Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Increased manufacturing flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

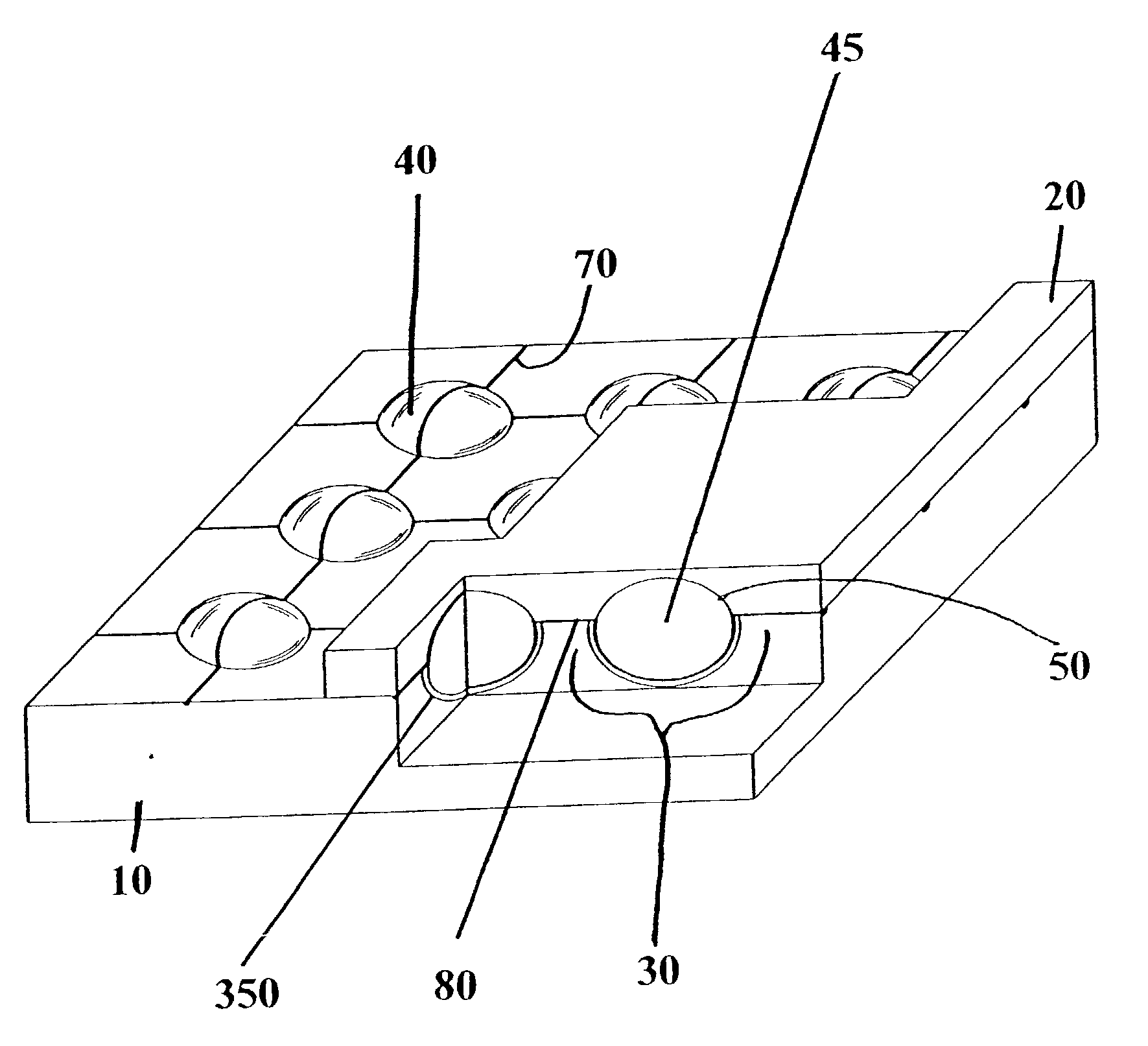

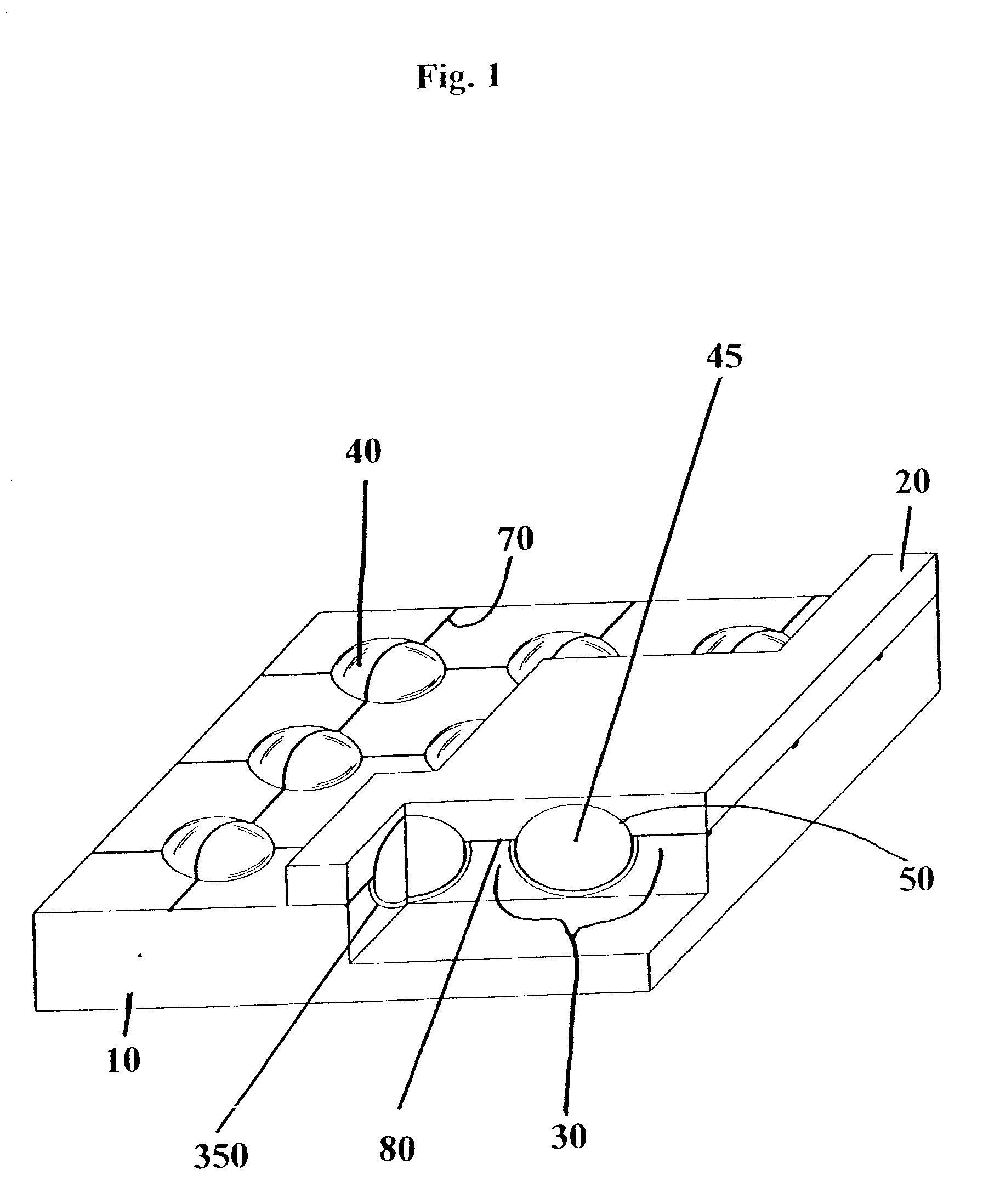

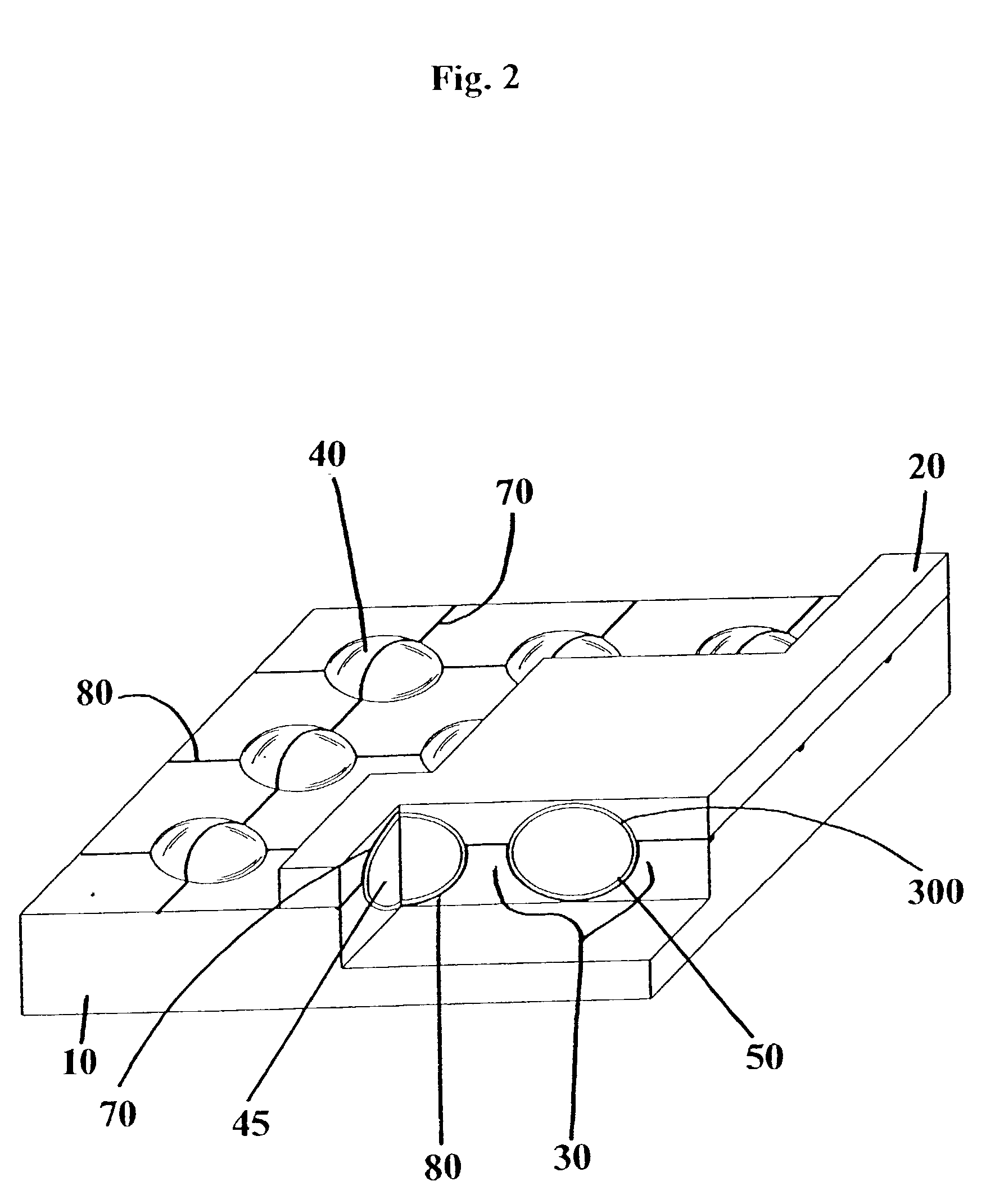

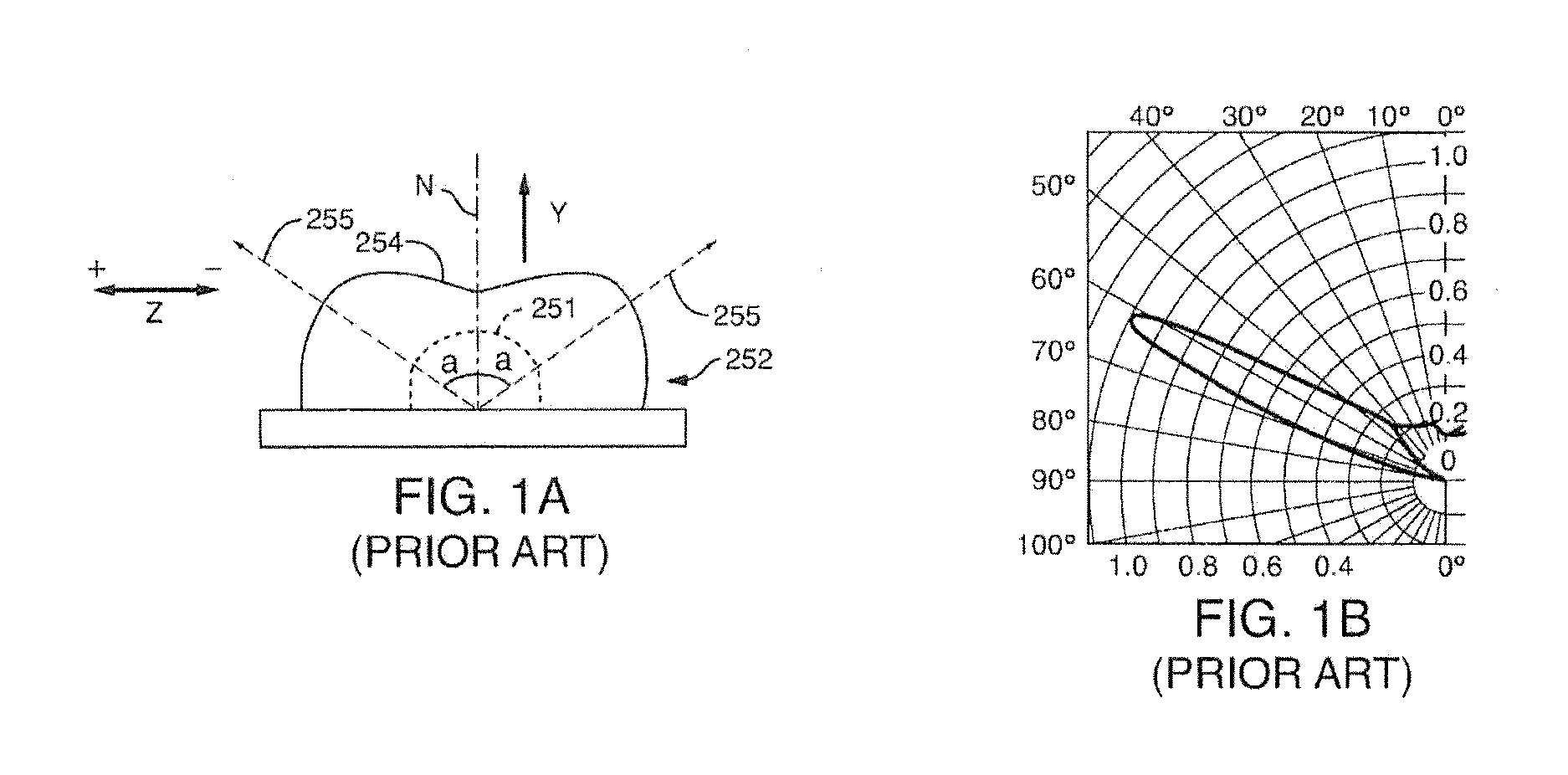

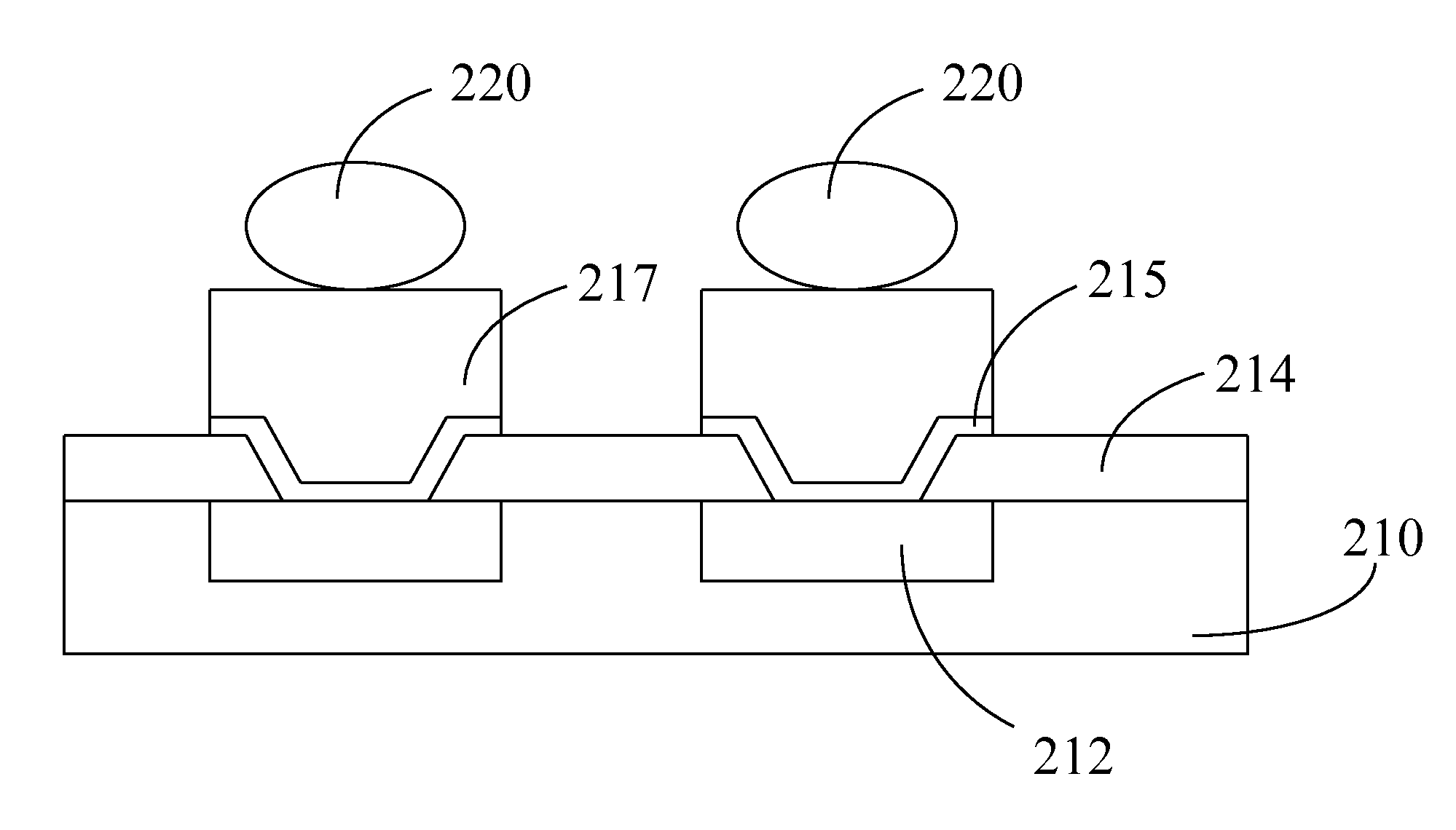

Modular light reflectors and assemblies for luminaire

InactiveUS8042968B2Reduce the numberSmall sizePlanar light sourcesNon-electric lightingLight equipmentEffect light

