A set of 3D hollow porous structures with isotropic properties

A hollow porous, isotropic technology, applied in instrumentation, computing, image data processing, etc., can solve the problem that structural anisotropy cannot meet application requirements, and achieve the effect of large optimization potential, high structural performance, and widening application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

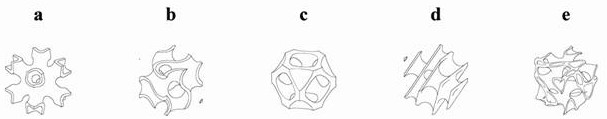

[0059] See Figure 1-8 , A set of three-dimensional porous structure having a hollow isotropic properties, including type IWP, a Gyroid type, Primitive type, type and S type Dimond minimal surface generated isotropic porous hollow structure, five kinds of porous hollow structure made of the same type infrastructure two different parameters generated by performing the Boolean operation on two particular parameters of the structure, a porous three-dimensional hollow structure, and the porous hollow structure having isotropic properties is obtained; at the same time, the five kinds of porous hollow structure having their unique structural features and performance, with different properties in different isotropic volume fraction.

[0060] Further, two different infrastructure functions as a level of a particular parameter set function, Boolean operations to generate expression of the porous hollow structure is F = min (F (x, y, z, t 1 ), - F (x, y, z, t 2 )); Where, F (x, y, z, t) repr...

Embodiment 2

[0073] Hollow porous structure characterized in that Gyroid presented on space the helical structure of the outer contour lines showing the spiral generated by the two Gyroid minimal surface structure type different parameters by Boolean operation; Gyroid minimal surface type unit cell structure the function of the expression is:

[0074]

[0075] Volume fraction is 0.2, the level of the parameter t 1 Was -2.4638 ± 0.1, the level of the parameter t 2 Of 3.714 ± 0.1, zener ratio 1.1108 ± 0.02;

[0076] Volume fraction is 0.3, the level of the parameter t 1 Was -4.0192 ± 0.1, the level of the parameter t 2 It was 5.1667 ± 0.1, zener ratio 1.1302 ± 0.02;

[0077] Volume fraction is 0.4, the level of the parameter t 1 Was -7.0533 ± 0.1, the level of the parameter t 2 It was 5.1375 ± 0.1, zener ratio 1.136 ± 0.02;

[0078] Volume fraction is 0.5, the level of the parameter t 1 Was -6.3741 ± 0.1, the level of the parameter t 2 It was 8.7823 ± 0.1, zener ratio 1.1273 ± 0.02;

[0079] V...

Embodiment 3

[0082] Primitive hollow porous structure characterized in that the six support to the positive direction on the spatial and six protruding surfaces are bonded, having a base structure identical thereto open holes in its internal structure, by two different parameters Primitive type minimal surface structure generated by the Boolean operation; Primitive type function of the expression minimal surface unit cell structure is:

[0083]

[0084] Volume fraction is 0.2, the level of the parameter t 1 Is -14.348 ± 0.1, the level of the parameter t 2 It was -6.0601 ± 0.1, zener ratio 0.9758 ± 0.02;

[0085] Volume fraction is 0.3, the level of the parameter t 1To -15.858 ± 0.1, horizontal parameter T 2 It is -3.3549 ± 0.1, Zenetbi is 0.9708 ± 0.02;

[0086] When the volume fraction is 0.4, the horizontal parameter t 1 To -17.24 ± 0.1, horizontal parameter T 2 It is -0.4946 ± 0.1, Zenetbie is 0.9603 ± 0.02;

[0087] When the volume fraction is 0.5, the horizontal parameter T 1 To -18.181...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com