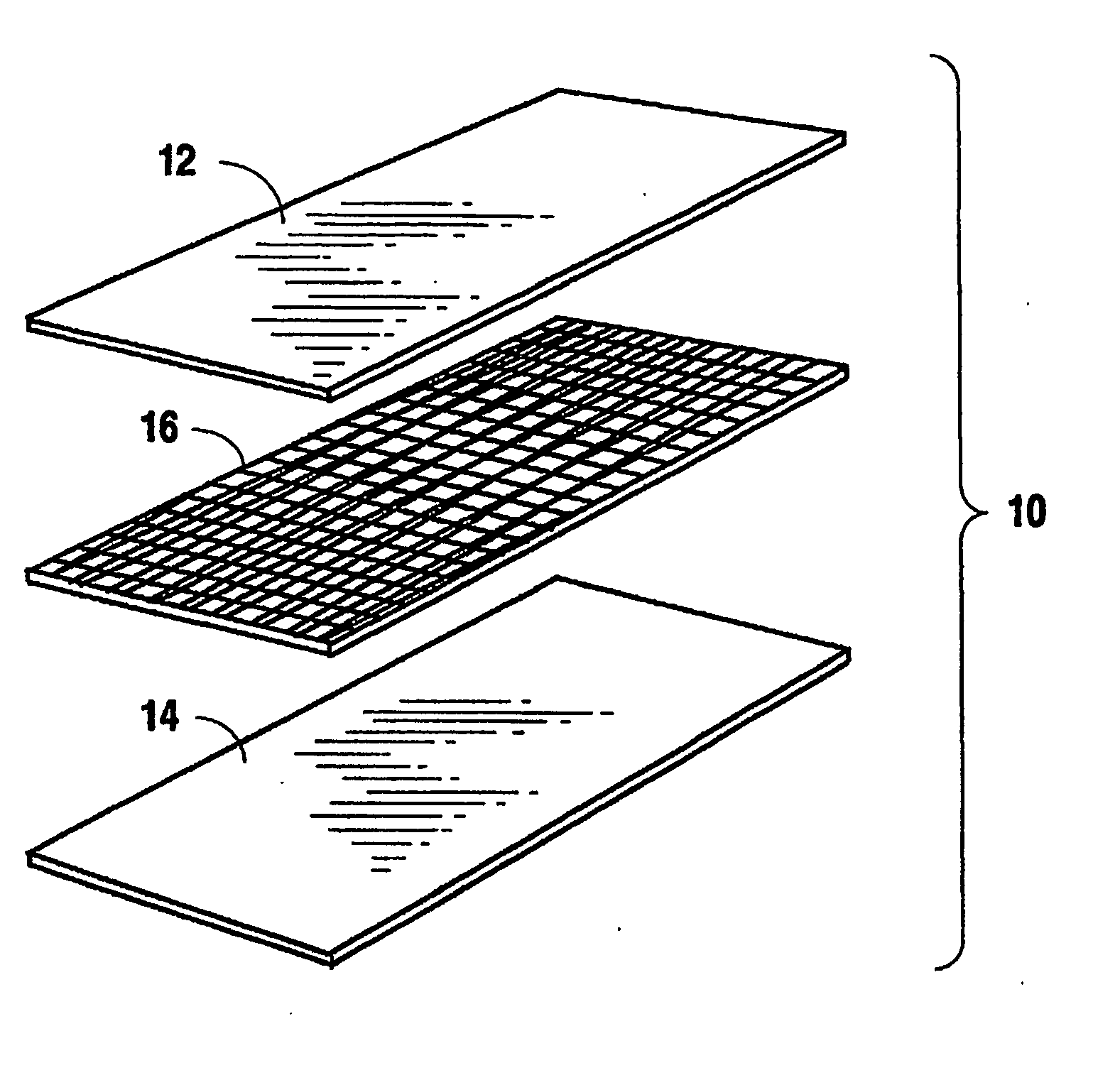

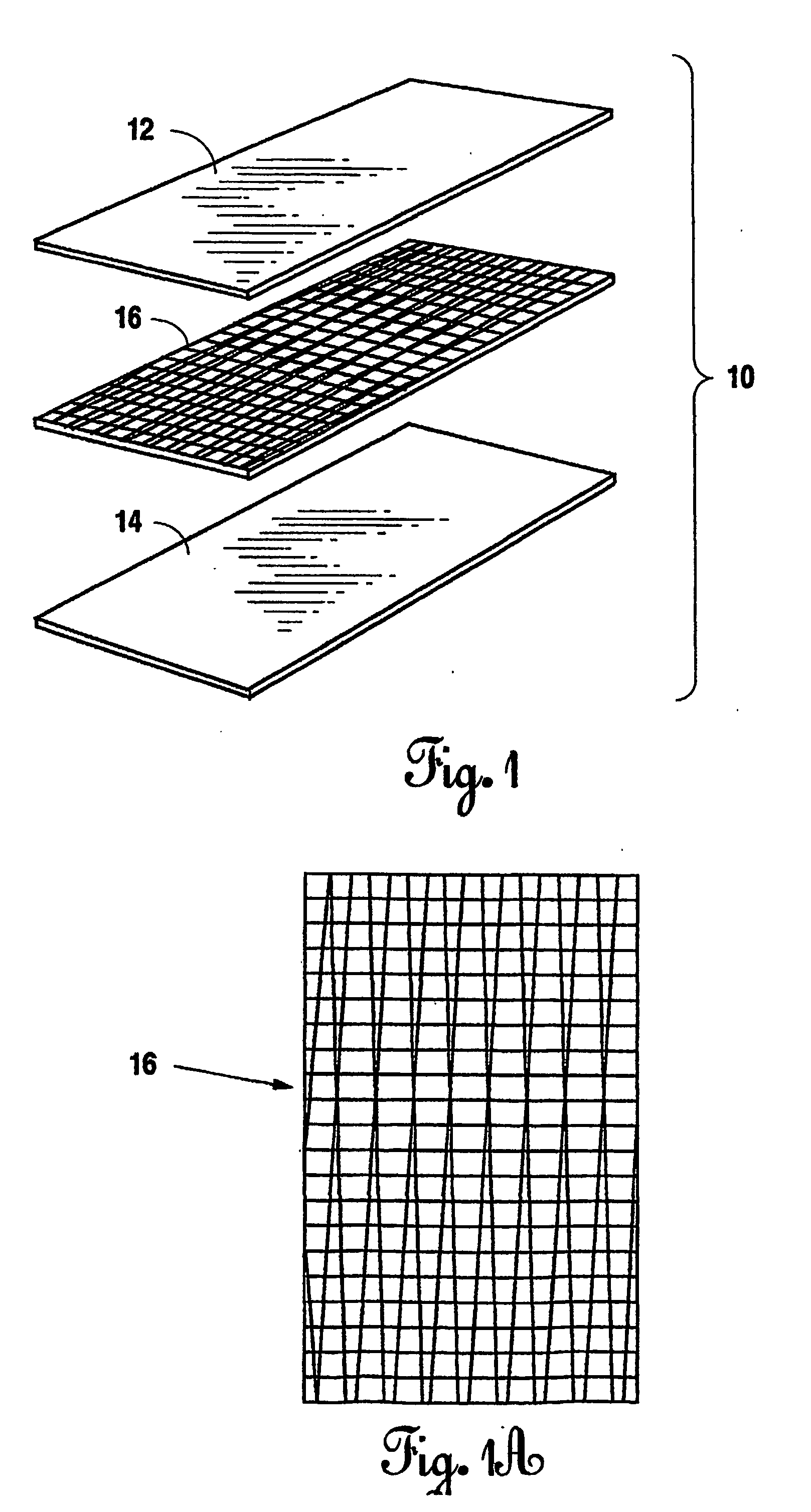

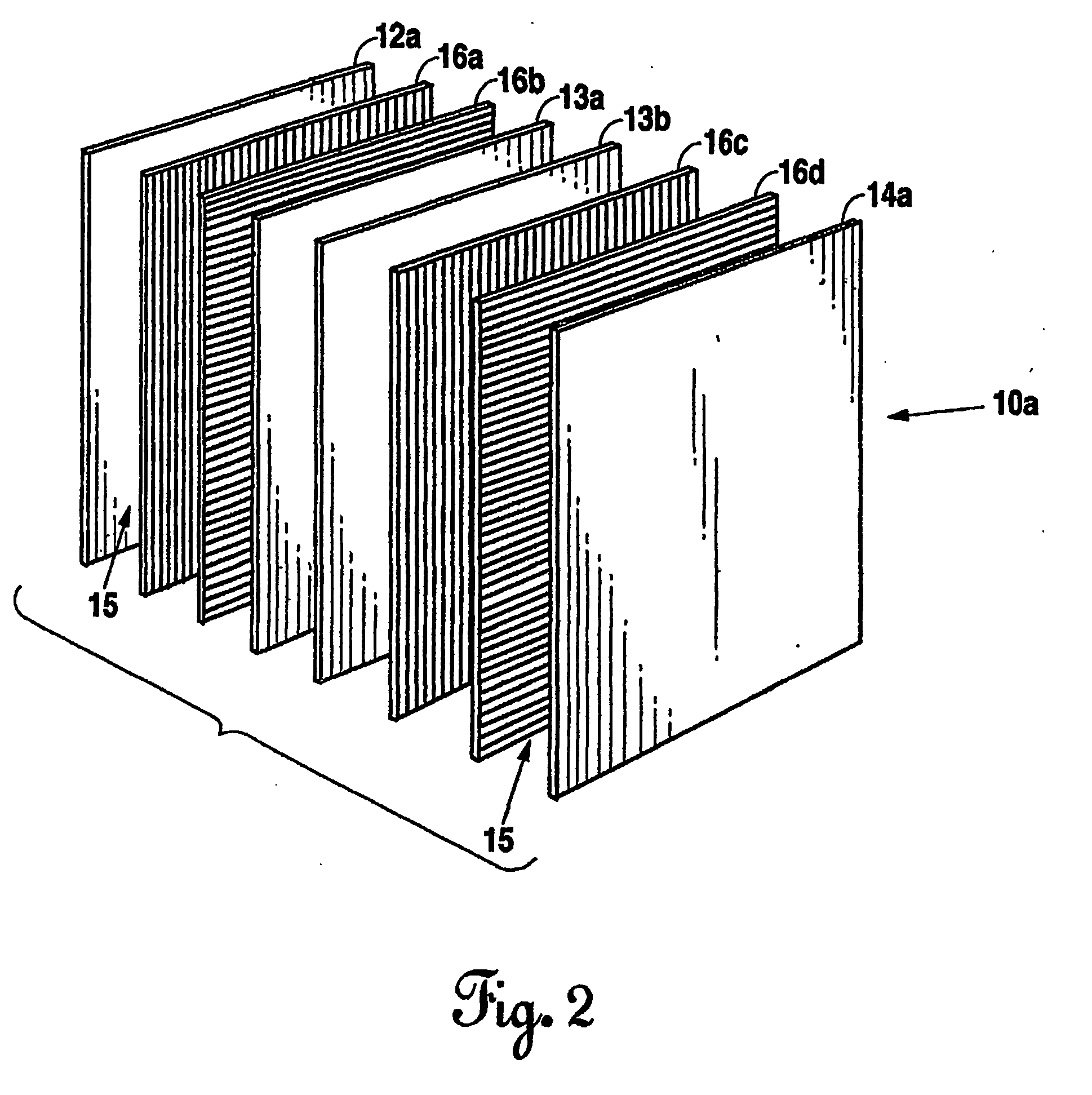

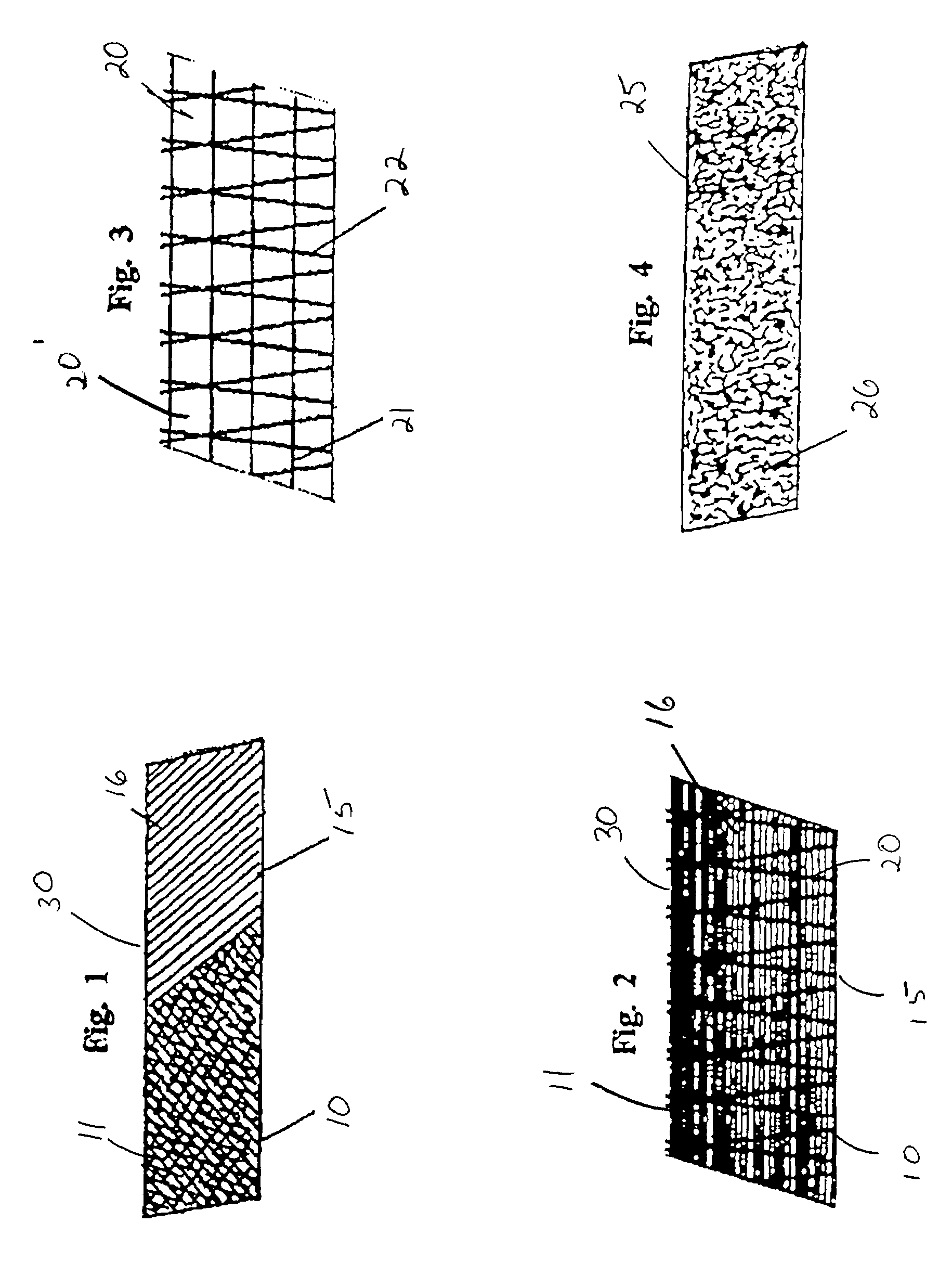

Structural reinforcement using composite strips

InactiveUS20020110680A1Reduce the potential for damageEasy to transportSynthetic resin layered productsBuilding repairsFiberEngineering

A composite structural reinforcing strip is affixed to a structure to be reinforced (such as a bridge span, foundation pillar, or similar structure) by the use of several fasteners which extend through the strip and into the structure. The reinforcing strip preferably includes elongated continuous parallel fibers which have lengths extending along the length of the strip, and nondirectional fibers distributed transversely across the strip, with a polymer matrix affixing the parallel and nondirectional fibers. The strip may be placed on the structure to be reinforced, and may be attached thereon by actuating a common powder-actuated fastener gun to send fasteners through the strip and into the structure.

Owner:WISCONSIN ALUMNI RES FOUND

Method for making a continuous laminate, in particular suitable as a spar cap or another part of a wind energy turbine rotor blade

The method for making a continuous laminate, in particular suitable as a spar cap or another part of a wind energy turbine rotor blade comprises the steps of providing a plurality of parallel fibers, embedding the fibers in a curable matrix material, curing the matrix material so as to obtain a fiber reinforced laminate having upper and lower major surfaces, and forming channels into at least one of the upper and lower major surfaces of the laminate wherein the channels on the upper and / or lower major surfaces are angled with respect to the direction of the fibers.

