Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Achieve isotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

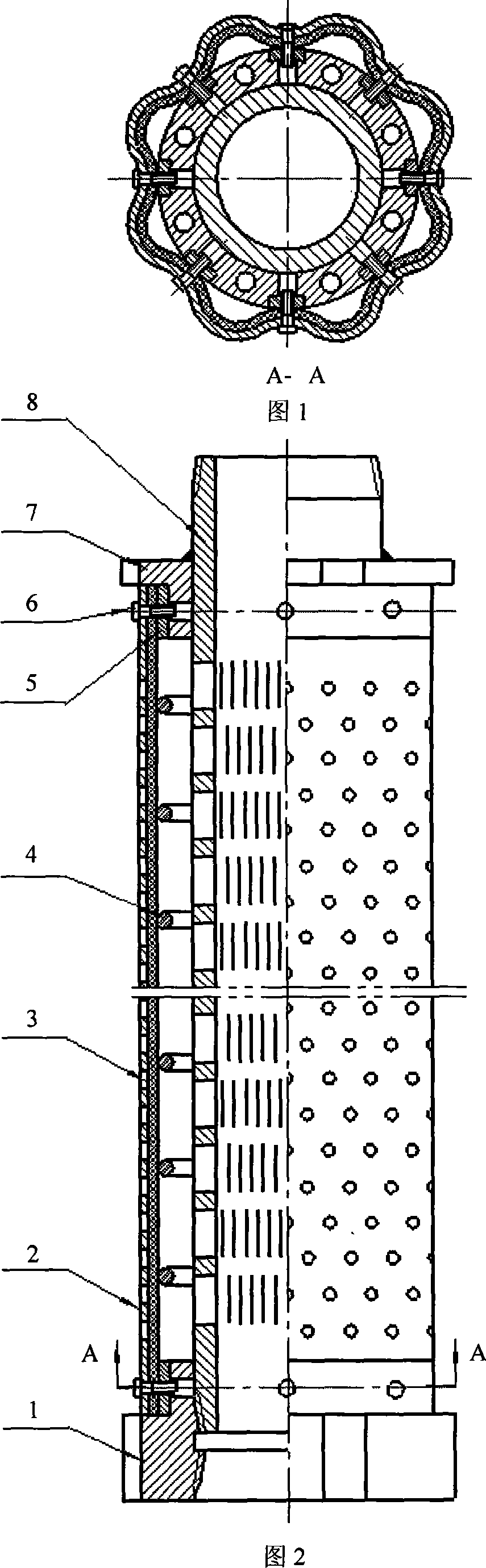

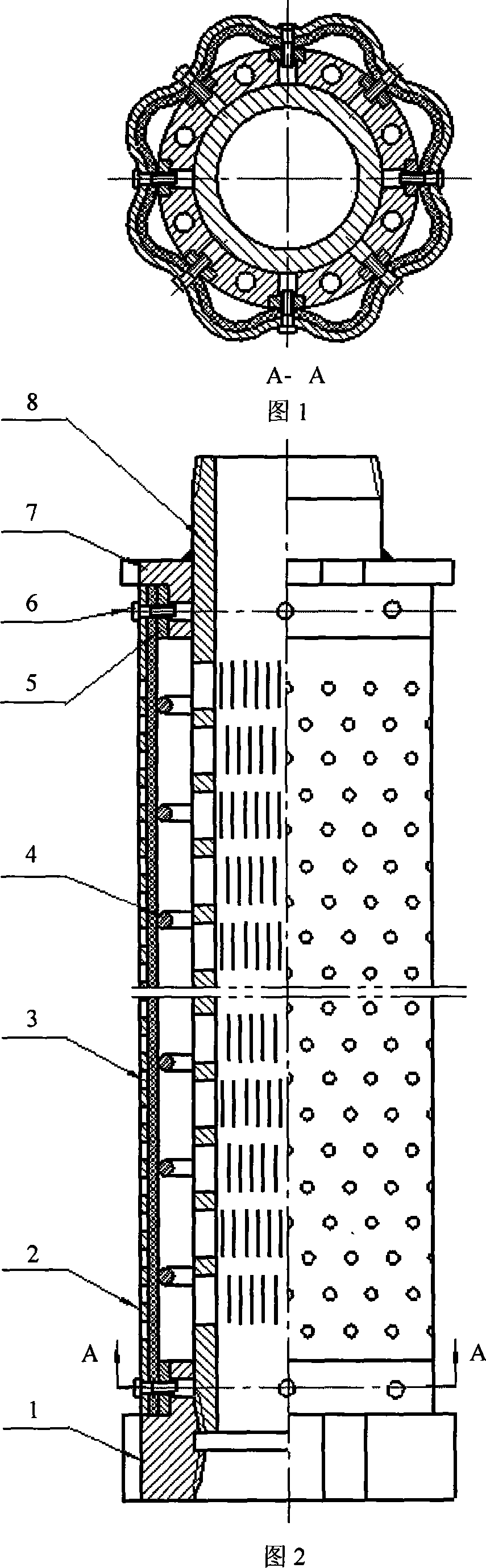

Adaptive filling expansion scree tube and expanding method thereof

ActiveCN101067370AReduce expansion forceReduce operating costsFluid removalEngineeringSolid particle

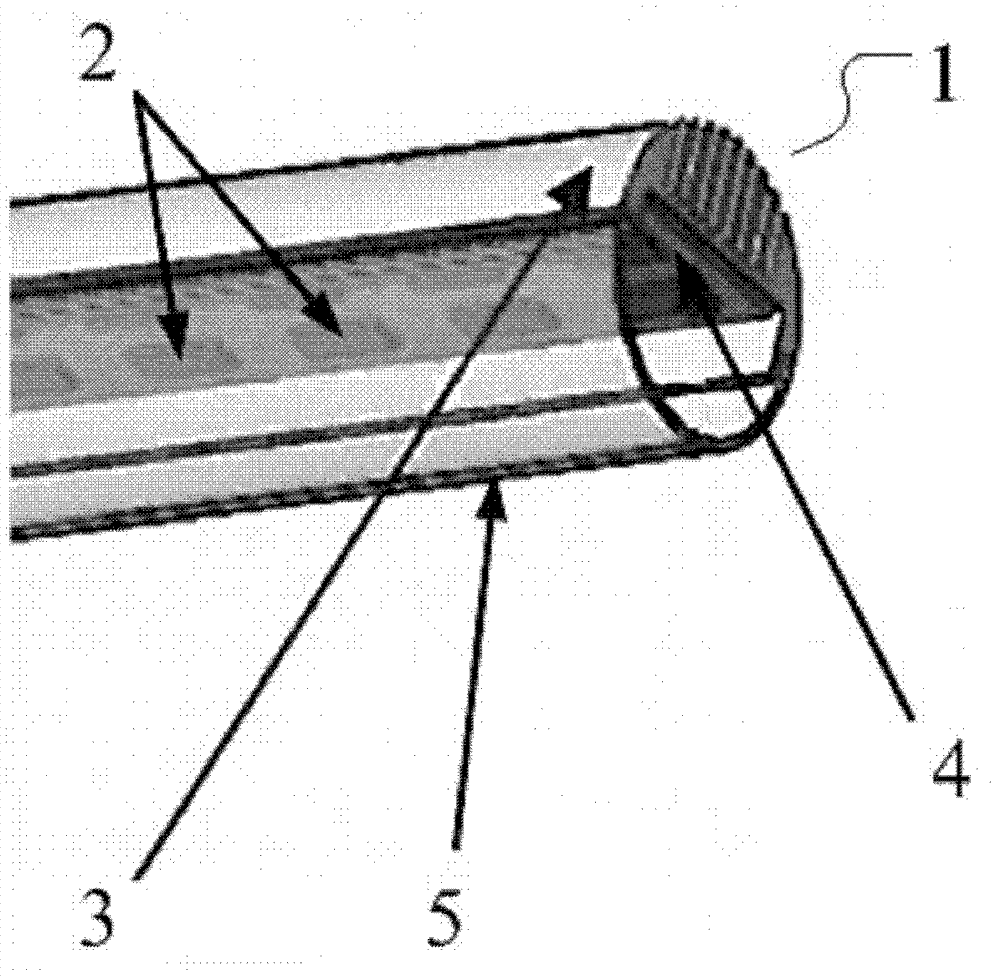

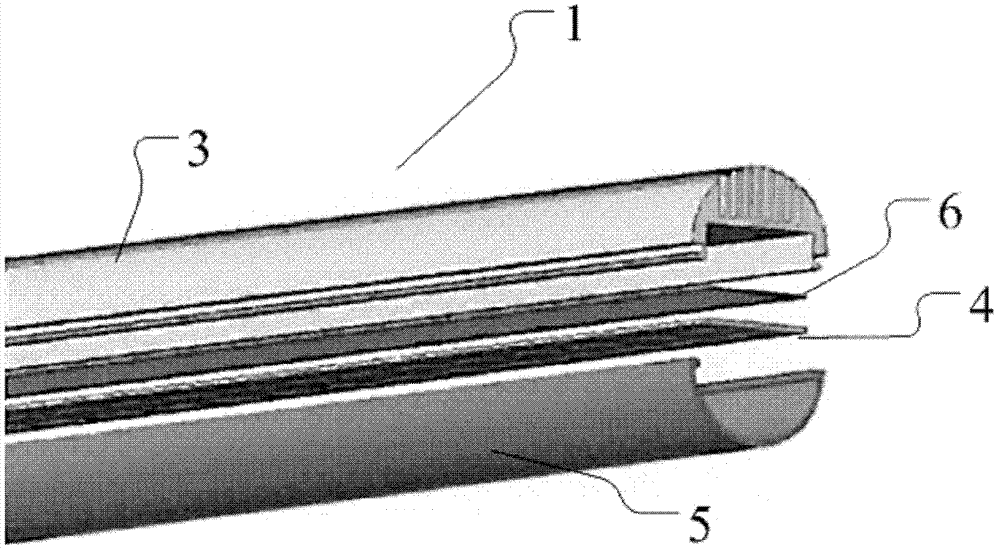

The present invention provides one kind of adaptive filled expanding sieve tube for preventing sand in oil and gas well, and belongs to the field of petroleum drilling and extracting tool technology. The adaptive filled expanding sieve tube consists of supporting slotted tube, special filling coupler, radial expanding cover, radial expanding composite filter element, supporting rack, expanding block, expanding screw, plug and other parts. During well operation, the adaptive filled expanding sieve tube is set in the oil reservoir and filled with high pressure carrying solid particles, so that the composite filter element and the radial expanding cover can expand radially to contact with the inner wall of the production casing or the uncased hole to block sand and control the size of the passed sand. Compared with available technology, the present invention has the advantages of lowered expanding force, low operation cost and other advantages.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

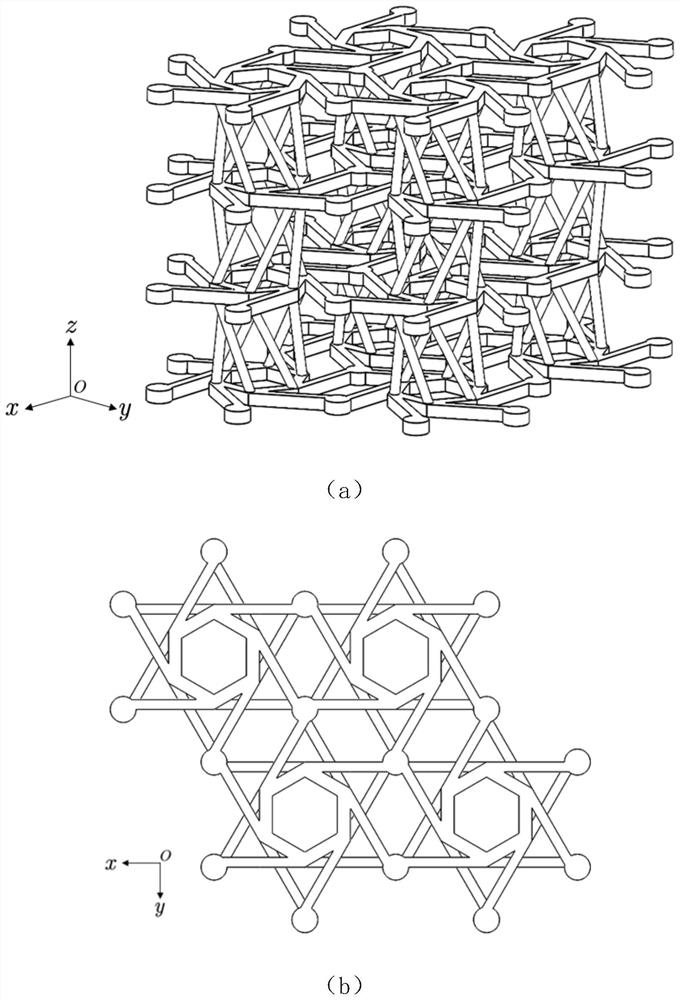

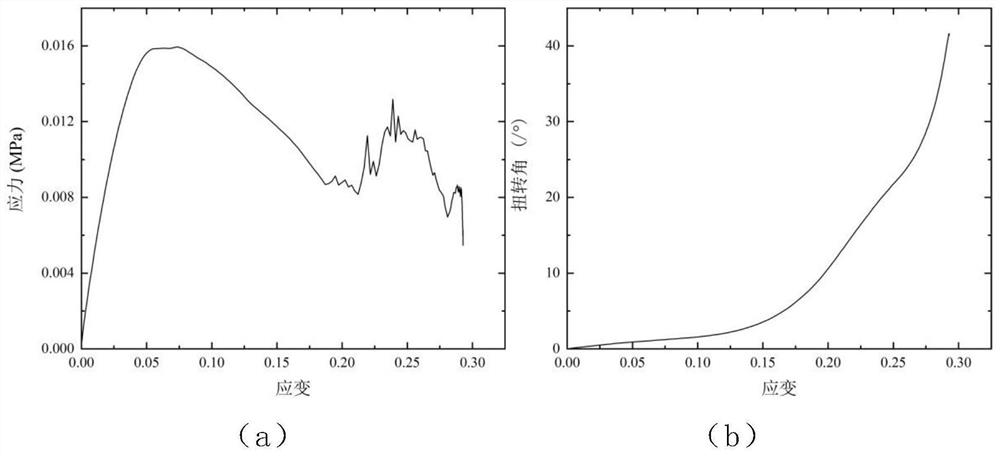

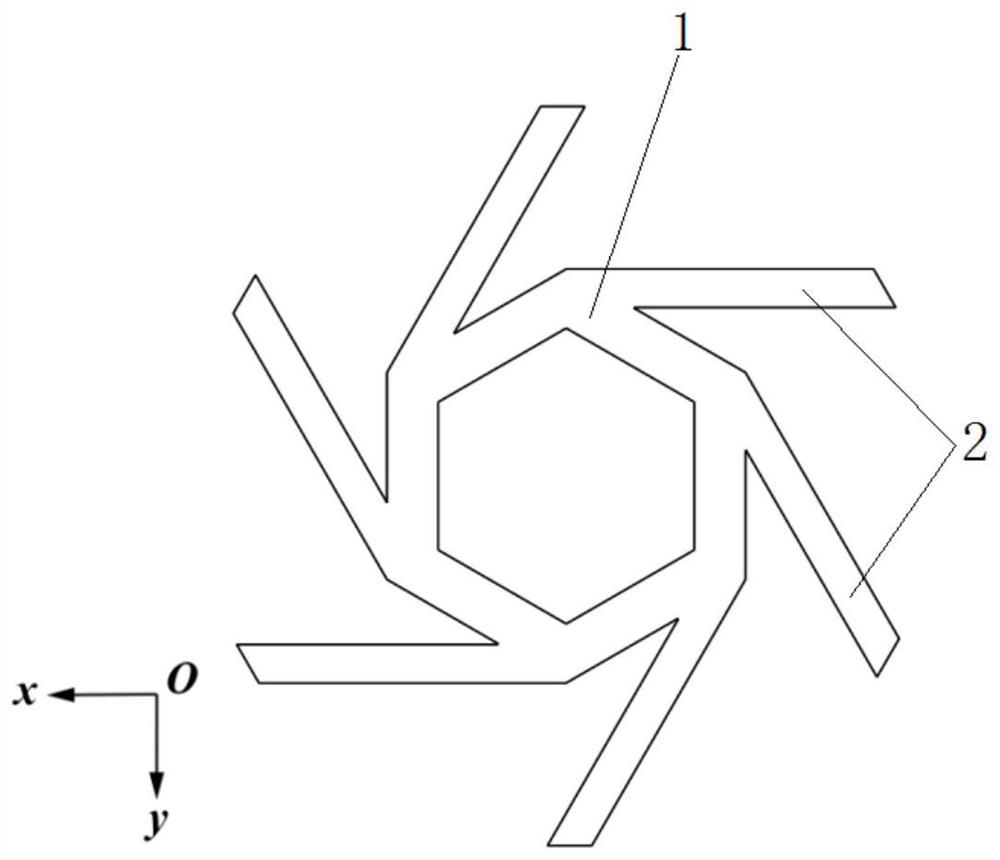

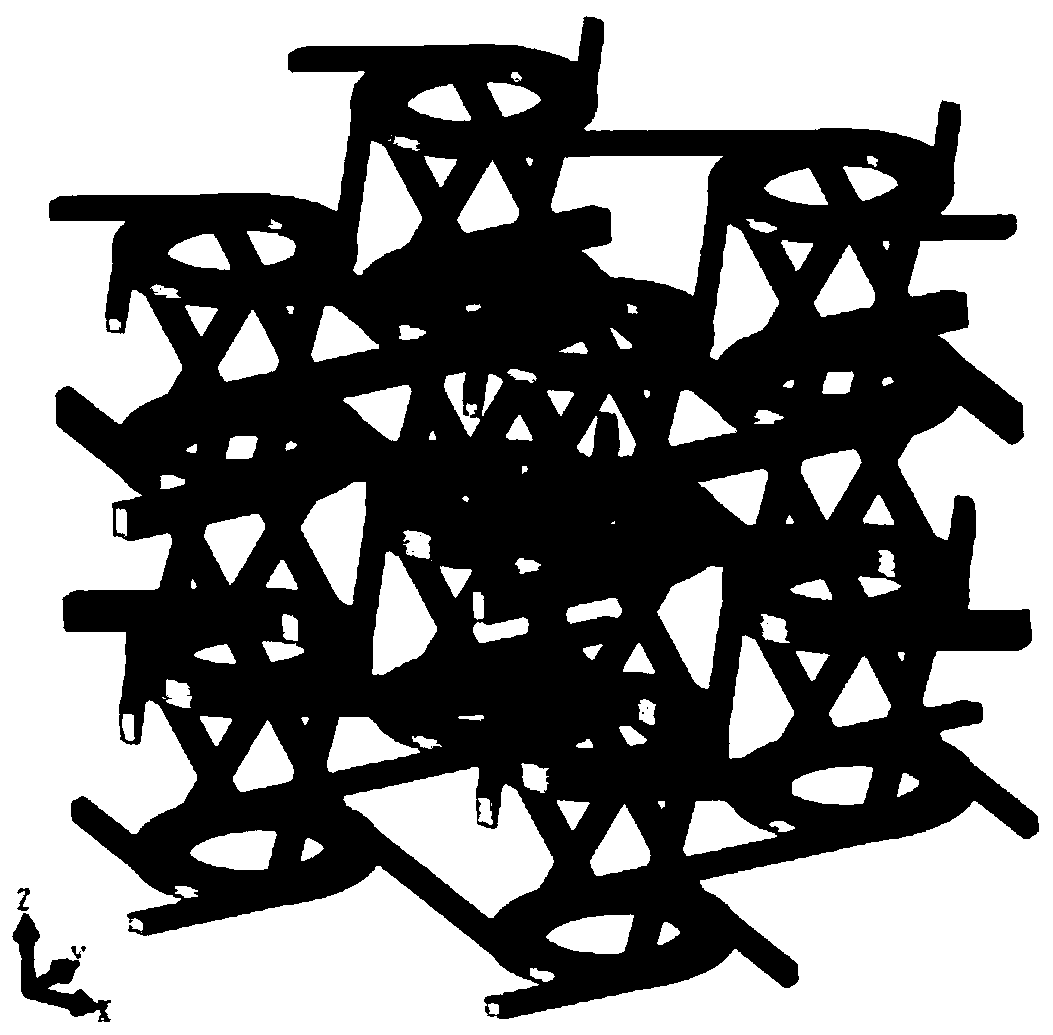

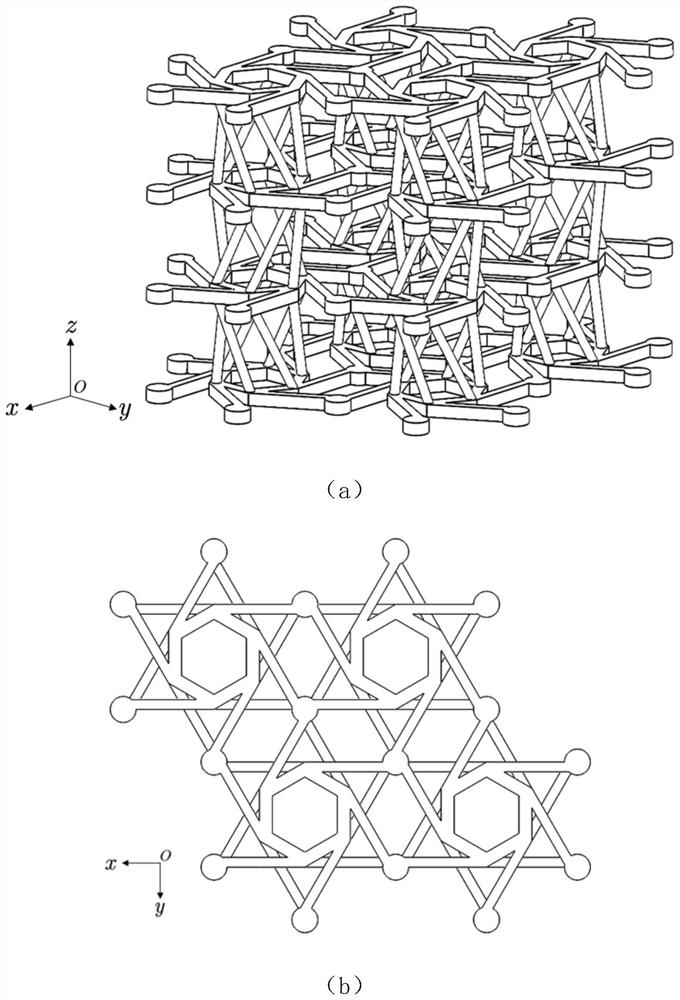

Chiral auxetic metamaterial structure with tension-torsion coupling characteristics and preparation method thereof

