Layer connection structure with designable oblique yarns in plane

A layered structure and planar technology, applied in fabrics, textiles, textiles, and papermaking, can solve problems such as unsatisfactory 2.5D structures, low efficiency, and difficulty in uniformity control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Using the layered structure that can be designed with the oblique yarn in the plane according to the present invention to prepare a plate-shaped fabric

[0045] The fabric size is 20mm in length, 8mm in width, and 2.5mm in thickness.

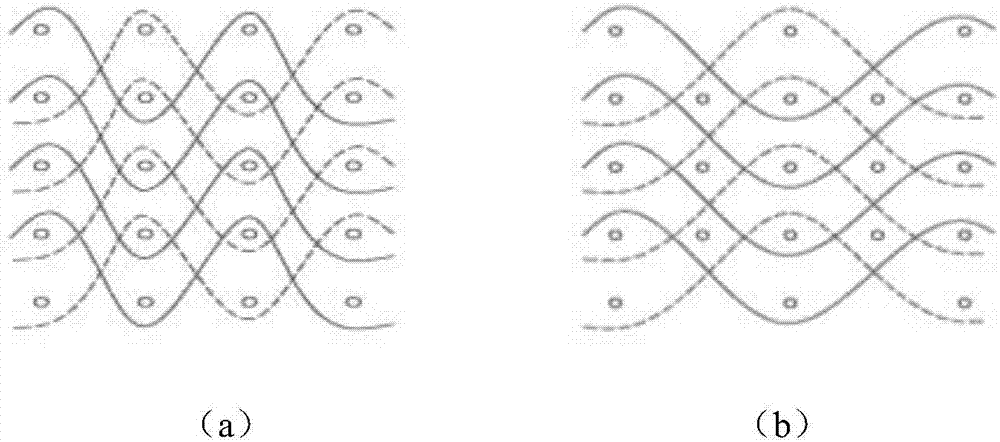

[0046] The layered structure can be designed by adopting oblique yarns in the plane; the inclined angle of the oblique yarns is required to be 20-30 degrees (the angle between the oblique yarns and the warp yarns); the fiber is made of 190Tex quartz fiber; the design warp yarns are 2 strands, and the oblique yarns are 2 strands , 5 layers of warp yarns, 6 layers of oblique yarns; the density of warp yarns is 8.0 yarns / cm, and the density of weft yarns is 2.0 yarns / cm.

[0047] The specific process implementation steps are described as follows:

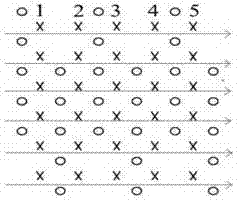

[0048] 1) Initial cloth yarn: 5 layers of warp yarns, 6 layers of oblique yarns, the arrangement method is a square matrix, the number of arrangement is 6 columns of warp yarns × 5 ...

Embodiment 2

[0077] Embodiment 2: Prepare the tubular fabric with the designable layered structure of the oblique yarn in the plane according to the present invention

[0078] The fabric dimensions are 12.7mm in diameter, 4mm in wall thickness, and 200mm in height.

[0079] The layered structure can be designed by adopting oblique yarns in the plane; the inclined angle of oblique yarns is required to be 40-50 degrees (the angle between oblique yarns and warp yarns); the fiber is made of 190Tex quartz fiber; 2 strands of warp yarns are designed, and 4 strands of oblique yarns , 5 layers of warp yarns, 6 layers of oblique yarns; the density of warp yarns is 8.0 yarns / cm, and the density of weft yarns is 1.5 yarns / cm.

[0080] The specific process implementation steps are described as follows:

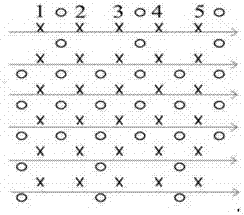

[0081] 1) Initial cloth yarn: 5 layers of warp yarns, 6 layers of oblique yarns, the arrangement method is a circular matrix, and the number of arrangement is 32 rows of warp yarns × 5 layers, 32 col...

Embodiment 3

[0096] Embodiment 3: Using the layered structure that can be designed with in-plane oblique yarns according to the present invention to prepare plate-shaped fabrics

[0097] The fabric size is 100mm in length, 8mm in width, and 3mm in thickness.

[0098] The fabric adopts oblique yarns in the plane to design a layered structure and introduce weft yarns; the oblique yarns are required to have an inclination angle of 15 to 20 degrees (the angle between the oblique yarns and the warp yarns); the fiber uses 190Tex quartz fiber; the warp yarns are designed to be 2 strands, 2 strands of direction yarn, 2 strands of weft yarn, 5 layers of warp yarn, and 6 layers of oblique yarn;

[0099] The specific process implementation steps are described as follows:

[0100] 1) Initial cloth yarn: 5 layers of warp yarns, 6 layers of oblique yarns, the arrangement method is a square matrix, the number of arrangement is 16 rows of warp yarns × 5 layers, 15 columns of oblique yarns × 6 layers, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com