Owner:LM WIND POWER US TECH APS

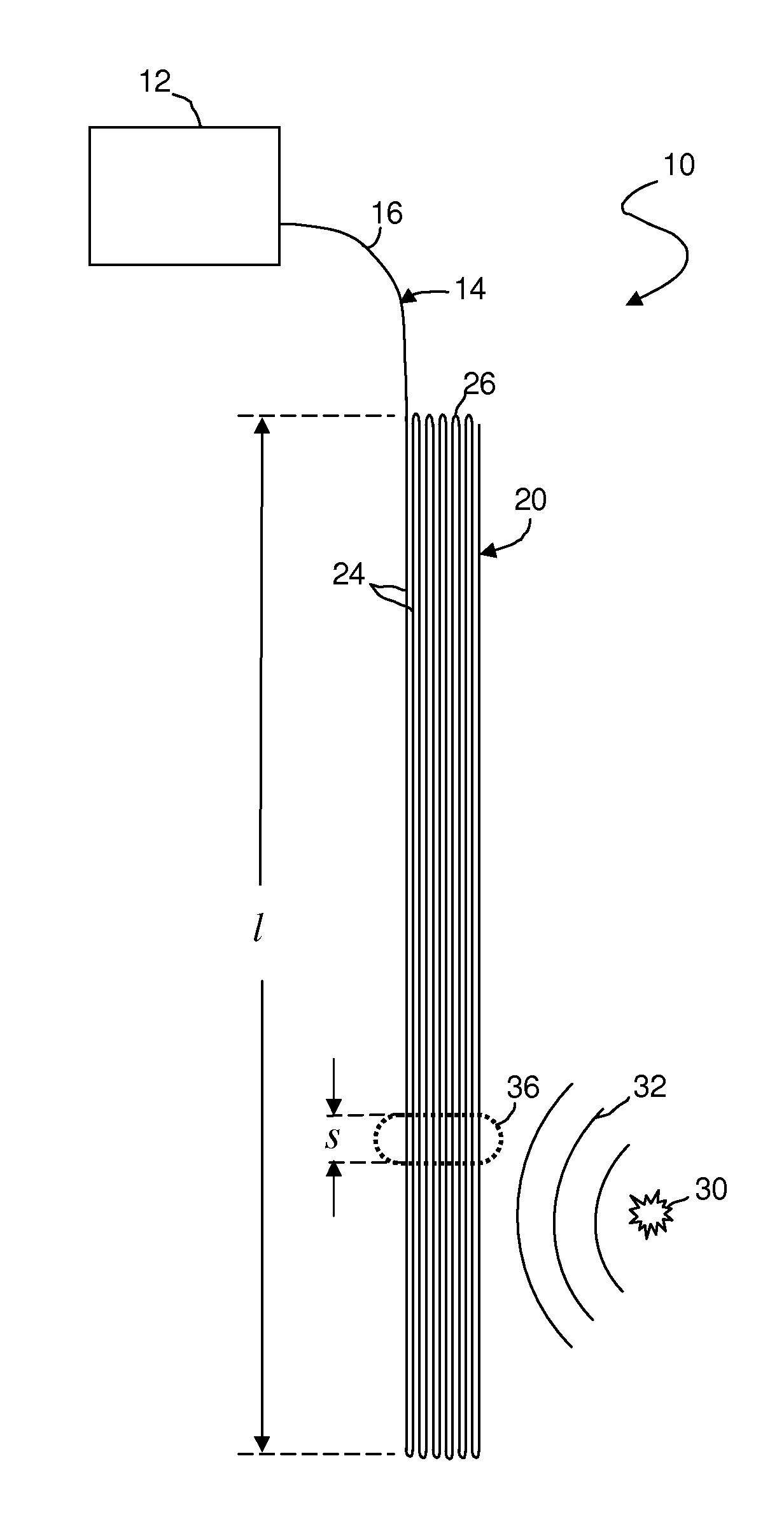

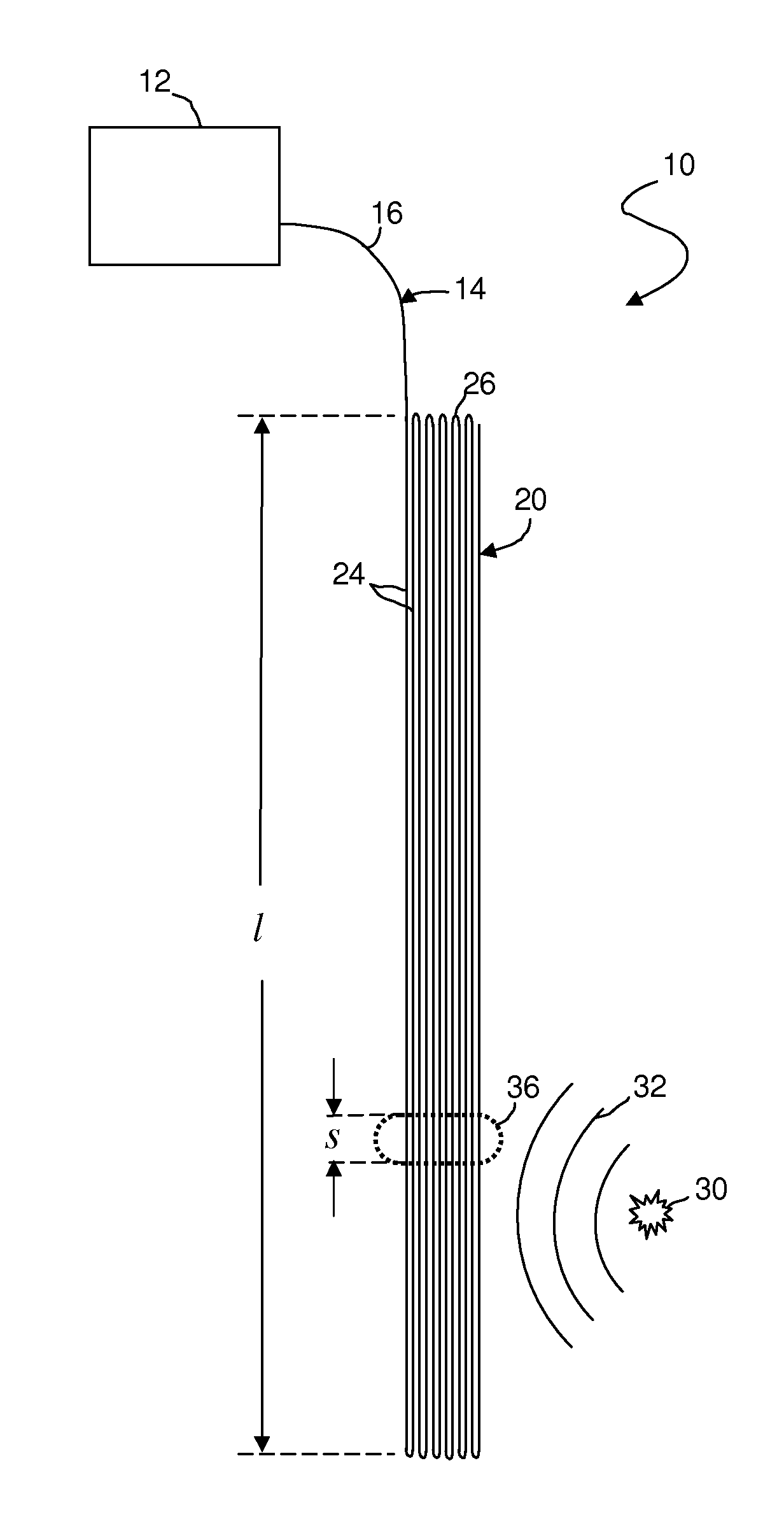

Signal stacking in fiber optic distributed acoustic sensing

ActiveUS9140815B2Improve signal-to-noise ratioLow costSeismic signal receiversSeismic signal processingFiberDistributed acoustic sensing

A method for obtaining information about a subsurface formation from acoustic signals that contain information about the subsurface formation, comprises a) transmitting an optical signal into a fiber optic cable (14) that includes a sensing apparatus (20) comprising a plurality of substantially parallel fiber lengths (24), b) collecting from the sensing apparatus a plurality of received optical signals, each received signal comprising a portion of the transmitted signal that has been reflected from a different segment of a cable length, wherein the different segments are each in different cable lengths and correspond to a single selected location along the sensing cable, and c) processing the collected signals so as to obtain information about an acoustic signal received at the different segments. The cable may be ribbon cable and the lateral distance between the different segments may be less than 10 meters.

Owner:SHELL USA INC

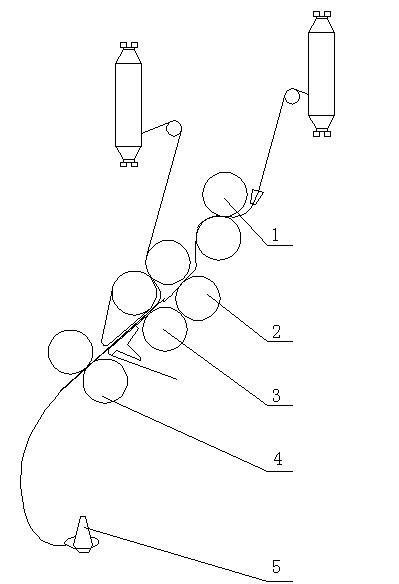

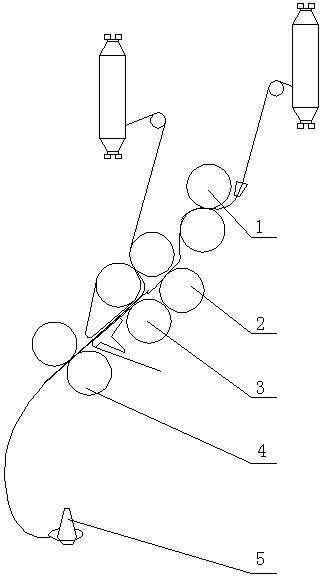

Slubby yarn and production method thereof

The invention discloses slubby yarn which comprises one part of parallel fiber bundles and one part of bamboo joint fiber bundles with raised bamboo joint sections. The invention further provides a production method of the slubby yarn. In the method, a ring spinning fine yarn machine provided with a slubby yarn device is adopted, wherein the ring spinning fine yarn machine comprises a front roller, a middle roller II, a middle roller I and a rear roller which are sequentially arranged for constituting a four-roller drafting device, and the production method comprises the following steps: inputting roving from the rear roller, and drafting by virtue of the front roller so as to form the bamboo joint fiber bundle; simultaneously drafting another type of fibers between the middle roller II and the front roller, and then forming the parallel fiber bundles; and converging the parallel fiber bundles and the bamboo joint fiber bundles at a front jaw, twisting the two into one yarn through a twisting structure, and outputting. The slubby yarn has the following beneficial effects: 1) the slubby yarn comprises one part of the parallel fiber bundles, thereby having great strength and enabling the slubby yarn to be applicable to being woven into a high-grade fabric; and 2) the four-roller fine yarn machine is adopted for production, the product fluctuation is small, the quality of the slubby yarn is improved, and the cost is reduced.

Owner:SHANDONG HONGYE TEXTILE

Signal stacking in fiber optic distributed acoustic sensing

ActiveUS20130100768A1Improve signal-to-noise ratioLow costSeismic signal receiversSeismic signal processingDistributed acoustic sensingFiber

A method for obtaining information about a subsurface formation from acoustic signals that contain information about the subsurface formation, comprises a) transmitting an optical signal into a fiber optic cable (14) that includes a sensing apparatus (20) comprising a plurality of substantially parallel fiber lengths (24), b) collecting from the sensing apparatus a plurality of received optical signals, each received signal comprising a portion of the transmitted signal that has been reflected from a different segment of a cable length, wherein the different segments are each in different cable lengths and correspond to a single selected location along the sensing cable, and c) processing the collected signals so as to obtain information about an acoustic signal received at the different segments. The cable may be ribbon cable and the lateral distance between the different segments may be less than 10 meters.