ActiveCN112049886AWith tension torsion coupling characteristicsImprove carrying capacityAdditive manufacturing apparatusIncreasing energy efficiencyStructural engineeringMechanical engineering

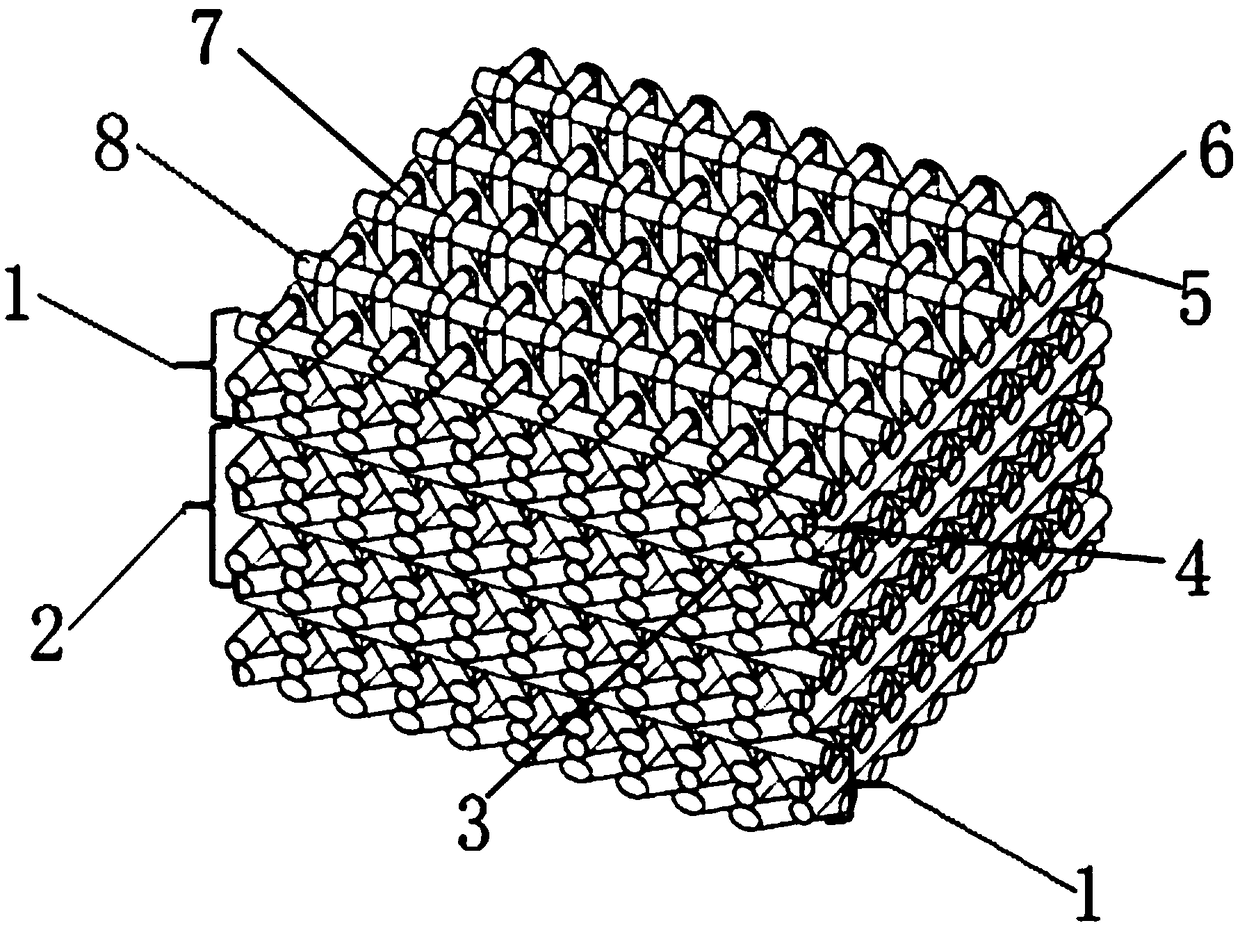

The invention discloses a chiral auxetic metamaterial structure with tension-torsion coupling characteristics and a preparation method thereof. The chiral auxetic metamaterial structure comprises a plurality of three-dimensional unit cell structures, each three-dimensional unit cell structure comprises two polygonal annular structures arranged up and down, and the vertexes of the upper and lower polygonal annular structures are connected through correspondingly-arranged inclined cylinders; a plurality of inclined cylinders are arranged in a staggered mode in the same direction, connecting rodsused for being connected with the adjacent three-dimensional unit cell structures are arranged at the vertexes of the two polygonal annular structures respectively, the plurality of three-dimensionalunit cell structures are arranged in a spatial array mode, and the chiral auxetic metamaterial structure with the tension-torsion coupling characteristics is formed by connecting the corresponding connecting rods.

Owner:XI AN JIAOTONG UNIV +1

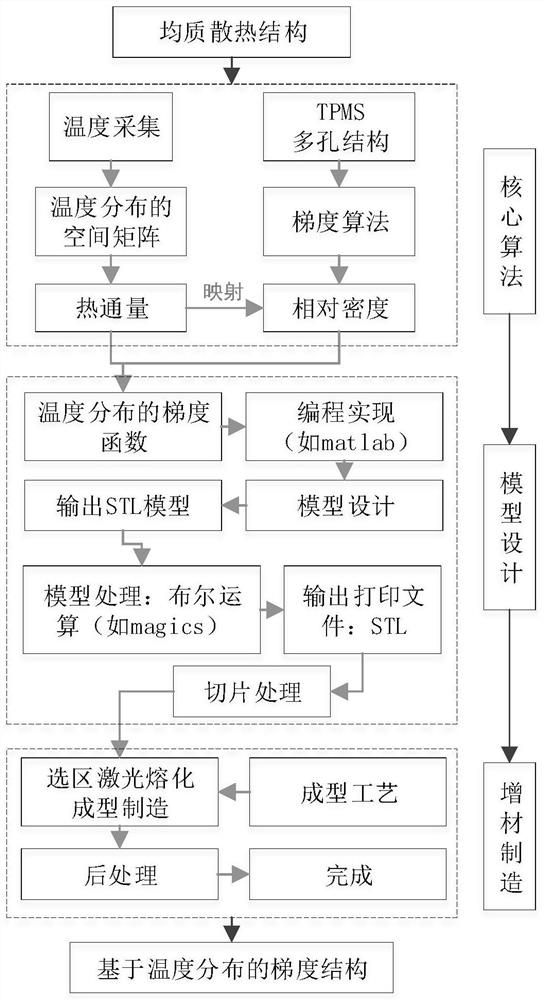

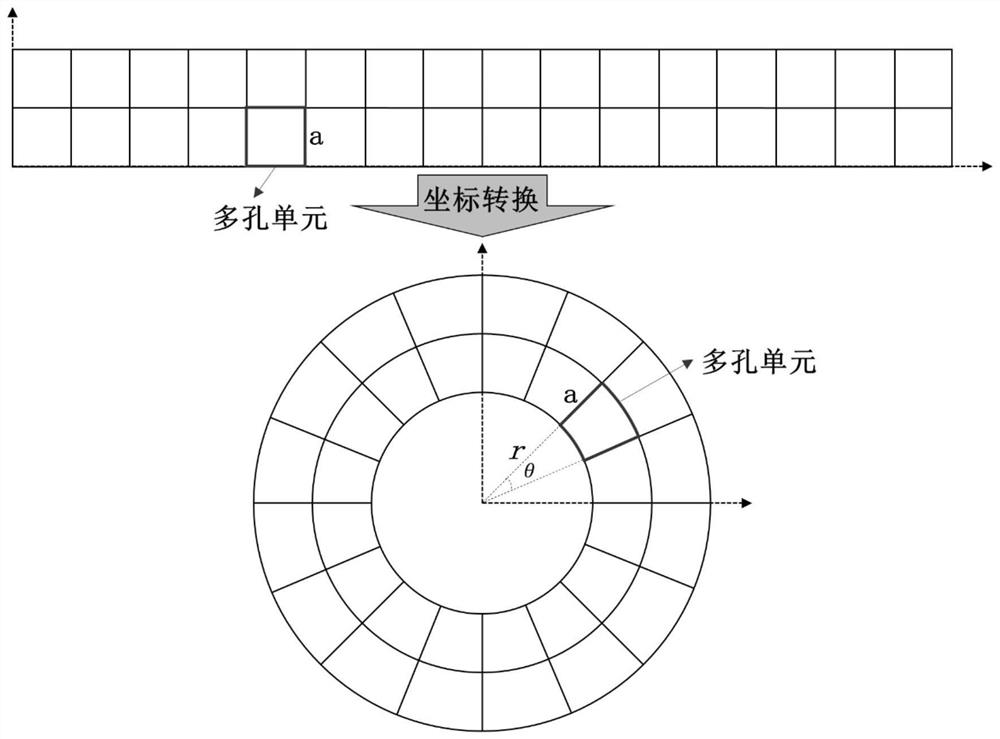

Design and additive manufacturing method of gradient porous structure heat dissipation device based on temperature distribution

ActiveCN112191849AImplement gradient buildingFast transferAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHeat Avoidance

The invention discloses a design and additive manufacturing method of a gradient porous structure heat dissipation device based on temperature distribution, and belongs to the technical field of heatexchange. The design and additive manufacturing method aims to overcome the defects of concentrated thermal stress and high temperature gradient of a heat exchanger designed by adopting the method, and have the advantages of compact structure, light weight, high heat exchange efficiency and the like. Firstly, a space matrix is established according to temperature distribution and mapped into the relative density of a porous structure, and the porous heat dissipation structure with continuous gradient change is obtained; then a design process of a typical radiator is given, and the design process comprises a Boltzmann fitting function algorithm and a structure design method; and finally, an additive manufacturing forming process of a high-strength and high-thermal-conductivity copper alloyis provided, and the device is integrally formed by adopting a selective laser melting process. The design method is suitable for occasions with special requirements for temperature uniformity, and high heat concentration can be effectively avoided; the gradient change porous structure also has the advantages of high specific surface area, light weight and high heat dissipation efficiency.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

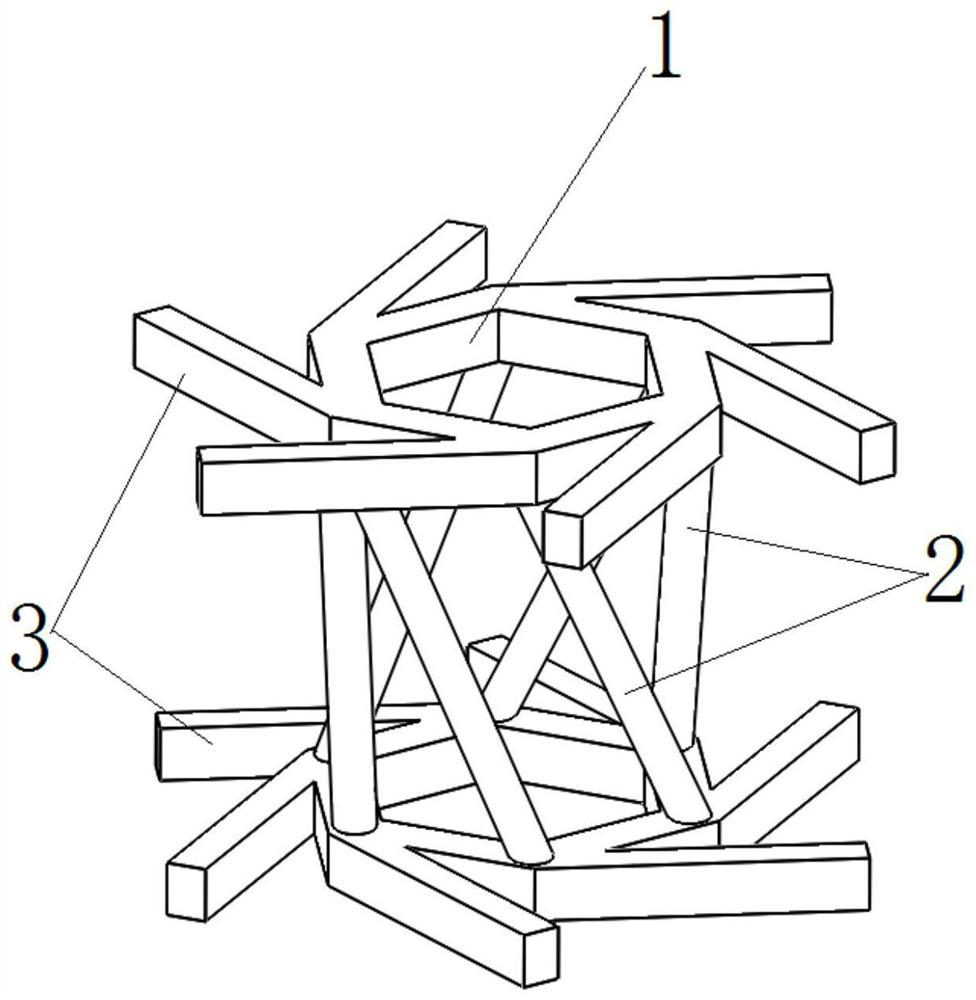

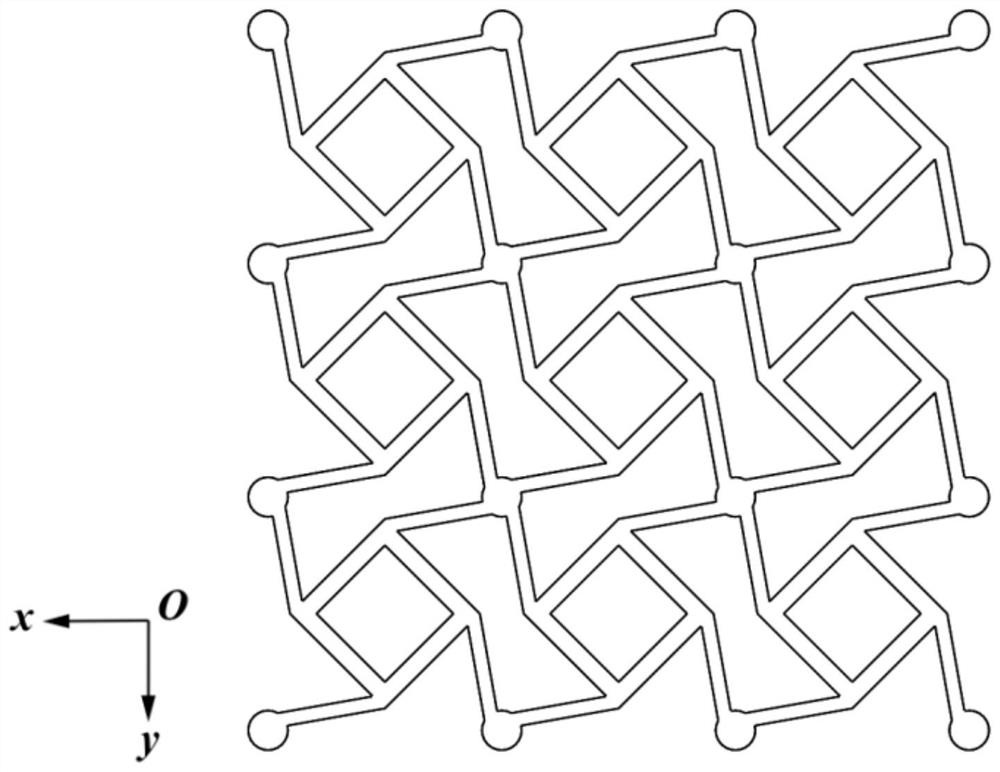

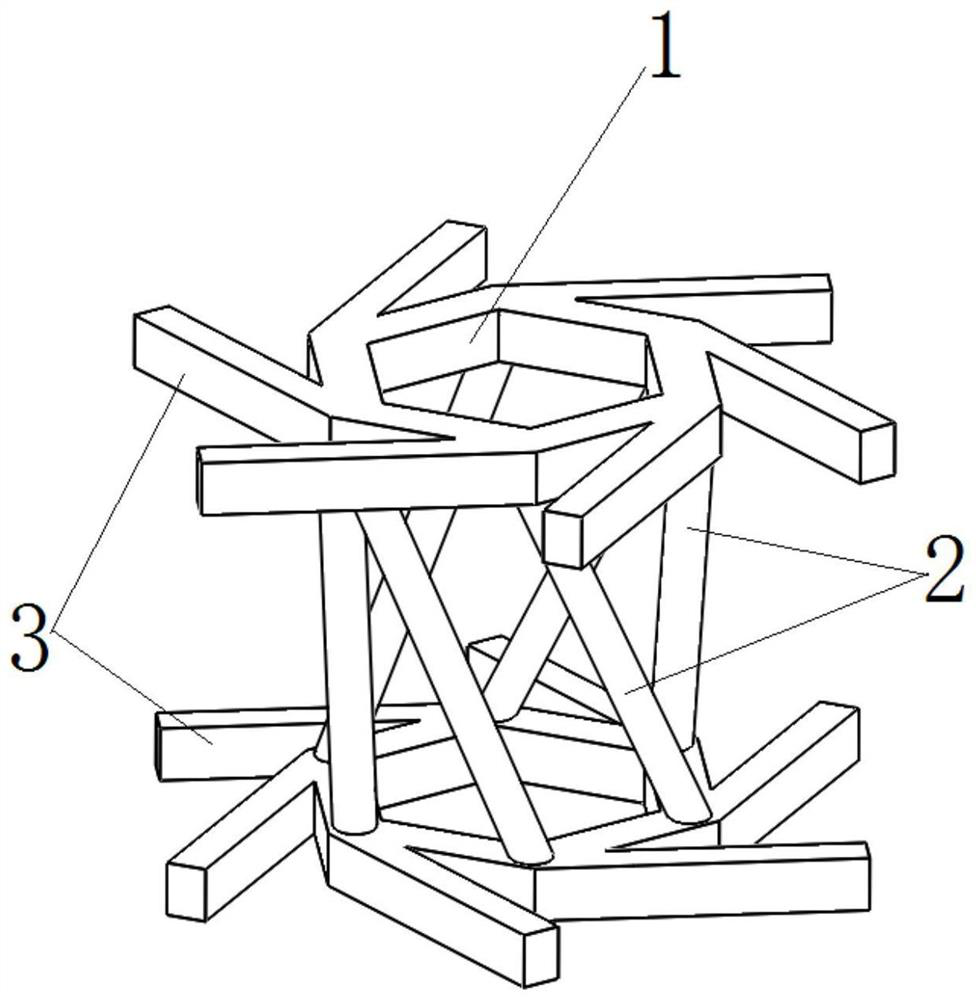

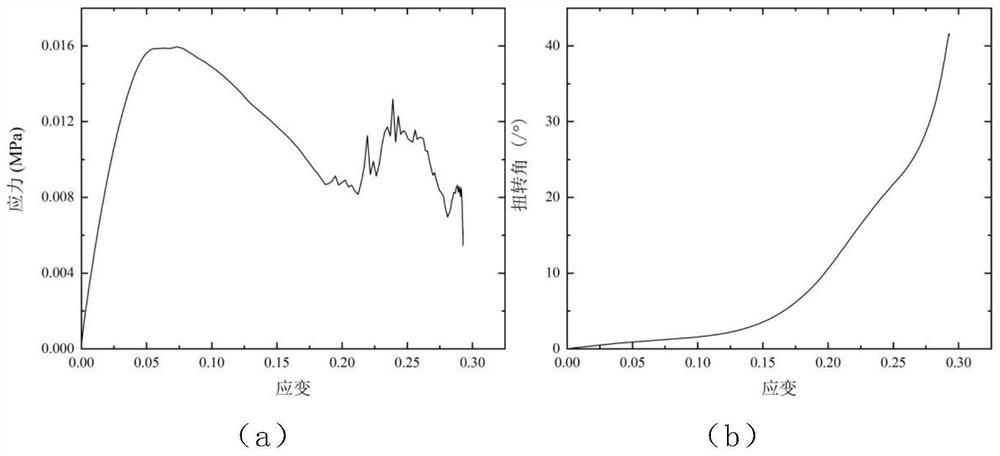

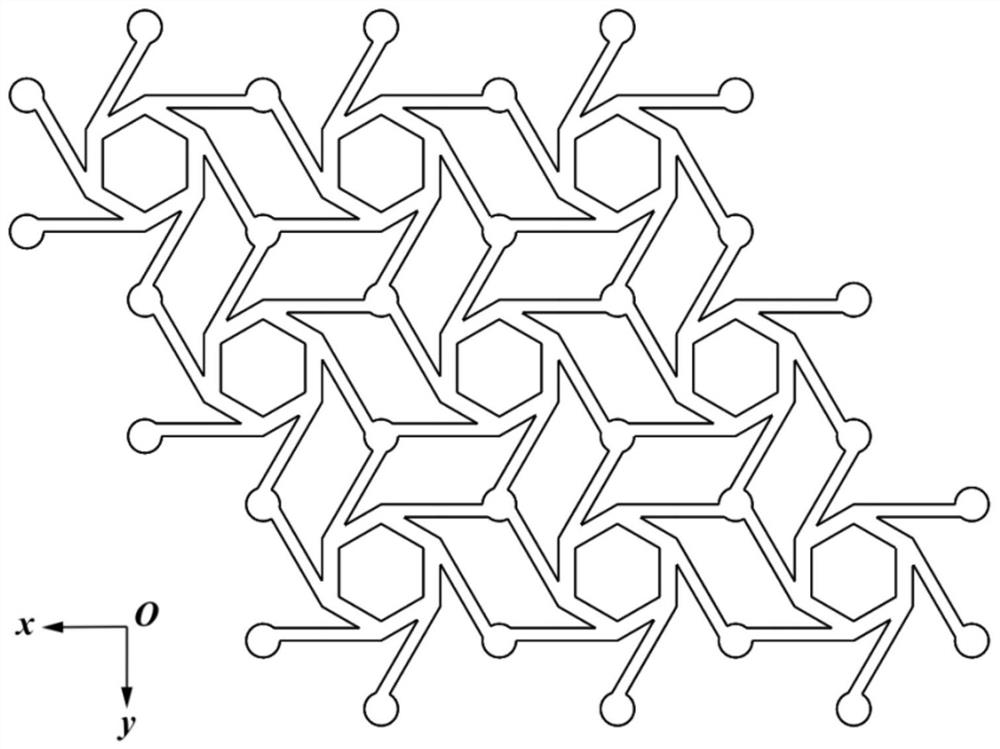

Chiral auxetic metamaterial structure with compression-shear coupling characteristic and preparation method thereof

