High-speed multi-directional line confocal digital holographic three-dimensional microscopic imaging method and device

A digital holographic and microscopic imaging technology, which is applied in the direction of instruments, can solve the problem that the two-dimensional lateral resolution isotropy cannot be achieved, and achieve the effect of high-speed multi-directional line confocal digital holographic microscopic imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

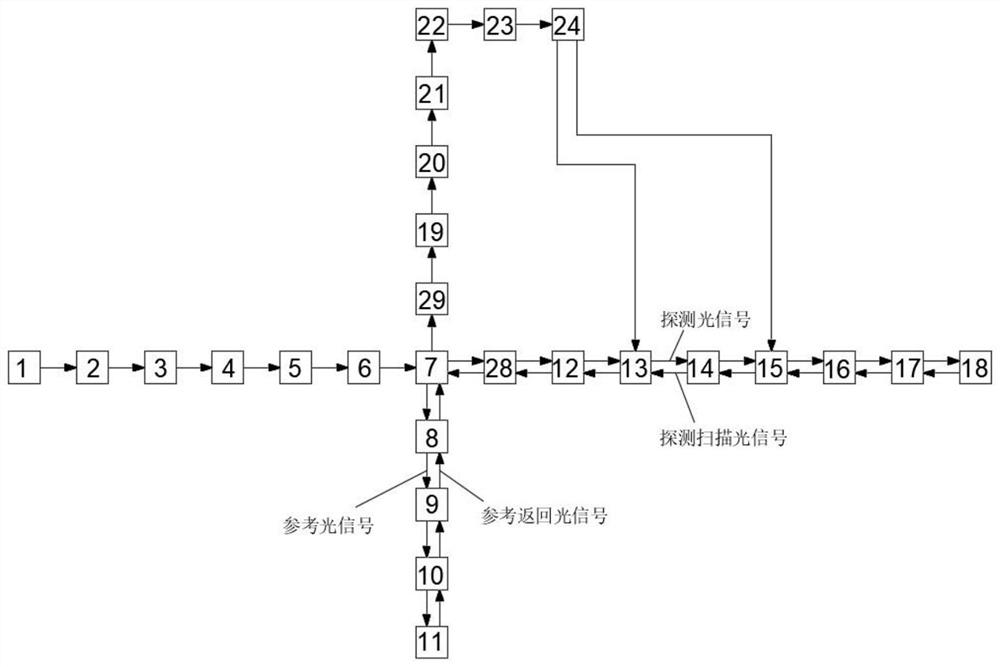

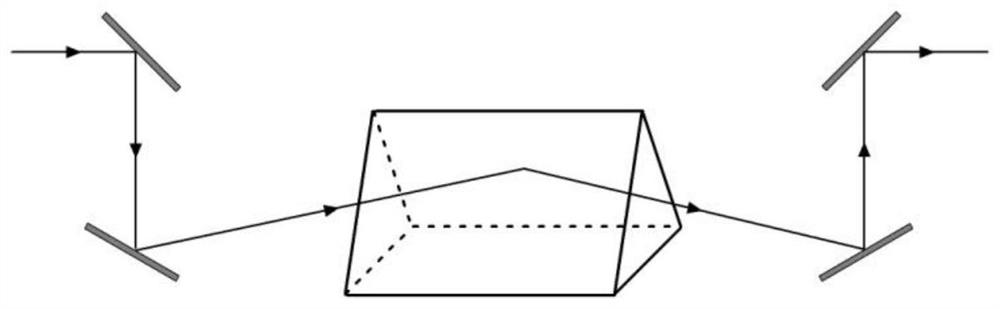

[0043] Embodiment 1: After the optical signal generated by the single-frequency single-mode continuous laser is polarized, beam expanded and focused by a cylindrical lens, it is divided into a reference optical signal and a detection optical signal by a polarization beam splitting prism; the reference optical signal is passed through the first The lens group is relayed to the total reflection mirror and receives the reference return light signal; the detection light signal is relayed to the sample platform through the second lens group and receives the detection scanning light signal, wherein the second lens group is equipped with a one-dimensional fast scanner and line The fast scanning direction switching unit uses a one-dimensional fast scanner to realize line scanning of a certain direction of the sample platform, and uses the fast line scanning direction switching unit to realize fast switching of multiple scanning directions; the reference return optical signal and the det...

Embodiment 2

[0045] Embodiment 2: On the basis of embodiment 1, specifically, adopt 633nm single-frequency single-mode continuous laser, laser line width 10kHz, output power is 20mW, the optical signal that single-frequency single-mode continuous laser produces at first through polarizing, ensures The polarization extinction ratio is greater than 25dB. The beam is expanded by a 10× beam expander, and then passes through a half-wave plate and a rectangular aperture. The rectangular aperture is located on the front focal plane of the cylindrical lens. The focal length of the cylindrical lens is 50mm, and the length of the rectangular aperture is 5mm. ; After the optical signal passes through the cylindrical lens, a focused line beam is generated on the rear focal plane and enters the 1×2 polarizing beam splitting prism, which is divided into a reference optical signal and a detection optical signal by the 1×2 polarizing beam splitting prism. The beam ratio is controlled by a half-wave plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com