Owner:SHELL USA INC

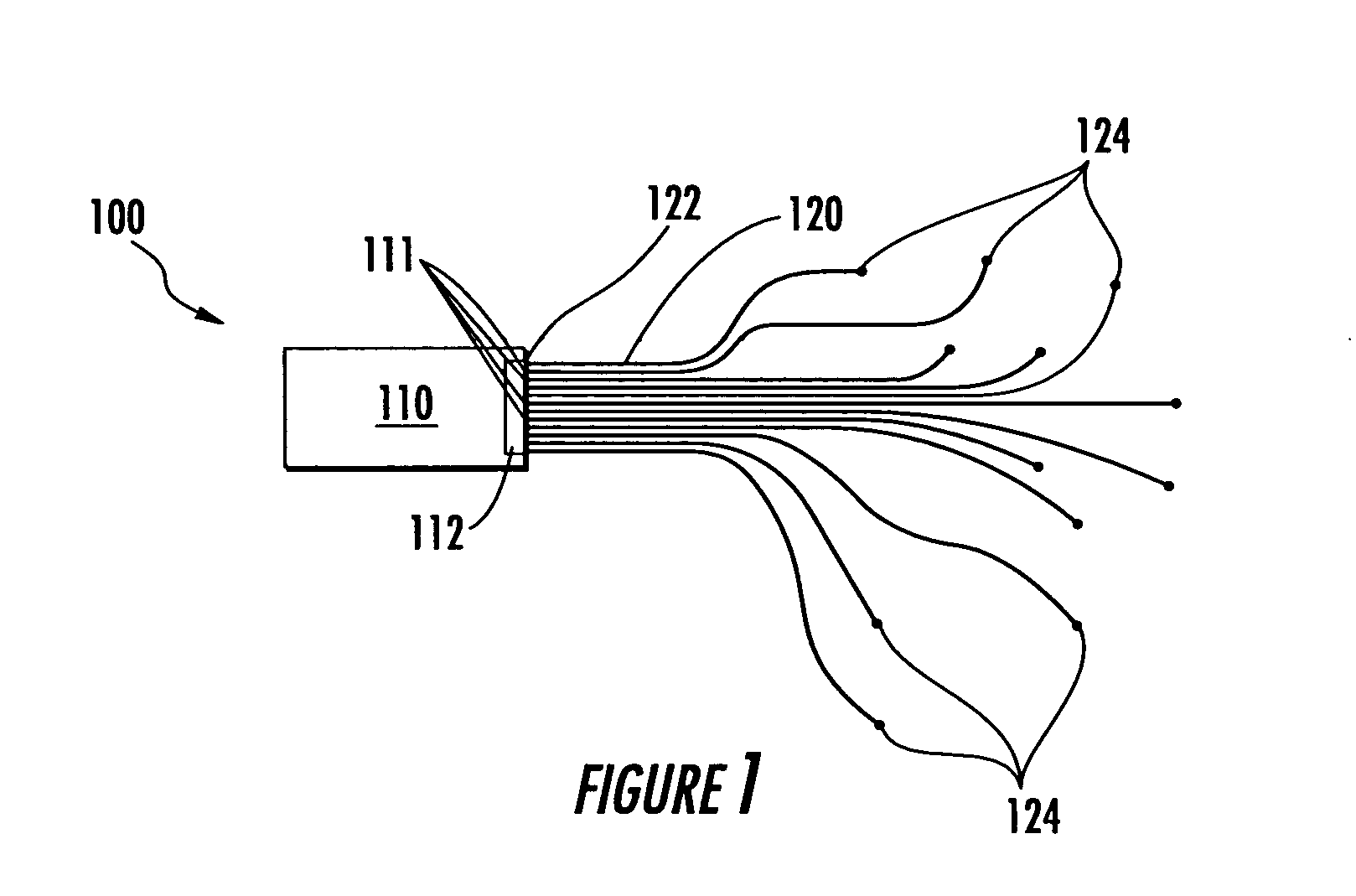

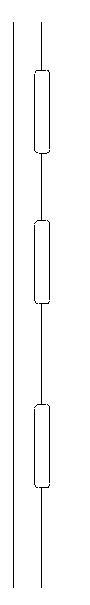

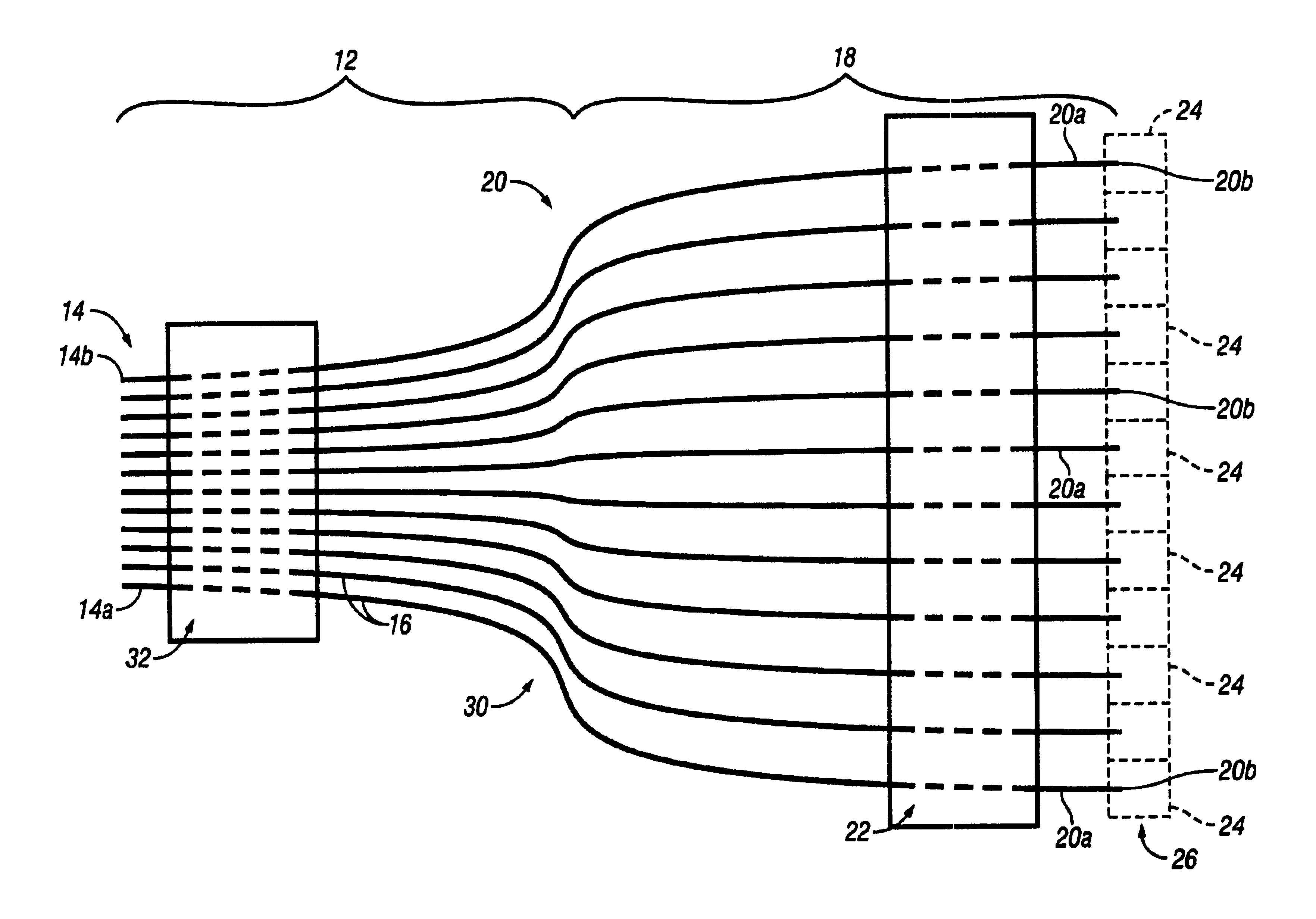

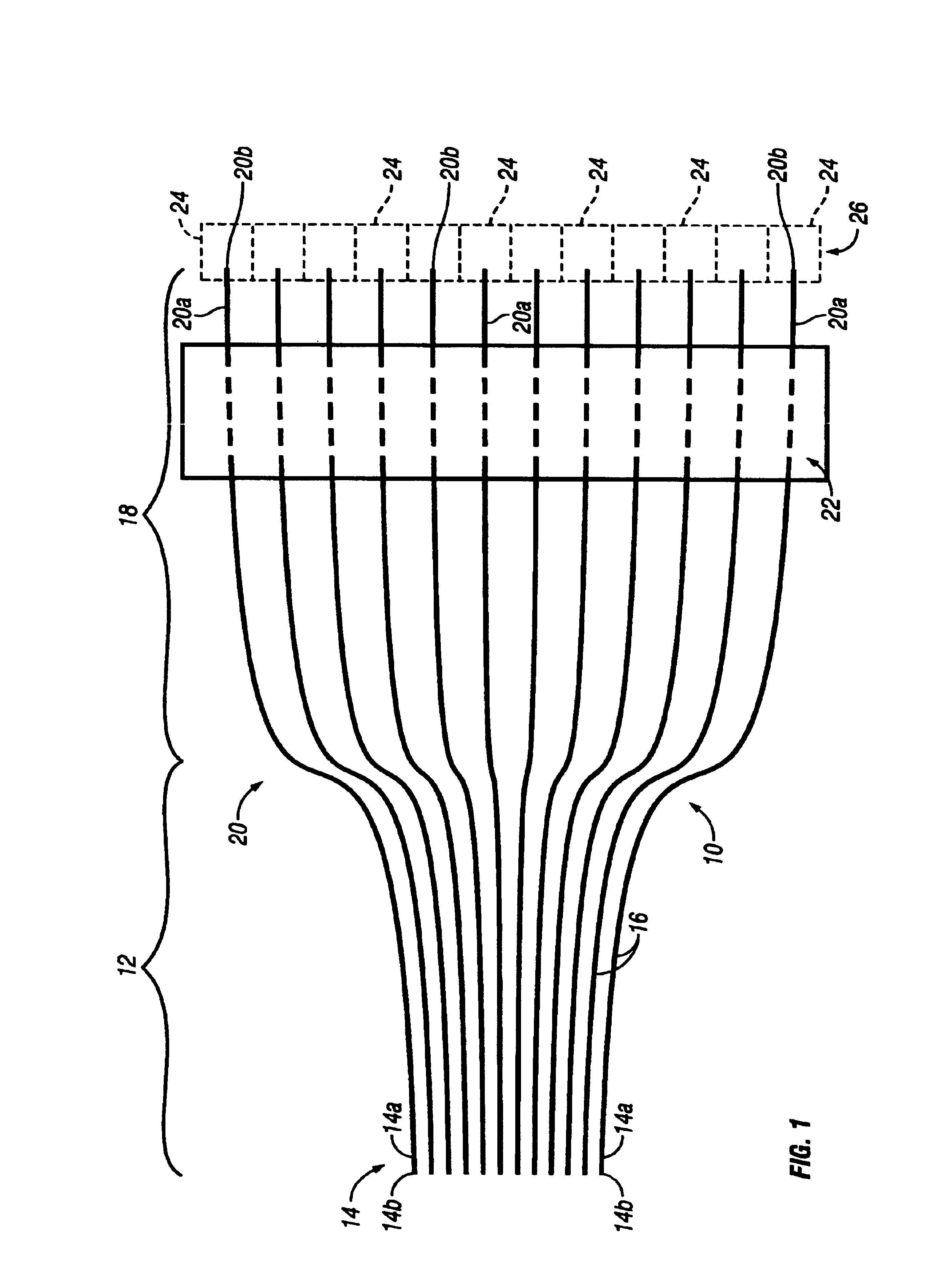

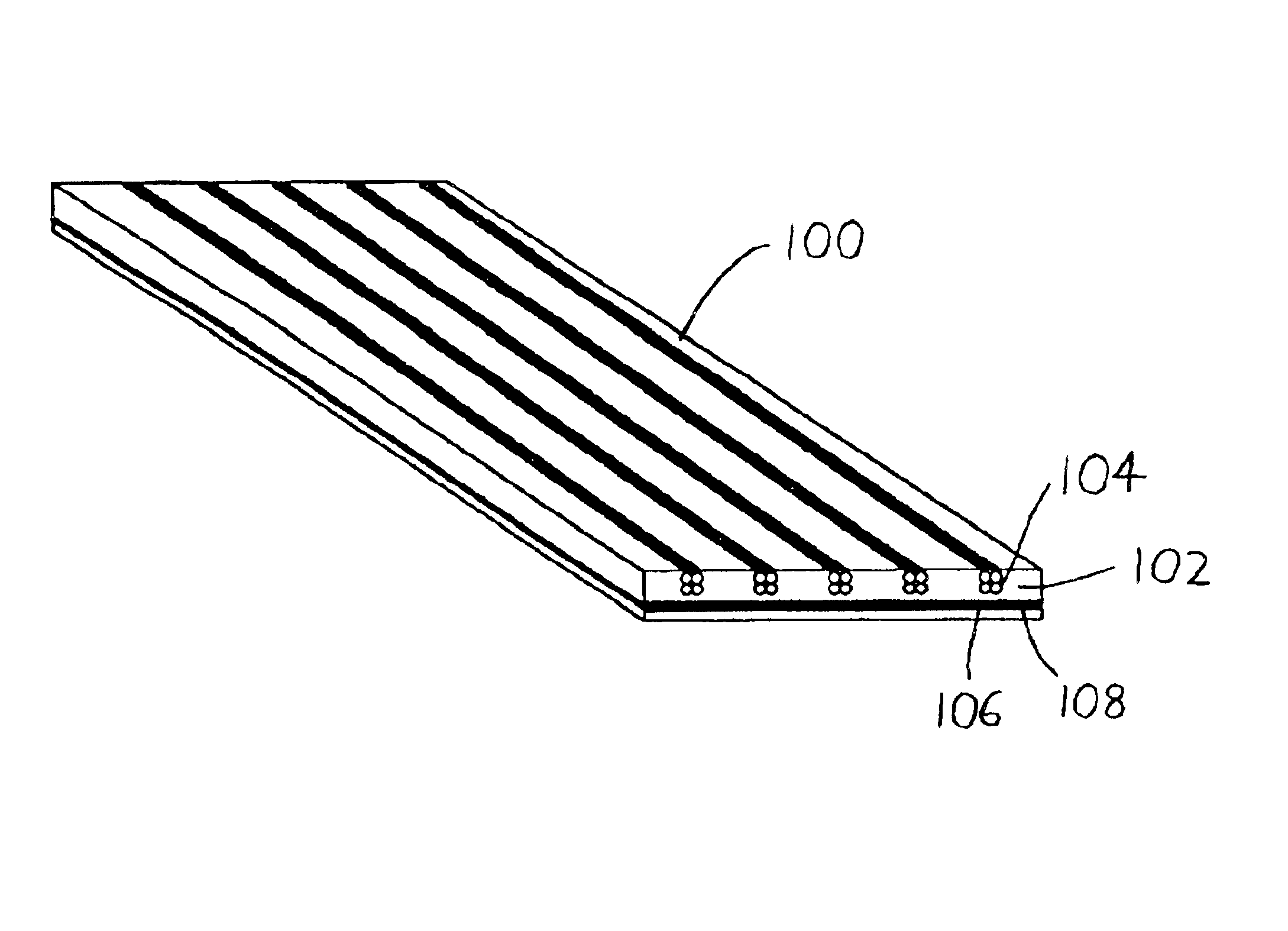

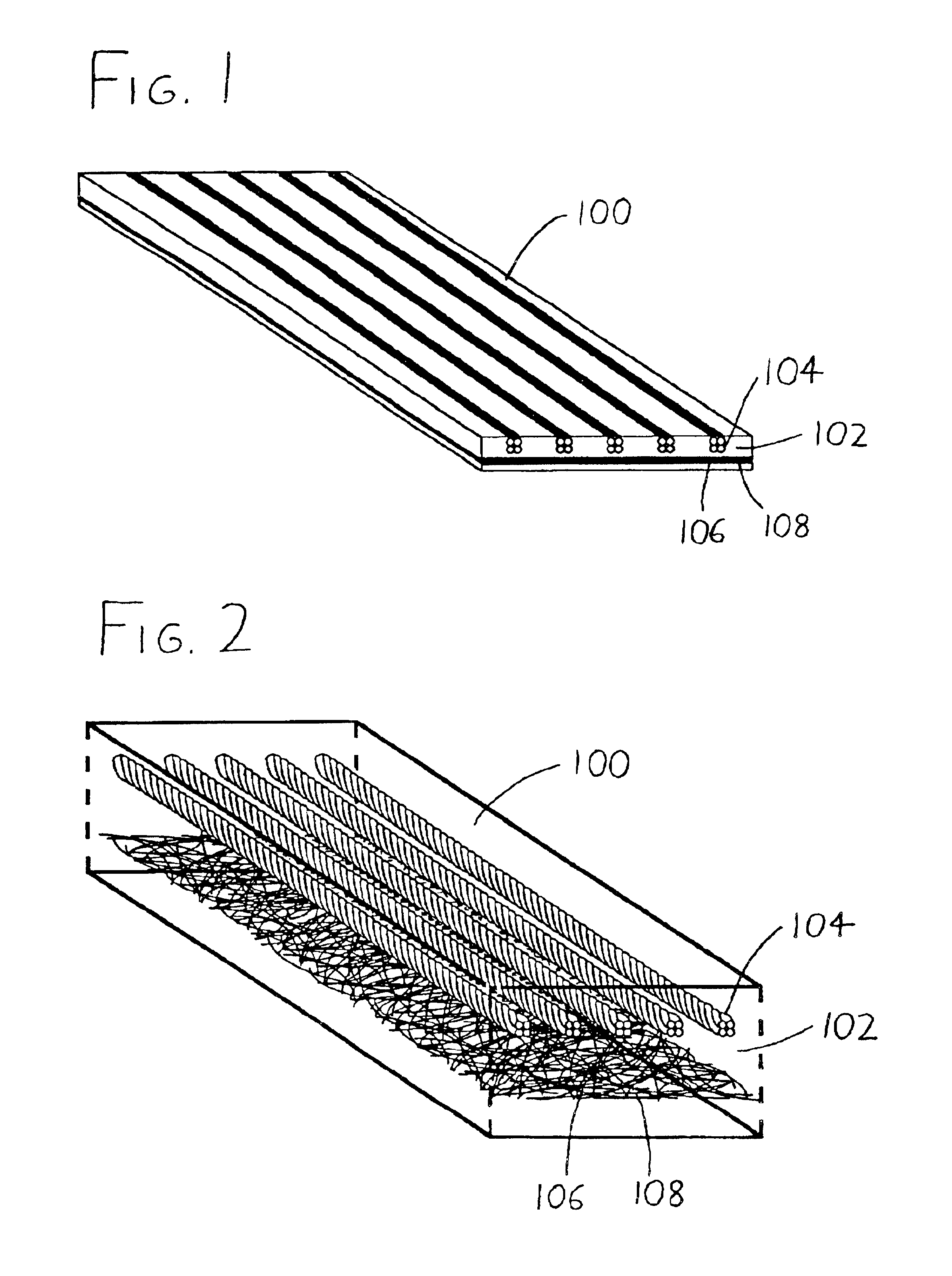

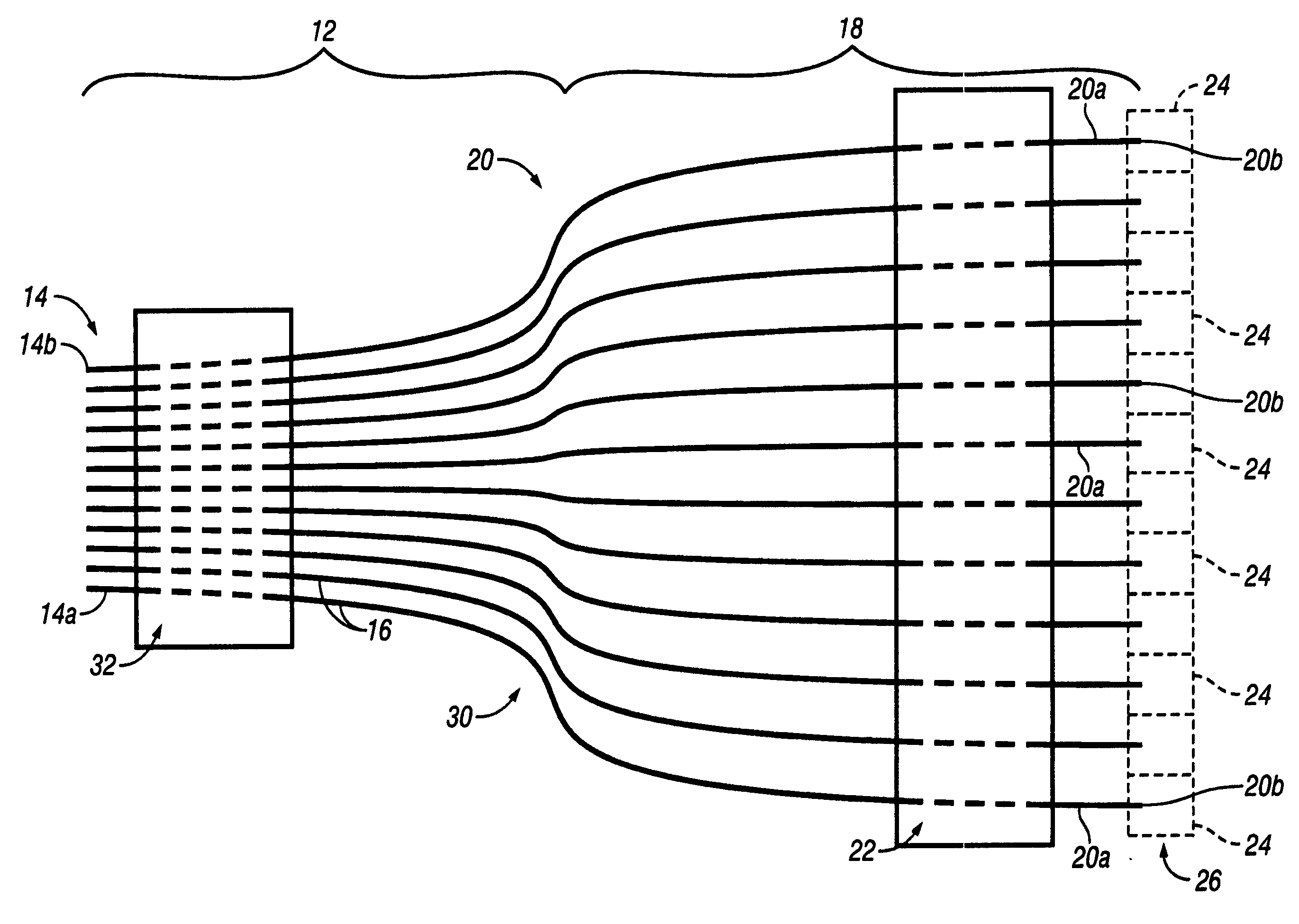

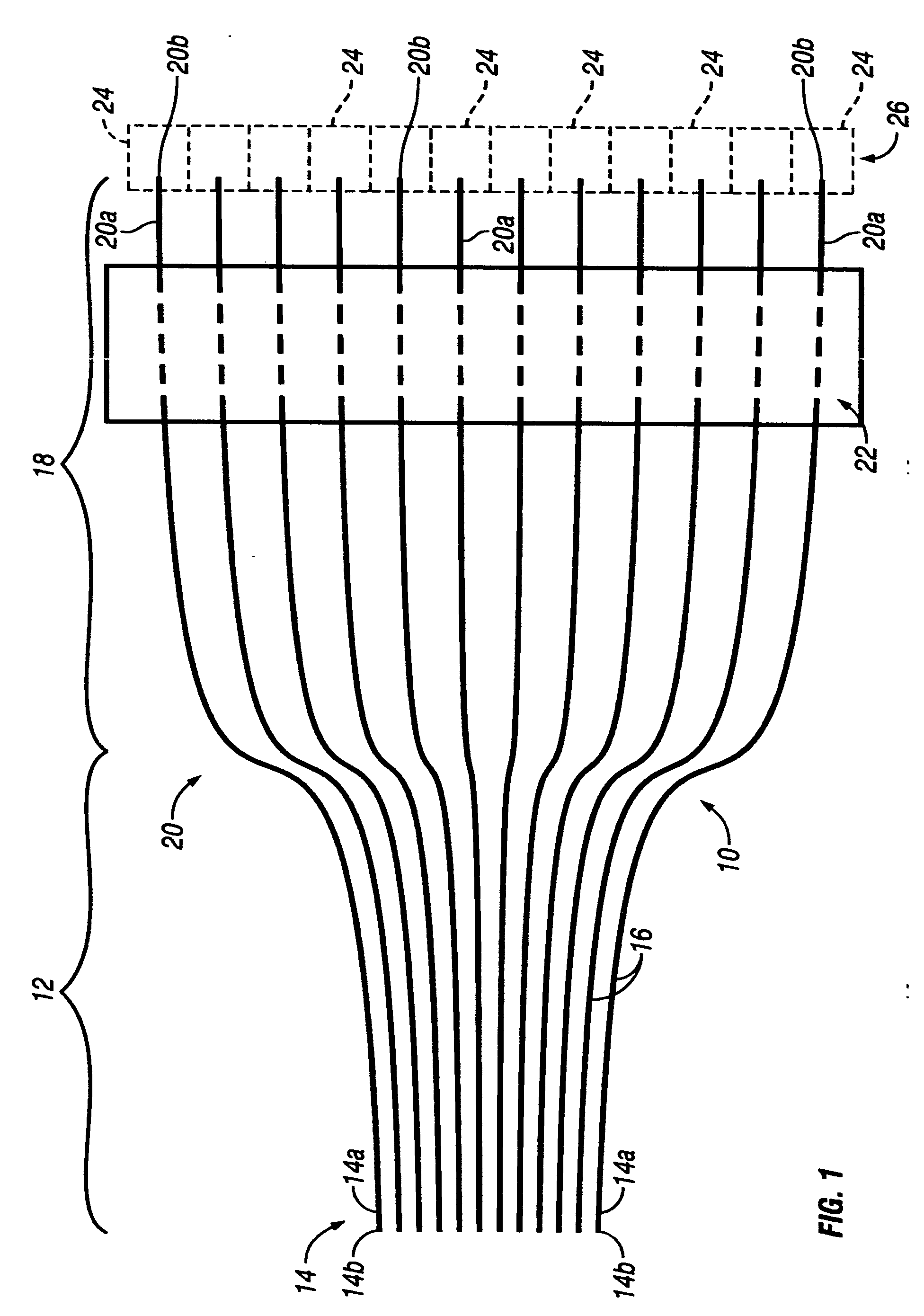

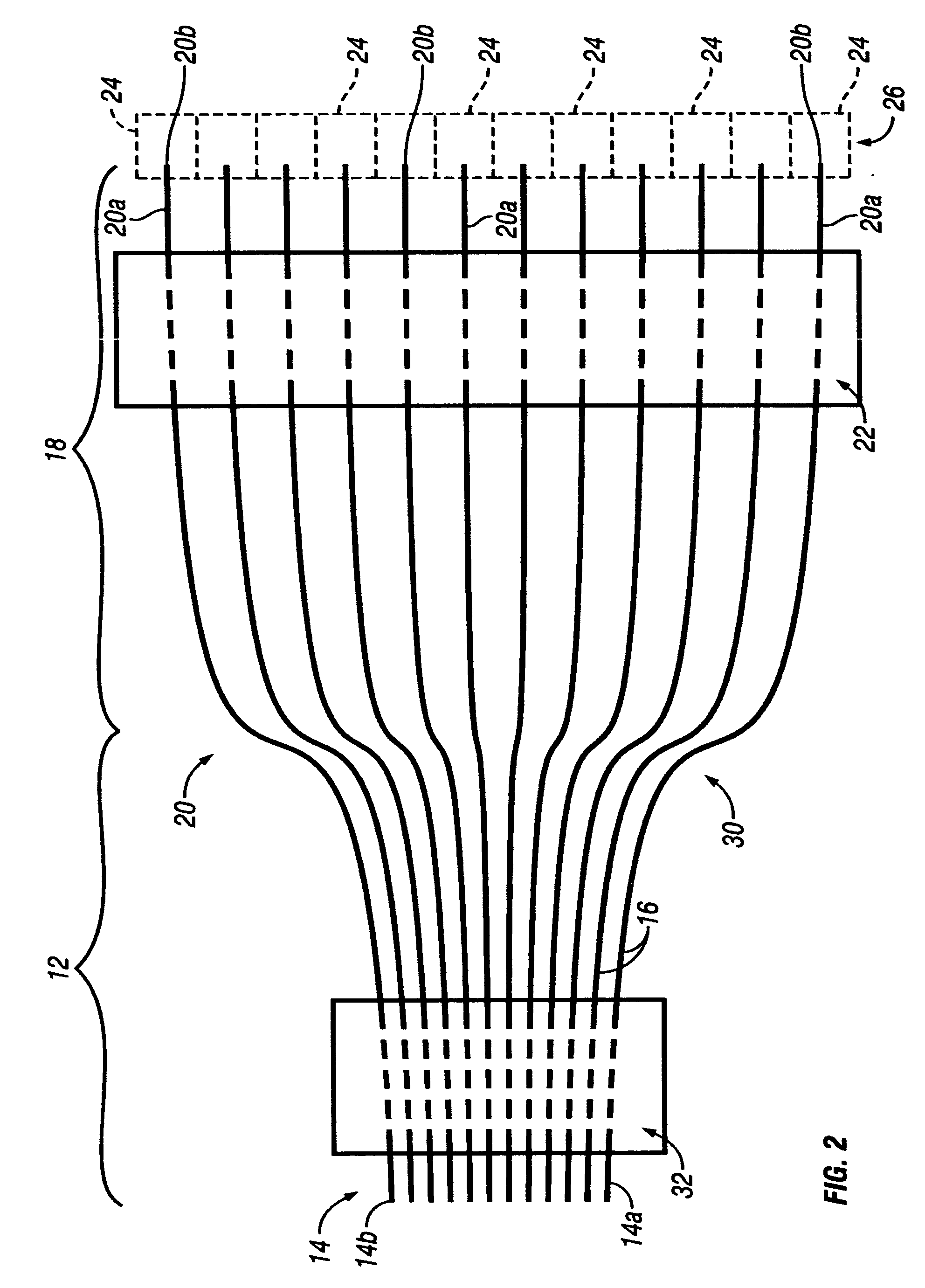

Parallel fiber-fan-out optical interconnect for fiber optic system

A fiber ribbon includes a plurality of first segments of optical fibers that extend in a planar side-by-side arrangement having a first predetermined pitch. A fiber-fan-out including a plurality of second segments of the optical fibers extends in a diverging arrangement from the fiber ribbon. A fiber holder extends across the plurality of second segments of the optical fibers for maintaining a plurality of terminal portions of the second segments in a second predetermined pitch that is greater than the first predetermined pitch so that the terminal portions can each be optically coupled to a corresponding optical subassembly (OSA) of a plurality of OSAs arranged in a linear array. An alternate embodiment uses a second fiber holder in place of the fiber ribbon. The holders can be replaced with a common housing assembly spanning all but the terminal portions of the optical fibers.

Owner:AGILENT TECH INC

Structural reinforcement using composite strips

InactiveUS6811861B2Reduce the potential for damageSimple structureStrutsSynthetic resin layered productsFiberParallel fiber

A composite structural reinforcing strip is affixed to a structure to be reinforced (such as a bridge span, foundation pillar, or similar structure) by the use of several fasteners which extend through the strip and into the structure. The reinforcing strip preferably includes elongated continuous parallel fibers which have lengths extending along the length of the strip, and nondirectional fibers distributed transversely across the strip, with a polymer matrix affixing the parallel and nondirectional fibers. The strip may be placed on the structure to be reinforced, and may be attached thereon by actuating a common powder-actuated fastener gun to send fasteners through the strip and into the structure.