ActiveCN112045990AStrong energy absorption and impact resistanceBroaden your optionsAdditive manufacturing apparatusElastic dampersCrystallographyEnergy absorption

The invention discloses a chiral auxetic metamaterial structure with a compression-shear coupling characteristic and a preparation method thereof. Polygonal chiral structures with different shapes areperiodically arranged and connected with each other, so that the chiral auxetic metamaterial structure simultaneously has excellent compression-shear coupling characteristic and auxetic characteristic; and as the intersections of connecting rods are connected in a circular manner, negative Poisson's ratio behaviors are generated through two deformation mechanisms of indenting and rotation when aload is borne, so that very strong energy absorption and impact resistance characteristics are formed. Simulation results show that the chiral auxetic metamaterial structure with the compression-shearcoupling characteristic has remarkable compression-shear coupling and auxetic characteristics and has a wide prospect in industrial application.

Owner:XI AN JIAOTONG UNIV +1

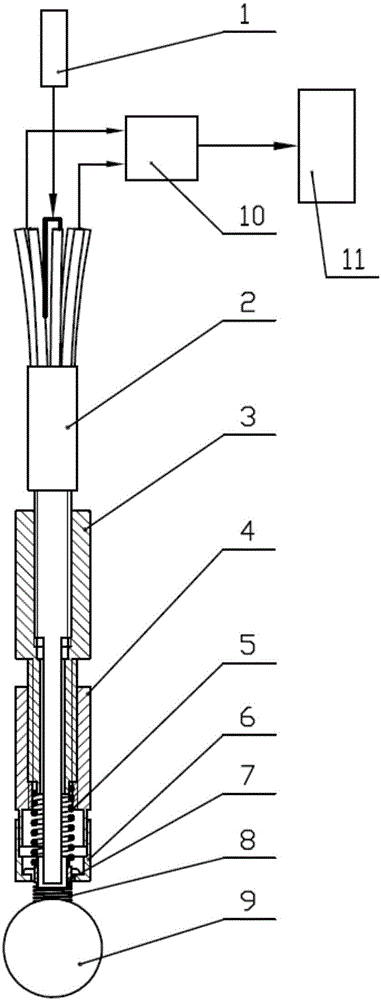

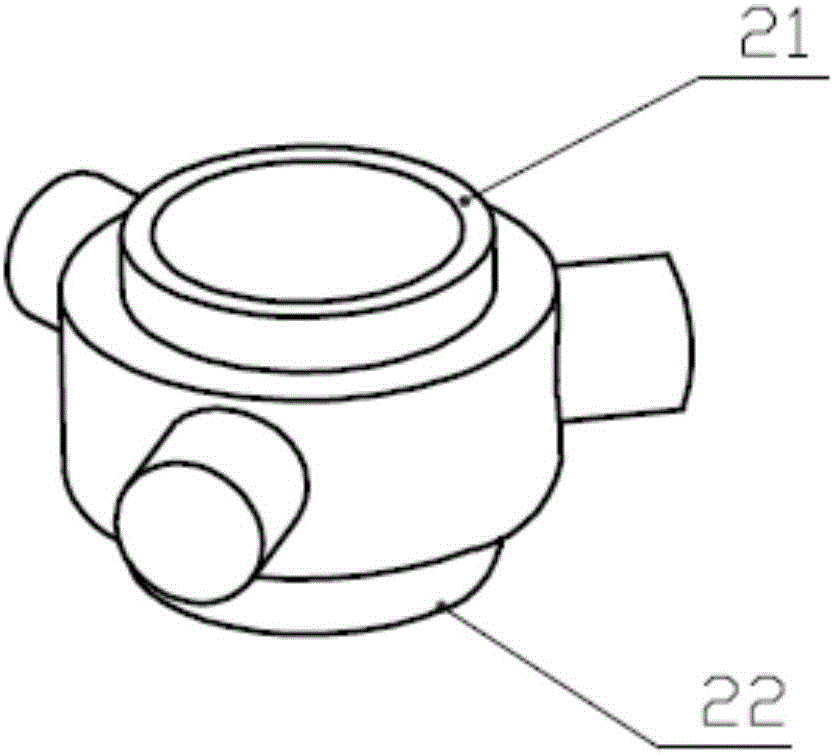

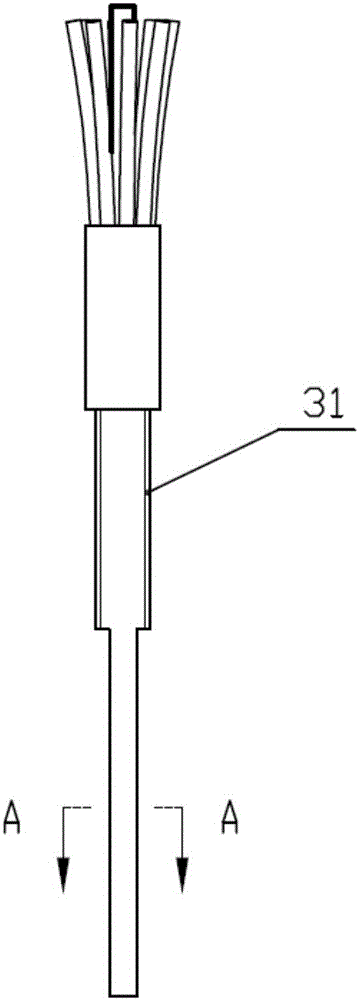

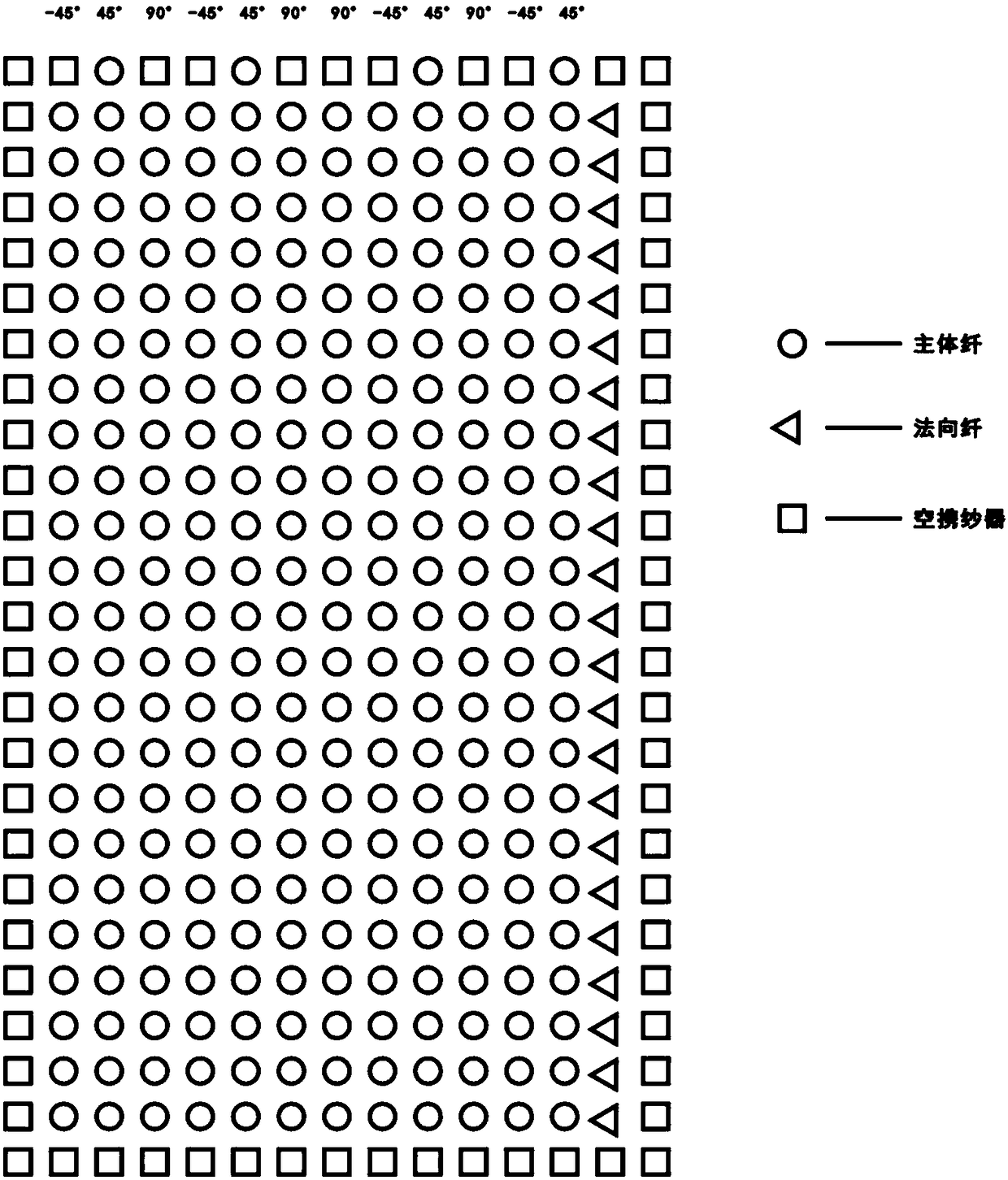

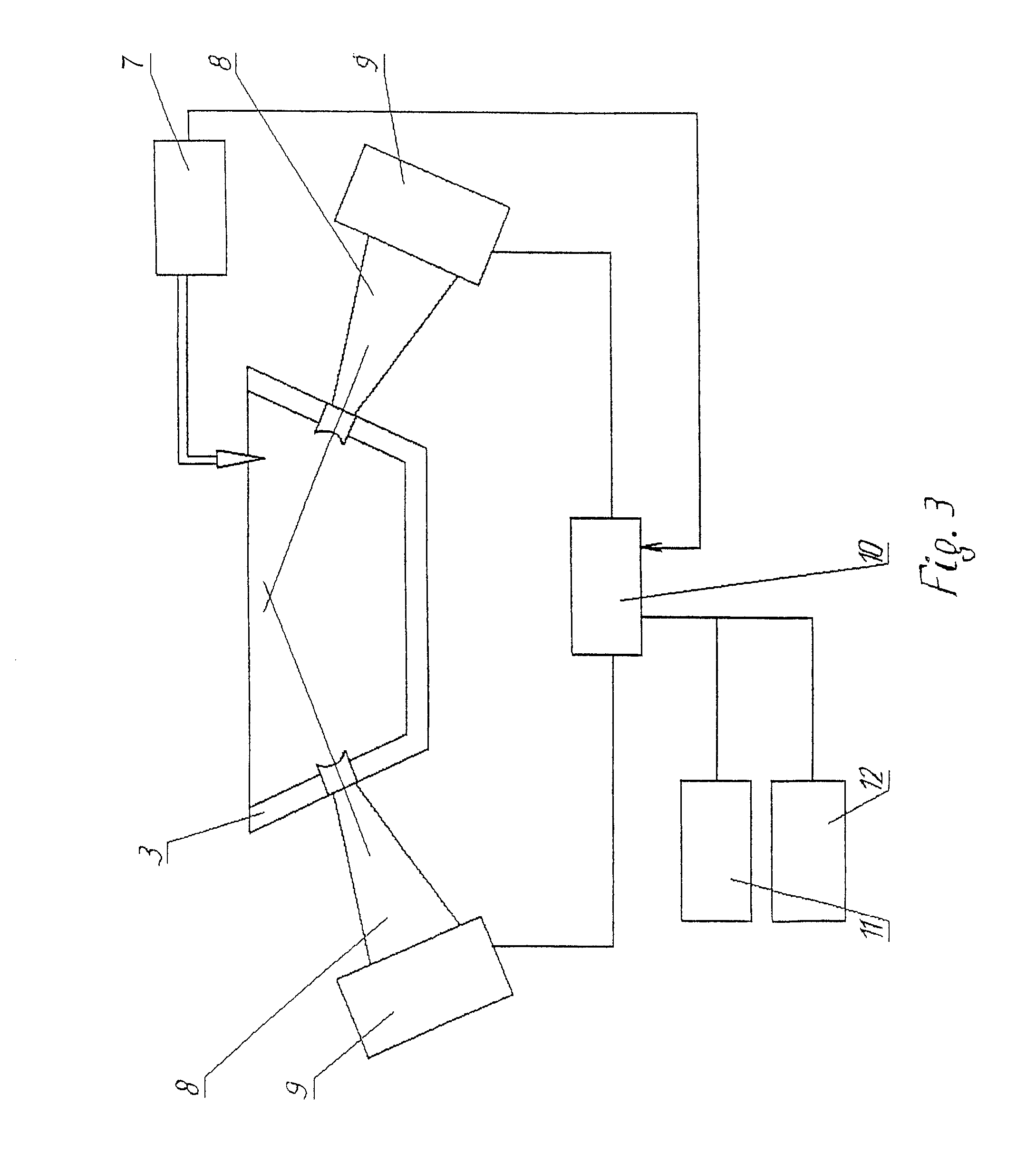

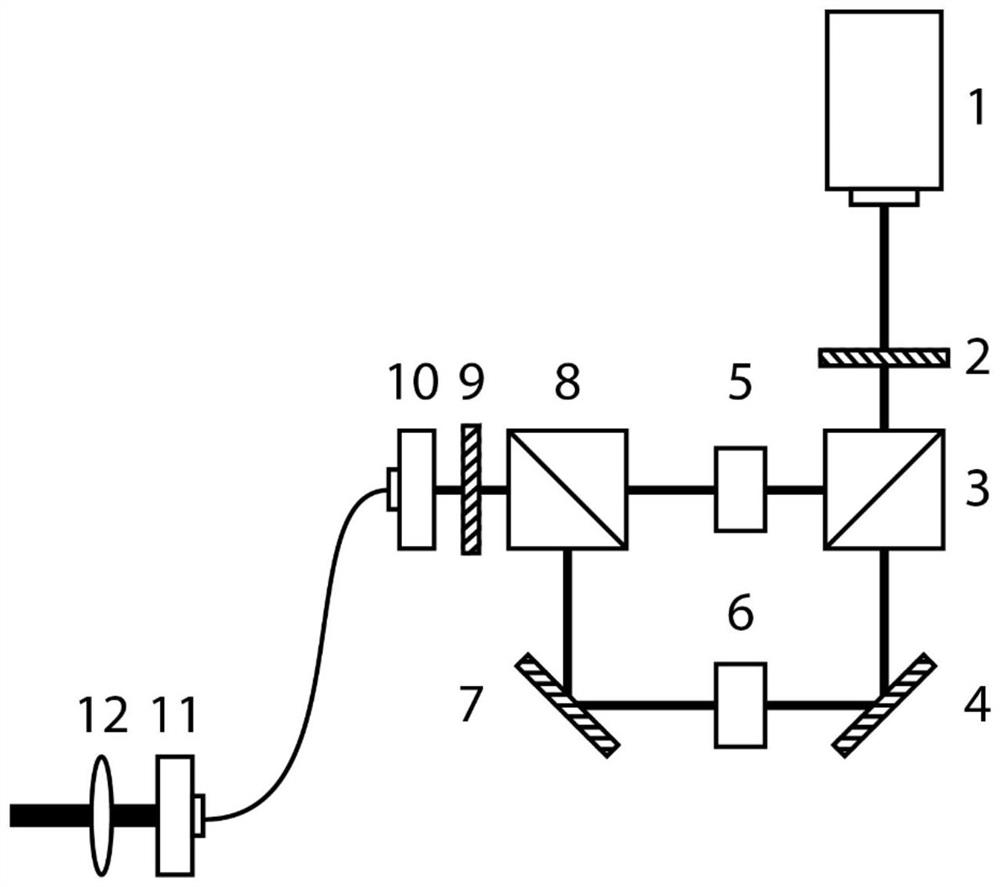

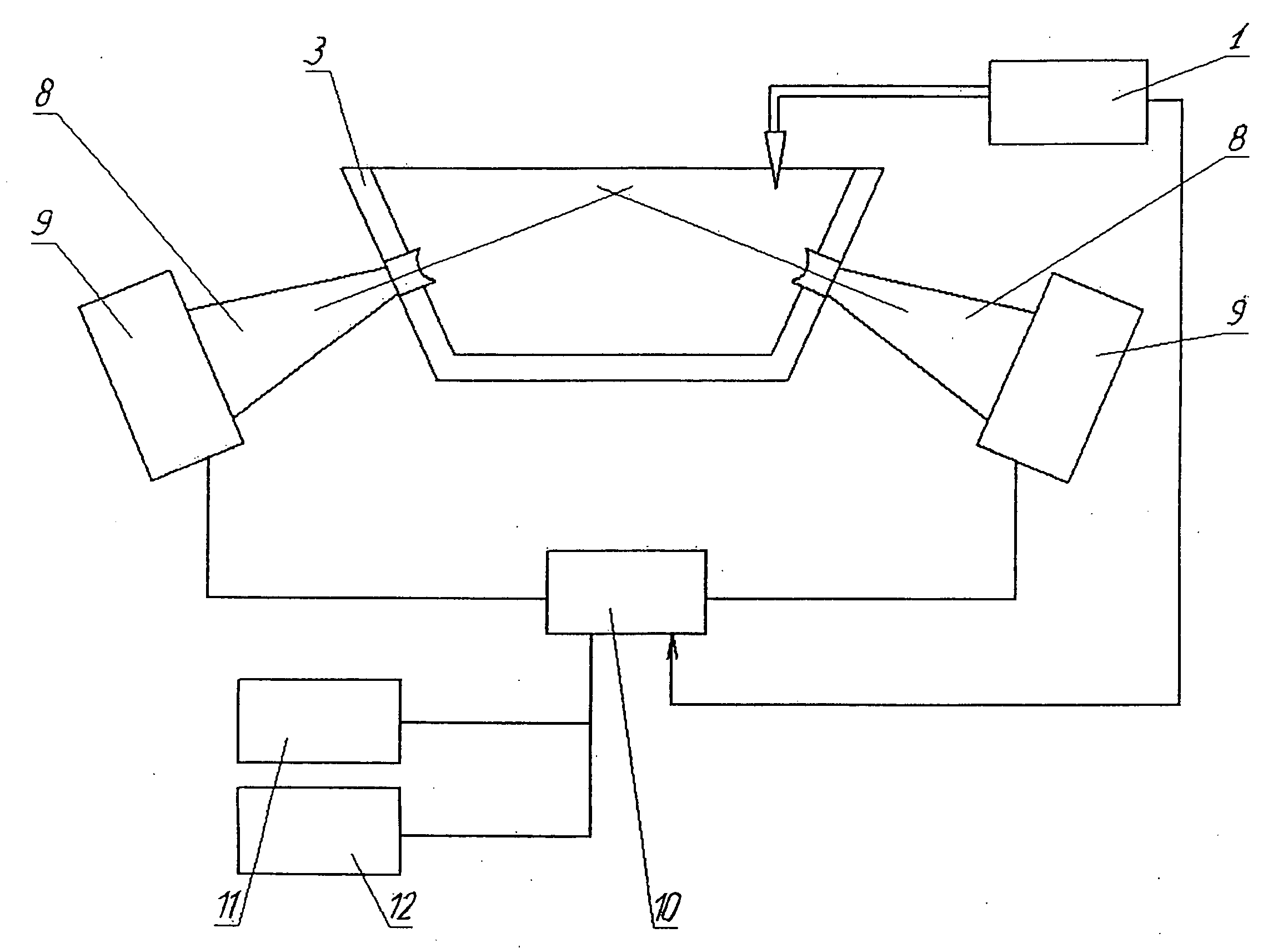

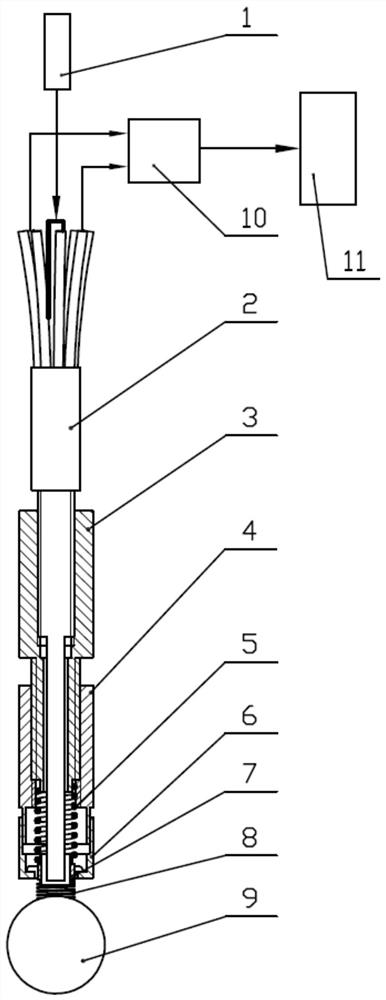

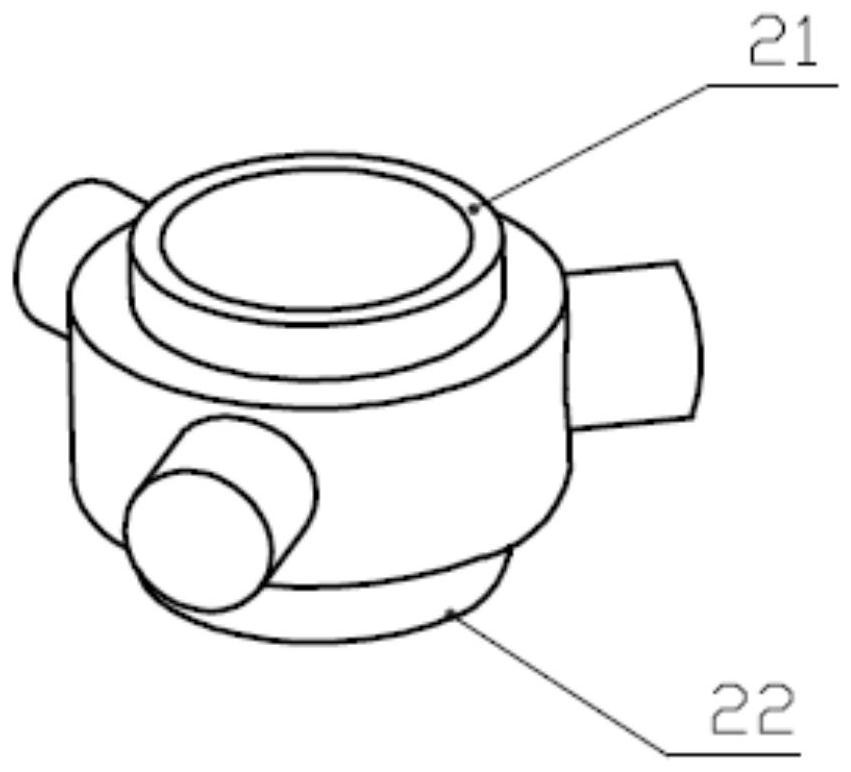

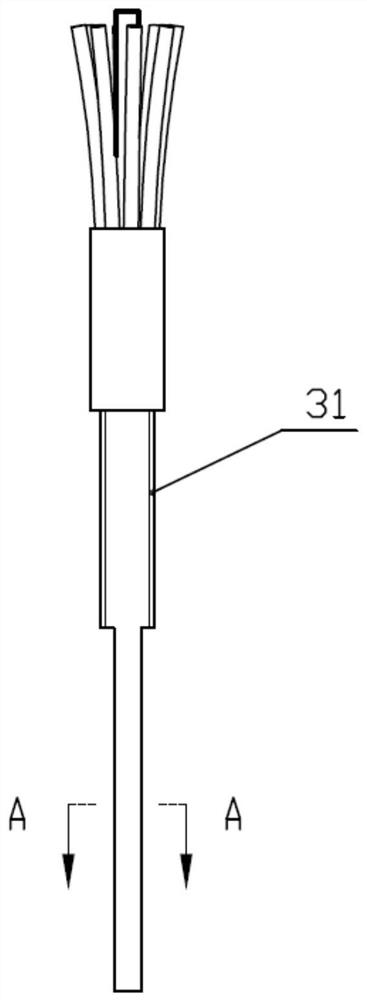

Optical fiber type three-dimensional trigger probe device and measuring method

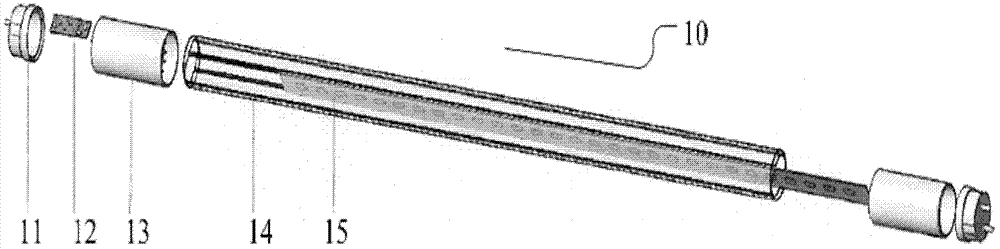

ActiveCN106595479ASolve the problem of anisotropyAchieve isotropyUsing optical meansFiberConstant power

The invention discloses an optical fiber type three-dimensional trigger probe device and measuring method. The device comprises a light source, a fiber measuring rod, an elastic resetting mechanism, a measuring ball plated with a reflection film and a photoelectric detection unit. The fiber measuring rod is provided with a central fiber and 4N receiving fibers uniformly distributed around the central fiber in a coaxial manner wherein N is