An optical fiber type three-dimensional trigger probe device and measurement method

A measurement method and optical fiber technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve problems such as false triggering, restriction of measurement accuracy, and structural limitations, to overcome measurement errors, high resolution, and achieve isotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is exemplary only, and is not intended to limit the scope of the invention and its application.

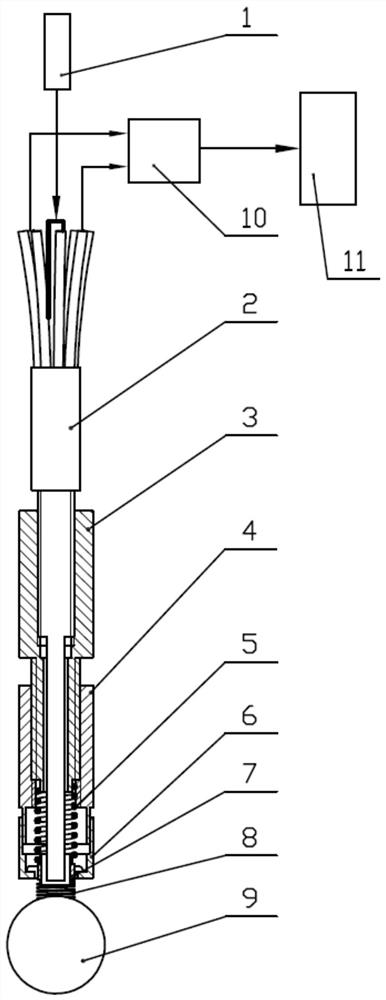

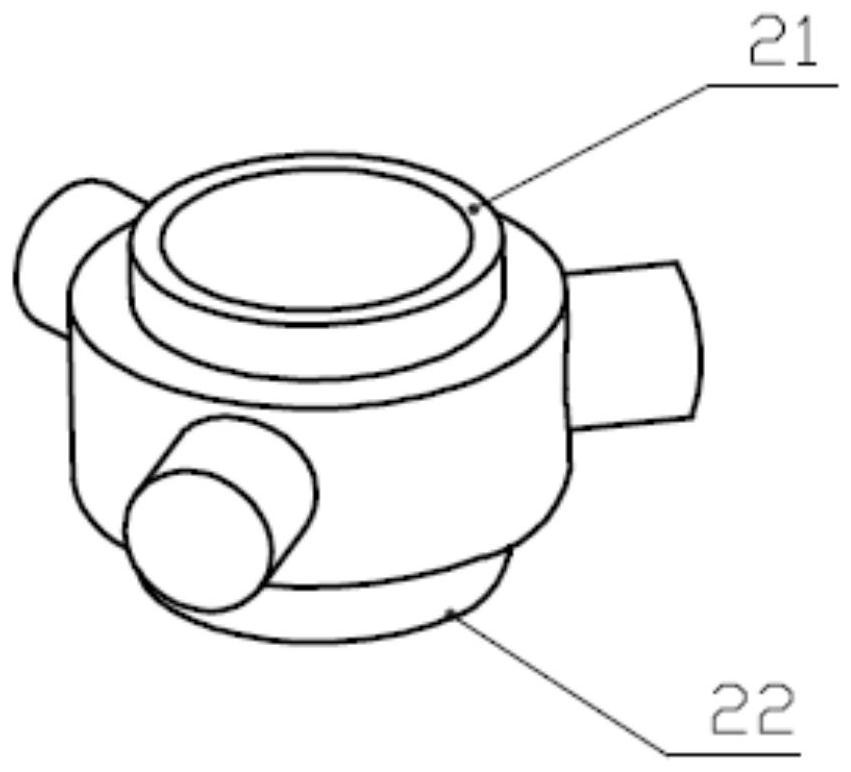

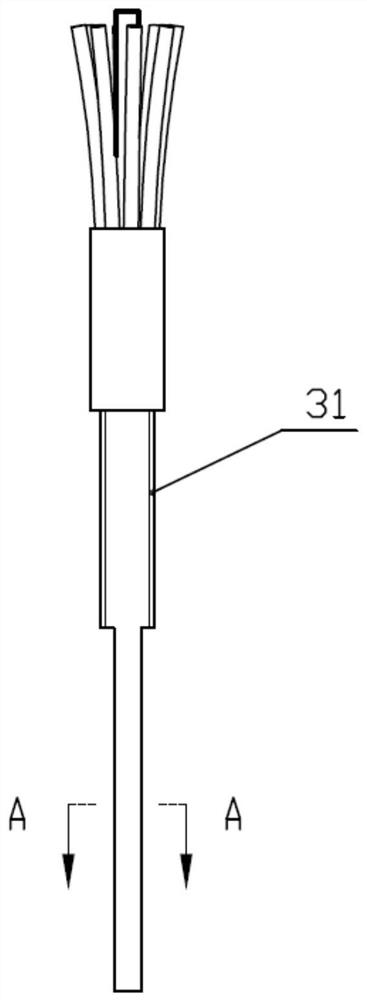

[0034] see Figure 1 to Figure 5 , in one embodiment, a fiber-optic three-dimensional trigger probe device, comprising a light source 1, a fiber-optic measuring rod 2, an elastic reset mechanism, a reflective film-coated measuring ball 9 and a photoelectric detection unit, the fiber-optic measuring rod 2 There is a central optical fiber 41 and 4N receiving optical fibers 42 uniformly distributed coaxially around the central optical fiber, N is a positive integer, and the elastic reset mechanism is arranged between the optical fiber measuring rod 2 and the measuring ball 9. During the time, it is used to reset the measuring ball 9 to the initial position, the light source 1 emits constant power light and transmits it to the measuring ball 9 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com