Owner:WISCONSIN ALUMNI RES FOUND

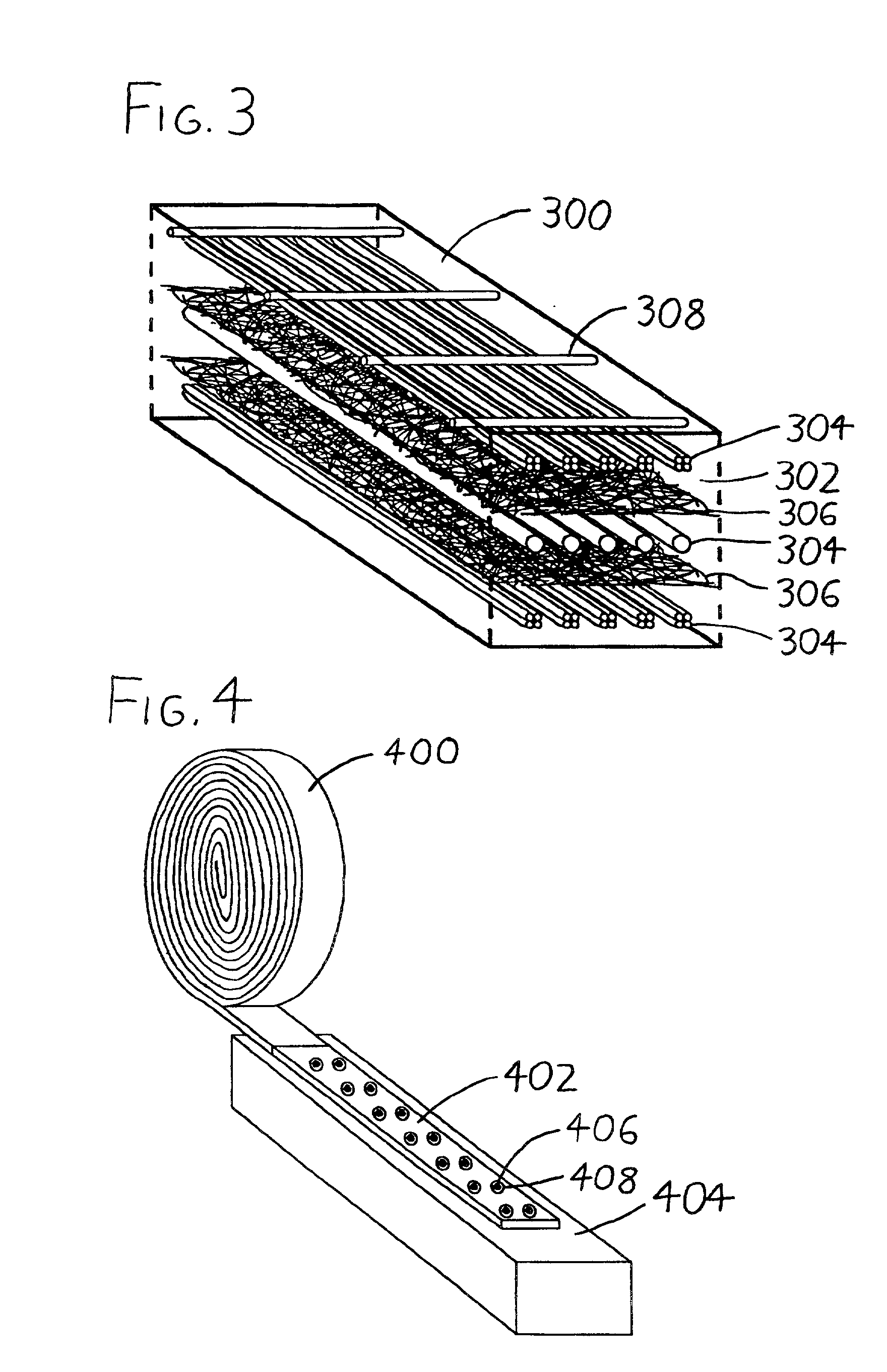

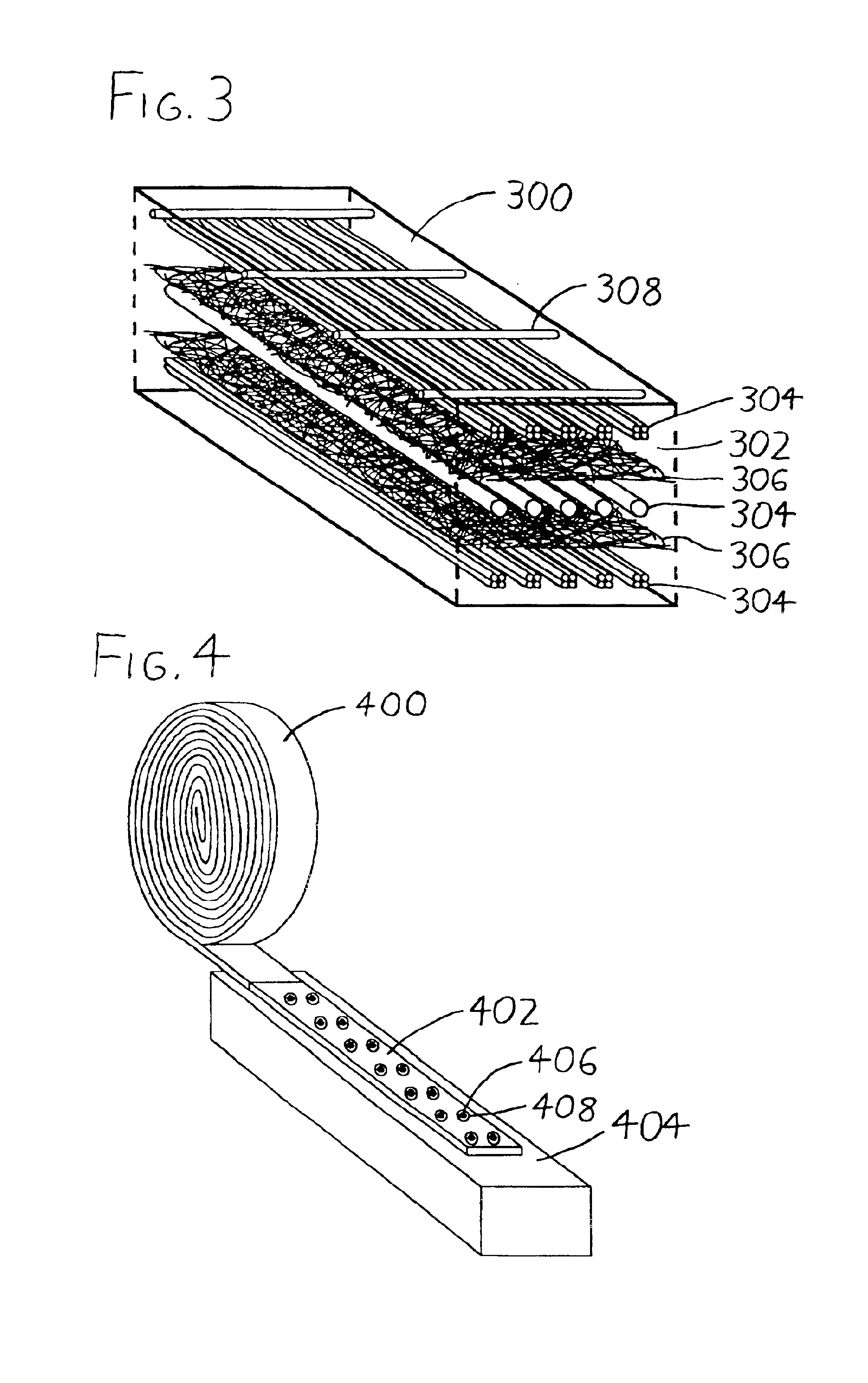

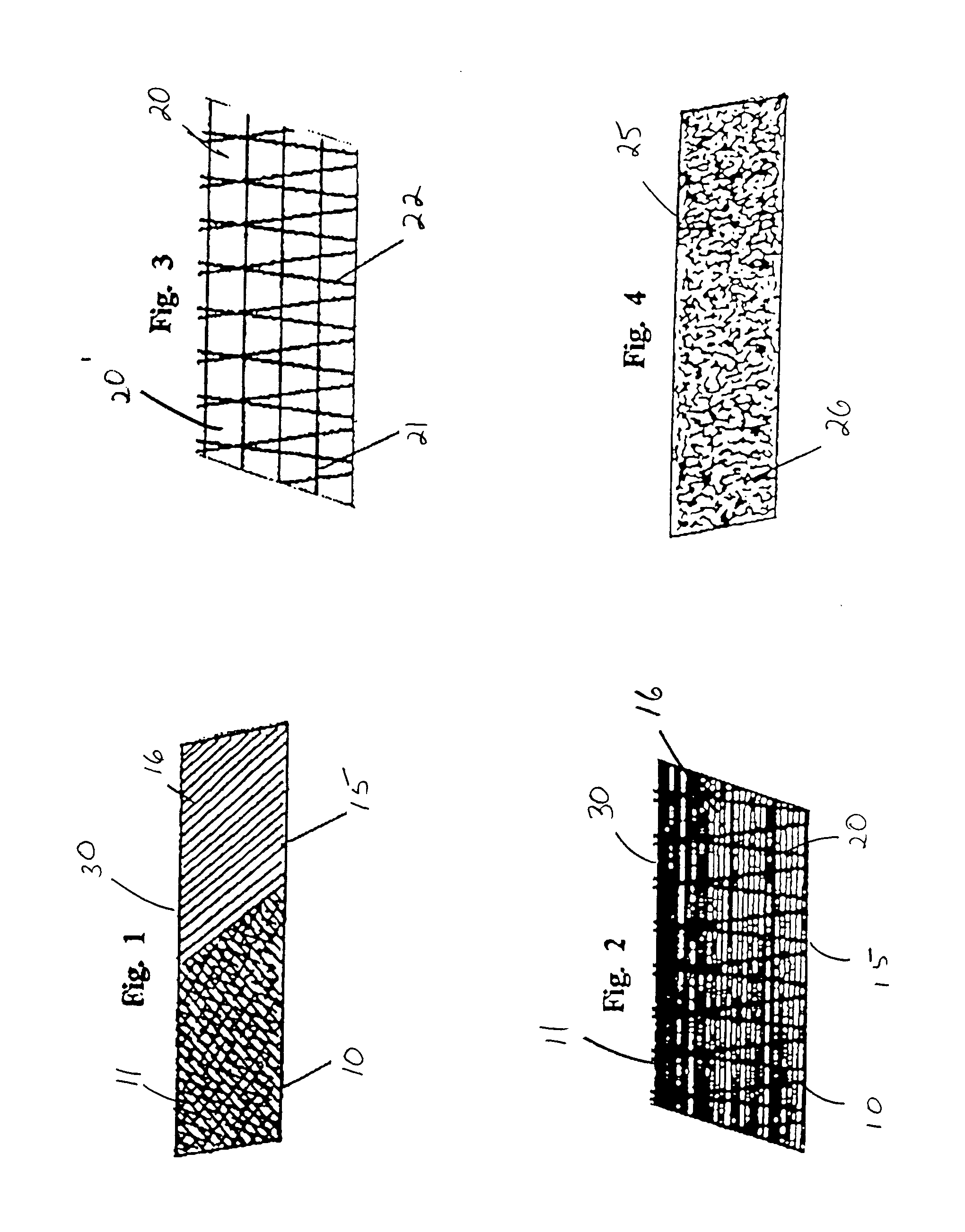

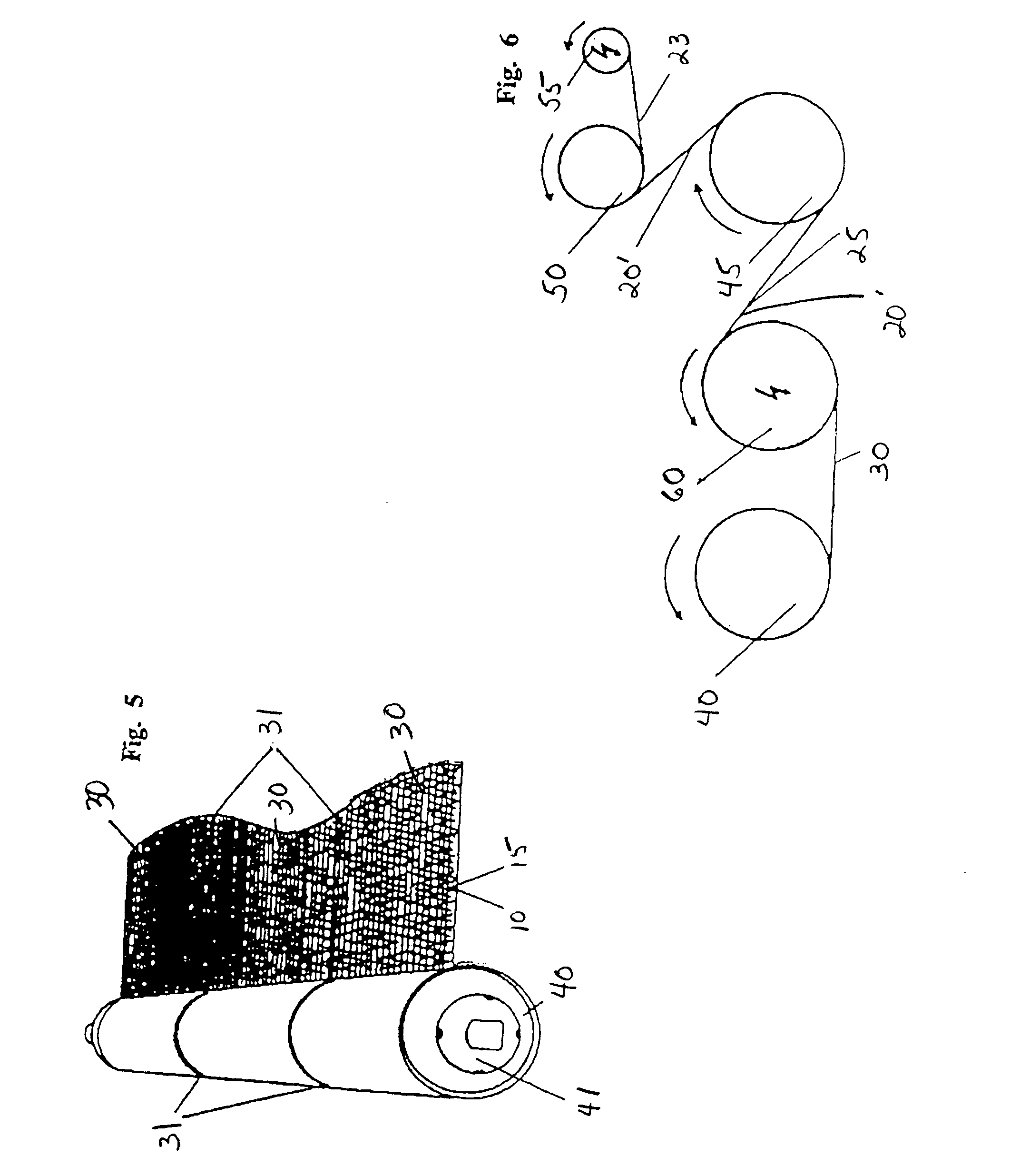

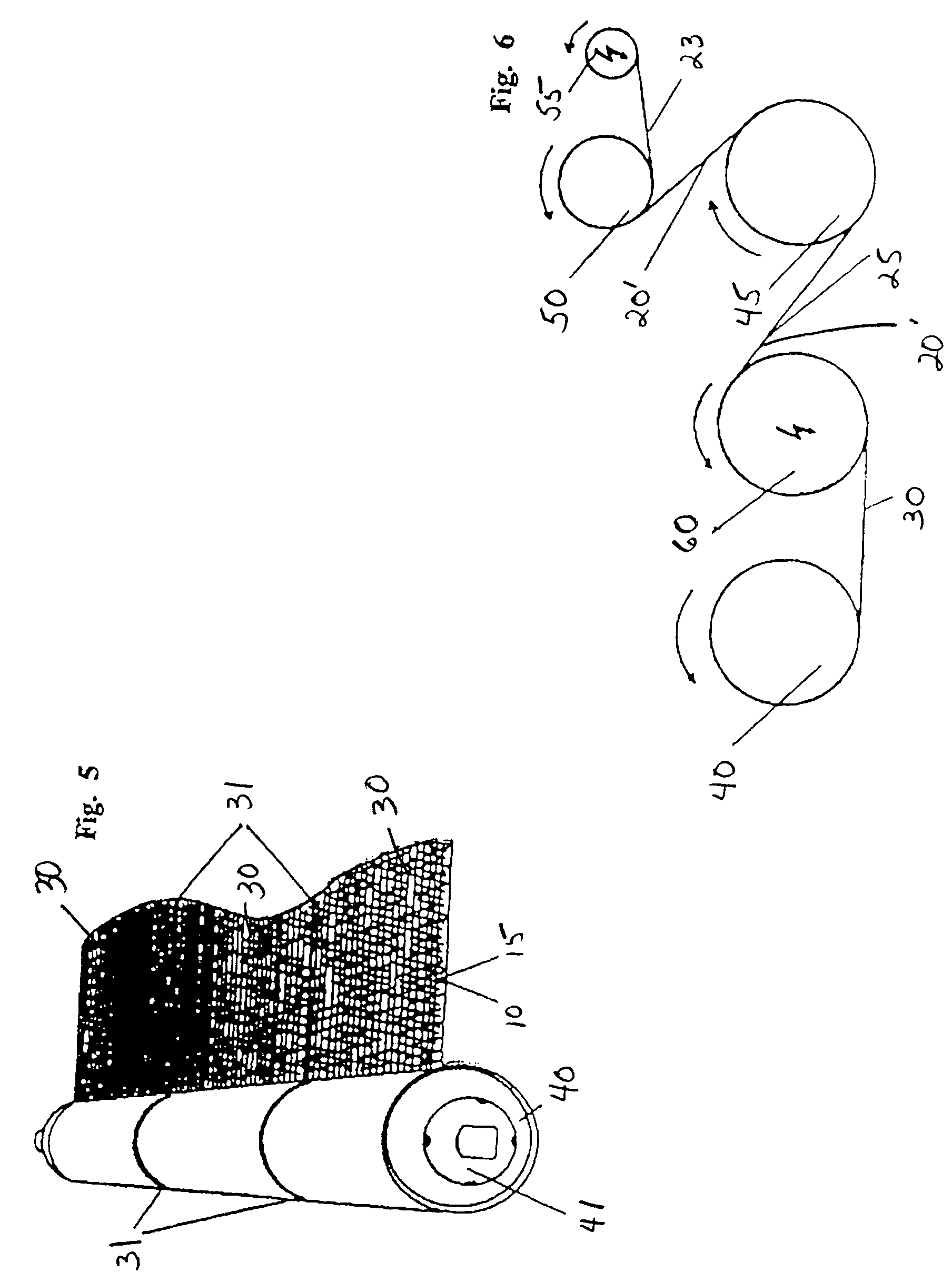

Multilayer textile reinforcement web

InactiveUS20050020168A1Easy laminate resin infusionReduce weightCellulosic plastic layered productsAbrasion apparatusSingle fiberEngineering

Multiple, single fiber webs, consisting of parallel fiber bundles and non-wovens connected by an adhesive thread grid, positioned on a common shaft for simultaneous unwinding. The single webs are dispensed under tension from a primary unwinding drum while, in the same process, an additional adhesive thread grid of non-woven or fiber mat is dispensed and, using tension winding, combined with the single webs into a homogeneous laminate.

Owner:MAGNELL CARL O +1

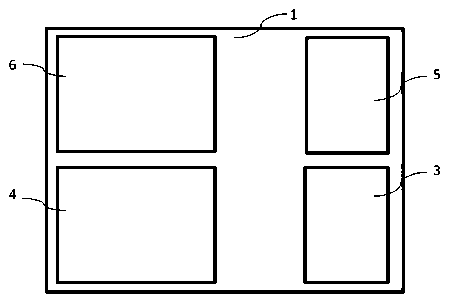

Planar optical waveguide type parallel optical assembly and optical module

InactiveCN103885141AIncrease Bandwidth DensityEasy to integrateCoupling light guidesLaser arrayWaveguide

Disclosed in the invention is a planar optical waveguide type parallel optical assembly comprising a circuit board, an optical waveguide, a laser array, a driver, an optical detector array and a transconductance amplifier. A photoelectric chip is installed at a first side of the circuit board in a back bonding mode. A light-transmitting device is arranged at the circuit board; and the optical waveguide is contacted to a second side of the circuit board and contains a 45-degree mirror surface. In addition, the invention also discloses a planar optical waveguide type parallel optical module. With the planar optical waveguide type parallel optical assembly and optical module, the bandwidth density of optical interconnection is improved; and the process based on the photoelectric integration scheme is simple, so that large-scale production can be realized beneficially. The photoelectric chip is installed by using the back bonding technique, thereby effectively reducing an electric parasitic effect. The light path enters the optical waveguide by a bending way and is directly coupled to a pluggable interface of the parallel fiber, so that the lens is not needed; the less optical elements are used, the coupling structure is simple, and the cost is low. The polymer film is used for manufacturing the optical waveguide; the bending radius is small; and the maneuverability is enhanced.

Owner:SHENZHEN NEOPHOTONICS TECH

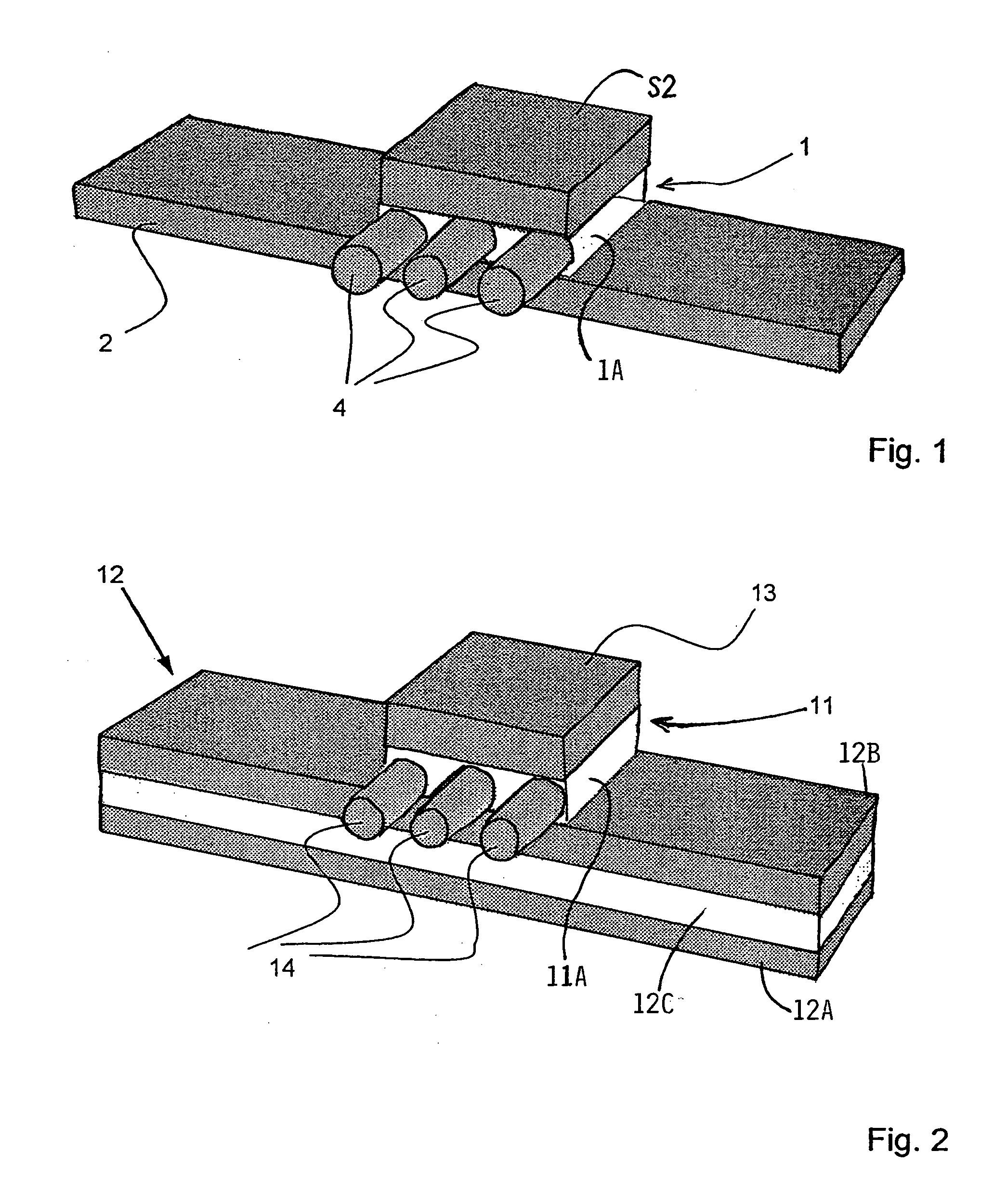

Lightweight structure especially for an aircraft and method for making such a structure

ActiveUS20050112347A1Decrease their propagationExtended service lifeNon-woven fabricsThin material handlingEngineeringParallel fiber

An additional fiber reinforced layer reduces crack propagation in a lightweight structure of an outer skin adhesively bonded to a reinforcing frame. For this purpose the additional fiber reinforced layer is interposed between the outer skin and the frame and adhesively bonded to the outer skin and to the frame. The additional layer has reinforcing fibers extending in parallel to each other or the reinforcing fibers are woven into a fabric embedded in a synthetic adhesive bonding material. The embedding of the parallel fibers or of the fiber fabric in the bonding material is performed either prior to the bonding or during the bonding of the additional layer to the outer skin and to the reinforcing frame.

Owner:AIRBUS OPERATIONS GMBH

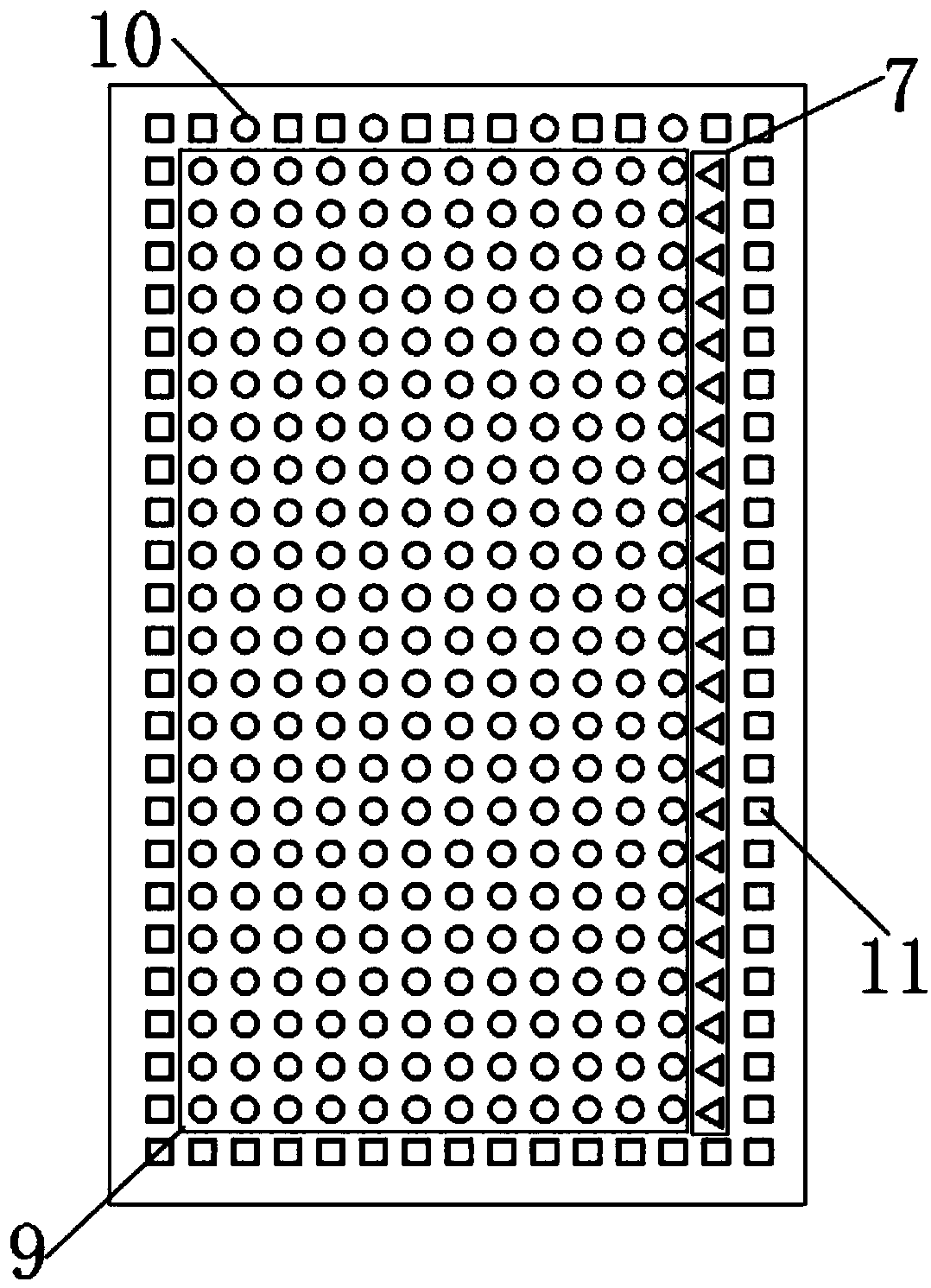

Parallel fiber array and photoelectron chip coupling component

InactiveCN104570240AGood optical performanceImprove reliabilityCoupling light guidesCouplingComputer module