Owner:LSI INDS

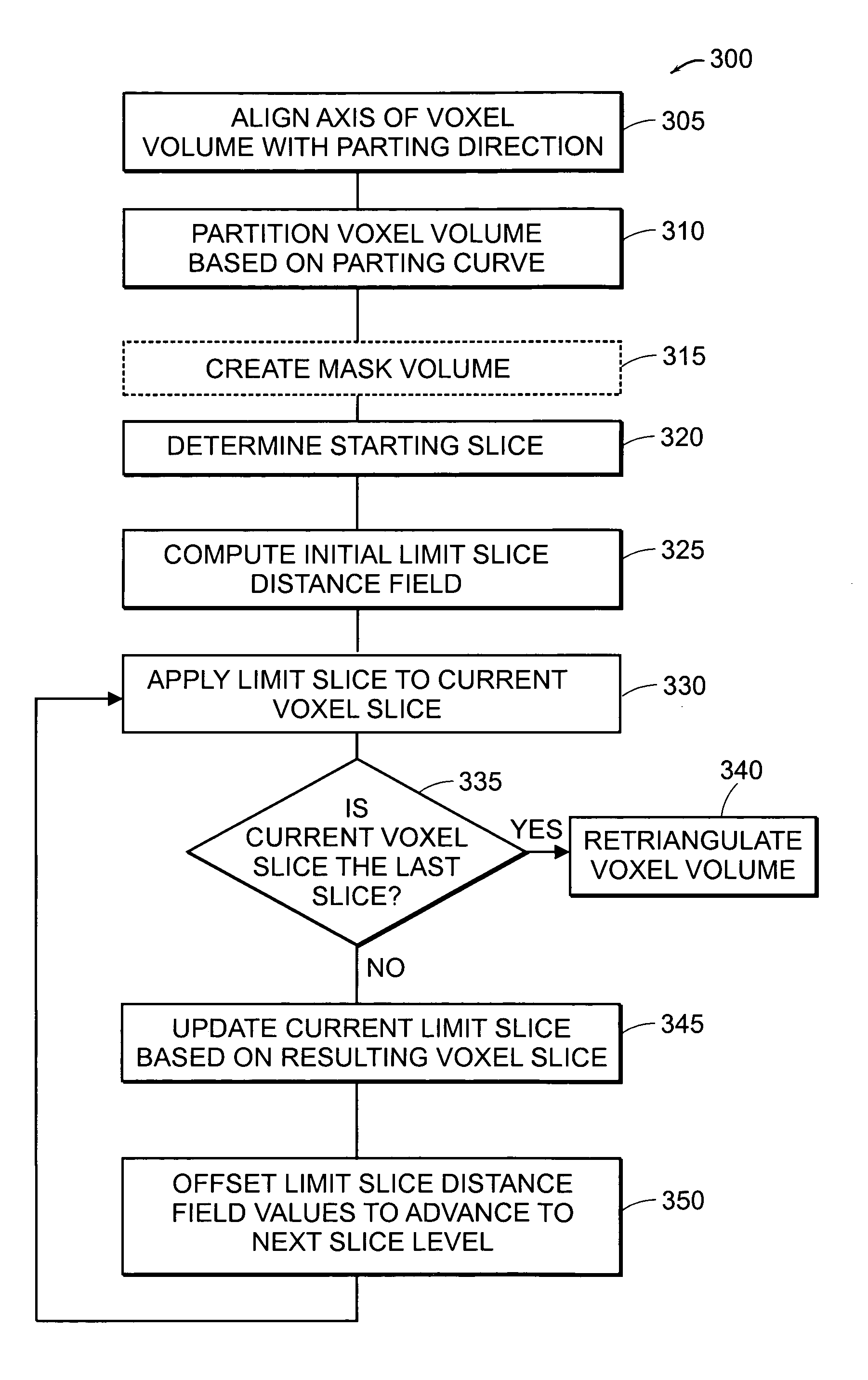

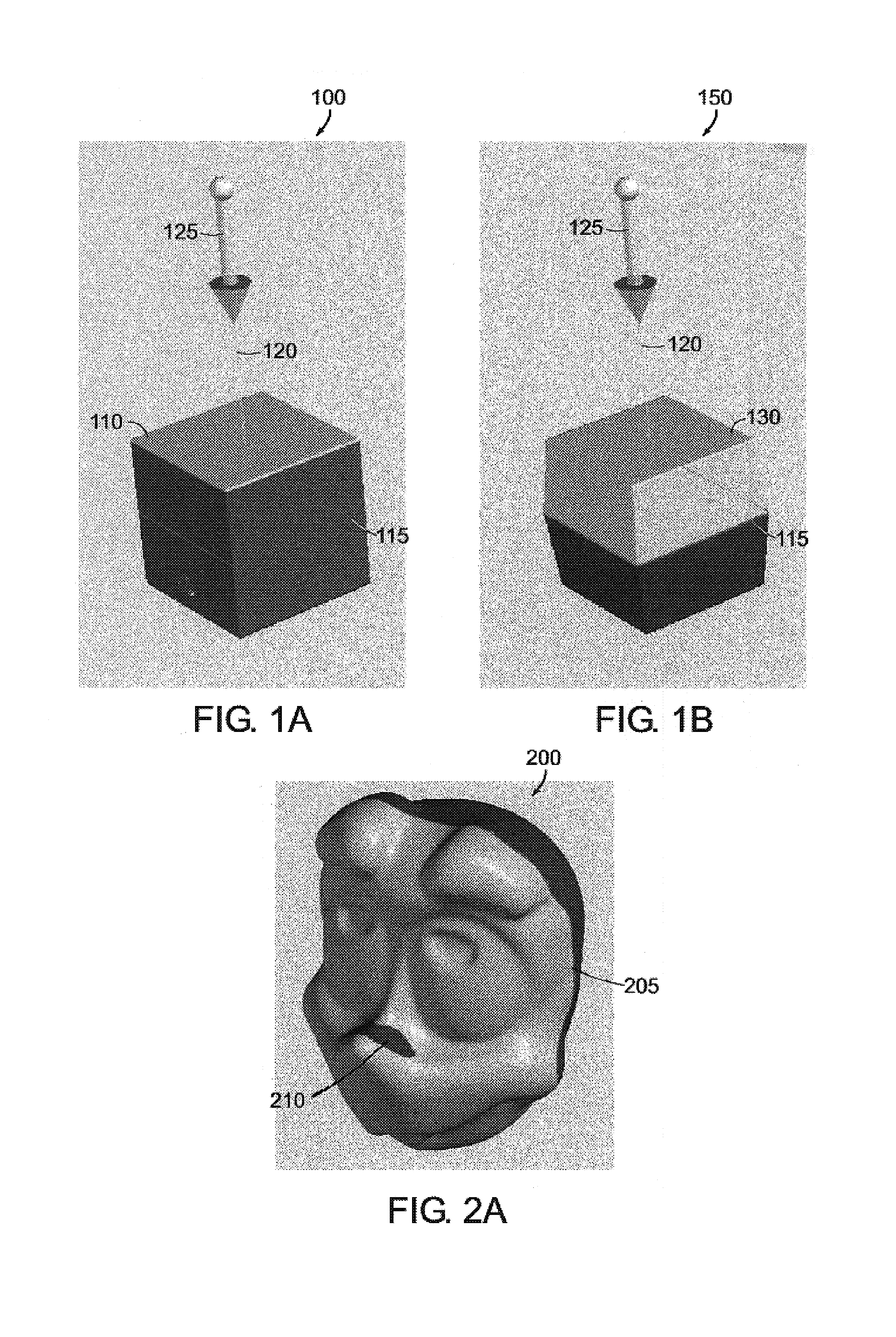

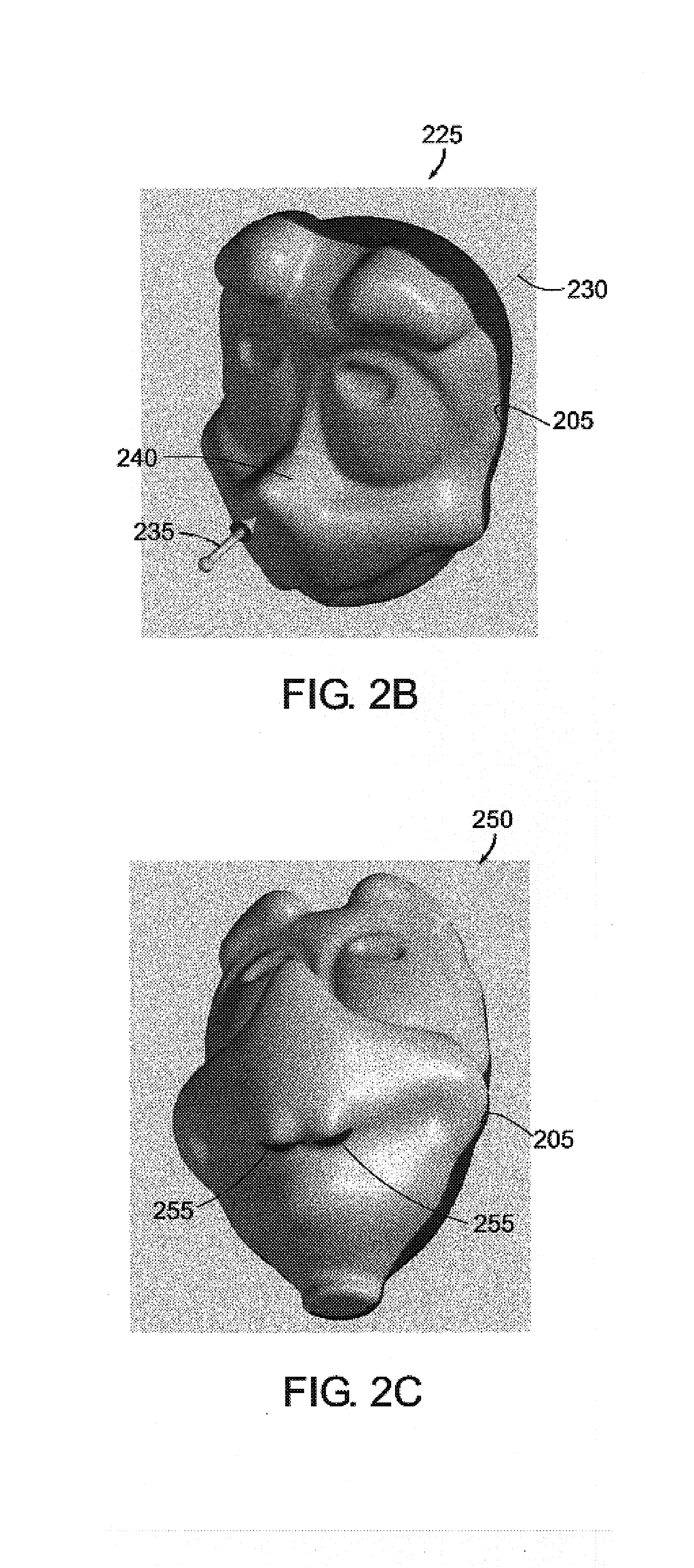

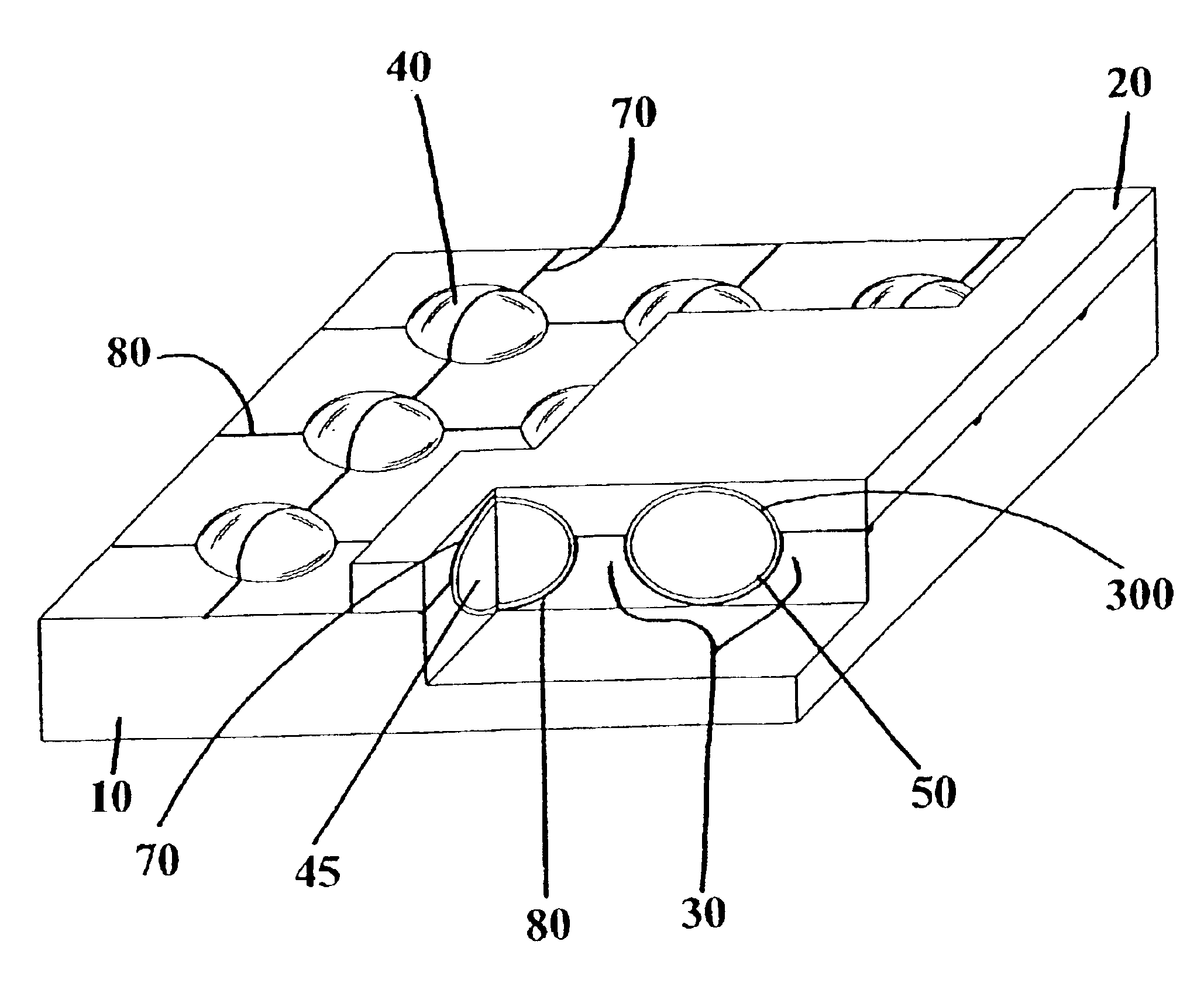

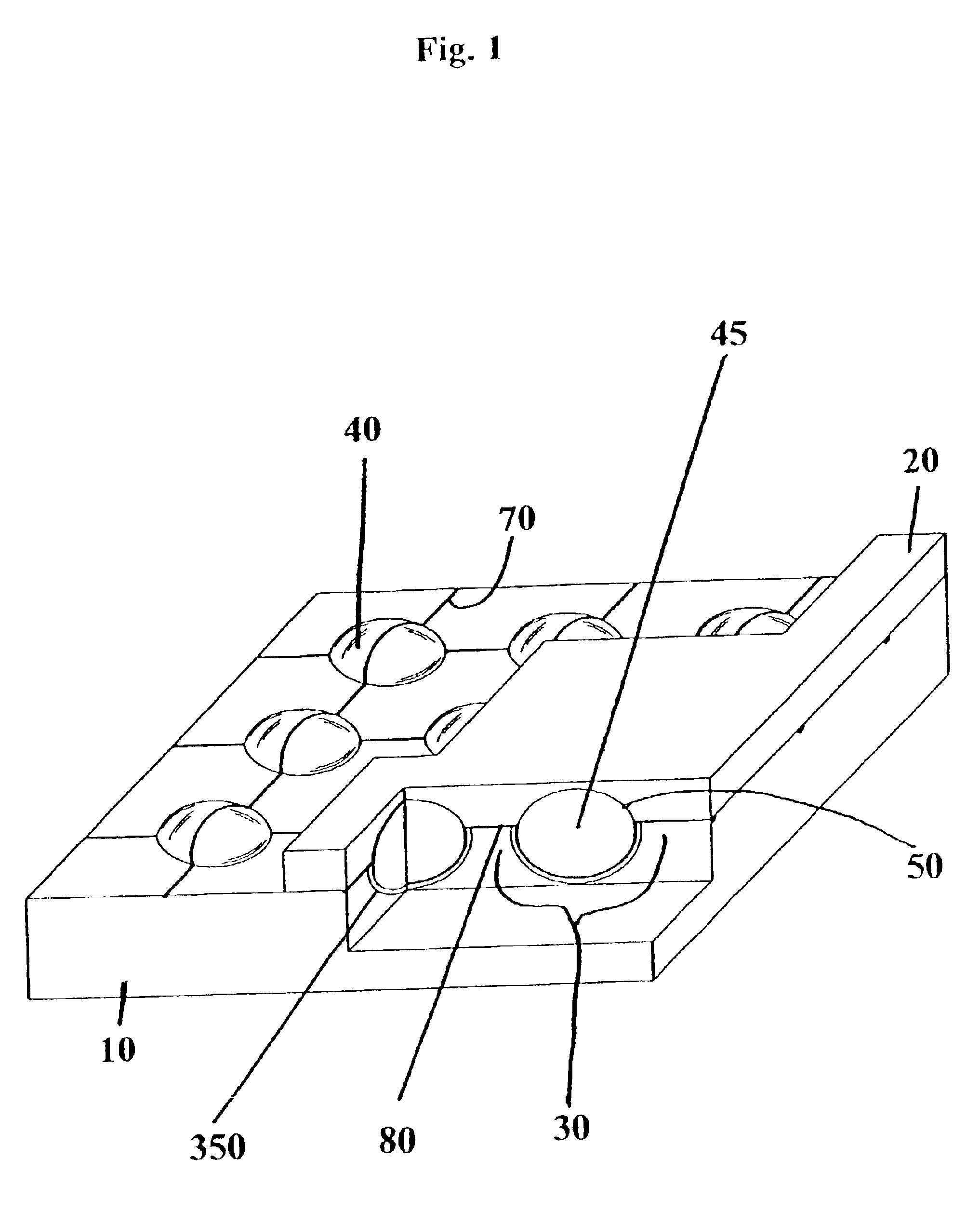

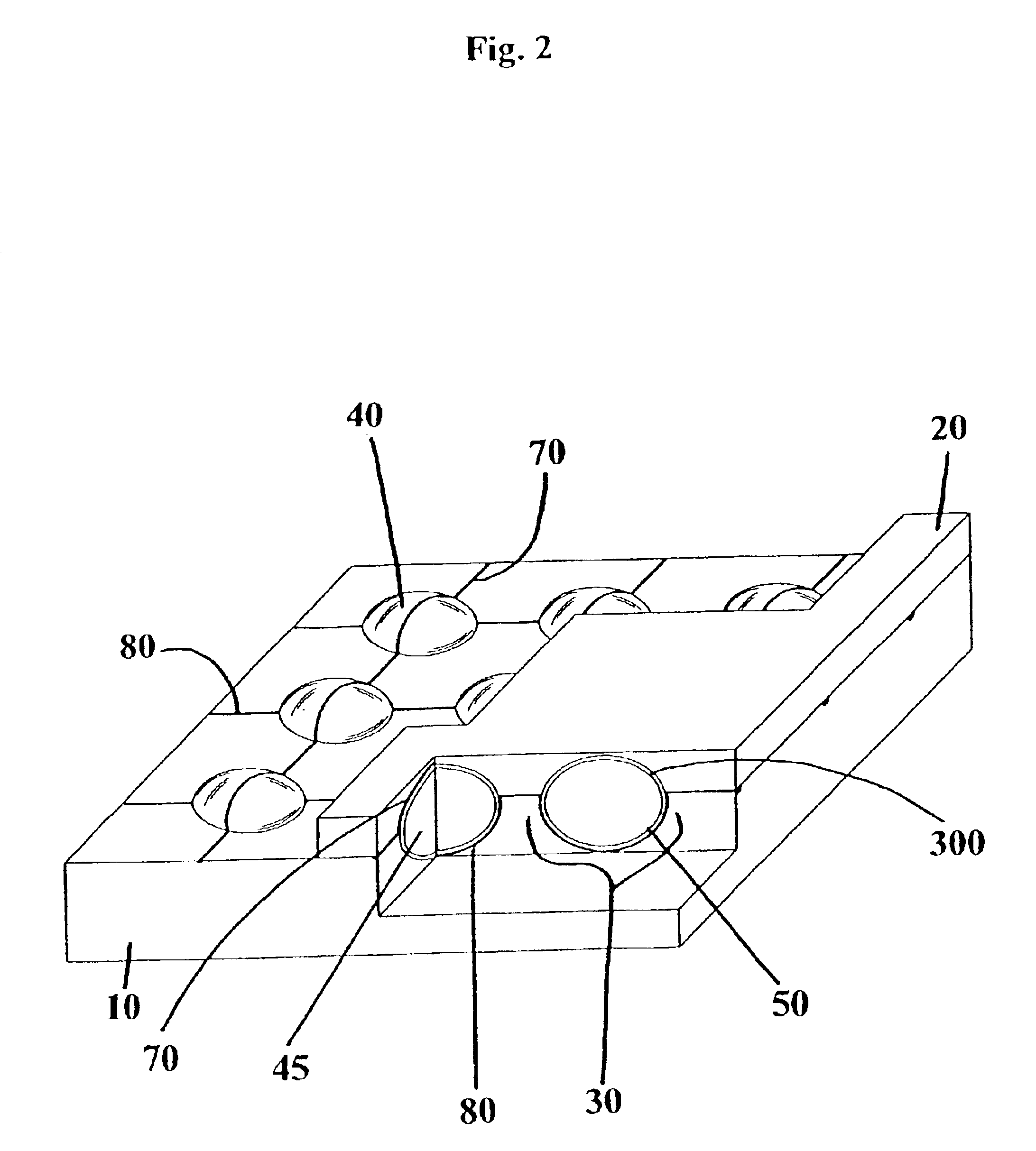

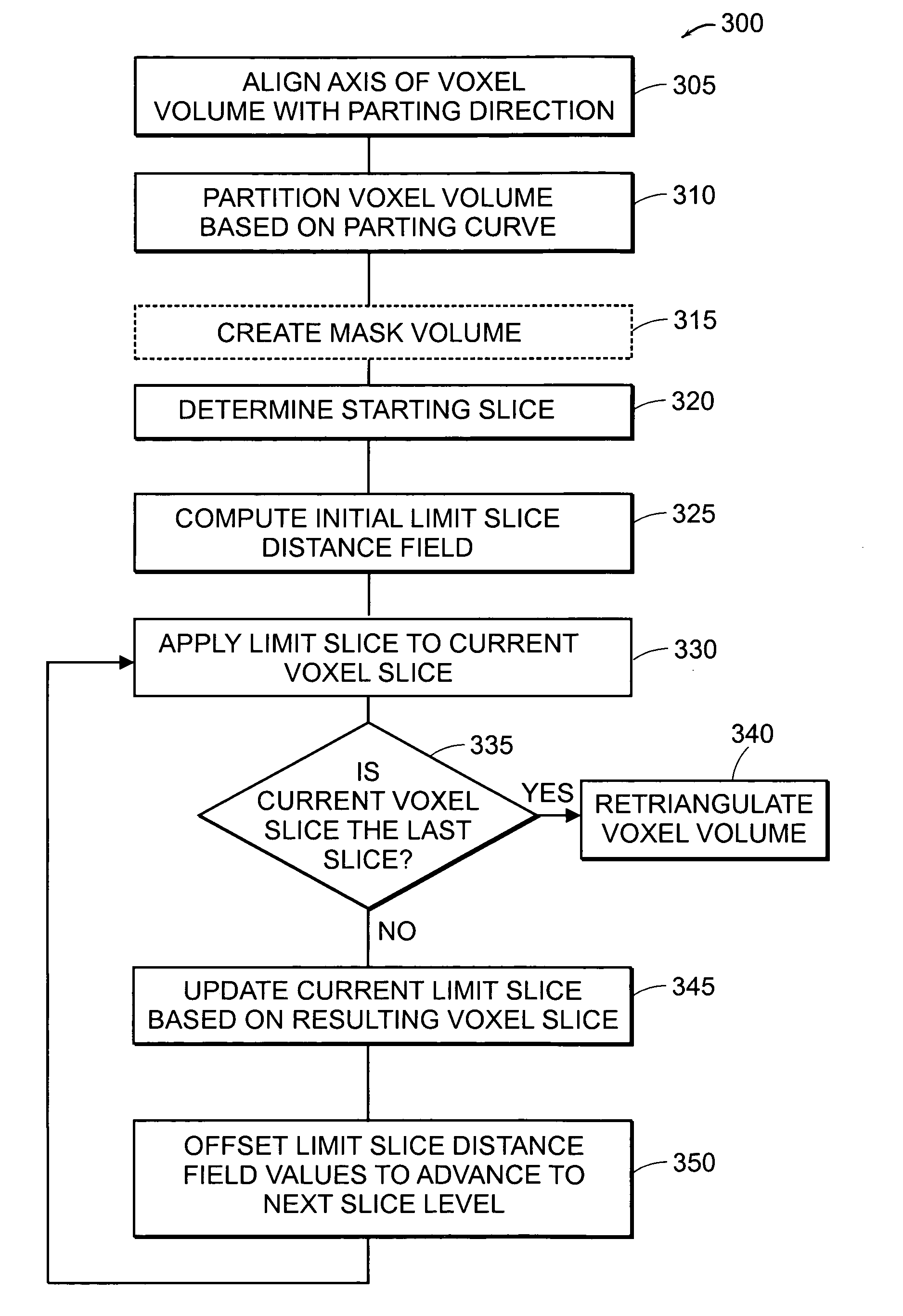

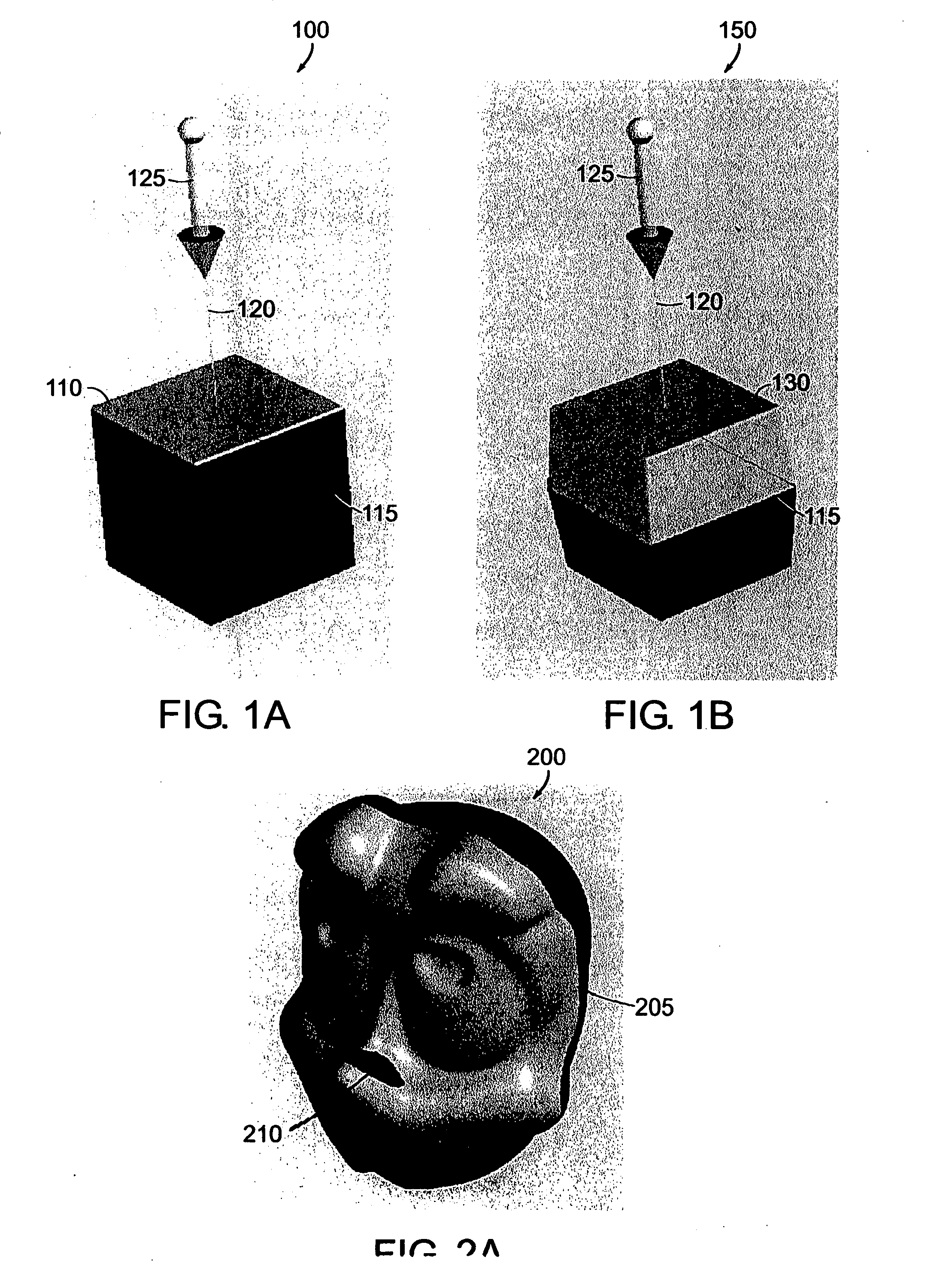

Apparatus and methods for modifying a model of an object to enforce compliance with a manufacturing constraint

ActiveUS7149596B2Increase flexibilityReduce design costAdditive manufacturing apparatusSpecial data processing applicationsVoxelEngineering

The invention provides an apparatus and methods for automatically modifying a computer model of an object to comply with a manufacturing constraint for production of the object. In one embodiment, the invention uses a voxel-based approach to automatically modify an arbitrarily-shaped model at any stage of the design process. For example, a method of the invention automatically modifies a model of a molded object to comply with a draft angle requirement.