a positive integer; the elastic resetting mechanism is arranged between the fiber measuring rod and the measuring ball to make the measuring ball reset to its original position. The light with constant power generated from the light source is transmitted to the measuring ball through the central fiber and the light reflected by the reflection film is transmitted to the photoelectric detection unit through the receiving fibers. The device of the invention is capable of overcoming the measurement errors brought about by the deformation of the measuring rod in the probing and at the same time, has a relatively high resolution and achieves precise measurement.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

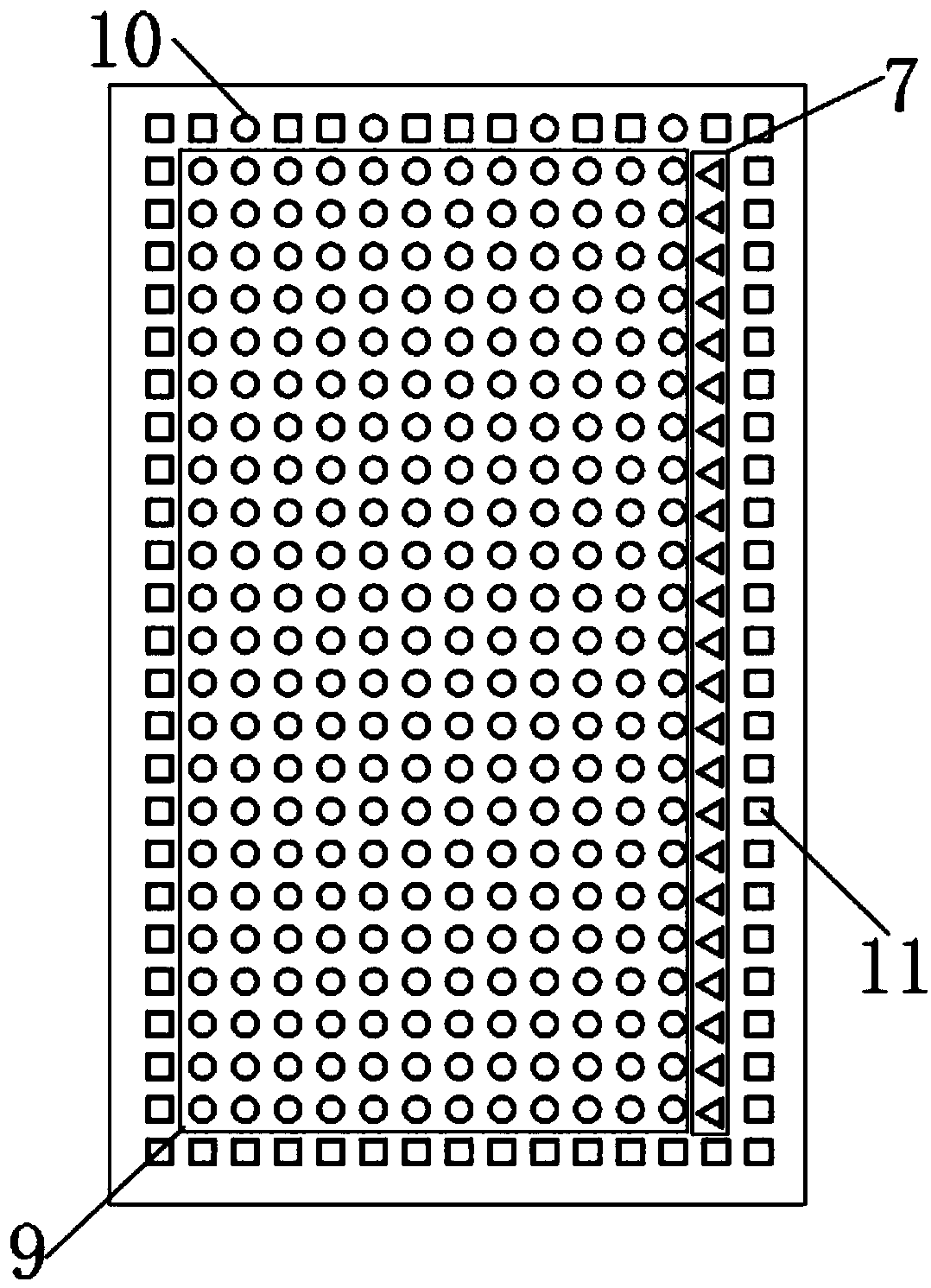

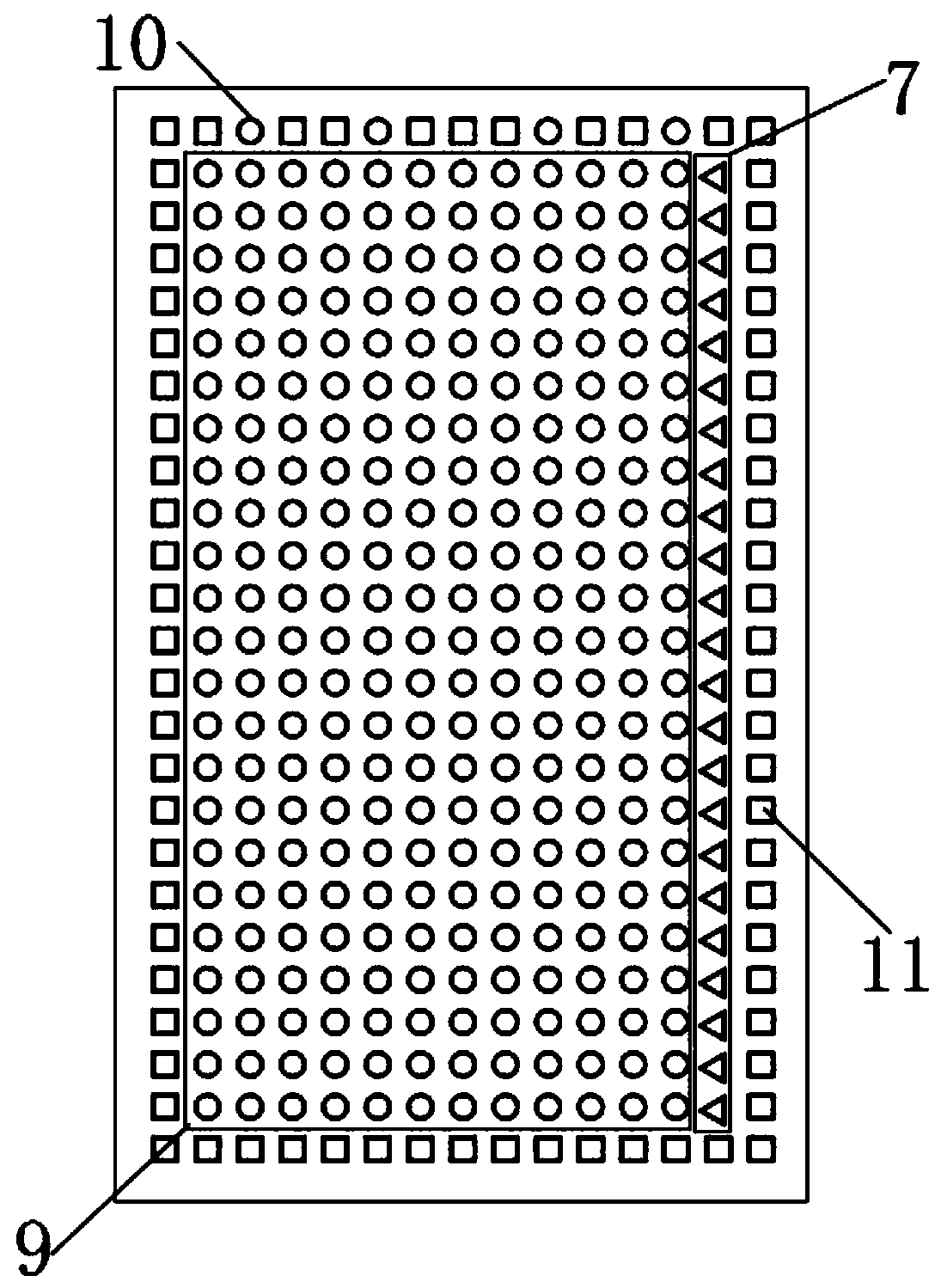

In-plane quasi-isotropic structure-stealthy composite material and preparation method thereof

The invention discloses an in-plane quasi-isotropic structure-stealthy composite material and further comprises a preparation method of the in-plane quasi-isotropic structure-stealthy composite material. The in-plane quasi-isotropic structure-stealthy composite material comprises a base body and a reinforcement body which are composited and solidified through a VARTM process. The base body is madeof resin; the reinforcement body is made of sandwich-type three-dimensional stereo woven material, the woven material is composed of a plurality of mutually-parallel fiber layers and normal fibers perpendicular to the fiber layers, and the fiber layers are bound together by the normal fibers through a weaving method. The preparation method specifically comprises the following steps of 1, weavingof the reinforcement body; 2, reinforcement body moulding; 3, glue injecting and solidifying; and 4, demoulding. The problems that as for a stealthy composite material in the prior art, the electromagnetic property is isotropic, the anti-impact property is poor, and the stealthy composite material is likely to be layered after being impacted are solved.

Owner:浙江世涛鼎革新材料有限责任公司

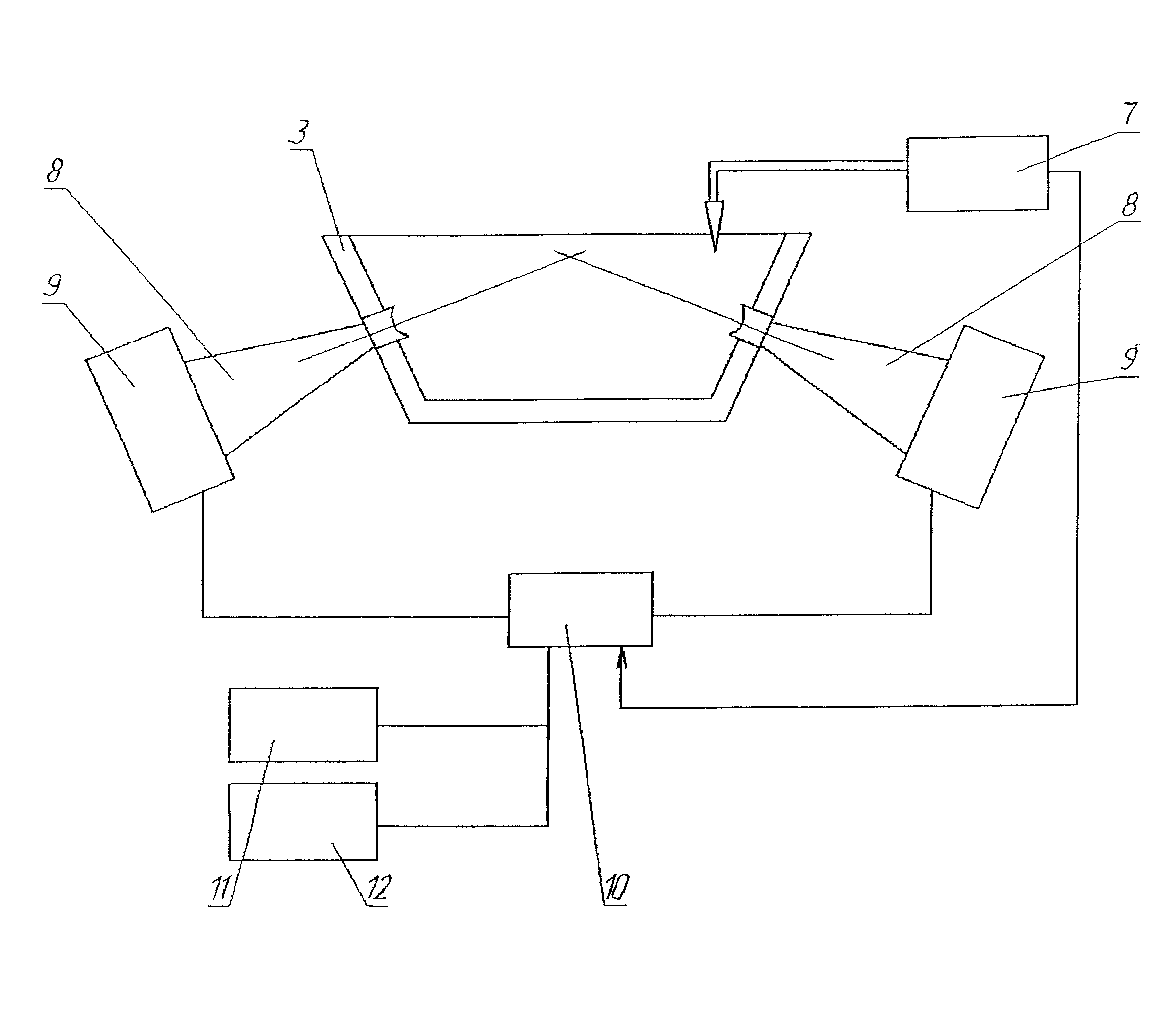

Method for making castings by directed solidification from a selected point of melt toward casting periphery