The invention provides a parallel fiber array and a photoelectron chip coupling component. The coupling component includes a printed circuit board (6), a photoelectron chip (8), a fiber array module (5) and a base (7), wherein the photoelectron chip (8) is arranged on the printed circuit board (6), head ends of the fiber array module (5) is aligned with each pixel of the photoelectron chip (8), the fiber array module (5) is arranged on the base (7), and the base (7) is fixed with the printed circuit board (6). The parallel fiber array and a photoelectron chip coupling component has the advantages of simple structure, good coupling performance and high reliability.

Owner:武汉耀晟互连科技有限公司

Method of selectively shaping hollow fibers of heat exchange catheter

InactiveUS7090792B1Widely distributedImprove the heating effectMechanical working/deformationHeat exchange apparatusFiberHollow fibre

Owner:ZOLL CIRCULATION

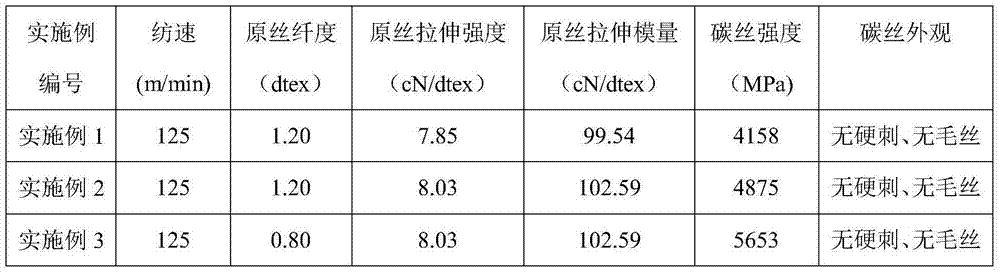

Preparation method of precursor fibers for wet-process spinning PAN-based carbon fibers

InactiveCN104846464AReduce manufacturing costMeet the production processMonocomponent synthetic polymer artificial filamentWet spinning methodsPolymer scienceCarbon fibers

The invention discloses a preparation method of precursor fibers for wet-process spinning PAN-based carbon fibers. The preparation method comprises the following steps: (1) preparation of a polyacrylonitrile raw solution; (A) dissolving raw materials; (B) carrying out polymerization reaction; (C) obtaining the polyacrylonitrile raw solution; and (2) a spinning process: carrying out a condensation and molding process, a water washing process, an oil applying process, a drying and densifying process, a high-pressure steam drafting process, secondary oil application and a loosening hot molding process on the prepared polyacrylonitrile raw solution to obtain the precursor fibers. The residual amount and gel of the raw solution prepared by the method are less and the hydrophily is great; primary fibers obtained by the raw solution in a spinning and condensation molding process are dense and have high transparency, so that the operation in a spinning process is stable when the spinning speed is increased to be more than 125m / min; the solvent residual amount of the precursor fibers is small, and no broken fibers and parallel fibers are formed; the single-path yield is greatly improved and the production cost of the precursor fibers is greatly reduced; and under a high-speed spinning condition, a production process of T700-grade and T800-grade precursor fibers is met.

Owner:HENGSHEN

Core-shell structure compound fiber, preparing method thereof and application of compound fiber to polymer base flexible compound thin film

InactiveCN109913978ASimple structureGood magnetic/electrical propertiesInorganic material artificial filamentsFilament/thread formingParallel fiberPulse power supply

The invention discloses a core-shell structure compound fiber, a preparing method thereof and application of the compound fiber to a polymer base flexible compound thin film. The core-shell structurecompound fiber is composed of a core and a shell which are coaxial. The core is a ferrite fiber with the strong magnetism. The shell is a ceramic fiber with the high dielectric constant. The polymer base flexible compound thin film is prepared from the core-shell structure compound fiber as the filler and polymer base body material, and nanometer fibers in the compound thin film are arrayed in parallel (perpendicular to the surface of the thin film) in the direction away from the thin film; by means of the parallel fibers in the outward direction, the compound thin film can have the high dielectric strength and energy storage density under the low field intensity. Thus, due to the novel compound fiber structure and the presented excellent dielectric performance, the prepared polymer compound thin film is expected to be widely applied on the aspects of embedded capacitors, pulsed power supply technologies and other energy storage devices.