Owner:3D SYST INC

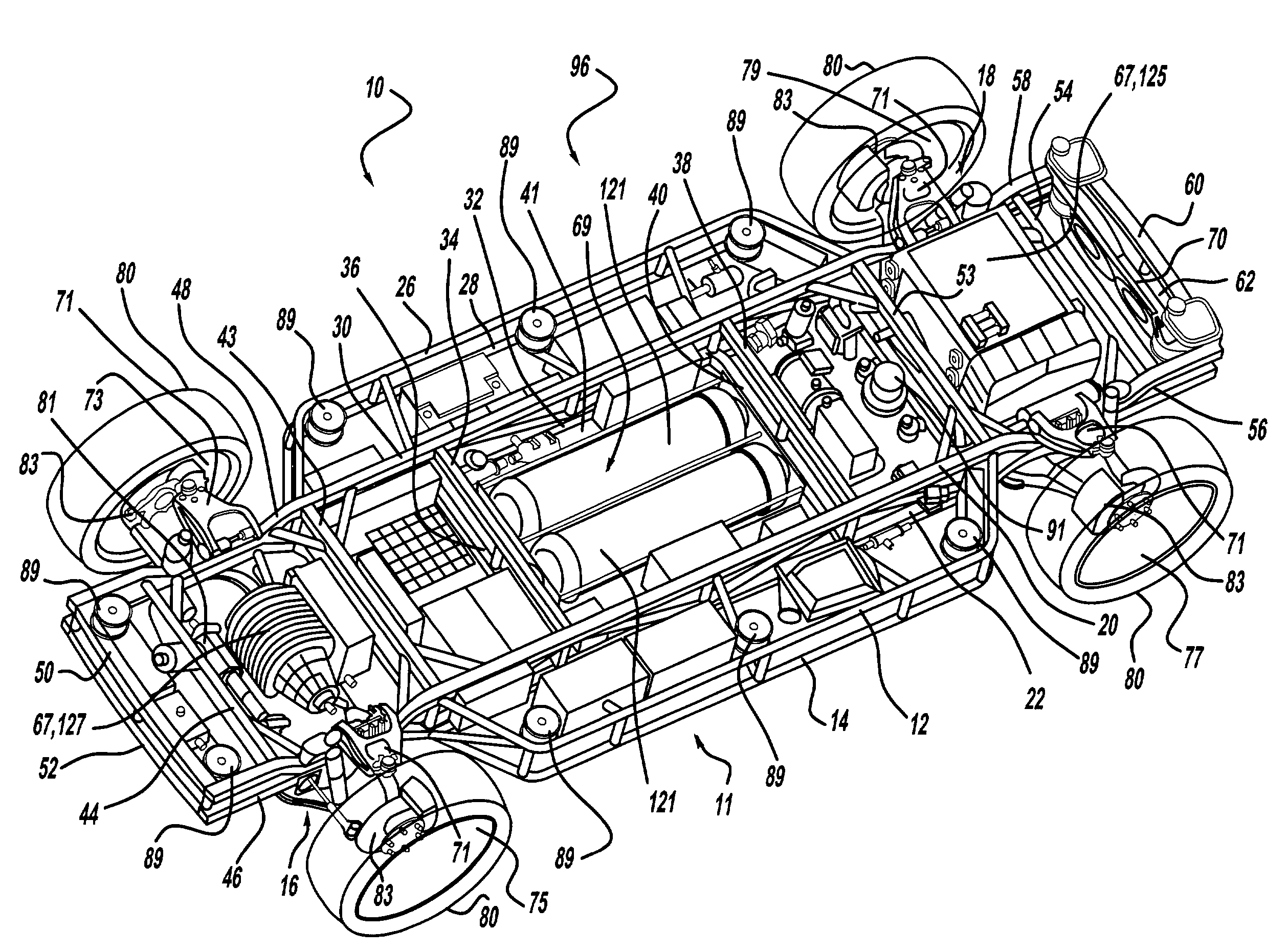

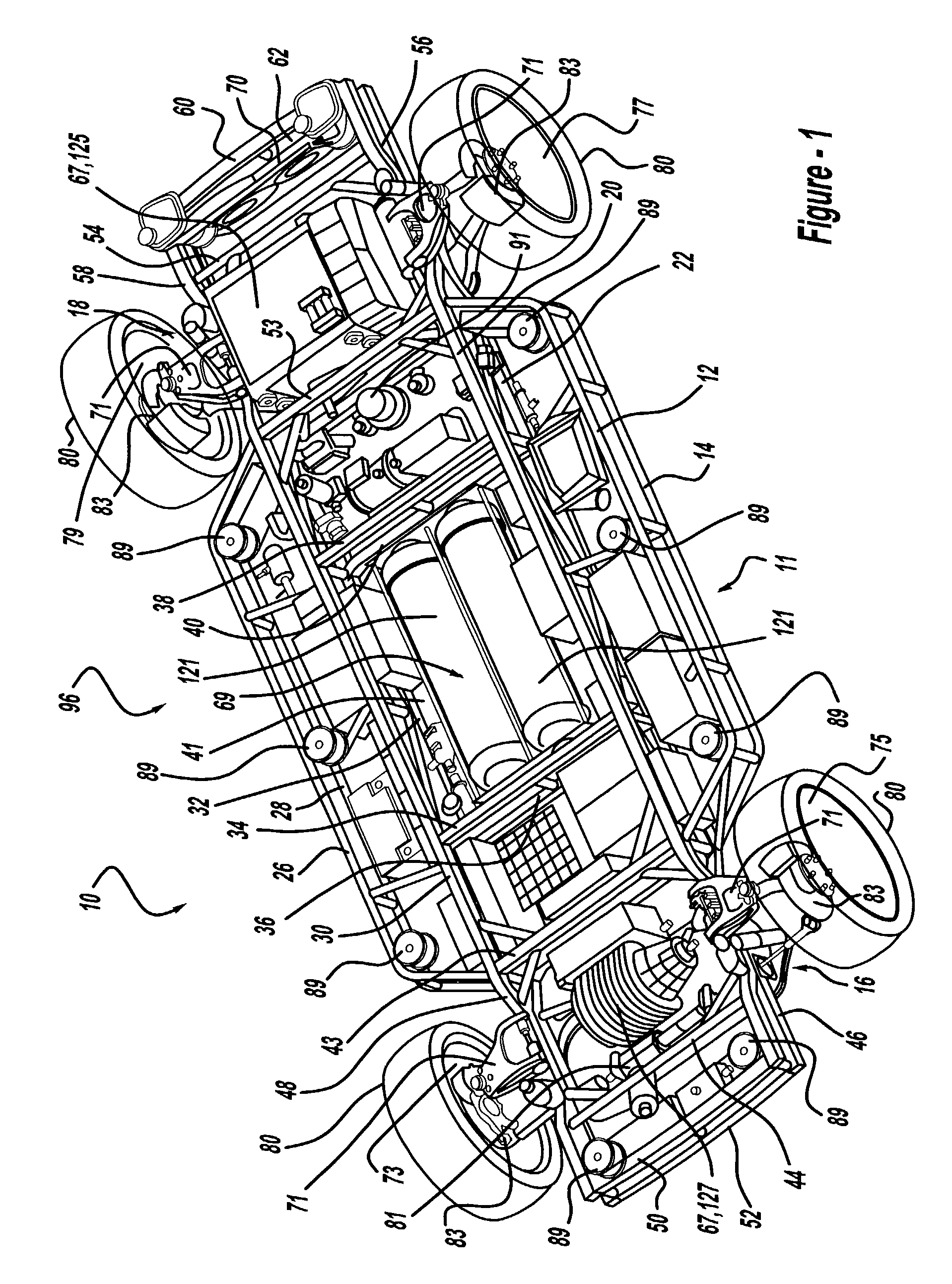

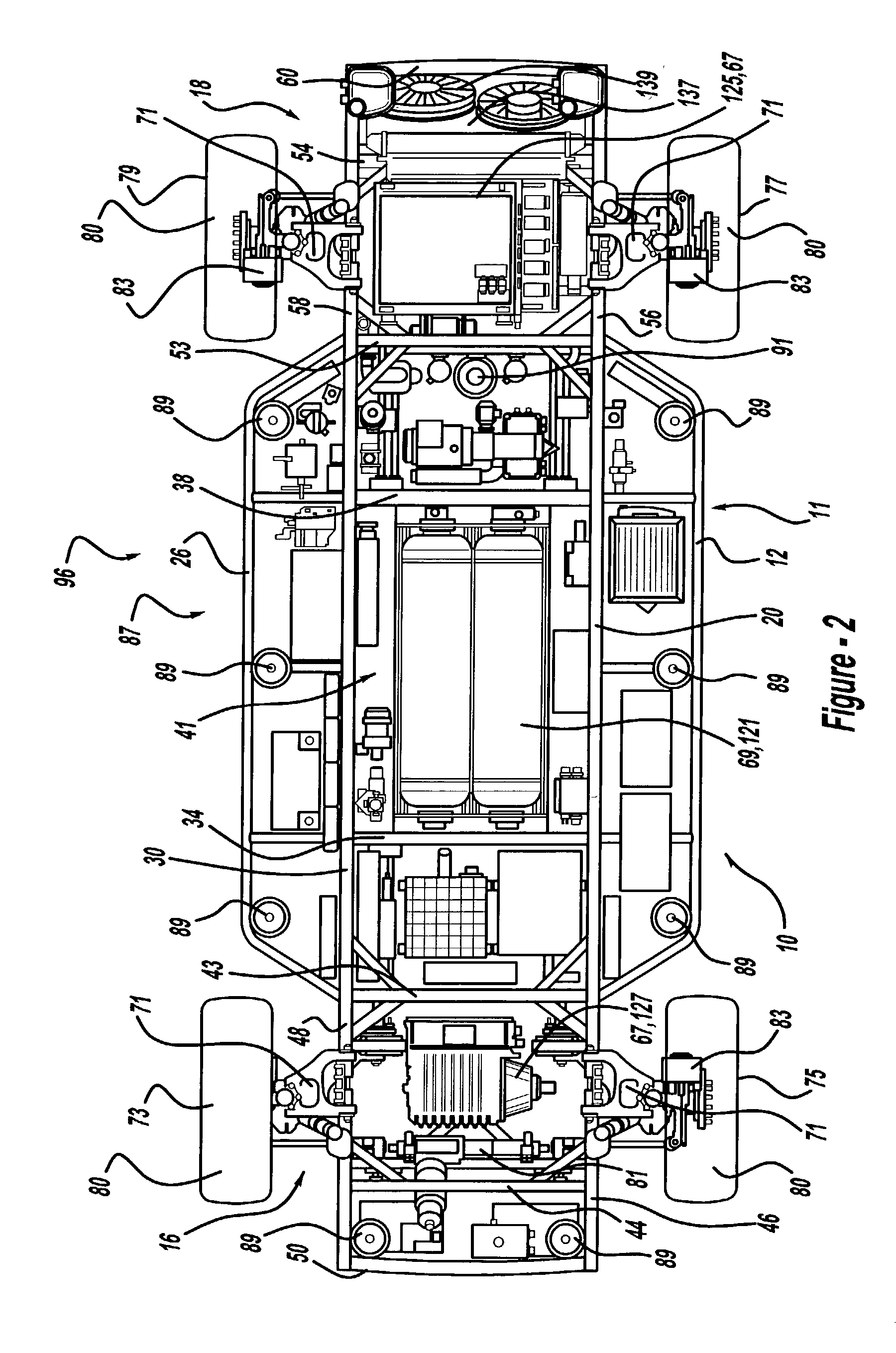

Modular chassis with simplified body-attachment interface

InactiveUS7441615B2Simple interfaceEliminateAuxillary drivesVehicle seatsControl signalComputer module

A chassis having systems responsive to a nonmechanical control signals and a simplified body-attachment interface includes preassembled modules to enhance ease and simplicity of chassis assembly. The chassis is preferably configured to minimize the possibility of a preassembled module being incorrectly positioned within the chassis. Methods for advantageously employing preassembled modules to assemble vehicle chassis are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

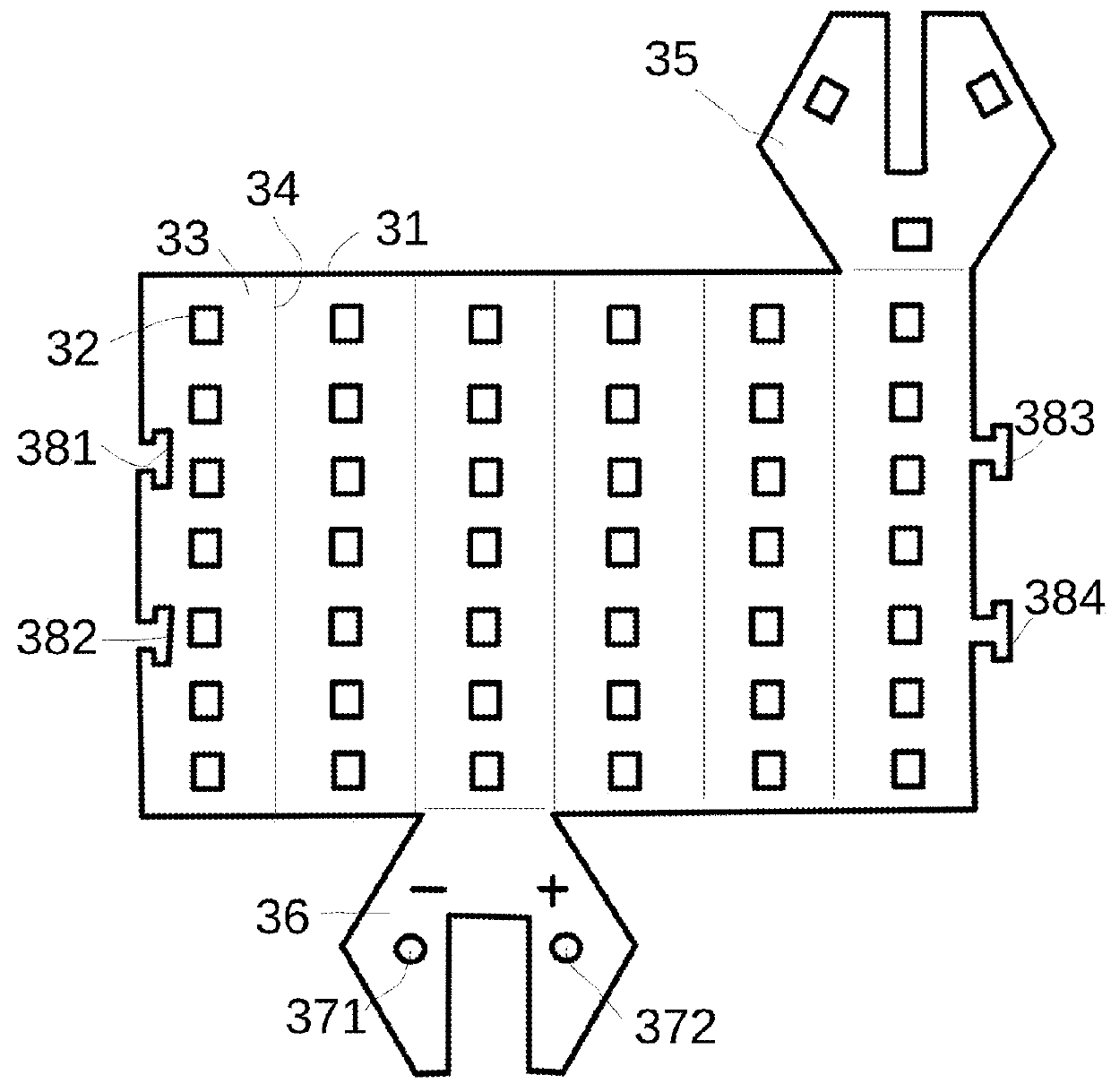

Method and apparatus for addressing micro-components in a plasma display panel

InactiveUS6801001B2Sufficient resolutionManufactured very thinPoint-like light sourceStatic indicating devicesDisplay deviceAlternative methods

An improved light-emitting display having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large trigger voltage is supplied across the micro-component by up to two triggering electrodes and ionization can be maintain by a sustain voltage supplied by up to two sustain electrodes. The display is further divided into a plurality of panels that can be individually addressed in parallel, preferably directly through the back of the panels and can include voltage multiplying circuitry to decrease the power demands for addressing circuitry. Alternative methods of addressing the micro-components include the use of directed light and arrangements of electrodes to address multiple micro-components with a single electrode.

Owner:LEIDOS

Preparation and uses of false proof highly-effective insecticide and bactericide

InactiveCN1788569AProtect interestsLow toxicityBiocideFungicidesOrganophosphorus pesticidesAgriculture

The anti-fake pesticide-germicide is prepared with boron, saponin, pyrethroid, organophosphorus pesticide and alcohol. After the pesticide-germicide is set into various kinds of dry small mouth bottle with the lid opened for 0.25-2 hr, white snowflake-like crystal will grow around the bottle mouth, and this makes it possible for the user to identify the truth of the pesticide-germicide. Compared with pesticide-germicide of alone pyrethroid and organophosphorus pesticide, the pesticide-germicide of the present invention has greatly raised effect, lowered toxicity, lowered cost and reduced consumption.

Owner:刘起麟

Apparatus and methods for modifying a model of an object to enforce compliance with a manufacturing constraint

ActiveUS20050154481A1Improve interactivityEasy to handleAdditive manufacturing apparatusSpecial data processing applicationsManufacturing engineeringVoxel

The invention provides an apparatus and methods for automatically modifying a computer model of an object to comply with a manufacturing constraint for production of the object. In one embodiment, the invention uses a voxel-based approach to automatically modify an arbitrarily-shaped model at any stage of the design process. For example, a method of the invention automatically modifies a model of a molded object to comply with a draft angle requirement.