Owner:ANISIMOV OLEG VLADIMIROVICH +1

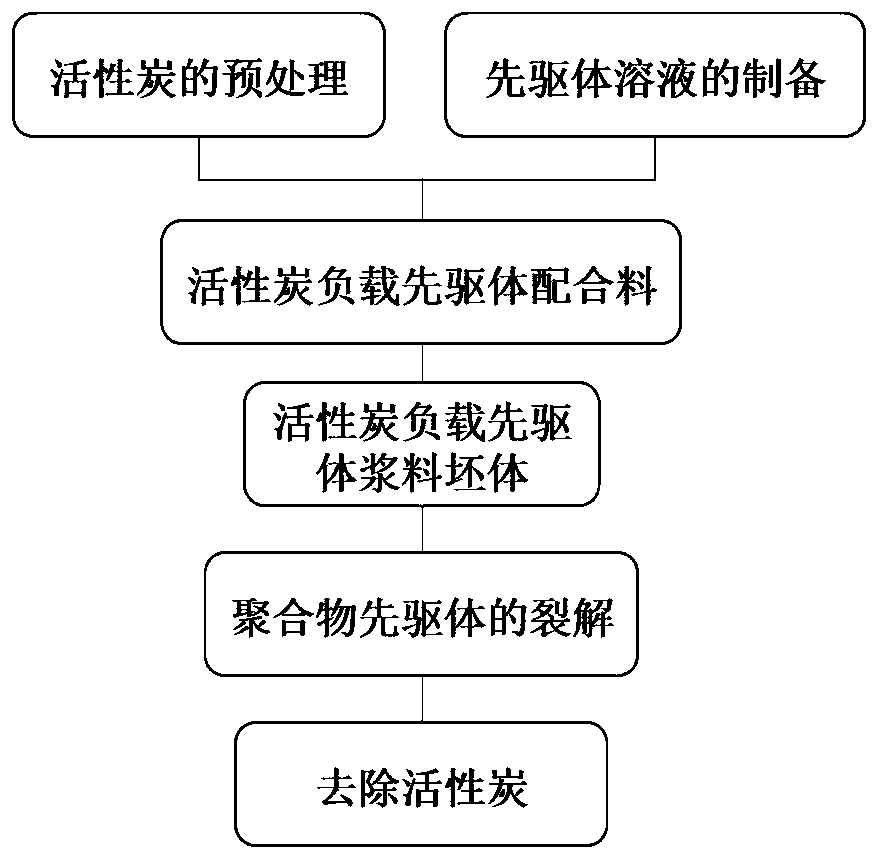

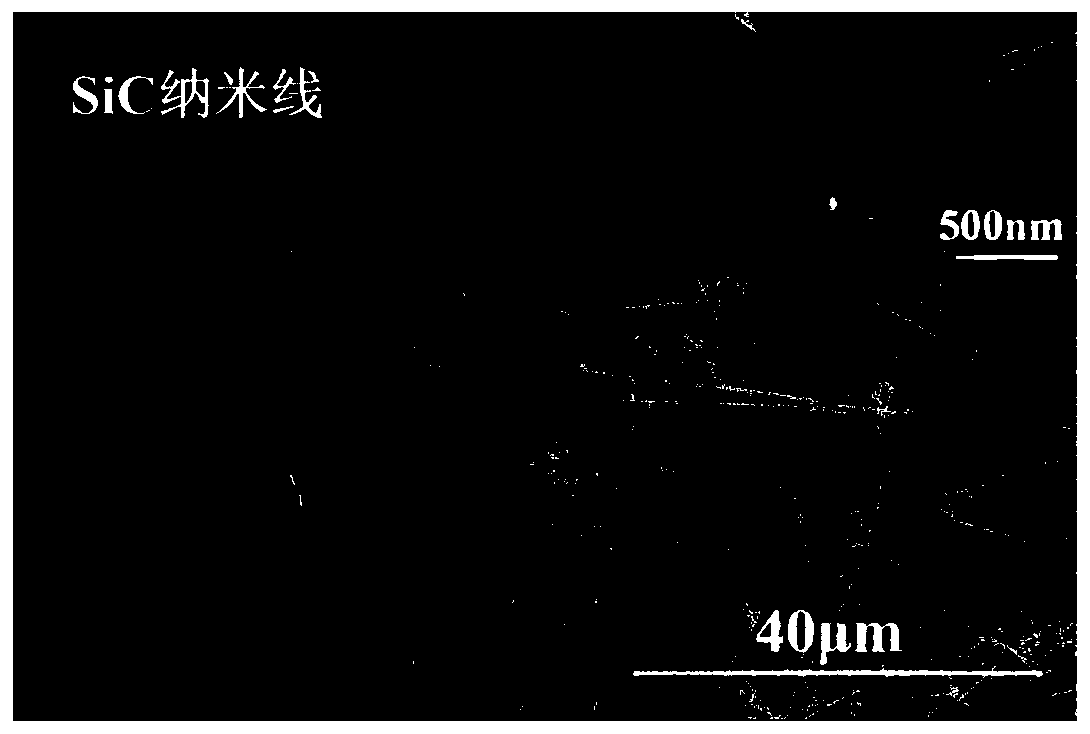

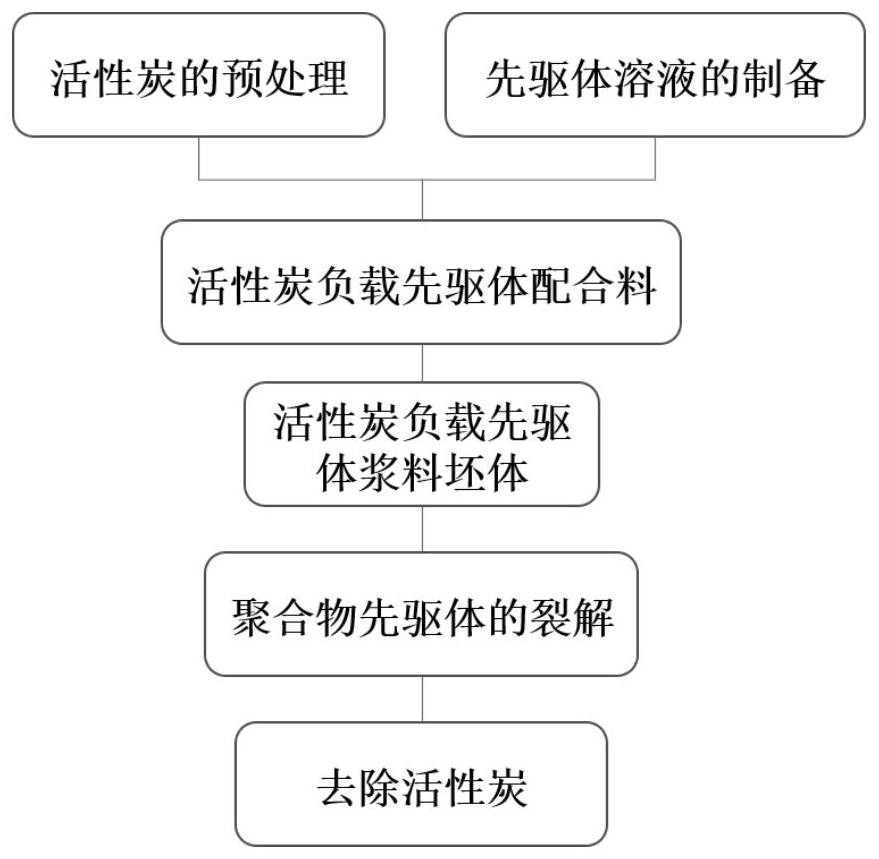

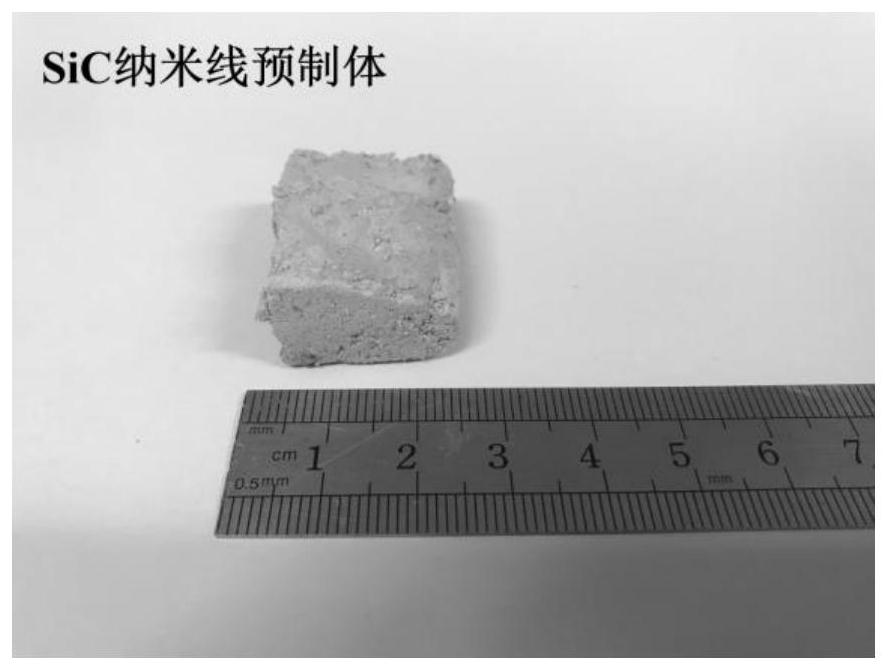

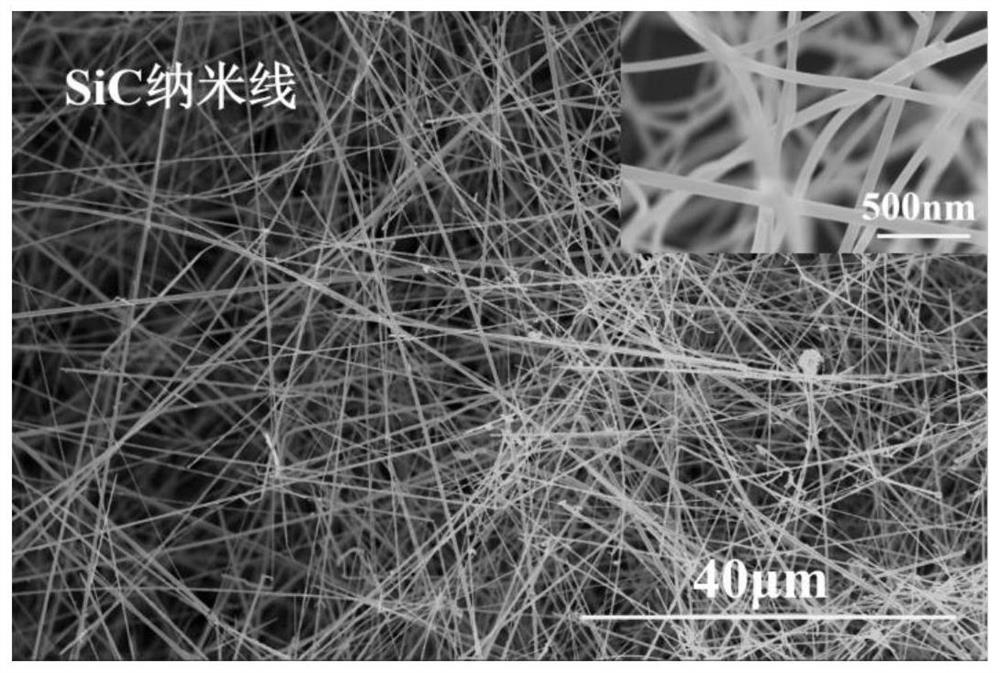

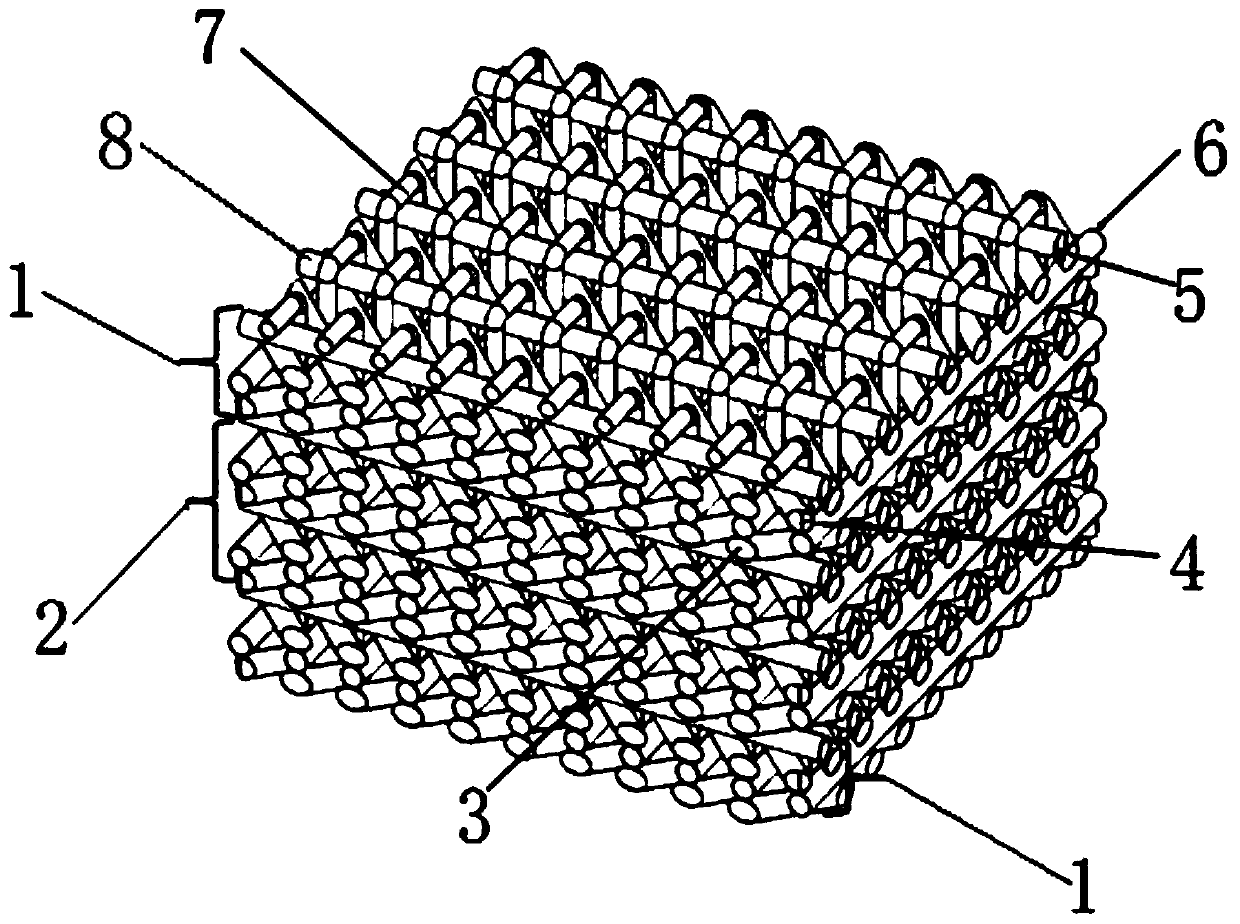

Preparation method of isotropic ceramic nanowire preform

ActiveCN110606747AGuaranteed outputImprove mechanical propertiesCarbon compoundsActivated carbonElectricity

The invention relates to a preparation method of an isotropic ceramic nanowire preform, which comprises the following steps: loading a polymer precursor on activated carbon powder to form a mixture, pressing the mixture into a green body template; cracking the polymer precursor on the template at a certain temperature to grow a large number of nanowires which are crossed and lapped with one another; then performing oxidation to remove the activated carbon to prepare the isotropic ceramic nanowire preform material with the interconnected three-dimensional network structure. The nanowires in theisotropic ceramic nanowire preform prepared by the method are pure in component, uniform in structure, controllable in size and adjustable in volume fraction. The method has the advantages of simpleprocess steps, short period, relatively low cost, good stability and good repeatability. Meanwhile, the ceramic nanowire preform has the functions of heat insulation, light weight, electricity, opticsand the like, requirement for multifunctional integration is expected to be met, and the application field of ceramic matrix composite materials is expanded.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

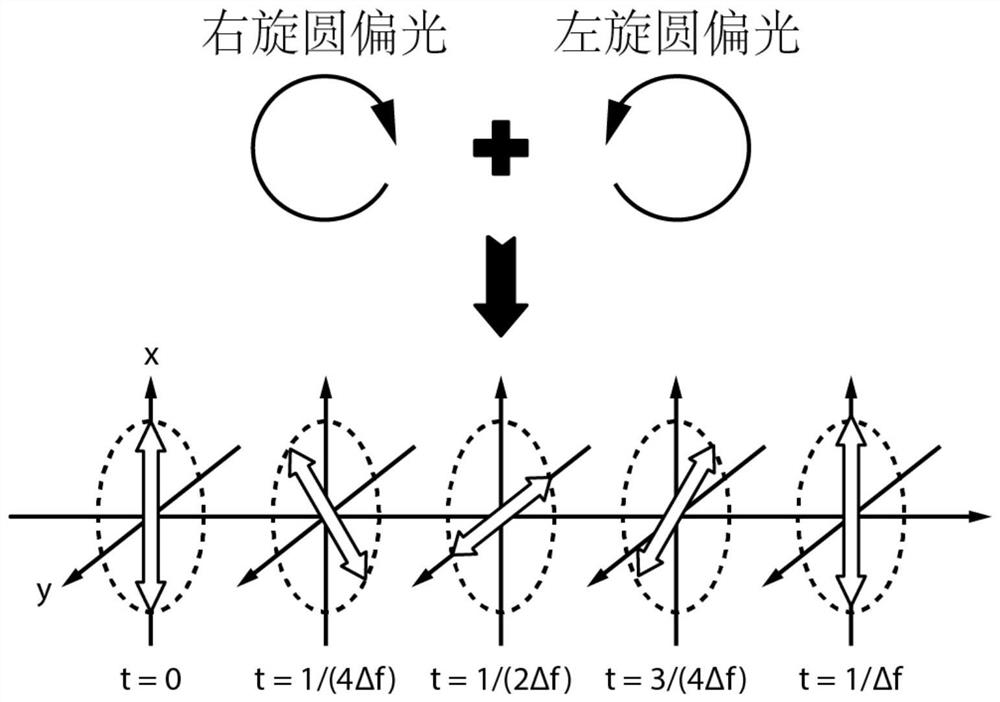

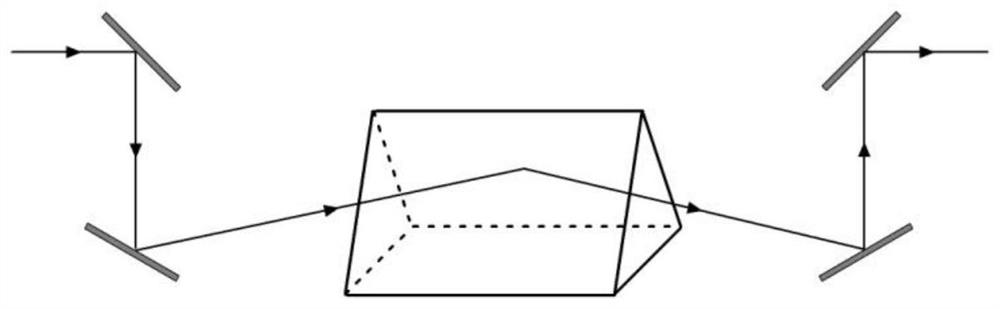

Optical chromatography microscopic imaging system and method for rapidly and continuously rotating sample

ActiveCN113777767AFast spinRotation continuous and non-jumpingMicroscopesMicroparticleOptical polarization

The invention discloses an optical chromatography microscopic imaging system and an optical chromatography microscopic imaging method for rapidly and continuously rotating a sample. Optical tweezers manufactured by linear polarization are used for capturing and rotating a sample, a single-beam gradient force trap is generated, microparticles or cells can be restrained near a focus in a three-dimensional space, anisotropic polarization in the sample is caused at the same time, and therefore a moment depending on an included angle between a birefringence polarization direction and an electric field direction is generated, the captured object can be controlled to synchronously rotate with the polarization direction of the light field. An optical heterodyne interference method is adopted to synthesize a polarized high-speed rotating linear polarized light field for generating optical tweezers, a target sample can be rapidly and continuously rotated in a non-contact mode, mechanical disturbance introduced by a scanning galvanometer is avoided, and especially for optical diffraction tomography, the axial resolution can be improved, and isotropy of the resolution can be achieved. The optical path is compact, and the miniature optical path can be realized.