Owner:WUHAN UNIV OF TECH

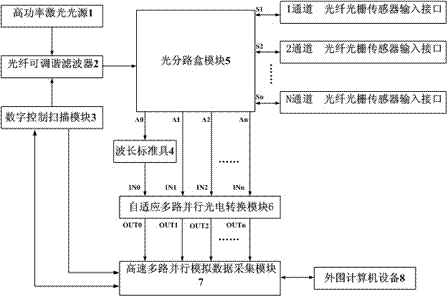

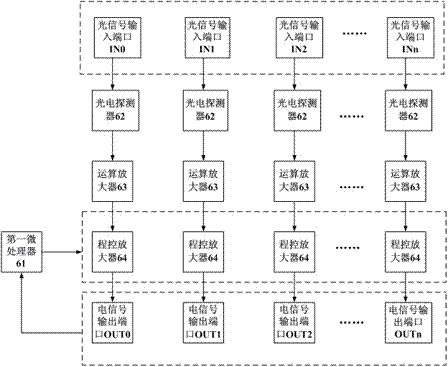

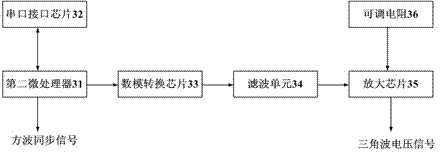

High-capacity parallel fiber bragg grating sensing analyzer

ActiveCN102419187AWide dynamic range of optical power inputWaveform is not distortedConverting sensor output opticallyGratingComputer module

The invention discloses a high-capacity parallel fiber bragg grating sensing analyzer. The sensing analyzer comprises a wavelength standard tool, an optical branching box module and an adaptive multi-channel parallel photoelectric conversion module. The optical branching box module is provided with an output port which is used for connecting the wavelength standard tool, a first bidirectional port, a second bidirectional port, ..., and an nth bidirectional port which are parallel to one another and used for connecting a fiber bragg grating sensor, and a first output port, a second output port, ..., and an nth output port which are used for connecting the adaptive multi-channel parallel photoelectric conversion module. The adaptive multi-channel parallel photoelectric conversion module is provided with n+1 optical signal input ports and n+1 electric signal output ports. An output port of the optical branching box module is connected with the input end of the wavelength standard tool. The output end of the wavelength standard tool, and the first output port, the second output port, ..., and the nth output port of the optical branching box module are respectively connected with the n+1 optical signal input ports of the adaptive multi-channel parallel photoelectric conversion module correspondingly one by one.

Owner:上海汉昆光电科技有限公司

Reinforced paper product and method for making same

A composite paper product has at least inner and outer layers of standard paper bonded to each other and a fiber strand network to form a reinforced paper product. The fiber strand network has a first set of strands extending in a first direction and a second set of strands overlapping the first set and extending in a second direction. In some embodiments the second set of fiber strands overlaps in opposite diagonal directions while overlaying a first set of generally transverse parallel fiber strands. A recyclable binding composition is used to glue the various fiber and paper layers together to yield a unitary sheet of reinforced composite paper.

Owner:GREENER BAGS LLC

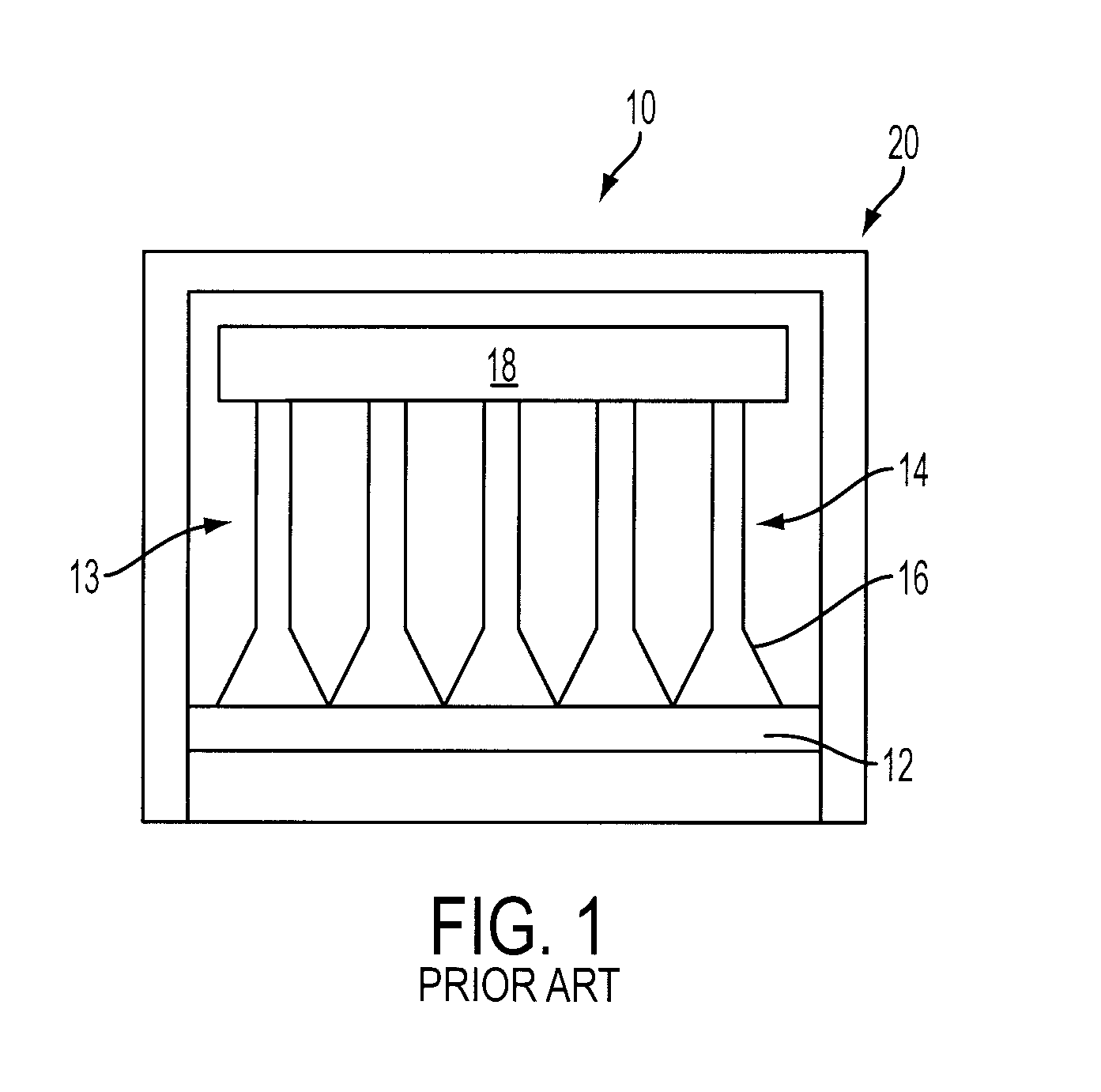

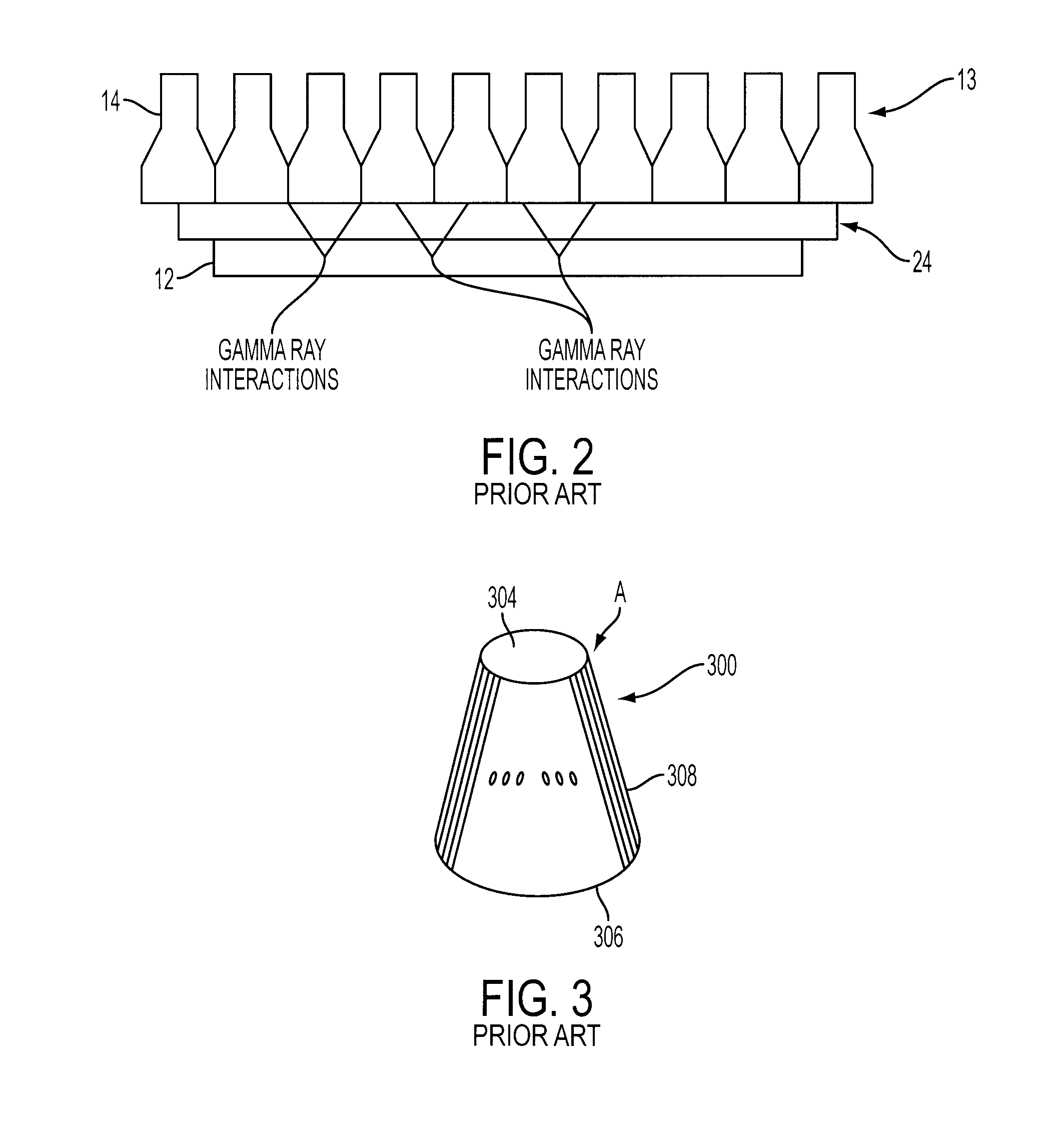

Radiation detector having a fiber optic wedge with a plurality of parallel fibers

InactiveUS20080061243A1Low priceCost effectiveMaterial analysis by optical meansRadiation intensity measurementFiberPhotovoltaic detectors

A radiation detector having a fiber optic wedge with a plurality of parallel optical fibers is provided for yielding a more cost-effective radiation detector by reading out more scintillator elements or crystals per photodetector surface area. The fiber optic wedge provides a cost efficient method for increasing the number of scintillators that may be read out by a single position-sensitive photodetector of the radiation detector, such as a PET camera.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

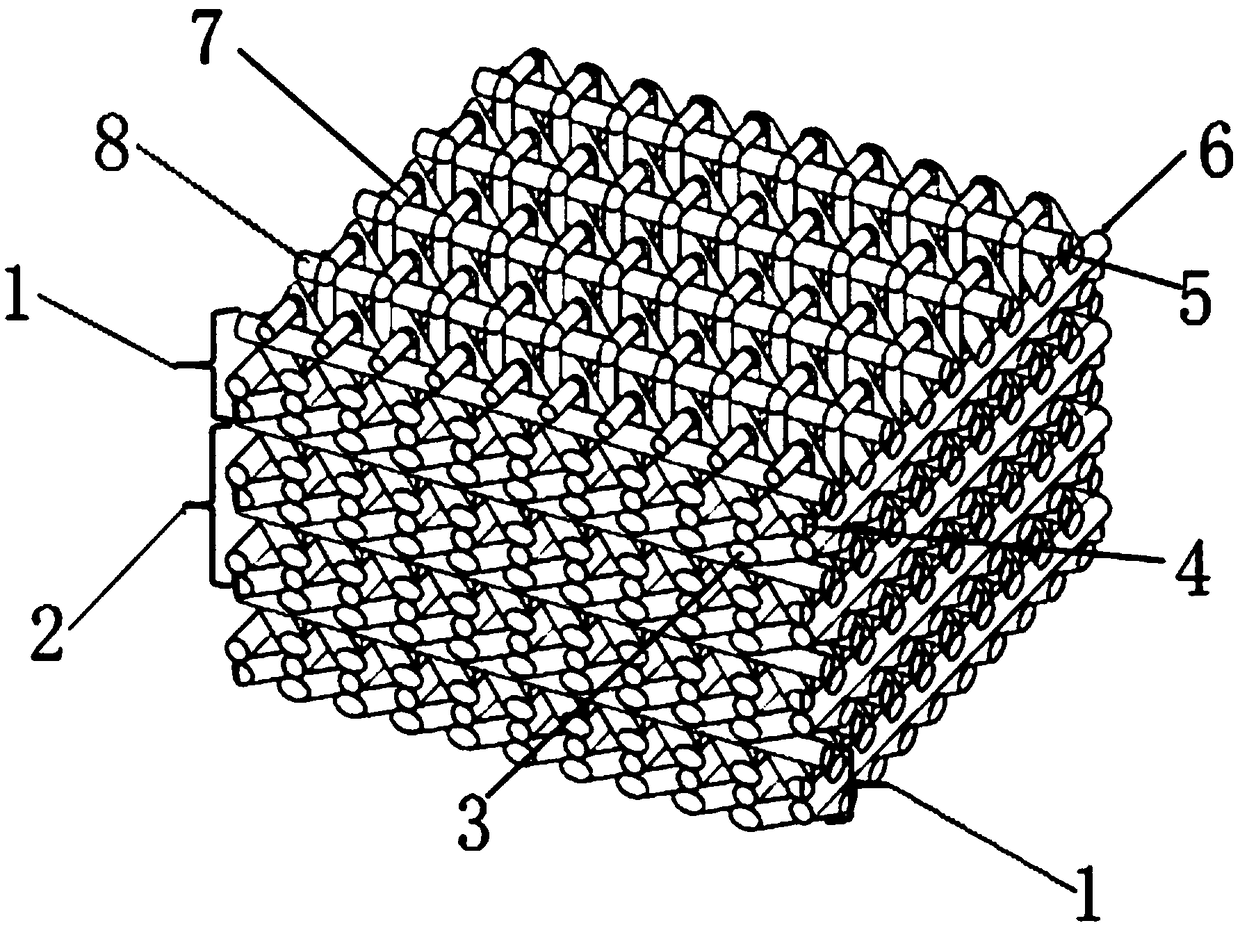

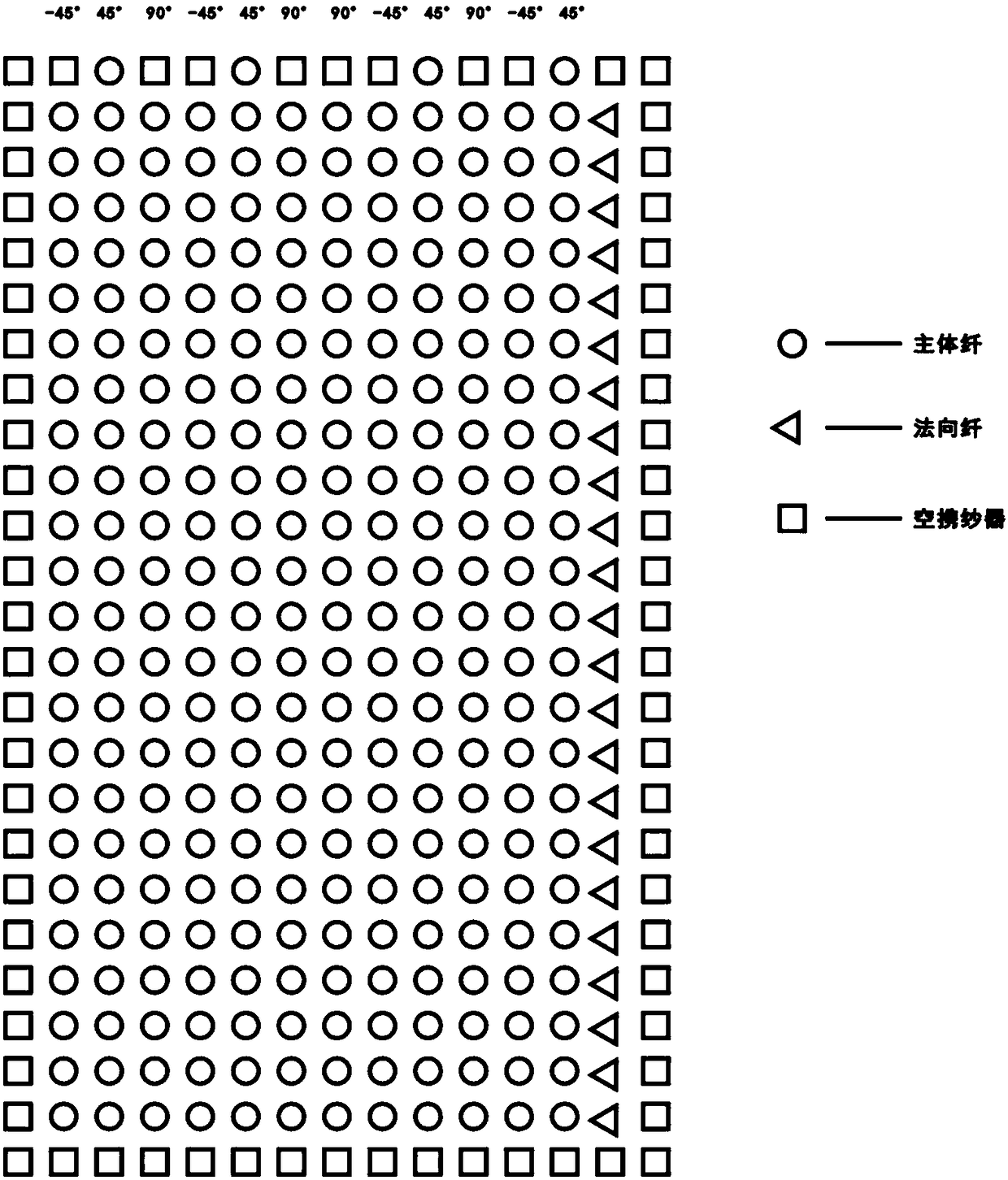

In-plane quasi-isotropic structure-stealthy composite material and preparation method thereof

The invention discloses an in-plane quasi-isotropic structure-stealthy composite material and further comprises a preparation method of the in-plane quasi-isotropic structure-stealthy composite material. The in-plane quasi-isotropic structure-stealthy composite material comprises a base body and a reinforcement body which are composited and solidified through a VARTM process. The base body is madeof resin; the reinforcement body is made of sandwich-type three-dimensional stereo woven material, the woven material is composed of a plurality of mutually-parallel fiber layers and normal fibers perpendicular to the fiber layers, and the fiber layers are bound together by the normal fibers through a weaving method. The preparation method specifically comprises the following steps of 1, weavingof the reinforcement body; 2, reinforcement body moulding; 3, glue injecting and solidifying; and 4, demoulding. The problems that as for a stealthy composite material in the prior art, the electromagnetic property is isotropic, the anti-impact property is poor, and the stealthy composite material is likely to be layered after being impacted are solved.