Owner:3D SYST INC

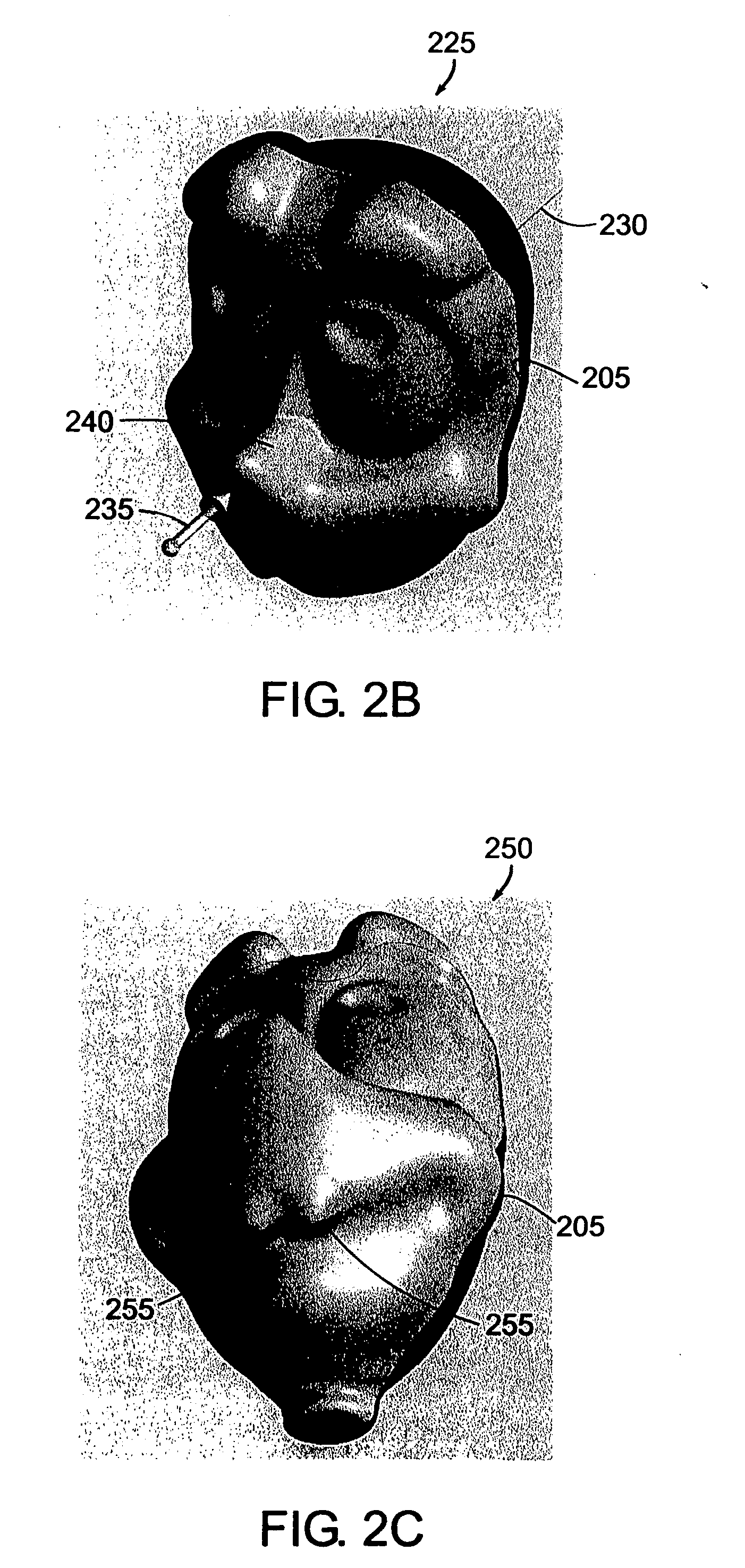

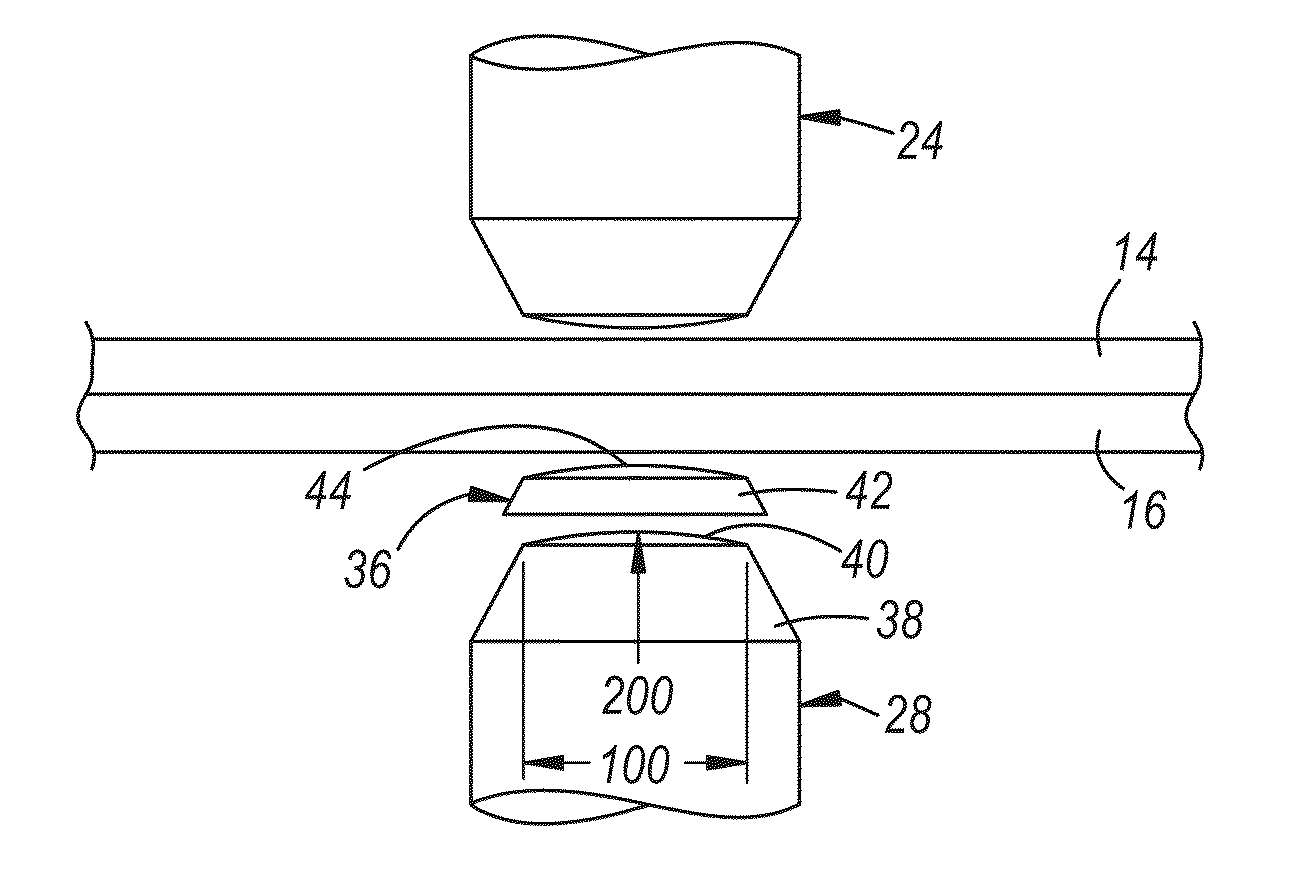

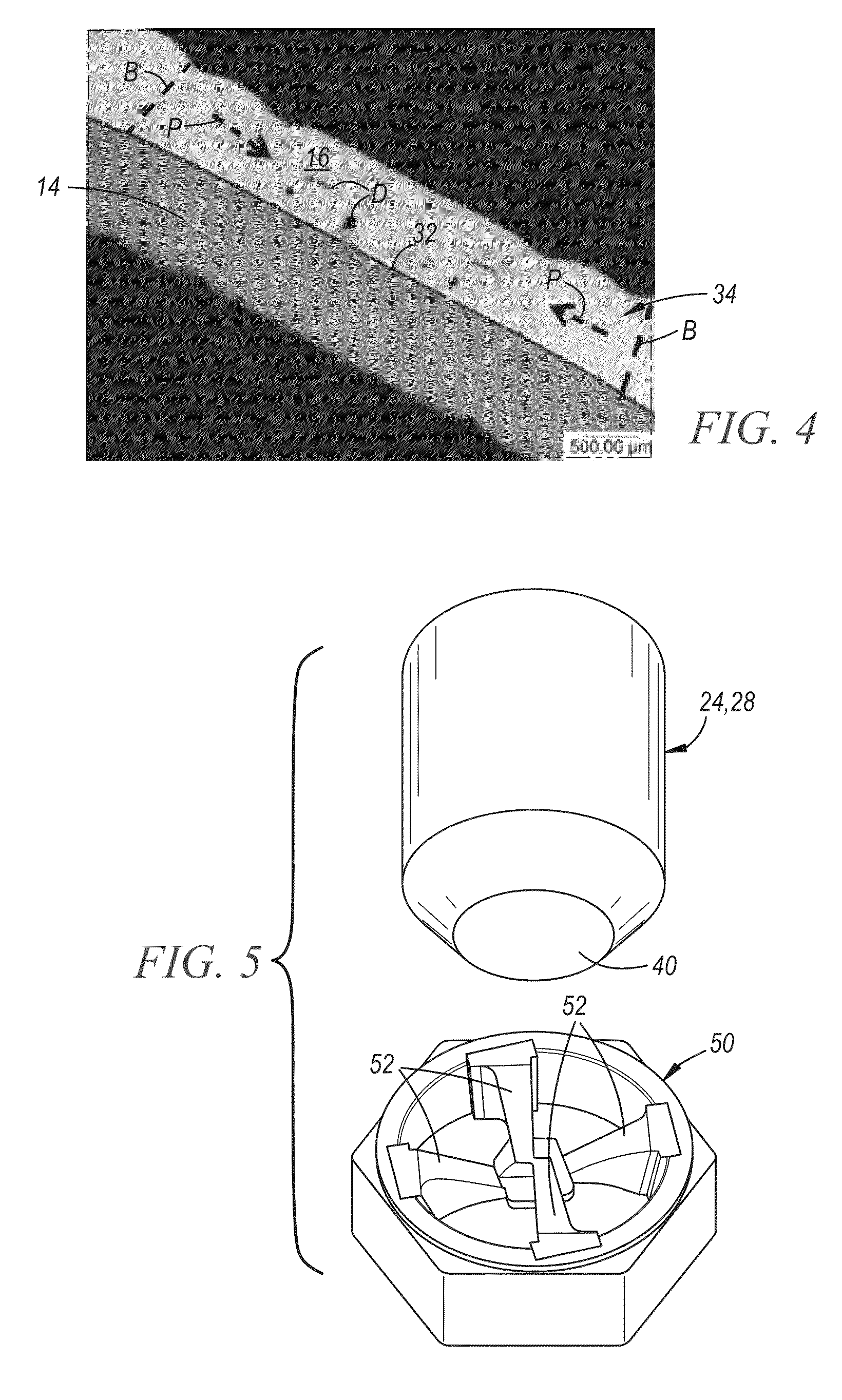

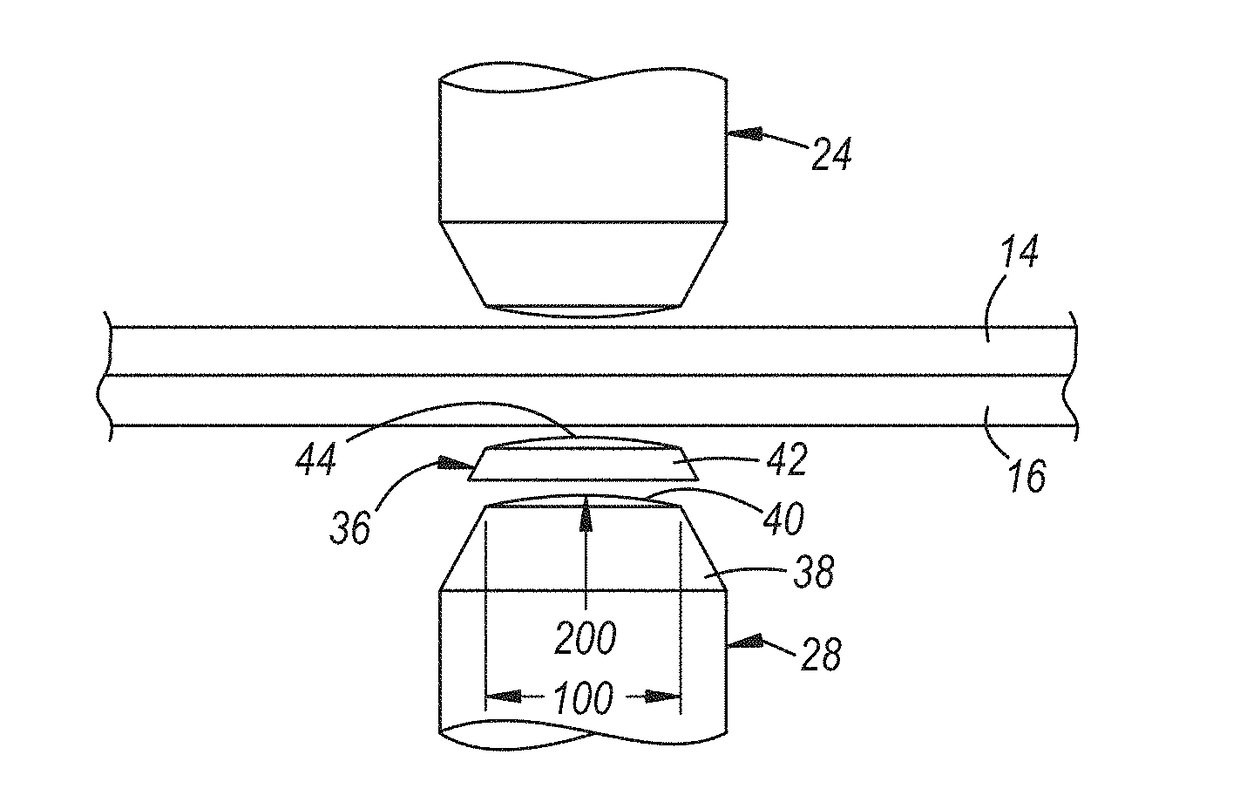

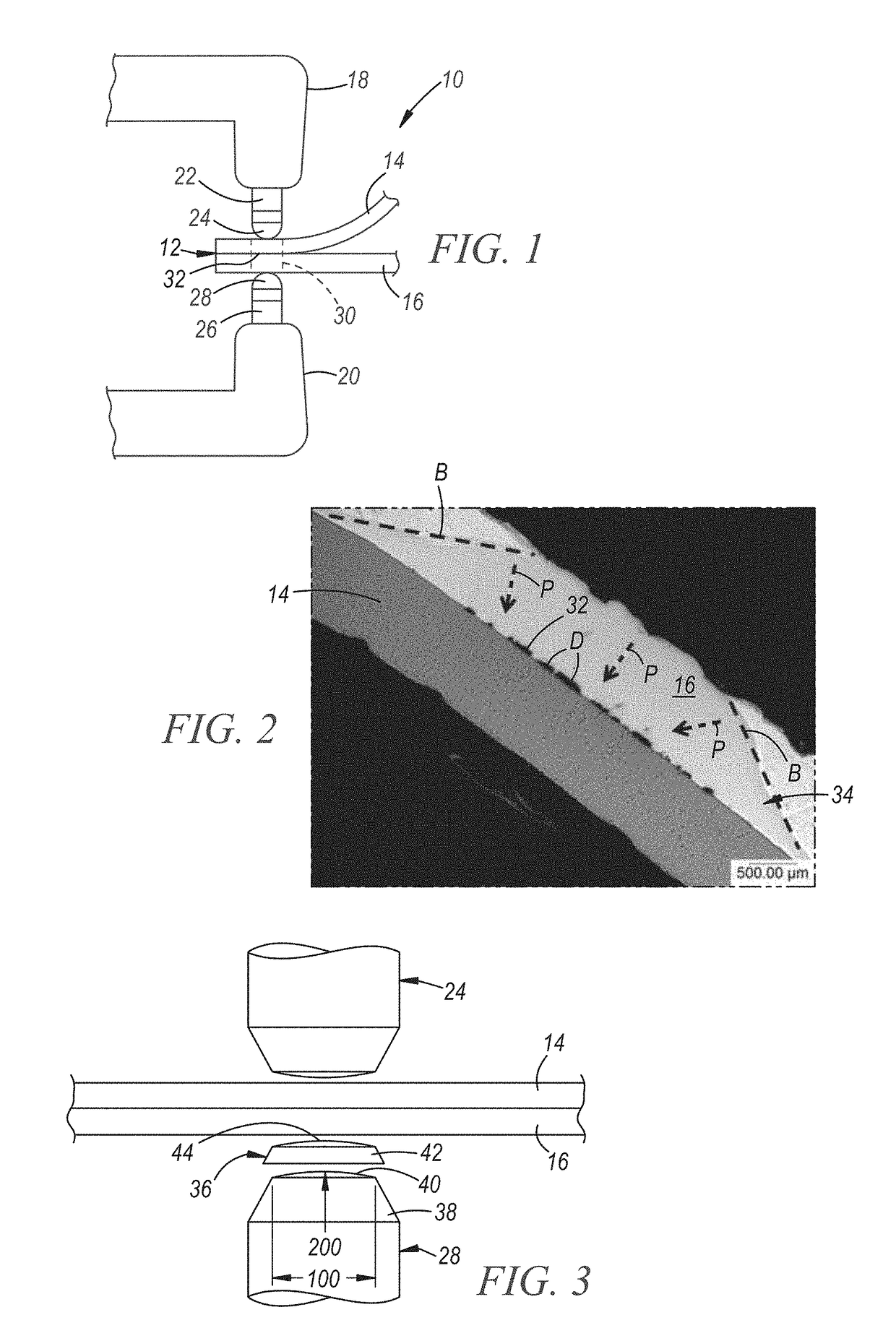

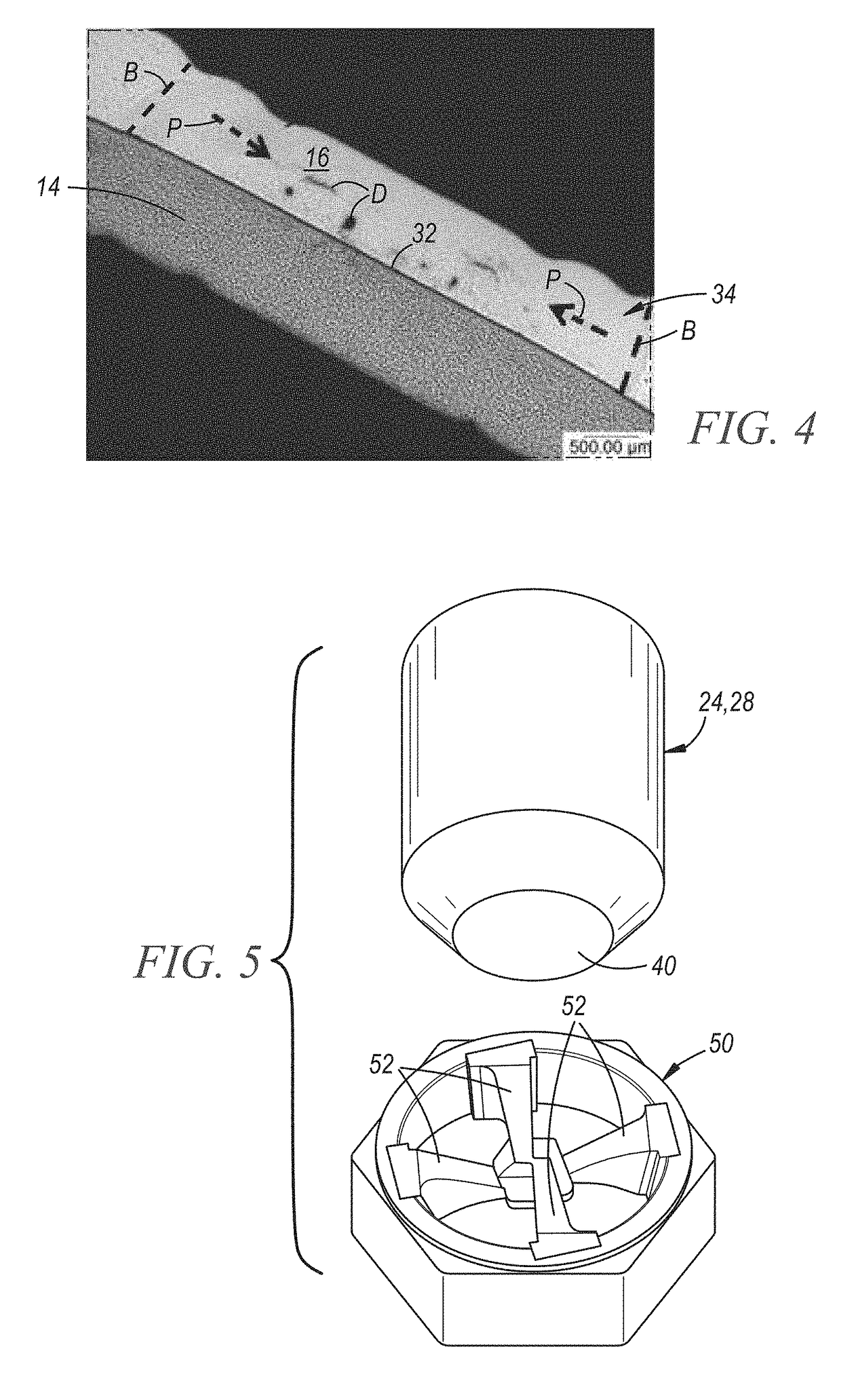

Resistance spot welding steel and aluminum workpieces using electrode weld face cover

ActiveUS20150053654A1Reduce heatReduce the overall heightOhmic-resistance electrodesElectrode supporting devicesMetallic materialsSpot welding

A method of resistance spot welding a steel workpiece and an aluminum or aluminum alloy (“aluminum”) workpiece together includes several steps. One step involves providing a workpiece stack-up with a steel workpiece and an aluminum workpiece. Another step involves attaching a cover over a weld face of a welding electrode. The cover is made of a metal material with an electrical resistivity that is greater than an electrical resistivity of a material of the welding electrode. Yet another step involves performing multiple individual resistance spot welds to the workpiece stack-up. The cover abuts the aluminum workpiece while the individual resistance spot welds are performed. And another step involves removing the cover from the welding electrode after the individual spot welds are performed.

Owner:GM GLOBAL TECH OPERATIONS LLC

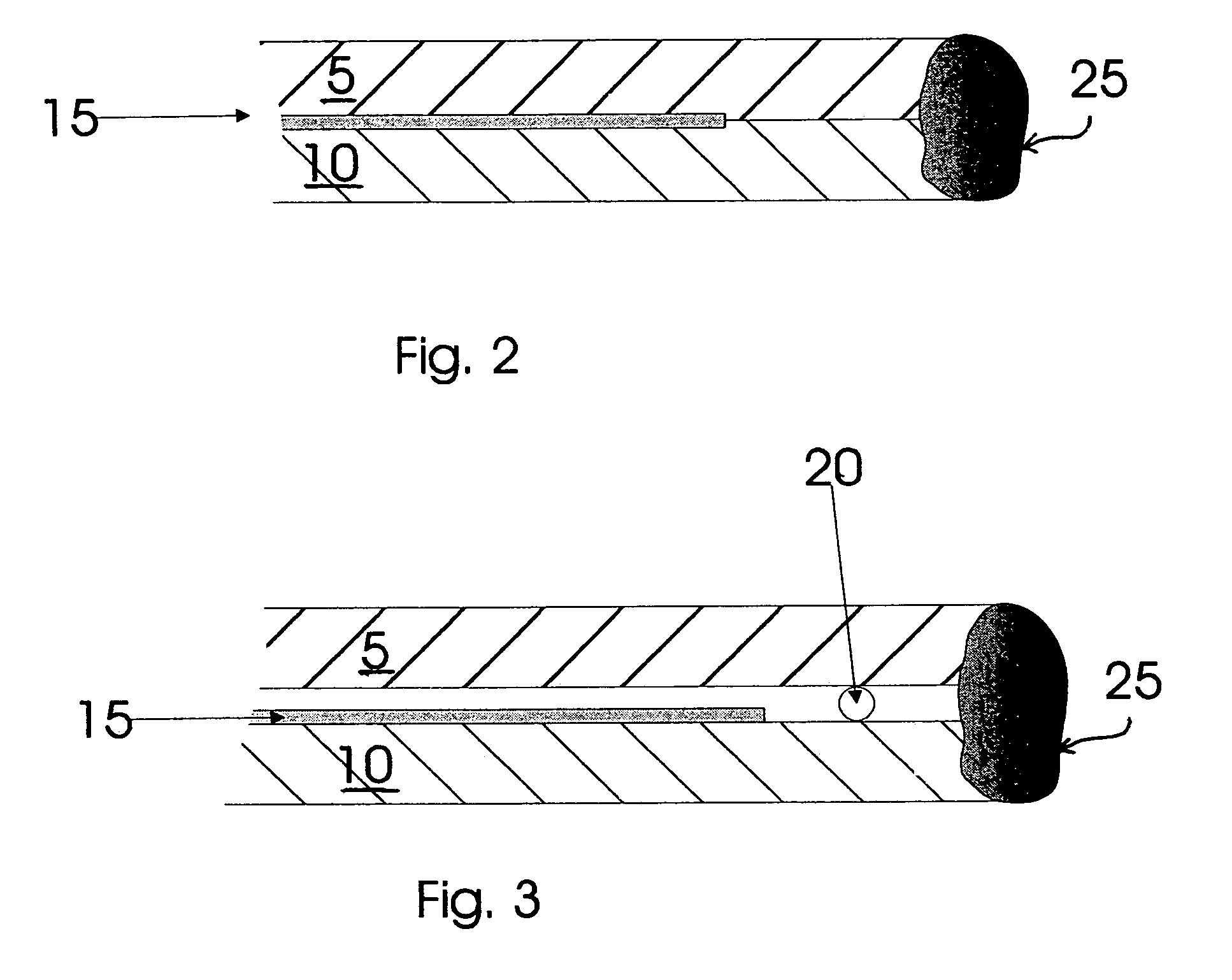

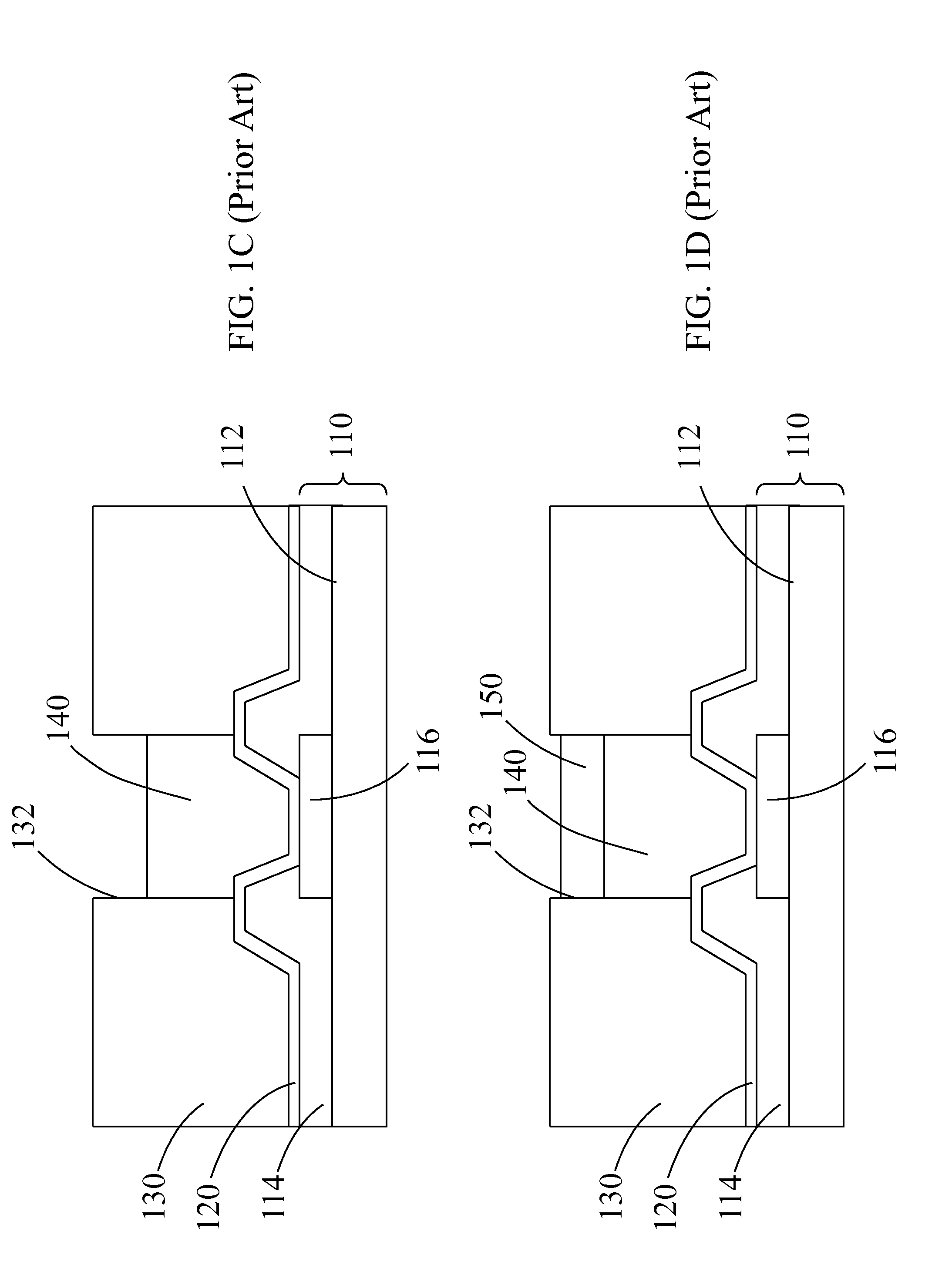

Sealing of organic thin-film light-emitting devices

ActiveUS7393257B2Allow flexibilityIncreased manufacturing flexibilitySolid-state devicesVessels or leading-in conductors manufactureHermetic sealEngineering

A method for hermetically sealing an organic thin-film light-emitting device between a substrate and a cover including the steps of bringing the substrate and cover into close proximity at a peripheral side edge of at least one of the substrate or cover, bringing an energy absorbing material into contact with the cover and substrate at the peripheral side edge of at least one of the substrate or cover, and applying energy directly to the energy absorbing material, causing the energy absorbing material to transfer heat to the substrate and the cover to fuse and form a hermetic seal along the peripheral side edge.

Owner:GLOBAL OLED TECH

Method and apparatus for addressing micro-components in a plasma display panel

InactiveUS20030214243A1Sufficient resolutionManufactured very thinPoint-like light sourceStatic indicating devicesDisplay deviceSubstitution method

An improved light-emitting display having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large trigger voltage is supplied across the micro-component by up to two triggering electrodes and ionization can be maintain by a sustain voltage supplied by up to two sustain electrodes. The display is further divided into a plurality of panels that can be individually addressed in parallel, preferably directly through the back of the panels and can include voltage multiplying circuitry to decrease the power demands for addressing circuitry. Alternative methods of addressing the micro-components include the use of directed light and arrangements of electrodes to address multiple micro-components with a single electrode.

Owner:LEIDOS

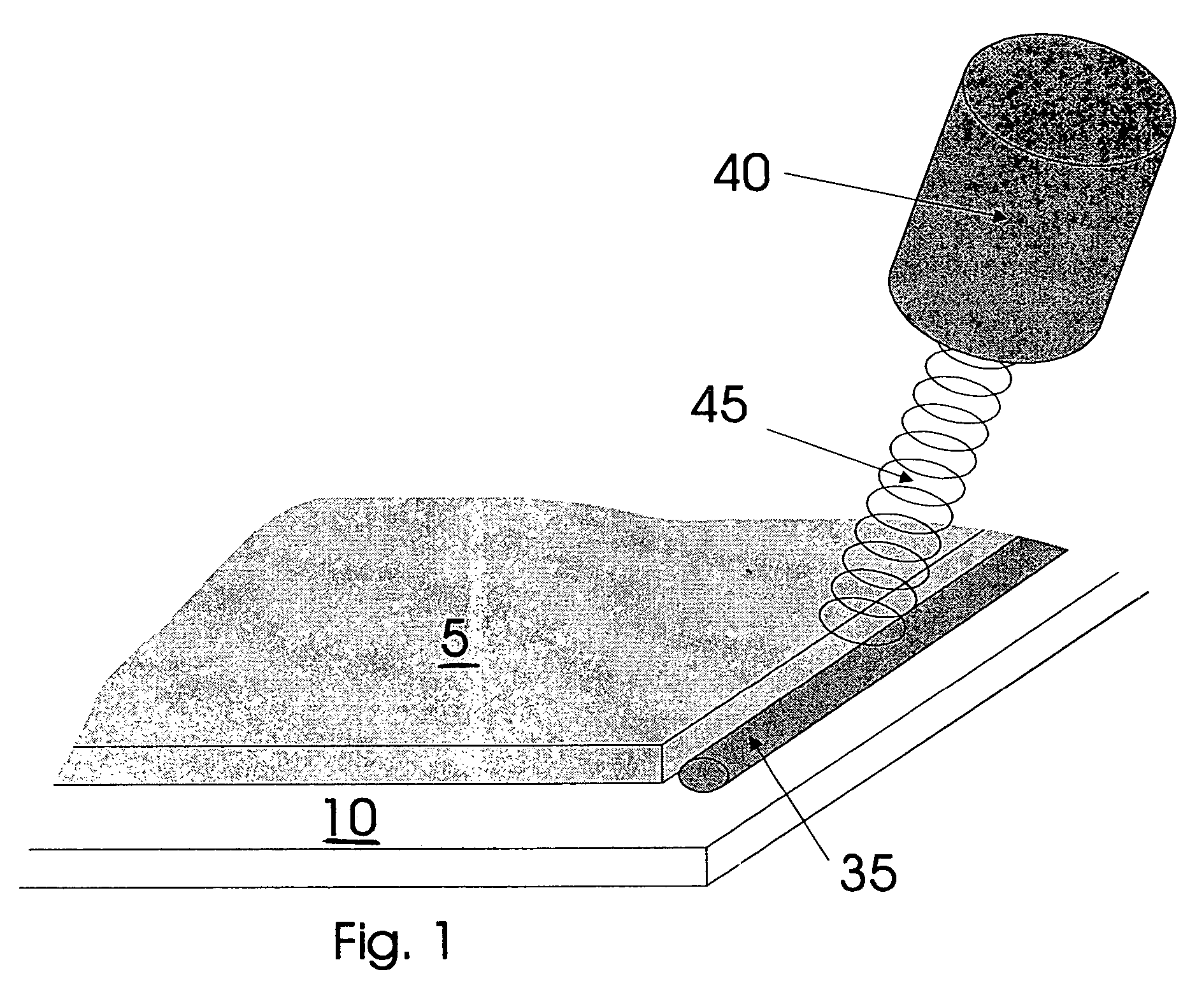

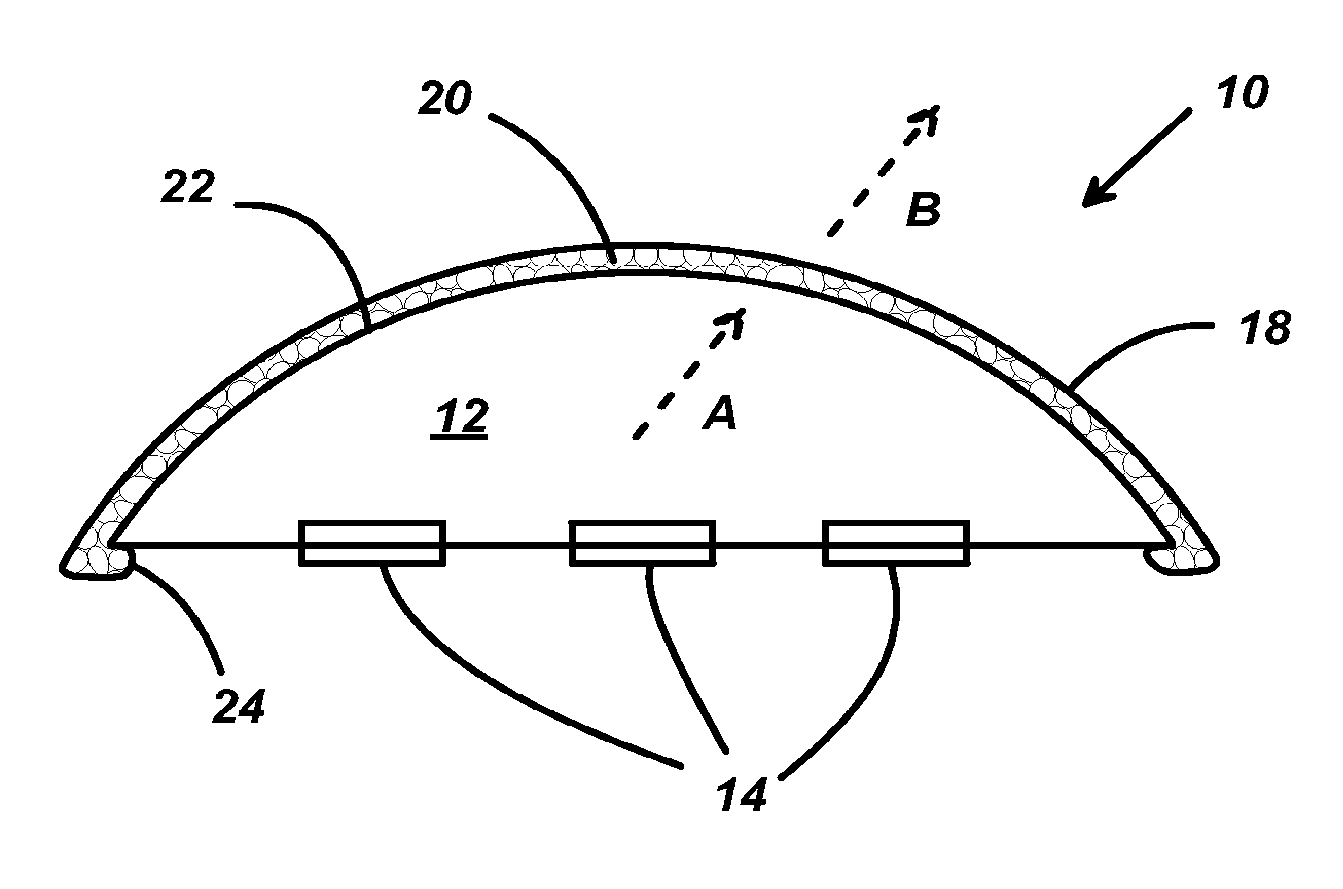

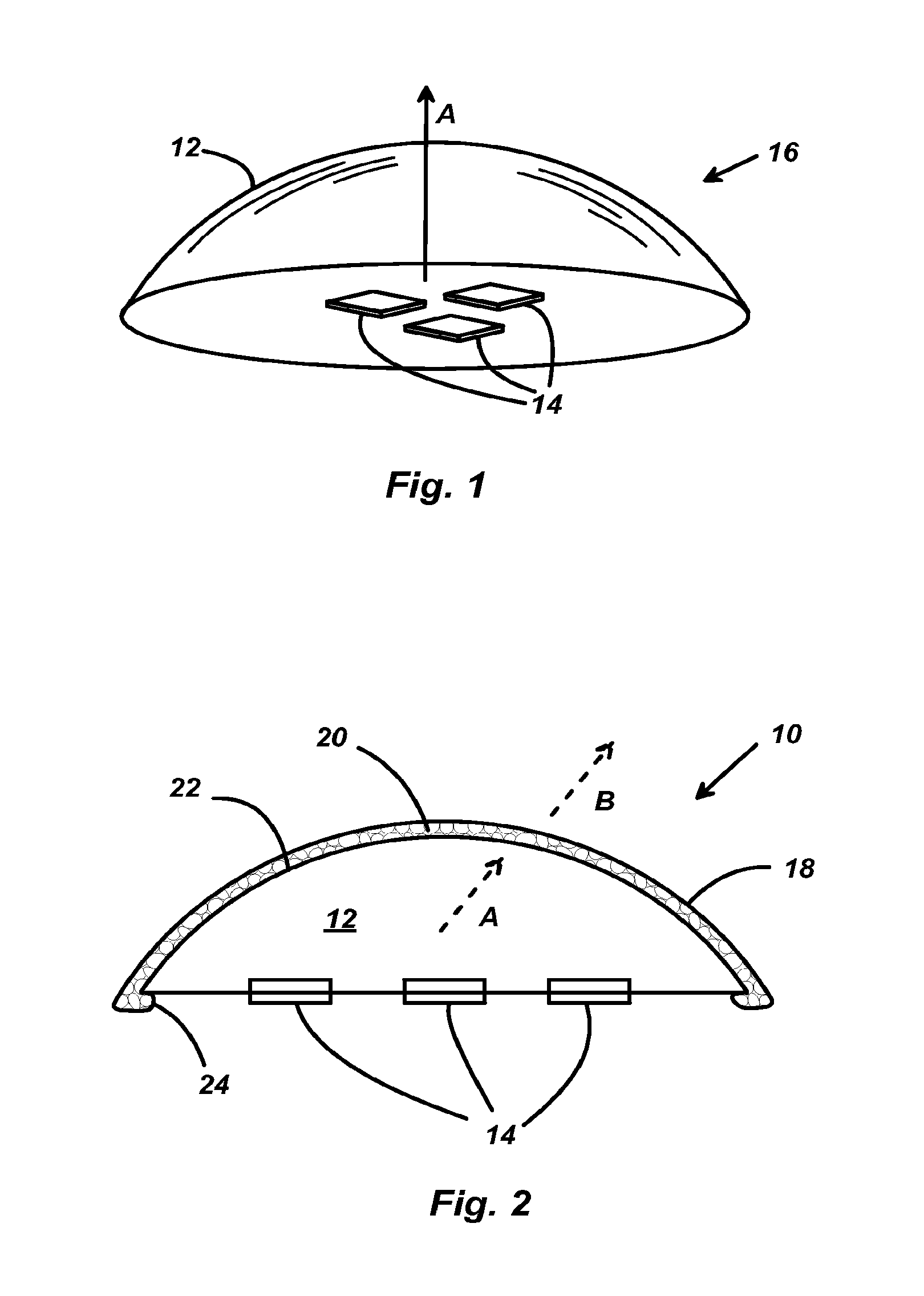

LED light engine and method of manufacture thereof

ActiveUS20120068205A1Optimize thermal designIncreased manufacturing flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingPhosphorLight-emitting diode

A light emitting diode (LED) light engine includes a solid transparent dome mounted on one or more LED dies to form a base module, a flexible sheath having embedded therein a phosphor that converts light of a first wavelength range to light of a second wavelength range, the sheath being attached to the base module so that the sheath conforms to a light emitting surface of the dome. The sheath emits light of the second wavelength range when the LED is emitting light of the first wavelength range. Further sheaths may be formed each with different phosphors or phosphor blends, and one of the sheaths may be selected to cover the base module depending on the color of light to be produced by the light engine.