Owner:北京大学长三角光电科学研究院

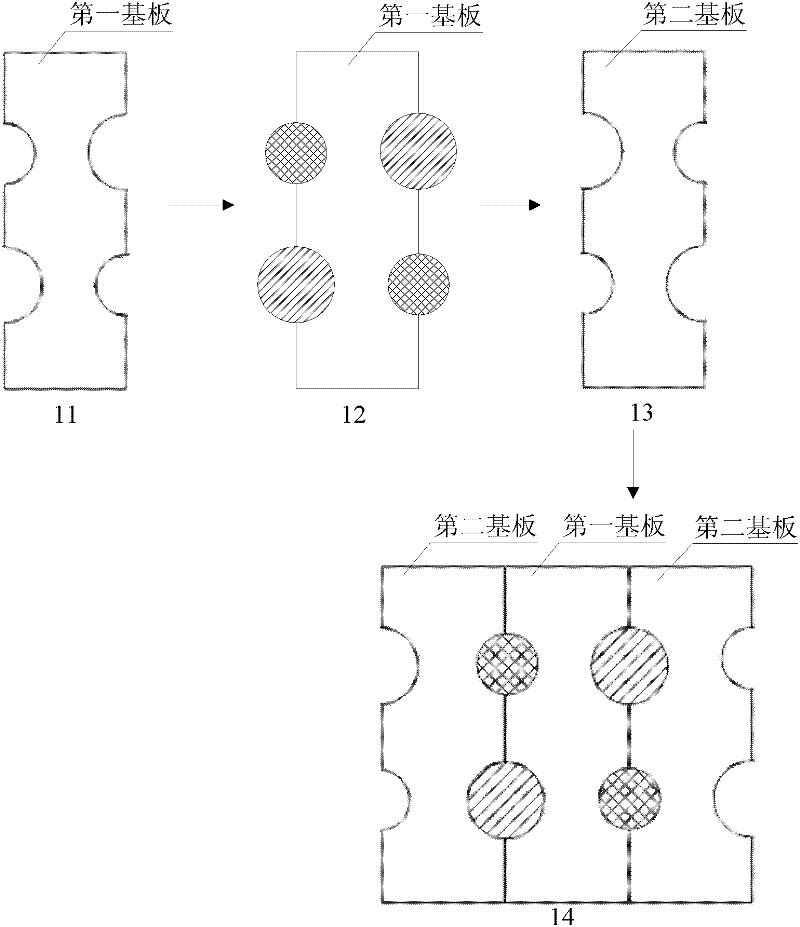

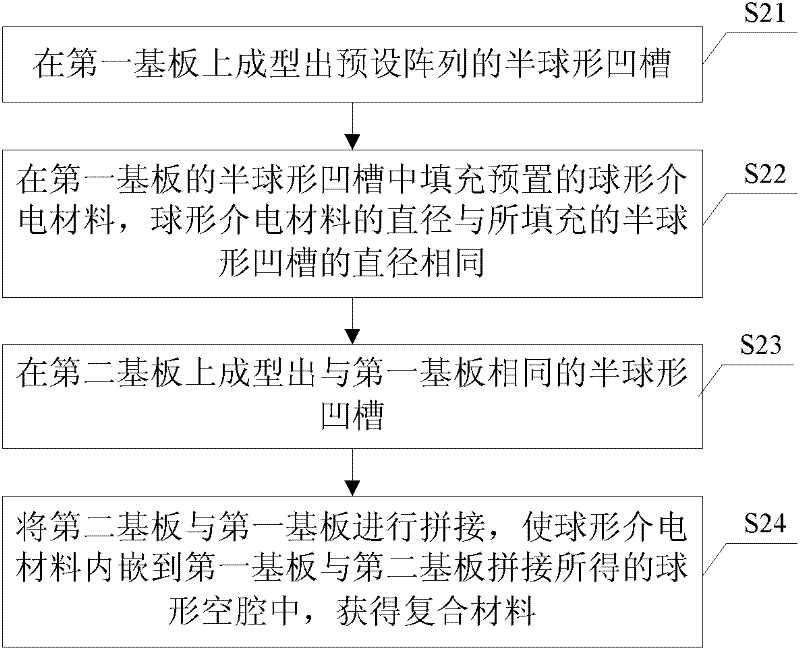

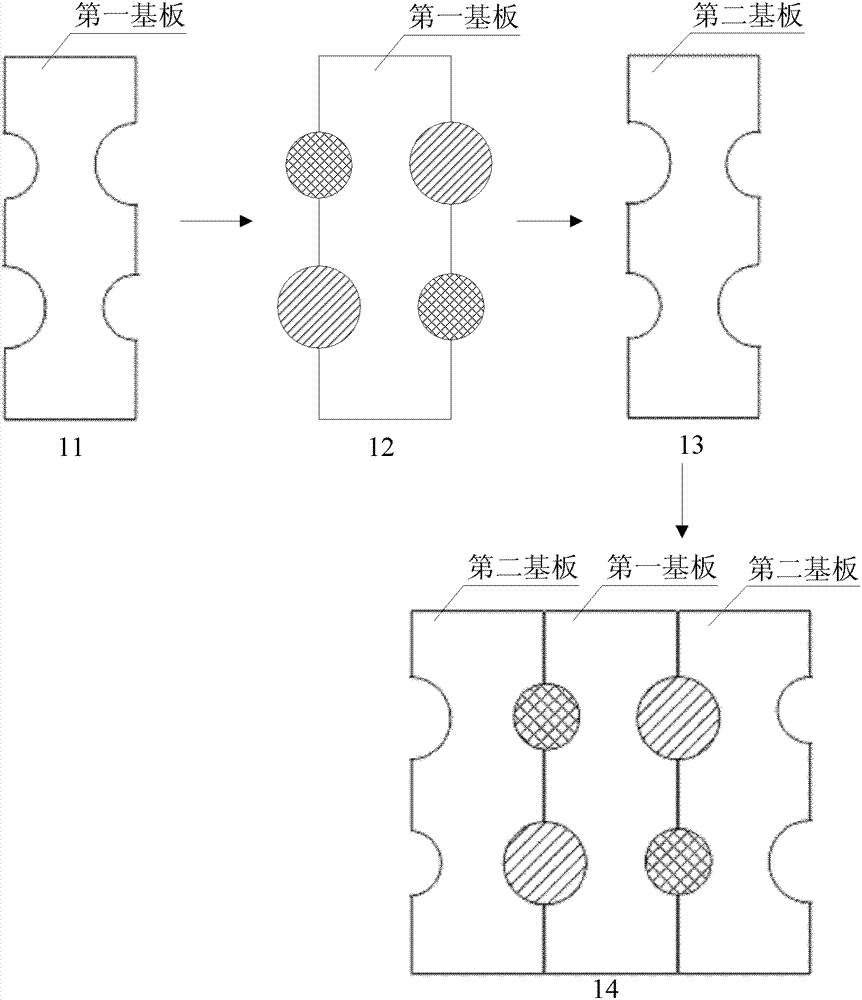

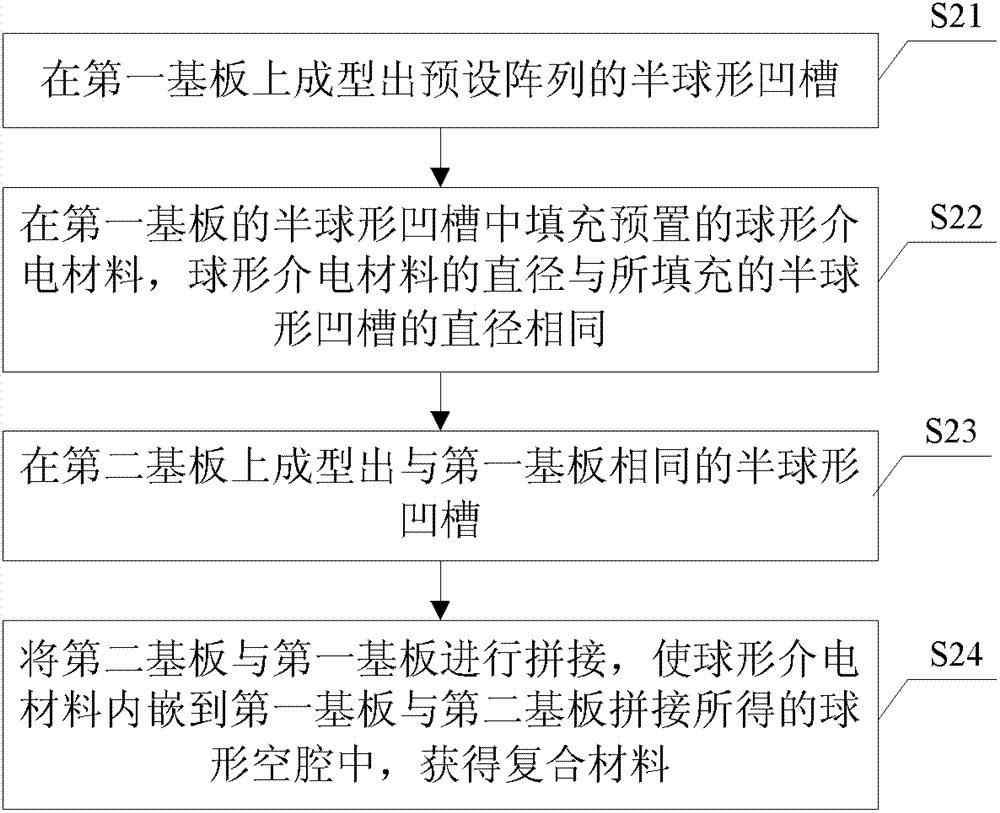

Method for preparing composite material

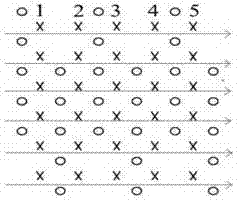

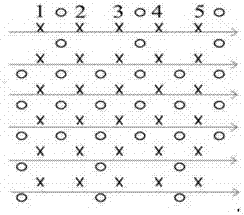

An embodiment of the invention provides a method for preparing a composite material. The method comprises the following steps of: forming a semispherical groove of a preset array on a first substrate; filling a preset spherical dielectric material in the semispherical groove of the first substrate, the diameter of the spherical dielectric material being the same as that of the semispherical groove; forming a semispherical groove the same as that of the first substrate on a second substrate; and splicing the first and second substrates to embed the spherical dielectric material in a spherical cavity formed by splicing the first and second substrates, thereby obtaining the composite material. The composite material is obtained by splicing the spherical dielectric material in the substrates to achieve isotropy and a simple process flow.

Owner:KUANG CHI INST OF ADVANCED TECH +1

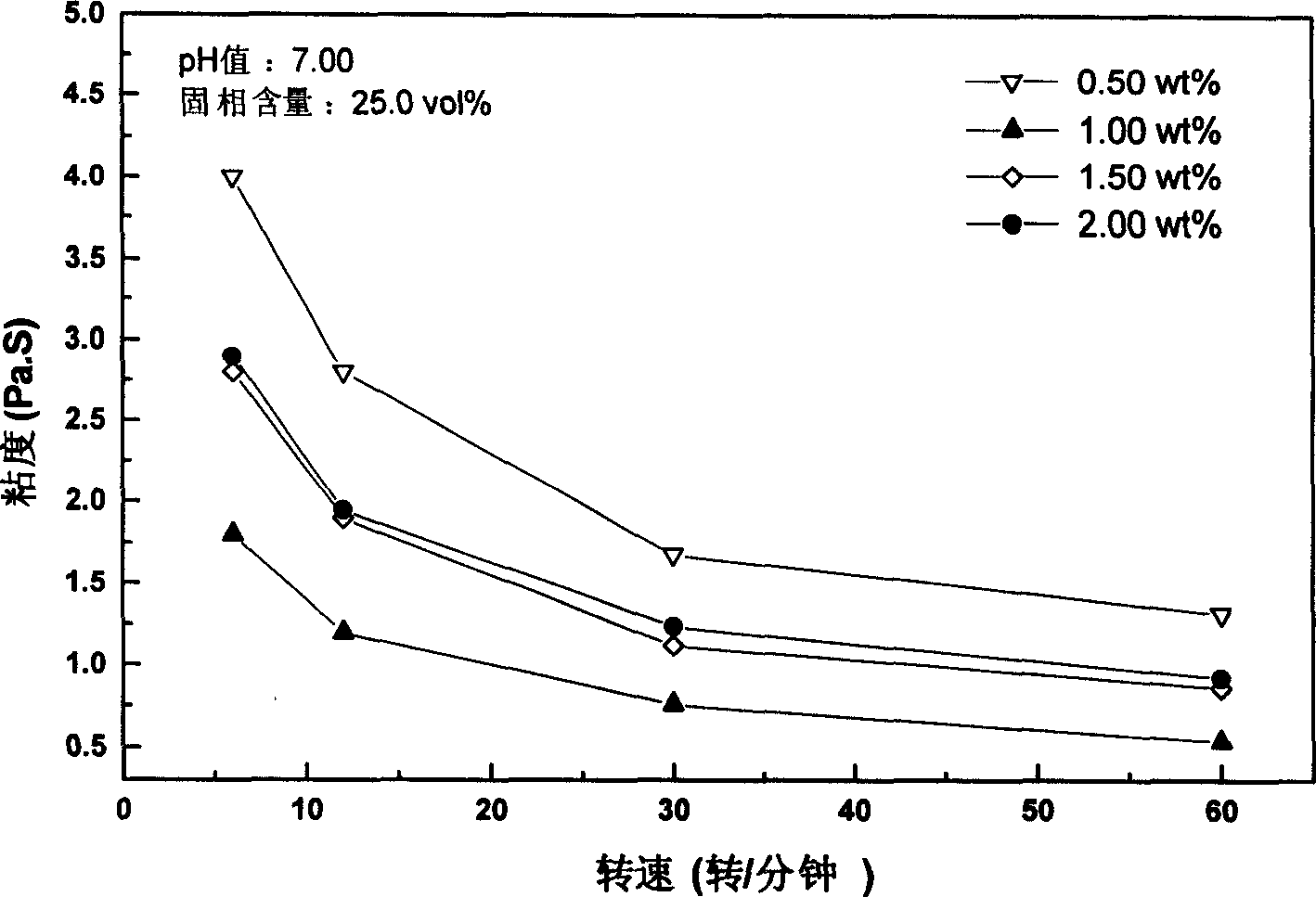

Injectiong coagulation shaping technology of high performance graphite product

Owner:OCEAN UNIV OF CHINA

Injectiong coagulation shaping technology of high performance graphite product

Owner:OCEAN UNIV OF CHINA

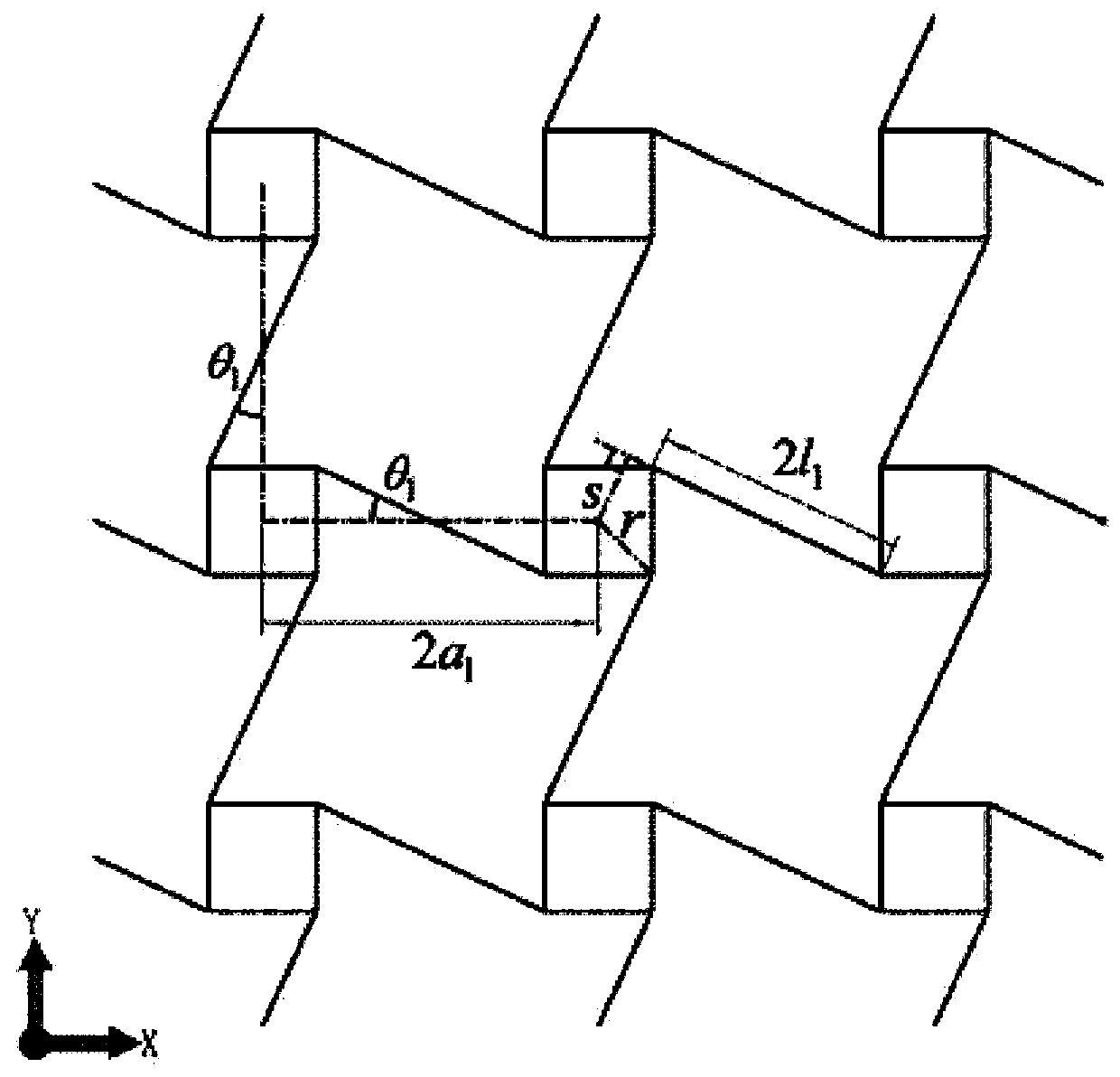

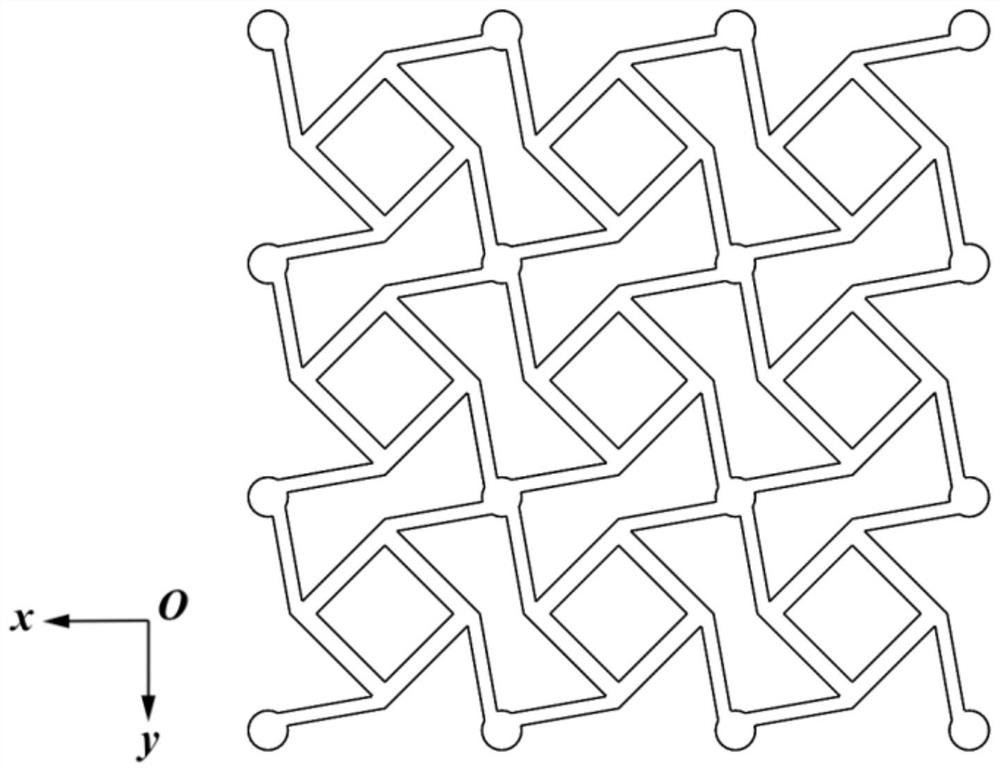

A porous material structure with partially oriented negative Poisson's ratio

InactiveCN108481821BEliminate tension-shear coupling effectsWide range of changesLayered productsNetwork structureEngineering

The invention provides a porous material structure having negative Poisson's ratios in partial directions. The porous material structure comprises a multi-layered network structure which is sequentially stacked in parallel along the Z-axis direction, the adjacent upper and lower network structures are connected by a support ligament and each layer of the network structure extends along the XOY plane. The porous material structure eliminates the tensile-shear coupling effect of the two-dimensional substructure on the XOY plane during deformation, so that the constitutive relationship of the three-dimensional structure is normally orthogonal under normal conditions so that design and analysis are convenient. By adjusting the geometrical dimensions, the structure can not only achieve isotropy, but also has a large change range of Poisson's ratios in three directions so that the choice of practical applications is increased.