Owner:浙江世涛鼎革新材料有限责任公司

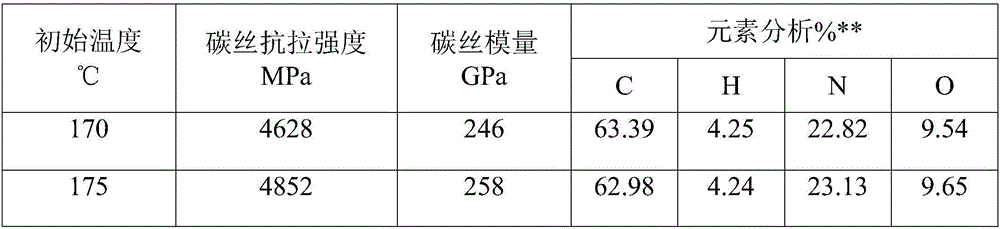

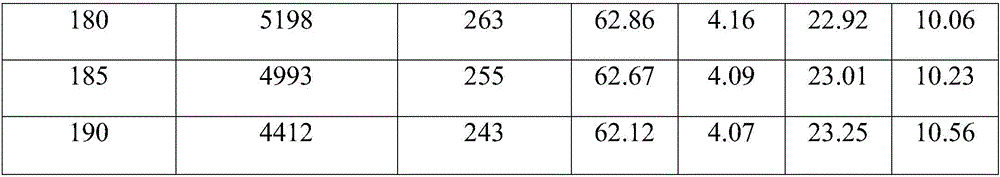

Method for preparing carbon fibers by carbonizing polyacrylonitrile precursors

ActiveCN106835365AImprove heat resistanceHigh degree of molecular orientationFibre chemical featuresPolymer scienceCarbon fibers

The invention provides a method for preparing carbon fibers by carbonizing polyacrylonitrile precursors. The method comprises the following steps: 1, pre-oxidizing in multiple temperature zones at the temperature of 160-310 DEGC for 60-120 minutes with the draft degree of 0.5-10 percent; 2, carbonizing in multiple temperature zones at low temperature of 400-1000 DEG C for 60-120 seconds with the total draft degree of 1-8 percent; and 3, carbonizing in multiple temperature zones at high temperature of 800-1600 DEG C for 60-120 seconds with the draft degree of negative 8 percent-negative 1 percent. According to the method, the temperature gradient, temperature range, draft ratio, wire traveling speed and other parameters in each stage of the carbonizing process are reasonably designed, so that the pre-oxidizing and carbonizing processes can be performed smoothly, and pre-oxidized fibers have good heat resistance, high molecular orientation degree and compact molecular distribution, uniform carbon fiber structure and few broken and paralleled fibers, and have a tensile strength of over 5000MPA, so that the aim of improving carbon fiber product quality can be achieved.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

Bicolor bamboo joint composite yarn and production method thereof

InactiveCN103147202AGood hygroscopicityExcellent antibacterial and anti-ultraviolet propertiesDrafting machinesYarnYarnFiber bundle

The invention discloses a bicolor bamboo joint composite yarn and a production method thereof. The bicolor bamboo joint composite yarn is produced by adopting a four-roller spinning frame; after horn mouths and roller notch grooves are additionally arranged, three strands of rough yarns can be simultaneously input and bamboo joint fiber bundles are subjected to independent immersing treatment and tensile failure treatment; after the bamboo joint fiber bundles are subjected to immersing treatment, the bamboo joint fiber bundles are tensioned off to form bamboo joint sections due to the fact that the roller movement is intermittent; and small sections are clamped and twisted between parallel fiber bundles of two strands of normal spinning, are in special fiber distribution and form the bamboo joint composite yarn with clear bamboo joint sections. The bicolor bamboo joint composite yarn has the advantages of multiple yarns; bamboo joints at two end heads of the tensioned bamboo joint sections are in special clear distribution and are different from raw materials of the parallel fiber bundles in difference and dyeing rate, so that the bamboo joints and the raw materials of the parallel fiber bundles have different special effects after being dyed; and the bicolor bamboo joint composite yarn is novel and varied in appearance and broad in market prospect and realizes the change of colors and the change of functions.

Owner:DONGHUA UNIV +1

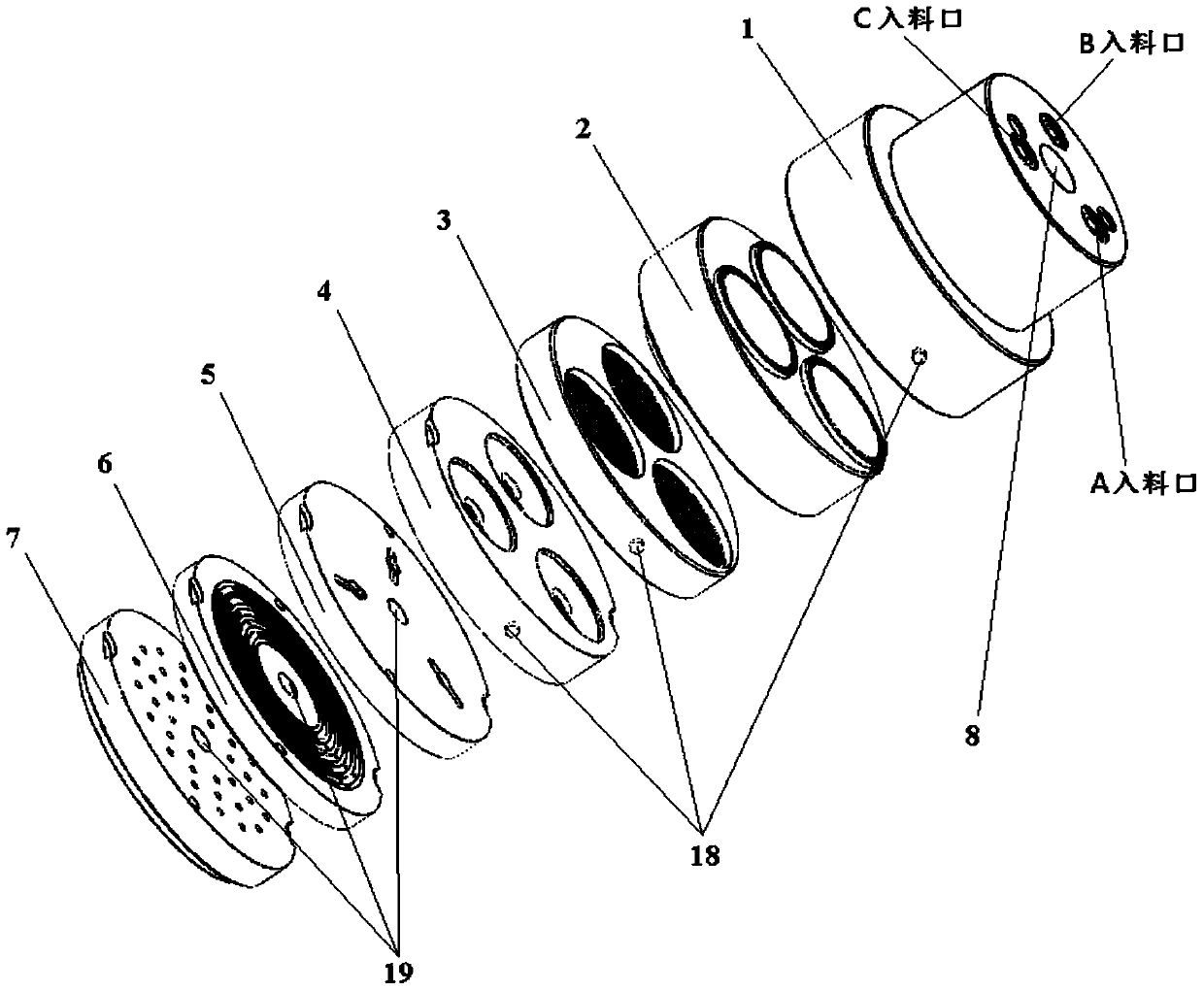

Spinning assembly for producing three-component parallel fibers

The invention relates to a spinning assembly for producing three-component parallel fibers. 7 flow guiding slots communicated with a third distribution plate are arranged at one face of a composite board to introduce fused materials, meanwhile 4 flow guiding slots are arranged at the positions, corresponding to the first, third, fifth and seventh flow guiding slots of the 7 flow guiding slots, at the other side of the composite board; radial communicated slots are arranged on drainage holes among the 4 flow guiding slots to composite three fused materials, and a spinneret plate with spinneret holes corresponding to the drainage holes among the 4 flow guiding slots is designed. Different types of three-component composite fibers can be produced by changing the variety of the fused materials or adding color master batches with different colors, the fibers can be applied to medical and anti-fake fibers and the three-component composite anti-fake fibers are obviously improved in anti-fake effect compared with single-component and dual-component composite fibers.

Owner:DONGHUA UNIV

Parallel fiber-fan-out optical interconnect for fiber optic system

A fiber ribbon includes a plurality of first segments of optical fibers that extend in a planar side-by-side arrangement having a first predetermined pitch. A fiber-fan-out including a plurality of second segments of the optical fibers extends in a diverging arrangement from the fiber ribbon. A fiber holder extends across the plurality of second segments of the optical fibers for maintaining a plurality of terminal portions of the second segments in a second predetermined pitch that is greater than the first predetermined pitch so that the terminal portions can each be optically coupled to a corresponding optical subassembly (OSA) of a plurality of OSAs arranged in a linear array. An alternate embodiment uses a second fiber holder in place of the fiber ribbon. The holders can be replaced with a common housing assembly spanning all but the terminal portions of the optical fibers.

Owner:AGILENT TECH INC

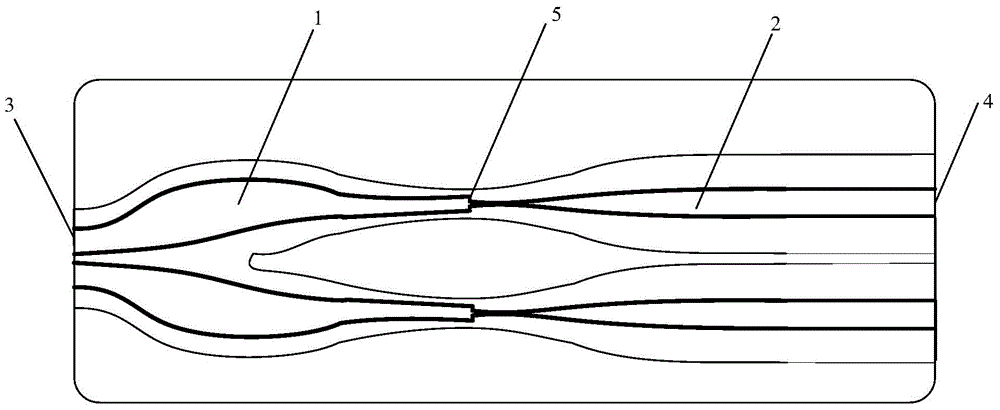

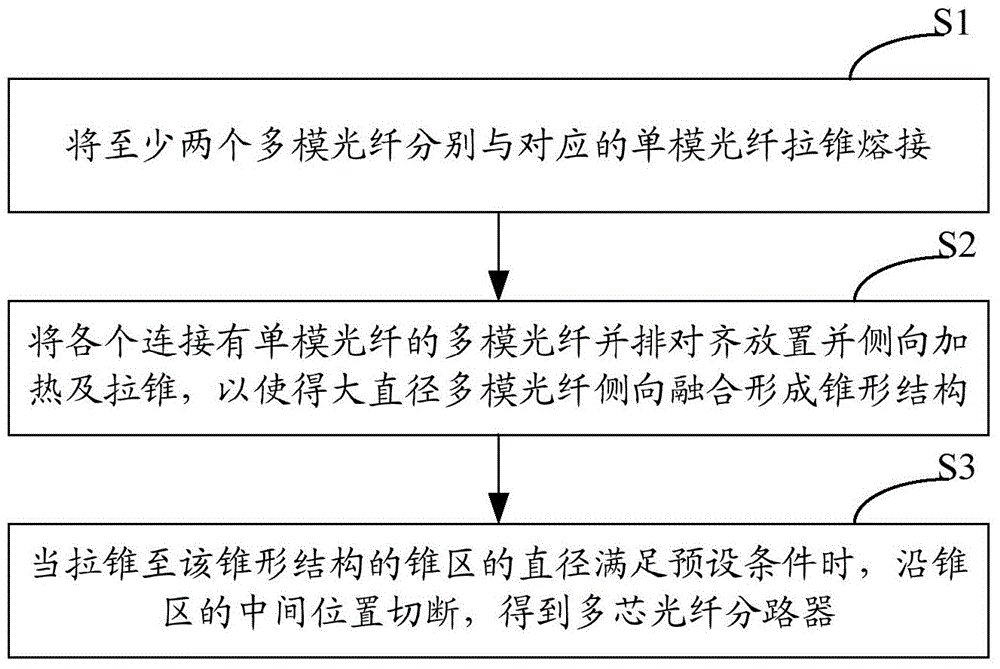

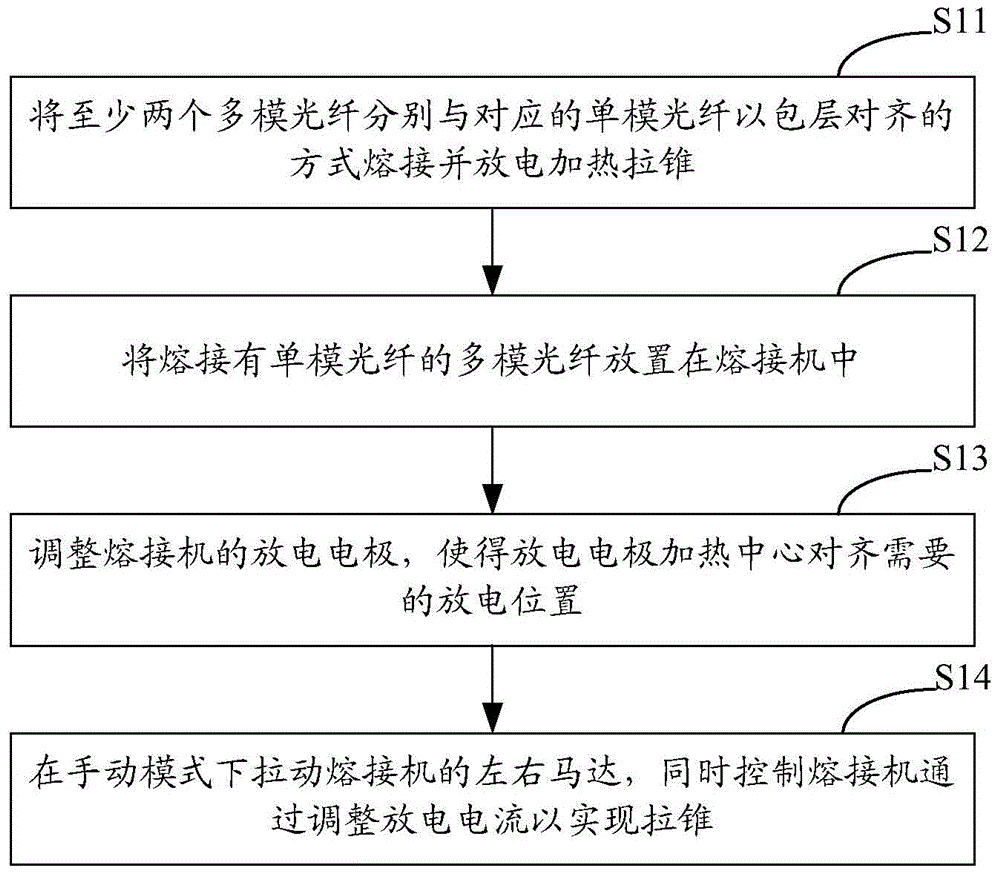

Multi-core fiber demultiplexer and manufacturing method thereof

ActiveCN104880771AAchieve single-mode outputLow insertion lossCoupling light guidesTwin-leadDual core

The invention belongs to the technical field of fibers, and provides a multi-core fiber demultiplexer and a manufacturing method thereof. The multi-core fiber demultiplexer includes at least two multi-mode fibers formed by tapering fusion. The non-fused end of each multi-mode fiber is welded to a single-mode fiber through tapering. Single-mode outputs are achieved, the insertion loss is low, and the multi-core fiber demultiplexer is simple in manufacturing method, functions reliably and is low in cost. When the multi-core fiber demultiplexer is a dual-core fiber demultiplexer, the light energy of two parallel fiber cores in a dual-core fiber is output with low loss and also in an optical coupling manner, thus greatly widening applications of the dual-core fiber in the field of sensing and communication. Meanwhile, two large semicircular fiber cores approaching to each other in distance are arranged on the transverse plane of the dual-core fiber demultiplexer, so the dual-core fiber demultiplexer is suitable for both a coupling type dual-core fiber with a small core distance and a non-coupling type dual-core fiber with a big core distance.

Owner:SHENZHEN UNIV

Armor plate and manufacturing method thereof

InactiveCN108759570AImprove ballistic performanceImprove adhesion strengthArmour platesRough surfaceEngineering

The invention provides an armor plate and a manufacturing method thereof. The armor plate comprises a ceramic layer, a connecting layer, a plurality of polyethylene fiber layers and bonding layers. The multiple polyethylene fiber layers are laminated from top to bottom. The adjacent polyethylene fiber layers are bonded through the bonding layers. Each polyethylene fiber layer is pressed and moldedthrough a laminating mode. Any polyethylene fiber layer is provided with a plurality of parallel fiber filaments arranged unidirectionally. Between everytwo adjacent polyethylene fiber layers, the fiber filaments of one polyethylene fiber layer and the fiber filaments of the other polyethylene fiber layer are arranged in an intersecting mode. The ceramic layer is combined with the multiple laminated polyethylene fiber layers through the connecting layer. The surface, making contact with the ceramic layer and the polyethylene fiber layers, of the connecting layer is the rough surface. Throughthe arrangement of the connecting layer, the bonding strength of the ceramic layer is enhanced. When the ceramic layer is broken through, left bullet holes cannot expand, propagating kinetic energy cannot cause looseness of other ceramic around, and the bulletproof property of the armor plate is remarkably improved.