Owner:OSRAM SYLVANIA INC

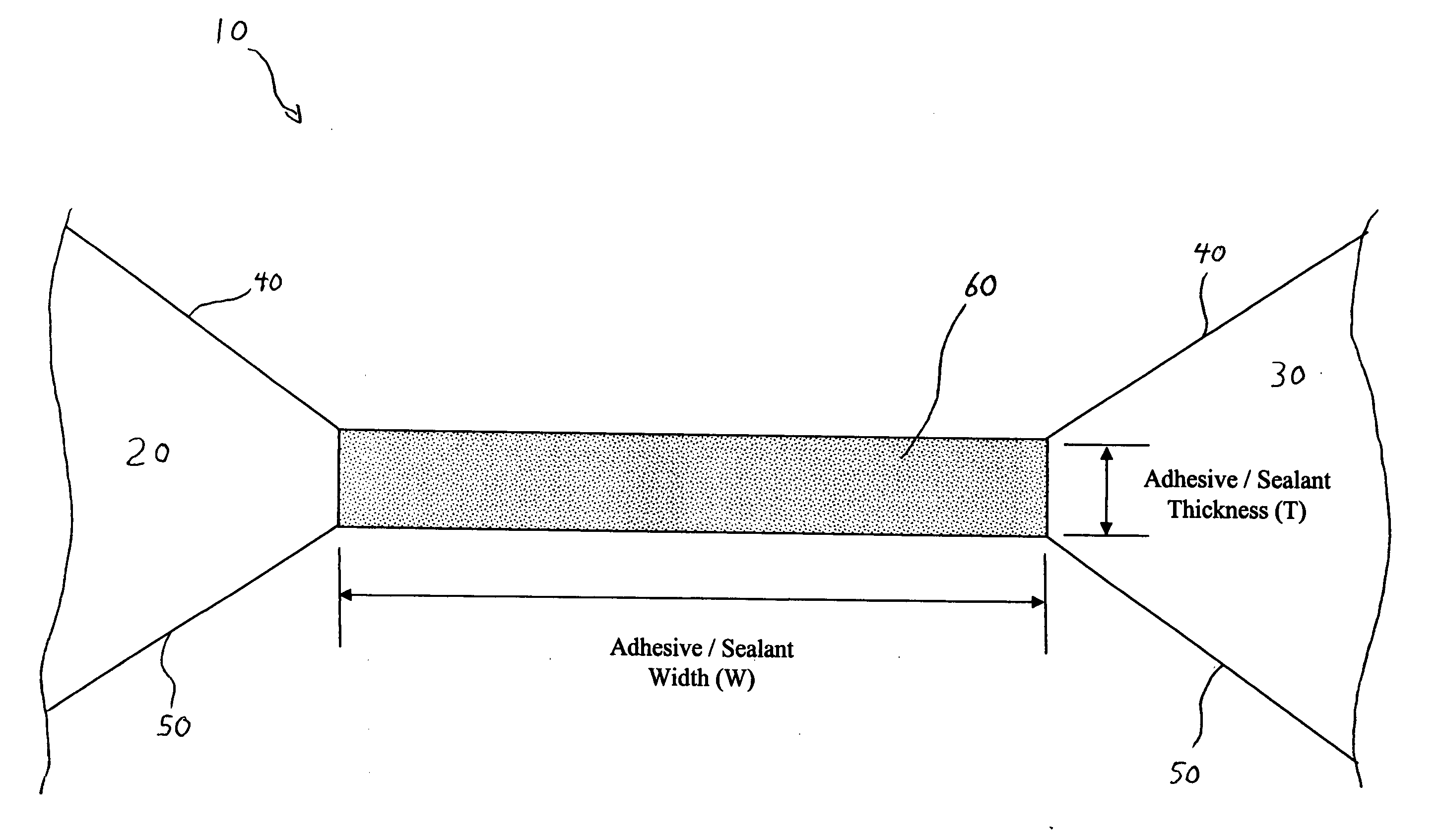

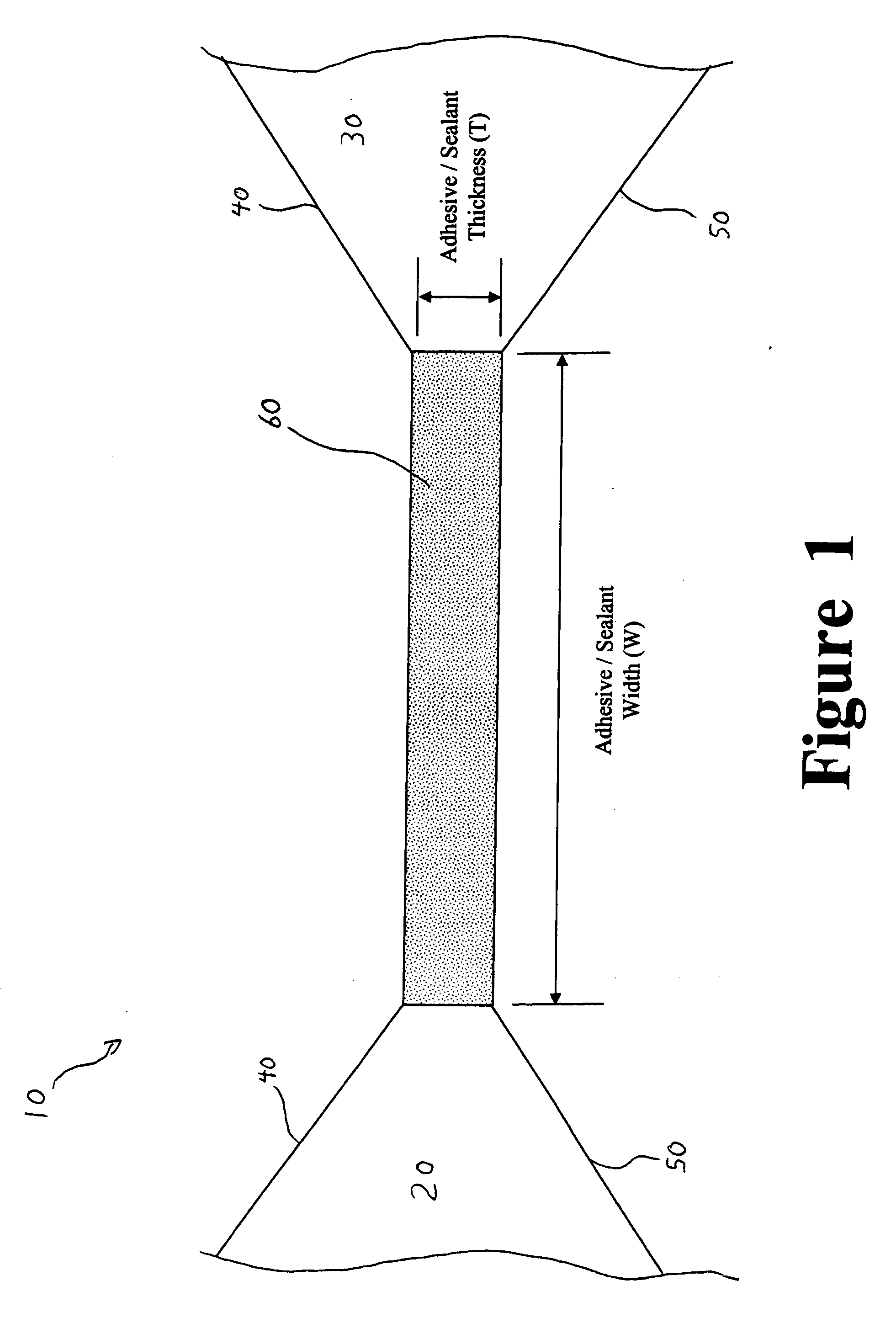

Sealed cushion

InactiveUS20060237957A1Enhanced air retention propertySimple designLayered productsPedestrian/occupant safety arrangementEngineeringAirbag deployment

A sealed cushion construction for an airbag for protecting the occupants of a vehicle during a collision. The construction may include at least two fabric panels that are connected by a seam that may be composed of an adhesive / sealant material. The seam may include sewing to reinforce the seam. Placement of the sewing within the boundaries of the seam may be designed to provide strength to the seam. The seam may have sewing along 100% of the length of the seam, less than 100% of the length of the seam, or not have any sewing along its length.

Owner:TAKATA RESTRAINT SYST

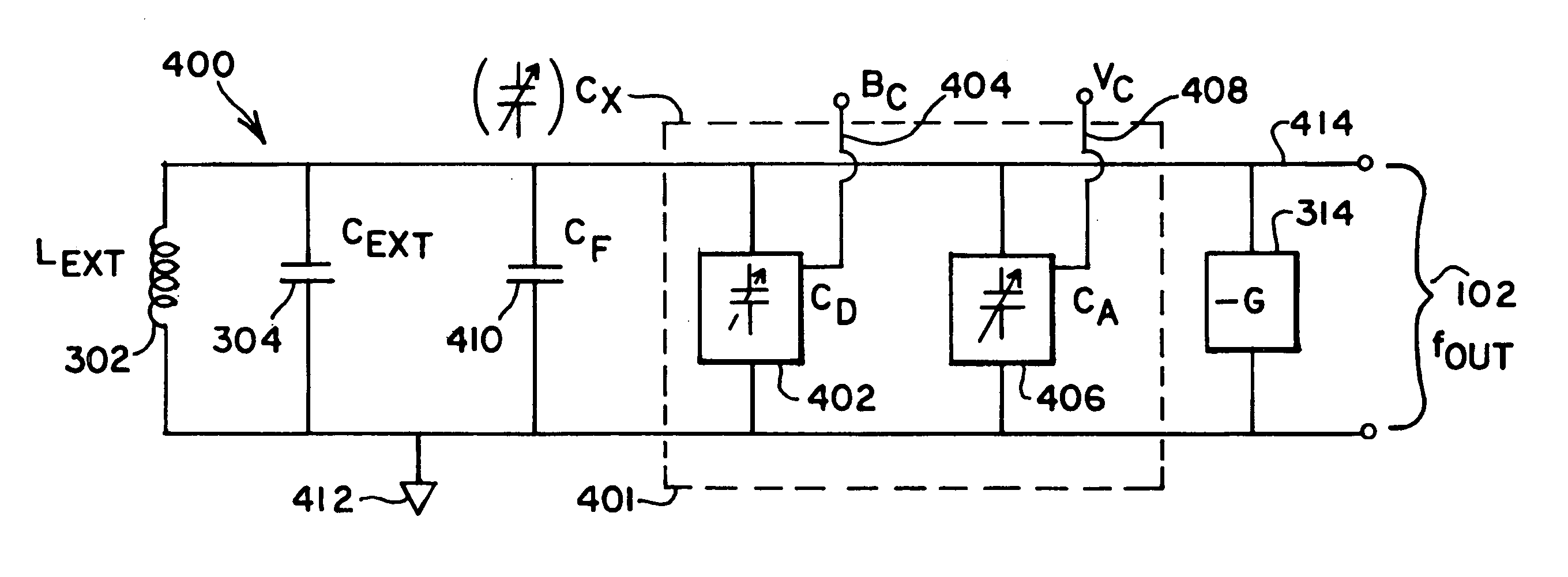

Method and apparatus for synthesizing high-frequency signals for wireless communications

InactiveUS20050242897A1Low costSimple circuitPulse automatic controlSemiconductor/solid-state device detailsSemiconductor packageInductance

Owner:SILICON LAB INC

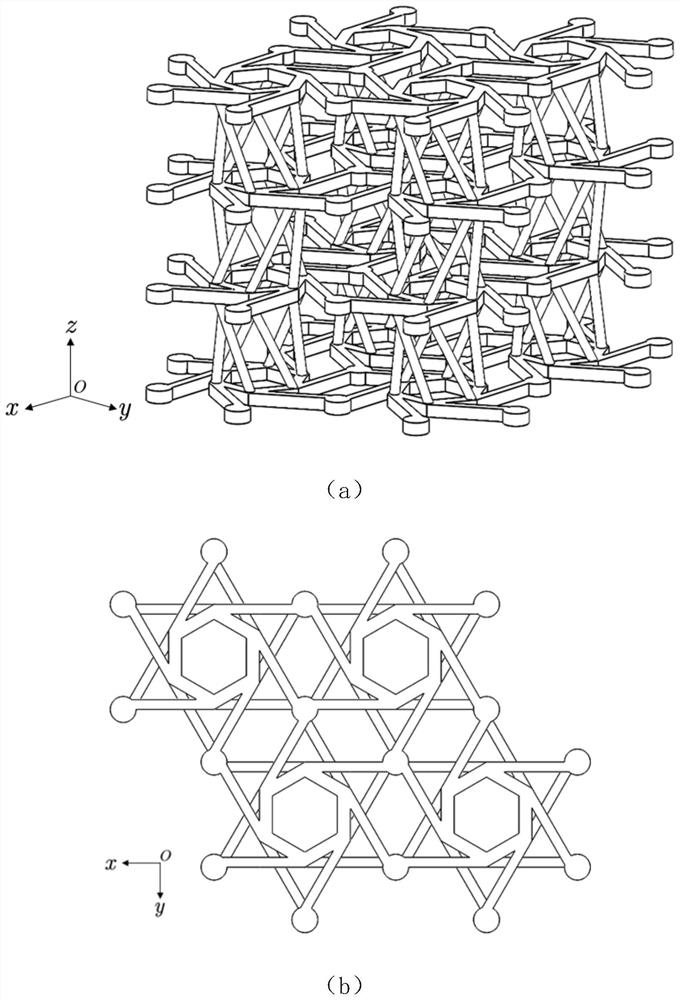

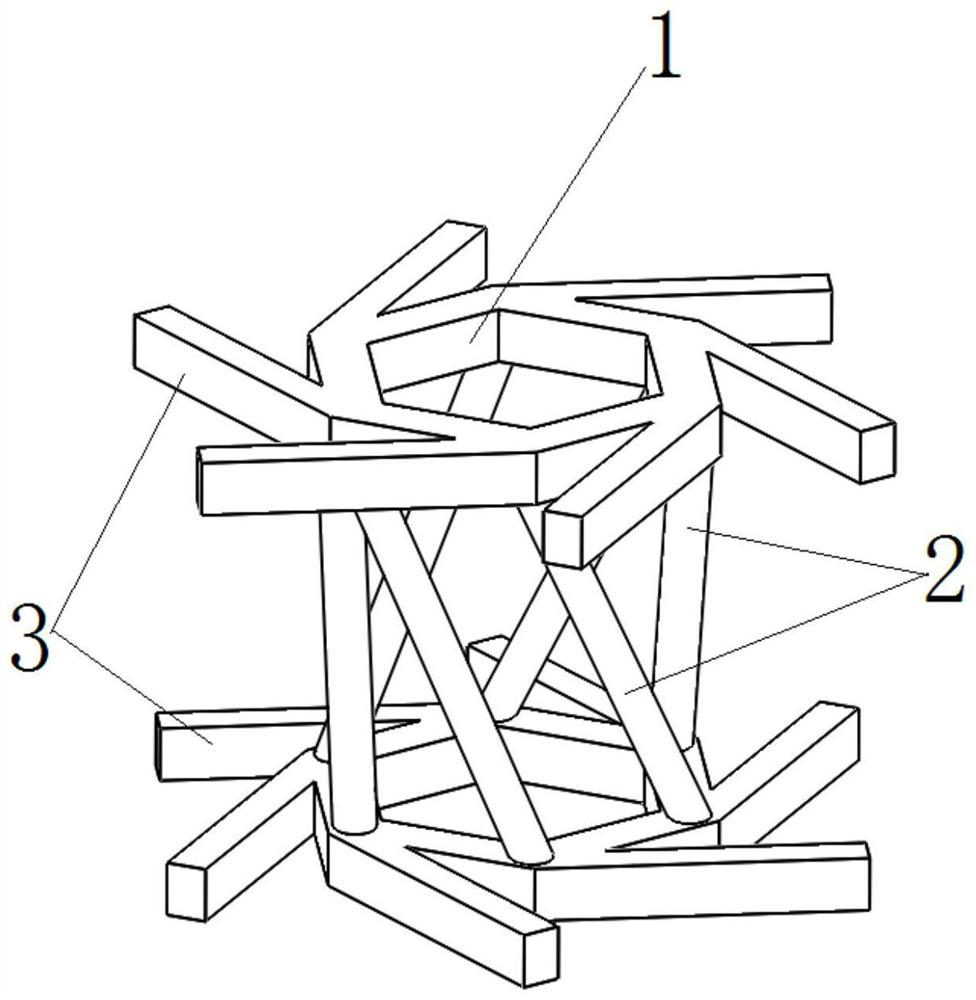

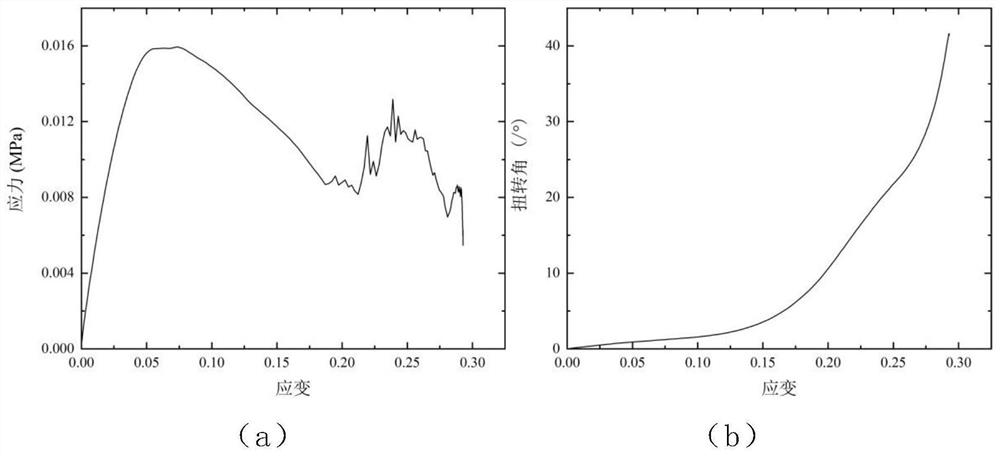

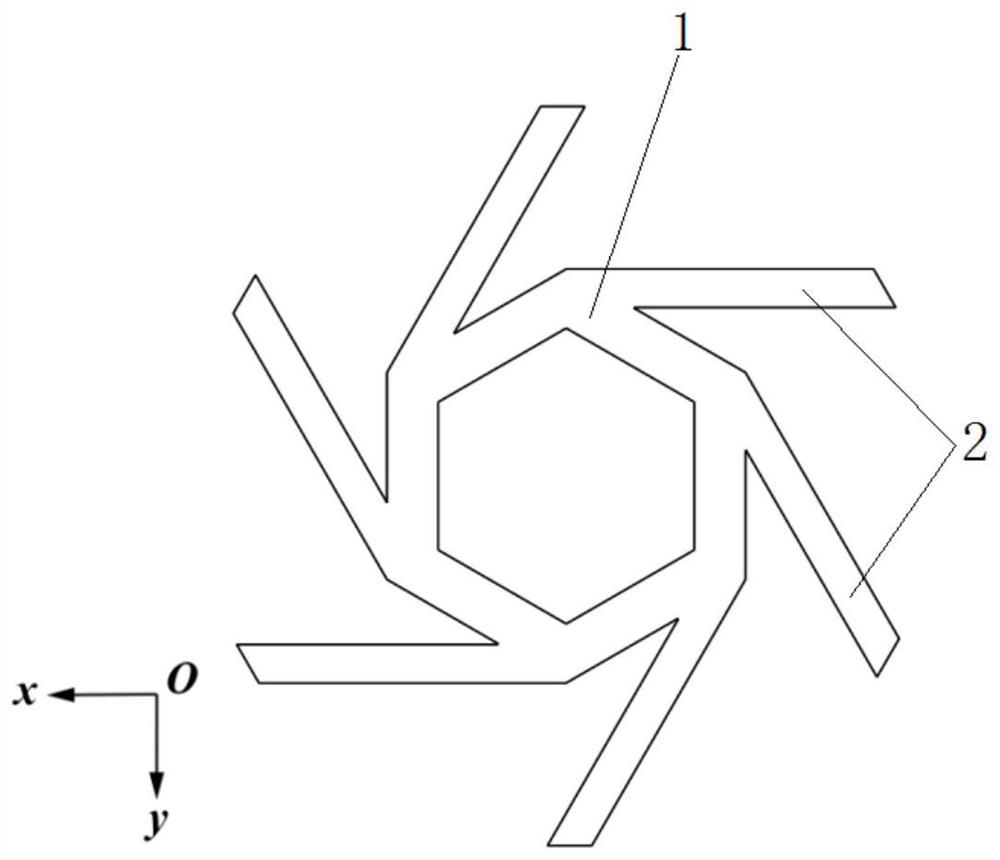

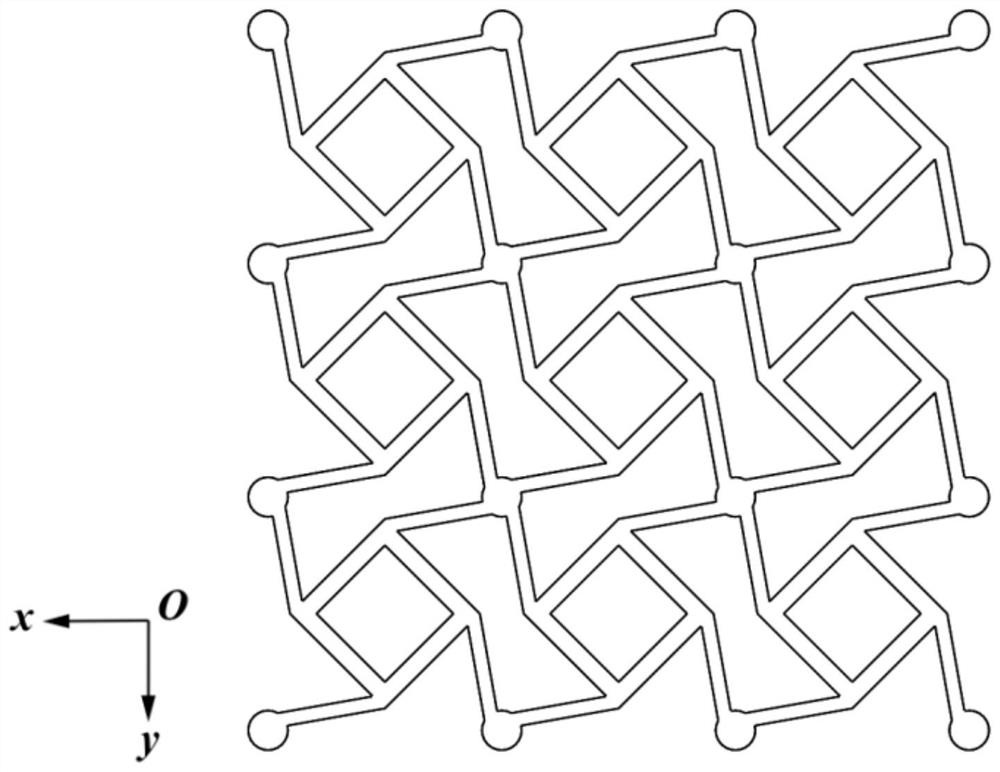

Chiral auxetic metamaterial structure with tension-torsion coupling characteristics and preparation method thereof

ActiveCN112049886AWith tension torsion coupling characteristicsImprove carrying capacityAdditive manufacturing apparatusIncreasing energy efficiencyStructural engineeringMechanical engineering

The invention discloses a chiral auxetic metamaterial structure with tension-torsion coupling characteristics and a preparation method thereof. The chiral auxetic metamaterial structure comprises a plurality of three-dimensional unit cell structures, each three-dimensional unit cell structure comprises two polygonal annular structures arranged up and down, and the vertexes of the upper and lower polygonal annular structures are connected through correspondingly-arranged inclined cylinders; a plurality of inclined cylinders are arranged in a staggered mode in the same direction, connecting rodsused for being connected with the adjacent three-dimensional unit cell structures are arranged at the vertexes of the two polygonal annular structures respectively, the plurality of three-dimensionalunit cell structures are arranged in a spatial array mode, and the chiral auxetic metamaterial structure with the tension-torsion coupling characteristics is formed by connecting the corresponding connecting rods.