Owner:SUN YAT SEN UNIV

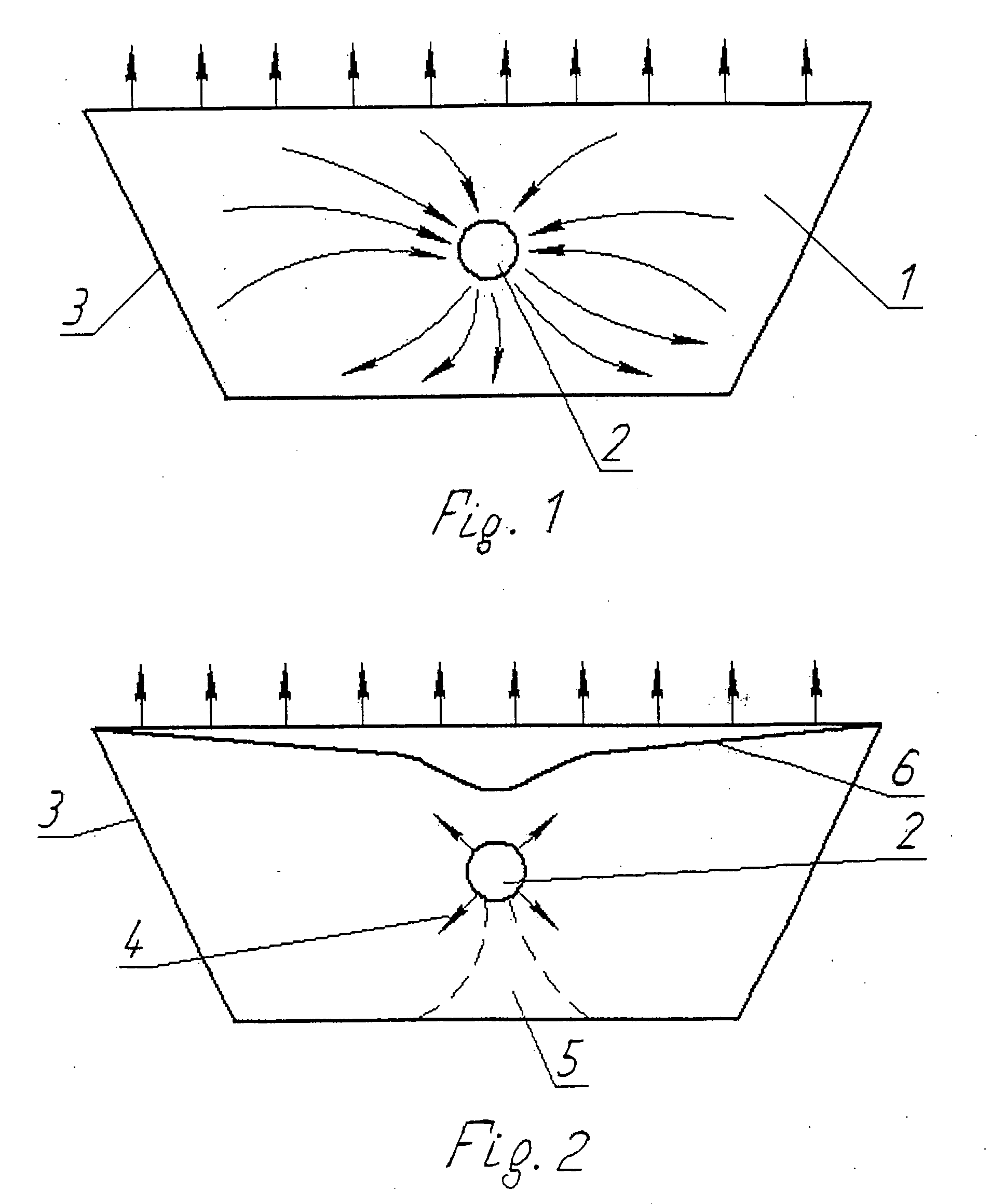

Method for making castings by directed solidification from a selected point of melt toward casting periphery

InactiveUS20090242166A1Sufficient maintenance timeGood strength propertiesDirectional solidificationHigh pressure

The invention is related to the foundry practice. According to this invention, the method for making castings by directed solidification from a selected point of the melt toward the periphery of the casting comprises forming a casting in a mold having thermodynamic characteristics that allow uniform volume cooling of the melt to be effected to a temperature at which natural solidification processes are completed. To improve the structural isotropy of the casting formed, the cooling is effected at a rate not exceeding 0.5° C. / sec. The casting is formed in a nonuniform field of force. The nonuniform field of force is set up by ultrasonic waves focused on a selected point of the melt to form therein a localized elevated pressure zone and to direct the solidification front from the zone toward the periphery of the casting. The nonuniform field of force is sustained in the mold until the cooling casting reaches a temperature at which the natural melt solidification processes are completed as the melt cools. Before the melt is poured into the mold, it is overheated to a level that, together with the thermodynamic characteristics of the mold allowing the melt therein to be cooled at a rate not exceeding 0.5 K / sec, sustains the liquid phase of the melt for a time sufficient for directed melt solidification to be effected from the selected point of the melt toward the periphery of the casting before the commencement of natural melt solidification processes as the melt cools. Subsequently, as the temperature at which natural solidification processes are completed is reached, the nonuniform field of force is removed, and casting cooling may continue at any reasonable rate.

Owner:ANISIMOV OLEG VLADIMIROVICH +1

Chiral auxetic metamaterial structure with tension-torsion coupling properties and its preparation method

ActiveCN112049886BWith tension torsion coupling characteristicsImprove carrying capacityAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMechanical engineering

The invention discloses a chiral auxetic superstructure material structure with tension-torsion coupling characteristics and a preparation method thereof, which includes a plurality of three-dimensional unit cell structures, each three-dimensional unit cell structure includes two polygonal ring structures arranged up and down, the upper and lower The vertices of the two polygonal ring structures are respectively connected by correspondingly arranged inclined cylinders, and the plurality of inclined cylinders are arranged in dislocation along the same direction, and the vertices of the two polygonal ring structures are respectively provided with connection points for connecting adjacent three-dimensional unit cell structures. Rods, several three-dimensional unit cell structures are arranged in a spatial array, connected by corresponding connecting rods to form a chiral auxetic metamaterial structure with tension-torsion coupling characteristics.

Owner:XI AN JIAOTONG UNIV +1

A kind of preparation method of isotropic ceramic nanowire preform

ActiveCN110606747BGuaranteed outputImprove mechanical propertiesActivated carbonActivated charcoal powder

The invention relates to a method for preparing an isotropic ceramic nanowire prefabricated body. The polymer precursor is loaded on activated carbon powder to form a mixture and pressed into a blank template, so that the polymer precursor on the template is cracked at a certain temperature. A large number of cross-overlapped nanowires are grown. The active carbon is then oxidized to remove, and an isotropic interconnected three-dimensional network structure ceramic nanowire prefabricated material is prepared. The nanowires in the isotropic ceramic nanowire prefabricated body prepared by the invention have pure composition, uniform structure, controllable size and adjustable volume fraction. The process steps are simple, the cycle is short, the cost is relatively low, and the process also has good stability and repeatability. At the same time, the ceramic nanowire prefabricated body has functions such as heat insulation, light weight, electricity, and optics, and is expected to meet the requirements of multifunctional integration and expand the application field of ceramic matrix composite materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of in-plane quasi-isotropic structure-stealth composite material and its preparation method

The invention discloses an in-plane quasi-isotropic structure-stealthy composite material and further comprises a preparation method of the in-plane quasi-isotropic structure-stealthy composite material. The in-plane quasi-isotropic structure-stealthy composite material comprises a base body and a reinforcement body which are composited and solidified through a VARTM process. The base body is madeof resin; the reinforcement body is made of sandwich-type three-dimensional stereo woven material, the woven material is composed of a plurality of mutually-parallel fiber layers and normal fibers perpendicular to the fiber layers, and the fiber layers are bound together by the normal fibers through a weaving method. The preparation method specifically comprises the following steps of 1, weavingof the reinforcement body; 2, reinforcement body moulding; 3, glue injecting and solidifying; and 4, demoulding. The problems that as for a stealthy composite material in the prior art, the electromagnetic property is isotropic, the anti-impact property is poor, and the stealthy composite material is likely to be layered after being impacted are solved.

Owner:浙江世涛鼎革新材料有限责任公司

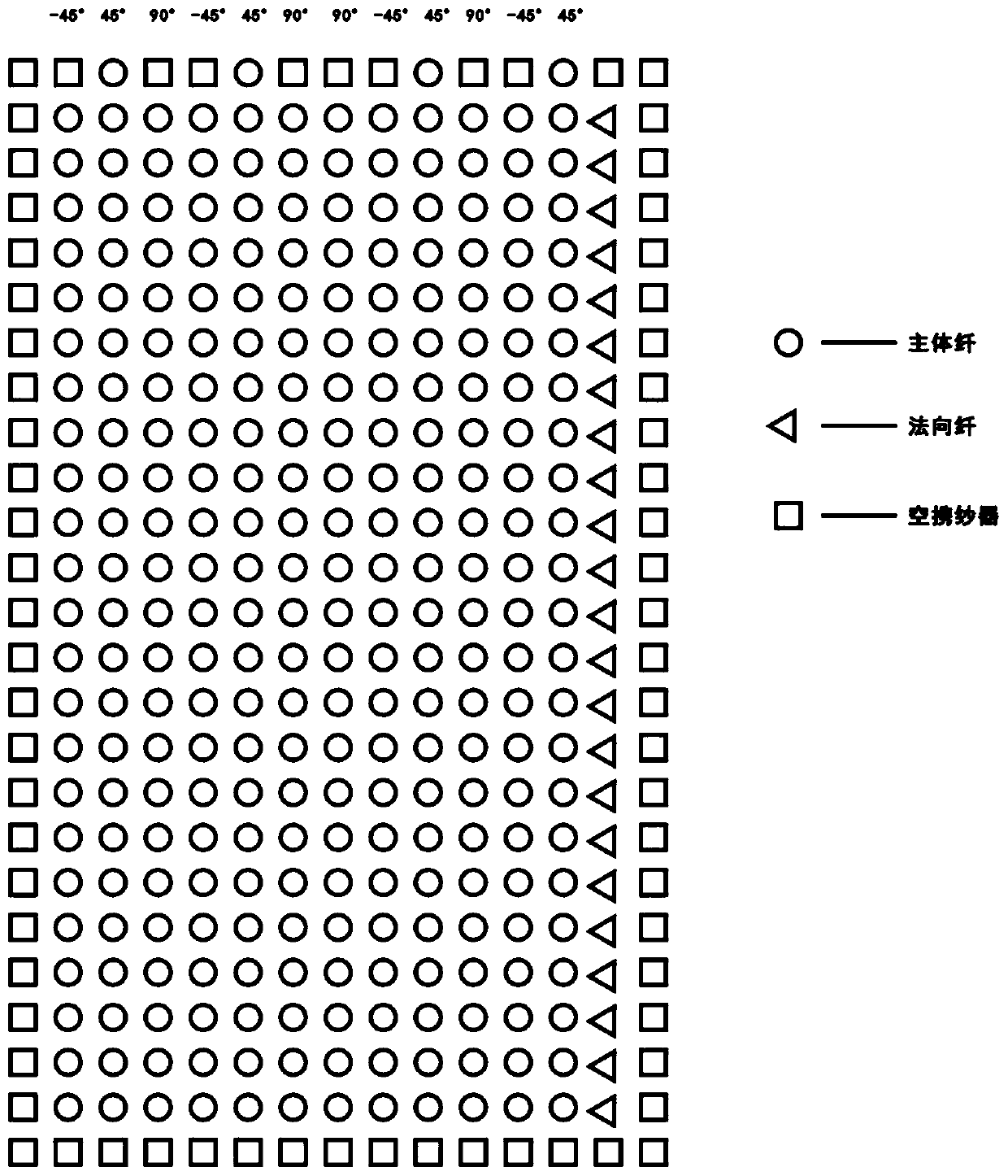

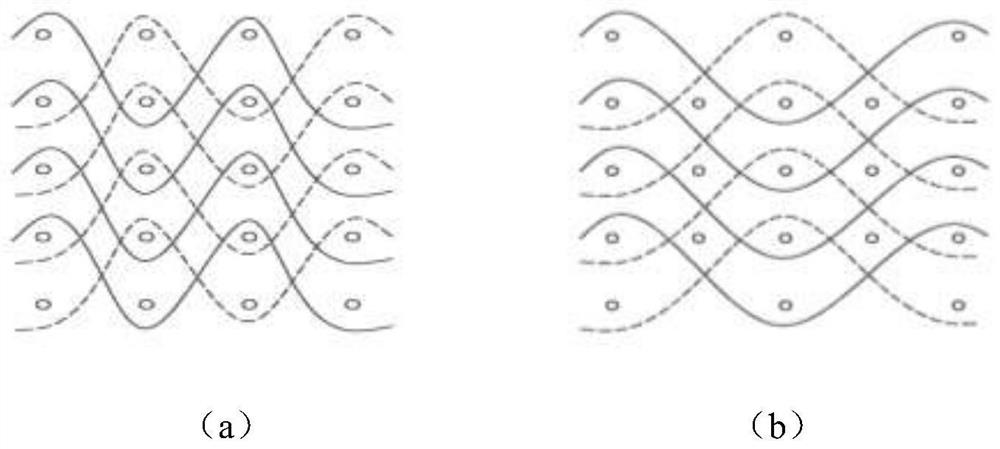

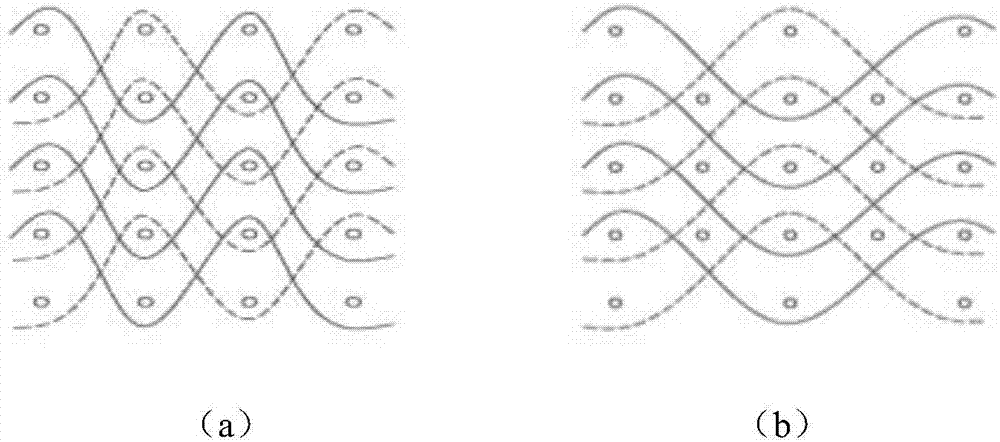

A Designable Laminated Structure of In-Plane Diagonal Yarns

The invention relates to a designable layered structure of oblique yarns in a plane, which has multiple layers, and each layer is composed of warp yarns and oblique yarns, wherein the warp yarns are distributed in a sinusoidal form along the length direction of the fabric; Extend forward or reverse spirally along the length direction at a certain angle with the warp yarns, and interweave with the warp yarns, the aforementioned included angle is an acute angle; while the oblique yarns interweave with the warp yarns of the current layer, they also interweave with the warp yarns of the adjacent layer. The invention can improve the in-plane isotropic performance, facilitate the realization of mechanized preparation, and can better meet the requirements of fabric uniformity, integrity, high damage tolerance, impact resistance, delamination resistance and fatigue resistance, and has good uniformity and performance Excellent, easy to operate, conducive to mechanized preparation, high efficiency and low cost. The present invention can be applied to the molding of plate-shaped fabrics, and can also be applied to the molding of rotary-shaped fabrics such as cylindrical, conical, and special-shaped fabrics.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

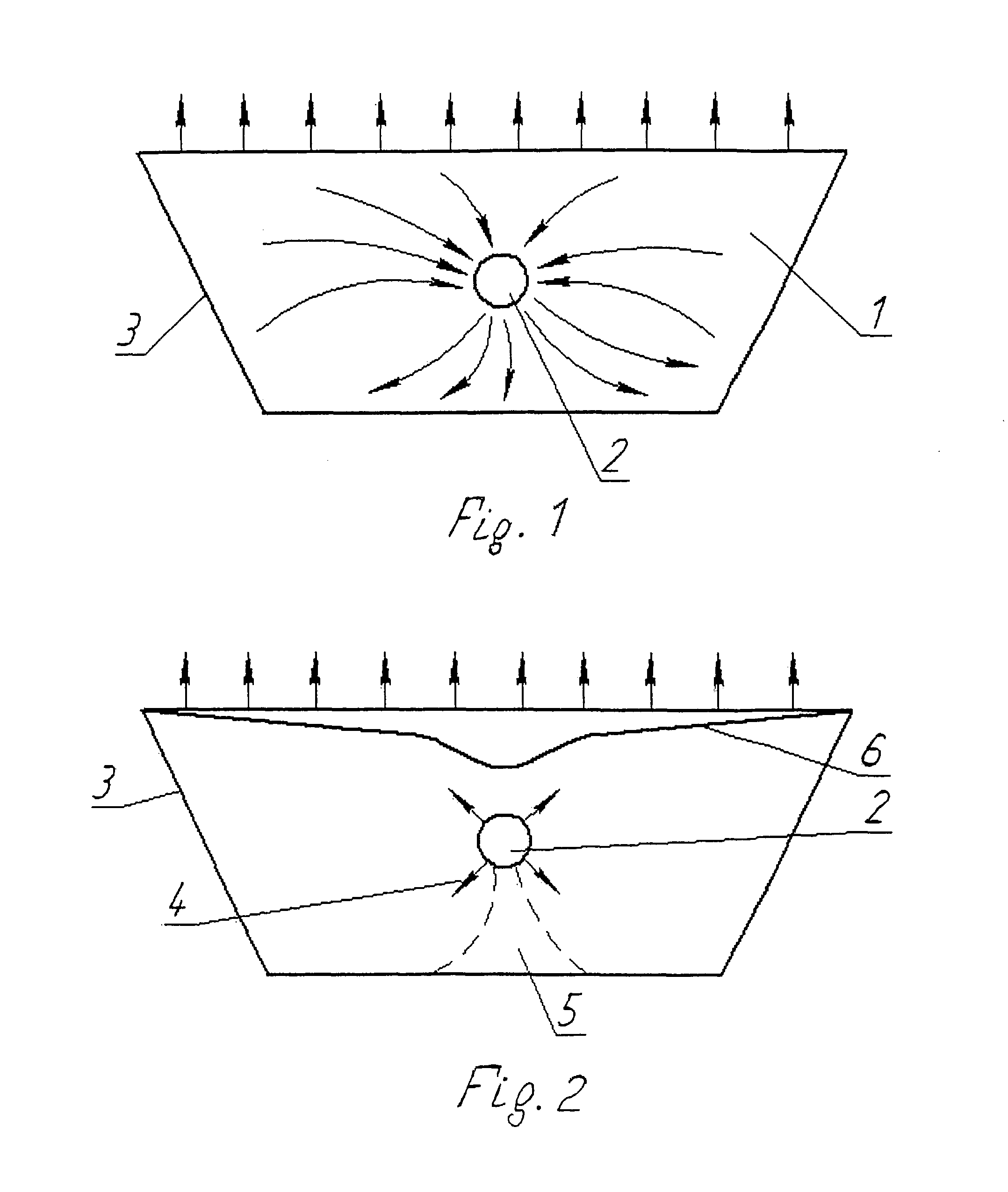

lighting equipment

ActiveCN103375695BAchieve isotropyLarge light distribution angleElongate light sourcesLighting heating/cooling arrangementsEngineering

The invention relates to light-emitting equipment which comprises a light-emitting element, a mounting part and a housing. Light emitted by the light-emitting element is different in intensity in different directions, the light-emitting element is mounted on the mounting part, and the housing is used for accommodating the light-emitting element and the mounting part. At least one part of the housing is formed into a light-transmitting area to enable the light emitted by the light-emitting element to be capable of penetrating the light-transmitting area to be emitted to the outside of the light-emitting equipment; moreover, the thickness of each position of the light-transmitting area is in negative correlation with the intensity of the light emitted by the light-emitting element in the direction of the position. By the arrangement, the intensity of the light emitted by the light-emitting element in all directions becomes more isotropic.