Owner:江苏安卡新材料科技有限公司

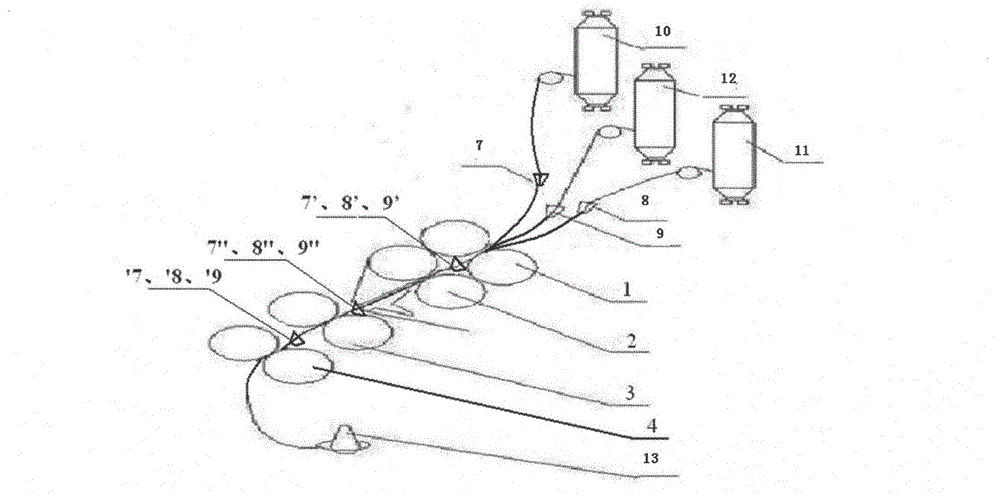

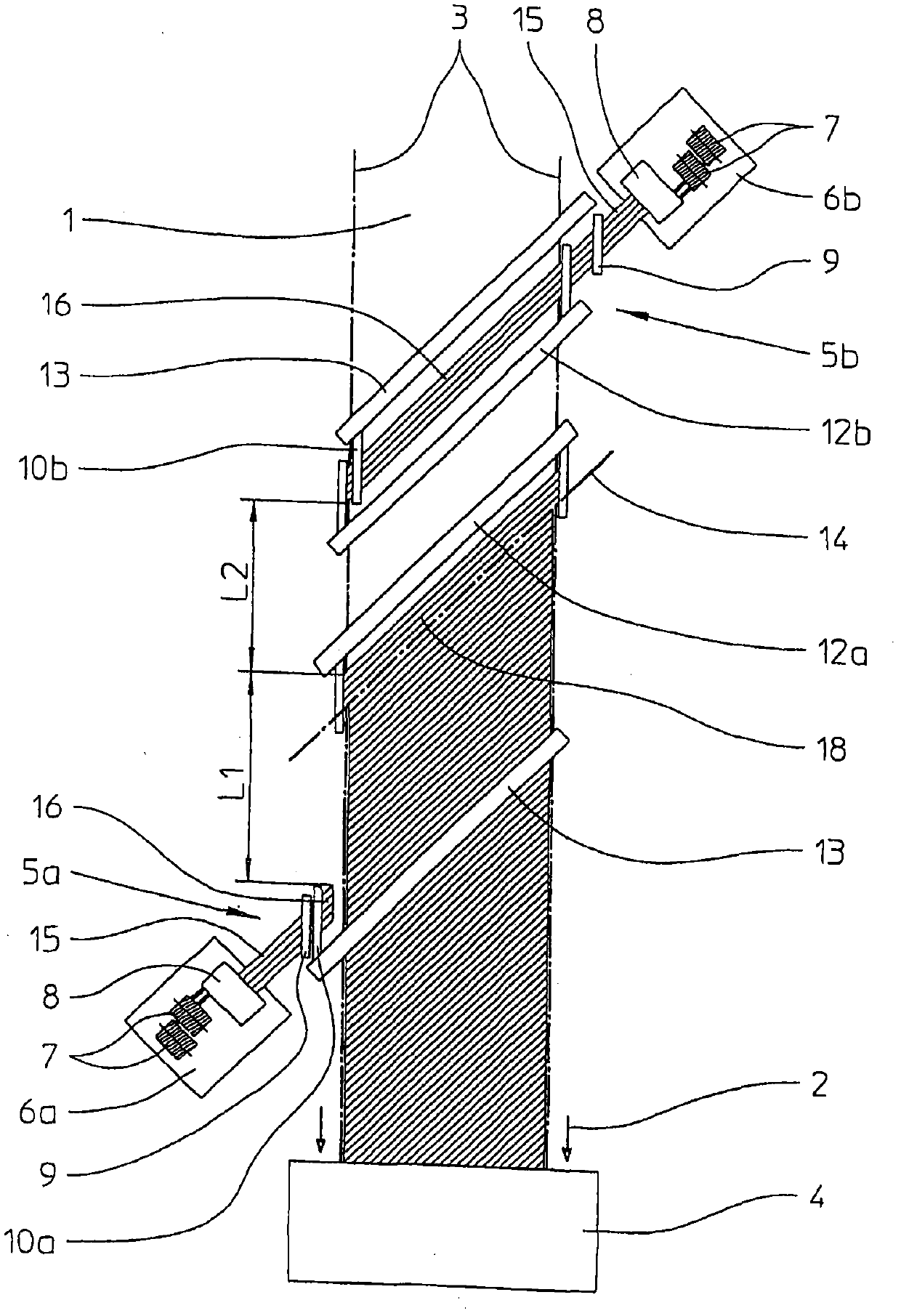

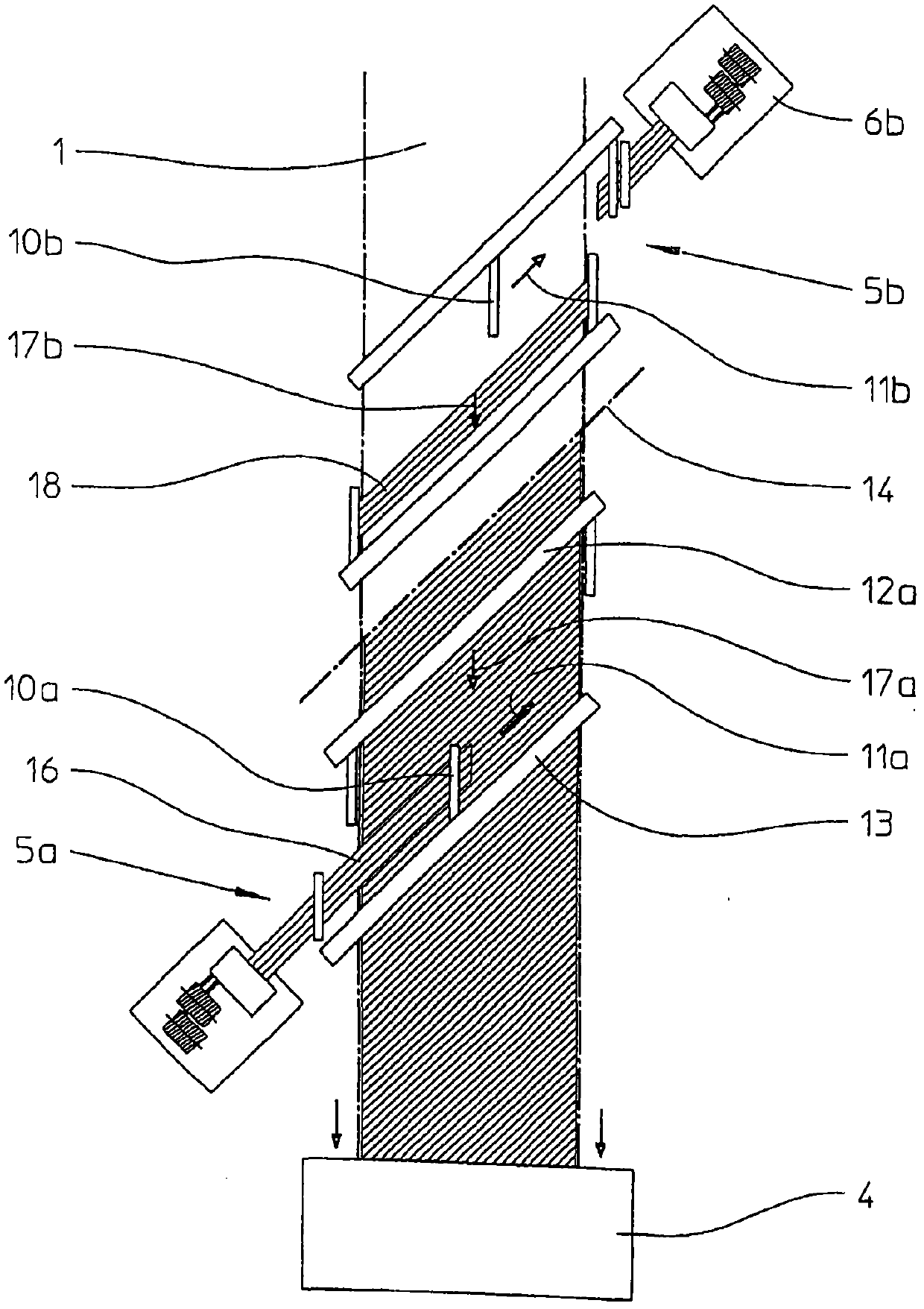

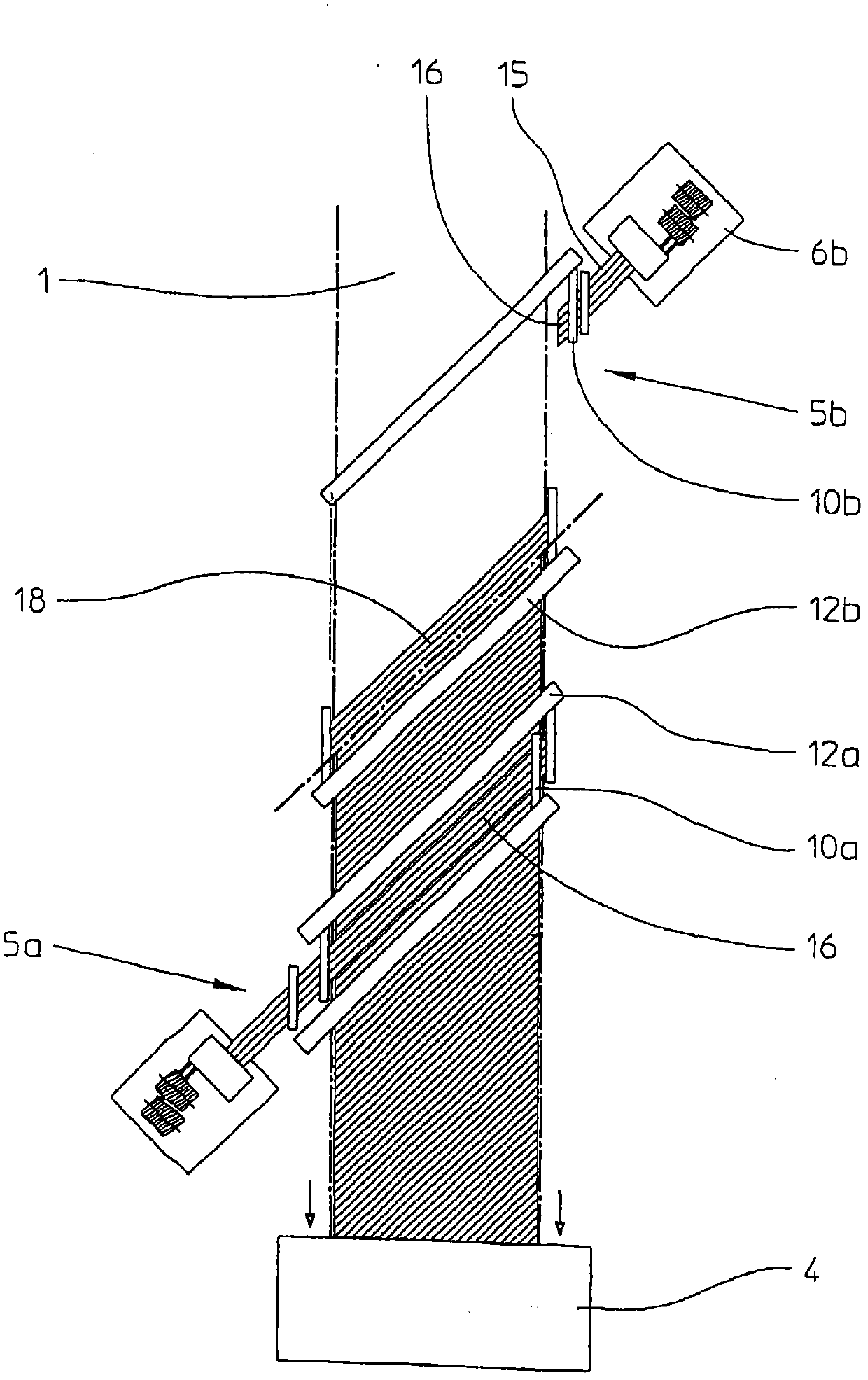

Method and device for laying unidirectional fiber layer on mobile bracket and method for producing multi axial cloth

ActiveCN102021738AMovement speed doubledDouble production speedNon-woven fabricsFlat warp knitting machinesYarnProduction rate

The invention relates to a device for laying a unidirectional fiber layer formed by a plurality of segments 18 on a mobile bracket 1, wherein the mobile bracket 1 is provided with two segment-feed stations 5a, 5b along the movement direction; each segment-feed station comprises a storage unit 6a, 6b and a paving device 12a, 12b; yarn clampers 10a, 10b are used for extracting parallel fibers from the storage units 6a, 6b; the fibers are cut out based on a fixed length and are paved on the bracket 1 by the paving devices 12a, 12b; the bracket 1 is formed by two annular conveying chains 3 in an ordinary mode; a station 4 is used in the following process, such as winding the produced unidirectional fiber layer on a yarn roller; the two segment-feed stations 5a, 5b are arranged along the movement direction and longitudinal direction of the bracket 1 one by one and are paved above clearance; a first segment-feed station is paved with a segment 18 having a clearance 19; and a second segment-feed station 6b is accurately filled in the clearance 19 by matching with the paved segment. In such a manner, the production rate is greatly increased.

Owner:KARL MAYER TECH TEXTILIEN GMBH

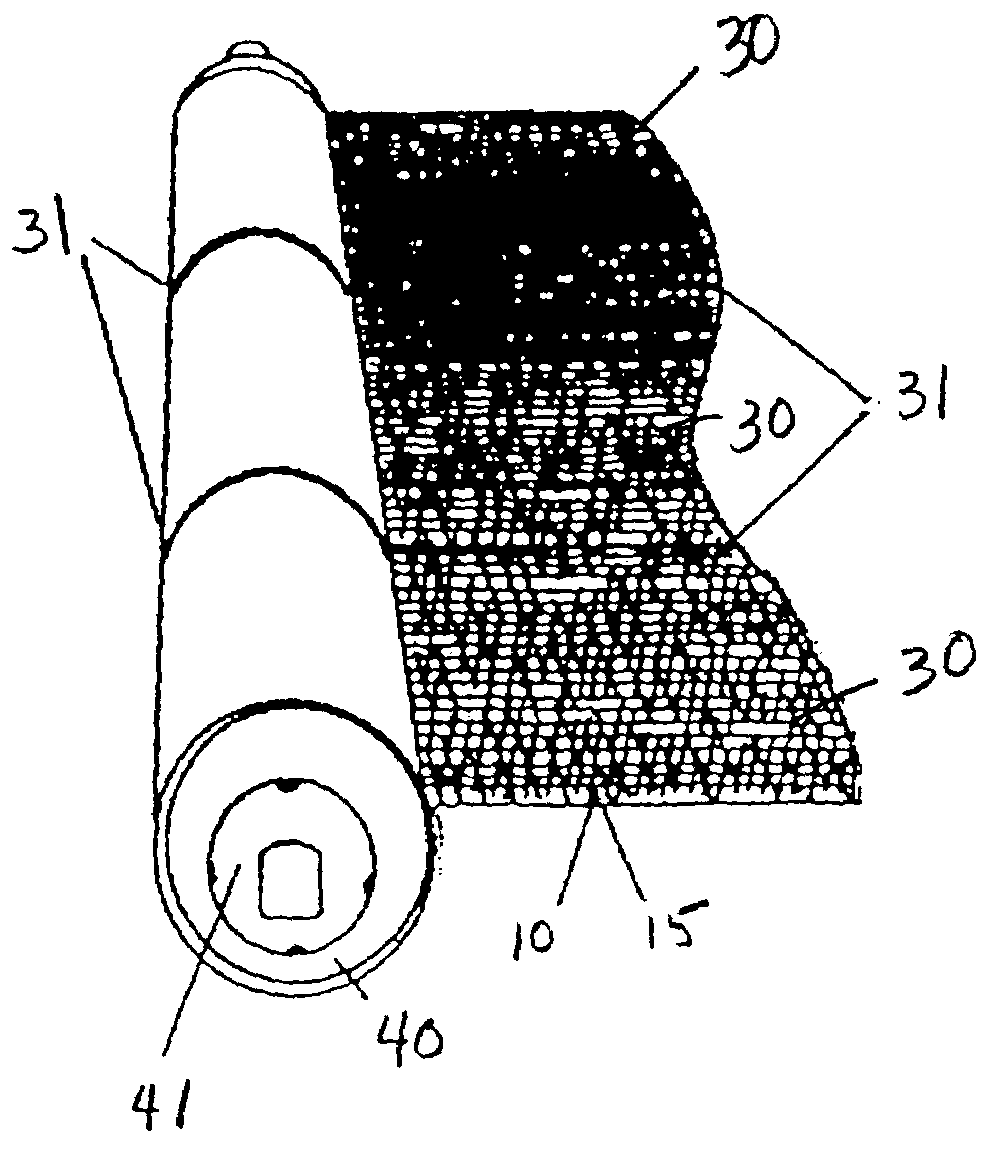

Multilayer textile reinforcement web

InactiveUS7504144B2Easy injectionReduce weightLaminationLamination apparatusSingle fiberParallel fiber

Multiple, single fiber webs, consisting of parallel fiber bundles and non-wovens connected by an adhesive thread grid, positioned on a common shaft for simultaneous unwinding. The single webs are dispensed under tension from a primary unwinding drum while, in the same process, an additional adhesive thread grid of non-woven or fiber mat is dispensed and, using tension winding, combined with the single webs into a homogeneous laminate.

Owner:MAGNELL CARL O +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com