Owner:XI AN JIAOTONG UNIV +1

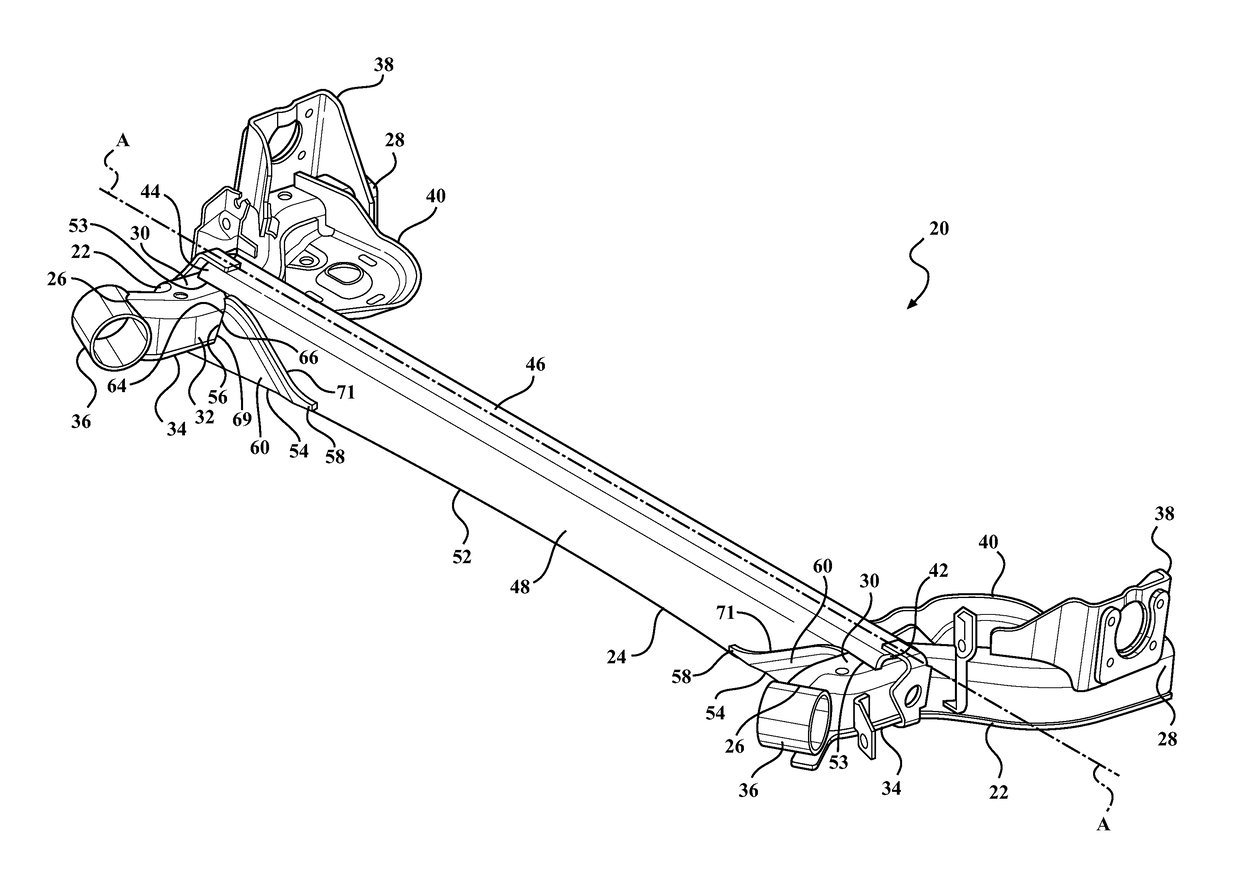

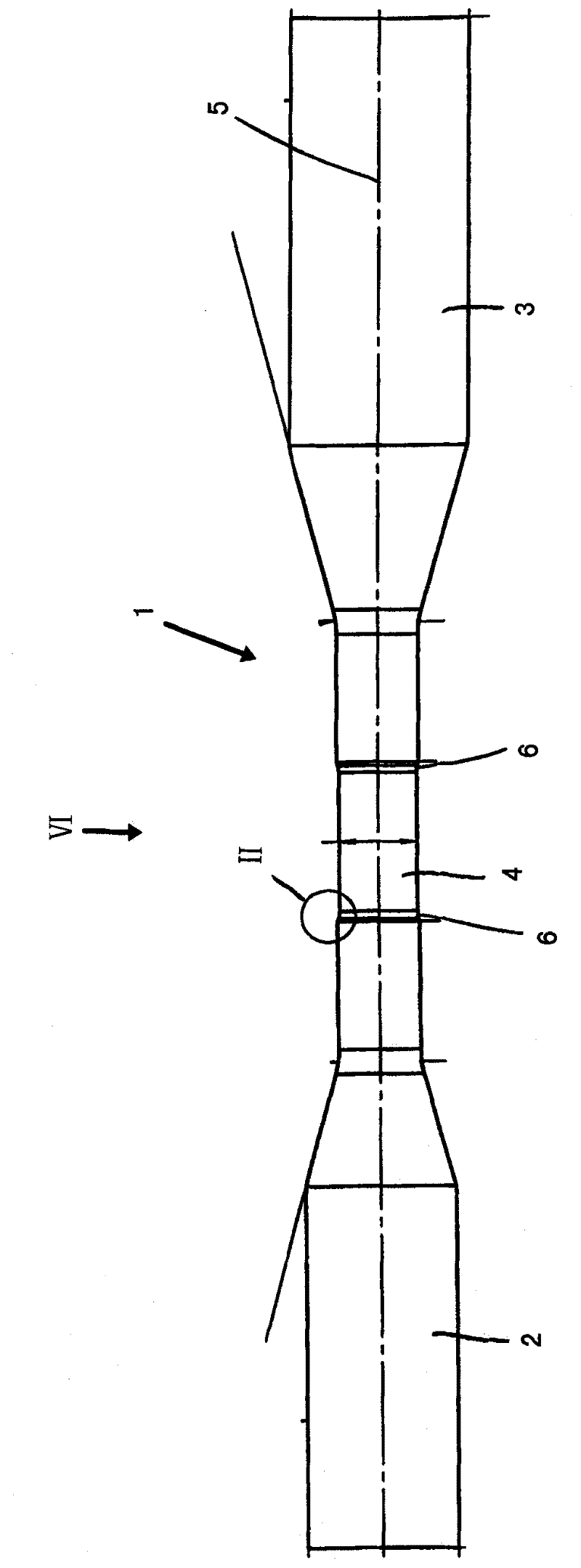

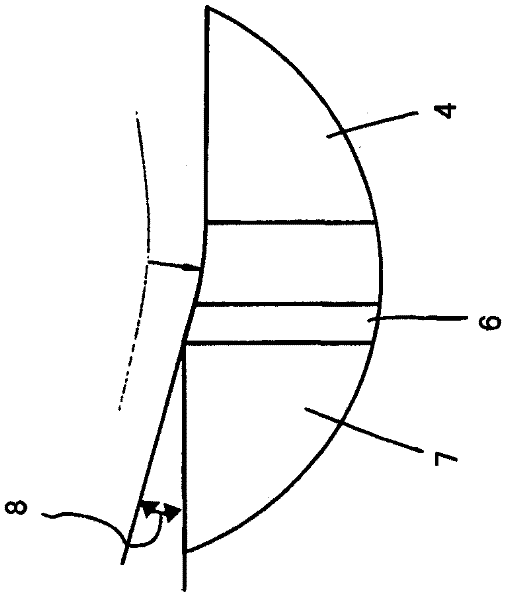

Twist Beam Axle Assembly With Lateral Adjustability

ActiveUS20170197487A1Increased manufacturing flexibilityInterconnection systemsAxle unitsMechanical engineeringBeam axle

A twist axle assembly (20) of a vehicle includes a pair of trailing arms (22) and a twist beam (24) having a base portion (46) extending along an axis (A) between first and second twist beam ends (42, 44). The twist beam (24) includes a pair of side walls (48) extending downwardly from the base portion (46) and each disposed in spaced relationship with the trailing arms (22). At least one mounting bracket (54) extends from a first mounting bracket end (56) disposed in abutting relationship with a respective trailing arm (22) to a second mounting bracket end (58) disposed in overlaying relationship the side walls (48) of the twist beam (24) for allowing the mounting bracket to axially slip or slide along the side walls (48) of the twist beam (24) and provide for lateral or axial adjustment of the twist axle assembly (20) during the manufacturing process.

Owner:MAGNA INTERNATIONAL INC

Chiral auxetic metamaterial structure with compression-shear coupling characteristic and preparation method thereof

ActiveCN112045990AStrong energy absorption and impact resistanceBroaden your optionsAdditive manufacturing apparatusElastic dampersCrystallographyEnergy absorption

The invention discloses a chiral auxetic metamaterial structure with a compression-shear coupling characteristic and a preparation method thereof. Polygonal chiral structures with different shapes areperiodically arranged and connected with each other, so that the chiral auxetic metamaterial structure simultaneously has excellent compression-shear coupling characteristic and auxetic characteristic; and as the intersections of connecting rods are connected in a circular manner, negative Poisson's ratio behaviors are generated through two deformation mechanisms of indenting and rotation when aload is borne, so that very strong energy absorption and impact resistance characteristics are formed. Simulation results show that the chiral auxetic metamaterial structure with the compression-shearcoupling characteristic has remarkable compression-shear coupling and auxetic characteristics and has a wide prospect in industrial application.

Owner:XI AN JIAOTONG UNIV +1

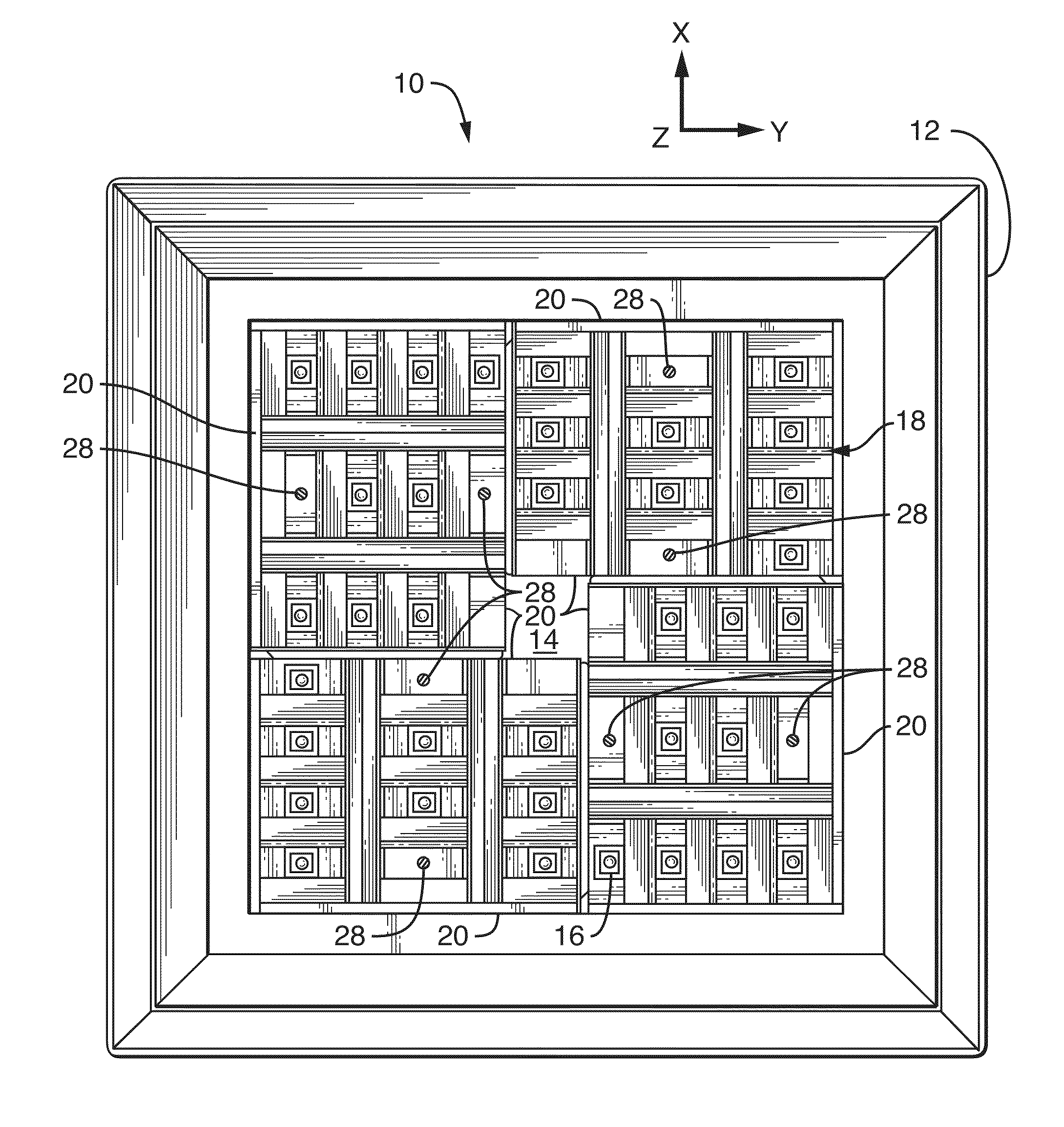

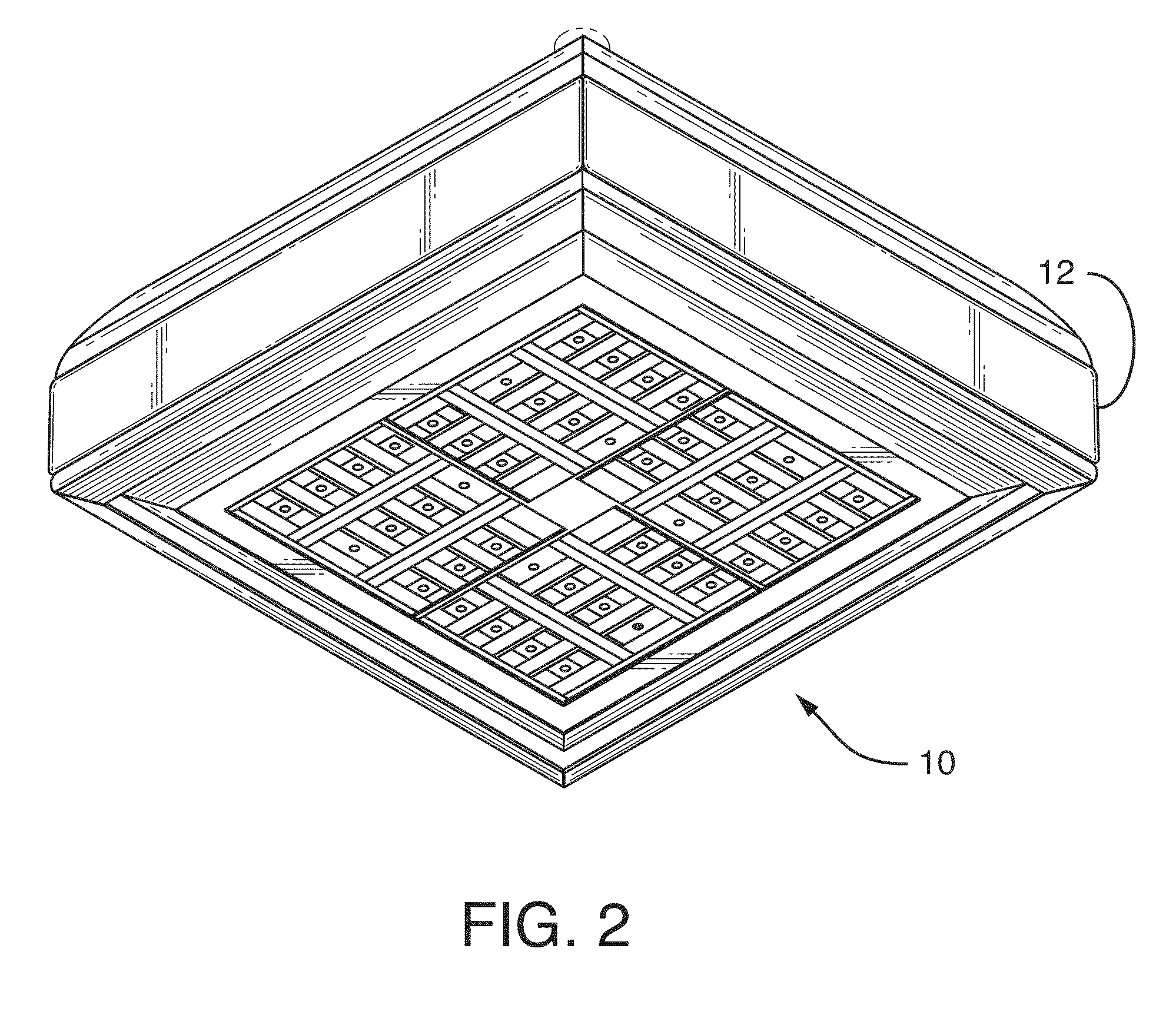

Modular Light Reflectors and Assemblies for Luminaire

ActiveUS20130051016A1Reduce the numberSmall sizePlanar light sourcesMechanical apparatusLight equipmentEffect light

A reflector assembly for a lighting apparatus, the reflector assembly comprising two or more reflector modules configured for associating with one or more light sources, each reflector module comprising one or more reflectors for being located adjacent to alight source when the reflector module is associated with the one or more light sources, the one or more reflectors configured to reflect light from the adjacent light source. The reflector modules may further comprising a cover plate defining a plurality of light source apertures for allowing a light source to protrude through the cover plate, at least a first of the one or more light source apertures disposed adjacent to an overhead reflector and at least a second of the one or more light source apertures disposed adjacent to a lateral reflector. The reflector assembly can comprising any number of reflector modules and the reflector modules can be arranged in different configurations to create different light distributions with the same reflector modules.

Owner:LSI INDS

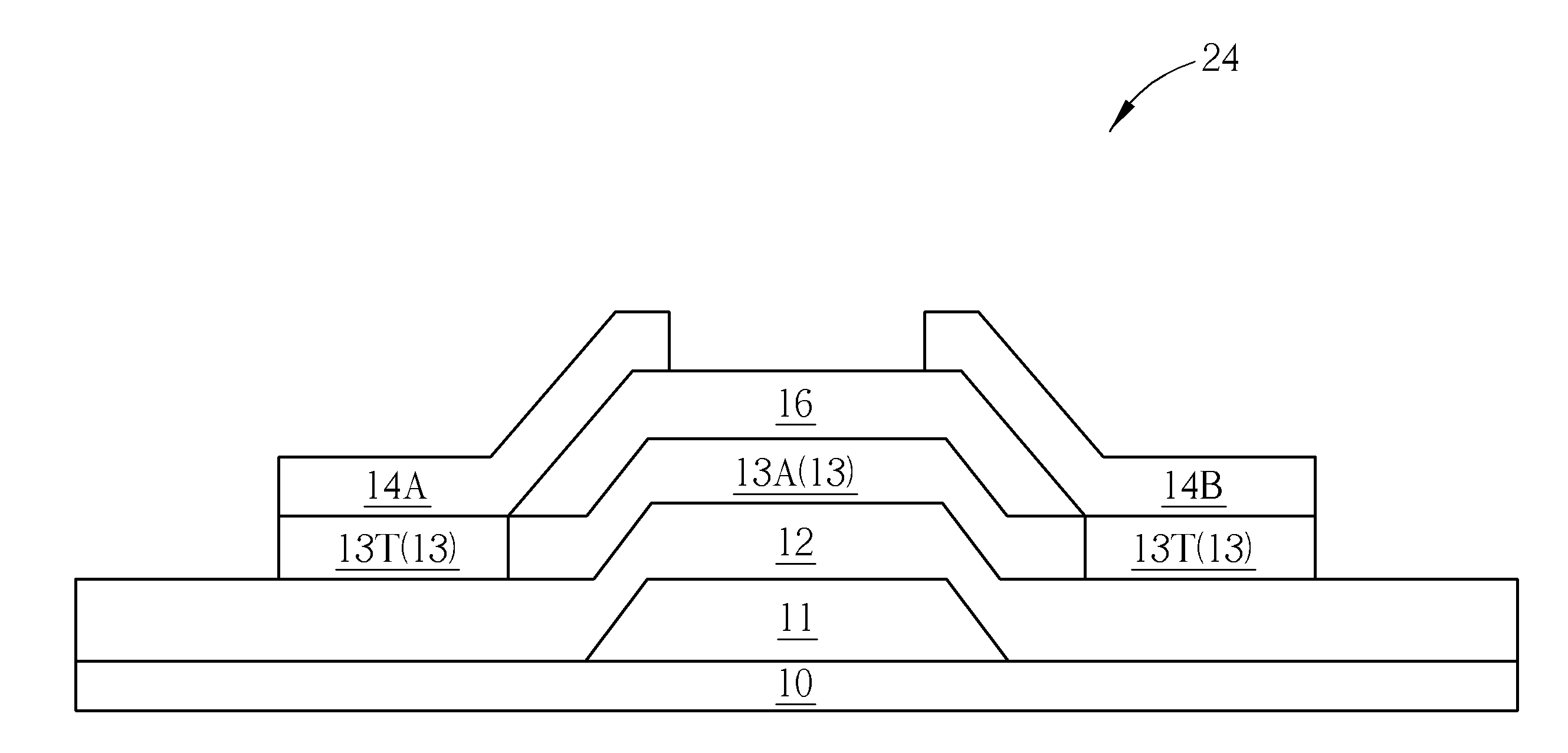

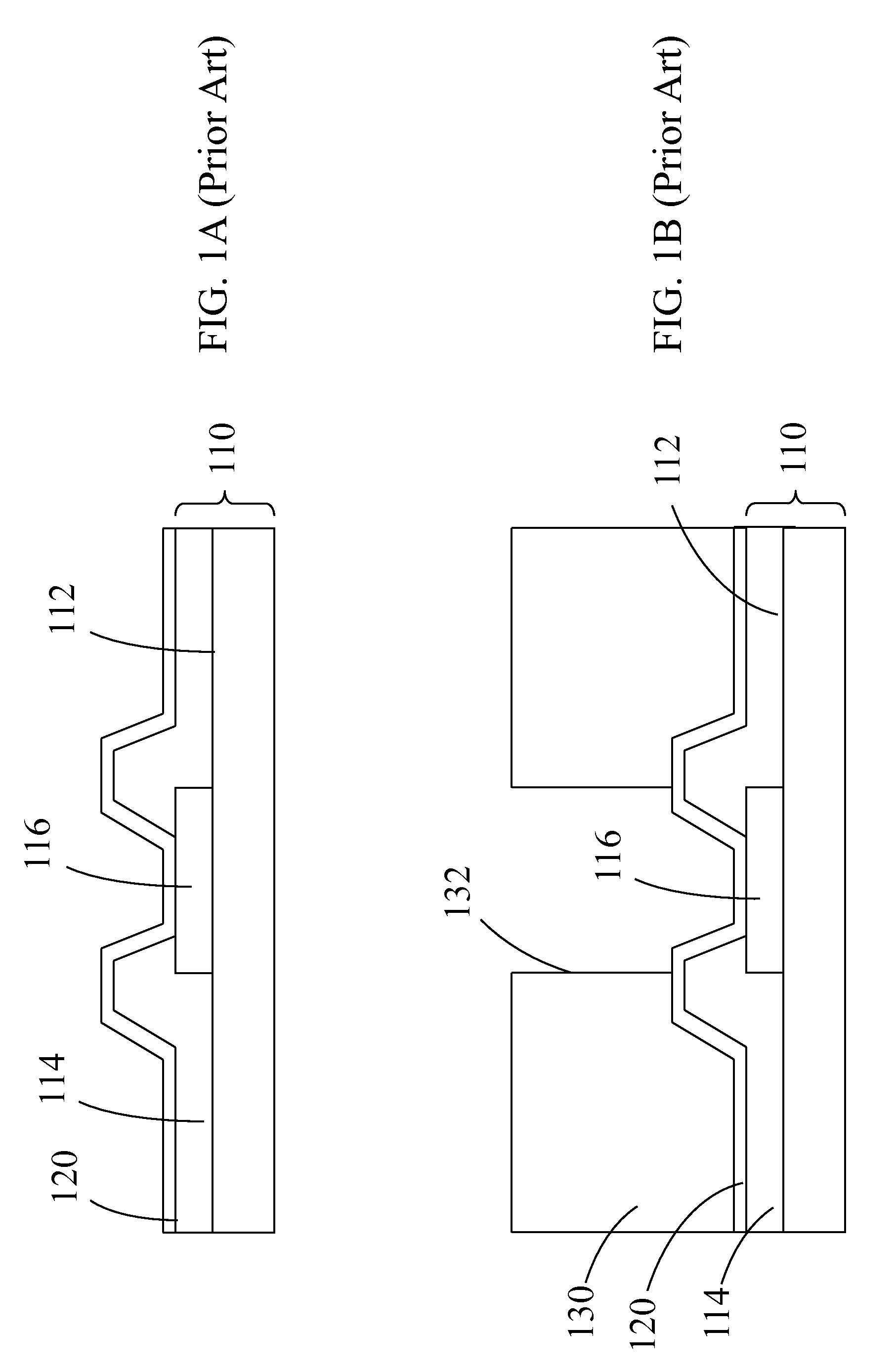

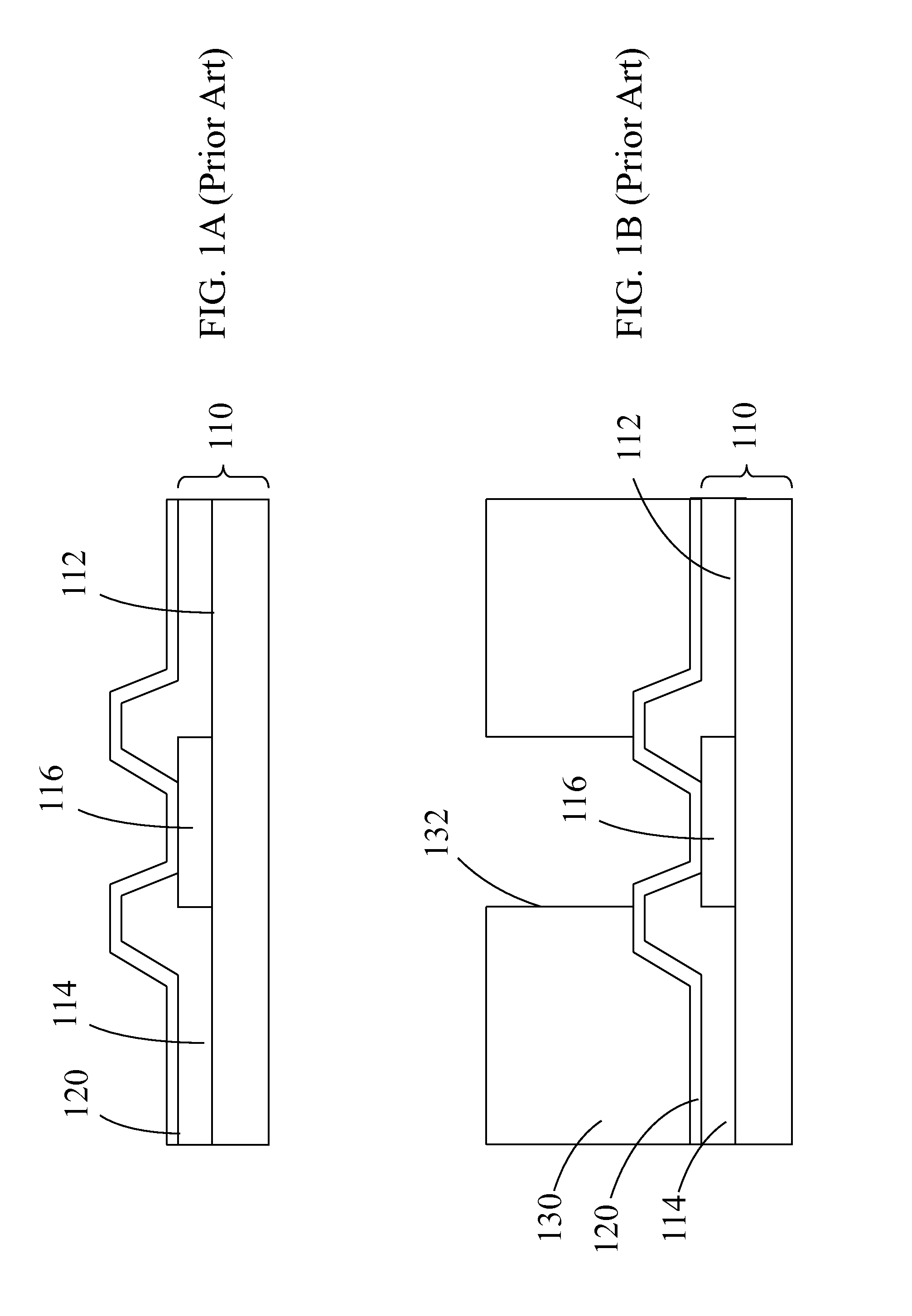

Manufacturing method of thin film transistor

InactiveUS20120231588A1Low electrical resistivityLower contact resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorOxide

A manufacturing method of thin film transistors is provided. The manufacturing method includes: providing a substrate; forming a gate electrode; forming a gate insulating layer; forming a patterned oxide semiconductor layer; forming a source electrode and a drain electrode; and executing a localized laser treatment. A laser beam is used to irradiate at least a part of the patterned oxide semiconductor layer in the localized laser treatment. An electrical resistitivity of the patterned oxide semiconductor layer irradiated by the laser beam is lower than an electrical resistitivity of the patterned oxide semiconductor layer without being irradiated by the laser beam.

Owner:CHUNGHWA PICTURE TUBES LTD

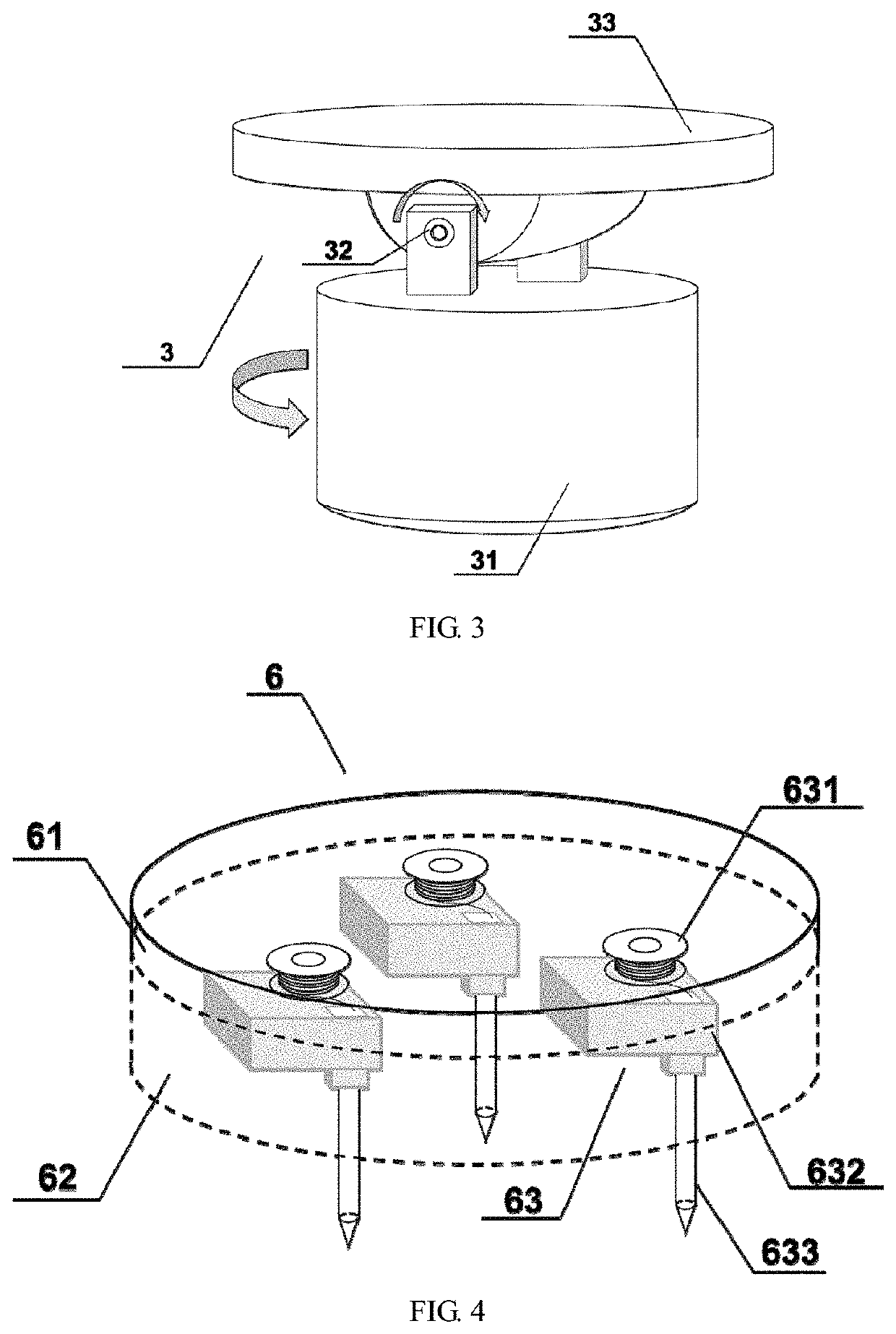

Polymer multi-material high-flexibility laser additive manufacturing system and method thereof

ActiveUS20200031057A1Reduce difficultyExtended service lifeManufacturing platforms/substratesManufacturing driving meansDetentErbium lasers

The invention belongs to the field of filament additive manufacturing, and discloses a polymer multi-material high-flexibility laser additive manufacturing system and a method thereof. The system comprises a first robot arm, a second robot arm, a positioner, a rotational extrusion nozzle in which a plurality of extrusion modules are disposed and a laser, each extrusion module is used for extruding one kind of filament, and the rotational extrusion nozzle is connected with the first robot which drives the rotational extrusion nozzle to move according to a preset trajectory; the laser is connected with the second robot, and is used for emitting a laser to fuse the filament extruded from the rotational extrusion nozzle, and through the cooperative motion of the first robot and the second robot, the extrusion and fusion of the filament are performed synchronously; the positioner serves as a forming mesa, and the rotation of the positioner cooperates with the motions of the two robots. With the present invention, problems such as easy blocking and short service life of the extrusion nozzle in the FDM forming are solved, thereby ensuring high flexibility of the manufacturing system and achieving the extrusion forming of the multi-material filaments.

Owner:HUAZHONG UNIV OF SCI & TECH

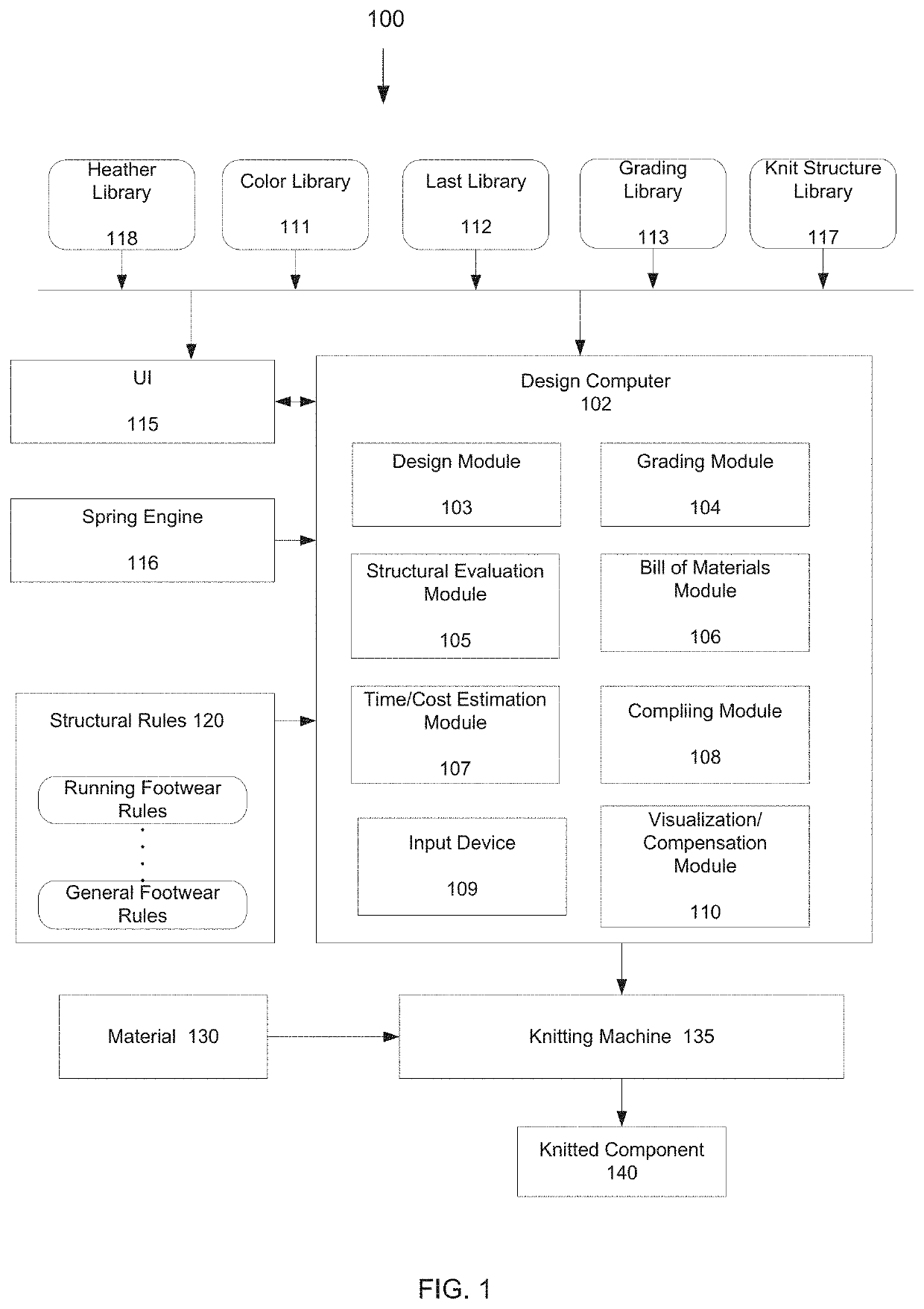

Tool for design and fabrication of knitted components

ActiveUS20190382931A1Increase flexibilityWasteful and costly and laboriousProgramme controlDesign optimisation/simulationDigital controlBraid

Computer based systems and methods for designing and manufacturing consumer products, including knit footwear uppers, and the like. The system provides digital controls for the customization of knitted components, including complex multi-structured knitted components. The system simulates deformations of knit structures and allows the user to control and visualize compensations in the structure(s) of the knitted component to better match between an intended knit design and the actual physical knitted component outcome. They system may manufacture / fabricate a knitted component based on the predicted / estimated deformation behavior of the knit.

Owner:NIKE INC

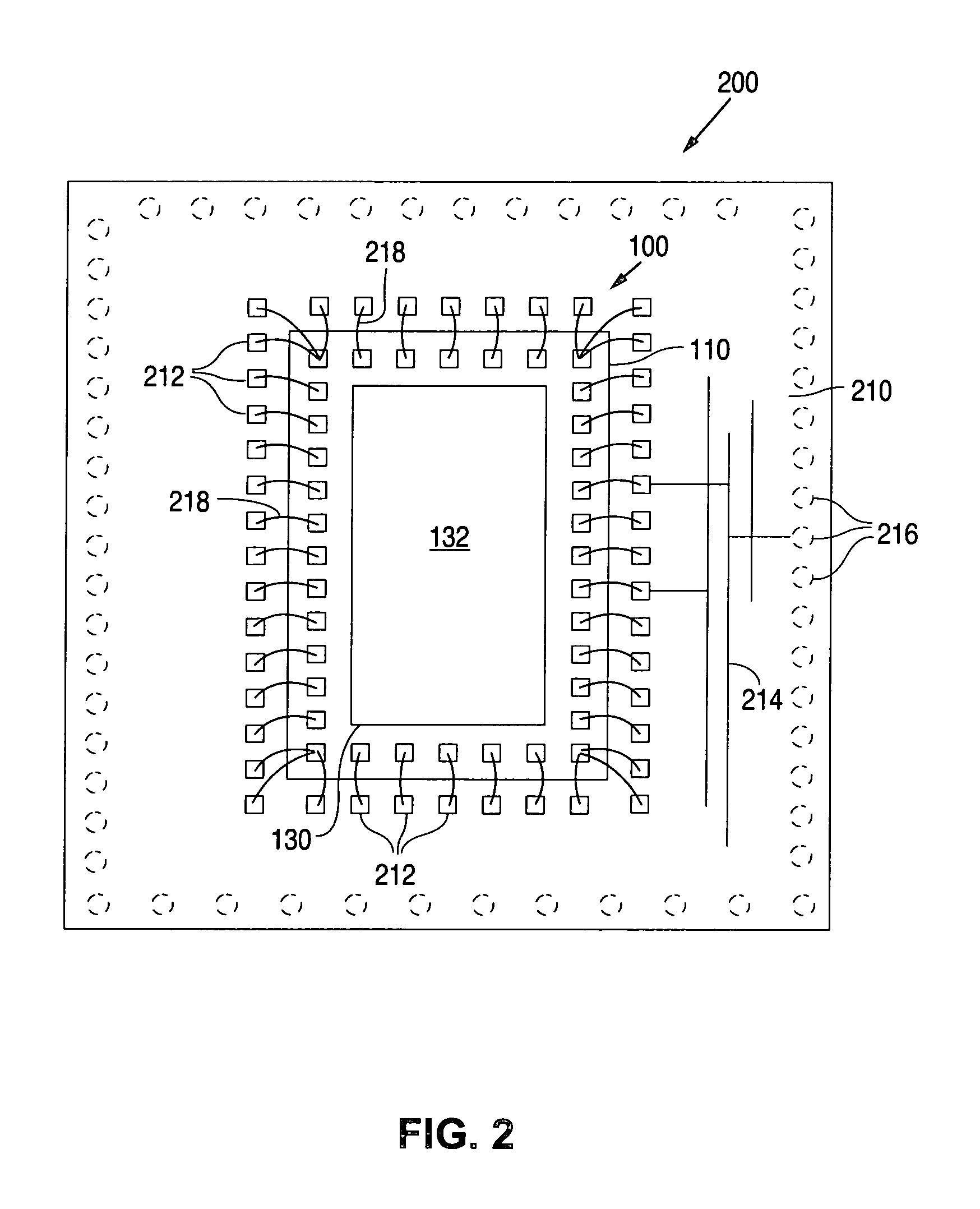

Method of forming the integrated circuit having a die with high Q inductors and capacitors attached to a die with a circuit as a flip chip

InactiveUS6946321B1Simple manufacturing processIncreased manufacturing flexibilitySemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsCapacitanceEngineering

A semiconductor integrated circuit with high Q inductors and capacitors is disclosed. A semiconductor electrical circuit is formed on a first die, while micro-electromechanical structures having inductance and capacitance are formed on a second die. The second die is attached and electrically connected to the first die as a flip chip.

Owner:NAT SEMICON CORP

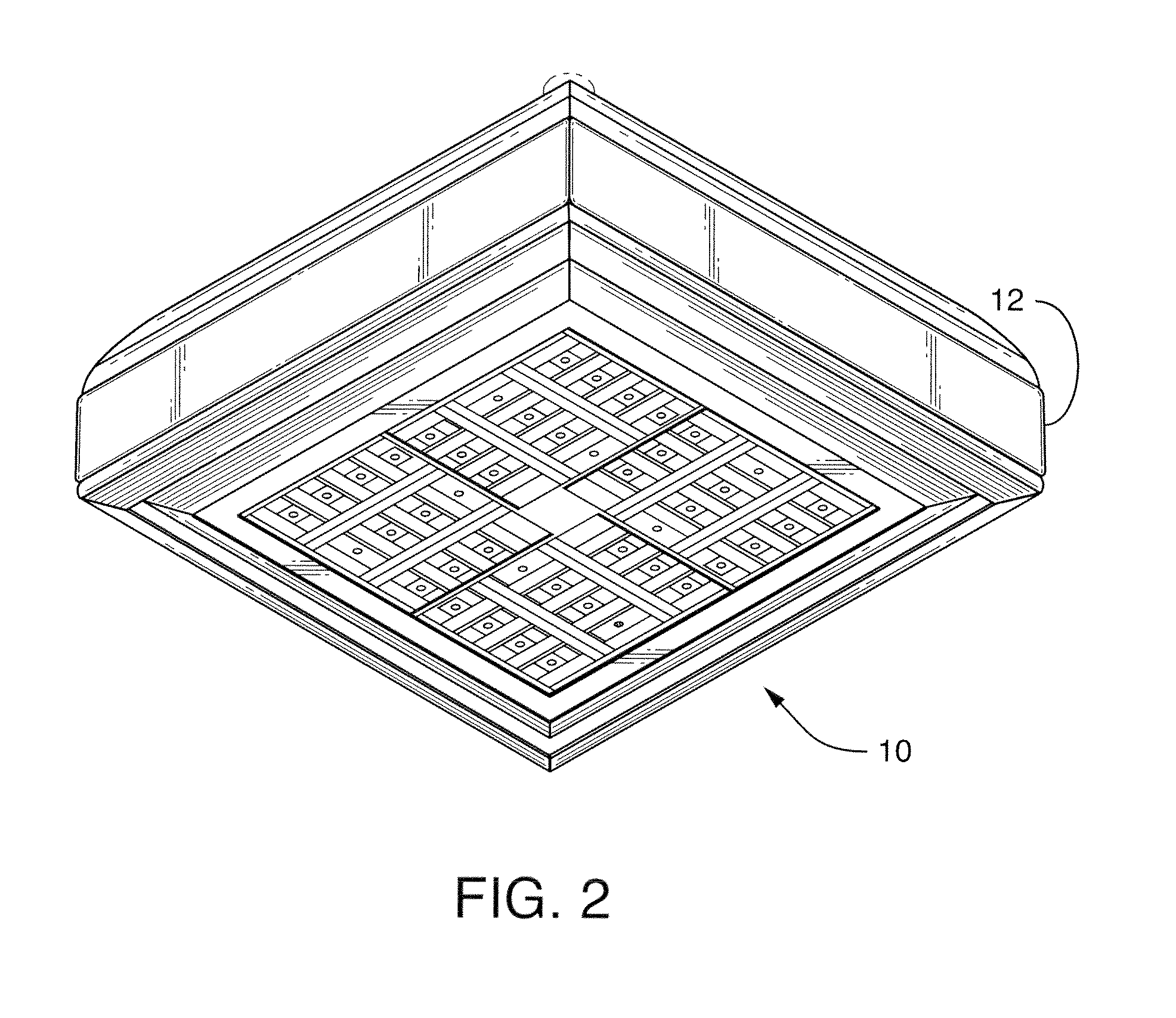

Light Emitting Diode Illumination Device

ActiveUS20180106434A1Reduce manufacturing costImprove stabilityPoint-like light sourceElectric circuit arrangementsSurface-mount technologyLight-emitting diode

A light emitting diode illumination device comprises a light-transmitting encapsulant, a transparent core, a light source plate stereoscopic structure and a power supply device. The light-transmitting encapsulant and the transparent core can be made of glass material. The light source plate stereoscopic structure is constituted by a plurality of connecting sub-light source plates. The light source plate stereoscopic structure installed in the light-transmitting encapsulant is connected to the transparent core, and is supported by the transparent core. The sub-light source plate comprises a circuit board body and light-emitting diode dies. The light-emitting diode dies can be installed on one surface of the circuit board body by surface-mount technology. The power supply device is used for supplying power to the sub-light source plates, so that a plurality of sub-light source plates may provide illumination through the light-transmitting encapsulant.

Owner:XIAMEN ECO LIGHTING CO LTD

Method for producing connecting elements by way of a pressure welding process and connecting element

InactiveCN102202828AIncrease the amount of forgingImprove carrying capacityArc welding apparatusWelding/soldering/cutting articlesOil drillingWelding process

Owner:布洛姆福斯石油工具有限公司

Resistance spot welding steel and aluminum workpieces using electrode weld face cover

ActiveUS10052710B2Reduce heatReduce the overall heightElectrode supporting devicesWelding/cutting media/materialsElectrical resistance and conductanceMetallic materials

A method of resistance spot welding a steel workpiece and an aluminum or aluminum alloy (“aluminum”) workpiece together includes several steps. One step involves providing a workpiece stack-up with a steel workpiece and an aluminum workpiece. Another step involves attaching a cover over a weld face of a welding electrode. The cover is made of a metal material with an electrical resistivity that is greater than an electrical resistivity of a material of the welding electrode. Yet another step involves performing multiple individual resistance spot welds to the workpiece stack-up. The cover abuts the aluminum workpiece while the individual resistance spot welds are performed. And another step involves removing the cover from the welding electrode after the individual spot welds are performed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Solder cap bump in semiconductor package and method of manufacturing the same

ActiveUS8431478B2Improve uniformityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor package

A semiconductor package with improved height uniformity of solder cap bumps therein is disclosed. In one embodiment, the semiconductor package includes a semiconductor substrate comprising a plurality of pads spacedly disposed on a top surface of the substrate, and a passivation layer formed on top of the pads, wherein a plurality of pad openings are created to expose at least a portion of the pads; a plurality of solder cap bumps formed at the pad openings of the passivation layer; and a carrier substrate having a plurality of bond pads electrically connected to the solder caps of the solder cap bumps on the semiconductor substrate. The solder cap bump includes a solder cap on top of a conductive pillar, and a patternable layer can be coated and patterned on a top surface of the conductive pillar to define an area for the solder ball to be deposited. The deposited solder ball can be reflowed to form the solder cap.

Owner:CHIPMOS TECH INC

Solder cap bump in semiconductor package and method of manufacturing the same

ActiveUS20130069231A1Improve uniformityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageSolder ball

A semiconductor package with improved height uniformity of solder cap bumps therein is disclosed. In one embodiment, the semiconductor package includes a semiconductor substrate comprising a plurality of pads spacedly disposed on a top surface of the substrate, and a passivation layer formed on top of the pads, wherein a plurality of pad openings are created to expose at least a portion of the pads; a plurality of solder cap bumps formed at the pad openings of the passivation layer; and a carrier substrate having a plurality of bond pads electrically connected to the solder caps of the solder cap bumps on the semiconductor substrate. The solder cap bump includes a solder cap on top of a conductive pillar, and a patternable layer can be coated and patterned on a top surface of the conductive pillar to define an area for the solder ball to be deposited. The deposited solder ball can be reflowed to form the solder cap.

Owner:CHIPMOS TECH INC

High frequency surface acoustic wave device

InactiveUS7615910B1Spread the wordHigh resolutionPiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface acoustic wave sensorSpeed of sound

The present invention relates to a high frequency surface acoustic wave device, which may be manufactured by the same manufacturing equipment, and with the same material, as those required for manufacturing a low frequency surface acoustic wave device. The disclosed high frequency surface acoustic wave device comprises: a piezoelectric substrate; a high acoustic velocity layer formed on the surface of the piezoelectric substrate whose acoustic velocity of the surface acoustic wave is larger than 5000 m / sec; an input transducing part; and an output transducing part; wherein the input transducing part and the output transducing part are formed in pair on or below the surface of the high acoustic velocity layer. Besides, the high acoustic velocity layer is preferably made of aluminum oxide, and formed on the surface of the piezoelectric substrate by an electron-beam evaporation process. The thickness thereof is preferably between 2 μm and 20 μm.