Owner:LEDVANCE GMBH

High-speed multi-directional line confocal digital holographic three-dimensional microscopic imaging method and device

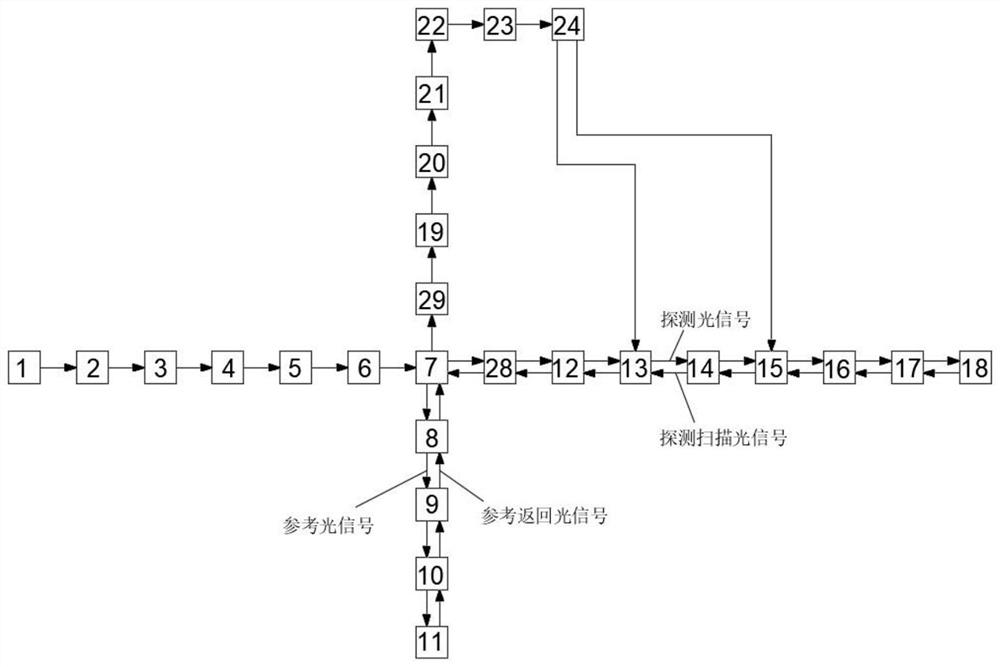

The invention discloses a high-speed multi-directional line confocal digital holographic three-dimensional microscopic imaging method and device. The optical signal is divided into a reference optical signal and a detection optical signal after being polarized, beam expanded and focused; the reference optical signal is relayed to The total reflection mirror receives the reference return light signal; the detection light signal is relayed to the sample platform and receives the detection scanning light signal; the reference return light signal and the detection scanning light signal are combined to filter out stray light, and then relayed to the high-speed linear array The photosensitive surface of the camera obtains multi-frame one-dimensional line confocal interferograms; multi-frame one-dimensional line confocal interferograms are collected and superimposed to generate reconstruction interference fields in multiple scanning directions, and then processed to realize the expansion of the object optical spectrum of the sample platform , and then process the expanded object light spectrum to reconstruct the three-dimensional phase distribution of the object light wave field. The invention can effectively realize high-speed multi-directional line confocal digital holographic microscopic imaging, and has the advantage of high resolution.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

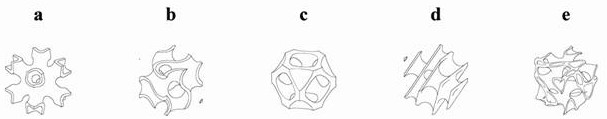

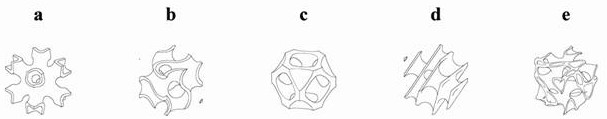

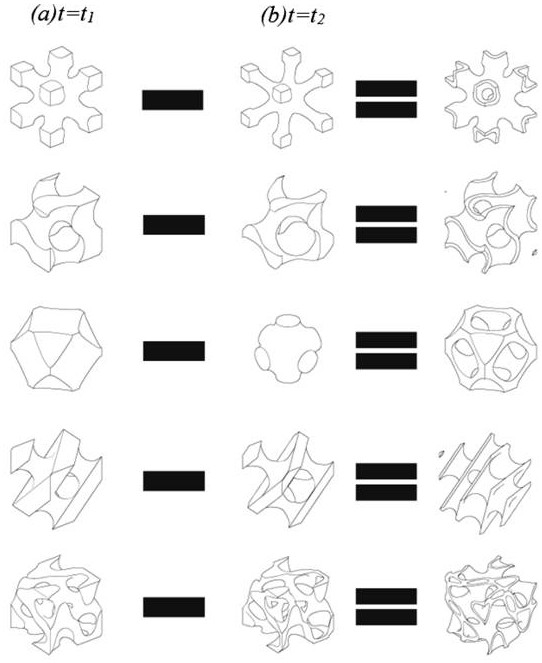

A set of 3D hollow porous structures with isotropic properties

The invention discloses a group of three-dimensional hollow porous structures with isotropic properties. The group of structures includes five different three-dimensional hollow porous structures, which are respectively generated by IWP type, Gyroid type, Primitive type, Dimond type and S-type minimal curved surfaces. isotropic hollow porous structure. The present invention obtains the topological configuration of the three-dimensional hollow porous structure under different volume fractions by performing Boolean operations on the minimum surface structure with specific parameters, and the obtained three-dimensional porous structure has isotropic properties, and is a three-dimensional isotropic porous structure The design provides a reference and has certain application prospects in the fields of lightweight, load bearing, energy absorption and impact resistance.

Owner:CHINA THREE GORGES UNIV

An optical fiber type three-dimensional trigger probe device and measurement method

ActiveCN106595479BRealize 3D trigger functionImprove resolutionUsing optical meansEngineeringOptical fiber transmission

A fiber-optic three-dimensional trigger probe device and measurement method, the device includes a light source, an optical fiber measuring rod, an elastic reset mechanism, a measuring ball coated with a reflective film, and a photoelectric detection unit, the optical fiber measuring rod has a central optical fiber and 4N receiving optical fibers coaxially and uniformly distributed around the central optical fiber, N is a positive integer, and the elastic reset mechanism is arranged between the optical fiber measuring rod and the measuring ball to reset the measuring ball to In the initial position, the light source emits constant power light and is transmitted to the measuring ball through the central optical fiber, and the light reflected by the reflective film is transmitted to the photoelectric detection unit through the receiving optical fiber. The device can overcome the measurement error caused by the force deformation of the measuring rod during detection, and has high resolution and measurement accuracy at the same time.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

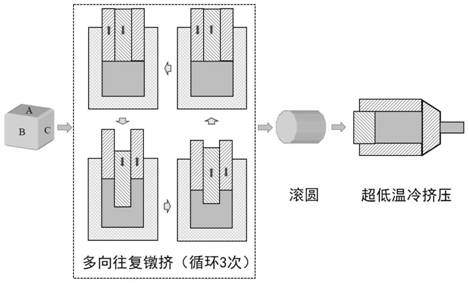

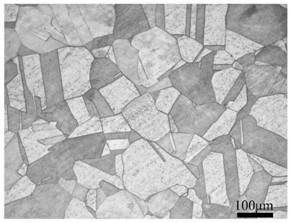

A preparation method of fine-grained and weak-textured blank for medicine-shaped mask

ActiveCN114134438BAchieve purificationTissue weakeningFurnace typesForging/hammering/pressing machinesMedicinePhysical chemistry

The invention provides a method for preparing a billet for a medicine-shaped cover, which sequentially performs multi-directional reciprocating and ultra-low temperature large-deformation extrusion; the multi-directional reciprocating upsetting extrusion is sequentially performed on three faces of the six-sided billet with the same apex Reciprocating upsetting extrusion, single extrusion ratio ≥ 1.5, complete 2 to 4 cycles of multi-directional reciprocating upsetting extrusion; the ultra-low temperature and large deformation extrusion is to subject the billet to cryogenic treatment for 60 to 150 minutes, and extrude the working part of the extrusion die The inner cone angle is 90°~140°, and the extrusion rate is 10~20mm / s. The invention can realize fine-grained and weak texture structure, and improve the isotropy, high yield ratio and high ductility of the liner.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

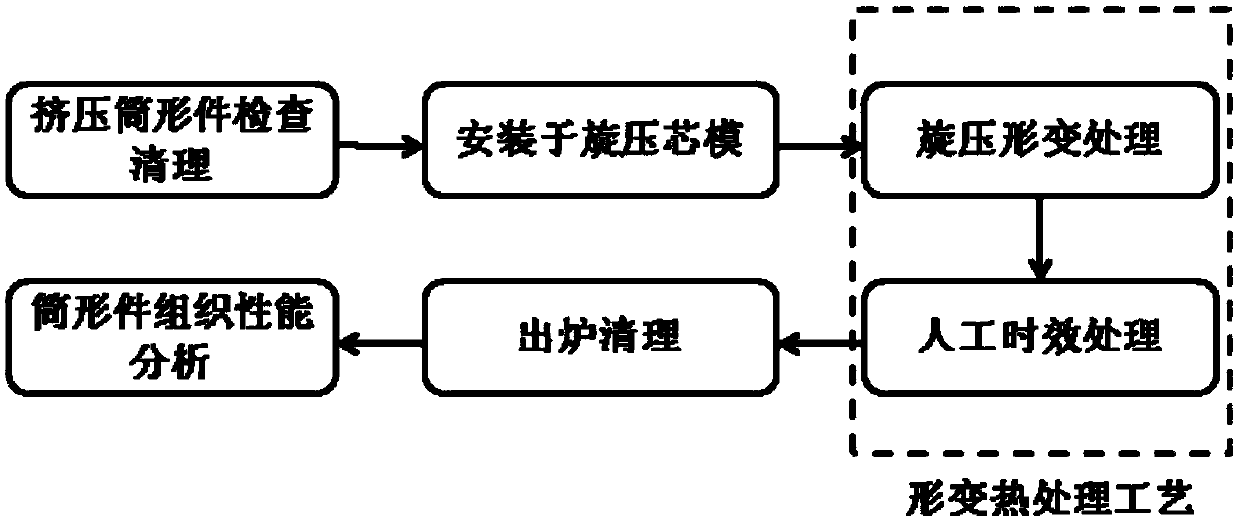

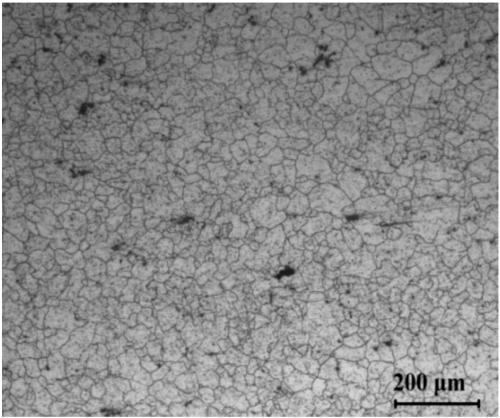

Deformation heat treatment process to improve the performance of high-strength heat-resistant deformed magnesium alloy cylindrical parts

ActiveCN107723636BUniform deformationIncrease the degree of deformationNonferrous metalBarrel Shaped

The invention relates to a thermo-mechanical treatment process for improving the performance of a high-strength heat-resistant wrought magnesium alloy barrel-shaped part, and belongs to the field of nonferrous materials and processes. The technology of aging heat treatment after spinning deformation is adopted, continuous and pointwise plastic deformation is generated through spinning point-contact deformation at high temperature, even deformation of the barrel-shaped part is realized, the deformation degree is improved, the structure performance is uniform, and the isotropy of the performanceof the wrought magnesium alloy barrel-shaped part is realized. The process is divided into two phases. In the first phase, the deformation degree of the barrel-shaped part is improved through high-temperature spinning deformation, the structure performance is uniform, the grain refinement strengthening effect of WE71M wrought magnesium alloy is played, and the mechanical performance of the WE71Mbarrel-shaped part is improved. In the second phase, aging heat treatment is conducted on the barrel-shaped part after being subjected to spinning deformation, separation of a discontinuously separated dispersion strengthening phase at the grain boundary is facilitated, and the performance of the material is improved. The performance of the barrel-shaped part is further improved after high-temperature deformation heat treatment, and the structure is more uniform.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Layer connection structure with designable oblique yarns in plane

The invention relates to a layer connection structure with designable oblique yarns in a plane. The structure comprises a plurality of layers, each layer comprises warp yarns and the oblique yarns, the warp yarns are distributed in a sinusoidal waveform along the length direction of a fabric, the oblique yarns spirally extend forwards or reversely along the length direction by a certain included angle formed between each oblique yarn and each warp yarn, the oblique yarns are interwoven with the warp yarns, and the included angle is an acute angle. When the oblique yarns are interwoven with thewarp yarns of one layer, the oblique yarns are further interwoven with the warp yarns of the adjacent layers. Various performances in the plane can be improved, mechanized preparation is convenientlyrealized, the requirements of the fabric for uniformity, integrity, high damage tolerance, impact resistance, layering resistance, fatigue resistance and the like can be effectively met, and the layer connection structure has the advantages of good uniformity, excellent performances, simplicity and convenience in operation, capability of facilitating mechanized preparation, high efficiency, low cost and the like. The layer connection structure can be applied to forming of the plate fabric and can also be applied to forming of cylindrical, conical and special-shaped rotary fabrics.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Method for preparing composite material

An embodiment of the invention provides a method for preparing a composite material. The method comprises the following steps of: forming a semispherical groove of a preset array on a first substrate; filling a preset spherical dielectric material in the semispherical groove of the first substrate, the diameter of the spherical dielectric material being the same as that of the semispherical groove; forming a semispherical groove the same as that of the first substrate on a second substrate; and splicing the first and second substrates to embed the spherical dielectric material in a spherical cavity formed by splicing the first and second substrates, thereby obtaining the composite material. The composite material is obtained by splicing the spherical dielectric material in the substrates to achieve isotropy and a simple process flow.

Owner:KUANG CHI INST OF ADVANCED TECH +1

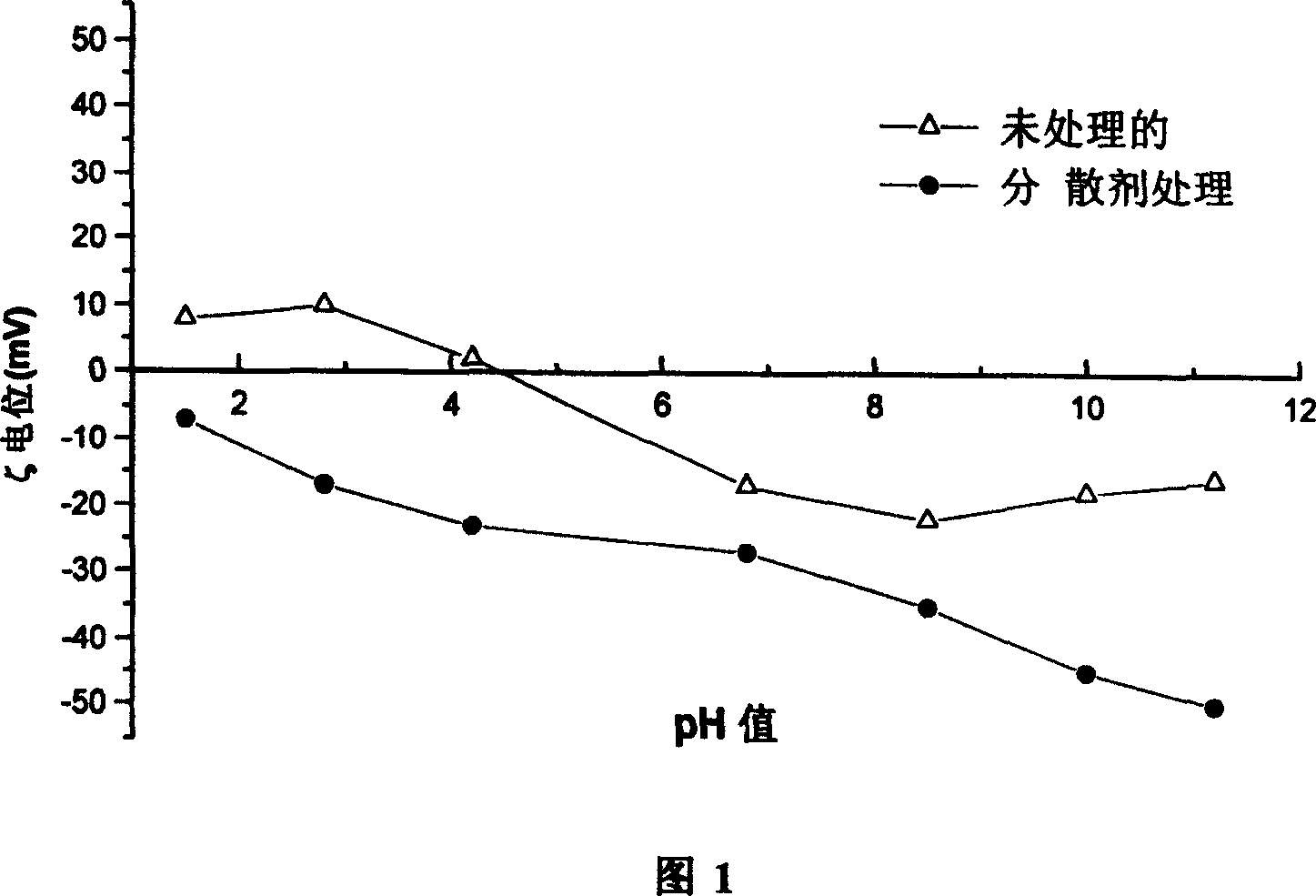

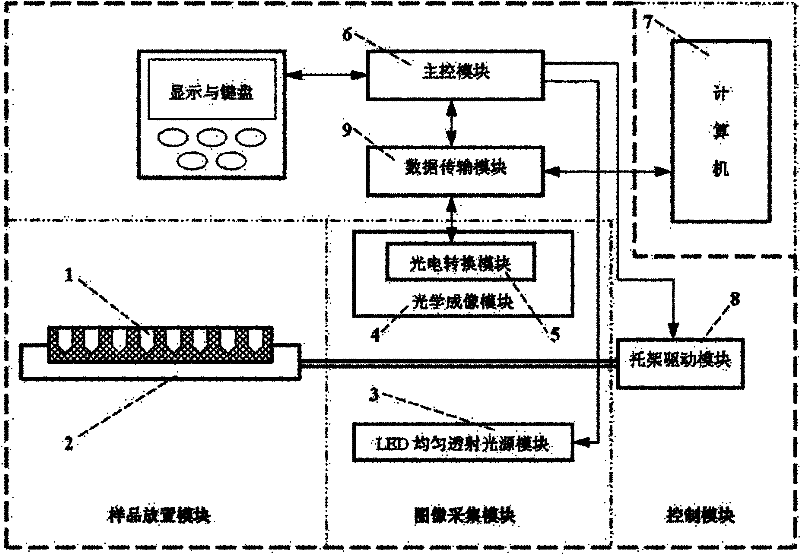

Device and method for analyzing transmission type charge-coupled device (CCD) imaged image

InactiveCN101968444BSmall overall deformationImprove imaging clarityTransmissivity measurementsColor/spectral properties measurementsPhotoelectric conversionData transmission

The invention discloses a device and a method for analyzing a transmission type charge-coupled device (CCD) imaged image. The device comprises a sample placing module, an image acquisition module and a control module, wherein the sample placing module comprises a porous liquid sample transparent vessel and a bracket; the image acquisition module comprises a light emitting diode (LED) uniform transmission light source module, an optical imaging module and a photoelectric conversion module; and the control module comprises a master control module, a computer, a bracket driver module and a data transmission module. The method comprises the following steps that: the image acquisition module and the control module in the device are reset; the porous liquid sample transparent vessel filled withexperiment samples is fixedly arranged in the bracket; the master control module controls the bracket to pass through a position between the LED uniform transmission light source module and the optical imaging module at a constant speed through the bracket driver module; and the image is acquired by the image acquisition modules, transmitted to the computer by the data transmission module and analyzed. The device can fast image a plurality of liquid samples at one time, can be smoothly operated and has high recognition accuracy rate.

Owner:广东达元食品药品安全技术有限公司

A group of three-dimensional hollow porous structures with isotropic properties

The invention discloses a group of three-dimensional hollow porous structures with isotropic properties, which comprises five different three-dimensional hollow porous structures, namely an isotropichollow porous structure generated by an IWP type, a Gyandroid type, a Primitive type, a Dimond type and an S type minimal curved surface. According to the method, Boolean operation is carried out on the minimal curved surface structure with specific parameters to obtain the topological configuration of the three-dimensional hollow porous structure under different volume fractions, and the obtainedthree-dimensional porous structure has isotropic properties, so that reference is provided for the design of various three-dimensional isotropic porous structures; certain application prospects are realized in the fields of light weight, bearing, energy absorption and impact resistance.

Owner:CHINA THREE GORGES UNIV

Adaptive filling expansion scree tube and expanding method thereof

ActiveCN101067370BReduce expansion forceReduce operating costsFluid removalEngineeringSolid particle

The present invention provides one kind of adaptive filled expanding sieve tube for preventing sand in oil and gas well, and belongs to the field of petroleum drilling and extracting tool technology. The adaptive filled expanding sieve tube consists of supporting slotted tube, special filling coupler, radial expanding cover, radial expanding composite filter element, supporting rack, expanding block, expanding screw, plug and other parts. During well operation, the adaptive filled expanding sieve tube is set in the oil reservoir and filled with high pressure carrying solid particles, so that the composite filter element and the radial expanding cover can expand radially to contact with the inner wall of the production casing or the uncased hole to block sand and control the size of the passed sand. Compared with available technology, the present invention has the advantages of lowered expanding force, low operation cost and other advantages.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Chiral auxetic metamaterial structure with compression-shear coupling properties and its preparation method

ActiveCN112045990BStrong energy absorption and impact resistanceBroaden your optionsAdditive manufacturing apparatusManufacturing data aquisition/processingOrganic chemistryImpact resistance

The invention discloses a chiral auxetic superstructural material structure with compression-shear coupling characteristics and a preparation method thereof. Polygonal chiral structures of different shapes are periodically arranged and connected to each other, so that it has excellent compression-shear coupling characteristics and The auxetic characteristics, and the connecting rods are connected in a circular manner, and the negative Poisson's ratio behavior is generated through two deformation mechanisms of concave and rotation when bearing the load, thus forming a strong energy absorption and impact resistance characteristic; the simulation results show that the The structure has remarkable compression-shear coupling and auxetic properties, and has broad prospects in industrial applications.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com