Owner:TATUNG UNIVERSITY +1

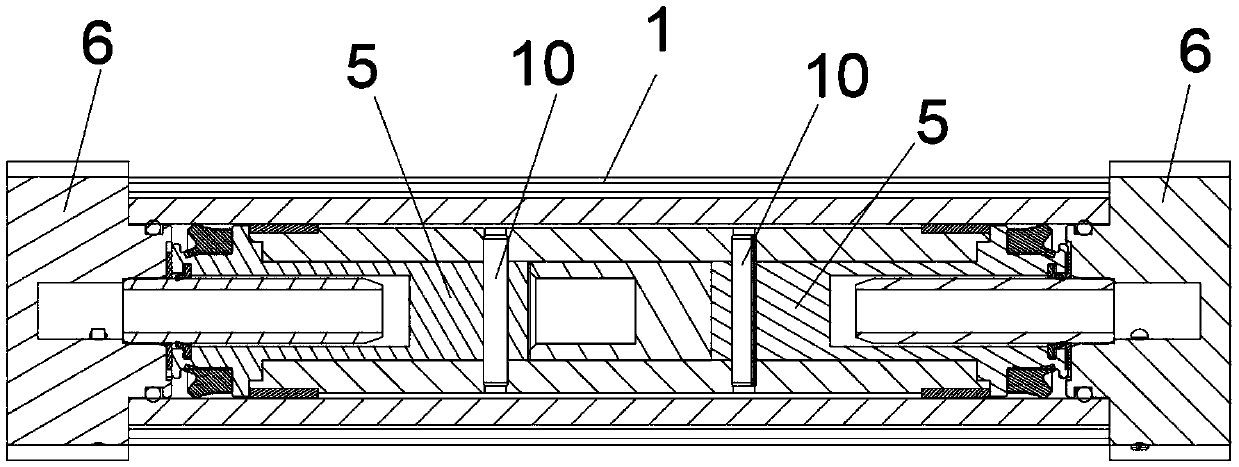

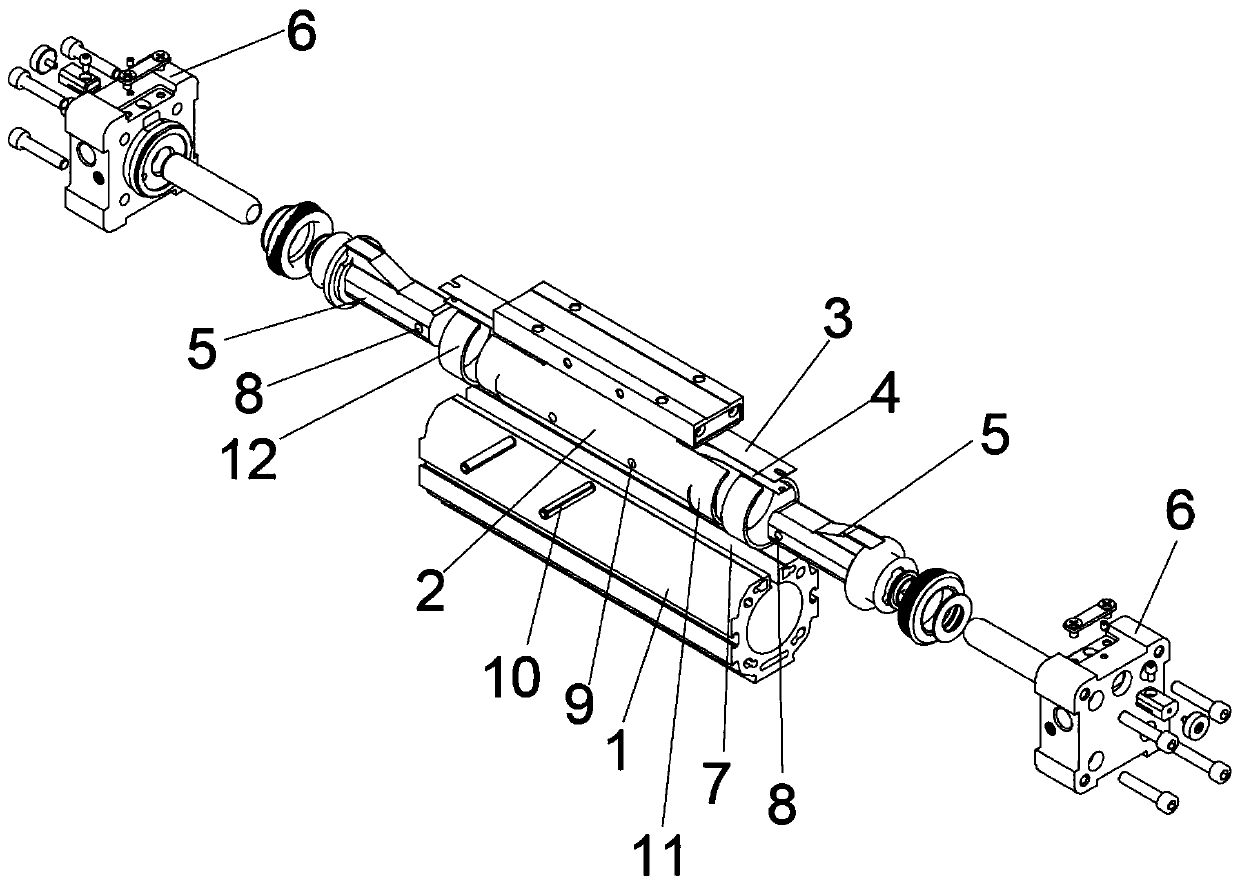

Rodless cylinder

PendingCN109099025AReduce use costAvoid restrictionsFluid-pressure actuatorsEngineeringMechanical engineering

The invention discloses a rodless cylinder. The rodless cylinder comprises a cylinder body, a piston body, an outer steel strip, an inner steel strip, two piston heads and two end covers; a sliding groove is formed in the cylinder body; a piston end of the piston body is arranged in the cylinder body; a sliding block end of the piston body penetrates through the sliding groove and is arranged outof the cylinder body; the outer steel strip and the inner steel strip are respectively mounted between the piston body and the exterior of the cylinder body and between the piston body and the interior of the cylinder body; the two end covers are respectively mounted at the two ends of the cylinder body; the two piston heads are respectively arranged at the two ends of the piston end of the pistonbody and extend into the piston end; pin holes are formed in the surfaces of the piston heads; mounting holes are formed in the surface of the piston ends corresponding to the pin holes; the piston heads are connected with the piston ends through locking pins; the locking pins, the mounting holes and the pin holes are matched for locking. According to the rodless cylinder, the production cost isgreatly reduced on the premise of ensuring connecting stability.

Owner:能手模组技术(无锡)有限公司

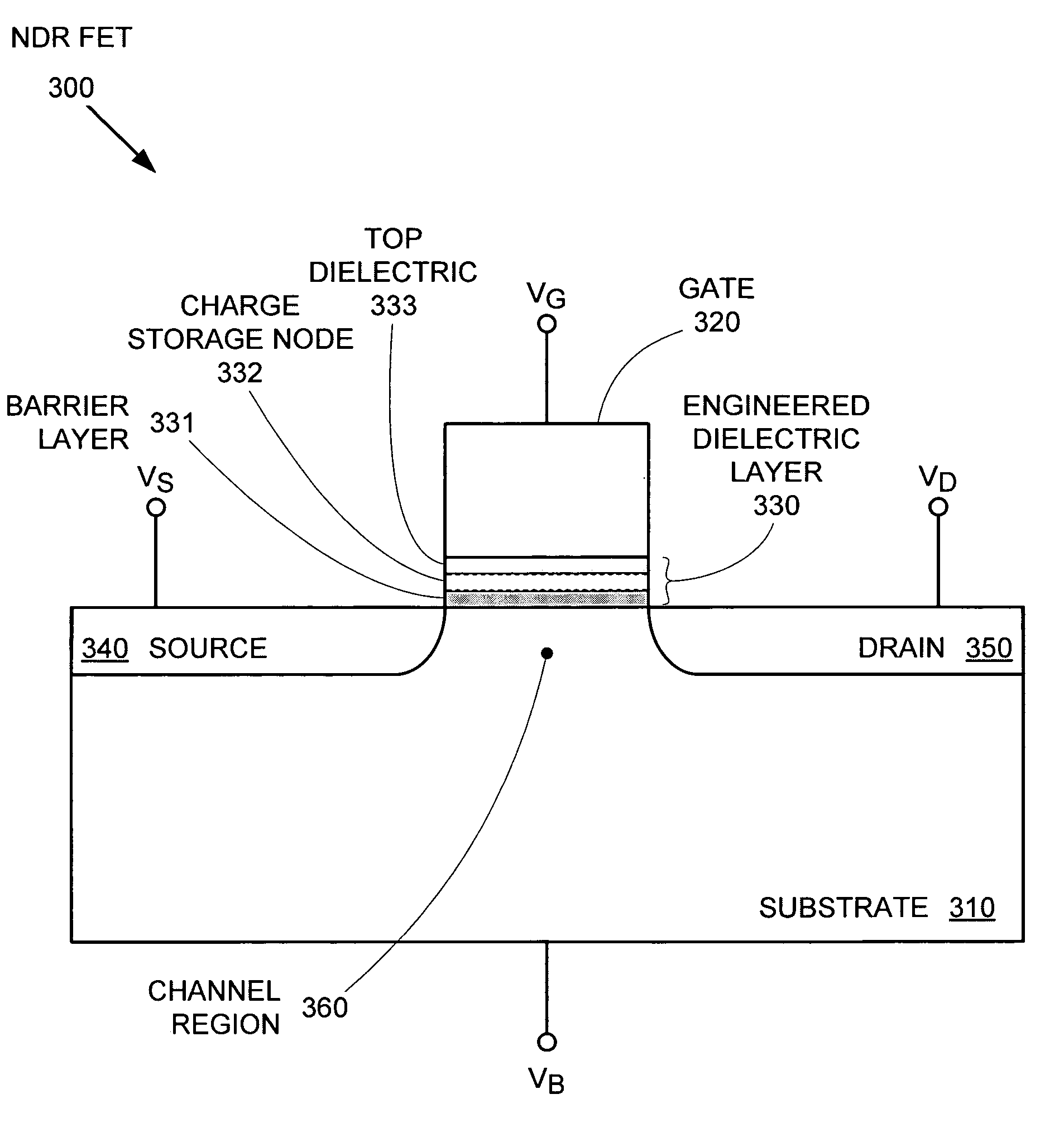

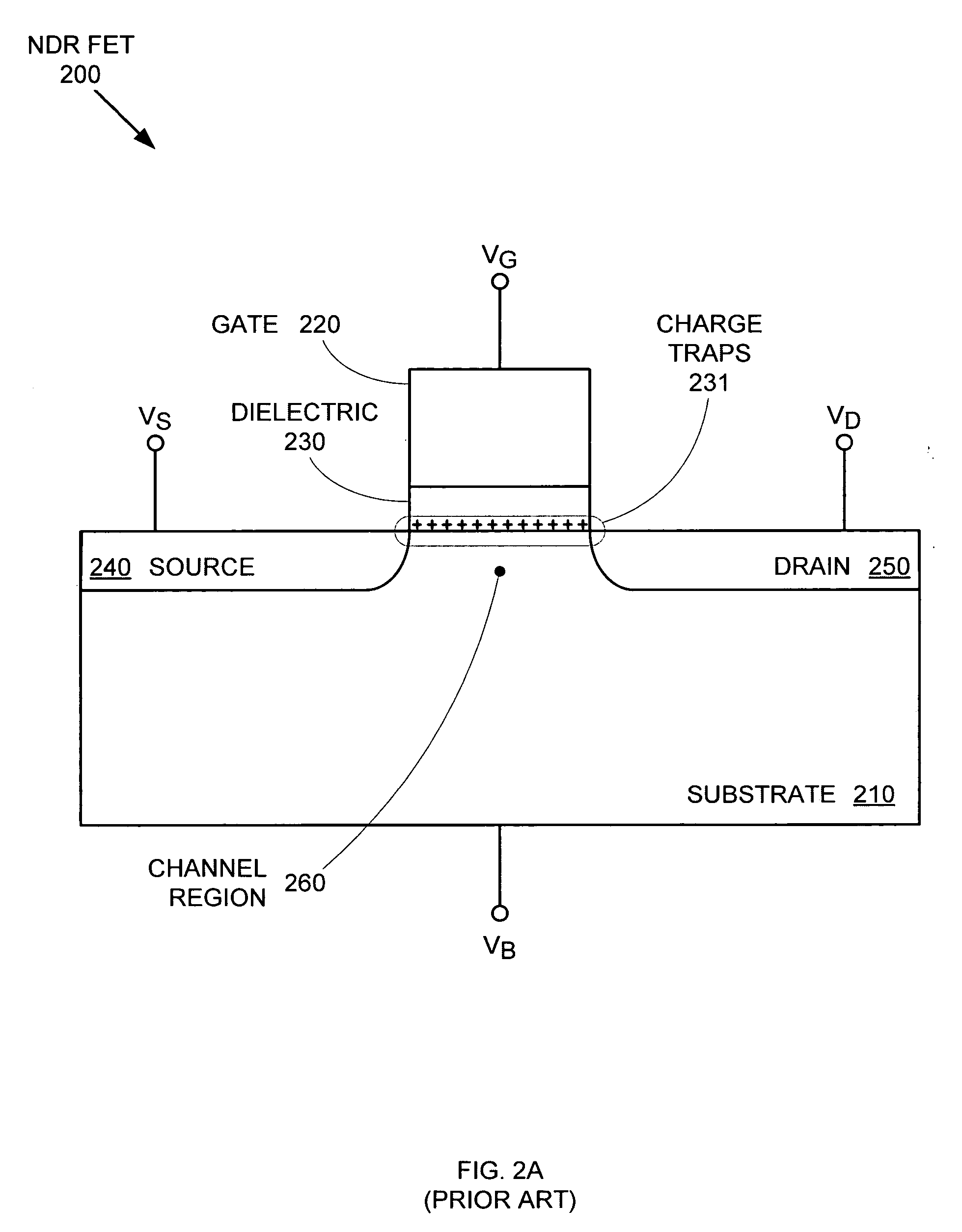

Engineered barrier layer and gate gap for transistors with negative differential resistance

InactiveUS20070120186A1Improve featuresEasy to controlSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceCharge carrier

A negative differential resistance (NDR) transistor includes a gate stack formed from a gate, a barrier layer, and a dielectric layer formed between the gate and barrier layer. To enable the NDR characteristic of the transistor, the barrier layer is configured to dynamically transfer charge carriers to and from the channel region of the transistor (e.g., to a charge storage node between the barrier layer and the dielectric layer), thereby adjusting the threshold voltage of the transistor. An NDR transistor can also be formed with a gap between the edge of the source region and the edge of the gate (stack) to enhance the electric field in the portion of the channel region corresponding to the gap. The enhanced electric field can concentrate the distribution of charge carriers removed from the channel region in the proximity of the source region, thereby enhancing the NDR performance of the transistor.

Owner:SYNOPSYS INC

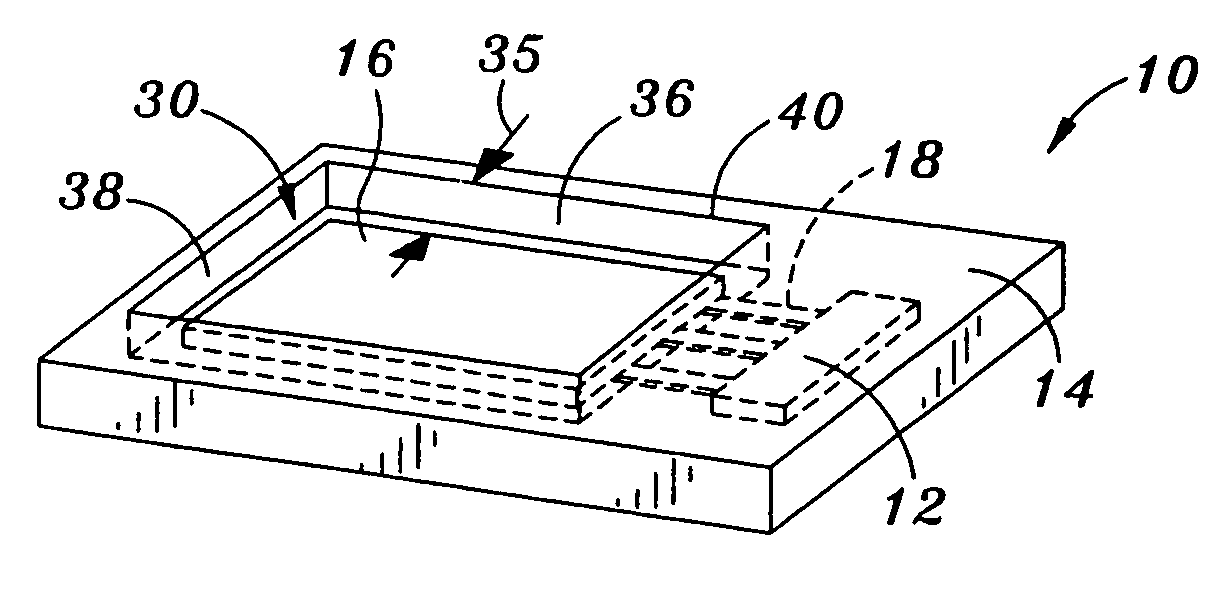

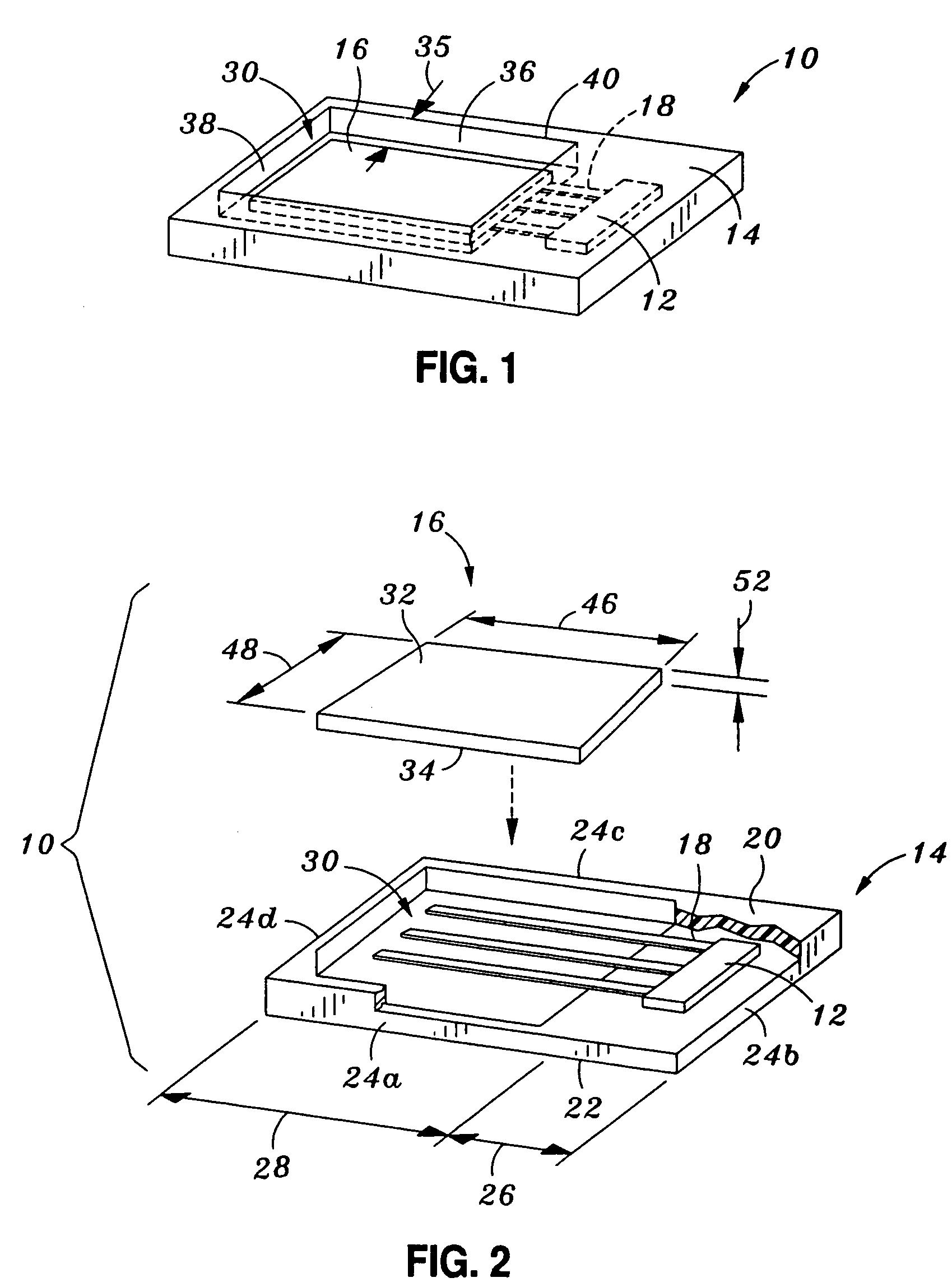

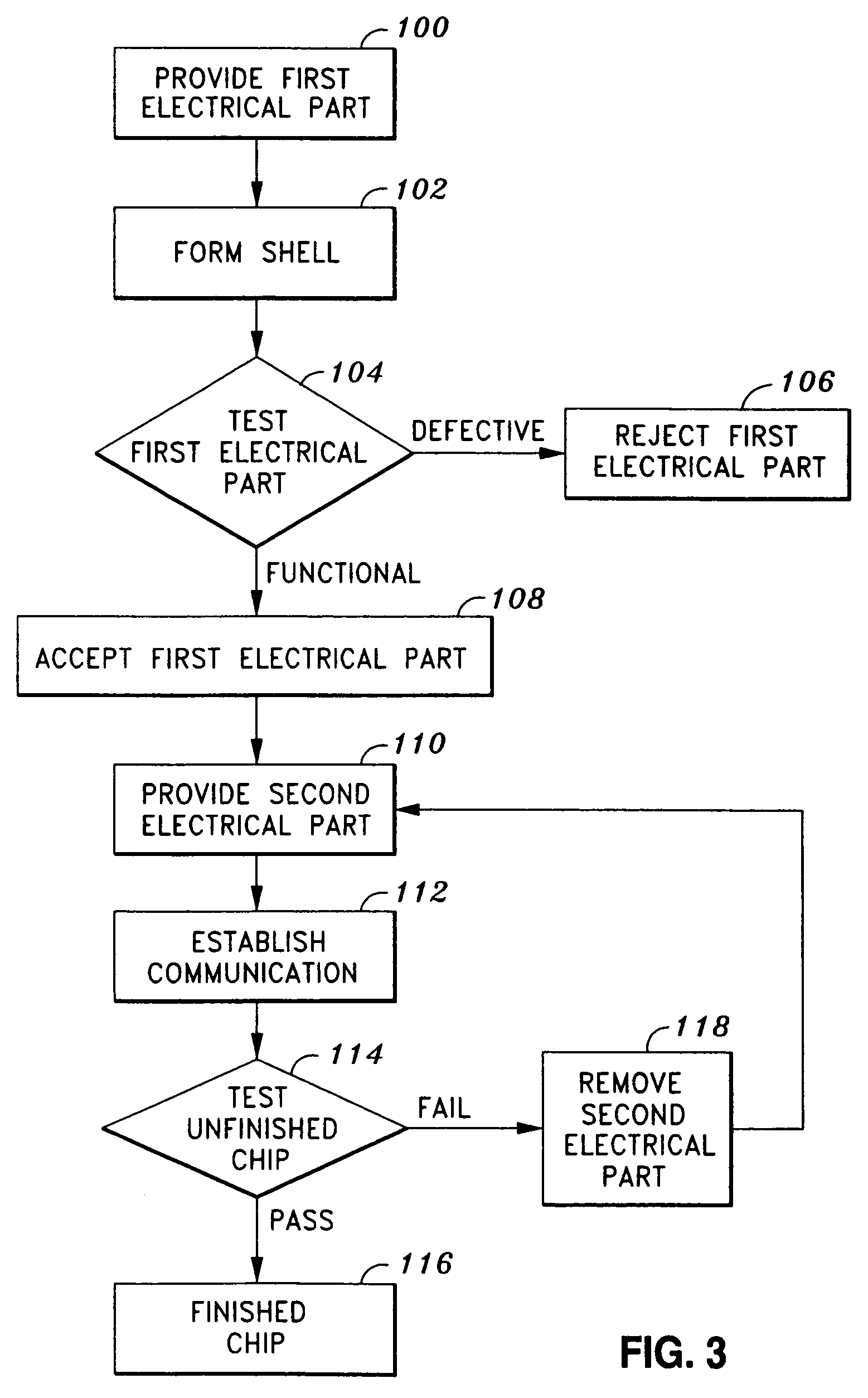

Method of fabricating a chip

ActiveUS7608469B2Reducing and eliminating possibilityIncreased manufacturing flexibilityEngagement/disengagement of coupling partsSemiconductor/solid-state device testing/measurementEngineeringElectrical and Electronics engineering

A method of fabricating a chip may include the step of providing a first electrical part. The method may also include the step of forming a shell with the first electrical part embedded in a first side portion of the shell and a cavity in a second side portion of the shell. The method may include the step of testing the embedded first electrical part to determine whether the first electrical part is defective or functional. The method may also include the steps of providing a second electrical part, inserting the second electrical part within the cavity of the shell second side portion, establishing electrical communication between the first and second electrical parts if a test result of the first electrical part indicates that the first electrical part is functional, and finishing the chip. Also, the method may include the step of rejecting the first electrical part if the test result of the first electrical part indicates that the first electrical part is defective.

Owner:KINGSTON DIGITAL CO LTD

Factory intelligent early-warning system

InactiveCN107146027AQuick extractionEfficient extractionDatabase management systemsResourcesEarly warning systemNeural network system

The invention discloses a factory intelligent early-warning system which comprises the following successively connected modules: a multivariate heterogeneous data fusion processing module which collects monitoring data generated by each system of a factory and performs fusion on mass multivariate heterogeneous data based on xml technology, and performs processing through statistics methods such as sampling and normalization; a machine learning module which performs training learning on data that are generated by the multivariate heterogeneous data fusion processing module and performs continuous adjustment for generating a neural network system model which is related with fault data and fault phenomena and is used for analyzing the multivariate heterogeneous data that are generated in a subsequent production system and performing forecasting; and an information early-warning module which intelligently pushes an analysis result that is generated by the machine learning module to related management personnel for reminding. According to the factory intelligent early-warning system, through directly using a deep learning neural network system which is established according to deep learning technology in analytical forecasting for real-time mass data of the factory, high efficiency and high intelligence are realized, and furthermore factory management by the people is facilitated in an automatic evolution manner.

Owner:EAST CHINA NORMAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com